Application of 3D Laser Scanning Technology Using Laser Radar System to Error Analysis in the Curtain Wall Construction

Abstract

1. Introduction

- (i)

- it is not only cumbersome but also time-consuming for dimension and location information collection and measurement;

- (ii)

- the measurement highly relies on the knowledge, and experience of engineers, which is less objective and effective, might bring inaccuracy, discrepancy, and errors to the measuring and locating results according to different implementers, thus potentially generate improperly developed design and manufacture, furthermore lead to even more serious circumstance such as material waste, installation rework, and construction process delay;

- (iii)

- it as well easily causes measure discrepancies due to temperature change, pulling force, or failure to keep as level in the process of tape measuring;

- (iv)

- it is difficult to synchronize and update data in a real-time manner.

2. Methodology

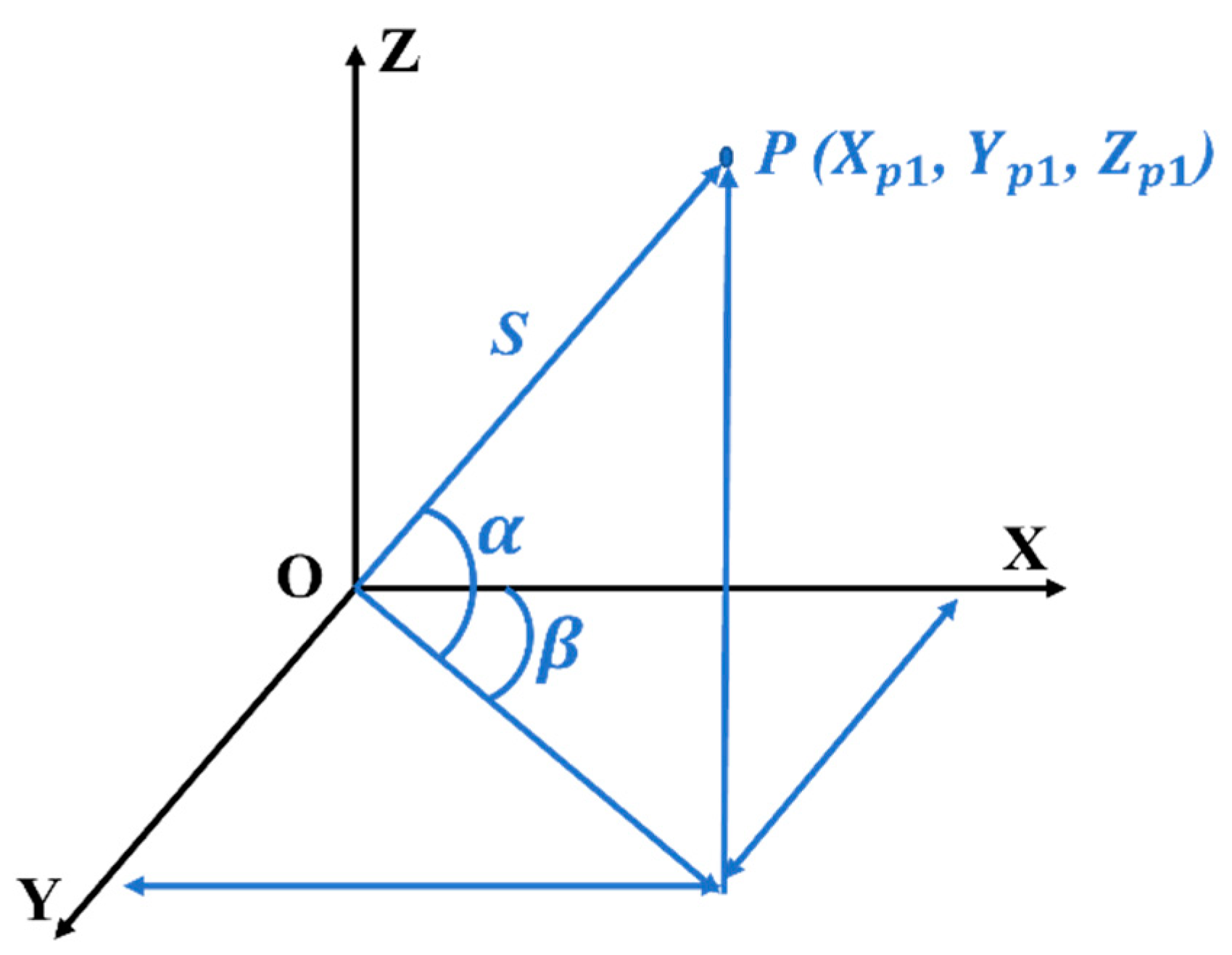

2.1. 3D Laser Scanning Technology

2.2. BIM Technology

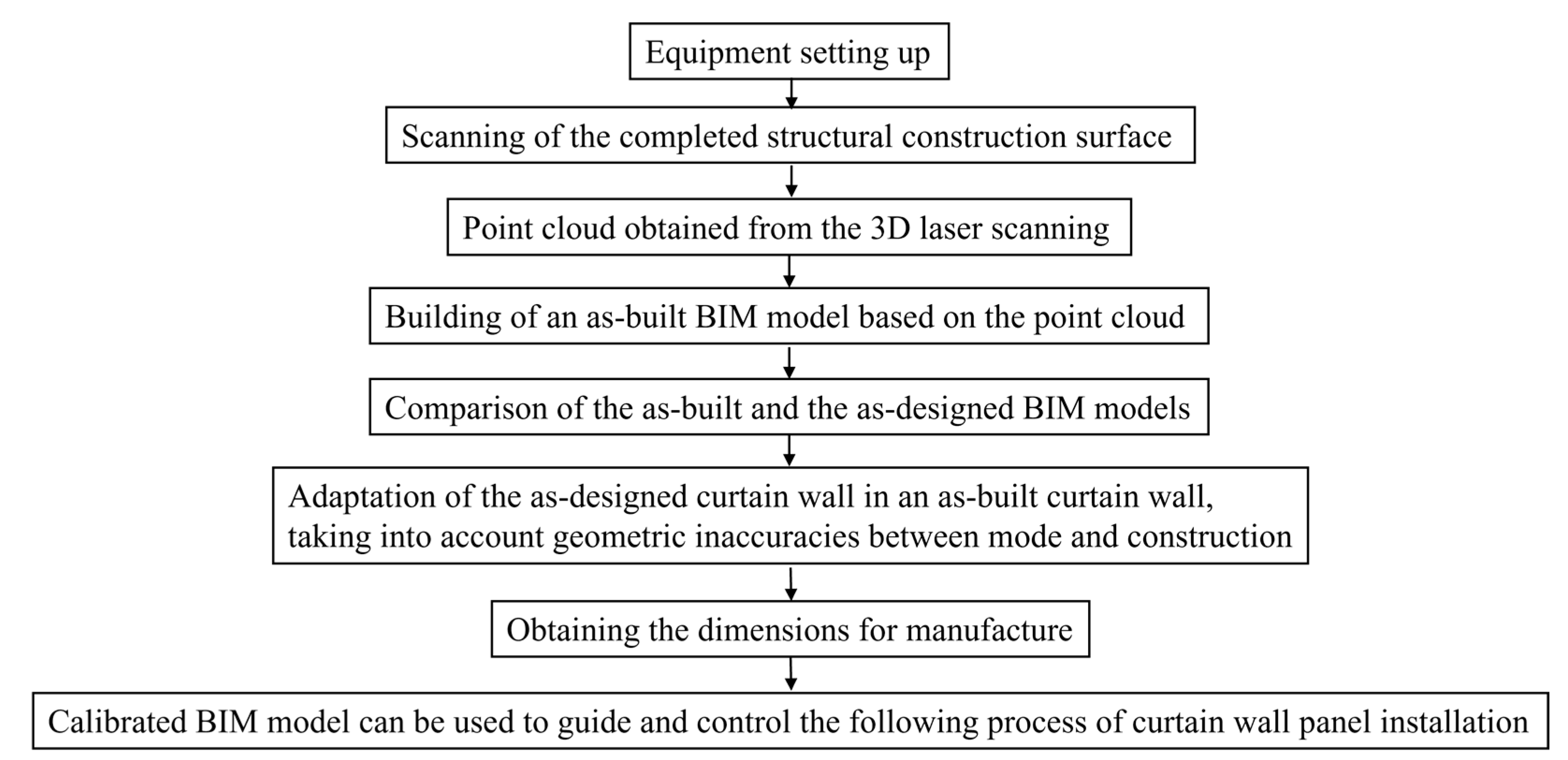

2.3. Applications in Curtain Wall Design and Installation

- Firstly, due to the completed structural construction surface being the foundation layer for the curtain wall system, the structural construction dimensions need to be rechecked and confirmed for the following developed design and installation of the curtain wall keels. Thus, the first phase of 3D laser scanning is mainly for data collection and size measurement of the completed structural construction surface, based on which a 3D BIM model representing the as-built condition of the structural construction as the foundation for the curtain wall keel can be established. Further, a comparison between the as-built and as-designed BIM models can be performed to detect the deviation in the locations and dimensions for the following production and installation work of curtain wall keels.

- Next, which is mainly aimed at a review and detection of deviation using 3D laser scanning after the curtain wall keels have been installed. By comparing the as-built andas-designed BIM models of the curtain wall keels that are foundations for curtain wall panels, it can be easily detected and obtained the discrepancies in the original-designed positions and dimensions of the curtain wall panels. Therefore, calibrated and confirmed information for the developed design and revisions on the original design of the curtain wall panels that might be manufactured by glasses or other materials can be accordingly obtained and consequently updated for curtain wall panel manufacture.

- Thirdly, after the complex 3D BIM model including both the completed structural construction surface and curtain wall keel surface established, the on-site curtain wall panel installation can thus be processed. The location and measurement information of the curtain wall system included in the final calibrated BIM model can help engineers determine the accurate anchor and connection points of the curtain wall panels and further guide the following installation progress accurately and efficiently.

3. Field Application in Curtain Wall Design and Installation

3.1. Field Project Description

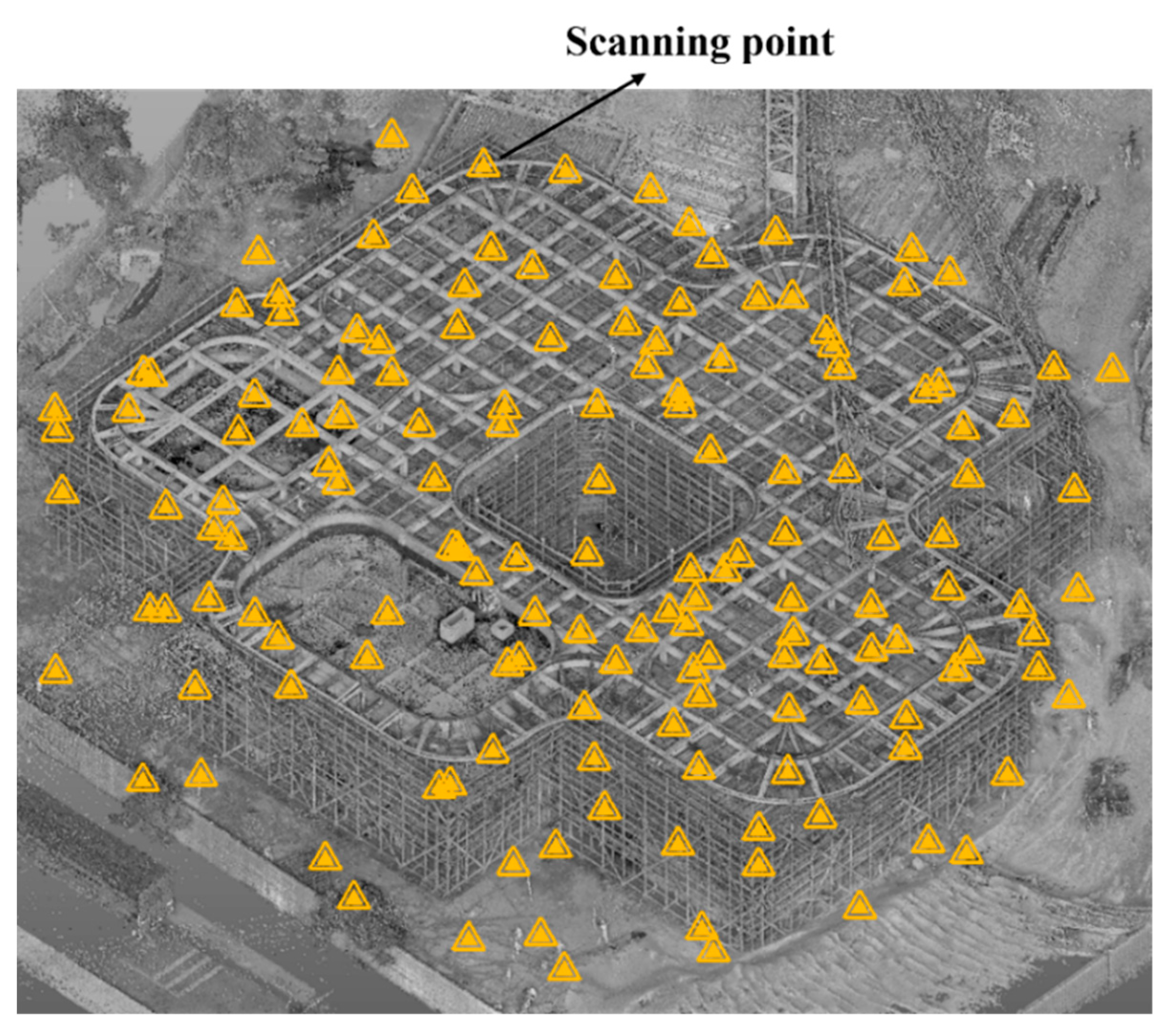

3.2. Scanning Operation

3.3. Data Acquisition and Processing

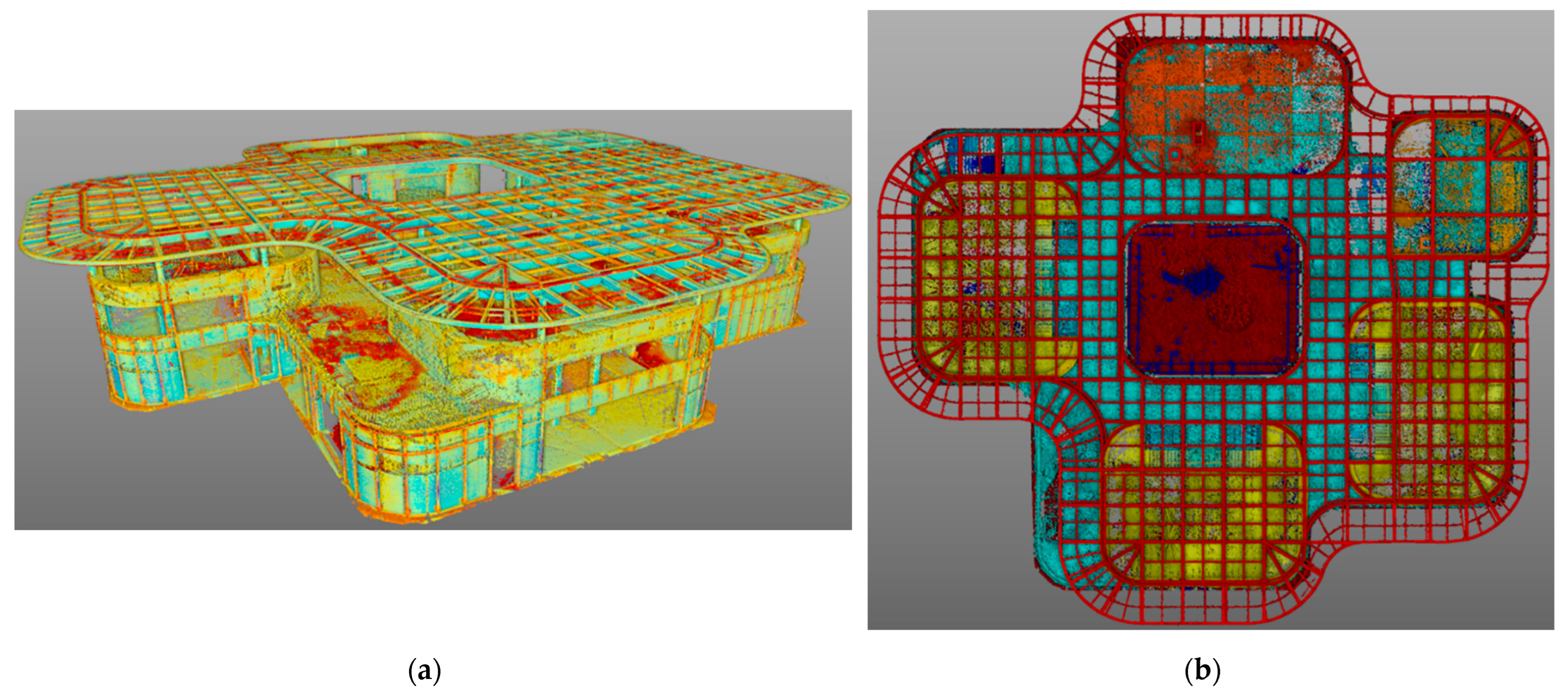

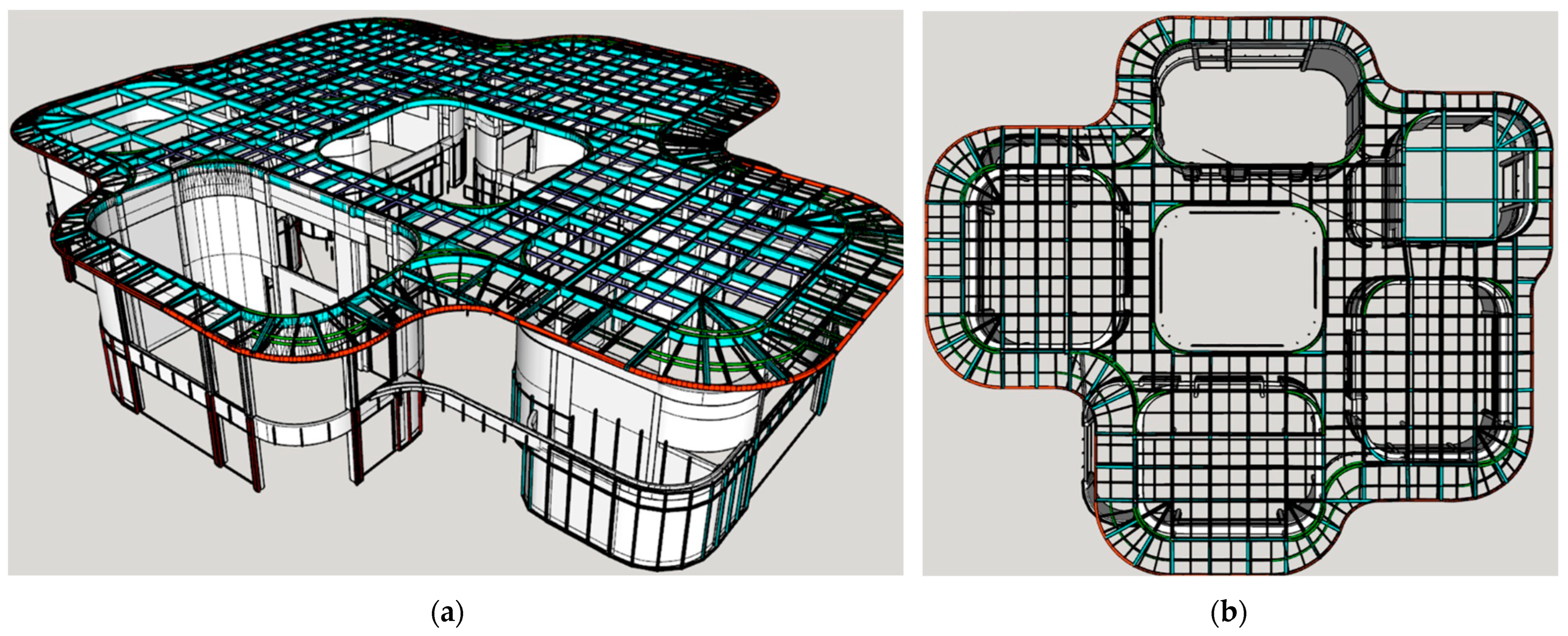

3.4. BIM Model Reconstruction from Point Cloud

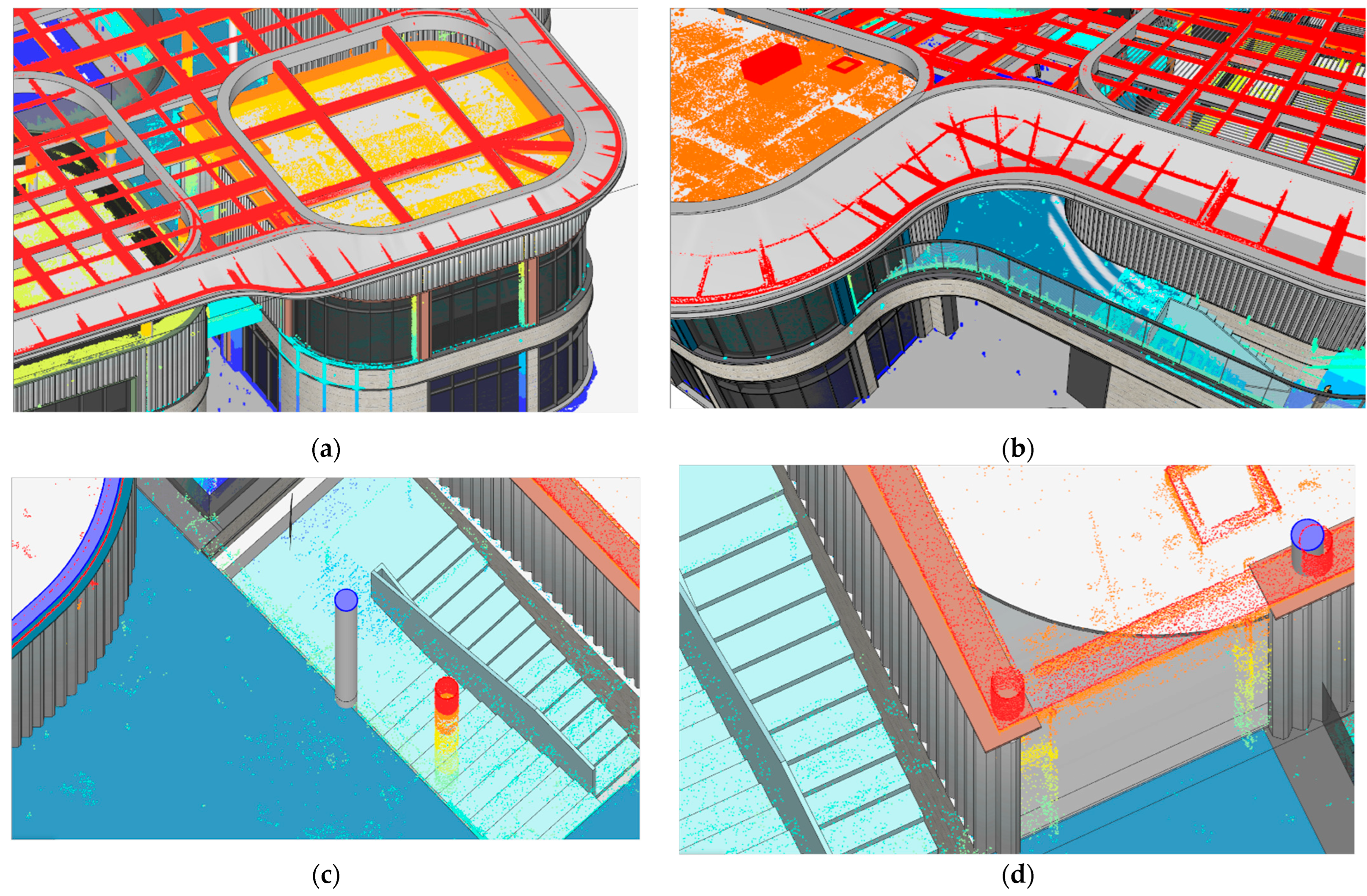

3.5. Data Fitting and Comparing of the BIM Model

3.6. Construction Setting out Using BIM

4. Discussion

4.1. Conceptual Comparison with the Conventional Method

4.2. Instructions, Limitations, and Recommendations

- (1)

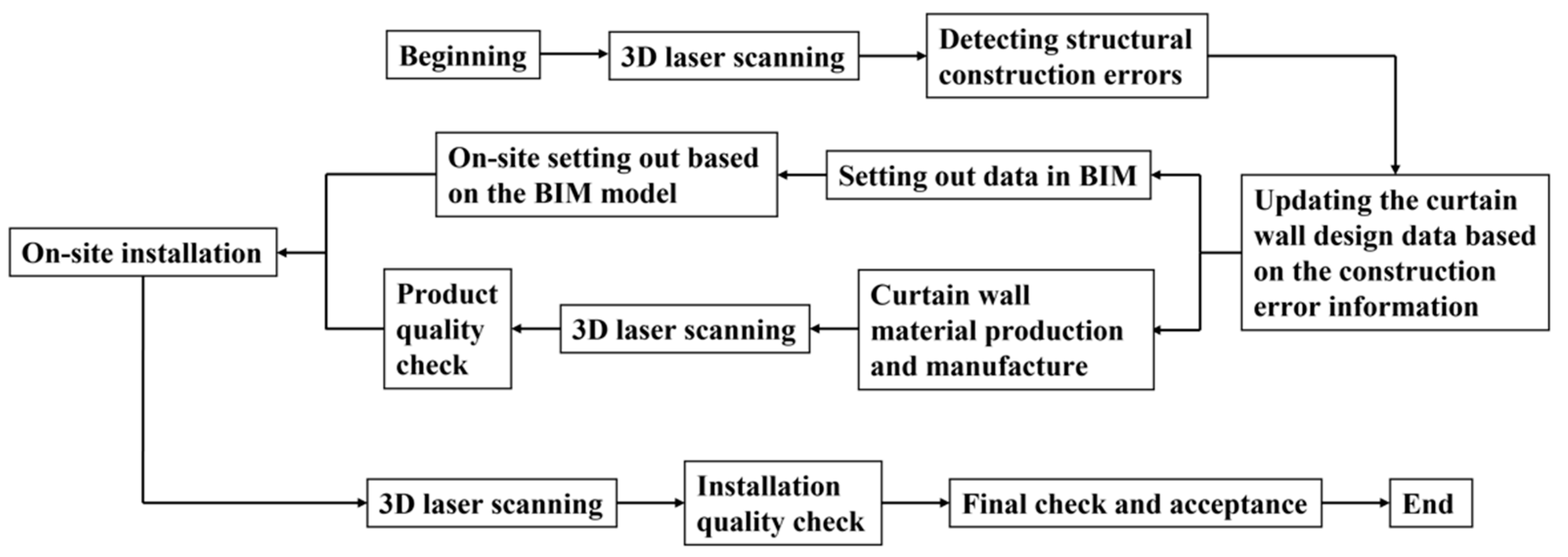

- The field case showed the potential and demonstrated the effectiveness of the application of 3D laser scanning, and is encouraging the value of the integration of 3D laser scanning and the BIM approach in the curtain wall construction field. A comprehensive workflow summarized based on this case is given in Figure 14. It should be noted that the quality control after the curtain wall system has been installed which is not mainly concerned in this paper is as well presented in this workflow in order to provide a complete concept.

- (2)

- The initial cost of the 3D laser scanning device (scanner and relevant accessories) is always higher than that of the conventional manual approach, which leads to a negative impact on a wide application of this technology. And, the operation of the 3D laser scanner and the following post-data processing need sufficient knowledge and training for engineers on site, while the method of operation is still unknown and less understood to engineers due to the lack of knowledge. In addition, even though this technology has been researched and applied in various industries, due to the lack of adopting professional training and imposing targeted measures for wide application in the curtain wall design and installation field, the promotion of this approach still needs more attention and attempt.

- (3)

- As previously described, the scanners can only collect and record point data of the object’s surface in their lighting and reflecting line, even though an overall coverage and a complete model of the entire building might be achieved by arranging multiple scans from different scanning sites, details of some locations, items that are hidden into the conjunctions might be still unable to obtain. Particularly for complex buildings, it might bring information missing or potential errors.

- (4)

- With performed in this field case, it is highly recommended a pre-observation of the outer surface and an information preparation including technical documents, built construction plans, structural design details, and other related documents for the 3D laser scanning planning. Based on a good understanding of the scanned target and requirements of the scanning purposes, an effective and applicable pre-designed scanning plan and operation path can be established, which potentially brings a positive impact and might be highly supportive for the following scanning task.

- (5)

- Another consideration for the practical application is the operation team organization. It can be seen that two main phases are required, data acquisition by 3D laser scanning, and BIM-based data processing and model reconstruction. Thus, at least two engineers are required for a well-organized group, one should be a well-trained operator who can perform the 3D laser scanning for collecting raw point cloud data, and another should be capable of conducting data processing and model reconstruction.

- (6)

- Currently, the post-processing on the “point cloud” was performed by manual work in this project. This can be considered because it is difficult to develop a promising automatic or semi-automatic data post-processing technique including point cloud splicing, noise selecting and removing with good accuracy and efficiency considering the huge amount, the complexity, and the disordering of the raw point dataset in this project. In the other words, the manual approach is still the most suitable way to process the raw point dataset and prepare it into the “point cloud” for the next steps.

4.3. Challenges and Future Directions

- Sufficient studies have not been conducted to quantify the increase of work efficiency in time, cost, work safety, etc. by using 3D laser scanning technology compared to the traditional manual approach that has been applied widely used in the current practice.

- The usage of 3D laser scanning technology is still in the early stages in the building construction field, and it is only considered applied in the construction phase, the possibility of its application in other phases, such as structural damage assessment, building management and maintenance, are expected and open to research.

- The point cloud data processing, including splicing the point cloud dataset, removing noise data, etc. in this project was performed in a manual way, automatical or semi-automatical approaches without manual intervention have not been achieved yet. This can be considered due to the huge data amount and complexity of the entire point cloud dataset. The alignment and collaboration with other newly-developed technologies, such as computer science-based data analysis, machine learning, and so on, might have great potential to be considered of value for these tasks.

- Further studies to quantify the performance of applying the 3D laser scanning technology, such as how much cost-and time-efficient rather than the traditional approach are required. Also, parametric studies and discussions are expected for investigating the influencing factors on the performance of applying the 3D laser scanning technology. For example, both traditional and 3D laser scanning approaches can be conducted on specimens in an experimental test or actual construction projects first. Next, results that can represent and quantify the performance of both approaches can be compared and discussed to verify the comparability of laser scanning with currently specified construction measurement and quantity determination methodology.

- To further increase work efficiency, automatic or semi-automatic based on newly-developed techniques are needed for the data post-processing on the collected huge amount of raw points to obtain the most suitable “point cloud” for next-step model reconstruction. For example, collaboration with computer science-based data analysis, machine learning, etc. might have great potential to be carefully considered and applied in the procedures of splicing the point cloud, data selection, and removing noise.

- The potential of 3D laser scanning technology in a wider scope including structural damage assessment, building management, and maintenance is open for further investigation.

- The 3D BIM model obtained from the point cloud data might be contributive to a cloud-based digital world in the short future. A larger range of applications, including scanners and other reality capture equipment, such as Virtual Reality (VR) devices, might be incorporated to improve the value of gathered point cloud data and the established BIM model.

- Using 3D laser scanning technology, it is also possible to predict the structural performance and location of condensation that may occur on the curtain wall materials, such as the serious cold bridge phenomenon that may exist at the metal frame and glass joints of the curtain wall panels, and additionally, provide corresponding thermal performance parameter prediction.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, D.L.; Cui, J.; Wang, S.Y. Application and Research of 3D Laser Scanning Technology in Steel Structure Installation and Deformation Monitoring. Appl. Mech. Mater. 2014, 580, 2838–2841. [Google Scholar]

- Edl, M.; Mizerák, M.; Trojan, J. 3D Laser Scanners: History and Applications. Int. Sci. J. About Simul. 2018, 4, 1–5. [Google Scholar] [CrossRef]

- Li, Y.; Liu, P.; Li, H.; Huang, F. A Comparison Method for 3D Laser Point Clouds in Displacement Change Detection for Arch Dams. ISPRS Int. J. Geo-Inf. 2021, 10, 184. [Google Scholar] [CrossRef]

- Bosché, F.; Ahmed, M.; Turkan, Y.; Haas, C.T.; Haas, R. The value of integrating Scan-to-BIM and Scan-vs-BIM techniques for construction monitoring using laser scanning and BIM: The case of cylindrical MEP components. Autom. Constr. 2015, 49, 201–213. [Google Scholar] [CrossRef]

- Kim, M.-K.; Wang, Q.; Park, J.-W.; Cheng, J.C.; Sohn, H.; Chang, C.-C. Automated dimensional quality assurance of full-scale precast concrete elements using laser scanning and BIM. Autom. Constr. 2016, 72, 102–114. [Google Scholar] [CrossRef]

- Du, J.-C.; Teng, H.-C. 3D laser scanning and GPS technology for landslide earthwork volume estimation. Autom. Constr. 2007, 16, 657–663. [Google Scholar] [CrossRef]

- Arayici, Y. An approach for real world data modelling with the 3D terrestrial laser scanner for built environment. Autom. Constr. 2007, 16, 816–829. [Google Scholar] [CrossRef]

- Tang, P.; Anil, E.B.; Akinci, B.; Huber, D. Efficient and effective quality assessment of as-is building information models and 3D laser-scanned data. In Proceedings of the International Workshop on Computing in Civil Engineering 2011, Miami, FL, USA, 19–22 June 2011; pp. 486–493. [Google Scholar]

- Bosché, F. Automated recognition of 3D CAD model objects in laser scans and calculation of as-built dimensions for dimensional compliance control in construction. Adv. Eng. Inform. 2010, 24, 107–118. [Google Scholar] [CrossRef]

- Barsanti, S.G.; Remondino, F.; Visintini, D. Photogrammetry and Laser Scanning for archaeological site 3D modeling–Some critical issues. In Proceedings of the 2nd Workshop on’The New Technologies for Aquileia, Aquileia, Italy, 25 June 2012; Volume 1, pp. 1–10. [Google Scholar]

- El-Omari, S.; Moselhi, O. Integrating 3D laser scanning and photogrammetry for progress measurement of construction work. Autom. Constr. 2008, 18, 1–9. [Google Scholar] [CrossRef]

- El Omari, S.; Moselhi, O. Integrating Automated Data Acquisition Technologies for Progress Reporting of Construction Projects. Autom. Constr. 2011, 20, 699–705. [Google Scholar] [CrossRef]

- Gikas, V. Three-Dimensional Laser Scanning for Geometry Documentation and Construction Management of Highway Tunnels during Excavation. Sensors 2012, 12, 11249–11270. [Google Scholar] [CrossRef] [PubMed]

- Rolfsen, C.N.; Lassen, A.K.; Han, D.; Hosamo, H.; Ying, C. The use of the BIM-model and scanning in quality assurance of bridge constructions. In ECPPM 2021–eWork and eBusiness in Architecture, Engineering and Construction; CRC Press: Boca Raton, FL, USA, 2021; pp. 357–360. [Google Scholar]

- Si, M.; Han, D.; Guo, J.; Yuan, Y.; Yang, Y.; Ying, C.; Bai, J.; Guo, T. Road Disease Analysis Method Based on 3D Laser Scanning Point Cloud. Sci. Technol. Eng. 2018, 19, 1671–1815. [Google Scholar]

- Yoon, S.; Wang, Q.; Sohn, H. Optimal placement of precast bridge deck slabs with respect to precast girders using 3D laser scanning. Autom. Constr. 2018, 86, 81–98. [Google Scholar] [CrossRef]

- Alomari, K.; Gambatese, J.; Olsen, M.J. Role of BIM and 3D laser scanning on job sites from the perspective of construction project management personnel. In Proceedings of the Construction Research Congress, San Juan, PR, USA, 31 May–2 June 2016; pp. 2532–2541. [Google Scholar]

- SMCHURDM; SBTAJCO. Shanghai BIM Technology Application & Development Reports (2021); Shanghai Housing and Urban-Rural Construction Administration Commission: Shanghai, China, 2021. [Google Scholar]

- Huber, D.; Akinci, B.; Tang, P.; Adan, A.; Okorn, B.; Xiong, X. Using laser scanners for modeling and analysis in architecture, engineering, and construction. In Proceedings of the 2010 44th Annual Conference on Information Sciences and Systems (CISS), Princeton, NJ, USA, 17–19 March 2010; pp. 1–6. [Google Scholar]

- Slattery, K.T.; Slattery, D.K.; Peterson, J.P. Road construction earthwork volume calculation using three-dimensional laser scanning. J. Surv. Eng. 2012, 138, 96–99. [Google Scholar] [CrossRef]

- Zhang, C.; Arditi, D. Automated progress control using laser scanning technology. Autom. Constr. 2013, 36, 108–116. [Google Scholar] [CrossRef]

- Shukor, S.A.; Wong, R.; Rushforth, E.; Basah, S.N.; Zakaria, A. 3D terrestrial laser scanner for managing existing building. J. Teknol. 2015, 76, 12. [Google Scholar]

- Liu, J.; Zhang, Q.; Wu, J.; Zhao, Y. Dimensional accuracy and structural performance assessment of spatial structure components using 3D laser scanning. Autom. Constr. 2018, 96, 324–336. [Google Scholar] [CrossRef]

- Binjin, C.; Shouyan, Y.; Xin, Y.; Qichen, J.; Xin, L. A Novel Construction Quality Control and Management Method Based on BIM and 3D Laser Scanning Technology. In Proceedings of the 2018 International Conference on 3D Immersion (IC3D), Brussels, Belgium, 5–6 December 2018; pp. 1–8. [Google Scholar]

- Rodrigues, F.; Teixeira, J.; Matos, R.; Rodrigues, H. Development of a web application for historical building management through BIM technology. Adv. Civ. Eng. 2019, 2019, 9872736. [Google Scholar] [CrossRef]

- Kim, M.K.; Cheng, J.C.; Sohn, H.; Chang, C.C. A framework for dimensional and surface quality assessment of precast concrete elements using BIM and 3D laser scanning. Autom. Constr. 2015, 49, 225–238. [Google Scholar] [CrossRef]

- Jrade, A.; Lessard, J. An integrated BIM system to track the time and cost of construction projects: A case study. J. Constr. Eng. 2015, 2015, 1–10. [Google Scholar] [CrossRef][Green Version]

- Nguyen, T.A.; Nguyen, P.T.; Do, S.T. Application of BIM and 3D laser scanning for quantity management in construction projects. Adv. Civ. Eng. 2020, 2020. [Google Scholar] [CrossRef]

- Sanhudo, L.P.; Ramos, N.M.; Martins, J.P.; Almeida, R.M.; Barreira, E.; Simões, M.L.; Cardoso, V.E. A framework for in-situ geometric data acquisition using laser scanning for BIM modelling. J. Build. Eng. 2020, 28, 101073. [Google Scholar] [CrossRef]

- Pica, D.; Abanda, F.H. Emerging BIM-3d-laser scanning integration in construction practice. In Collaboration and Integration in Construction, Engineering, Management and Technology; Springer: Cham, Switzerland, 2021; pp. 345–350. [Google Scholar]

- Bassier, M.; Yousefzadeh, M.; Van Genechten, B. Evaluation of data acquisition techniques and workflows for Scan to BIM. In Geo Bussiness; Geo Bussiness: London, UK, 2015. [Google Scholar]

- Liu, J.; Xu, D.; Hyyppä, J.; Liang, Y. A Survey of Applications with Combined BIM and 3D Laser Scanning in the Life Cycle of Buildings. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2021, 14, 5627–5637. [Google Scholar] [CrossRef]

- Elbshbeshi, A.; Gomaa, A.; Mohamed, A.; Othman, A.; Ghazala, H. Applying geomatics techniques for documenting heritage buildings in Aswan region, Egypt: A Case study of the Temple of Abu Simbel. Research 2022. [Google Scholar] [CrossRef]

| Comparison Item | 3D Laser Scanning Approach | Conventional Manual Approach |

|---|---|---|

| Tools | 3D Laser Scanner | Tape measure, scale, laser rangefinder, drawings, total station |

| Measurement method | Completely non-contact, long-distance measurement, not affected by the environmental conditions (illumination, etc.) | Contact, close distance measurement, affected by the environment conditions (illumination, etc.) |

| Field drawing work | Unnecessary, automatic data collection | Necessary |

| Measuring efficiency | High efficiency, complete single-station panoramic scan within 1 min | Low efficiency, can only measure point-to-point distance, and labor-intensive |

| Degree of security | Non-contact measurement to ensure personnel safety | Degree of security |

| Result form | Point cloud data can be imported into REVIT\Autocad\3DMAX\Navisworks\ArchiCAD and other BIM software; easily obtain a series of evaluation distance, slope distance, vertical distance, clearance, diameter, angle, azimuth, slope, inclination angle, and coordinates Data; BIM model is accurately modified and reviewed according to point cloud data. | Label data on drawings based on measured point-to-point distances |

| Modeling method | Efficient reverse modeling based on point cloud | Draw CAD drawings based on on-site manuscripts, and then perform 3D modeling based on CAD drawings |

| Accuracy | All-round acquisition of on-site conditions, which can be accurately reflected through 3D point cloud data. According to the point cloud data, the size data of artificially unmeasurable positions can be obtained, with high accuracy. Millimeter-level accuracy avoids wasting capital and materials due to rework | Only based on the experience of the on-site review personnel measure the data that is considered to be reviewed, might occur interference affected by human factors, the measurement data is partial, subjective, and prone to produce human errors |

| Skills requirement | The 3D scanner operation, the collection method of the point cloud, and the data processing approach are easy to learn | A measurement team composed of experienced workers is needed |

| Applicability | Suitable for all difficult curtain wall projects, especially projects with complex structures, high precision requirements, large space, and difficult manual measurement. | Simple structure, small area, and low precision-required structures |

| Visualization | 3D visualization | 2D Plane visualization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yi, T.; Liang, X.; Ueda, T. Application of 3D Laser Scanning Technology Using Laser Radar System to Error Analysis in the Curtain Wall Construction. Remote Sens. 2023, 15, 64. https://doi.org/10.3390/rs15010064

Wang J, Yi T, Liang X, Ueda T. Application of 3D Laser Scanning Technology Using Laser Radar System to Error Analysis in the Curtain Wall Construction. Remote Sensing. 2023; 15(1):64. https://doi.org/10.3390/rs15010064

Chicago/Turabian StyleWang, Jiehui, Tianqi Yi, Xiao Liang, and Tamon Ueda. 2023. "Application of 3D Laser Scanning Technology Using Laser Radar System to Error Analysis in the Curtain Wall Construction" Remote Sensing 15, no. 1: 64. https://doi.org/10.3390/rs15010064

APA StyleWang, J., Yi, T., Liang, X., & Ueda, T. (2023). Application of 3D Laser Scanning Technology Using Laser Radar System to Error Analysis in the Curtain Wall Construction. Remote Sensing, 15(1), 64. https://doi.org/10.3390/rs15010064