Quantification of the Mechanized Ballast Cleaning Process Efficiency Using GPR Technology

Abstract

1. Introduction

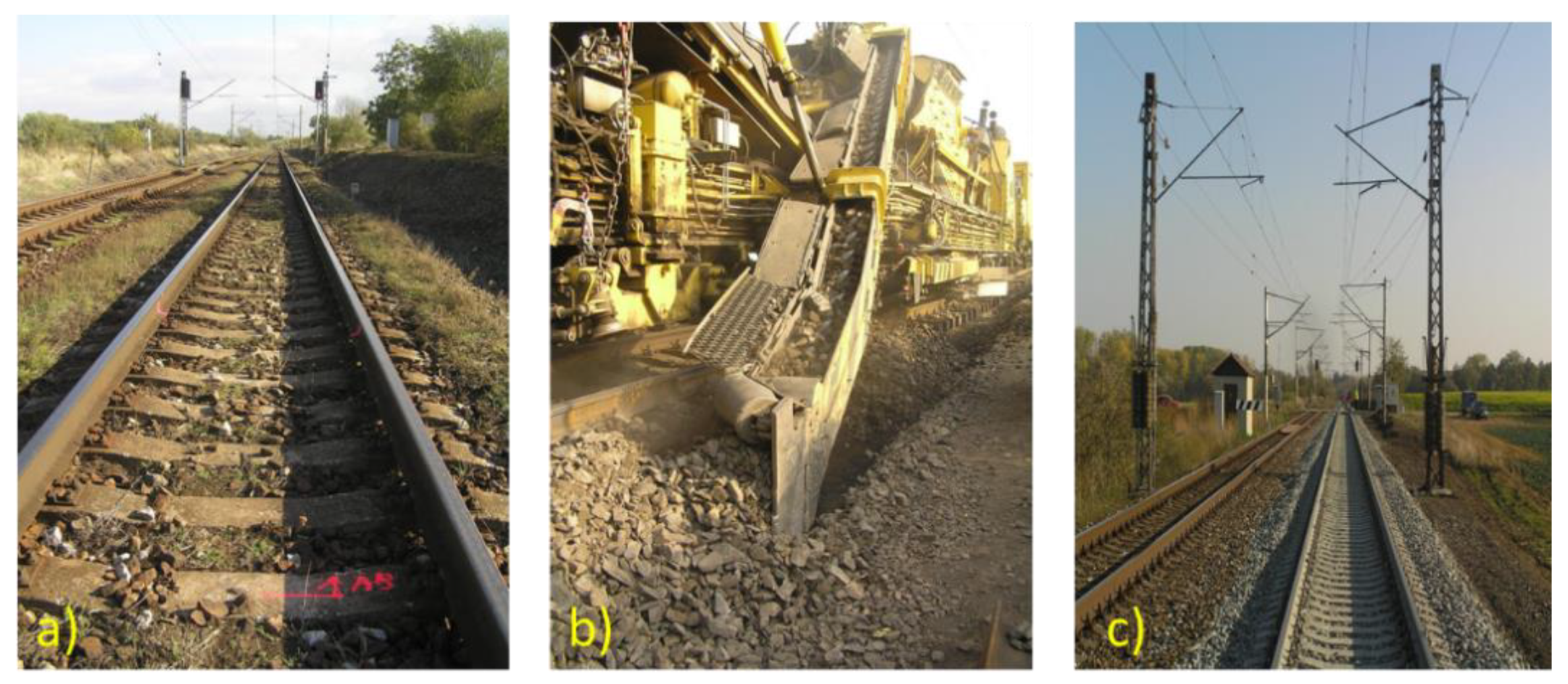

1.1. Mechanized Ballast Cleaning Activity on Railways

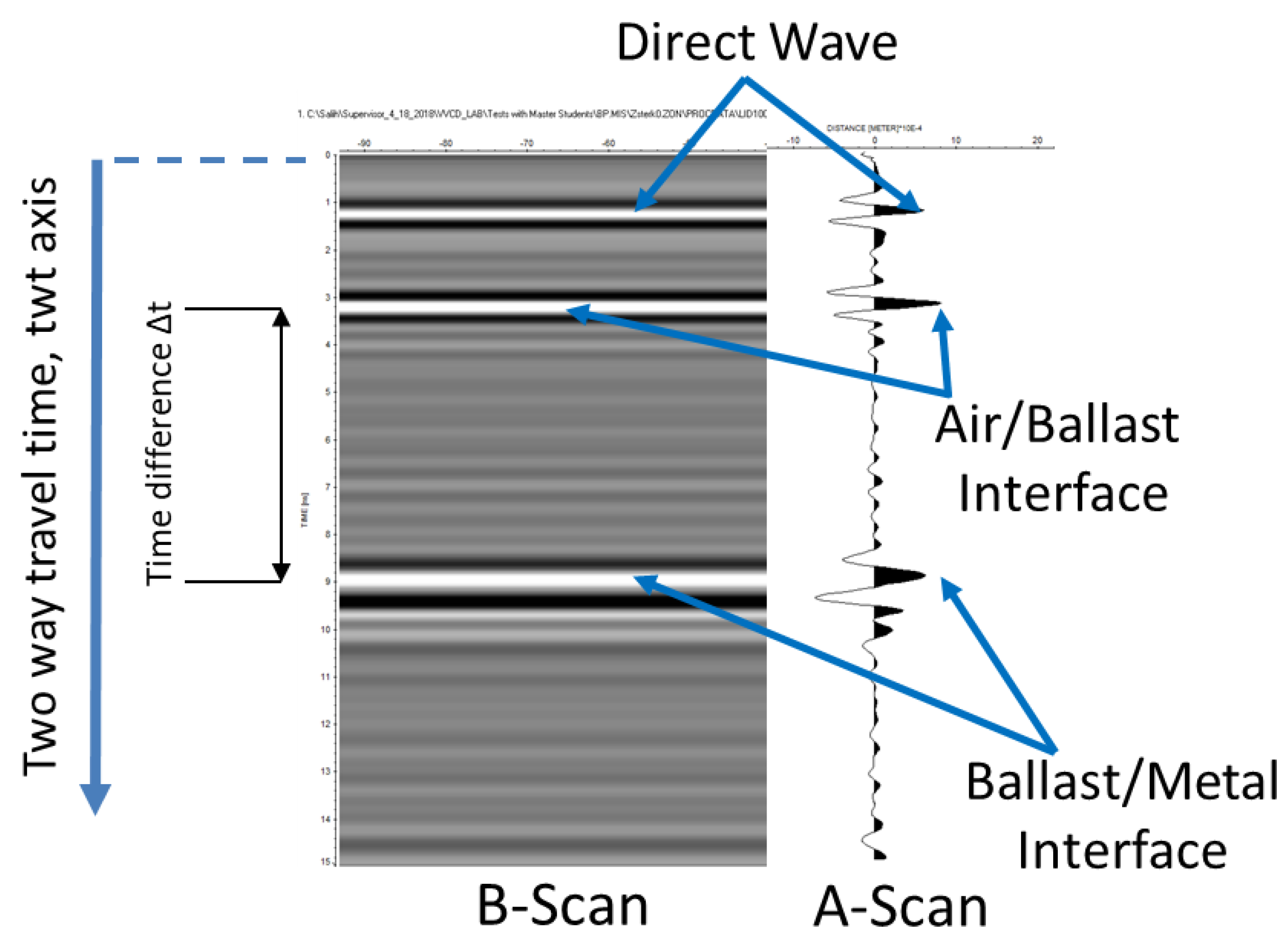

1.2. Ground Penetrating Radar

1.3. Railway Ballast Assessment by GPR

- Crib—the portion of ballast between the sleepers;

- Shoulder—the ballast aggregates between the edge of the sleeper and down to the top of the sub-ballast layer;

- Top ballast—the upper portion of the ballast aggregates where tamping intervention is often performed.

- Bottom ballast—the lower portion of the ballast aggregates supporting the whole structure.

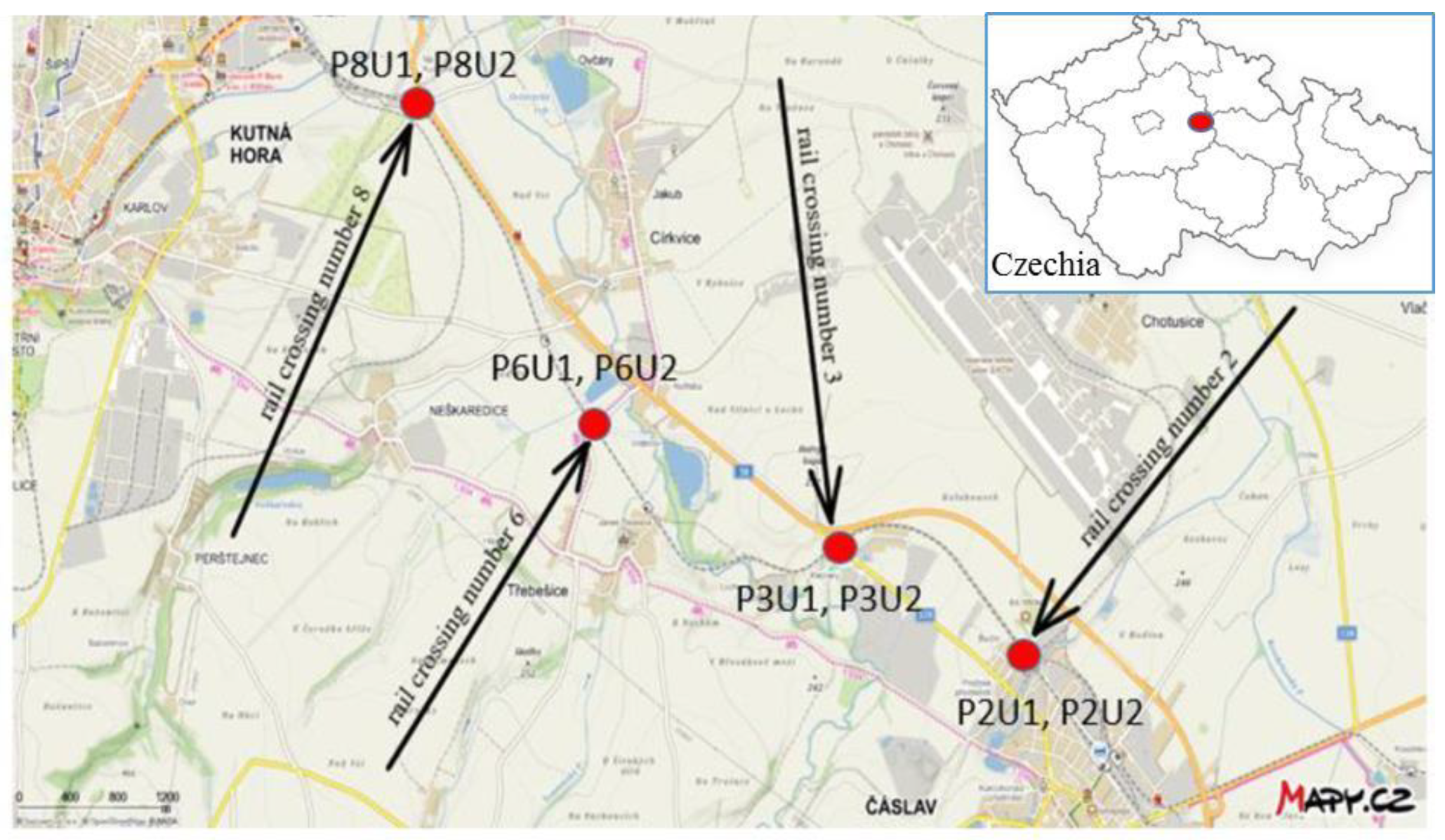

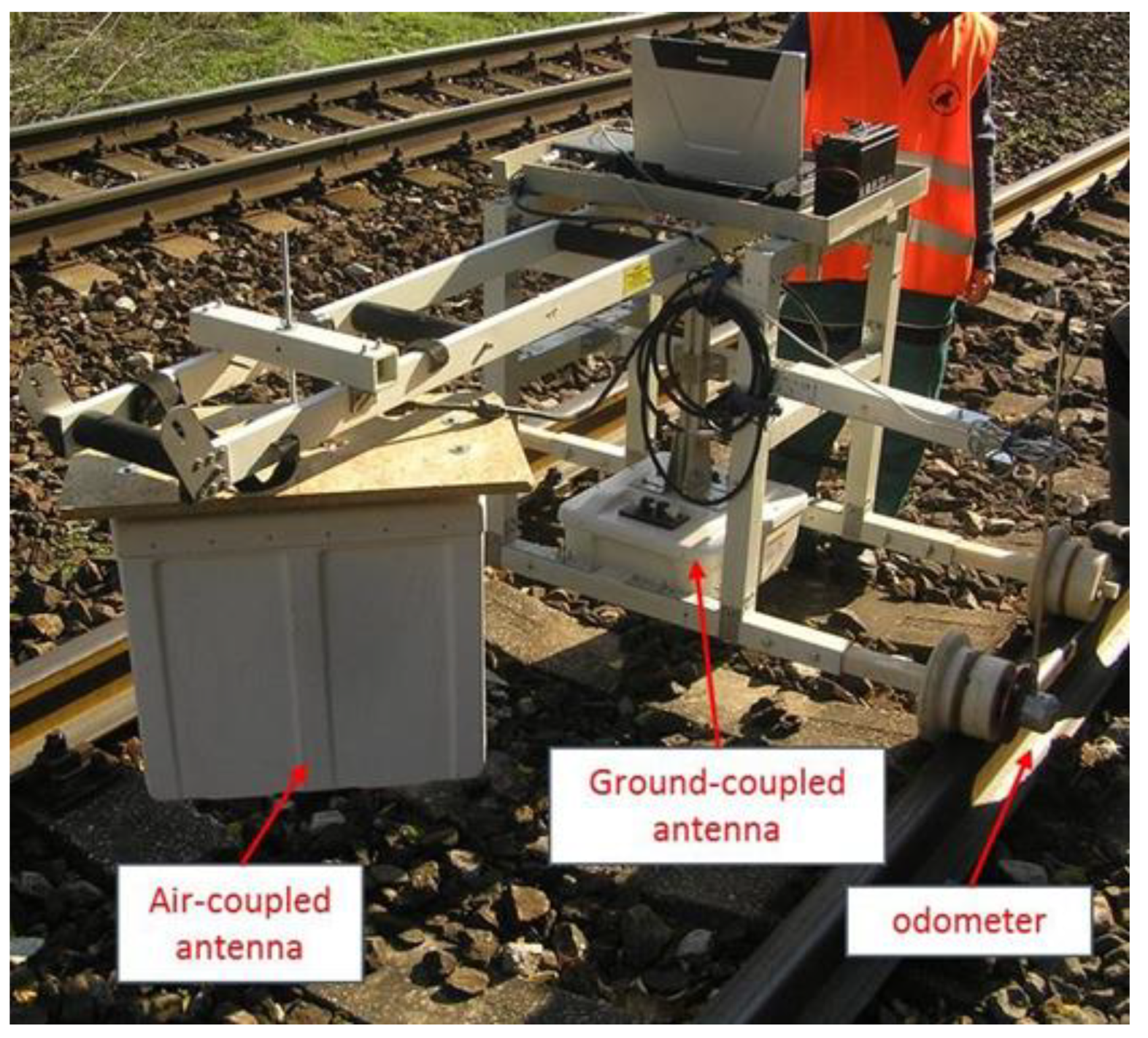

2. Survey Site and Equipment Used

3. Track Surveys, Laboratory Tests, and GPR Data Processing

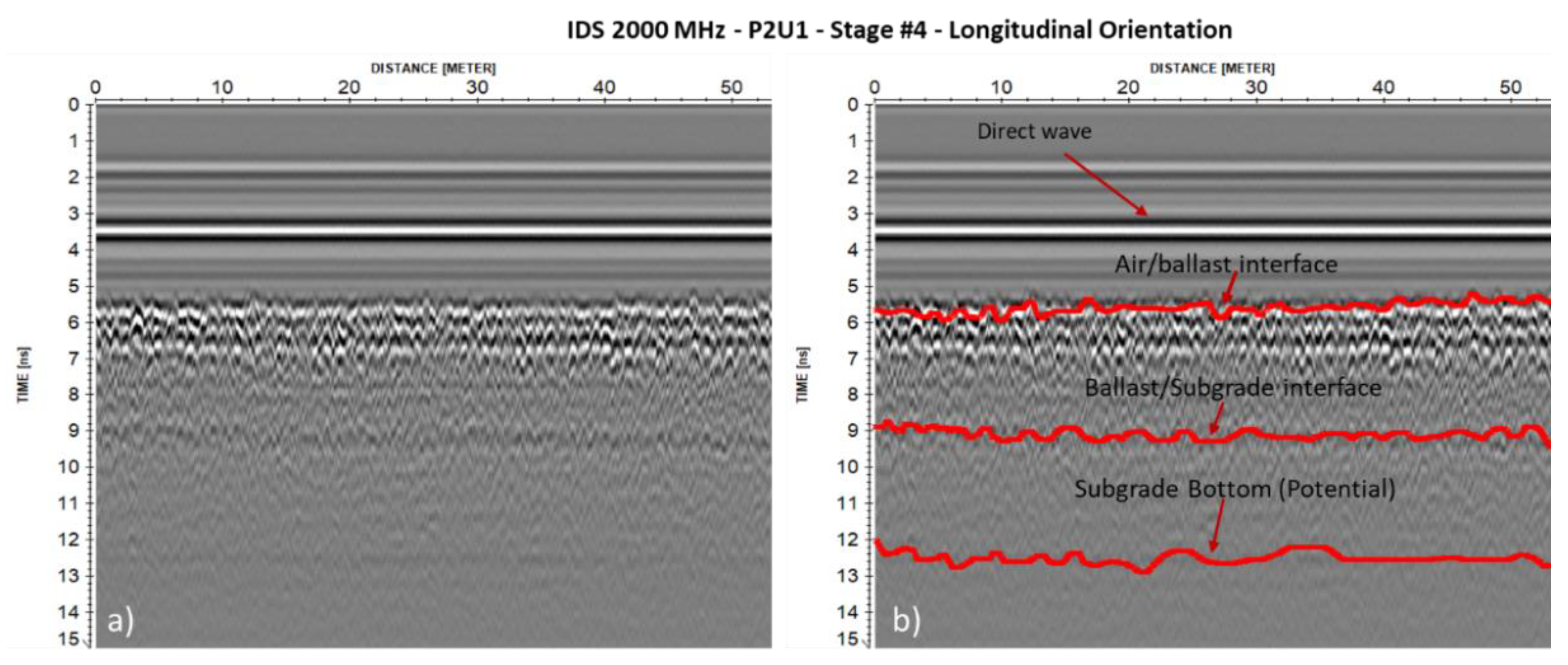

3.1. In Situ GPR Surveys

- Surveys undertaken by SŽDC in 2014

- Surveys undertaken by SŽDC in 2017

- Surveys carried out before any reconstruction activities began (12 October 2018)

- Surveys carried out just after the ballast cleaning process (17 October 2018)

- Surveys carried out in the final state after all the reconstruction activities were completed (19 October 2018)

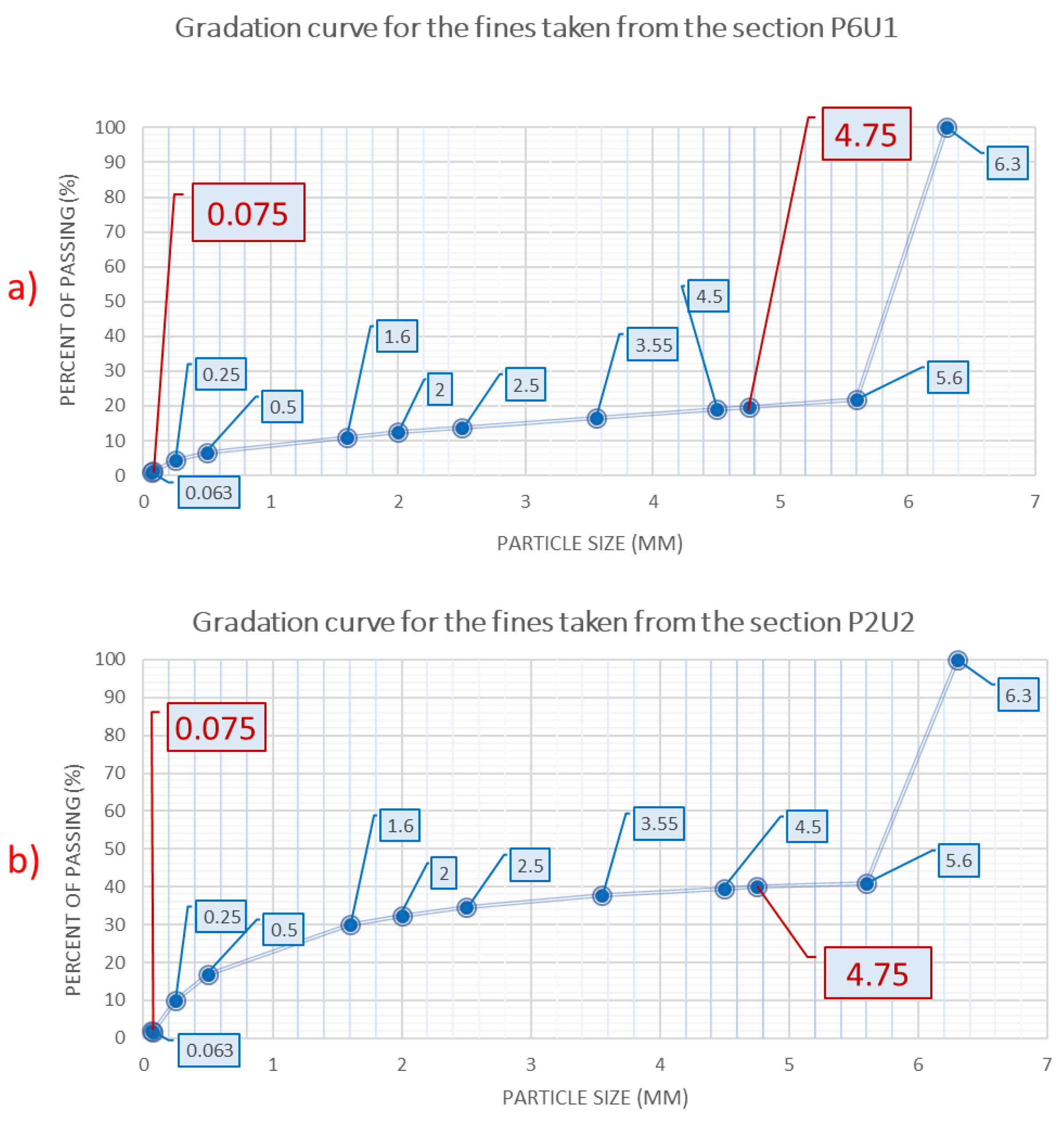

3.2. Laboratory Tests

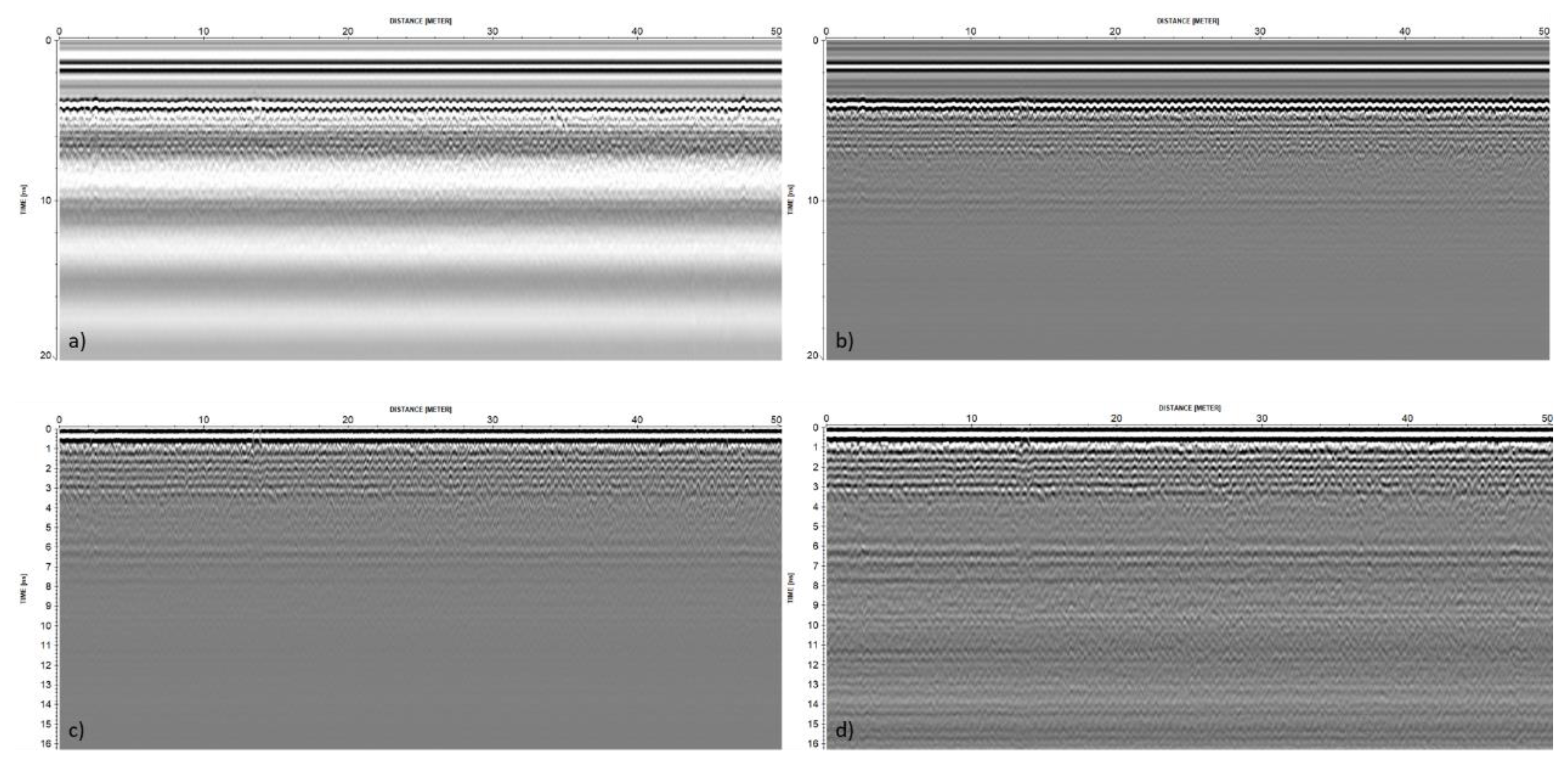

3.3. GPR Data Processing

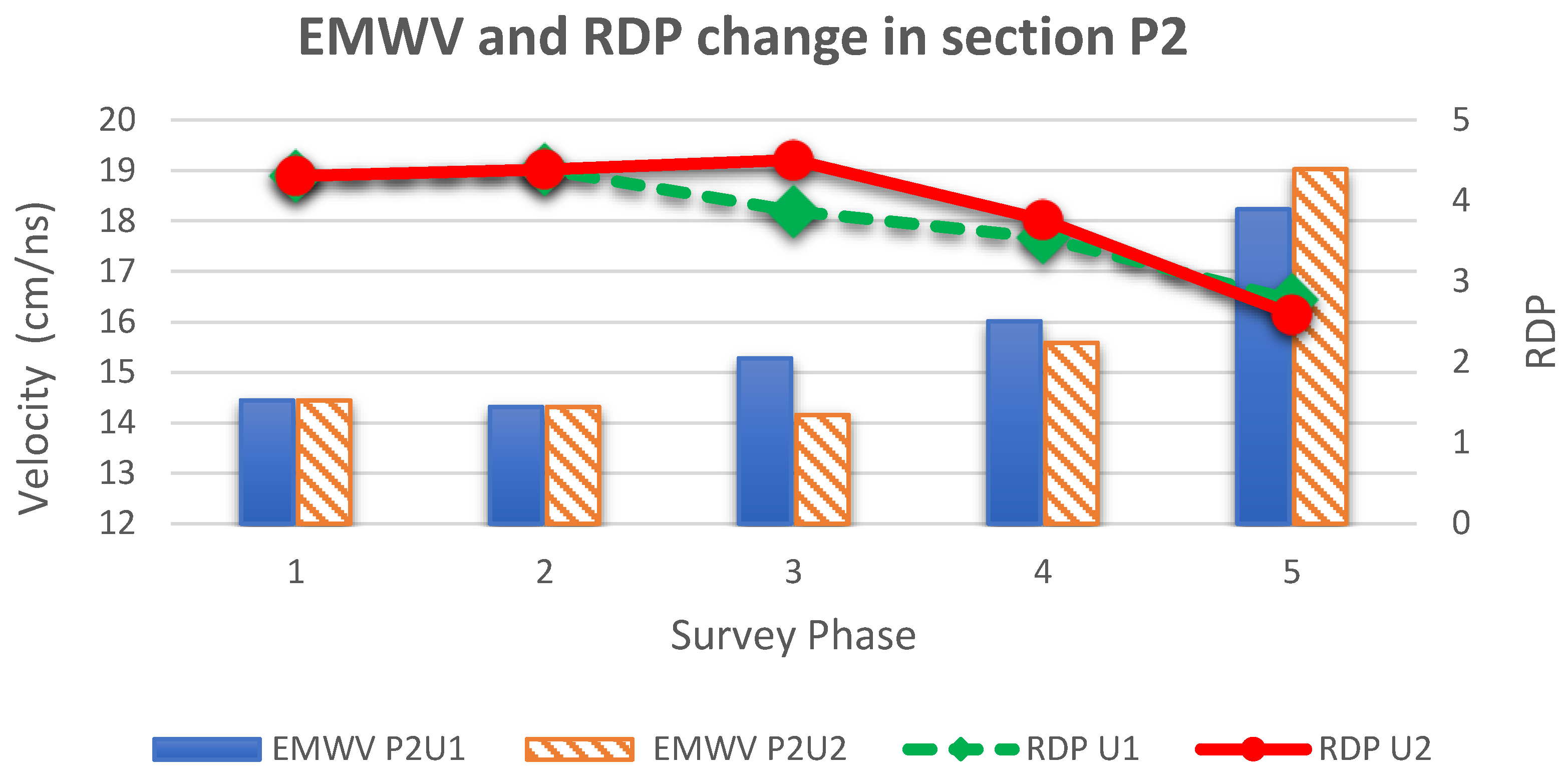

4. Results

5. Discussion

- Determination of GPR survey conditions, equipment criteria, and settings,

- Determination of a data processing flow on the basis of step 1, (time-domain),

- Computation of RDP/EMWV values on the basis of steps 1 and 2, (time-domain),

- Selecting the standard fouling indicator(s) for ballast material(s) and setting its threshold

- Comparison/correlation of RDP/EMWV values from step 3 and standard fouling indicator from step 4,

- Decision-making as to when/whether the mechanized ballast cleaning intervention should be initiated.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qian, Y.; Dersch, M.S.; Gao, Z.; Edwards, J.R. Railroad infrastructure 4.0: Development and application of an automatic ballast support condition assessment system. Transp. Geotech. 2019, 19, 19–34. [Google Scholar] [CrossRef]

- Tamrakar, P.; Azari, H.; Yuan, D.; Nazarian, S. Implementation of spectral analysis of surface waves approach for characterization of railway track substructures. Transp. Geotech. 2017, 12, 101–111. [Google Scholar] [CrossRef]

- Mvelase, G.M.; Gräbe, P.J.; Anochie-Boateng, J.K. The use of laser technology to investigate the effect of railway ballast roundness on shear strength. Transp. Geotech. 2017, 11, 97–106. [Google Scholar] [CrossRef]

- Schmidt, S.; Shah, S.; Moaveni, M.; Landry, B.J.; Tutumluer, E.; Basye, C.; Li, D. Railway Ballast Permeability and Cleaning Considerations. Transp. Res. Rec. 2017, 2607, 24–32. [Google Scholar] [CrossRef]

- Ižvolt, L.; Dobeš, P.; Mečár, M. Calibration of TDR Test Probes for Measuring Moisture Changes in the Construction Layers of the Railway Line. Procedia Eng. 2016, 161, 1057–1063. [Google Scholar] [CrossRef]

- Pieš, J.; Môcová, L. Application of TDR Test Probe for Determination of Moisture Changes of Railway Substructure Materials. Transp. Res. Proc. 2019, 40, 74–81. [Google Scholar] [CrossRef]

- Bianchini Ciampoli, L.; Calvi, A.; D’Amico, F. Railway ballast monitoring by GPR: A test site investigation. Rem Sens. 2019, 11, 2381. [Google Scholar] [CrossRef]

- Tosti, F.; Bianchini Ciampoli, L.; Calvi, A.; Alani, A.M.; Benedetto, A. An investigation into the railway ballast dielectric properties using different GPR antennas and frequency systems. NDT E Int. 2018, 93, 131–140. [Google Scholar] [CrossRef]

- Benedetto, A.; Pajewski, L. Civil Engineering Applications of Ground Penetrating Radar; Springer International Publishing: Cham, Germany, 2015. [Google Scholar] [CrossRef]

- Artagan, S.S.; Bianchini Ciampoli, L.; D’Amico, F.; Calvi, A.; Tosti, F. Non-destructive Assessment and Health Monitoring of Railway Infrastructures. Surv. Geophys. 2020, 41, 447–483. [Google Scholar] [CrossRef]

- Jack, R.; Jackson, P. Imaging attributes of railway track formation and ballast using ground probing radar. NDT E Int. 1999, 32, 457–462. [Google Scholar] [CrossRef]

- Gallagher, G.P.; Leiper, Q.; Williamson, R.; Clark, M.R.; Forde, M.C. The application of time domain ground penetrating radar to evaluate railway track ballast. NDT E Int. 1999, 32, 463–468. [Google Scholar] [CrossRef]

- Hugenschmidt, J. Railway track inspection using GPR. J. Appl. Geophys. 2000, 43, 147–155. [Google Scholar] [CrossRef]

- Hyslip, J.P.; Smith, S.S.; Olhoeft, G.R.; Selig, E.T. Assessment of railway track substructure condition using ground penetrating radar. In Proceedings of the 2003 annual conference of AREMA, Chicago, IL, USA, 5–8 October 2003. [Google Scholar]

- Alemu, A.Y. Survey of Railway Ballast Selection and Aspects of Modelling Techniques. Master’s Thesis, Royal Institute of Technology, Stockholm, Sweden, 2011. [Google Scholar]

- Anbazhagan, P.; Dixit, P.S.N.; Bharatha, T.P. Identification of Type and Degree of Railway Ballast Fouling Using Ground Coupled GPR Antennas. J. Appl. Geophys. 2016, 126, 183–190. [Google Scholar] [CrossRef]

- Misar, H. Criteria for cost-effective ballast cleaning: Machine design considerations. Rail. Eng. Int. 2005, 4. [Google Scholar]

- Schilling, R. Ballast cleaning of single-track railway lines: A strategic analysis. Rail. Eng. Int. 2005, 1, 8–12. [Google Scholar]

- Korolev, V.; Loktev, A.; Shishkina, I.; Zapolnova, E.; Kuskov, V.; Basovsky, D.; Aktisova, O. Technology of crushed stone ballast cleaning. IOP Conf. Ser. Earth Environ. Sci. 2019, 403, 012194. [Google Scholar] [CrossRef]

- Tzanakakis, K. The Railway Track and Its Long Term Behavior: A Handbook for a Railway Track of High Quality. Springer Tracts on Transportation and Traffic; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Annan, A.P.; Davis, J.L. Ground penetrating radar—Coming of age at last‼. In Geophysics and Geochemistry at the Millennium; GEO F/X: Johnsburg, IL, USA, 1997; pp. 515–522. [Google Scholar]

- Jol, H. Ground Penetrating Radar Theory and Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Grote, K.; Hubbard, S.; Harvey, J.; Rubin, Y. Evaluation of infiltration in layered pavements using surface GPR reflection techniques. J. Appl. Geophys. 2005, 57, 125–129. [Google Scholar] [CrossRef]

- Daniels, D.J. Ground penetrating Radar, 2nd ed.; The Institution of Electrical Engineers: London, UK, 2004. [Google Scholar]

- Artagan, S.S. Use of Ground Penetrating Radar in Condition Assessment of Railway Ballast. Ph.D. Thesis, Univesity of Pardubice, Pardubice, Czechia, 2018. [Google Scholar]

- Selig, E.T.; Waters, J.M. Track Geotechnology and Substructure Management; Thomas Telford Publications: London, UK, 1994. [Google Scholar]

- Foun, D. Planning ballast cleaning using ballast fouling levels determined with ground-penetrating radar online. In Proceedings of the CORE 2012: Global Perspectives; Conference on railway engineering, Brisbane, Australia, 10–12 September 2012; pp. 697–705. [Google Scholar]

- Anbazhagan, P. Characterization of Rail Track Ballast Fouling Using Ground Penetration Radar and Field Sampling. Project Report; Indian Institute of Science: Bangalore, India, 2013. [Google Scholar]

- Fontul, S.; Fortunato, E.; Chiara, F.D. Evaluation of ballast fouling using GPR. In Proceedings of the 15th International Conference on Ground Penetrating Radar, Brussels, Belgium, 30 June–4 July 2014; ISBN 978-14-799-6789-6. [Google Scholar] [CrossRef]

- Lalagüe, A. Use of Ground Penetrating Radar for Transportation Infrastructure Maintenance. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2015. [Google Scholar]

- Clark, M.R. Electromagnetic properties of railway ballast. NDT E Int. 2001, 34, 305–311. [Google Scholar] [CrossRef]

- Sussmann, T.R. Application of Ground Penetrating Radar to Railway Track Substructure Maintenance Management. Ph.D. Thesis, University of Massachusett–Amherst, Amherts, MA, USA, 1999. [Google Scholar]

- Leng, Z.; Al-Qadi, I. Railroad Ballast Evaluation Using Ground-Penetrating Radar: Laboratory Investigation and Field Validation. Transp. Res. Rec. J. Transp. Res. Board. 2010. [CrossRef]

- Artagan, S.S.; Borecký, V. Advances in the nondestructive condition assessment of railway ballast: A focus on GPR. NDT E Int. 2020, 115, 102290. [Google Scholar] [CrossRef]

- Maturana, R.M.; Bautista, B.D.; Aguacil, Á.A.; Plaza, M.R.; Castaño, S.S. Preventive Maintenance of Railway Infrastructures using GPR–Ground Penetrating Radar. In Proceedings of the 9th World Congress on Railway Research, Lille, France, 22–26 May 2011. [Google Scholar]

- Roberts, R.; Al-Qadi, I.L.; Tutumluer, E.; Kathage, A. Ballast fouling assessment using 2 GHz horn antennas-GPR and ground truth comparison from 238 km of track. In Proceedings of the 9th International Railway Engineering Conference, London, UK, 1 June 2007. [Google Scholar]

- Roberts, R.; Rudy, J.; GSSI, S. Railroad ballast fouling detection using ground penetrating radar. A new approach based on scattering from voids. In Proceedings of the 9th European Conference on NDT, Berlin, Germany, 25–29 September 2006. ECNDT 2006–Th. 4.5 1.. [Google Scholar]

- Al-Qadi, I.L.; Xie, W.; Roberts, R. Scattering analysis of ground-penetrating radar data to quantify railroad ballast contamination. NDT E Int. 2008, 41, 441–447. [Google Scholar] [CrossRef]

- Su, L.-J.; Rujikiatkamjorn, C.; Indraratna, B. An Evaluation of Fouled Ballast in a Laboratory Model Track Using Ground Penetrating Radar. Geotech. Test. J. 2010, 33, 103045. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Xie, W.; Roberts, R.; Leng, Z. Data analysis techniques for GPR used for assessing railroad ballast in high radio-frequency environment. J. Transp. Eng. 2010, 136, 392–399. [Google Scholar] [CrossRef]

- De Bold, R.P. Non-Destructive Evaluation of Railway Trackbed Ballast. Ph.D. Thesis, University of Edinburgh, School of Engineering, Glasgow, Scotland, 2011. [Google Scholar]

- Zhang, Q.; Gascoyne, J.; Eriksen, A. Characterisation of ballast materials in trackbed using ground penetrating radar: Part 1. In Proceedings of the Railway Condition Monitoring and Non-Destructive Testing, 2011, (RCM 2011), 5th IET Conference On. IET, Kuala Lumpur, Malaysia, 5–6 September 2018; pp. 1–8. [Google Scholar]

- Anbazhagan, P.; Lijun, S.; Buddhima, I.; Cholachat, R. Model track studies on fouled ballast using ground penetrating radar and multichannel analysis of surface wave. J. Appl. Geophys. 2011, 74, 175–184. [Google Scholar] [CrossRef]

- De Chiara, F.; Fontul, S.; Fortunato, E. GPR Laboratory Tests for Railways Materials Dielectric Properties Assessment. Remote Sens. 2014, 6, 9712–9728. [Google Scholar] [CrossRef]

- Kashani, H.; Ho, C.L.; Oden, C.P.; Smith, S.S. Model Track Studies by Ground Penetrating Radar (GPR) on Ballast with Different Fouling and Geotechnical Properties. In Proceedings of the Joint Rail Conference ASME, San Jose, CA, USA, 23–26 March 2015. [Google Scholar] [CrossRef]

- Benedetto, A.; Tosti, F.; Bianchini Ciampoli, L.; Calvi, A.; Brancadoro, M.G. Alani, A.M. Railway ballast condition assessment using ground-penetrating radar—An experimental, numerical simulation and modelling development. Constr. Build. Mater. 2017, 140, 508–520. [Google Scholar] [CrossRef]

- Kashani, H. Evaluating the Influence of Breakdown Fouling and Moisture Content on Mechanical and Electromagnetic Properties of Ballasted Railroad Track. Ph.D. Thesis, University of Massachusett–Amherst, Amherst, MA, USA, 2017. [Google Scholar]

- Fontul, S.; Paixão, A.; Solla, M.; Pajewski, L. Railway Track Condition Assessment at Network Level by Frequency Domain Analysis of GPR Data. Remote Sens. 2018, 10, 599. [Google Scholar] [CrossRef]

- Barrett, B.E.; Day, H.; Gascoyne, J.; Eriksen, A. Understanding the capabilities of GPR for the measurement of ballast fouling conditions. J. Appl. Geophys. 2019, 169, 183–198. [Google Scholar] [CrossRef]

- Keogh, T.; Mesher, D.E.; Keegan, T.R. An Integrated System for Accurate Tie and Ballast Condition Assessment; Rail Radar ™ Inc; Canadian National Railway: Alberta, Canada, 2006. [Google Scholar]

- Sussmann, T.R.; O’Hara, K.R.; Selig, E.T. Development of material properties for railway application of ground-penetrating radar. In Proceedings of the Resented at the Ninth International Conference on Ground Penetrating Radar (GPR2002), Santa Barbara, CA, USA, 29 April–2 May 2002; pp. 42–47. [Google Scholar] [CrossRef]

- Göbel, C.; Hellmann, R.; Petzold, H. Georadar-model and in-situ investigations for inspection of railway tracks. In Proceedings of the Fifth International Conferention on Ground Penetrating Radar, Kitchener, Canada, 12–16 June 1994. [Google Scholar]

- Artagan, S.S.; Borecký, V.; Bartoš, J.; Kurel, R. Moisture Influence on the GPR-Measured RDP Values of Granite Ballast under Clean and Fouled Conditions. In Proceedings of the 7th International Scientific Conference of the Faculty of Transport Engineering, Pardubice, Czech Republic, 6–7 September 2018. [Google Scholar]

- Benedetto, F.; Tosti, F.; Alani, A.M. An entropy-based analysis of GPR data for the assessment of railway ballast conditions. IEEE Trans. Geosci. Rem. Sens. 2017, 55, 3900–3908. [Google Scholar] [CrossRef]

- Bianchini Ciampoli, L.; Tosti, F.; Brancadoro, M.G.; D’Amico, F.; Alani, A.M.; Benedetto, A. A spectral analysis of ground-penetrating radar data for the assessment of the railway ballast geometric properties. NDT E Int. 2017, 90, 39–47. [Google Scholar] [CrossRef]

- Benedetto, A.; Bianchini Ciampoli, L.; Brancadoro, M.G.; Alani, A.M.; Tosti, F. A computer-aided model for the simulation of railway ballast by random sequential adsorption process. Comput. Aided. Civ. Infrastruct. Eng. 2018, 33, 243–257. [Google Scholar] [CrossRef]

- Fontul, S.; Mínguez, R.; Solla, M.; Santos-Assunção, S. The use of geophysics for the condition assessment of railway infrastructure. In Non-Destructive Techniques for the Evaluation of Structures and Infrastructure; Riveiro, B., Solla, M., Eds.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Solla, M.; Pérez-Gracia, V.; Fontul, S. A Review of GPR Application on Transport Infrastructures: Troubleshooting and Best Practices. Remote Sens. 2021, 13, 672. [Google Scholar] [CrossRef]

- Ferrante, C.; Bianchini Ciampoli, L.; Benedetto, A.; Alani, A.M.; Tosti, F. Non-destructive Technologies for a Sustainable Assessment and Monitoring of Railway Infrastructures: A Focus on GPR and InSAR Methods. 2021. Available online: https://assets.researchsquare.com/files/rs-216510/v1_stamped.pdf (accessed on 1 March 2021).

- Khakiev, Z.; Shapovalov, V.; Kruglikov, A.; Yavna, V. GPR determination of physical parameters of railway structural layers. J. Appl. Geophys. 2014, 106, 139–145. [Google Scholar] [CrossRef]

- Khakiev, Z.; Shapovalov, V.; Kruglikov, A.; Morozov, A.; Yavna, V. Investigation of long term moisture changes in trackbeds using GPR. J. Appl. Geophys. 2014, 110, 1–4. [Google Scholar] [CrossRef]

- Bianchini Ciampoli, L.; Tosti, F.; Economou, N.; Benedetto, F. Signal Processing of GPR Data for Road Surveys. Geoscience 2019, 9, 96. [Google Scholar] [CrossRef]

- Bianchini Ciampoli, L.; Artagan, S.S.; Tosti, F.; Gagliardi, V.; Alani, A.M.; Benedetto, A. A comparative investigation of the effects of concrete sleepers on the GPR signal for the assessment of railway ballast. In Proceedings of the 17th international conference on ground penetrating radar (GPR2018), Rapperswil, Switzerland, 18–21 June 2018. [Google Scholar] [CrossRef]

| Ballast Condition | References | ||||

|---|---|---|---|---|---|

| Clark et al. [31] | Sussmann [32] | Leng and Al-Qadi [33] | Artagan and Borecky [34] | ||

| Clean | Dry clean | 3.00 | 3.60 | 3.25 | 3.09 |

| Moist clean | 3.50 | 4.00 | 4.59 | ||

| Saturated clean | 26.90 | 26.40 | 25.50 | ||

| Fouled | Dry fouled | 4.30 | 3.70 | 3.77 | 3.85 |

| Moist fouled | 7.80 | 5.10 | 5.21 | ||

| Saturated fouled | 38.50 | ||||

| Level Crossing | Section | Start Mileage (km) | End Mileage (km) | Length (m) |

|---|---|---|---|---|

| P2 | U1 | 279.150 | 279.200 | 50 |

| U2 | 279.250 | 279.300 | 50 | |

| P3 | U1 | 281.100 | 281.150 | 50 |

| U2 | 281.200 | 281.250 | 50 | |

| P6 | U1 | 283.675 | 283,725 | 50 |

| U2 | 283.775 | 283.825 | 50 | |

| P8 | U1 | 286.400 | 286.450 | 50 |

| U2 | 286.500 | 286.550 | 50 |

| Material Fraction | Weight | Percentage |

|---|---|---|

| Coarse fraction 31.5–63 mm | 79.240 kg | 86% |

| Fine fraction < 31.5 mm | 12.900 kg | 14% |

| Total material | 92.140 kg | 100% |

| Material Fraction | Weight | Percentage |

|---|---|---|

| Coarse fraction 31.5–63 mm | 31.551 kg | 66.66% |

| Fine fraction <31.5 mm | 15.780 kg | 33,34% |

| Total material | 47.331 kg | 100% |

| Post-processing Step Parameters According to the Nominal Frequency | 400 MHz | 900 MHz | 2000 MHz |

|---|---|---|---|

| Time-zero correction | According to the surface reflection twt | ||

| De-wow (ns) | 2.5 | 1.1 | 0.5 |

| Correct max phase tool | – | – | Surface reflection twt frame |

| Band-pass filtering (Low pass–high pass in MHz) | 100–700 | 225–1575 | 500–3500 |

| Background removal | Whole line/distance range | ||

| Running average (# of traces) | 3 | 3 | 3 |

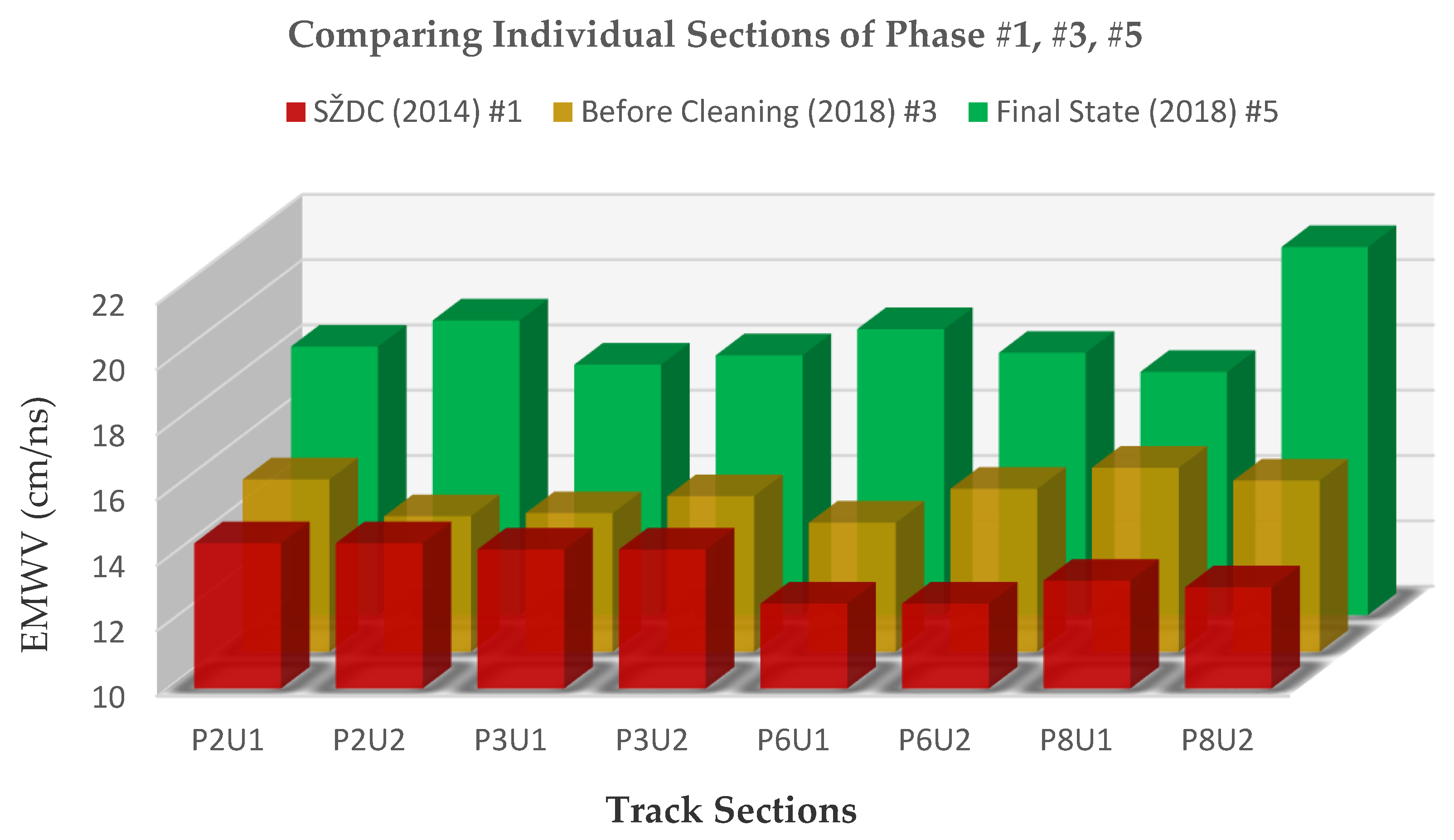

| Track Sections | EMWV before Ballast Cleaning Phase #3 (cm/ns) | EMWV in the Final State Phase #5 (cm/ns) | Percentage Improvement |

|---|---|---|---|

| P2U1 | 0.153 | 0.182 | 19.3 |

| P2U2 | 0.142 | 0.190 | 34.4 |

| P3U1 | 0.142 | 0.177 | 24.1 |

| P3U2 | 0.148 | 0.180 | 21.6 |

| P6U1 | 0.140 | 0.188 | 34.4 |

| P6U2 | 0.150 | 0.180 | 20.3 |

| P8U1 | 0.156 | 0.175 | 11.6 |

| P8U2 | 0.152 | 0.213 | 39.6 |

| Average Improvement in all surveyed track sections | 25.7 | ||

| Fouling Category | Interval for EMWV (cm/ns) | Interval for RDP |

|---|---|---|

| Clean 1 | ≥16 | ≤3.52 |

| Slightly fouled 1 | 13–16 | 3.52–5.33 |

| Highly fouled 1 | 9–13 | 5.33–11.11 |

| Unrecommended for traffic 1 | <9 | >11 |

| SECTIONS | #1 | #2 | #3 | #4 | #5 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SZDC | SZDC | RDP before Cleaning Process | RDP after Cleaning Process | RDP after Handing Over the Construction Site | ||||||||

| 23 September 2014 | 29 August 2017 | 12 October 2018 | 17 October 2018 | 19 October 2018 | ||||||||

| 400 MHz GSSI | 400 MHz GSSI | 400 MHz IDS | 900 MHz IDS | 2 GHz IDS | 400 MHz IDS | 900 MHz IDS | 2 GHz IDS | 400 MHz IDS | 900 MHz IDS | 2 GHz IDS | ||

| P2 | U1 | 4.31 | 4.39 | 3.65 | 3.65 | 4.31 | 3.09 | 3.42 | 4.13 | 2.20 | 2.68 | 3.44 |

| U2 | 4.31 | 4.39 | 4.92 | 4.34 | 4.26 | 3.09 | 3.79 | 4.42 | 1.80 | 2.88 | 3.10 | |

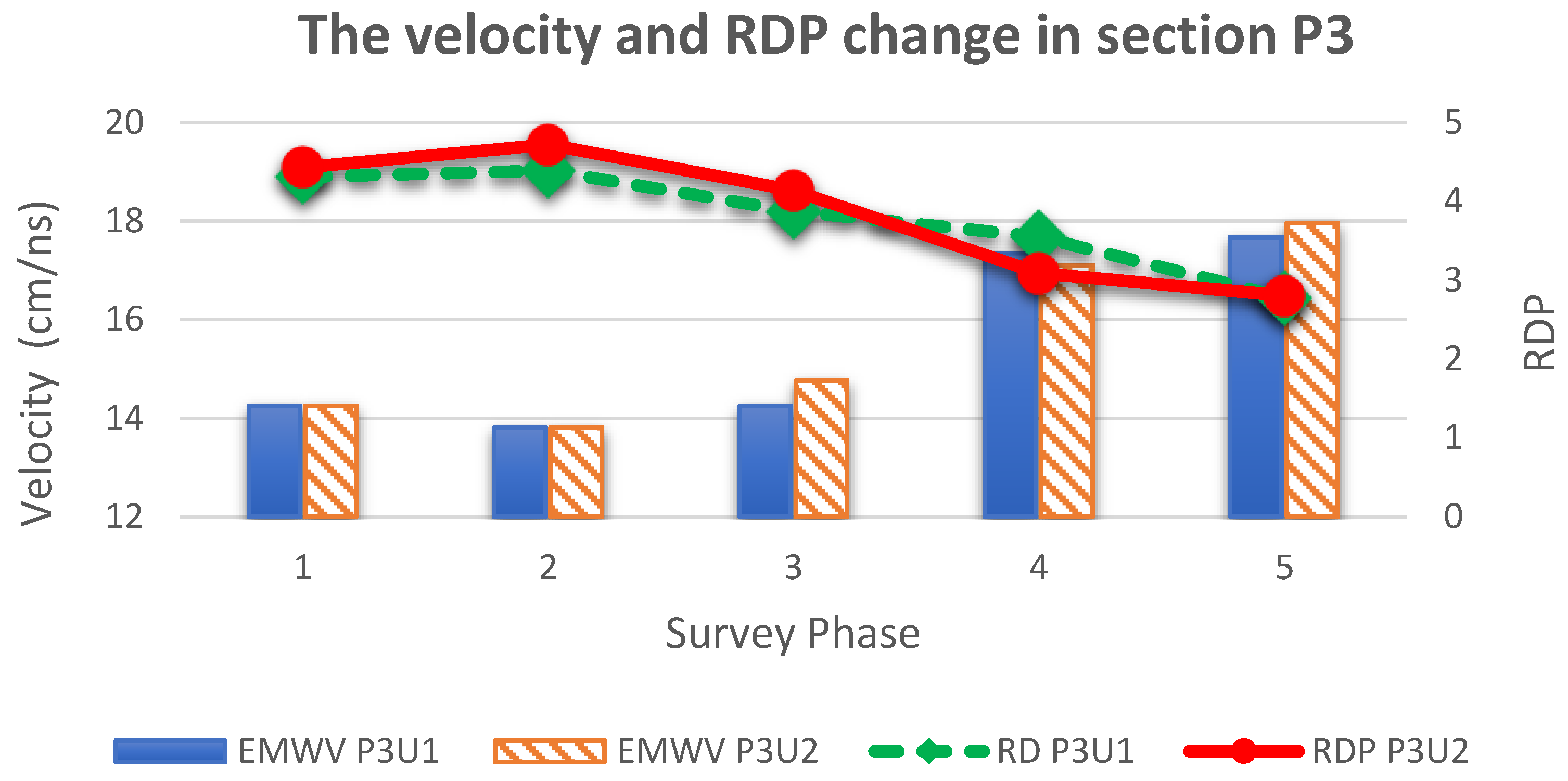

| P3 | U1 | 4.43 | 4.72 | 4.70 | 4.34 | 4.29 | 2.88 | 2.72 | 3.45 | 2.75 | 2.52 | 3.50 |

| U2 | 4.43 | 4.72 | 3.85 | 4.26 | 4.29 | 2.93 | 3.36 | 2.96 | 2.72 | 2.57 | 3.11 | |

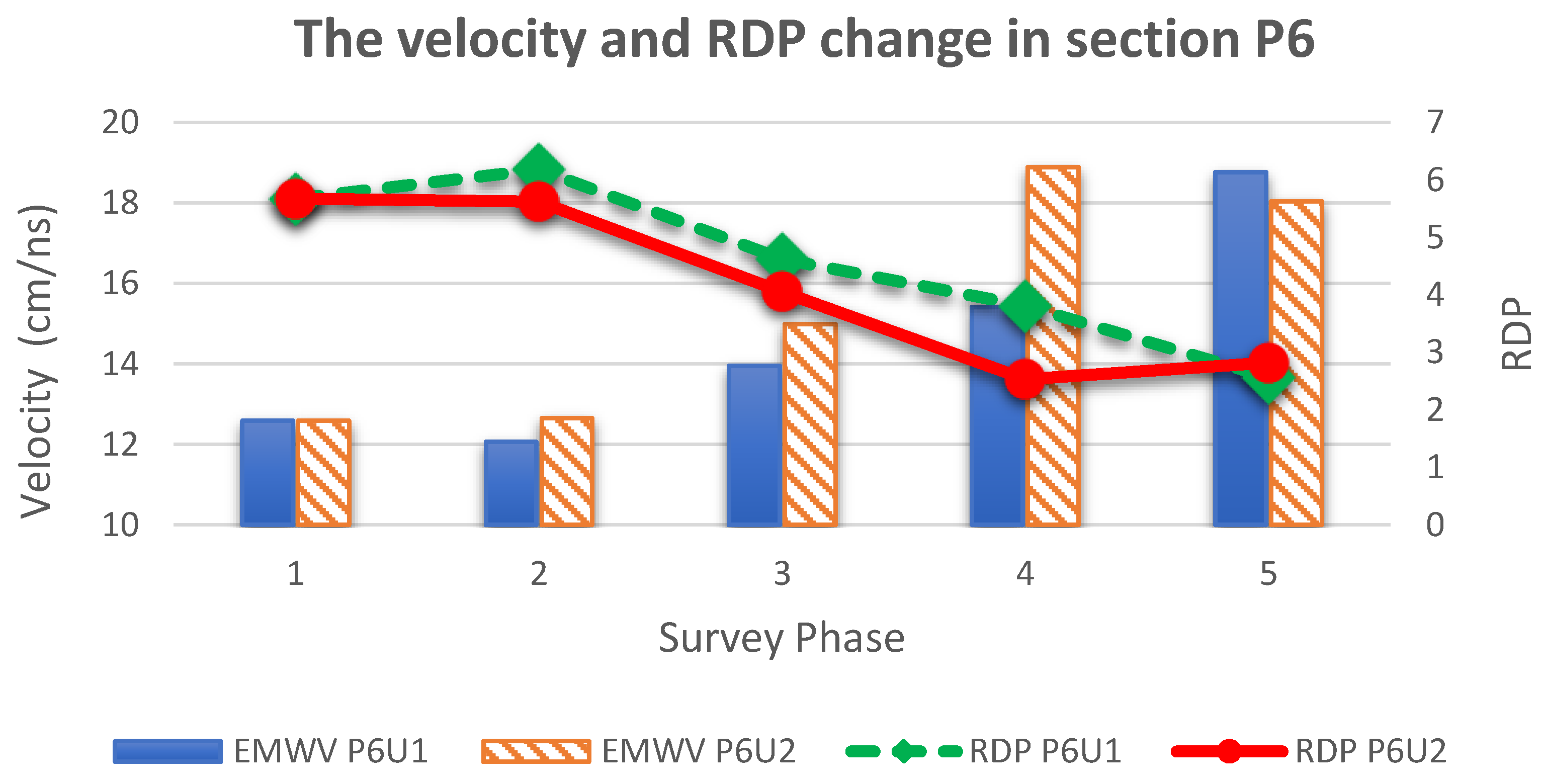

| P6 | U1 | 5.68 | 6.19 | 4.85 | 4.68 | 4.35 | 3.73 | 4.29 | 3.41 | 2.33 | 2.57 | 2.80 |

| U2 | 6.68 | 5.63 | 3.31 | 4.43 | 4.43 | 2.56 | 2.82 | 2.23 | 2.27 | 3.37 | 2.82 | |

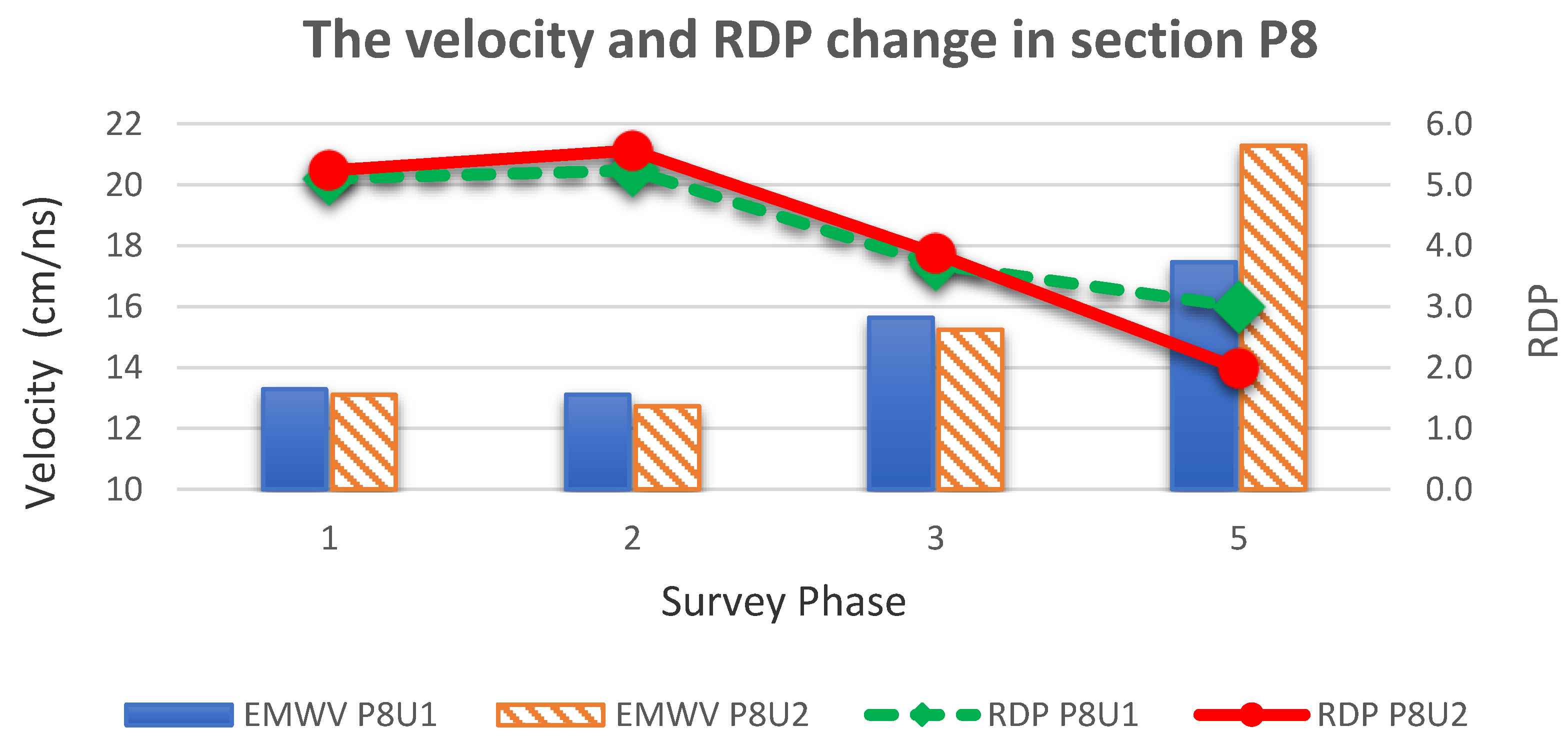

| P8 | U1 | 5.10 | 5.24 | 3.35 | 3.84 | 3.89 | – | – | – | 3.63 | 2.66 | 2.72 |

| U2 | 5.24 | 5.56 | 3.73 | 3.98 | 3.91 | – | – | – | 1.99 | 2.04 | 1.94 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borkovcová, A.; Borecký, V.; Artagan, S.S.; Ševčík, F. Quantification of the Mechanized Ballast Cleaning Process Efficiency Using GPR Technology. Remote Sens. 2021, 13, 1510. https://doi.org/10.3390/rs13081510

Borkovcová A, Borecký V, Artagan SS, Ševčík F. Quantification of the Mechanized Ballast Cleaning Process Efficiency Using GPR Technology. Remote Sensing. 2021; 13(8):1510. https://doi.org/10.3390/rs13081510

Chicago/Turabian StyleBorkovcová, Anna, Vladislav Borecký, Salih Serkan Artagan, and Filip Ševčík. 2021. "Quantification of the Mechanized Ballast Cleaning Process Efficiency Using GPR Technology" Remote Sensing 13, no. 8: 1510. https://doi.org/10.3390/rs13081510

APA StyleBorkovcová, A., Borecký, V., Artagan, S. S., & Ševčík, F. (2021). Quantification of the Mechanized Ballast Cleaning Process Efficiency Using GPR Technology. Remote Sensing, 13(8), 1510. https://doi.org/10.3390/rs13081510