1. Introduction

In western China, especially in the sandy areas, surface cracks are one of the geological environmental problems caused by coal mining [

1]. Surface cracks have caused deformation of buildings, damage to underground pipelines, damage to cultivated land, accelerated soil moisture evaporation, vegetation destruction, and soil erosion [

2,

3,

4]. This creates considerable difficulties for mining area management staff. Therefore, it is necessary to obtain real-time, objective, and high-precision distribution information of surface cracks in mining areas, which can be used to study the development regularity of surface cracks and evaluate the risk to provide guarantees for land reclamation [

5].

Traditional surface crack information acquisition methods mainly include field surveys, radar detection technology [

6,

7], and satellite remote sensing images [

8]. Although field survey accuracy is high, the cost is expensive [

9]. Airborne radar technology is used in landslide monitoring and surface crack detection [

10]. However, due to the complex geological environment in the mining area, the application conditions of using radar to detect ground crack are limited. Mining caused the surface to collapse, making airborne radar unable to cover the entire area. Crack extraction through images can effectively extract cracks. Mohan summarized some crack detection techniques based on the type of the image used, including camera image, IR (infrared) image, Ultrasonic Image, Time of Flight Diffraction image, Laser image, and various other distinctive image types through a review [

11]. Satellite remote sensing image is a method of extracting cracks from images, but the resolution of satellite remote sensing is difficult to extract small cracks. Unmanned air vehicles (UAVs) have significant advantages, such as high resolution, flexible maneuverability, high efficiency, and low operating costs [

12]. Their resolution can reach the level of centimeters [

13], which provides an ideal data source for information extraction of surface cracks in mining areas. At present, the methods for extracting surface cracks from UAV image data are mainly object-oriented [

13,

14], edge detection [

15], threshold segmentation [

16], and artificial visual interpretation [

9].

The object-oriented method achieved good results in surface crack extraction, but its class and inheritance characteristics led to many more pointer operations in the program for locating the function entry and maintaining additional virtual method tables and other additional work causes the program’s processing efficiency to be relatively low. The object-oriented method for surface crack extraction needs to be divided into multiple steps. First, spectral feature extraction must be performed, then whether the extraction results satisfies geometric features, linear features, and fractal dimension features in turn. It is difficult to distinguish because the spectral color characteristics of surface cracks and withered vegetation on the ground are similar. At the same time, stepwise detection also requires a lot of additional work, resulting in low efficiency [

14]. Methods such as edge detection and threshold segmentation can cause many error points, and the accuracy of crack extraction is poor, which affects the extraction effect of surface cracks. Edge detection is used to identify the characteristic points with obvious brightness changes in the image. Because the surface of the mining area contains a lot of vegetation, the edge detection method will also extract the contour of the vegetation to appear as error points, which makes the cracks extraction have low efficiency [

16]. The threshold segmentation method is to extract the ground crack pixel gray value range to extract it. Because the spectral color characteristics of surface crack and withered vegetation on the ground are similar, many error points will appear in the extraction result [

17]. The artificial visual interpretation method requires workers to manually process each image [

9]. This method is too complicated and has low efficiency and poor timeliness, so it is not popular or practical. Machine learning has been widely used in the field of graphic recognition. It can not only improve accuracy but also greatly improve efficiency. Deep learning techniques for feature extraction of image have been applied over a wide range of applications through UAV image [

18]. Fei Y. uses deep learning to detect cracks in 3D asphalt pavement images [

19]. N. Ammour using convolutional neuron network(CNN) and SVM for car detection and counting, which is superior in accuracy and computational time [

20]. Zeggada, proposing a novel method based on convolutional neural networks to solve problem of multilabeling UAV image, typically characterized by a high level of information content [

21]. However, the complexity of land surface information in mining areas has limited its application. Therefore, finding a method to reasonably apply machine learning to the extraction of surface cracks in mining areas is a key requirement.

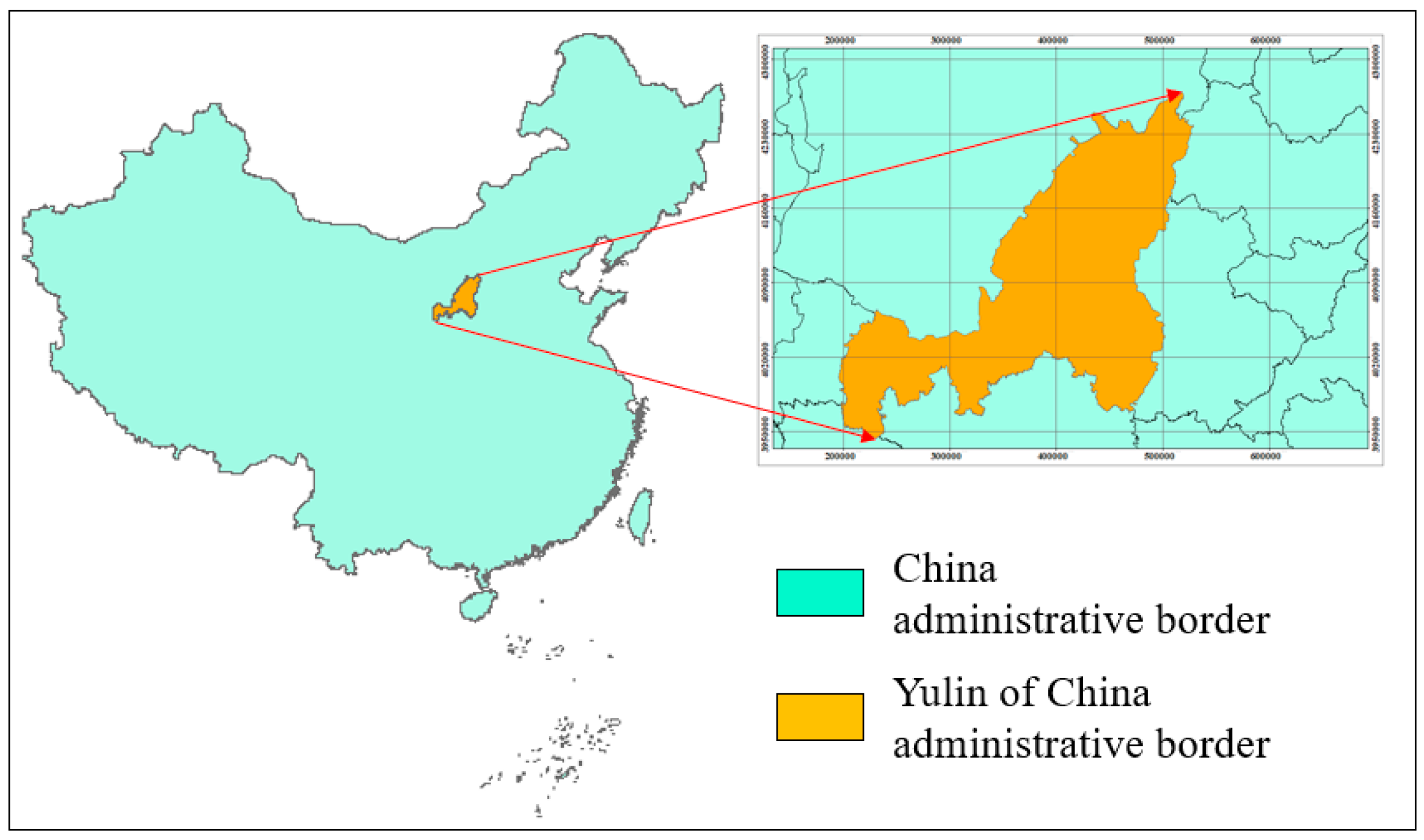

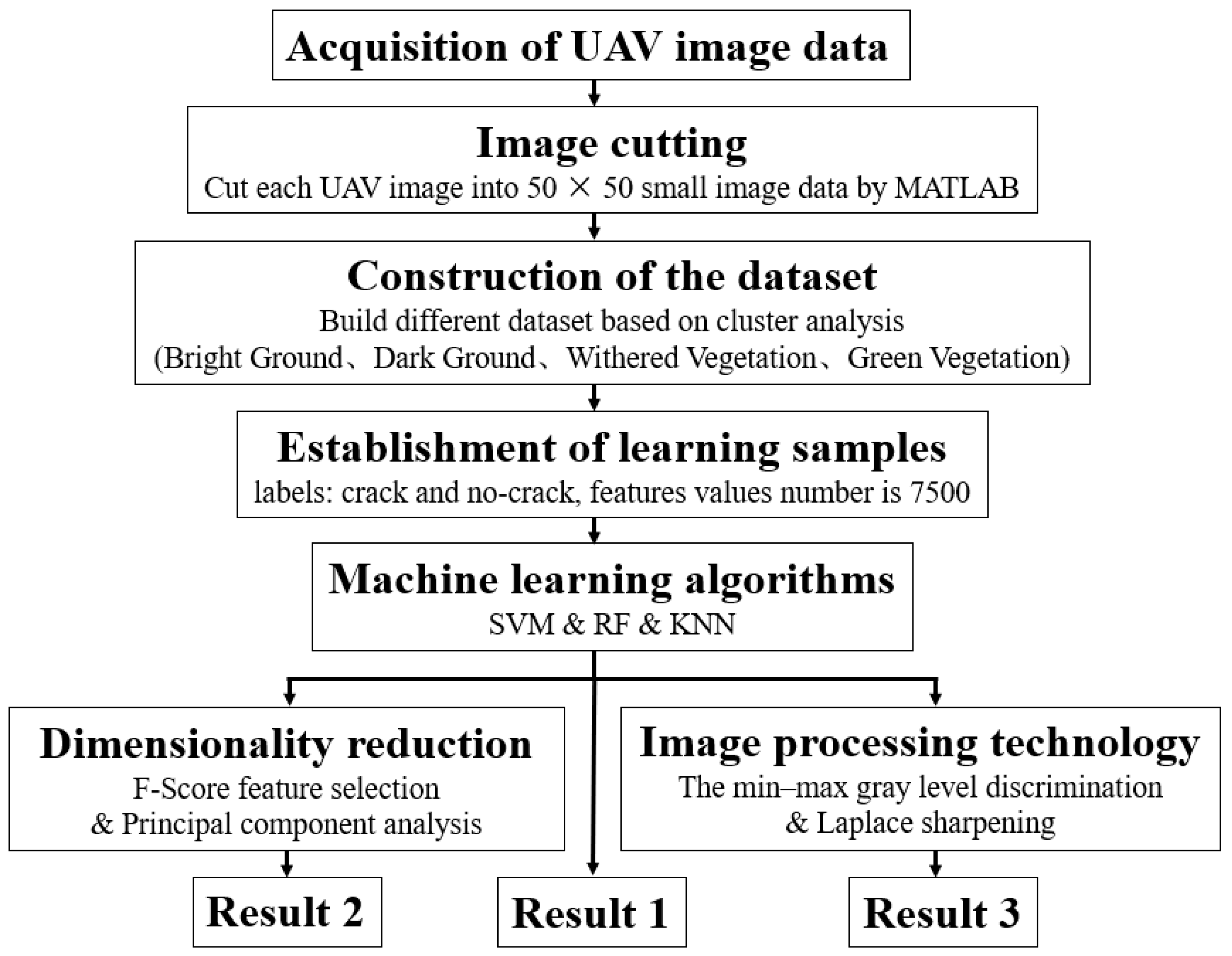

To solve the problems mentioned above, this article provides a method for detecting surface cracks in areas with complex geological environments, such as mining areas, using UAV images as data sources; machine learning as technical means; and optimizing the best machines learning algorithms, dimensionality reduction methods, and image processing methods through comparative analysis. The detailed research method idea is introduced into the second part. This method can effectively reduce the interference from complex surface environments such as vegetation on the extraction of cracks.

The rest of the article is organized as follows.

Section 2 introduces the materials and methods,

Section 3 shows the experimental results, and

Section 4 discusses and concludes the study in the final section.

4. Discussion

4.1. Machine Learning Methods

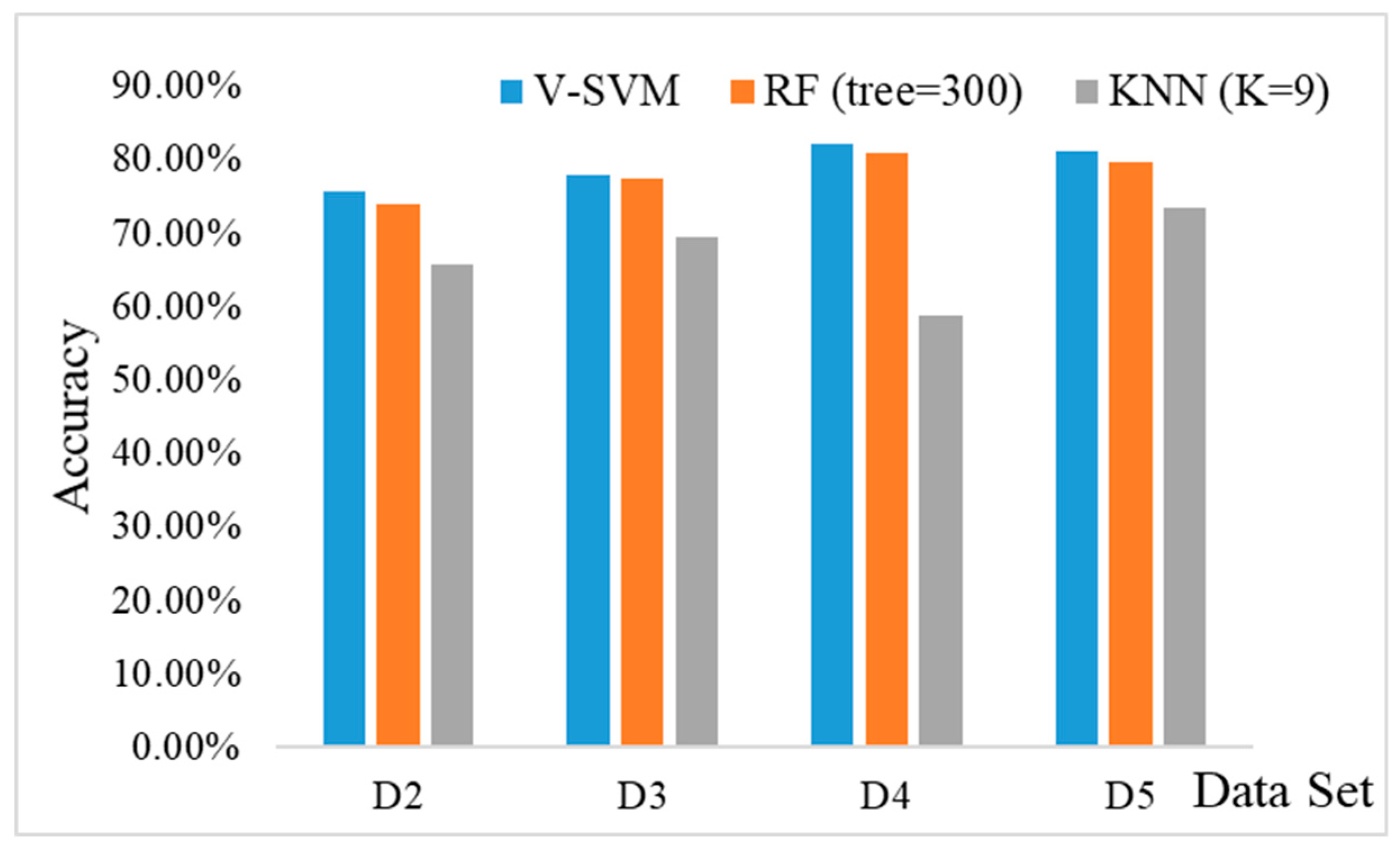

In the SVM machine learning algorithm, when the parameter penalty function C of C-SVM tends to infinity, it means that samples with classification errors are not allowed to exist, and it easily causes hard-margin SVM overfitting. When C approaches 0, it means no longer focus on whether the classification is correct; only the interval needs to be maximized, which easily leads to underfitting of the algorithm. V-SVM uses a new parameter V instead of C, which can be used to control the number and error of support vectors and is relatively easy to choose. Therefore, better classification results are achieved.

In the RF machine learning algorithm, the classification effect improves correspondingly with the increase in the tree within a certain range. When it reaches a certain number, it will be balanced. However, when the number of trees is too large, it will cause overfitting. Instead, the classification accuracy of the random forest is reduced. Therefore, the final selection number of trees is 300 through comparative analysis.

In the KNN machine learning algorithm, the classification effect improves as the k value decreases in a certain range. However, when the k value is too low, it will cause overfitting. Therefore, this article finally chooses the k value of 9 through comparative analysis.

Among the three machine learning algorithms for surface crack extraction in mining areas, SVM is superior to RF and KNN. It has the best classification effect, which is consistent with the conclusions of Hoang. in research on road crack extraction [

23].

4.2. Dimensionality Reduction Method

In the F-score feature selection, as the UAV images have been cut, the information contained in each image has been sufficiently simplified. Therefore, full feature selection has been adopted to achieve better classification results. When PCA is used to reduce the dimensions to 95% of the original variance, its classification accuracy and AUC value are greater, which has a better classification effect. This is consistent with the conclusions of Chen W. in research on face detection and recognition using PCA for dimensionality reduction has a better detection success rate [

40].

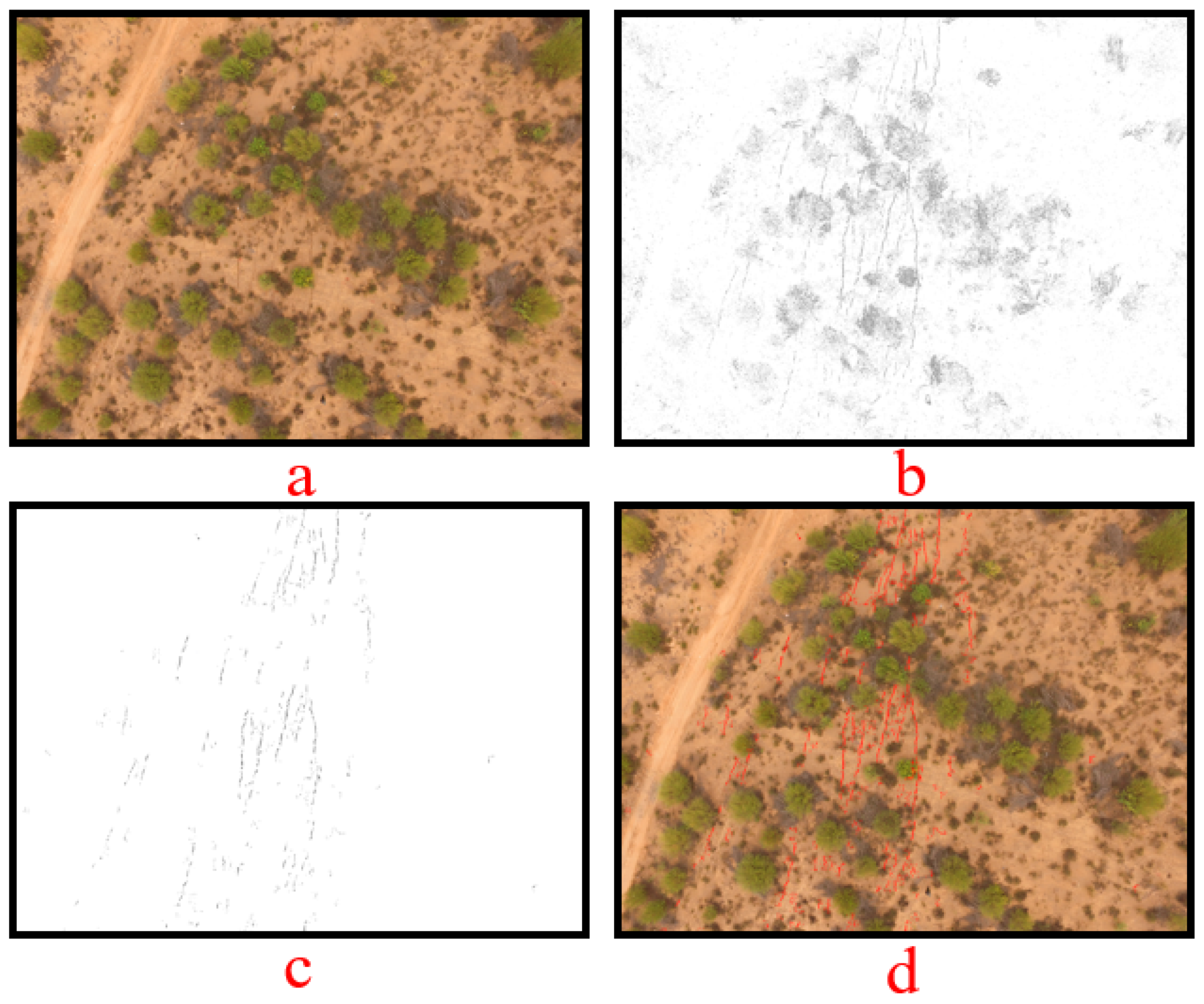

4.3. Image Processing Technology

Before performing machine learning, images are usually preprocessed first, among which image enhancement methods are widely used. In this article, the min–max gray level discrimination (M2GLD) and Laplace sharpening image enhancement methods are selected for research. M2GLD is an image gray enhancement method that has no effect on the classification accuracy of surface cracks in mining areas. This may be because when the color image is converted into a gray image to enhance the crack information, the background interference information is also enhanced, resulting in worse classification results. Laplace sharpening is an image color enhancement method that can effectively enhance the crack information of the land in the mining area and has achieved a good classification effect. Jijun W. uses the four-neighbor laplace sharpening to enhance image detail information and obtain more effective results [

41]. This is consistent with our results using laplace sharpening to enhance the image crack information and obtain higher classification accuracy.

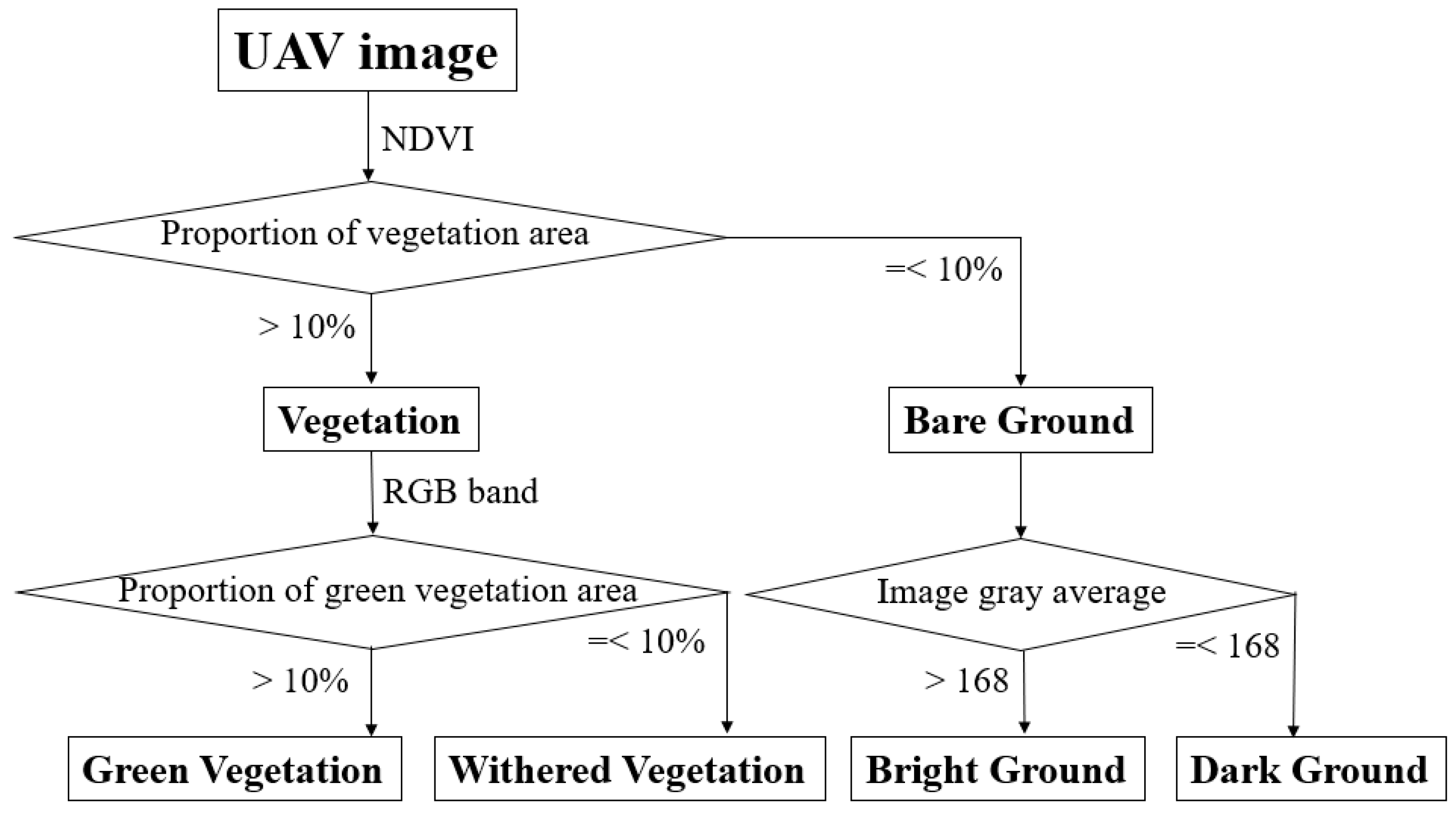

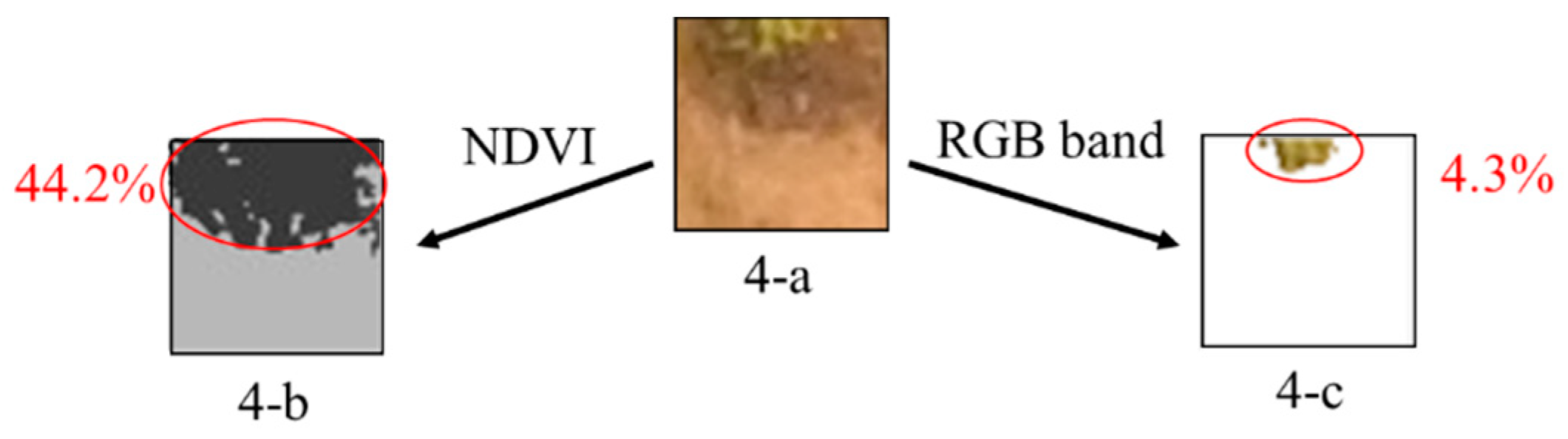

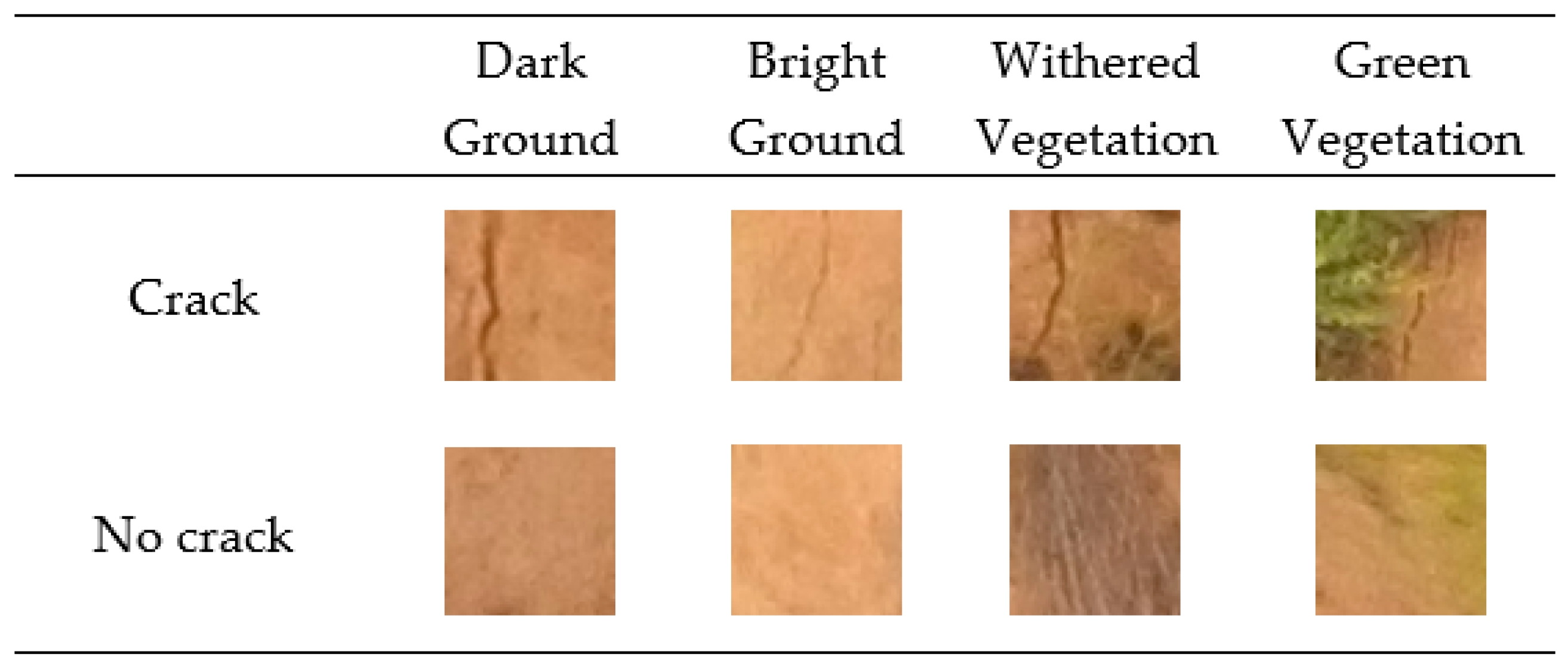

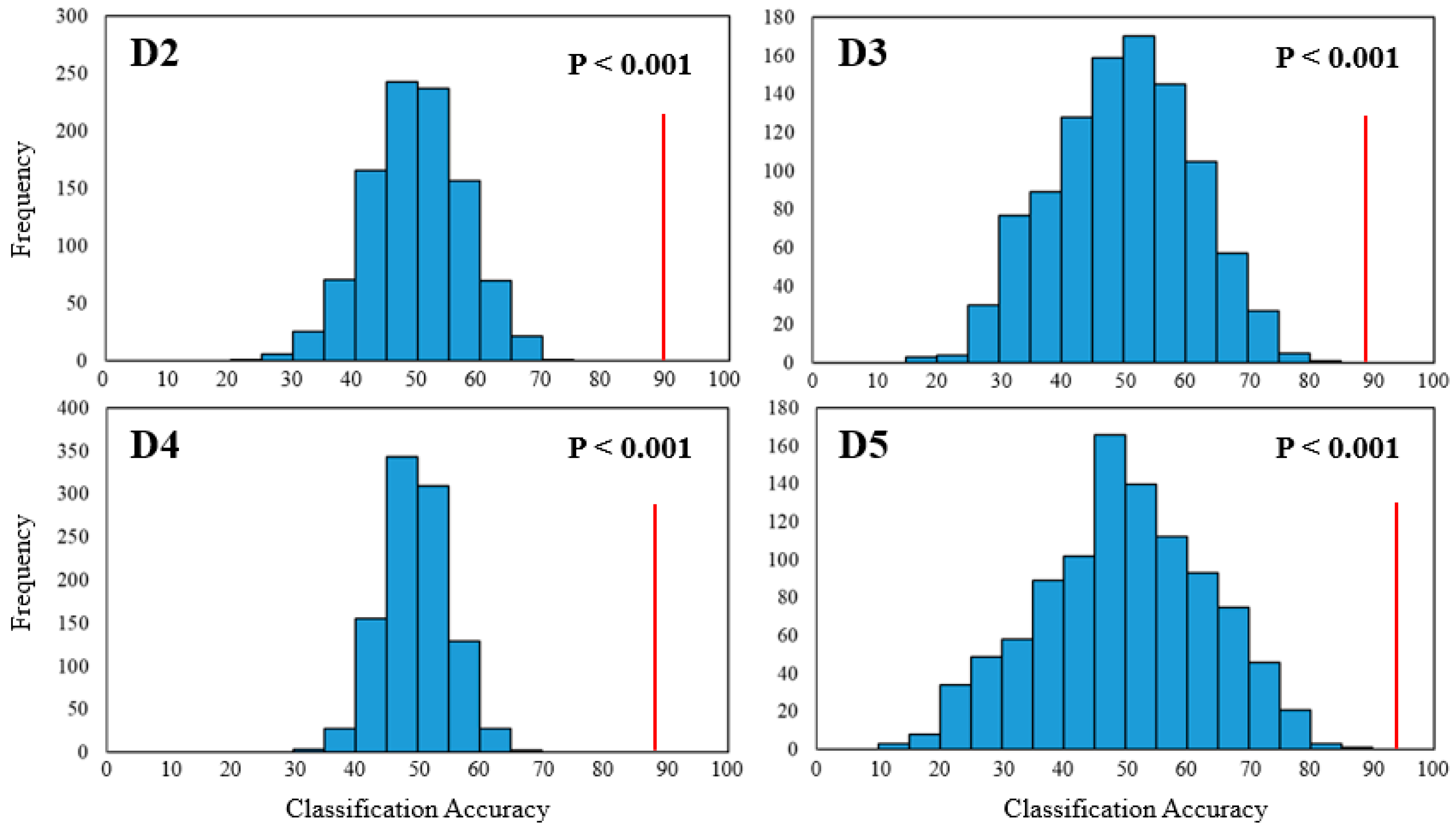

4.4. Cluster Analysis Results

UAV remote sensing technology plays an important role in land reclamation in mining areas and has the characteristics of low cost and high efficiency. Machine learning has been widely used in the field of pattern recognition. This article proposes a new identification method for surface cracks from UAV images based on machine learning in coal mining areas. This method first cuts the drone images to simplify the surface information contained in each image and then uses the idea of cluster analysis to differentiate the background information of the images. Clustering is performed twice so that images with similar background information are combined to build datasets: bright ground, dark ground, withered vegetation, and green vegetation. Therefore, this method can effectively reduce the interference of background information on the classification results. The overall accuracy is improved to 88.99%.