Sensor Reliability in Cyber-Physical Systems Using Internet-of-Things Data: A Review and Case Study

Abstract

1. Introduction

2. Reliability of Sensors in Cyber-Physicals Systems. A Brief State-of-the-Art Review

3. CPS-Based Reliability Approach

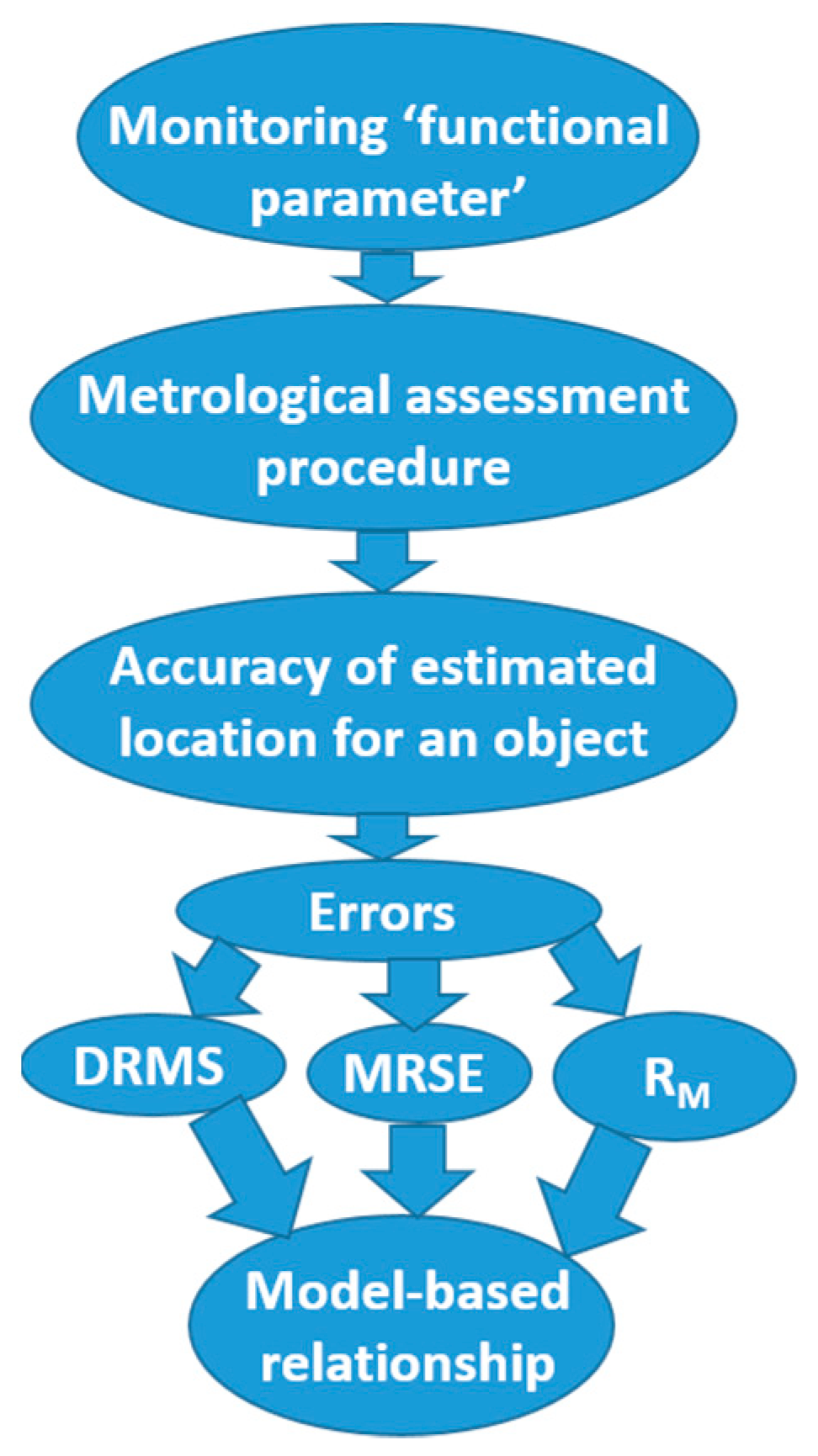

3.1. Sensor Reliability Assesment

3.2. Statistical and Artificial Intelligence-Based Methods

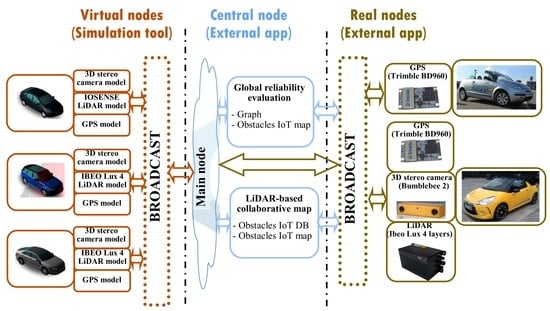

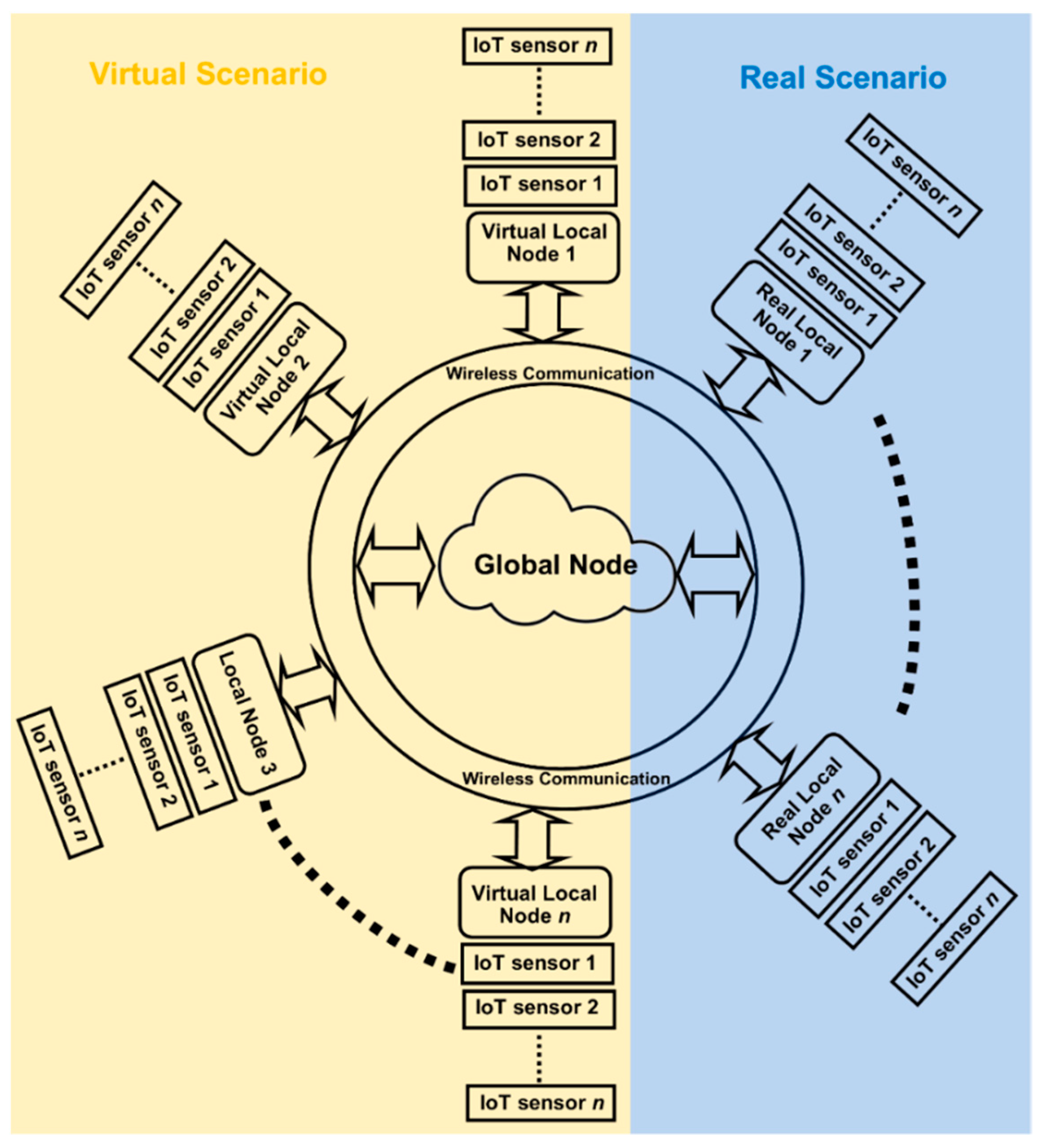

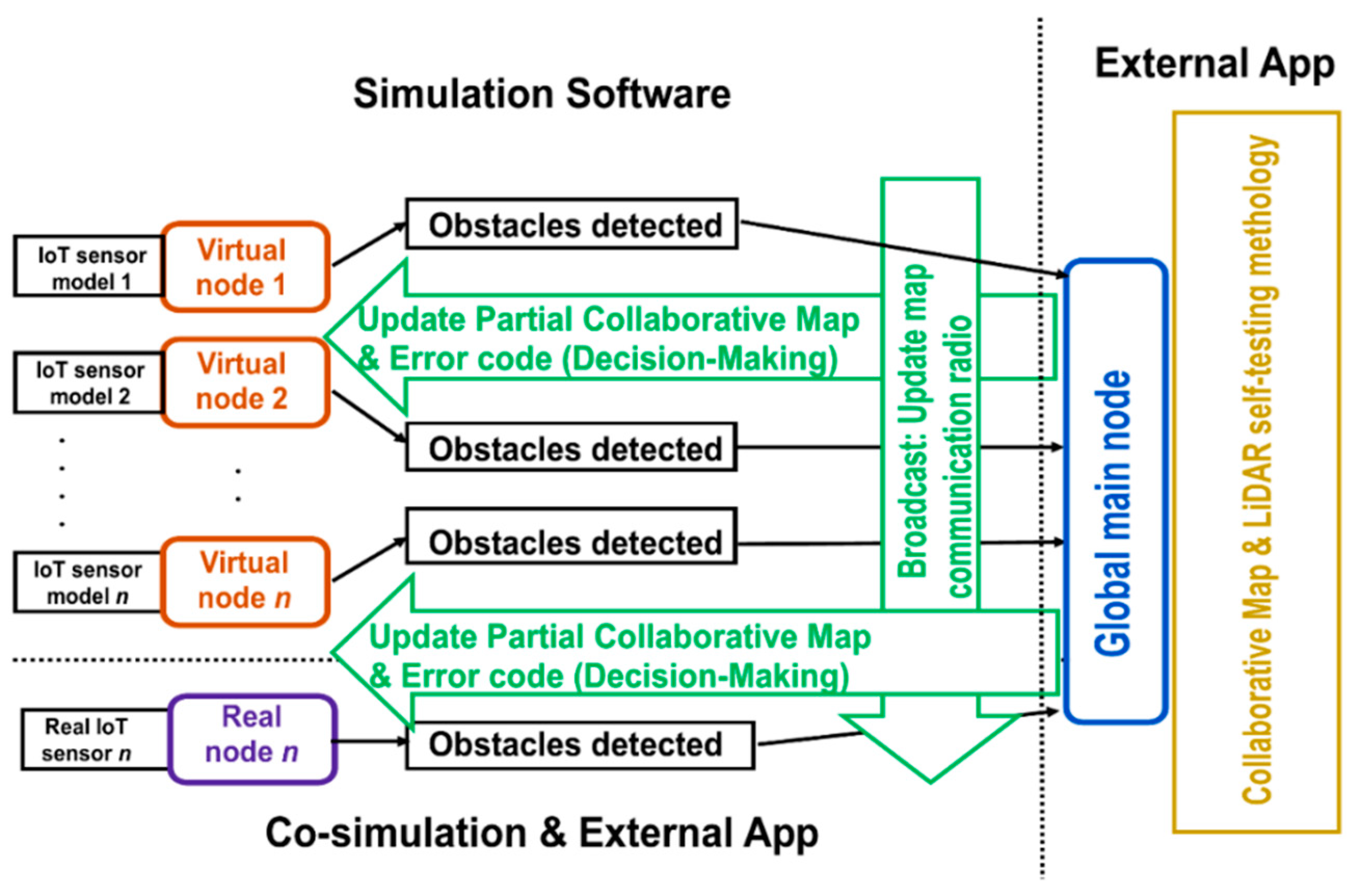

4. CPS-Based Co-Simulation Framework

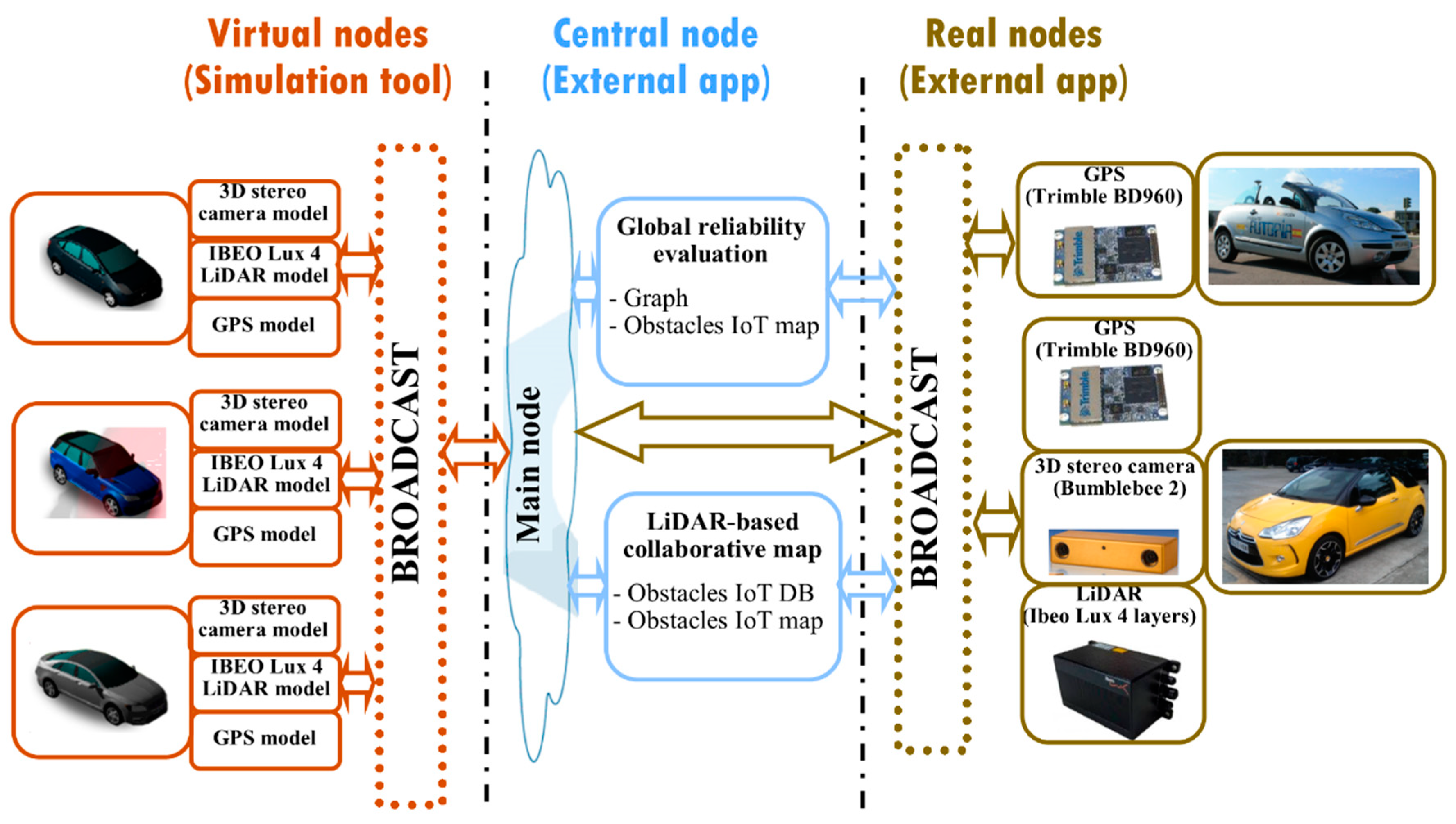

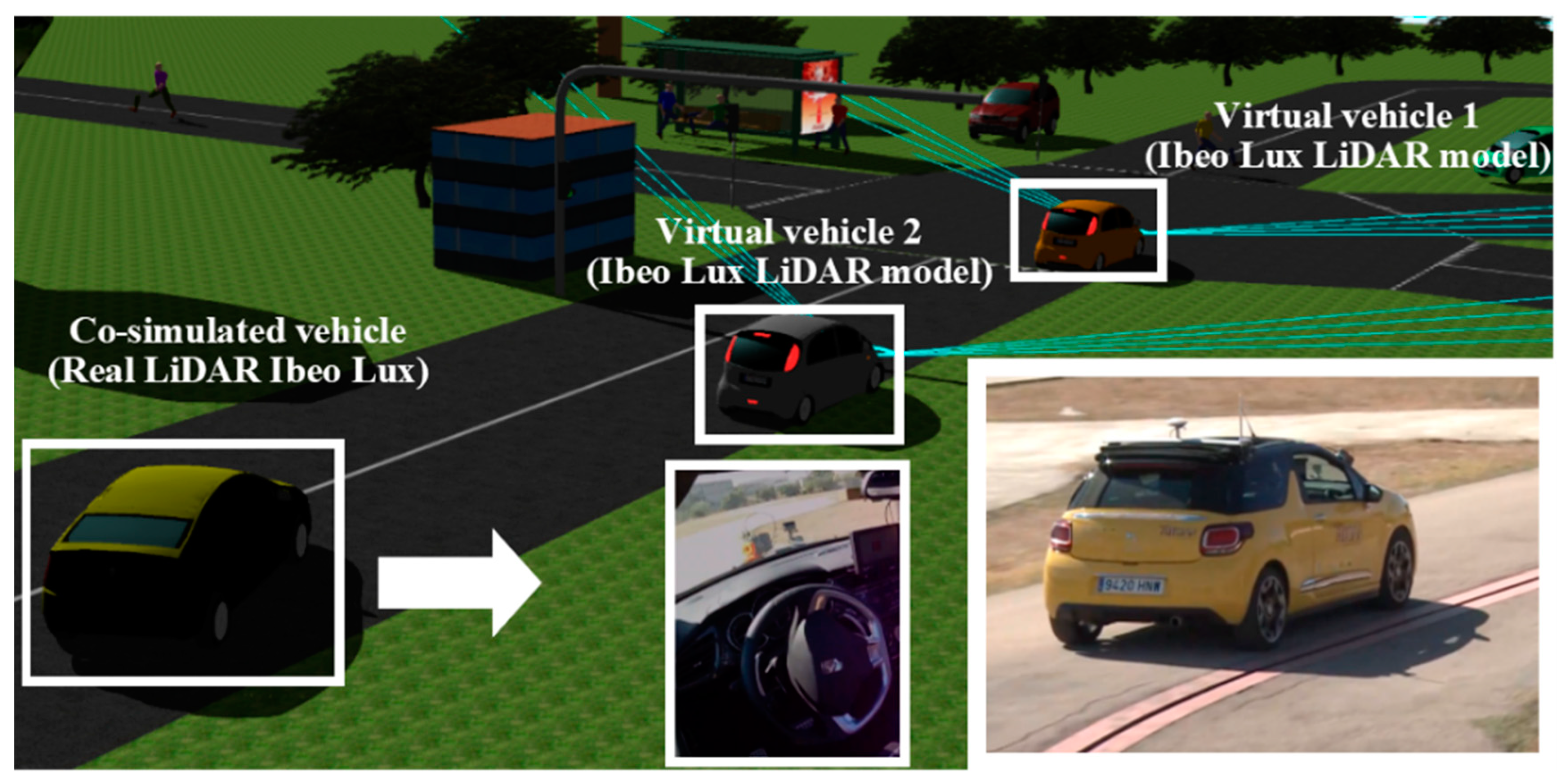

4.1. CPS-based Co-simulation Framework

4.1.1. Conceptual Scheme

4.1.2. Procedure Description

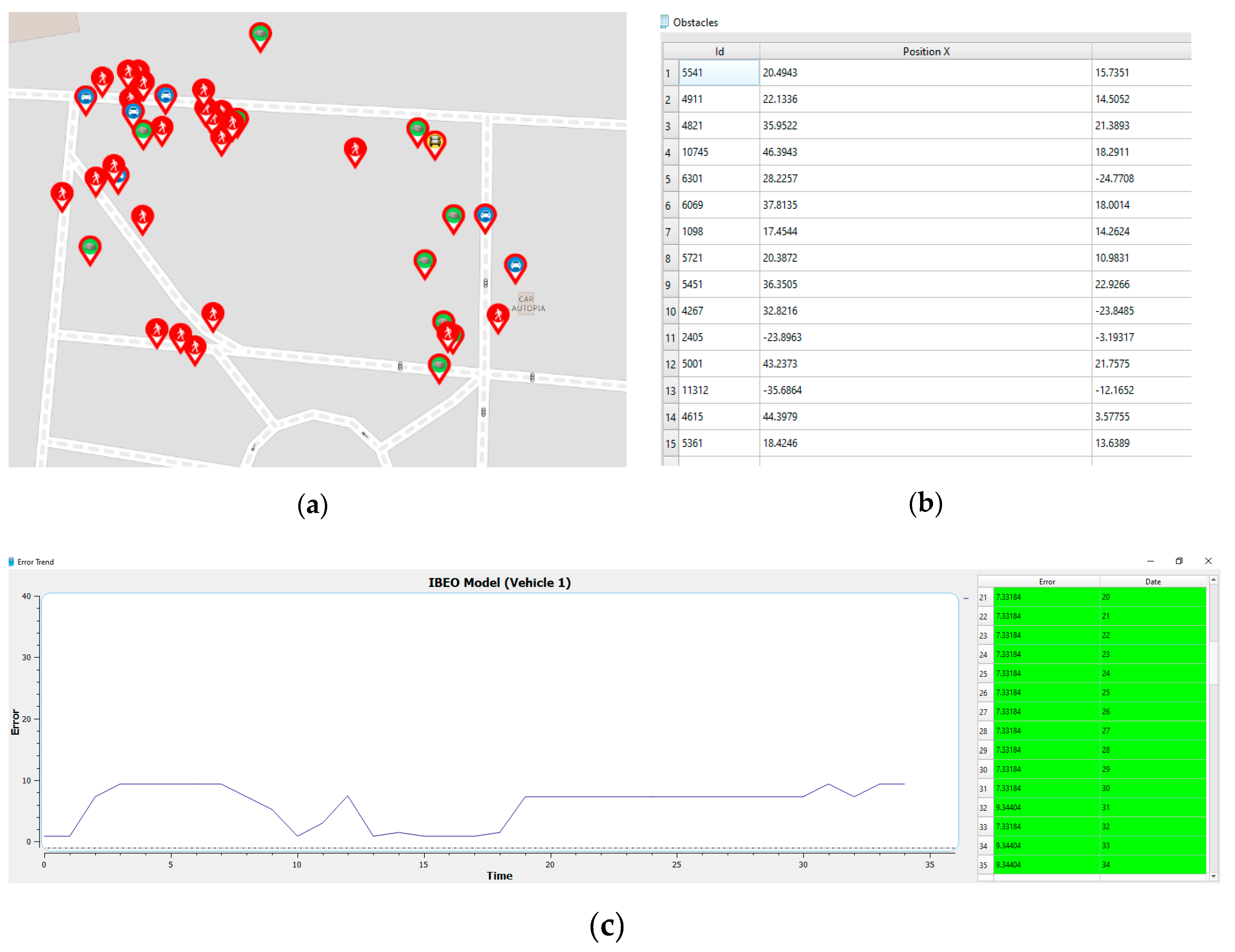

5. IoT LiDAR-based Collaborative Mapping – A Case Study

5.1. Obstacle Detection in the IoT Application

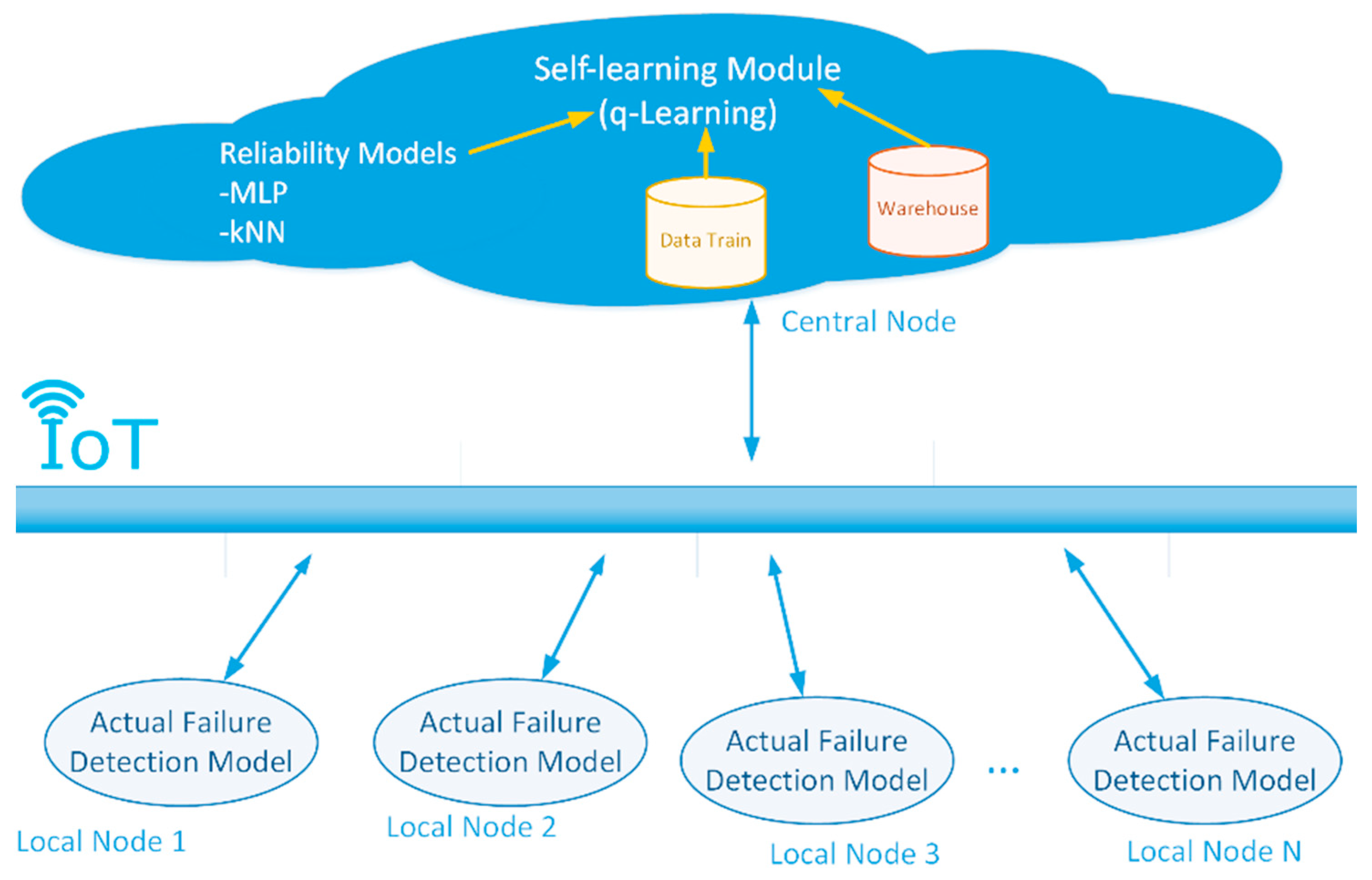

5.2. LiDAR Selft-testing Application

5.2.1. Reliability Prediction Models

5.2.2. Model Parametrization and Validation

5.2.3. Self-Learning-Based Decision-Making. Q-Learning Algorithm

6. Experimental Results

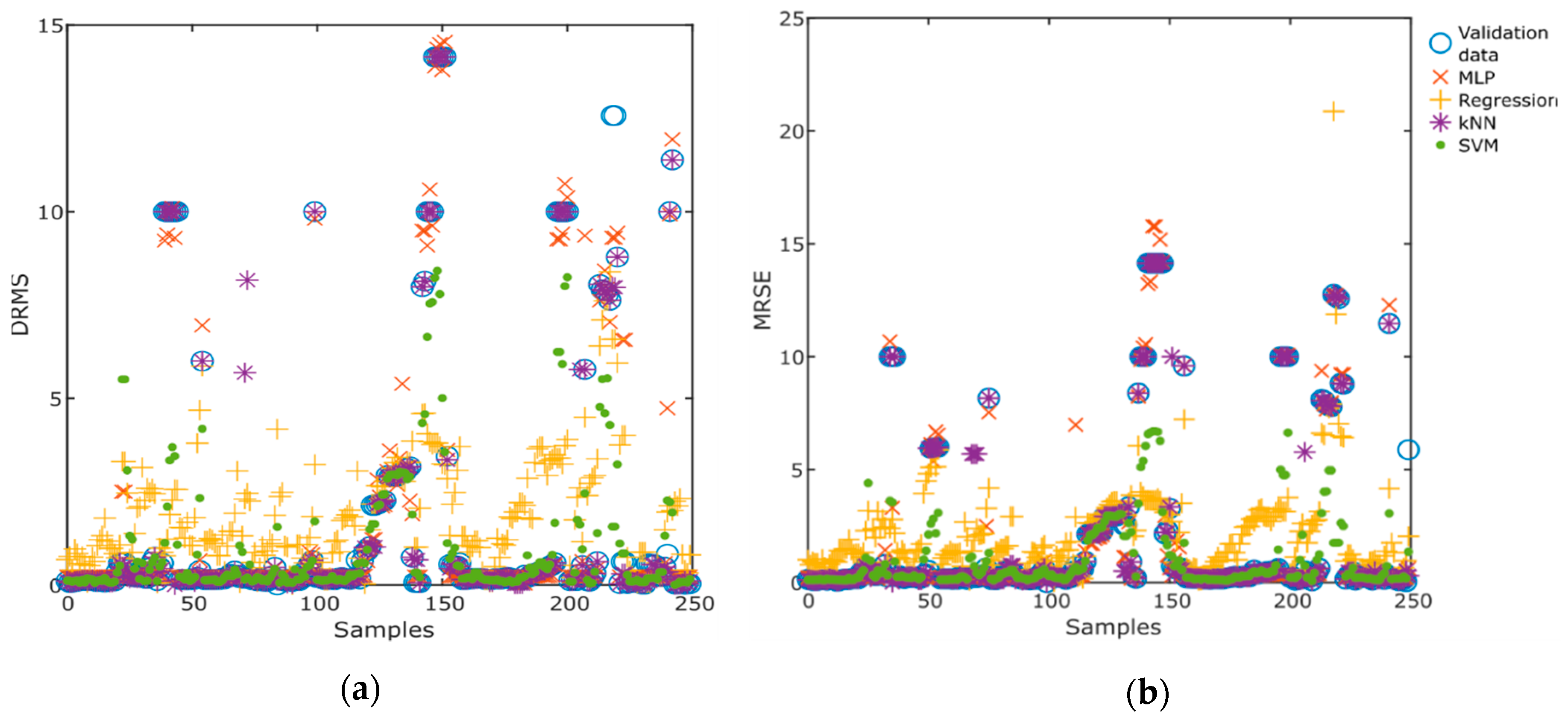

6.1. Reliability Model-based Validation

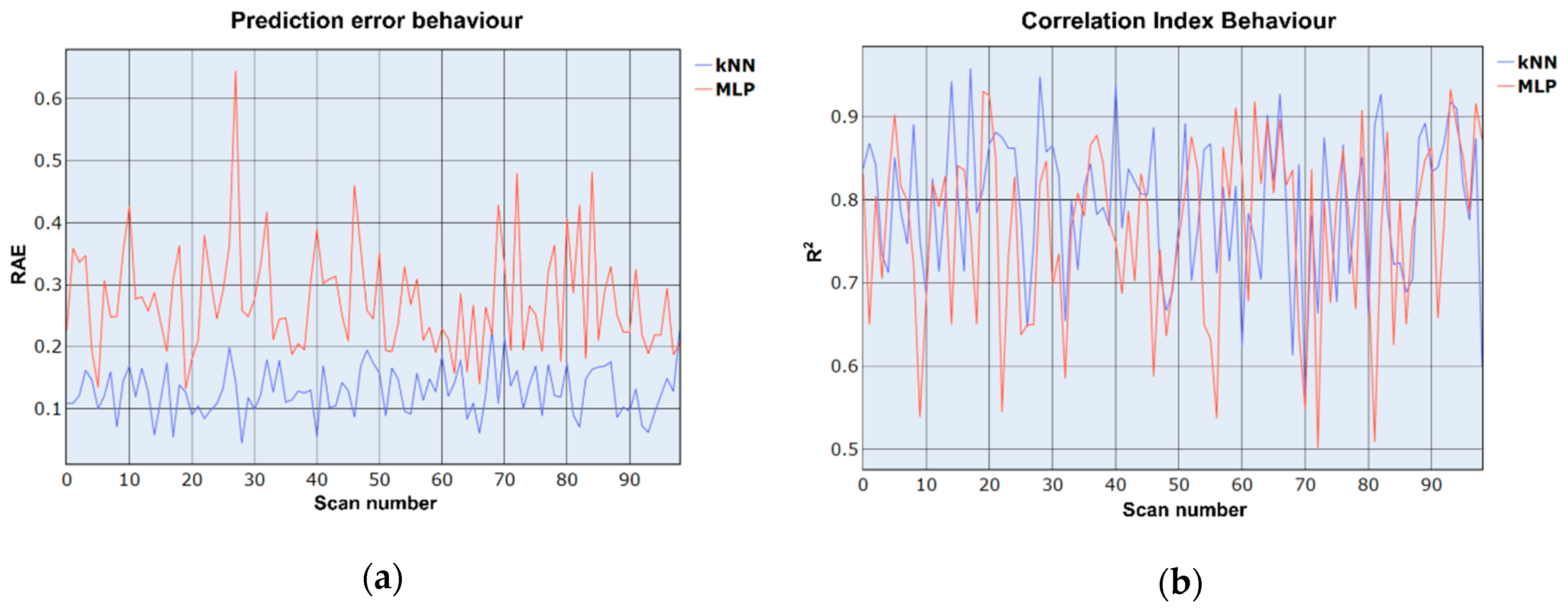

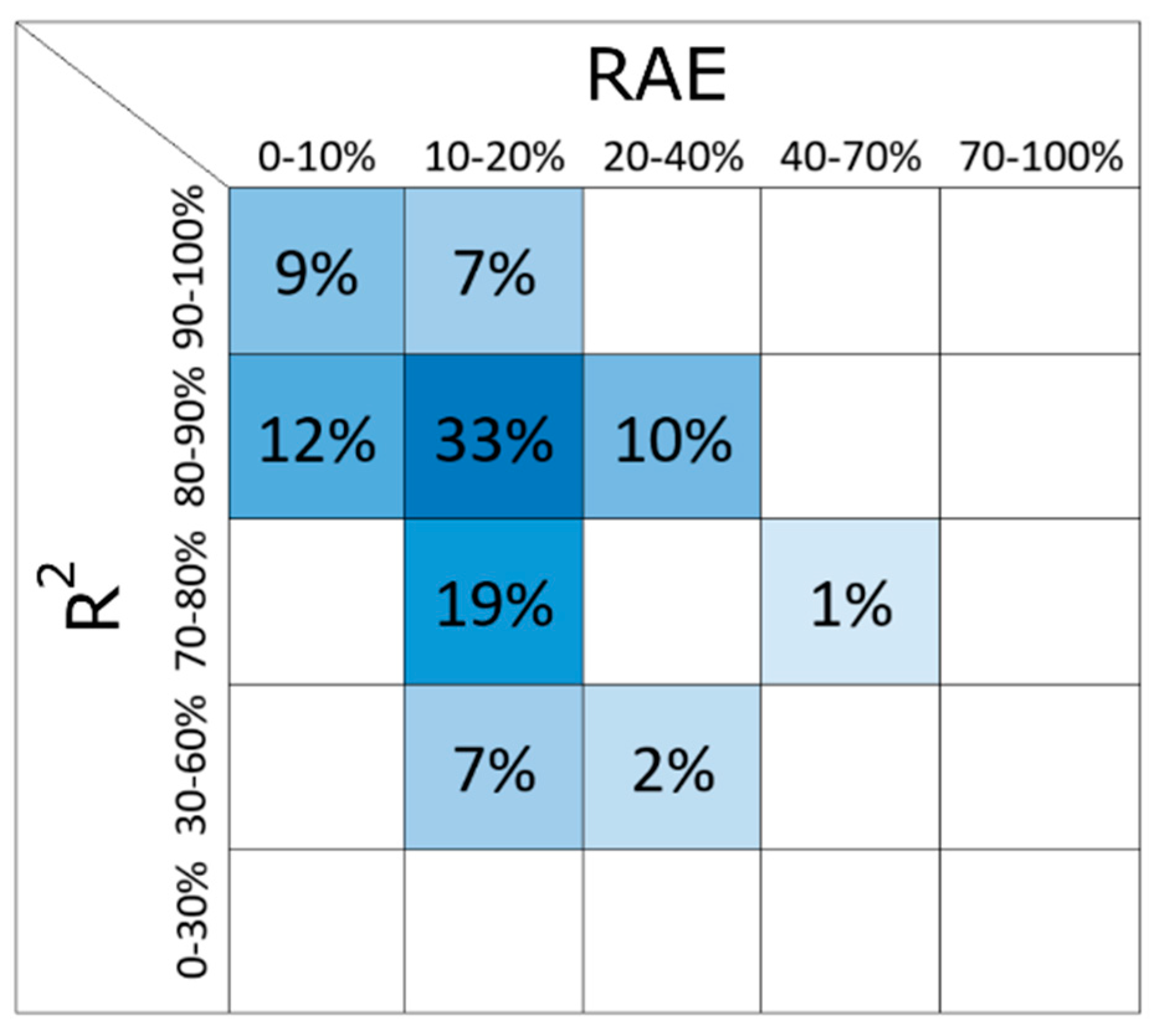

6.2. Self-Learning for Decision-Making Evaluation

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Beruvides, G.; Quiza, R.; Del Toro, R.; Haber, R.E. Sensoring systems and signal analysis to monitor tool wear in microdrilling operations on a sintered tungsten-copper composite material. Sens. Actuators A Phys. 2013, 199, 165–175. [Google Scholar] [CrossRef]

- Iarovyi, S.; Mohammed, W.M.; Lobov, A.; Ferrer, B.R.; Lastra, J.L.M. Cyber-Physical Systems for Open-Knowledge-Driven Manufacturing Execution Systems. Proc. IEEE 2016, 104, 1142–1154. [Google Scholar] [CrossRef]

- Kabashkin, I.; Kundler, J. Reliability of Sensor Nodes in Wireless Sensor Networks of Cyber Physical Systems. Procedia Comput. Sci. 2017, 104, 380–384. [Google Scholar] [CrossRef]

- Jakovljevic, Z.; Petrovic, M.; Mitrovic, S.; Miljkovic, Z. Intelligent sensing systems—Status of research at KaProm. In Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2018; pp. 18–36. [Google Scholar]

- Godoy, J.; Pérez, J.; Onieva, E.; Villagrá, J.; Milanés, V.; Haber, R. A driverless vehicle demonstration on motorways and in urban environments. Transport 2015, 30, 253–263. [Google Scholar] [CrossRef]

- Routh, D.; Seegmiller, L.; Bettigole, C.; Kuhn, C.; Oliver, C.D.; Glick, H.B. Improving the reliability of mixture tuned matched filtering remote sensing classification results using supervised learning algorithms and cross-validation. Remote Sens. 2018, 10, 1675. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, D.; Yu, L.; See, L.; Fritz, S.; Perger, C.; Gong, P. Assessing and improving the reliability of volunteered land cover reference data. Remote Sens. 2017, 9, 1034. [Google Scholar] [CrossRef]

- Hao, X.; Wang, L.; Yao, N.; Geng, D.; Chen, B. Topology control game algorithm based on Markov lifetime prediction model for wireless sensor network. Ad Hoc Netw. 2018, 78, 13–23. [Google Scholar] [CrossRef]

- Hessner, K.G.; El Naggar, S.; von Appen, W.J.; Strass, V.H. On the reliability of surface current measurements by X-Band marine radar. Remote Sens. 2019, 11, 1030. [Google Scholar] [CrossRef]

- Jia, F.; Lichti, D.D. A model-based design system for terrestrial laser scanning networks in complex sites. Remote Sens. 2019, 11, 1749. [Google Scholar] [CrossRef]

- Guo, H.; Shi, W.; Deng, Y. Evaluating Sensor Reliability in Classification Problems Based on Evidence Theory. IEEE Trans. Syst. Man Cybern. Part B 2006, 36, 970–981. [Google Scholar] [CrossRef]

- Lei, L.; Qiu, C.; Li, Z.; Han, D.; Han, L.; Zhu, Y.; Wu, J.; Xu, B.; Feng, H.; Yang, H.; et al. Effect of leaf occlusion on leaf area index inversion of maize using UAV-LiDAR data. Remote Sens. 2019, 11, 1067. [Google Scholar] [CrossRef]

- Okhrimenko, M.; Coburn, C.; Hopkinson, C. Multi-spectral lidar: Radiometric calibration, canopy spectral reflectance, and vegetation vertical SVI profiles. Remote Sens. 2019, 11, 1556. [Google Scholar] [CrossRef]

- Chen, P.; Pan, D. Ocean optical profiling in South China Sea Using Airborne LiDAR. Remote Sens. 2019, 11, 1826. [Google Scholar] [CrossRef]

- Dash, J.P.; Watt, M.S.; Paul, T.S.H.; Morgenroth, J.; Pearse, G.D. Early detection of invasive exotic trees using UAV and manned aircraft multispectral and LiDAR Data. Remote Sens. 2019, 11, 1812. [Google Scholar] [CrossRef]

- Kerfoot, W.C.; Hobmeier, M.M.; Green, S.A.; Yousef, F.; Brooks, C.N.; Shuchman, R.; Sayers, M.; Lin, L.; Luong, P.; Hayter, E.; et al. Coastal ecosystem investigations with LiDAR (Light Detection and Ranging) and bottom reflectance: Lake superior reef threatened by migrating tailings. Remote Sens. 2019, 11, 1076. [Google Scholar] [CrossRef]

- Xiao, L.; Wang, R.; Dai, B.; Fang, Y.; Liu, D.; Wu, T. Hybrid conditional random field based camera-LIDAR fusion for road detection. Inf. Sci. 2018, 432, 543–558. [Google Scholar] [CrossRef]

- Zeng, Y.; Yu, H.; Dai, H.; Song, S.; Lin, M.; Sun, B.; Jiang, W.; Meng, M. An Improved Calibration Method for a Rotating 2D LIDAR System. Sensors 2018, 18, 497. [Google Scholar] [CrossRef]

- Kempf, J.; Arkko, J.; Beheshti, N.; Yedavalli, K. Thoughts on reliability in the internet of things. In Proceedings of the Interconnecting Smart Objects with the Internet Workshop 2011, Prague, Czech, 25 March 2011; Volume 1, pp. 1–4. [Google Scholar]

- Ahmad, M. Reliability Models for the Internet of Things: A Paradigm Shift. In Proceedings of the 2014 IEEE International Symposium on Software Reliability Engineering Workshops, Naples, Italy, 3–6 November 2014; pp. 52–59. [Google Scholar]

- Zhang, H.; Liu, J.; Pang, A.-C. A Bayesian network model for data losses and faults in medical body sensor networks. Comput. Netw. 2018, 143, 166–175. [Google Scholar] [CrossRef]

- Serpen, G.; Li, J.; Liu, L. AI-WSN: Adaptive and Intelligent Wireless Sensor Network. Procedia Comput. Sci. 2013, 20, 406–413. [Google Scholar] [CrossRef]

- Nsabagwa, M.; Mugume, I.; Kasumba, R.; Muhumuza, J.; Byarugaba, S.; Tumwesigye, E.; Otim, J.S. Condition Monitoring and Reporting Framework for Wireless Sensor Network-based Automatic Weather Stations. In Proceedings of the 2018 IST-Africa Week Conference (IST-Africa), Gaborone, Botswana, 9–11 May 2018; pp. 1–8. [Google Scholar]

- Chuan, Y.; Chen, L. The Application of Support Vector Machine in the Hysteresis Modeling of Silicon Pressure Sensor. IEEE Sens. J. 2011, 11, 2022–2026. [Google Scholar] [CrossRef]

- Commission, E. Project impact articles. In Electronic Components and Systems for European Leadership (ECSEL) Joint Undertaking; 2019; Available online: https://www.ecsel.eu/project-impact (accessed on 20 September 2019).

- Mäyrä, A.; Hietala, E.; Kutila, M.; Pyykönen, P.; Tiihonen, M.; Jokela, T. Experimental study on spectral absorbance in fog as a function of temperature, liquid water content, and particle size. In Proceedings of the SPIE REMOTE SENSING, Optics in Atmospheric Propagation and Adaptive Systems, Warsaw, Poland, 11–14 September 2017. [Google Scholar]

- Castaño, F.; Beruvides, G.; Villalonga, A.; Haber, R.E. Self-tuning method for increased obstacle detection reliability based on internet of things LiDAR sensor models. Sensors 2018, 18, 1508. [Google Scholar] [CrossRef]

- Godoy, J.; Haber, R.; Muñoz, J.J.; Matía, F.; García, Á. Smart sensing of pavement temperature based on low-cost sensors and V2I communications. Sensors 2018, 18, 2092. [Google Scholar] [CrossRef]

- Le, V.H.; den Hartog, J.; Zannone, N. Security and privacy for innovative automotive applications: A survey. Comput. Commun. 2018, 132, 17–41. [Google Scholar] [CrossRef]

- Valencia, J.; Goswami, D.; Goossens, K. Comparing platform-aware control design flows for composable and predictable TDM-based execution platforms. ACM Trans. Des. Autom. Electron. Syst. 2019, 24, 32. [Google Scholar] [CrossRef]

- Druml, N.; Macher, G.; Stolz, M.; Armengaud, E.; Watzenig, D.; Steger, C.; Herndl, T.; Eckel, A.; Ryabokon, A.; Hoess, A.; et al. PRYSTINE—PRogrammable sYSTems for INtelligence in AutomobilEs. In Proceedings of the 2018 21st Euromicro Conference on Digital System Design (DSD), Prague, Czech Republic, 29–31 August 2018; pp. 618–626. [Google Scholar]

- Godoy, J.; Artuñedo, A.; Villagra, J. Self-Generated OSM-Based Driving Corridors. IEEE Access 2019, 7, 20113–20125. [Google Scholar] [CrossRef]

- Guerra, R.H.; Quiza, R.; Villalonga, A.; Arenas, J.; Castano, F. Digital Twin-Based Optimization for Ultraprecision Motion Systems with Backlash and Friction. IEEE Access 2019, 7, 93462–93472. [Google Scholar] [CrossRef]

- La Fe-Perdomo, I.; Beruvides, G.; Quiza, R.; Haber, R.; Rivas, M. Automatic Selection of Optimal Parameters Based on Simple Soft-Computing Methods: A Case Study of Micromilling Processes. IEEE Trans. Ind. Inform. 2019, 15, 800–811. [Google Scholar] [CrossRef]

- Toma, D.M.; Masmitja, I.; del Río, J.; Martinez, E.; Artero-Delgado, C.; Casale, A.; Figoli, A.; Pinzani, D.; Cervantes, P.; Ruiz, P.; et al. Smart embedded passive acoustic devices for real-time hydroacoustic surveys. Measurement 2018, 125, 592–605. [Google Scholar] [CrossRef]

- Lizé, E.; Rébillat, M.; Mechbal, N.; Bolzmacher, C. Optimal dual-PZT sizing and network design for baseline-free SHM of complex anisotropic composite structures. Smart Mater. Struct. 2018, 27, 115018. [Google Scholar] [CrossRef]

- Fratarcangeli, F.; Savastano, G.; D’Achille, M.C.; Mazzoni, A.; Crespi, M.; Riguzzi, F.; Devoti, R.; Pietrantonio, G. VADASE reliability and accuracy of real-time displacement estimation: Application to the Central Italy 2016 earthquakes. Remote Sens. 2018, 10, 1201. [Google Scholar] [CrossRef]

- Elouedi, Z.; Mellouli, K.; Smets, P. Assessing Sensor Reliability for Multisensor Data Fusion within the Transferable Belief Model. IEEE Trans. Syst. Man Cybern. Part B 2004, 34, 782–787. [Google Scholar] [CrossRef]

- Guna, J.; Jakus, G.; Pogačnik, M.; Tomažič, S.; Sodnik, J. An analysis of the precision and reliability of the leap motion sensor and its suitability for static and dynamic tracking. Sensors 2014, 14, 3702–3720. [Google Scholar] [CrossRef]

- AboElFotoh, H.M.F.; Iyengar, S.S.; Chakrabarty, K. Computing reliability and message delay for cooperative wireless distributed sensor networks subject to random failures. IEEE Trans. Reliab. 2005, 54, 145–155. [Google Scholar] [CrossRef]

- Felemban, E.; Lee, C.G.; Ekici, E. MMSPEED: Multipath Multi-SPEED Protocol for QoS guarantee of reliability and timeliness in wireless sensor networks. IEEE Trans. Mob. Comput. 2006, 5, 738–753. [Google Scholar] [CrossRef]

- Di Francesco, M.; Anastasi, G.; Conti, M.; Das, S.K.; Neri, V. Reliability and energy-efficiency in IEEE 802.15.4/ZigBee sensor networks: An adaptive and cross-layer approach. IEEE J. Sel. Areas Commun. 2011, 29, 1508–1524. [Google Scholar] [CrossRef]

- Pak, J.M.; Ahn, C.K.; Shmaliy, Y.S.; Lim, M.T. Improving Reliability of Particle Filter-Based Localization in Wireless Sensor Networks via Hybrid Particle/FIR Filtering. IEEE Trans. Ind. Inform. 2015, 11, 1089–1098. [Google Scholar] [CrossRef]

- Shen, J.; Tan, H.; Wang, J.; Wang, J.; Lee, S. A novel routing protocol providing good transmission reliability in underwater sensor networks. J. Internet Technol. 2015, 16, 171–178. [Google Scholar]

- Silva, I.; Guedes, L.A.; Portugal, P.; Vasques, F. Reliability and availability evaluation of wireless sensor networks for industrial applications. Sensors 2012, 12, 806–838. [Google Scholar] [CrossRef]

- Mitchell, R.; Chen, I.-R. Effect of Intrusion Detection and Response on Reliability of Cyber Physical Systems. IEEE Trans. Reliab. 2013, 62, 199–210. [Google Scholar] [CrossRef]

- Shiliang, L.; Lianglun, C.; Bin, R.; Quanmin, Z. An Improved Intelligent Ant Colony Algorithm for the Reliability Optimization Problem in Cyber-Physical Systems. J. Softw. 2014, 9, 20–25. [Google Scholar]

- Yang, Y.; Xu, Y.; Li, X.; Chen, C. A Loss Inference Algorithm for Wireless Sensor Networks to Improve Data Reliability of Digital Ecosystems. IEEE Trans. Ind. Electron. 2011, 58, 2126–2137. [Google Scholar] [CrossRef]

- Xueying, G.; Singh, R.; Kumar, P.R.; Zhisheng, N. A high reliability asymptotic approach for packet inter-delivery time optimization in cyber-physical systems. arXiv 2015, arXiv:1504.03076. [Google Scholar]

- Kartakis, S.; Yang, S.; McCann, J.A. Reliability or Sustainability: Optimal Data Stream Estimation and Scheduling in Smart Water Networks. ACM Trans. Sens. Netw. 2017, 13, 18. [Google Scholar] [CrossRef]

- Tian, D.-A.; Sansavini, G. Impact of cyber dependencies in critical infrastructures: The reliability of grid splitting in power systems. J. Risk Reliab. 2018, 232, 491–504. [Google Scholar] [CrossRef]

- Ozer, E.; Feng, M.Q. Structural Reliability Estimation with Participatory Sensing and Mobile Cyber-Physical Structural Health Monitoring Systems. Appl. Sci. 2019, 9, 2840. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, Y.; Xiao, F. Modelling and analysis of real-time and reliability for WSN-based CPS. Int. J. Internet Protoc. Technol. 2019, 12, 76–84. [Google Scholar] [CrossRef]

- Deif, D.; Gadallah, Y. A comprehensive wireless sensor network reliability metric for critical Internet of Things applications. EURASIP J. Wirel. Commun. Netw. 2017, 2017, 145. [Google Scholar] [CrossRef]

- Duking, P.; Fuss, F.K.; Holmberg, H.-C.; Sperlich, B. Recommendations for Assessment of the Reliability, Sensitivity, and Validity of Data Provided by Wearable Sensors Designed for Monitoring Physical Activity. JMIR mHealth uHealth 2018, 6, e102. [Google Scholar] [CrossRef]

- Yue, Y.-G.; He, P. A comprehensive survey on the reliability of mobile wireless sensor networks: Taxonomy, challenges, and future directions. Inf. Fusion 2018, 44, 188–204. [Google Scholar] [CrossRef]

- Beyranvand, H.; Levesque, M.; Maier, M.; Salehi, J.A.; Verikoukis, C.; Tipper, D. Toward 5G: FiWi Enhanced LTE-A HetNets with Reliable Low-Latency Fiber Backhaul Sharing and WiFi Offloading. IEEE ACM Trans. Netw. 2017, 25, 690–707. [Google Scholar] [CrossRef]

- Kartsakli, E.; Antonopoulos, A.; Lalos, A.; Tennina, S.; Renzo, M.; Alonso, L.; Verikoukis, C. Reliable MAC design for ambient assisted living: Moving the coordination to the cloud. IEEE Commun. Mag. 2015, 53, 78–86. [Google Scholar] [CrossRef]

- Wang, X.; Shi, T.; Yan, M.; Yang, S. The affirmation of sensor signal reliability for a machine monitoring and fault diagnosing system. J. Huazhong Univ. Sci. Technol. 1993, 21, 57–62. [Google Scholar]

- Pourali, M.; Mosleh, A. A Bayesian approach to sensor placement optimization and system reliability monitoring. J. Risk Reliab. 2013, 227, 327–347. [Google Scholar] [CrossRef]

- Pozna, C.; Precup, R.E.; Tar, J.K.; Škrjanc, I.; Preitl, S. New results in modelling derived from Bayesian filtering. Knowl. Based Syst. 2010, 23, 182–194. [Google Scholar] [CrossRef]

- Duan, R.; Fan, J. Dynamic Diagnosis Strategy for Redundant Systems Based on Reliability Analysis and Sensors under Epistemic Uncertainty. J. Sens. 2015, 2015, 592142. [Google Scholar] [CrossRef]

- Song, Y.; Wang, X.; Zhu, J.; Lei, L. Sensor dynamic reliability evaluation based on evidence theory and intuitionistic fuzzy sets. Appl. Intell. 2018, 48, 3950–3962. [Google Scholar] [CrossRef]

- Yuan, K.; Xiao, F.; Fei, L.; Kang, B.; Deng, Y. Modeling Sensor Reliability in Fault Diagnosis Based on Evidence Theory. Sensors 2016, 16, 113. [Google Scholar] [CrossRef]

- Jiang, W.; Zhuang, M.; Xie, C. A Reliability-Based Method to Sensor Data Fusion. Sensors 2017, 17, 1575. [Google Scholar] [CrossRef]

- Zichang, H.; Wen, J. Quantum Mechanical Approach to Modeling Reliability of Sensor Reports. IEEE Sens. Lett. 2017, 1, 7500304. [Google Scholar]

- Song, K.; Xu, P.; Wei, G.; Chen, Y.; Wang, Q. Health Management Decision of Sensor System Based on Health Reliability Degree and Grey Group Decision-Making. Sensors 2018, 18, 2316. [Google Scholar] [CrossRef]

- Rodrigues, C.E.D.; Da Silva, R.P.M.; Nunes, R.A. Metrological assessment of LIDAR signals in water. Measurement 2011, 44, 11–17. [Google Scholar] [CrossRef]

- Yang, X.; Quan, Z.; Dan, J. The effect of INS and GPS random error on positioning accuracy of airborne LIDAR system. J. Comput. Inf. Syst. 2011, 7, 3795–3802. [Google Scholar]

- Maalek, R.; Sadeghpour, F. Accuracy assessment of ultra-wide band technology in locating dynamic resources in indoor scenarios. Autom. Constr. 2016, 63, 12–26. [Google Scholar] [CrossRef]

- Dan, J.; Yang, X. Modeling of range and scan angle random errors from airborne LIDAR. J. Comput. Inf. Syst. 2013, 9, 2747–2753. [Google Scholar]

- Wu, H.C. Bayesian system reliability assessment under fuzzy environments. Reliab. Eng. Syst. Saf. 2004, 83, 277–286. [Google Scholar] [CrossRef]

- Wu, H.C. Fuzzy Bayesian system reliability assessment based on exponential distribution. Appl. Math. Model. 2006, 30, 509–530. [Google Scholar] [CrossRef]

- Du, K.L.; Swamy, M.N.S. Probabilistic and Bayesian Networks. In Neural Networks and Statistical Learning; Springer: Berlin/Heidelberg, Germany, 2014; pp. 563–619. [Google Scholar]

- Gheisari, S.; Meybodi, M.R. A new reasoning and learning model for Cognitive Wireless Sensor Networks based on Bayesian networks and learning automata cooperation. Comput. Netw. 2017, 124, 11–26. [Google Scholar] [CrossRef]

- Haber, R.E.; Alique, J.R. Nonlinear internal model control using neural networks: An application for machining processes. Neural Comput. Appl. 2004, 13, 47–55. [Google Scholar] [CrossRef]

- Ramírez, M.; Haber, R.; Peña, V.; Rodríguez, I. Fuzzy control of a multiple hearth furnace. Comput. Ind. 2004, 54, 105–113. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, D.; Zeng, J.; Asundi, A. Genetic algorithm-support vector regression for high reliability SHM system based on FBG sensor network. Opt. Lasers Eng. 2012, 50, 148–153. [Google Scholar] [CrossRef]

- Li, Z.; Kang, R. Strategy for reliability testing and evaluation of cyber physical systems. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2015; pp. 1001–1006. [Google Scholar]

- Vo, M.-T.; Thanh Nghi, T.T.; Tran, V.-S.; Mai, L.; Le, C.-T. Wireless Sensor Network for Real Time Healthcare Monitoring: Network Design and Performance Evaluation Simulation; Springer International Publishing: Cham, Switzerland, 2015; pp. 87–91. [Google Scholar]

- Cacciagrano, D.; Culmone, R.; Micheletti, M.; Mostarda, L. Energy-Efficient Clustering for Wireless Sensor Devices in Internet of Things. In Performability in Internet of Things; Springer: Berlin/Heidelberg, Germany, 2019; pp. 59–80. [Google Scholar]

- Hossain, S.; Fayjie, A.R.; Doukhi, O.; Lee, D.-J. CAIAS Simulator: Self-driving Vehicle Simulator for AI Research. In Proceedings of the International Conference on Intelligent Computing & Optimization, Pattaya, Thailand, 4–5 October 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 187–195. [Google Scholar]

- Nannapaneni, S.; Mahadevan, S.; Pradhan, S.; Dubey, A. Towards Reliability-Based Decision Making in Cyber-Physical Systems. In Proceedings of the 2016 IEEE International Conference on Smart Computing, SMARTCOMP 2016, St. Louis, MO, USA, 18–20 May 2016. [Google Scholar]

- Liu, X.; He, W.; Zheng, L. Transportation cyber-physical systems: Reliability modeling and analysis framework. In Proceedings of the National Workshop for Research on High-Confidence Transportation Cyber-Physical Systems: Automotive, Aviation and Rail, Seattle, WA, USA, 18–20 November 2008; pp. 18–20. [Google Scholar]

- Lu, T.; Zhao, J.; Zhao, L.; Li, Y.; Zhang, X. Towards a framework for assuring cyber physical system security. Int. J. Secur. Appl. 2015, 9, 25–40. [Google Scholar] [CrossRef]

- Parvin, S.; Hussain, F.K.; Hussain, O.K.; Thein, T.; Park, J.S. Multi-cyber framework for availability enhancement of cyber physical systems. Computing 2013, 95, 927–948. [Google Scholar] [CrossRef]

- Almorsy, M.; Grundy, J.; Ibrahim, A.S. Collaboration-based cloud computing security management framework. In Proceedings of the 2011 IEEE 4th International Conference on Cloud Computing, CLOUD 2011, Washington, DC, USA, 4–9 July 2011; pp. 364–371. [Google Scholar]

- Kim, M.J.; Kang, S.; Kim, W.T.; Chun, I.G. Human-interactive hardware-in-the-loop simulation framework for cyber-physical systems. In Proceedings of the 2013 2nd International Conference on Informatics and Applications, ICIA 2013, Lodz, Poland, 23–25 September 2013; pp. 198–202. [Google Scholar]

- Artuñedo, A.; Del Toro, R.M.; Haber, R.E. Consensus-based cooperative control based on pollution sensing and traffic information for urban traffic networks. Sensors 2017, 17, 953. [Google Scholar] [CrossRef]

- Castaño, F.; Beruvides, G.; Haber, R.E.; Artuñedo, A. Obstacle Recognition Based on Machine Learning for On-Chip LiDAR Sensors in a Cyber-Physical System. Sensors 2017, 17, 2109. [Google Scholar] [CrossRef]

- Michel, O. Cyberbotics Ltd. Webots™: Professional mobile robot simulation. Int. J. Adv. Robot. Syst. 2004, 1, 5. [Google Scholar] [CrossRef]

- Huang, F.; Zhu, Q.; Zhou, J.; Tao, J.; Zhou, X.; Jin, D.; Tan, X.; Wang, L. Research on the Parallelization of the DBSCAN Clustering Algorithm for Spatial Data Mining Based on the Spark Platform. Remote Sens. 2017, 9, 1301. [Google Scholar] [CrossRef]

- Banerjee, T.P.; Das, S. Multi-sensor data fusion using support vector machine for motor fault detection. Inf. Sci. 2012, 217, 96–107. [Google Scholar] [CrossRef]

- Niu, G.; Yang, B.-S.; Pecht, M. Development of an optimized condition-based maintenance system by data fusion and reliability-centered maintenance. Reliab. Eng. Syst. Saf. 2010, 95, 786–796. [Google Scholar] [CrossRef]

- Castaño, F.; Beruvides, G.; Villalonga, A.; Haber, R.E. Computational Intelligence for Simulating a LiDAR Sensor. In Sensor Systems Simulations; Springer: Berlin/Heidelberg, Germany, 2020; pp. 149–178. [Google Scholar]

- Premebida, C.; Ludwig, O.; Nunes, U. Exploiting LIDAR-based features on pedestrian detection in urban scenarios. In Proceedings of the 2009 12th International IEEE Conference on Intelligent Transportation Systems, St. Louis, MO, USA, 4–7 October 2009; pp. 1–6. [Google Scholar]

- Haber, R.E.; Juanes, C.; Del Toro, R.; Beruvides, G. Artificial cognitive control with self-x capabilities: A case study of a micro-manufacturing process. Comput. Ind. 2015, 74, 135–150. [Google Scholar] [CrossRef]

- Beruvides, G.; Juanes, C.; Castaño, F.; Haber, R.E. A self-learning strategy for artificial cognitive control systems. In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015; pp. 1180–1185. [Google Scholar]

| Horizon 2020 Initiative | Main Sensors | Application Field | Reference |

|---|---|---|---|

| RobustSENSE: Reliable, Secure, Trustable Sensors. For automated driving | Laser scanners, position, Virtual sensors | Automotive | Mäyrä et al. [26] |

| IoSense: Flexible FE/BE Sensor Pilot Line for the Internet of Everything | Microphones, force, pressure, gas, camera, LiDAR, accelerometer, others | Manufacturing, automotive, energy, environment | Castaño et al. [27] Godoy et al. [28] |

| SECREDAS: Cyber Security for Cross Domain Reliable Dependable Automated Systems | Cameras, position, ultrasounds, LiDAR, pressure | Automotive | Le et al. [29] |

| I-MECH: Intelligent Motion Control Platform for Smart Mechatronic Systems | Position, vision, force | Manufacturing, pharmaceutic, health | Valencia et al. [30] |

| PRYSTINE: Programmable Systems for Intelligence in Automobiles | Cameras, LiDAR, position, ultrasounds | Automotive | Druml et al. [31] Godoy et al. [32] |

| Power2Power: Providing next-generation silicon-based power solutions in transport and machinery for significant decarbonisation in the next decade | Temperature, PZT, radar, current, voltage, accelerometers | Manufacturing, energy, industrial machinery | Guerra et al. [33] La Fe et al. [34] |

| NeXOS: Next Generation Web-Enabled Sensors for the Monitoring of a Changing Ocean | optics, passive acoustics sensors, detectors | Environment | Toma et al. [35] |

| ReMAP: Integrated Fleet Management solution aimed at replacing fixed-interval inspections with adaptive condition-based interventions | Piezo-electric, acoustic emission, optical-fibber | Aeronautic | Lizé et al. [36] |

| Model | MAE | RMSE | RAE | RRSE | R2 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| DMRS | MRSE | DMRS | MRSE | DMRS | MRSE | DMRS | MRSE | DMRS | MRSE | |

| MLP | 0.0046 | 0.0035 | 1.275 | 1.270 | 0.187 | 0.188 | 0.395 | 0.392 | 0.933 | 0.933 |

| k-NN | 0.002 | 0.0002 | 1.014 | 1.010 | 0.114 | 0.114 | 0.371 | 0.365 | 0.963 | 0.961 |

| LR | 0.6781 | 0.6530 | 2.305 | 2.285 | 0.701 | 0.695 | 0.782 | 0.788 | 0.434 | 0.435 |

| SVM | 0.4735 | 0.4740 | 2.072 | 2.065 | 0.442 | 0.447 | 0.773 | 0.773 | 0.692 | 0.684 |

| R2 | RAE | ||||

|---|---|---|---|---|---|

| 0–10% | 10–20% | 20–40% | 40–70% | >70% | |

| 90–100% | 1 | 0.9 | 0.8 | 0.5 | 0.2 |

| 80–90% | 0.85 | 0.8 | 0.65 | 0.4 | 0.15 |

| 70–80% | 0.7 | 0.6 | 0.5 | 0.3 | 0.1 |

| 30–60% | 0.5 | 0.4 | 0.3 | 0.2 | 0.05 |

| 0–30% | 0.3 | 0.2 | 0.15 | 0.1 | 0.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castaño, F.; Strzelczak, S.; Villalonga, A.; Haber, R.E.; Kossakowska, J. Sensor Reliability in Cyber-Physical Systems Using Internet-of-Things Data: A Review and Case Study. Remote Sens. 2019, 11, 2252. https://doi.org/10.3390/rs11192252

Castaño F, Strzelczak S, Villalonga A, Haber RE, Kossakowska J. Sensor Reliability in Cyber-Physical Systems Using Internet-of-Things Data: A Review and Case Study. Remote Sensing. 2019; 11(19):2252. https://doi.org/10.3390/rs11192252

Chicago/Turabian StyleCastaño, Fernando, Stanisław Strzelczak, Alberto Villalonga, Rodolfo E. Haber, and Joanna Kossakowska. 2019. "Sensor Reliability in Cyber-Physical Systems Using Internet-of-Things Data: A Review and Case Study" Remote Sensing 11, no. 19: 2252. https://doi.org/10.3390/rs11192252

APA StyleCastaño, F., Strzelczak, S., Villalonga, A., Haber, R. E., & Kossakowska, J. (2019). Sensor Reliability in Cyber-Physical Systems Using Internet-of-Things Data: A Review and Case Study. Remote Sensing, 11(19), 2252. https://doi.org/10.3390/rs11192252