Probabilistic Linguistic VIKOR Method to Evaluate Green Supply Chain Initiatives

Abstract

:1. Introduction

- (1).

- We develop a new comparison method of PLTSs to effectively determine the probabilistic linguistic positive ideal solution and the probabilistic linguistic negative ideal solution;

- (2).

- We introduce a new defuzzification function of PLTSs to take into account the main-criteria weights and the sub-criteria weights which are represented by PLTSs;

- (3).

- We present the probabilistic linguistic group utility measure, the probabilistic linguistic individual regret measure and the probabilistic linguistic compromise measure;

- (4).

- We provide the compromise solution which is obtained based on these three probabilistic linguistic measures.

2. Literature Review

2.1. Green Supply Chain

2.2. Application of MCDM Techniques in Green Supply Chain

3. Basic Concepts

3.1. The Classical VIKOR Approach

- C1.

- Acceptable advantage: ;

- C2.

- Acceptable stability in decision making: The alternative is also the alternative with the first position in the ranking lists derived by and/or .

3.2. Basic Concept of PLTSs

- (1)

- If the PLTS is a partial PLTS, i.e., , then the PLTS should be normalized into the complete PLTS as below:where .

- (2)

- Let and , if , the set of linguistic terms should be added in the PLTS until , and the probabilities of all the added linguistic terms are zero.

4. Proposed Probabilistic Linguistic VIKOR Approach

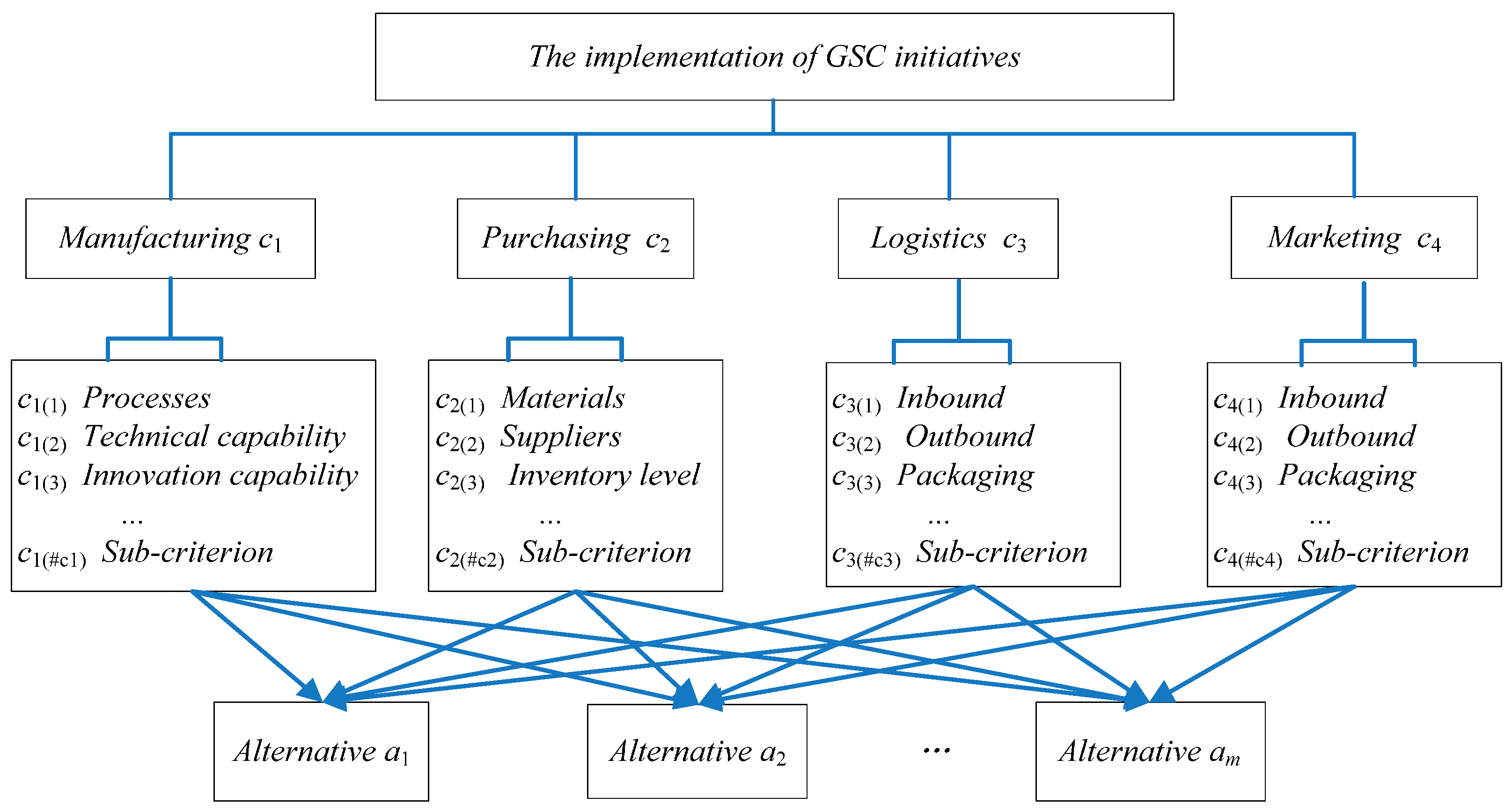

4.1. The Evaluating Framework of the Green Supply Chain Initiatives

4.2. To Determine the Probabilistic Linguistic Ideal Solutions

- (1)

- ;

- (2)

- if and only if , and theoretically the is the smallest expectation among all PLTSs based on the LTS L;

- (3)

- if and only if , and theoretically the is the greatest expectation among all PLTSs based on the LTS L.

- (1)

- According to the definition of PLTSs, it is easy to see that . Thus, we have:

- (1)

- If , then ;

- (2)

- If , then .

- (1)

- ;

- (2)

- ;

- (3)

- if , then .

4.3. Measuring the Closeness Indices of Alternatives to the Ideal solutions

4.4. Procedures for the Developed Method

- Step 1.

- Formulate the MCDM problem, identify the probabilistic linguistic decision matrix, and determine the probabilistic linguistic weights of the main-criteria and sub-criteria.

- Step 2.

- Determine the probabilistic linguistic positive ideal solution and the probabilistic linguistic negative ideal solution by employing Equation (16) and Equation (17), respectively.

- Step 3.

- Calculate the overall weight of each sub-criterion by using Equation (20).

- Step 4.

- Compute the probabilistic linguistic group utility measures of alternatives by using Equation (21).

- Step 5.

- Calculate the probabilistic linguistic individual regret measures of all alternatives by using Equation (22).

- Step 6.

- Calculate the compromise measures of alternatives by employing Equation (23).

- Step 7.

- Identify the compromise solution(s) according to the values of .

5. A Case Study for the Evaluation of Green Supply Chain Initiatives

5.1. Description

5.2. The Decision Making Processes

5.3. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chan, H.K.; Wang, X.; White, G.R.T.; Yip, N. An extended fuzzy-AHP approach for the evaluation of green product designs. IEEE Trans. Eng. Manag. 2013, 60, 327–339. [Google Scholar] [CrossRef]

- Wang, X.; Chan, H.K. A hierarchical fuzzy TOPSIS approach to assess improvement areas when implementing green supply chain initiatives. Int. J. Prod. Res. 2013, 51, 3117–3130. [Google Scholar] [CrossRef]

- Opricovic, S. Multicriteria Optimization of Civil Engineering Systems. Ph.D. Thesis, Faculty of Civil Engineering, University of Belgrade, Belgrade, Serbia, 1998; pp. 5–21. [Google Scholar]

- Pang, Q.; Wang, H.; Xu, Z.S. Probabilistic linguistic term sets in multi-attribute group decision making. Inform. Sci. 2016, 369, 128–143. [Google Scholar] [CrossRef]

- Entezaminia, A.; Heydari, M.; Rahmani, D.A. multi-objective model for multi-product multi-site aggregate production planning in a green supply chain: Considering collection and recycling centers. J. Manuf. Syst. 2016, 40, 63–75. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Ahmad, J.; Ali, D. Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Sarkis, J.; Wang, X. Assessing green supply chain practices in the Ghanaian mining industry: A framework and evaluation. Int. J. Prod. Econ. 2016, 181, 325–341. [Google Scholar] [CrossRef]

- Tramarico, C.L.; Salomon, V.A.P.; Marins, F.A.S. Multi-criteria assessment of the benefits of a supply chain management training considering green issues. J. Clean. Prod. 2017, 142, 249–256. [Google Scholar] [CrossRef]

- Wang, Z.; Mathiyazhagan, K.; Xu, L.; Diabat, A. A decision making trial and evaluation laboratory approach to analyze the barriers to Green Supply Chain Management adoption in a food packaging company. J. Clean. Prod. 2016, 117, 19–28. [Google Scholar] [CrossRef]

- Sarkis, J. How Green Is the Supply Chain? Practice and Research; Graduate School of Management, Clark University: Worcester, MA, USA, 1999. [Google Scholar]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Sarmiento, R.; Thomas, A. Identifying improvement areas when implementing green initiatives using a multitier AHP approach. Benchmark. Int. J. 2010, 17, 452–463. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Vachon, S. Green supply chain practices and the selection of environmental technologies. Int. J. Prod. Res. 2007, 45, 4357–4379. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Green supply chain management implications for “closing the loop”. Transp. Res. E Logist. Transp. Rev. 2008, 44, 1–18. [Google Scholar] [CrossRef]

- Govindan, K.; Kadziński, M.; Sivakumar, R. Application of a novel PROMETHEE-based method for construction of a group compromise ranking to prioritization of green suppliers in food supply chain. Omega 2017, 71, 129–145. [Google Scholar] [CrossRef]

- Azadi, M.; Shabani, A.; Khodakarami, M.; Reza, F.S. Planning in feasible region by two-stage target-setting DEA methods: An application in green supply chain management of public transportation service providers. Transp. Res. E Logist. Transp. Rev. 2014, 70, 324–338. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Diabat, A.; Al-Refaie, A. Application of analytical hierarchy process to evaluate pressures to implement green supply chain management. J. Clean. Prod. 2015, 107, 229–236. [Google Scholar] [CrossRef]

- Sari, K. A novel multi-criteria decision framework for evaluating green supply chain management practices. Comput. Ind. Eng. 2017, 105, 338–347. [Google Scholar] [CrossRef]

- Tseng, M.L.; Lin, Y.H.; Tan, K.; Chen, R.H.; Chen, Y.H. Using TODIM to evaluate green supply chain practices under uncertainty. Appl. Math. Model. 2014, 38, 2983–2995. [Google Scholar] [CrossRef]

- Uygun, Ö.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Comput. Ind. Eng. 2016, 102, 502–511. [Google Scholar] [CrossRef]

- Yu, M.C.; Su, M.H. Using Fuzzy DEA for Green Suppliers Selection Considering Carbon Footprints. Sustainability 2017, 9, 495. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Vafadarnikjoo, A. Intuitionistic fuzzy based DEMATEL method for developing green practices and performances in a green supply chain. Expert. Syst. Appl. 2015, 42, 7207–7220. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Bai, C.; Sarkis, J.; Wang, X.P. Green supply chain practices evaluation in the mining industry using a joint rough sets and fuzzy TOPSIS methodology. Resour. Pol. 2015, 46, 86–100. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Govindan, K.; Esmaeili, A.; Sabaghi, S. Application of fuzzy VIKOR for evaluation of green supply chain management practices. Ecol. Indic. 2015, 49, 188–203. [Google Scholar] [CrossRef]

- Shen, L.; Olfat, L.; Govindan, K.; Khodaverdi, R.; Diabat, A. A fuzzy multi criteria approach for evaluating green supplier’s performance in green supply chain with linguistic preferences. Resour. Conserv. Recycl. 2013, 74, 170–179. [Google Scholar] [CrossRef]

- Tseng, M.L.; Lim, M.; Wu, K.J.; Zhou, L.; Dat Bui, D.T. A novel approach for enhancing green supply chain management using converged interval-valued triangular fuzzy numbers-grey relation analysis. Resour. Conserv. Recycl. 2017. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Z.; Liu, M. Hesitant trapezoidal fuzzy QUALIFLEX method and its application in the evaluation of green supply chain initiatives. Sustainability 2016, 8, 952. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. A novel hybrid MCDM approach based on fuzzy DEMATEL, fuzzy ANP and fuzzy TOPSIS to evaluate green suppliers. Expert Syst. Appl. 2012, 39, 3000–3011. [Google Scholar] [CrossRef]

- Chithambaranathan, P.; Subramanian, N.; Gunasekaran, A.; Palaniappan, K. Service supply chain environmental performance evaluation using grey based hybrid MCDM approach. Int. J. Prod. Econ. 2015, 166, 163–176. [Google Scholar] [CrossRef]

- Liao, C.N.; Fu, Y.K.; Wu, L.C. Integrated FAHP, ARAS-F and MSGP methods for green supplier evaluation and selection. Technol. Econ. Dev. Econ. 2016, 22, 651–669. [Google Scholar] [CrossRef]

- Malviya, R.K.; Kant, R. Hybrid decision making approach to predict and measure the success possibility of green supply chain management implementation. J. Clean. Prod. 2016, 135, 387–409. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Zolfani, S.H. Integrated QFD-MCDM framework for green supplier selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Zolfani, S.H.; Chen, I.S.; Rezaeiniya, N.; Tamošaitienė, J. A hybrid MCDM model encompassing AHP and COPRAS-G methods for selecting company supplier in Iran. Technol. Econ. Dev. Econ. 2012, 18, 529–543. [Google Scholar] [CrossRef]

- Mardani, A.; Jusoh, A.; Zavadskas, E.K.; Cavallaro, F.; Khalifah, Z. Sustainable and renewable energy: An overview of the application of multiple criteria decision making techniques and approaches. Sustainability 2015, 7, 13947–13984. [Google Scholar] [CrossRef]

- Mardani, A.; Zavadskas, E.K.; Khalifah, Z.; Zakuan, N.; Jusoh, A.; Nor, K.M.; Khoshnoudi, M. A review of multi-criteria decision-making applications to solve energy management problems: Two decades from 1995 to 2015. Renew. Sustain. Energy Rev. 2017, 71, 216–256. [Google Scholar] [CrossRef]

- San Cristóbal, J.R. Multi-criteria decision-making in the selection of a renewable energy project in spain: The Vikor method. Renew. Energy 2011, 36, 498–502. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.H. Multicriteria planning of post-earthquake sustainable reconstruction. Comput. Aided Civ. Infrastruct. Eng. 2002, 17, 211–220. [Google Scholar] [CrossRef]

- Yalcin, N.; Bayrakdaroglu, A.; Kahraman, C. Application of fuzzy multi-criteria decision making methods for financial performance evaluation of Turkish manufacturing industries. Expert Syst. Appl. 2012, 39, 350–364. [Google Scholar] [CrossRef]

- Tzeng, G.H.; Lin, C.W.; Opricovic, S. Multi-criteria analysis of alternative-fuel buses for public transportation. Energy Pol. 2005, 33, 1373–1383. [Google Scholar] [CrossRef]

- Zhang, X. Multicriteria Pythagorean fuzzy decision analysis: A hierarchical QUALIFLEX approach with the closeness index-based ranking methods. Inf. Sci. 2016, 330, 104–124. [Google Scholar] [CrossRef]

- Li, K.W.; Wang, Z.J.; Tong, X. Acceptability analysis and priority weight elicitation for interval multiplicative comparison matrices. Eur. J. Oper. Res. 2016, 250, 628–638. [Google Scholar] [CrossRef]

- Wang, Z.J.; Li, K.W. A multi-step goal programming approach for group decision making with incomplete interval additive reciprocal comparison matrices. Eur. J. Oper. Res. 2015, 242, 890–900. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Z. Interval programming method for hesitant fuzzy multi-attribute group decision making with incomplete preference over alternatives. Comput. Ind. Eng. 2014, 75, 217–229. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Z.; Wang, H. Heterogeneous multiple criteria group decision making with incomplete weight information: A deviation modeling approach. Inf. Fusion 2015, 25, 49–62. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, K.W.; Wang, Z.J. Prioritization and aggregation of intuitionistic preference relations: a multiplicative-transitivity-based transformation from intuitionistic judgment data to priority weights. Group Decis. Negot. 2017, 26, 409–436. [Google Scholar] [CrossRef]

- Sayadi, M.K.; Heydari, M.; Shahanaghi, K. Extension of VIKOR method for decision making problem with interval numbers. Appl. Math. Model. 2009, 33, 2257–2262. [Google Scholar] [CrossRef]

- Kaya, T.; Kahraman, C. Multicriteria renewable energy planning using an integrated fuzzy VIKOR & AHP methodology: The case of Istanbul. Energy 2010, 35, 2517–2527. [Google Scholar]

- Chen, L.Y.; Wang, T.C. Optimizing partners’ choice in IS/IT outsourcing projects: The strategic decision of fuzzy VIKOR. Int. J. Prod. Econ. 2009, 120, 233–242. [Google Scholar] [CrossRef]

- Opricovic, S. Fuzzy VIKOR with an application to water resources planning. Expert Syst. Appl. 2011, 38, 12983–12990. [Google Scholar] [CrossRef]

- Shemshadi, A.; Shirazi, H.; Toreihi, M.; Tarokh, M.J. A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting. Expert Syst. Appl. 2011, 38, 12160–12167. [Google Scholar] [CrossRef]

- Devi, K. Extension of VIKOR method in intuitionistic fuzzy environment for robot selection. Expert Syst. Appl. 2011, 38, 14163–14168. [Google Scholar] [CrossRef]

- Park, J.H.; Cho, H.J.; Kwun, Y.C. Extension of the VIKOR method for group decision making with interval-valued intuitionistic fuzzy information. Fuzzy Optim. Decis. Mak. 2011, 10, 233–253. [Google Scholar] [CrossRef]

- Liao, H.; Xu, Z.A. VIKOR-based method for hesitant fuzzy multi-criteria decision making. Fuzzy Optim. Decis. Mak. 2013, 12, 373–392. [Google Scholar] [CrossRef]

- Zhang, N.; Wei, G. Extension of VIKOR method for decision making problem based on hesitant fuzzy set. Appl. Math. Model. 2013, 37, 4938–4947. [Google Scholar] [CrossRef]

- Liao, H.; Xu, Z.; Zeng, X.J. Hesitant fuzzy linguistic VIKOR method and its application in qualitative multiple criteria decision making. IEEE Trans. Fuzzy Syst. 2015, 23, 1343–1355. [Google Scholar] [CrossRef]

- Mardani, A.; Zavadskas, E.K.; Govindan, K.; Aslan, A.M.; Ahmad, J. VIKOR technique: a systematic review of the state of the art literature on methodologies and applications. Sustainability 2016, 8, 37. [Google Scholar] [CrossRef]

- Zhang, X. Non-homogeneous linguistic multi-criteria group decision making with aspiration. Tech. Rep. 2017, 1–15. [Google Scholar]

- Yager, R. An approach to ordinal decision making. Int. J. Approx. Reason. 1995, 12, 237–261. [Google Scholar] [CrossRef]

- Rodriguez, R.M.; Martinez, L.; Herrera, F. Hesitant fuzzy linguistic term sets for decision making. IEEE Trans. Fuzzy Syst. 2012, 20, 109–119. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, J. Possibility distribution-based approach for MAGDM with hesitant fuzzy linguistic information. IEEE Trans. Cybern. 2016, 46, 694–705. [Google Scholar] [CrossRef] [PubMed]

- Gu, X.J.; Xu, Z.S. Novel Basic Operational Laws for Linguistic Terms, Hesitant Fuzzy Linguistic Term Sets and Probabilistic Linguistic Term Sets. Inform. Sci. 2016, 372, 407–427. [Google Scholar] [CrossRef]

- Lin, M.; Xu, Z.; Zhai, Y. Multi-attribute group decision-making under probabilistic uncertain linguistic environment. J. Oper. Res. Soc. 2017. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Z.; Wang, H.; Liao, H. Consistency-based risk assessment with probabilistic linguistic preference relation. Appl. Soft. Comput. 2016, 49, 817–833. [Google Scholar] [CrossRef]

- Zhai, Y.; Xu, Z.; Liao, H. Probabilistic linguistic vector-term set and its application in group decision making with multi-granular linguistic information. Appl. Soft. Comput. 2016, 49, 801–816. [Google Scholar] [CrossRef]

| Alternatives | Evaluation main-criteria and sub-criteria | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| … | … | … | … | ||||||||||

| a1 | … | … | … | … | |||||||||

| a2 | … | … | … | … | |||||||||

| … | … | … | … | … | … | … | … | … | … | … | … | … | … |

| am | … | … | … | … | |||||||||

| Main-Criteria | Weights of Main-Criteria | Sub-Criteria | Weights of Sub-Criteria |

|---|---|---|---|

| c1 Manufacturing | c1(1) Processes | ||

| c1(2) Technical capability | |||

| c1(3) Innovation capability | |||

| c1(4) Production capacity | |||

| c2 Purchasing | c2(1) Raw material availability | ||

| c2(2) Suppliers | |||

| c2(3) Inventory level | |||

| c2(4) Assurance of supply | |||

| c3 Logistics | c3(1) Inbound logistics | ||

| c3(2) Outbound logistics | |||

| c3(3) Packaging | |||

| c3(4) Shipment accuracy | |||

| c4 Marketing | c4(1) Salability | ||

| c4(2) Growth | |||

| c4(3) Marketability | |||

| c4(4) Customer service |

| Criteria | The implementation time windows | |||

|---|---|---|---|---|

| Implement Now a1 | Implement in 4 Months a2 | Implement in 8 Months a3 | Implement in 12 Months a4 | |

| c1(1) | ||||

| c1(2) | ||||

| c1(3) | ||||

| c1(4) | ||||

| c2(1) | ||||

| c2(2) | ||||

| c2(3) | ||||

| c2(4) | ||||

| c3(1) | ||||

| c3(2) | ||||

| c3(3) | ||||

| c3(4) | ||||

| c4(1) | ||||

| c4(2) | ||||

| c4(3) | ||||

| c4(4) | ||||

| Sub-Criteria | Positive Ideal Solutions | Negative Ideal Solutions |

|---|---|---|

| c1(1) | ||

| c1(2) | ||

| c1(3) | ||

| c1(4) | ||

| c2(1) | ||

| c2(2) | ||

| c2(3) | ||

| c2(4) | ||

| c3(1) | ||

| c3(2) | ||

| c3(3) | ||

| c3(4) | ||

| c4(1) | ||

| c4(2) | ||

| c4(3) | ||

| c4(4) |

| Main-Criteria | Defuzzification Values of Main-Criteria Weights | Sub-Criteria | Defuzzification Values of Sub-Criteria Weights | The Overall Weights of Sub-Criteria |

|---|---|---|---|---|

| c1 | 0.2951 | c1(1) | 0.4160 | 0.1228 |

| c1(2) | 0.2734 | 0.0807 | ||

| c1(3) | 0.1783 | 0.0526 | ||

| c1(4) | 0.1324 | 0.0391 | ||

| c2 | 0.2530 | c2(1) | 0.4085 | 0.1033 |

| c2(2) | 0.1341 | 0.0339 | ||

| c2(3) | 0.3201 | 0.0810 | ||

| c2(4) | 0.1372 | 0.0347 | ||

| c3 | 0.1484 | c3(1) | 0.1341 | 0.0199 |

| c3(2) | 0.3201 | 0.0475 | ||

| c3(3) | 0.4085 | 0.0606 | ||

| c3(4) | 0.1372 | 0.0204 | ||

| c4 | 0.3035 | c4(1) | 0.2951 | 0.0896 |

| c4(2) | 0.2530 | 0.0768 | ||

| c4(3) | 0.3035 | 0.0921 | ||

| c4(4) | 0.1484 | 0.0450 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Xing, X. Probabilistic Linguistic VIKOR Method to Evaluate Green Supply Chain Initiatives. Sustainability 2017, 9, 1231. https://doi.org/10.3390/su9071231

Zhang X, Xing X. Probabilistic Linguistic VIKOR Method to Evaluate Green Supply Chain Initiatives. Sustainability. 2017; 9(7):1231. https://doi.org/10.3390/su9071231

Chicago/Turabian StyleZhang, Xiaolu, and Xiaoming Xing. 2017. "Probabilistic Linguistic VIKOR Method to Evaluate Green Supply Chain Initiatives" Sustainability 9, no. 7: 1231. https://doi.org/10.3390/su9071231

APA StyleZhang, X., & Xing, X. (2017). Probabilistic Linguistic VIKOR Method to Evaluate Green Supply Chain Initiatives. Sustainability, 9(7), 1231. https://doi.org/10.3390/su9071231