Evaluation of Third Party Logistics Providers Considering Social Sustainability

Abstract

:1. Introduction

2. Literature Review

2.1. Evaluation Criteria for the 3PL Provider

2.2. Evaluation Methodologies

2.3. Contribution of Research

3. Social Sustainability of 3PL Providers

3.1. Social Sustainability

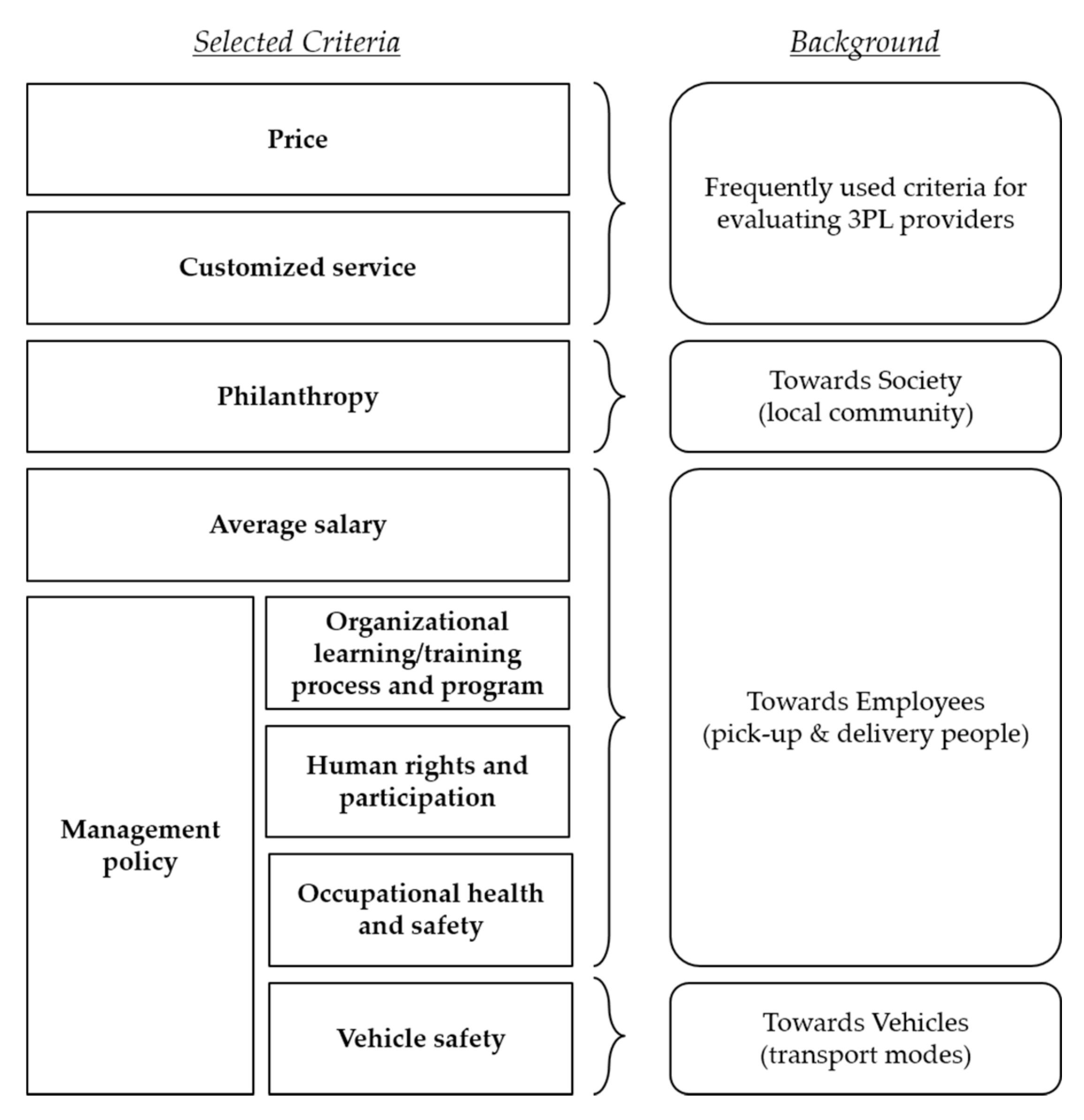

3.2. Definition and Evaluation Criteria of Social Sustainability for 3PL Providers

- Social sustainability of the 3PL provider means to operate its 3PL services considering their impact on internal and external stakeholders (i.e., society and employees) in terms of welfare, safety, and wellness

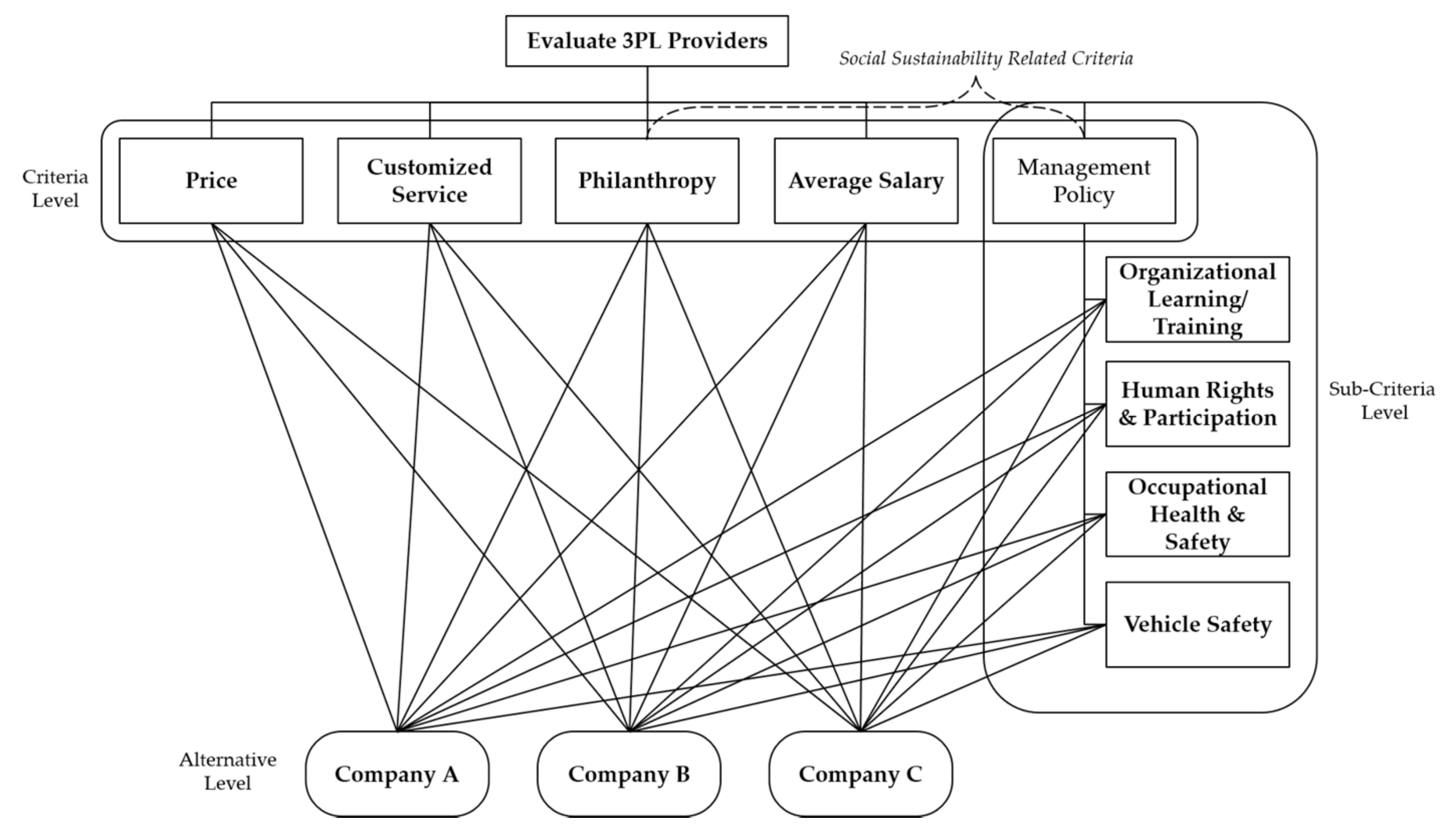

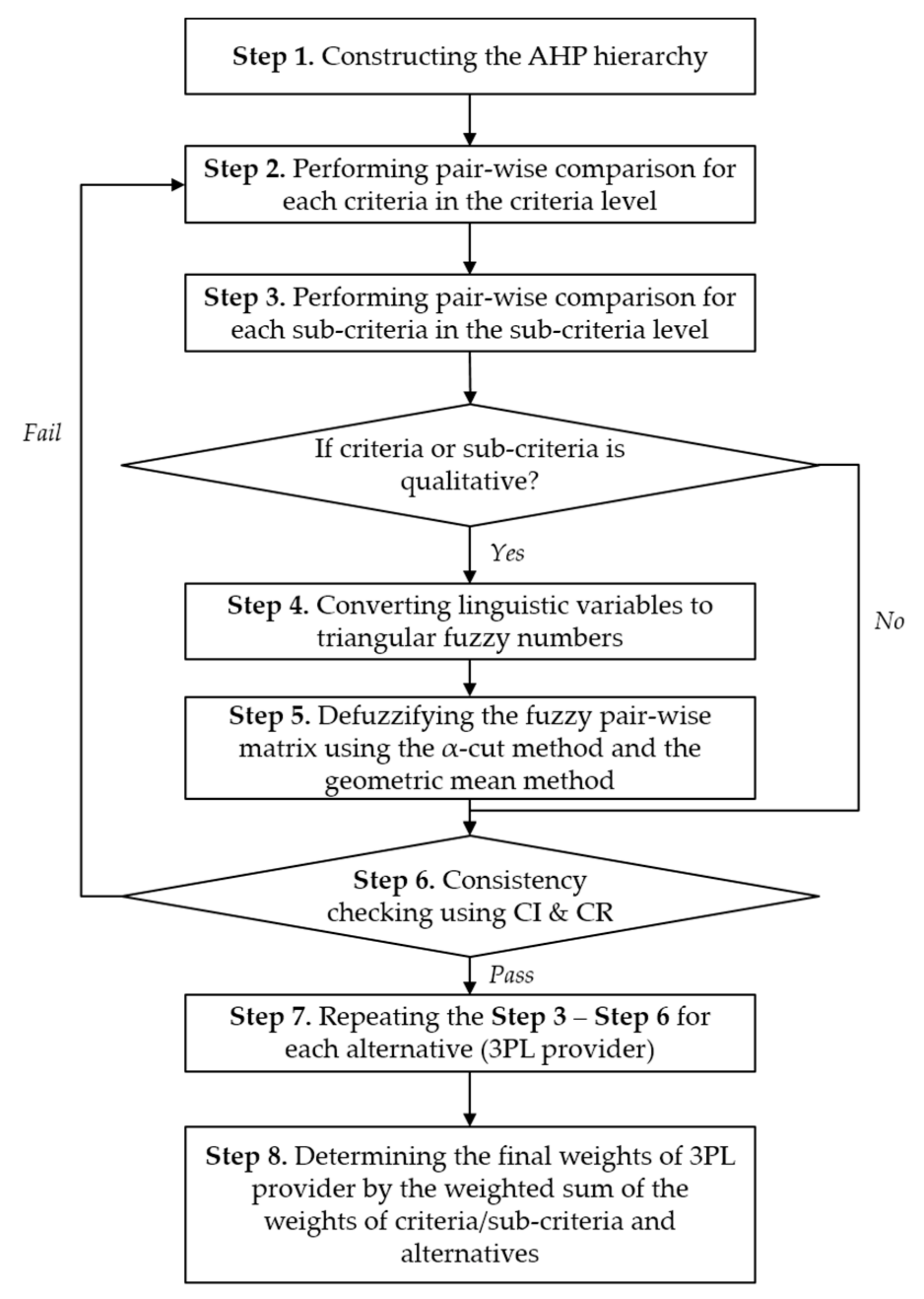

4. Proposed Approach

5. Illustrative Example

- A product is packed in the box, and the price proposed by the 3PL provider is based on its standard size and weight: the size (=length + width + height) is under 80 cm and the weight is under 2 kg (i.e., 4.4 lb.)

- The price proposed by the 3PL provider includes delivery service from the D/C to customers only without any inventory management service in the D/C.

6. Conclusions

Acknowledgments

Conflicts of Interest

References

- Hertz, S.; Alfredsson, M. Strategic Development of Third Party Logistics Providers. Ind. Mark. Manag. 2003, 32, 139–149. [Google Scholar] [CrossRef]

- Tyan, J.C.; Wang, F.; Du, T.C. An Evaluation of Freight Consolidation Policies in Global Third Party Logistics. Omega 2003, 31, 55–62. [Google Scholar] [CrossRef]

- Jung, H.; Chen, F.; Jeong, B. Decentralized Supply Chain Planning Framework for Third Party Logistics Partnership. Comput. Ind. Eng. 2008, 55, 348–364. [Google Scholar] [CrossRef]

- Bumstead, J.; Cannons, K. From 4PL to Managed Supply-Chain Operations. Logist. Transp. Focus 2002, 4, 18–24. [Google Scholar]

- Hannon, D. Third-Party Logistics: Maximizing Value of Outsource Partners Requires New Skills. Purchasing 2003, 132, 50–52. [Google Scholar]

- Marasco, A. Third-Party Logistics: A Literature Review. Int. J. Prod. Econ. 2008, 113, 127–147. [Google Scholar] [CrossRef]

- Aguezzoul, A. Third-Party Logistics Selection Problem: A Literature Review on Criteria and Methods. Omega 2014, 49, 69–78. [Google Scholar] [CrossRef]

- Menon, M.K.; McGinnis, M.A.; Ackerman, K.B. Selection Criteria for Providers of Third-Party Logistics Services: An Exploratory Study. J. Bus. Logist. 1998, 19, 121. [Google Scholar]

- Meade, L.; Sarkis, J. A Conceptual Model for Selecting and Evaluating Third-Party Reverse Logistics Providers. Supply Chain Manag. 2002, 7, 283–295. [Google Scholar] [CrossRef]

- Bottani, E.; Rizzi, A. A Fuzzy TOPSIS Methodology to Support Outsourcing of Logistics Services. Supply Chain Manag. 2006, 11, 294–308. [Google Scholar] [CrossRef]

- Jharkharia, S.; Shankar, R. Selection of Logistics Service Provider: An Analytic Network Process (ANP) Approach. Omega 2007, 35, 274–289. [Google Scholar] [CrossRef]

- Qureshi, M.; Kumar, D.; Kumar, P. An Integrated Model to Identify and Classify the Key Criteria and their Role in the Assessment of 3PL Services Providers. Asia Pac. J. Mark. Logist. 2008, 20, 227–249. [Google Scholar] [CrossRef]

- Liu, H.; Wang, W. An Integrated Fuzzy Approach for Provider Evaluation and Selection in Third-Party Logistics. Expert Syst. Appl. 2009, 36, 4387–4398. [Google Scholar] [CrossRef]

- Ho, W.; He, T.; Lee, C.K.M.; Emrouznejad, A. Strategic Logistics Outsourcing: An Integrated QFD and Fuzzy AHP Approach. Expert Syst. Appl. 2012, 39, 10841–10850. [Google Scholar] [CrossRef]

- Hassini, E.; Surti, C.; Searcy, C. A Literature Review and a Case Study of Sustainable Supply Chains with a Focus on Metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Lieb, R.C.; Lieb, K.J. The North American Third Party Logistics Industry in 2010: The Provider Ceo Perspective. Supply Chain Forum 2011, 12, 44–52. [Google Scholar]

- Kudla, N.L.; Klaas-Wissing, T. Sustainability in Shipper-Logistics Service Provider Relationships: A Tentative Taxonomy Based on Agency Theory and Stimulus-Response Analysis. J. Purch. Supply Manag. 2012, 18, 218–231. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Hutchins, M.J.; Sutherland, J.W. An Exploration of Measures of Social Sustainability and their Application to Supply Chain Decisions. J. Clean. Prod. 2008, 16, 1688–1698. [Google Scholar] [CrossRef]

- Norris, C.B. Data for Social LCA. Int. J. Life Cycle Assess. 2014, 19, 261. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Dejax, P.; Miemczyk, J.; Péton, O. Sustainable Supply Chain Network Design: An Optimization-Oriented Review. Omega 2015, 54, 11–32. [Google Scholar] [CrossRef]

- Large, R.O.; Kramer, N.; Hartmann, R.K. Procurement of Logistics Services and Sustainable Development in Europe: Fields of Activity and Empirical Results. J. Purch. Supply Manag. 2013, 19, 122–133. [Google Scholar] [CrossRef]

- Boukherroub, T.; Ruiz, A.; Guinet, A.; Fondrevelle, J. An Integrated Approach for Sustainable Supply Chain Planning. Comput. Oper. Res. 2015, 54, 180–194. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Smith, S.R. Logistics Measurement and Performance for United States-Mexican Operations under NAFTA. Transp. J. 1995, 34, 25–34. [Google Scholar]

- Dapiran, P.; Lieb, R.; Millen, R.; Sohal, A. Third Party Logistics Services Usage by Large Australian Firms. Int. J. Phys. Distrib. Logist. Manag. 1996, 26, 36–45. [Google Scholar] [CrossRef]

- Millen, R.; Sohal, A.; Dapiran, P.; Lieb, R.; Van Wassenhove, L.N. Benchmarking Australian Firms’ Usage of Contract Logistics Services: A Comparison with American and Western European Practice. Benchmark. Qual. Manag. Technol. 1997, 4, 34–46. [Google Scholar] [CrossRef]

- Murphy, P.R.; Daley, J.M. Investigating Selection Criteria for International Freight Forwarders. Transp. J. 1997, 37, 29–36. [Google Scholar]

- Bhatnagar, R.; Sohal, A.S.; Millen, R. Third Party Logistics Services: A Singapore Perspective. Int. J. Phys. Distrib. Logist. Manag. 1999, 29, 569–587. [Google Scholar] [CrossRef]

- Lai, K.; Ngai, E.; Cheng, T. Measures for Evaluating Supply Chain Performance in Transport Logistics. Transp. Res. Part E Logist. Transp. Rev. 2002, 38, 439–456. [Google Scholar] [CrossRef]

- Yeung, A.C. The Impact of Third-Party Logistics Performance on the Logistics and Export Performance of Users: An Empirical Study. Mar. Econ. Logist. 2006, 8, 121–139. [Google Scholar] [CrossRef]

- Van Donk, P.D.; Mortensen, O.; Lemoine, O.W. Integration between Manufacturers and Third Party Logistics Providers? Int. J. Oper. Prod. Manag. 2008, 28, 331–359. [Google Scholar]

- Göl, H.; Çatay, B. Third-Party Logistics Provider Selection: Insights from a Turkish Automotive Company. Supply Chain Manag. 2007, 12, 379–384. [Google Scholar] [CrossRef]

- Leina, Z.; Tiejun, P.; Guoqing, Y. The Process Integration Evaluation Method of the Fourth Party Logistics using Fuzzy Theory. In Proceedings of the 2010 International Conference on Management of E-Commerce and E-Government, Chengdu, China, 23–24 October 2010; pp. 313–316. [Google Scholar]

- Hsu, C.; Liou, J.J.; Chuang, Y. Integrating DANP and Modified Grey Relation Theory for the Selection of an Outsourcing Provider. Expert Syst. Appl. 2013, 40, 2297–2304. [Google Scholar] [CrossRef]

- Ge, X.; Gu, Y. Research on Functional Logistics Provider Selection Based on QFD Modeling. J. Appl. Sci. 2013, 13, 3563–3568. [Google Scholar]

- Huang, J.; Hu, M.H.; Wee, H. Evaluation of Lead Logistics Provider using the SMART Process: A Case Study in a Taiwan Automotive Industry. Oper. Supply Chain Manag. 2013, 6, 26–35. [Google Scholar]

- Perçin, S. Evaluation of Third-Party Logistics (3PL) Providers by using a Two-Phase AHP and TOPSIS Methodology. Benchmarking 2009, 16, 588–604. [Google Scholar] [CrossRef]

- Lehmusvaara, A.; Tuominen, M.; Korpela, J. An Integrated Approach for Truck Carrier Selection. Int. J. Logist. Res. Appl. 1999, 2, 5–20. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Feyzioğlu, O.; Nebol, E. Selection of the Strategic Alliance Partner in Logistics Value Chain. Int. J. Prod. Econ. 2008, 113, 148–158. [Google Scholar] [CrossRef]

- Efendigil, T.; Önüt, S.; Kongar, E. A Holistic Approach for Selecting a Third-Party Reverse Logistics Provider in the Presence of Vagueness. Comput. Ind. Eng. 2008, 54, 269–287. [Google Scholar] [CrossRef]

- Falsini, D.; Fondi, F.; Schiraldi, M.M. A Logistics Provider Evaluation and Selection Methodology Based on AHP, DEA and Linear Programming Integration. Int. J. Prod. Res. 2012, 50, 4822–4829. [Google Scholar] [CrossRef]

- Thakkar, J.; Deshmukh, S.; Gupta, A.; Shankar, R. Selection of Third-Party Logistics (3PL): A Hybrid Approach using Interpretive Structural Modeling (ISM) and Analytic Network Process (ANP). Supply Chain Forum 2005, 6, 32–46. [Google Scholar]

- Liou, J.J.H.; Chuang, Y. Developing a Hybrid Multi-Criteria Model for Selection of Outsourcing Providers. Expert Syst. Appl. 2010, 37, 3755–3761. [Google Scholar] [CrossRef]

- Kannan, G.; Pokharel, S.; Sasi Kumar, P. A Hybrid Approach using ISM and Fuzzy TOPSIS for the Selection of Reverse Logistics Provider. Resour. Conserv. Recycl. 2009, 54, 28–36. [Google Scholar] [CrossRef]

- Govindan, K.; Palaniappan, M.; Zhu, Q.; Kannan, D. Analysis of Third Party Reverse Logistics Provider using Interpretive Structural Modeling. Int. J. Prod. Econ. 2012, 140, 204–211. [Google Scholar] [CrossRef]

- Sasikumar, P.; Haq, A.N. Integration of Closed Loop Distribution Supply Chain Network and 3PRLP Selection for the Case of Battery Recycling. Int. J. Prod. Res. 2011, 49, 3363–3385. [Google Scholar] [CrossRef]

- De Almeida, A.T. Multicriteria Decision Model for Outsourcing Contracts Selection Based on Utility Function and ELECTRE Method. Comput. Oper. Res. 2007, 34, 3569–3574. [Google Scholar] [CrossRef]

- Işıklar, G.; Alptekin, E.; Büyüközkan, G. Application of a Hybrid Intelligent Decision Support Model in Logistics Outsourcing. Comput. Oper. Res. 2007, 34, 3701–3714. [Google Scholar] [CrossRef]

- Li, F.; Li, L.; Jin, C.; Wang, R.; Wang, H.; Yang, L. A 3PL Supplier Selection Model Based on Fuzzy Sets. Comput. Oper. Res. 2012, 39, 1879–1884. [Google Scholar] [CrossRef]

- Cheng, Y.; Lee, F. Outsourcing Reverse Logistics of High-Tech Manufacturing Firms by using a Systematic Decision-Making Approach: TFT-LCD Sector in Taiwan. Ind. Mark. Manag. 2010, 39, 1111–1119. [Google Scholar] [CrossRef]

- Chai, J.; Liu, J.N.; Ngai, E.W. Application of Decision-Making Techniques in Supplier Selection: A Systematic Review of Literature. Expert Syst. Appl. 2013, 40, 3872–3885. [Google Scholar] [CrossRef]

- Wood, D.J. Social Issues in Management: Theory and Research in Corporate Social Performance. J. Manag. 1991, 17, 383–406. [Google Scholar] [CrossRef]

- Lafferty, W.M.; Langhelle, O. Sustainable development as concept and norm. In Towards Sustainable Development; Lafferty, W.M., Langhelle, O., Eds.; Palgrave Macmillan: London, UK, 1999; pp. 1–29. [Google Scholar]

- Sharma, S.; Ruud, A. On the Path to Sustainability: Integrating Social Dimensions into the Research and Practice of Environmental Management. Bus. Strategy Environ. 2003, 12, 205–214. [Google Scholar] [CrossRef]

- Mani, V.; Agarwal, R.; Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Childe, S.J. Social Sustainability in the Supply Chain: Construct Development and Measurement Validation. Ecol. Ind. 2016, 71, 270–279. [Google Scholar] [CrossRef]

- McCarthy, I.P.; Lawrence, T.B.; Wixted, B.; Gordon, B.R. A Multidimensional Conceptualization of Environmental Velocity. Acad. Manag. Rev. 2010, 35, 604–626. [Google Scholar] [CrossRef]

- Missimer, M.; Robèrt, K.; Broman, G.; Sverdrup, H. Exploring the Possibility of a Systematic and Generic Approach to Social Sustainability. J. Clean. Prod. 2010, 18, 1107–1112. [Google Scholar] [CrossRef]

- Missimer, M.; Robèrt, K.; Broman, G. A Strategic Approach to Social Sustainability—Part 1: Exploring the Social System. J. Clean. Prod. 2017, 140, 32–41. [Google Scholar] [CrossRef]

- Littig, B.; Grießler, E. Social Sustainability: A Catchword between Political Pragmatism and Social Theory. Int. J. Sustain. Dev. 2005, 8, 65–79. [Google Scholar] [CrossRef]

- Kunz, J. Social Sustainability and Community Involvement in Urban Planning; University of Tampere: Tampere, Finland, 2006. [Google Scholar]

- Cuthill, M. Strengthening the ‘social’ in Sustainable Development: Developing a Conceptual Framework for Social Sustainability in a Rapid Urban Growth Region in Australia. Sustain. Dev. 2010, 18, 362–373. [Google Scholar] [CrossRef]

- Colantonio, A. Social Sustainability: A Review and Critique of Traditional Versus Emerging Themes and Assessment Methods. Available online: http://eprints.lse.ac.uk/35867/ (accessed on 3 May 2017).

- Dempsey, N.; Bramley, G.; Power, S.; Brown, C. The Social Dimension of Sustainable Development: Defining Urban Social Sustainability. Sustain. Dev. 2011, 19, 289–300. [Google Scholar] [CrossRef]

- Missimer, M.; Robèrt, K.; Broman, G. A Strategic Approach to Social Sustainability—Part 2: A Principle-Based Definition. J. Clean. Prod. 2017, 140, 42–52. [Google Scholar] [CrossRef]

- Carter, C.R.; Jennings, M.M. The Role of Purchasing in Corporate Social Responsibility: A Structural Equation Analysis. J. Bus. Logist. 2004, 25, 145–186. [Google Scholar] [CrossRef]

- Edgeman, R.; Neely, A.; Eskildsen, J.; Kozlowski, A.; Searcy, C.; Bardecki, M. Corporate Sustainability Reporting in the Apparel Industry: An Analysis of Indicators Disclosed. Int. J. Prod. Perform. Manag. 2015, 64, 377–397. [Google Scholar]

- Tate, W.L.; Ellram, L.M.; Kirchoff, J.F. Corporate Social Responsibility Reports: A Thematic Analysis Related to Supply Chain Management. J. Supply Chain Manag. 2010, 46, 19–44. [Google Scholar] [CrossRef]

- Yusuf, Y.Y.; Gunasekaran, A.; Musa, A.; El-Berishy, N.M.; Abubakar, T.; Ambursa, H.M. The UK Oil and Gas Supply Chains: An Empirical Analysis of Adoption of Sustainable Measures and Performance Outcomes. Int. J. Prod. Econ. 2013, 146, 501–514. [Google Scholar] [CrossRef]

- Gugler, P.; Shi, J.Y. Corporate Social Responsibility for Developing Country Multinational Corporations: Lost War in Pertaining Global Competitiveness? J. Bus. Ethics 2009, 87, 3–24. [Google Scholar] [CrossRef]

- Walker, H.; Seuring, S.; Sarkis, J.; Klassen, R.; Huq, A.; Stevenson, M.; Zorzini, M. Social Sustainability in Developing Country Suppliers: An Exploratory Study in the Ready made Garments Industry of Bangladesh. Int. J. Oper. Prod. Manag. 2014, 34, 610–638. [Google Scholar]

- Global Reporting Initiative. Sustainability Reporting Guidelines Version 3.0. Available online: https://www.globalreporting.org/resourcelibrary/G3-Guidelines-Incl-Technical-Protocol.pdf (accessed on 3 May 2017).

- Harik, R.; El Hachem, W.; Medini, K.; Bernard, A. Towards a Holistic Sustainability Index for Measuring Sustainability of Manufacturing Companies. Int. J. Prod. Res. 2015, 53, 4117–4139. [Google Scholar] [CrossRef]

- Clarkson, M.E. A Stakeholder Framework for Analyzing and Evaluating Corporate Social Performance. Acad. Manag. Rev. 1995, 20, 92–117. [Google Scholar]

- Hubbard, G. Measuring Organizational Performance: Beyond the Triple Bottom Line. Bus. Strategy Environ. 2009, 18, 177–191. [Google Scholar] [CrossRef]

- Simón, C.; Martínez, J.L.; Agüero, A. Solidarity Day at Union Fenosa in Spain. Bus. Horiz. 2005, 48, 161–168. [Google Scholar] [CrossRef]

- Villaseñor, L.E.P. Employee Turnover and Length of Stay in the Maquiladora Industry of Chihuahua, México; Harvard Graduate School of Education: Cambridge, MA, USA, 1994. [Google Scholar]

- Oh, S.S.; Lewis, G.B. Stemming Inequality? Employment and Pay of Female and Minority Scientists and Engineers. Soc. Sci. J. 2011, 48, 397–403. [Google Scholar] [CrossRef]

- Yakovleva, N.; Sarkis, J.; Sloan, T. Sustainable Benchmarking of Supply Chains: The Case of the Food Industry. Int. J. Prod. Res. 2012, 50, 1297–1317. [Google Scholar] [CrossRef]

- Kolk, A. A Decade of Sustainability Reporting: Developments and Significance. Int. J. Environ. Sustain. Dev. 2004, 3, 51–64. [Google Scholar] [CrossRef]

- Husgafvel, R.; Pajunen, N.; Virtanen, K.; Paavola, I.; Päällysaho, M.; Inkinen, V.; Heiskanen, K.; Dahl, O.; Ekroos, A. Social Sustainability Performance Indicators–experiences from Process Industry. Int. J. Sustain. Eng. 2015, 8, 14–25. [Google Scholar] [CrossRef]

- Kleindorfer, P.R.; Singhal, K.; Wassenhove, L.N. Sustainable Operations Management. Prod. Oper. Manag. 2005, 14, 482–492. [Google Scholar] [CrossRef]

- Folke, C.; Hahn, T.; Olsson, P.; Norberg, J. Adaptive Governance of Social-Ecological Systems. Annu. Rev. Environ. Resour. 2005, 30, 441–473. [Google Scholar] [CrossRef]

- Westley, F.; Scheffer, M.; Brock, W.; Holmgren, M. Dynamic Interaction of Societies and Ecosystems—Linking Theories from Ecology, Economy and Sociology. In Panarchy: Understanding Transformations in Human and natural Systems; Gunderson, L.H., Holling, C.S., Eds.; Island Press: Washington, DC, USA, 2002; pp. 195–240. [Google Scholar]

- Dreyer, L.C.; Hauschild, M.Z.; Schierbeck, J. Characterisation of Social Impacts in LCA. Int. J. Life Cycle Assess. 2010, 15, 247–259. [Google Scholar] [CrossRef]

- Rajak, S.; Vinodh, S. Application of Fuzzy Logic for Social Sustainability Performance Evaluation: A Case Study of an Indian Automotive Component Manufacturing Organization. J. Clean. Prod. 2015, 108, 1184–1192. [Google Scholar] [CrossRef]

- Sharma, S.; Vredenburg, H. Proactive Corporate Environmental Strategy and the Development of Competitively Valuable Organizational Capabilities. Strateg. Manag. J. 1998, 729–753. [Google Scholar] [CrossRef]

- Jennings, M.M.; Entine, J. Business with a Soul: A Reexamination of what Counts in Business Ethics. J. Public Law Policy 1999, 20, 1–88. [Google Scholar]

- Chow, W.S.; Chen, Y. Corporate Sustainable Development: Testing a New Scale Based on the Mainland Chinese Context. J. Bus. Ethics 2012, 105, 519–533. [Google Scholar] [CrossRef]

- Sancha, C.; Gimenez, C.; Sierra, V. Achieving a Socially Responsible Supply Chain through Assessment and Collaboration. J. Clean. Prod. 2016, 112, 1934–1947. [Google Scholar] [CrossRef]

- Lee, P.K.; Lau, A.K.; Cheng, T. Employee Rights Protection and Financial Performance. J. Bus. Res. 2013, 66, 1861–1869. [Google Scholar] [CrossRef]

- Carter, C.R.; Jennings, M. Purchasing’s Contribution to the Socially Responsible Management of the Supply Chain. Available online: https://www.instituteforsupplymanagement.org/files/sr/capsarticle_purchasingscontribution.pdf (accessed on 3 May 2017).

- Ciliberti, F.; Pontrandolfo, P.; Scozzi, B. Investigating Corporate Social Responsibility in Supply Chains: A SME Perspective. J. Clean. Prod. 2008, 16, 1579–1588. [Google Scholar] [CrossRef]

- Glavič, P.; Lukman, R. Review of Sustainability Terms and their Definitions. J. Clean. Prod. 2007, 15, 1875–1885. [Google Scholar] [CrossRef]

- Ho, W. Integrated Analytic Hierarchy Process and its applications—A Literature Review. Eur. J. Oper. Res. 2008, 186, 211–228. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Review of the Main Developments in the Analytic Hierarchy Process. Expert Syst. Appl. 2011, 38, 14336–14345. [Google Scholar] [CrossRef]

- Subramanian, N.; Ramanathan, R. A Review of Applications of Analytic Hierarchy Process in Operations Management. Int. J. Prod. Econ. 2012, 138, 215–241. [Google Scholar] [CrossRef]

- Sipahi, S.; Timor, M. The Analytic Hierarchy Process and Analytic Network Process: An Overview of Applications. Manag. Decis. 2010, 48, 775–808. [Google Scholar] [CrossRef]

- Thomas, S. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation; University of Pittsburgh: Pittsburgh, PA, USA, 1980. [Google Scholar]

- Wang, Y.; Chin, K. A Linear Goal Programming Priority Method for Fuzzy Analytic Hierarchy Process and its Applications in New Product Screening. Int. J. Approx. Reason. 2008, 49, 451–465. [Google Scholar] [CrossRef]

- Lee, A.H.; Kang, H.; Wang, W. Analysis of Priority Mix Planning for the Fabrication of Semiconductors under Uncertainty. Int. J. Adv. Manuf. Technol. 2006, 28, 351–361. [Google Scholar] [CrossRef]

- Chan, F.T.; Kumar, N. Global Supplier Development Considering Risk Factors using Fuzzy Extended AHP-Based Approach. Omega 2007, 35, 417–431. [Google Scholar] [CrossRef]

- Chamodrakas, I.; Batis, D.; Martakos, D. Supplier Selection in Electronic Marketplaces using Satisficing and Fuzzy AHP. Expert Syst. Appl. 2010, 37, 490–498. [Google Scholar] [CrossRef]

- Miller, G.A. The Magical Number Seven, Plus or Minus Two: Some Limits on our Capacity for Processing Information. Psychol. Rev. 1956, 63, 81. [Google Scholar] [CrossRef] [PubMed]

- Guneri, A.F.; Yucel, A.; Ayyildiz, G. An Integrated Fuzzy-LP Approach for a Supplier Selection Problem in Supply Chain Management. Expert Syst. Appl. 2009, 36, 9223–9228. [Google Scholar] [CrossRef]

- Güngör, Z.; Serhadlıoğlu, G.; Kesen, S.E. A Fuzzy AHP Approach to Personnel Selection Problem. Appl. Soft Comput. 2009, 9, 641–646. [Google Scholar] [CrossRef]

- Vahidnia, M.H.; Alesheikh, A.A.; Alimohammadi, A. Hospital Site Selection using Fuzzy AHP and its Derivatives. J. Environ. Manag. 2009, 90, 3048–3056. [Google Scholar] [CrossRef] [PubMed]

- Saaty, T.L. How to make a Decision: The Analytic Hierarchy Process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Ayağ, Z.; Özdemir, R. An Intelligent Approach to ERP Software Selection through Fuzzy ANP. Int. J. Prod. Res. 2007, 45, 2169–2194. [Google Scholar] [CrossRef]

| Category | Criteria | Definition | Measure | References |

|---|---|---|---|---|

| Society Related | Philanthropy | The extent to which the company actively participates in aiding the society through donations and commercial initiatives | The budget percentage set aside for philanthropy | [19,55,71,72,73,74] |

| Investment in local community | The extent to which the company actively participates in aiding the local community | The budget percentage invested in the local community | [72,75] | |

| Employee Related | Employee average duration of stay | The turnover rate indicating the loyalty of employees | The number of years an employee remains in the industry | [72,74,76] |

| Minority | The distribution of minorities | The percentage of minority employees | [72,77,78] | |

| Average salary | The extent to which the company actively treats its employees by payment | The average employee salary | [19,55,72,78,79,80] | |

| Management Policy 1 Related | Organizational learning/training process and program | The existence, variety, and level of the processes or programs related to the certification and internal/external education | Qualitative measure | [58,72,74,80,81,82,83] |

| Appraisal/Recognition systems and development | The existence, variety, and level of the system related to employee appraisal and recognition (e.g., peer comparison, multi-dimensional performance measures) | Qualitative measure | [72,84,85] | |

| Human rights and participation | The existence and level of the policy related to employee rights and participation (e.g., whistle blowing, unions and incentives) | Qualitative measure | [55,72,86,87,88,89] | |

| Occupational health and safety | The existence and level of the policy related to occupational health and safety | Qualitative measure | [19,55,67,72,80,85,90,91,92] |

| Category | Criteria | Definition | Measure | |

|---|---|---|---|---|

| Price | Price (C1) | Service price of 3PL service | Quantitative measure | |

| Service | Customized service (C2) | The variety of service or flexibility of service from the 3PL provider, which can respond to the customers’ requests | Qualitative measure | |

| Social Sustainability | Philanthropy (C3) | The extent to which the 3PL provider actively participates in aiding the society through donations and commercial initiatives (the ratio of the philanthropy budget to sales) | Quantitative measure | |

| Average salary (C4) | The extent to which the 3PL provider actively treats its employees by payment | Quantitative measure | ||

| Management Policy (C5) | Organizational learning/training process and program (C5-1) | The existence, variety, and level of the educational programs related to safe driving, safe handling of parcels, and customer services | Qualitative measure | |

| Human rights and participation (C5-2) | The existence and level of the policy related to the employee rights (e.g., giving enough time for the employee to rest) | Qualitative measure | ||

| Occupational health and safety (C5-3) | The existence and level of the policy related to the occupational health and safety of employees | Qualitative measure | ||

| Vehicle safety (C5-4) | The existence and level of the rules related to vehicle safety (e.g., regular vehicle inspection) | Qualitative measure | ||

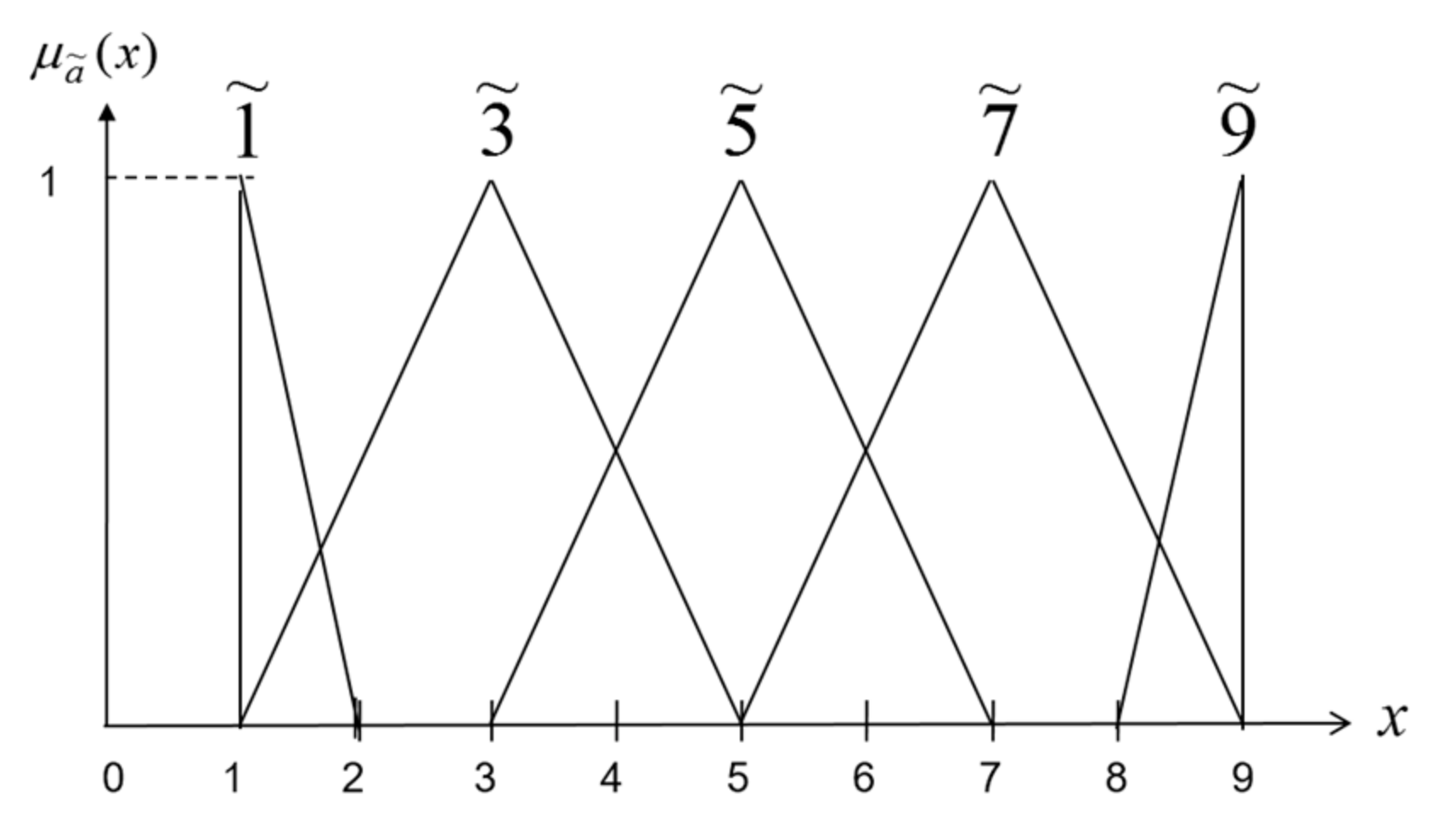

| Linguistic Judgments | Fuzzy Number | |

|---|---|---|

| Equally important | Equally preferred | (1, 1, 2) |

| Moderately more important | Moderately more preferred | (1, 3, 5) |

| Strongly more important | Strongly more preferred | (3, 5, 7) |

| Very strongly more important | Very strongly more preferred | (5, 7, 9) |

| Absolutely more important | Absolutely more preferred | (8, 9, 9) |

| Criteria/Sub-Criteria | Measure | 3PL-A | 3PL-B | 3PL-C |

|---|---|---|---|---|

| Price (C1) | The proposed price of 3PL service (monetary unit) | 2.00/box | 1.97/box | 1.89/box |

| Philanthropy (C3) | The budget percentage invested in the local community (the ratio of the philanthropy budget to sales) | 0.20% | 0.16% | 0.10% |

| Average salary (C4) | The average employee salary (monetary unit) | 57,000 | 53,000 | 50,000 |

| Fuzzy Comparison Matrix | Crisp Comparison Matrix | Weight | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C1 | C2 | C3 | C4 | C5 | ||

| C1 | 1 | [2.6, 3.4] | [4.6, 5.4] | [6.6, 7.4] | [2.6, 3.4] | 1 | 3.080 | 5.080 | 7.080 | 3.080 | 0.464 |

| C2 | [1/3.4, 1/2.6] | 1 | [2.6, 3.4] | [4.6, 5.4] | [1.0, 1.2] | 0.348 | 1 | 3.080 | 5.080 | 1.120 | 0.207 |

| C3 | [1/5.4, 1/4.6] | [1/3.4, 1/2.6] | 1 | [2.6, 3.4] | [1/3.4, 1/2.6] | 0.205 | 0.348 | 1 | 3.080 | 0.348 | 0.086 |

| C4 | [1/7.4, 1/6.6] | [1/5.4, 1/4.6] | [1/3.4, 1/2.6] | 1 | [1/5.4, 1/4.6] | 0.145 | 0.205 | 0.348 | 1 | 0.205 | 0.042 |

| C5 | [1/3.4, 1/2.6] | [1/1.2, 1/1.0] | [2.6, 3.4] | [4.6, 5.4] | 1 | 0.348 | 0.933 | 3.080 | 5.080 | 1 | 0.201 |

| Fuzzy Comparison Matrix | Crisp Comparison Matrix | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C5-1 | C5-2 | C5-3 | C5-4 | C5-1 | C5-2 | C5-3 | C5-4 | ||

| C5-1 | 1 | [1.0, 1.2] | [1/3.4, 1/2.6] | [1/5.4, 1/4.6] | 1 | 1.120 | 0.348 | 0.205 | 0.099 |

| C5-2 | [1/1.2, 1/1.0] | 1 | [1/3.4, 1/2.6] | [1/5.4, 1/4.6] | 0.933 | 1 | 0.348 | 0.205 | 0.094 |

| C5-3 | [2.6, 3.4] | [2.6, 3.4] | 1 | [1/3.4, 1/2.6] | 3.080 | 3.080 | 1 | 0.348 | 0.251 |

| C5-4 | [4.6, 5.4] | [4.6, 5.4] | [2.6, 3.4] | 1 | 5.080 | 5.080 | 3.080 | 1 | 0.556 |

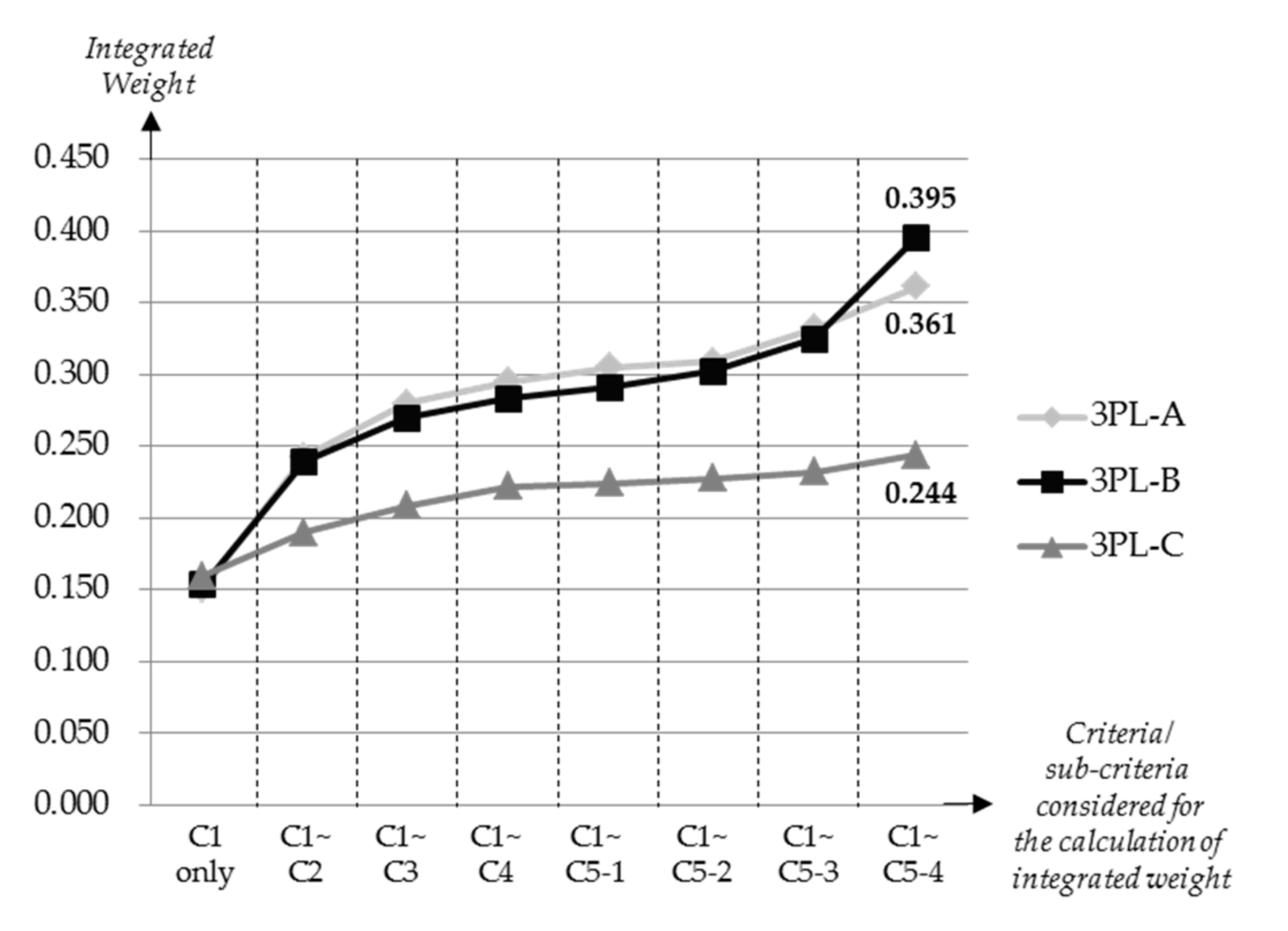

| Criteria | C1 | C2 | C3 | C4 | C5 | Final Weights for Alternatives | |||

|---|---|---|---|---|---|---|---|---|---|

| Weight | 0.46 | 0.21 | 0.09 | 0.04 | 0.20 | ||||

| Sub-Criteria | C5-1 | C5-2 | C5-3 | C5-4 | |||||

| Weight | 0.10 | 0.09 | 0.25 | 0.56 | |||||

| 3PL-A | 0.325 | 0.441 | 0.435 | 0.356 | 0.493 | 0.207 | 0.468 | 0.260 | 0.361 |

| 3PL-B | 0.330 | 0.415 | 0.348 | 0.331 | 0.393 | 0.599 | 0.441 | 0.635 | 0.395 |

| 3PL-C | 0.344 | 0.144 | 0.217 | 0.313 | 0.114 | 0.195 | 0.091 | 0.105 | 0.244 |

| CI | 0.000 | 0.032 | 0.000 | 0.000 | 0.036 | 0.032 | 0.021 | 0.049 | |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, H. Evaluation of Third Party Logistics Providers Considering Social Sustainability. Sustainability 2017, 9, 777. https://doi.org/10.3390/su9050777

Jung H. Evaluation of Third Party Logistics Providers Considering Social Sustainability. Sustainability. 2017; 9(5):777. https://doi.org/10.3390/su9050777

Chicago/Turabian StyleJung, Hosang. 2017. "Evaluation of Third Party Logistics Providers Considering Social Sustainability" Sustainability 9, no. 5: 777. https://doi.org/10.3390/su9050777

APA StyleJung, H. (2017). Evaluation of Third Party Logistics Providers Considering Social Sustainability. Sustainability, 9(5), 777. https://doi.org/10.3390/su9050777