Analysis of the Effect of the CaCl2 Mass Fraction on the Efficiency of a Heat Pump Integrated Heat-Source Tower Using an Artificial Neural Network Model

Abstract

:1. Introduction

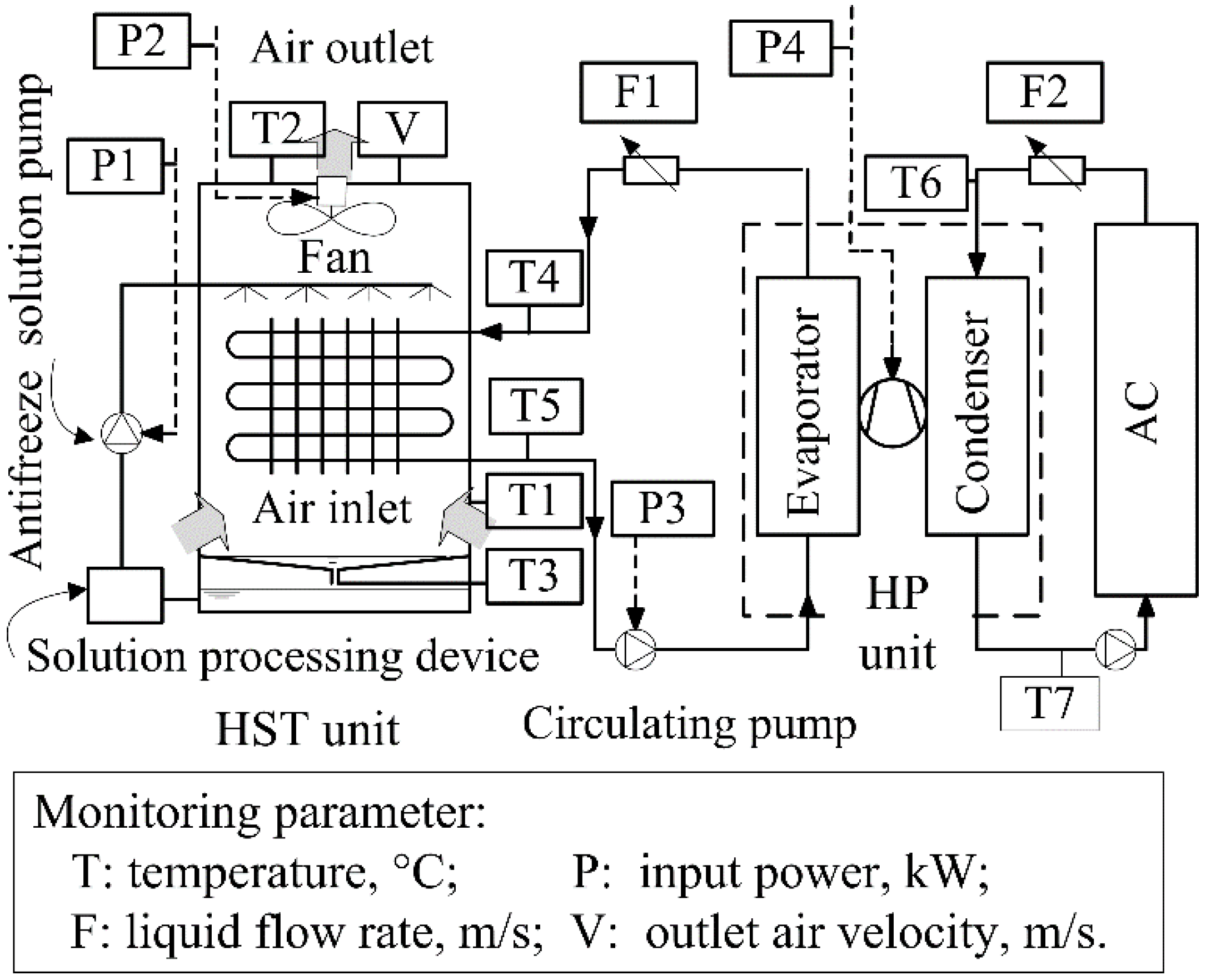

2. Experimental Apparatus and Procedure

2.1. Description of the Closed HSTHP System

2.2. System Performance Indexes

2.3. Testing Procedure

2.4. Uncertainty Analysis

3. ANN Modeling

3.1. Three-Layer BP Network

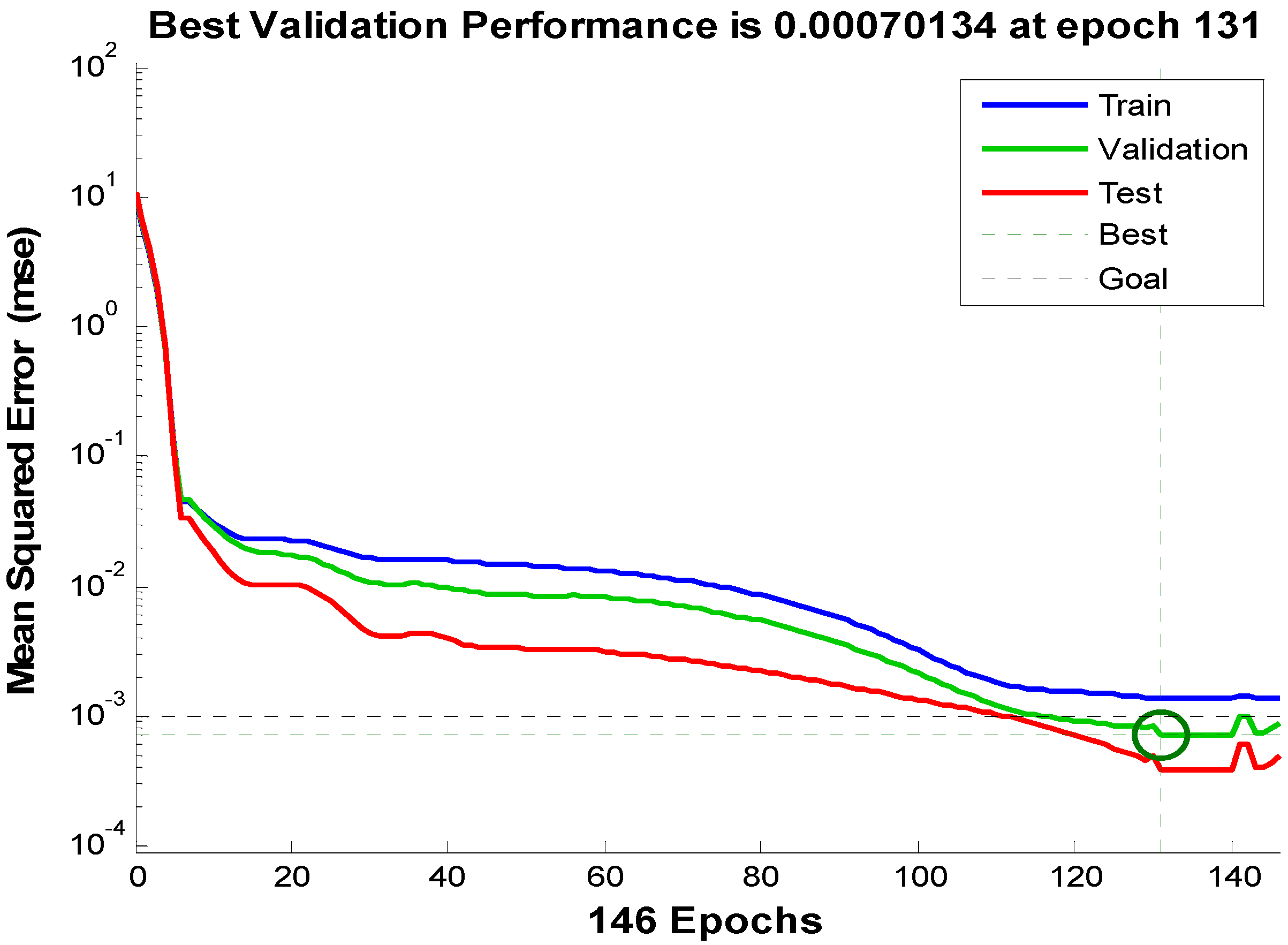

3.2. Performance Analysis of ANN

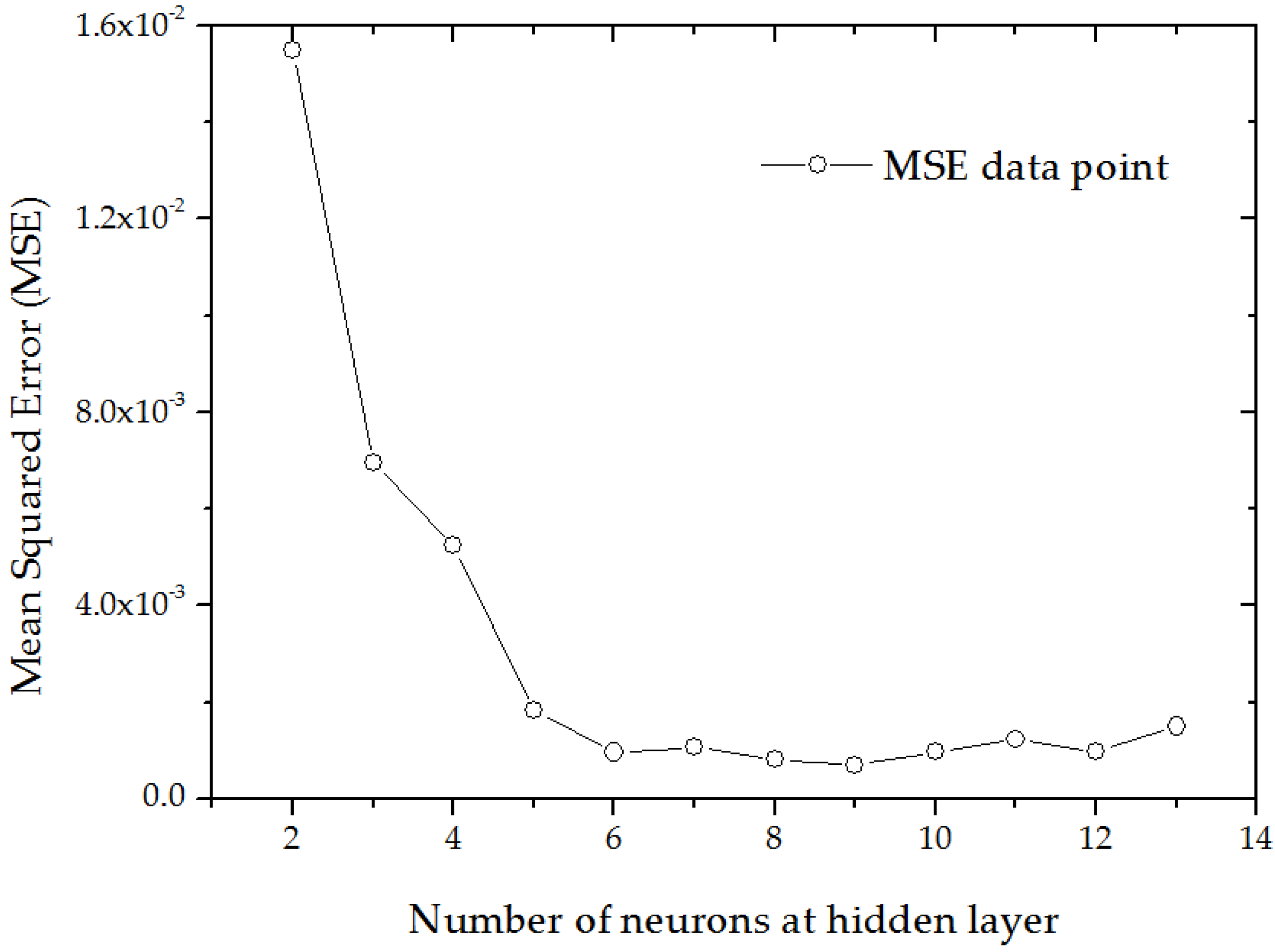

3.3. Determination of the Node Number in the Hidden Layer

4. Results and Discussions

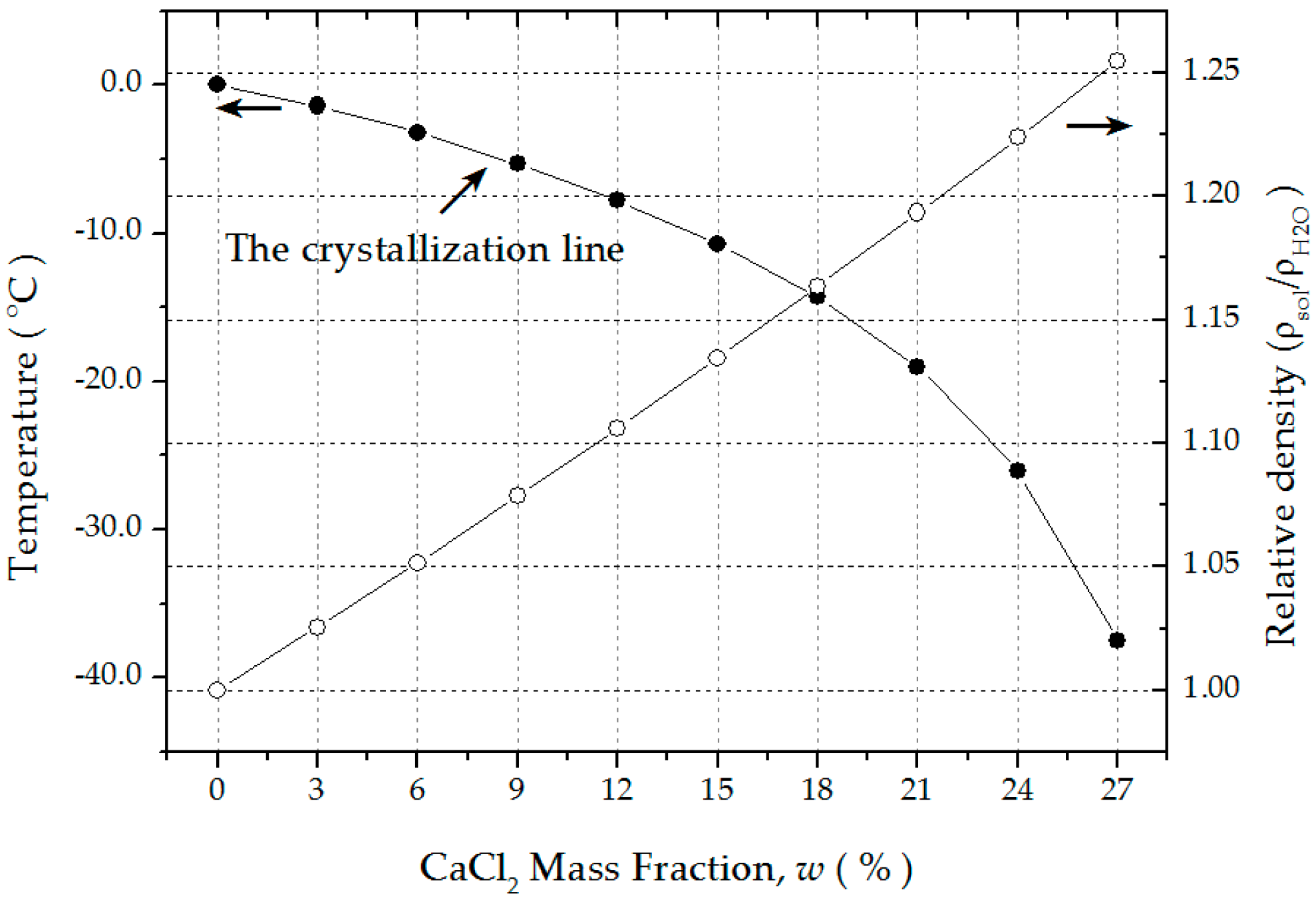

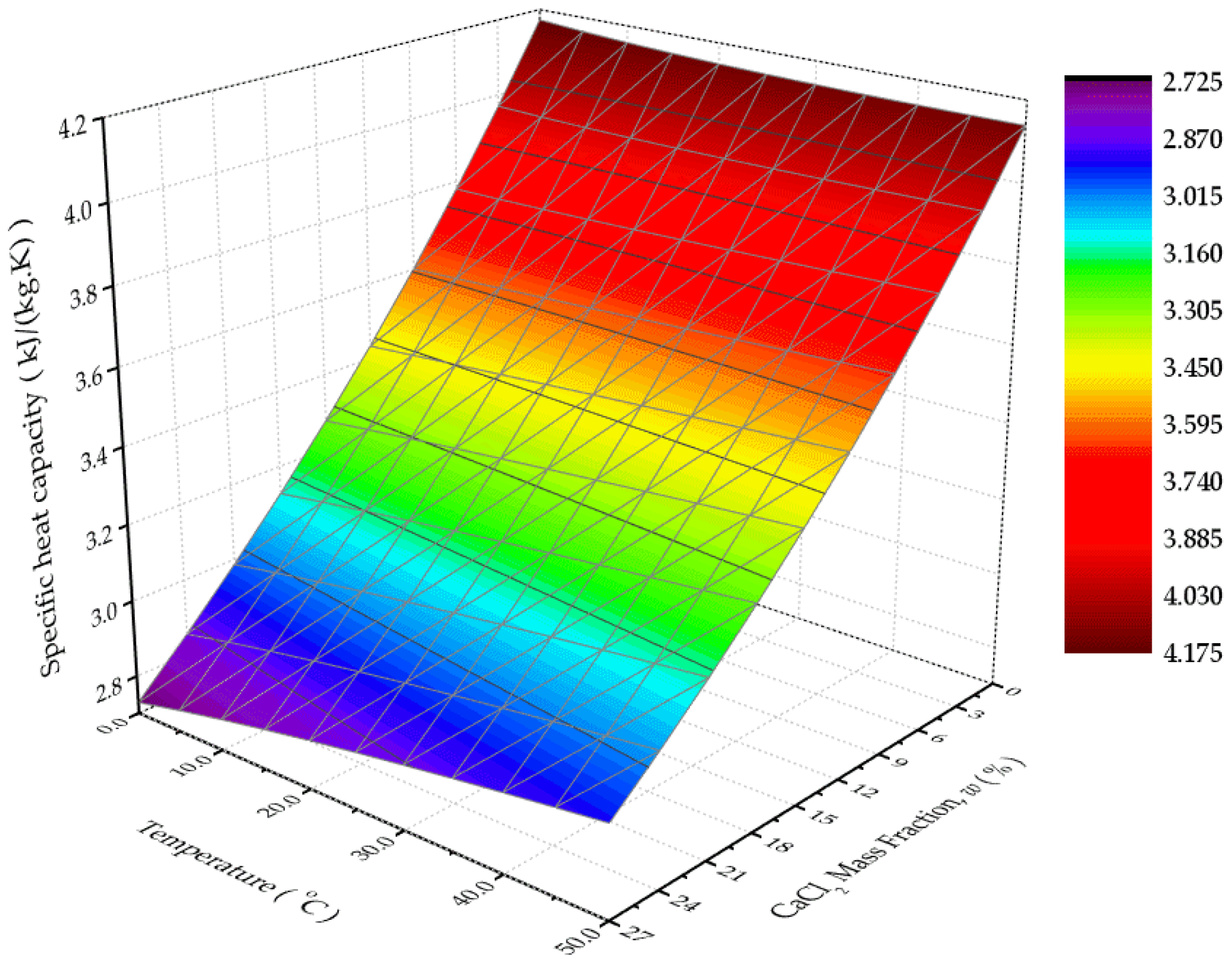

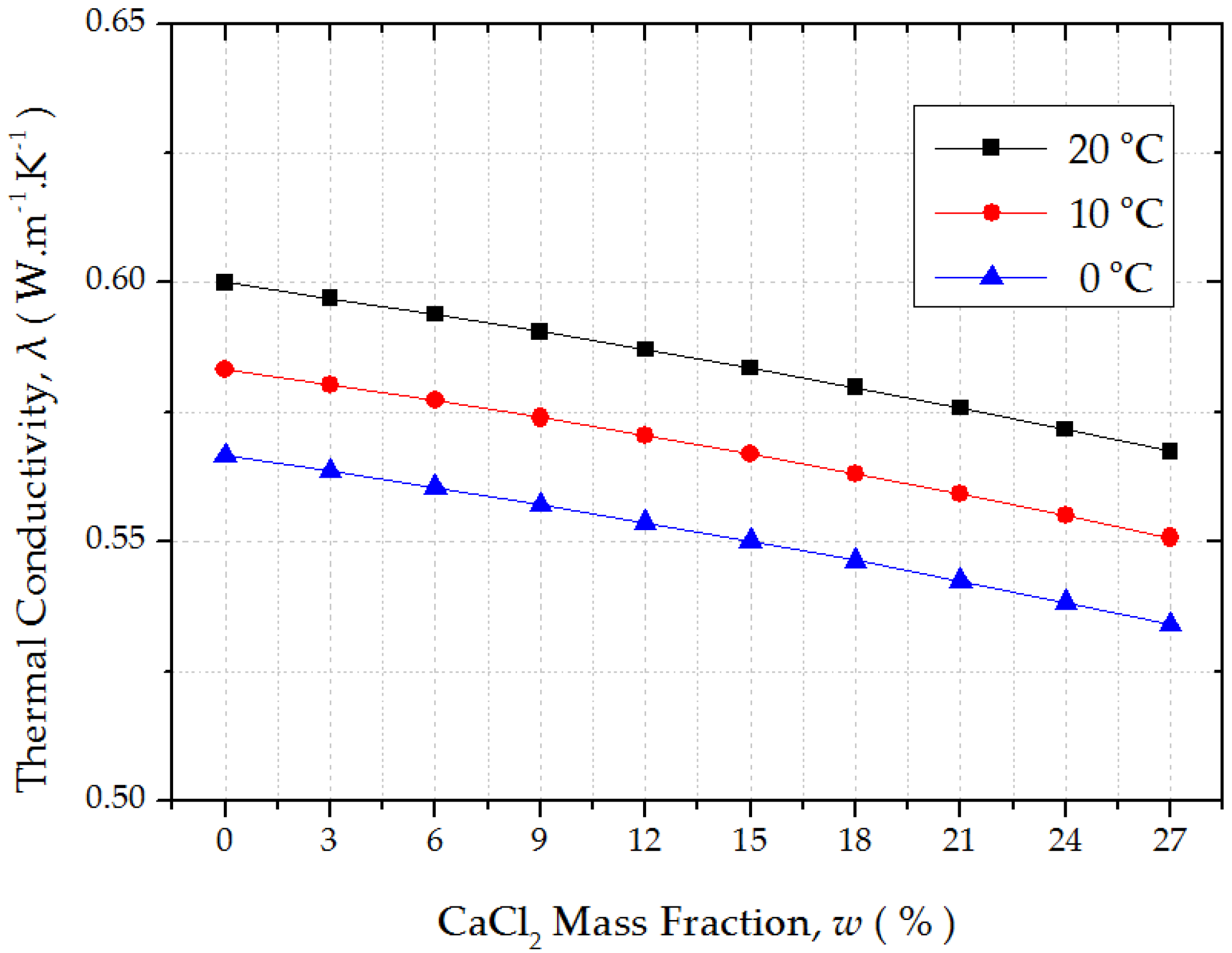

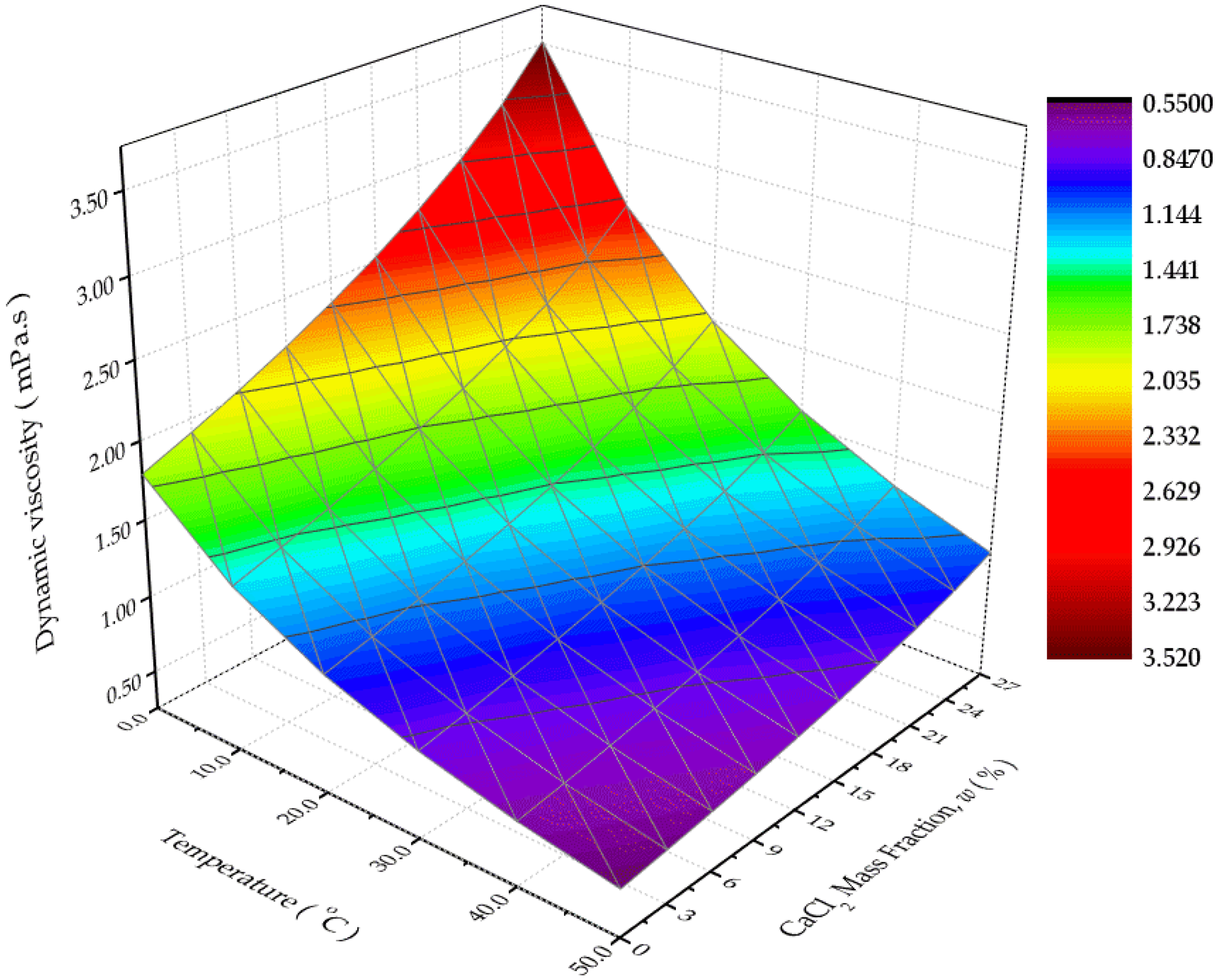

4.1. Thermo-Physical Properties of CaCl2 Aqueous Solution

4.2. Training Results and Performance Analysis of the ANN Model

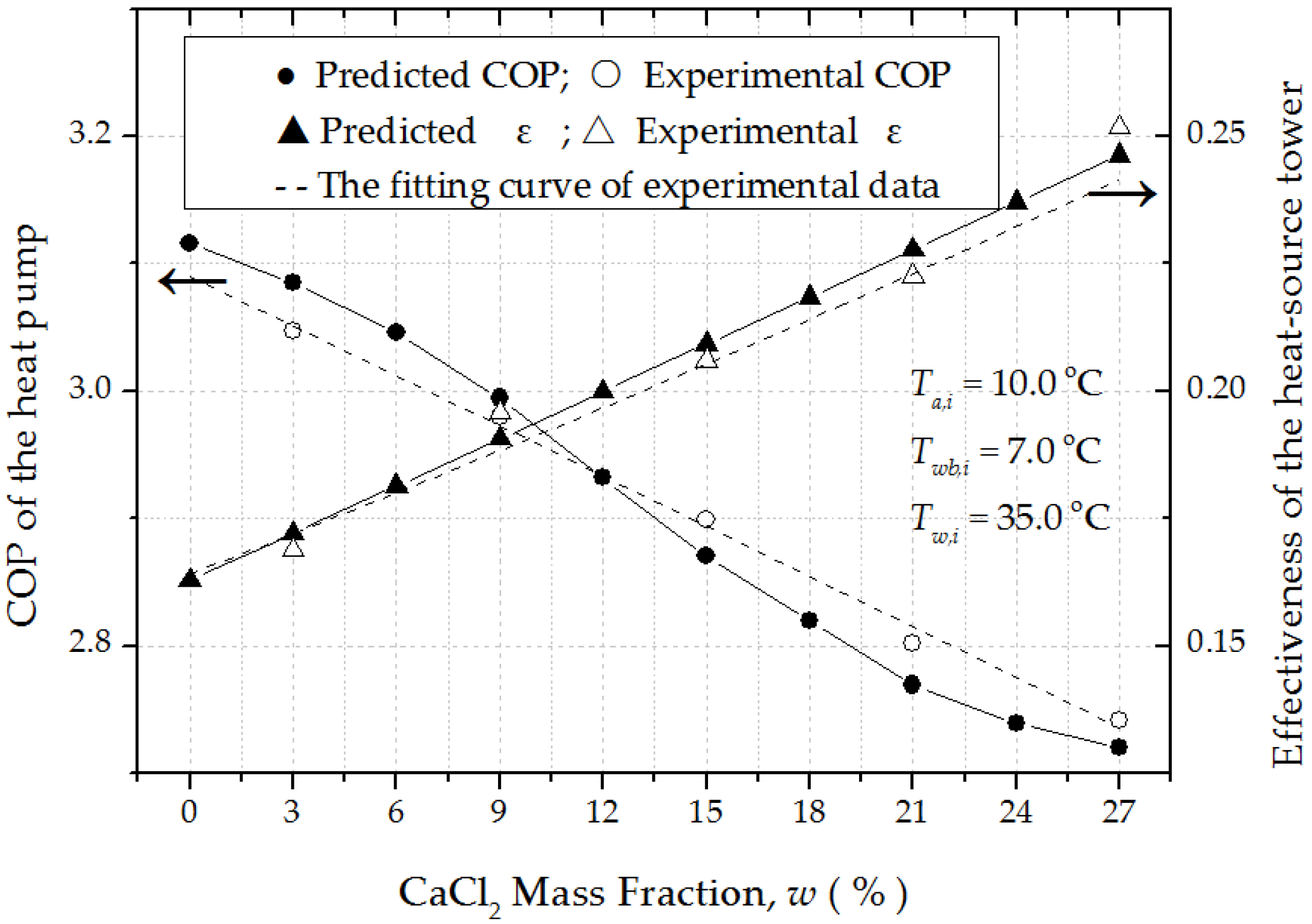

4.3. Effects of CaCl2 Mass Fraction on the Efficiency of the HSTHP

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of interest

Nomenclature

| Roman symbols | |

| ai | the experimental values |

| bi | the network output values |

| c | specific heat, kJ/(kg·°C) |

| cw | specific heat of cooling water at constant pressure, 4.1868 kJ/(kg·°C) |

| c0 | a constant belongs to [1,10] |

| n1 | the node numbers in the hidden layer |

| n | the node numbers in the input layer |

| m | the node numbers in the output layer |

| mw | mass flow rate, kg/s |

| P | input power, kW |

| Q | heating capacity, kW |

| R | correlation coefficient |

| w | CaCl2 mass fraction, % |

| T | temperature, °C |

| N | sample number |

| E | the expected value |

| V | outlet average air velocity, m/s |

| F | liquid flow rate, m/s |

| v | volume flow rate, m3/s |

| Greek symbols | |

| η | total efficiency of compressor |

| ρ | density, kg/m3 |

| μa, μb | The mean value of a set and b set |

| ε | tower effectiveness |

| Acronyms | |

| HST | Heat-Source Tower |

| HP | Heat Pump |

| COP | Coefficient of Performance |

| ANN | Artificial Neural Network |

| MRE | Mean relative error |

| RMSE | Root mean squared error |

| BP | Back-propagation |

| Subscripts | |

| a | air |

| aq | CaCl2 aqueous solution |

| comp | compressor |

| w | hot water |

| i | inlet |

| o | outlet |

| wb | ambient wet-bulb |

References

- Hajidavalloo, E.; Shakeri, R.; Mehrabian, M.A. Thermal performance of cross flow cooling towers in variable wet bulb temperature. Energy Convers. Manag. 2010, 51, 1298–1303. [Google Scholar] [CrossRef]

- Jin, G.Y.; Cai, W.J.; Lu, L.; Lee, E.L.; Chiang, A. A simplified modeling of mechanical cooling tower for control and optimization of HVAC systems. Energy Convers. Manag. 2007, 48, 355–365. [Google Scholar] [CrossRef]

- Khan, J.U.R.; Yaqub, M.; Zubair, S.M. Performance characteristics of counter flow wet cooling towers. Energy Convers. Manag. 2003, 44, 2073–2091. [Google Scholar] [CrossRef]

- Lemouari, M.; Boumaza, M. Experimental investigation of the performance characteristics of a counterflow wet cooling tower. Int. J. Therm. Sci. 2010, 49, 2049–2056. [Google Scholar] [CrossRef]

- Deng, S.; Song, Z.; Tan, K. Air-cooled heat pump with desuperheater: Retrofit for year-round service hot water supply. Build. Serv. Eng. 1998, 19, 129–133. [Google Scholar] [CrossRef]

- Heat-Source-Tower Heat Pump. Available online: http://www.climatesolver.org/innovations/living/heat-source-tower-heat-pump (accessed on 5 March 2009).

- Song, Y.; Ma, H.; Long, W. Application and analysis of energy tower heat pump technology in air conditioning engineering. Heat. Vent. Air Cond. 2011, 41, 20–23. [Google Scholar]

- Wu, J.; Zhang, G.; Zhang, Q.; Zhou, J.; Guo, Y.; Shen, W. Experimental Investigation of the Performance of a Reversibly Used Cooling Tower Heating System Using Heat Pump in Winter. In Proceedings of the 2011 Asia-Pacific Power and Energy Engineering Conference (APPEEC), Wuhan, China, 25–28 March 2011; pp. 1–4.

- Liang, C.; Wen, X.; Liu, C.; Zhang, X. Performance analysis and experimental study of heat-source tower solution regeneration. Energy Convers. Manag. 2014, 85, 596–602. [Google Scholar] [CrossRef]

- Wen, X.; Liang, C.; Zhang, X. Experimental study on heat transfer coefficient between air and liquid in the cross-flow heat-source tower. Build. Environ. 2012, 57, 205–213. [Google Scholar] [CrossRef]

- Cheng, J.L.; Zou, S.; Chen, S. Application Research on the Closed-loop Heat-source-Tower Heat Pump Air Conditioning System in Hot-summer and Cold-winter Zone. Proced. Eng. 2015, 121, 922–929. [Google Scholar] [CrossRef]

- Cheng, J.; Li, N.; Wang, K. Study of Heat-source-Tower Heat Pump System Efficiency. Proced. Eng. 2015, 121, 915–921. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, J.S.; Zhang, G.Q.; Zhou, J.; Guo, Y.H.; Wei, S. Calculations on performance characteristics of counterflow reversibly used cooling towers. Int. J. Refrig. 2012, 35, 424–433. [Google Scholar] [CrossRef]

- Wu, J.; Yu, Y.; Cao, L.; Zhang, G. Analysis on Influence Factors of Lewis Number in a Crossflow Reversibly Used Cooling Tower by Experimental Investigation. In Proceedings of 8th International Symposium on Heating, Ventilation and Air Conditioning, Volume 2: Hvac&R Component and Energy System; Springer: Berlin Heidelberg, Germany, 2014; Volume 262, pp. 327–332. [Google Scholar]

- Wu, J.S.; Zhang, G.Q.; Zhang, Q.; Zhou, J.; Wu, Y. Artificial neural network analysis of the performance characteristics of a reversibly used cooling tower under cross flow conditions for heat pump heating system in winter. Energy Build. 2011, 43, 1685–1693. [Google Scholar] [CrossRef]

- Wu, J.S.; Zhang, G.Q.; Zhang, Q.; Zhou, J.; Guo, Y.H.; Shen, W. A reversibly used cooling tower with adaptive neuro-fuzzy inference system. J. Cent. South Univ. 2012, 19, 715–720. [Google Scholar] [CrossRef]

- Tan, K.; Deng, S. A simulation study on a water chiller complete with a desuperheater and a reversibly used water cooling tower (RUWCT) for service hot water generation. Build. Environ. 2002, 37, 741–751. [Google Scholar] [CrossRef]

- Tan, K.X.; Deng, S.M. A method for evaluating the heat and mass transfer characteristics in a reversibly used water cooling tower (RUWCT) for heat recovery. Int. J. Refrig. Rev. Int. Froid 2002, 25, 552–561. [Google Scholar] [CrossRef]

- Tan, K.X.; Deng, S.M. A numerical analysis of heat and mass transfer inside a reversibly used water cooling tower. Build. Environ. 2003, 38, 91–97. [Google Scholar] [CrossRef]

- Cortinovis, G.F.; Paiva, J.L.; Song, T.W.; Pinto, J.M. A systemic approach for optimal cooling tower operation. Energy Convers. Manag. 2009, 50, 2200–2209. [Google Scholar] [CrossRef]

- Cortinovis, G.F.; Ribeiro, M.T.; Paiva, J.L.; Song, T.W.; Pinto, J.M. Integrated analysis of cooling water systems: Modeling and experimental validation. Appl. Therm. Eng. 2009, 29, 3124–3131. [Google Scholar] [CrossRef]

- Panjeshahi, M.H.; Ataei, A.; Gharaie, M.; Parand, R. Optimum design of cooling water systems for energy and water conservation. Chem. Eng. Res. Des. 2009, 87, 200–209. [Google Scholar] [CrossRef]

- Rubio-Castro, E.; Serna-González, M.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Synthesis of cooling water systems with multiple cooling towers. Appl. Therm. Eng. 2013, 50, 957–974. [Google Scholar] [CrossRef]

- Gao, M.; Sun, F.; Zhou, S.; Shi, Y.; Zhao, Y.; Wang, N. Performance prediction of wet cooling tower using artificial neural network under cross-wind conditions. Int. J. Therm. Sci. 2009, 48, 583–589. [Google Scholar] [CrossRef]

- Hosoz, M.; Ertunc, H.M.; Bulgurcu, H. Performance prediction of a cooling tower using artificial neural network. Energy Convers. Manag. 2007, 48, 1349–1359. [Google Scholar] [CrossRef]

- Qi, X.; Liu, Z.; Li, D. Numerical simulation of shower cooling tower based on artificial neural network. Energy Convers. Manag. 2008, 49, 724–732. [Google Scholar] [CrossRef]

- Melinder, Å. Thermophysical Properties of Aqueous Solutions Used as Secondary Working Fluids. Ph.D. Thesis, Energiteknik, Helsingborg, Sweden, January 2007. [Google Scholar]

- Mohammad, A.T.; Mat, S.B.; Sulaiman, M.Y.; Sopian, K.; Al-Abidi, A.A. Artificial neural network analysis of liquid desiccant dehumidifier performance in a solar hybrid air-conditioning system. Appl. Therm. Eng. 2013, 59, 389–397. [Google Scholar] [CrossRef]

- Islamoglu, Y. A new approach for the prediction of the heat transfer rate of the wire-on-tube type heat exchanger––Use of an artificial neural network model. Appl. Therm. Eng. 2003, 23, 243–249. [Google Scholar] [CrossRef]

- Chow, T.T.; Zhang, G.Q.; Lin, Z.; Song, C.L. Global optimization of absorption chiller system by genetic algorithm and neural network. Energy Build. 2002, 34, 103–109. [Google Scholar] [CrossRef]

- González, P.A.; Zamarreño, J.M. Prediction of hourly energy consumption in buildings based on a feedback artificial neural network. Energy Build. 2005, 37, 595–601. [Google Scholar] [CrossRef]

- Yetilmezsoy, K.; Demirel, S. Artificial neural network (ANN) approach for modeling of Pb(II) adsorption from aqueous solution by Antep pistachio (Pistacia Vera L.) shells. J. Hazard. Mater. 2008, 153, 1288–1300. [Google Scholar] [CrossRef] [PubMed]

- Xie, Q.S. Neural Net Method in Mechanical Engineering; China Machine Press: Beijing, China, 2003. [Google Scholar]

- Gao, M.; Shi, Y.; Wang, N.; Zhao, Y.; Sun, F. Artificial neural network model research on effects of cross-wind to performance parameters of wet cooling tower based on level Froude number. Appl. Therm. Eng. 2013, 51, 1226–1234. [Google Scholar] [CrossRef]

- Xin, F. Basic Theory and Method of Neural Net Intelligence; Southwest Jiaotong University Press: Chengdu, China, 2000. [Google Scholar]

- Yao, Y.B.; Wang, J.L. Research on raising BP network training speed. Inf. Technol. 2002, 1, 4–6. [Google Scholar]

- Conde, M.R. Properties of aqueous solutions of lithium and calcium chlorides: Formulations for use in air conditioning equipment design. Int. J. Therm. Sci. 2004, 43, 367–382. [Google Scholar] [CrossRef]

- China Academy of Building Research. CECS 362–2014 Technical Specification for Heat-Source-Tower Heat Pump System; China Planning Press: Beijing, China, 2014. [Google Scholar]

| Parameters (Test Point As Shown in Figure 1) | Instruments (Type) | Accuracy |

|---|---|---|

| Dry- and wet-bulb temperature of inlet (T1) and outlet (T2) air | Platinum resistance thermometer (PT100) | ±0.2 °C |

| Discharge temperature of condensate water(T3) | ||

| Inlet (T4) and outlet (T5) aqueous solution temperature | ||

| Inlet (T6) and outlet (T7) water temperatures | ||

| Aqueous solution flow rate(F1) | Ultrasonic flowmeter (PFSE) | ±1% |

| Water flow rate (F2) | ||

| Outlet air velocity (V) | Hot-wire anemometer (TSI 8347) | ±0.01 m/s |

| Input power of antifreeze solution pump (P1), fan (P2), circuiting pump (P3), compressor (P4) | Digital Clamp Multimeters (UT202A UNI-T) | ±1.5% |

| Convenient data statistics | Color paperless recorders (EN880) | Sampling interval |

| Input Parameters | Value Ranges |

|---|---|

| Ta,i (°C) | 8.1–20.3 |

| Twb,i (°C) | 6.3–14.2 |

| Tw,i (°C) | 31.2–43.7 |

| w (%) | 3, 9, 15, 21, 27 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, X.; Li, N.; Peng, J.; Cheng, J.; Su, L.; Hu, J. Analysis of the Effect of the CaCl2 Mass Fraction on the Efficiency of a Heat Pump Integrated Heat-Source Tower Using an Artificial Neural Network Model. Sustainability 2016, 8, 410. https://doi.org/10.3390/su8050410

Wei X, Li N, Peng J, Cheng J, Su L, Hu J. Analysis of the Effect of the CaCl2 Mass Fraction on the Efficiency of a Heat Pump Integrated Heat-Source Tower Using an Artificial Neural Network Model. Sustainability. 2016; 8(5):410. https://doi.org/10.3390/su8050410

Chicago/Turabian StyleWei, Xiaoqing, Nianping Li, Jinqing Peng, Jianlin Cheng, Lin Su, and Jinhua Hu. 2016. "Analysis of the Effect of the CaCl2 Mass Fraction on the Efficiency of a Heat Pump Integrated Heat-Source Tower Using an Artificial Neural Network Model" Sustainability 8, no. 5: 410. https://doi.org/10.3390/su8050410

APA StyleWei, X., Li, N., Peng, J., Cheng, J., Su, L., & Hu, J. (2016). Analysis of the Effect of the CaCl2 Mass Fraction on the Efficiency of a Heat Pump Integrated Heat-Source Tower Using an Artificial Neural Network Model. Sustainability, 8(5), 410. https://doi.org/10.3390/su8050410