1. Introduction

In the two past decades, nanomaterials have shown many outstanding characteristics compared to common materials. Therefore, lots of research is focused on nanomaterials nowadays. Especially in medicine, pure titanium (99.9%) is a preferred material for medical applications. Medical applications are a new field for titanium due to its high biocompatibility in the body [

1]. In medicine, titanium can be used to make hips, pacemakers, bone-plates and screws, and cranial plates for skull fractures. It has also been used to attach dentures. Because it is biocompatible (nontoxic and not rejected by the body), titanium is widely used in a gamut of medical applications, including surgical implements and implants. The titanium hip balls and titanium sockets (joint replacement) can stay in place for up to 20 years. Therefore, lots of researchers pay attention to using titanium for medical applications. Lorenzetti

et al. [

2] focused on improving the corrosion resistance of titanium. The overall results indicated that the hydrothermally prepared anatase coatings had appropriate morphology and surface properties for using in medical devices. Better corrosion protection of the implant could be expected. Bsat

et al. used alkali-acid-heat for surface treatment on porous titanium and improved its apatite-forming ability [

3]. This could produce highly porous structures that resemble the mechanical properties and structure of native bones. Frank

et al. used the method of cathodic polarization to coat titanium for bone implant materials to enhance bone healing and bone growth. Pure titanium was fabricated to create nano-titanium which was applied for knee replacement applications with longer biocompatibility time [

4].

There are many different methods to produce nano-titanium. However, this study applies the equal channel angular pressing (ECAP) method which is well known as a simple and economical way. ECAP is one of the techniques in metal-forming processes in which an ultra-large plastic strain is imposed on a bulk material in order to make an ultrafine grain and nano-crystalline metals and alloys [

5,

6]. This technique is a viable forming procedure to extrude materials by using specially designed channel dies without substantially changing the geometry by imposing severe plastic deformation (SPD). This technique has the potential for a high strain rate of super plasticity to the level of the submicron scale or nano scale [

7]. The suggested titanium samples are cylinders with a length of 70 mm and diameter of 14.6 mm [

8].

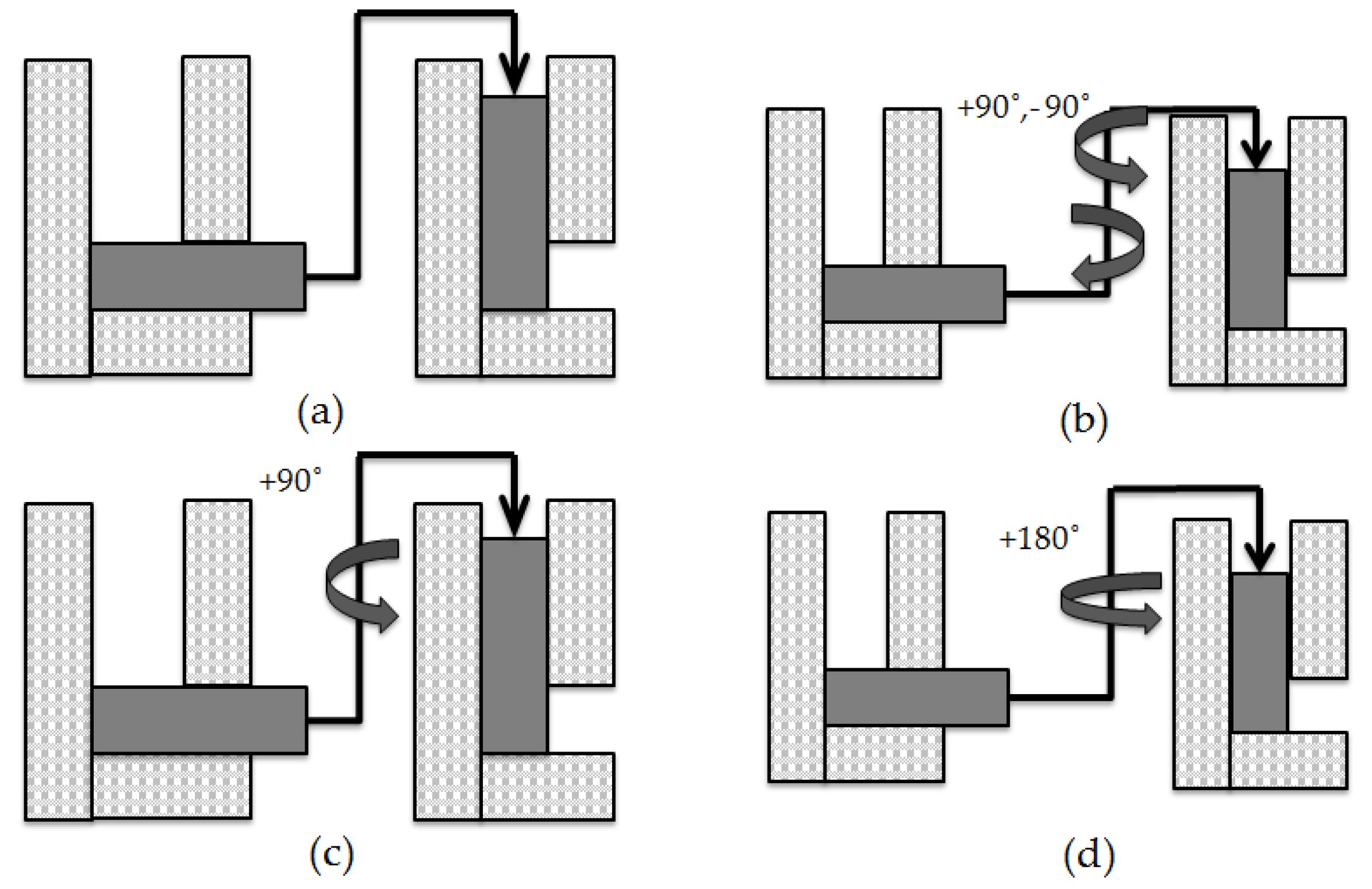

Four ECAP routes, namely A, Bc, Ba, and C, are used to investigate the influences of ECAP routes on microstructure and mechanical properties [

9]. These are shown in

Figure 1 [

8]. The study presses titanium bulk by following route Bc which rotates the titanium billet along its longitudinal direction 90° clockwise among consecutive passes, and it yields an equal grain structure. Titanium bulk is rotated four times per cycle until the rotation of titanium bulk reaches 3600. After each cycle (rotation four times) is complete, the grain of the titanium is cut down smaller. Therefore, the titanium bulk is conducted to press in multiples of four, such as four, eight, 12,

etc., to reach the refined grain size. However, this study just presses titanium bulk 12 times because the grain structure of titanium can be a destructed deformation if pressing over 12 times. The grain structure of titanium, by passing the channel, increases the ductility and strength of the titanium.

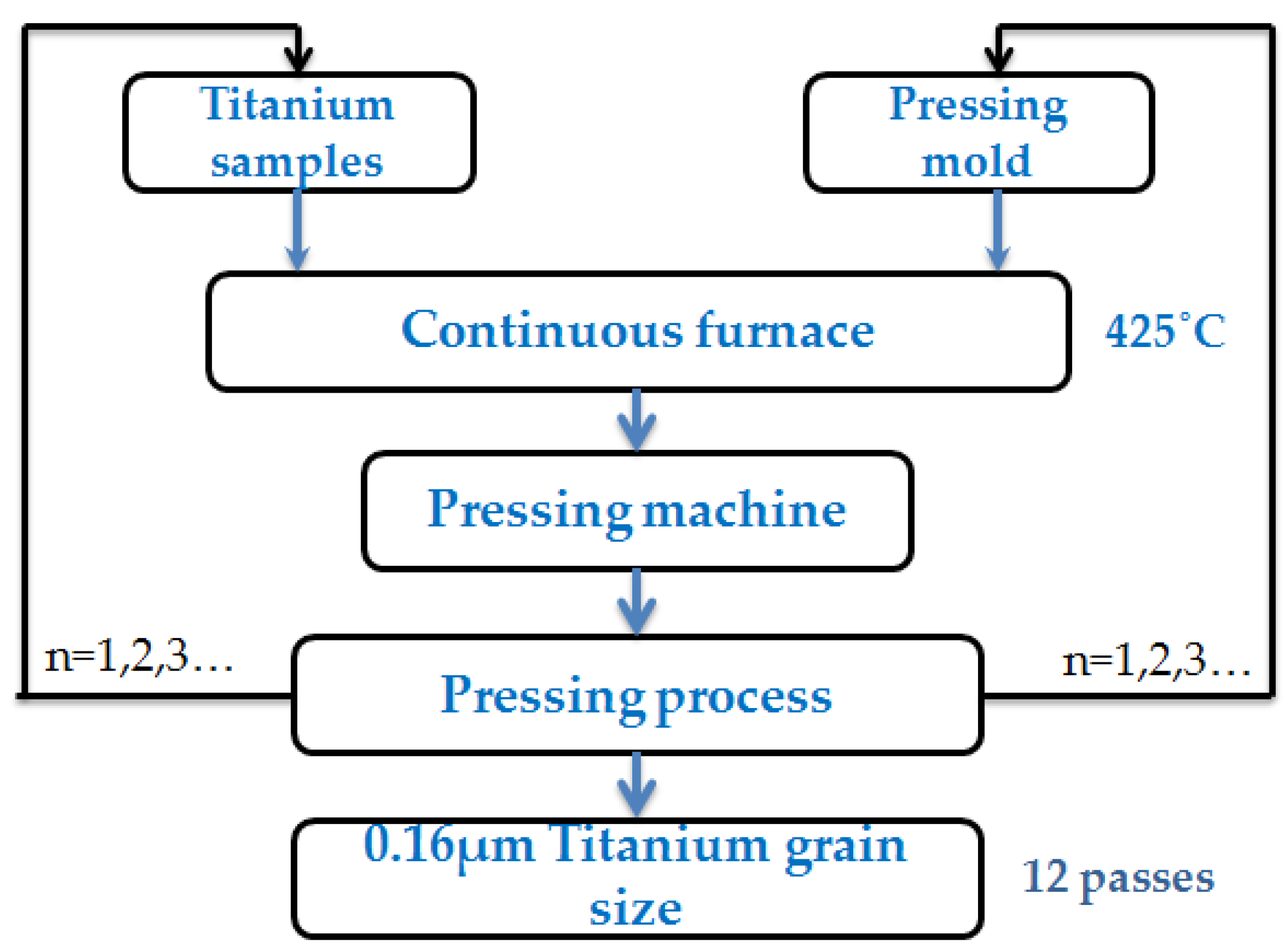

Figure 2 is the flow chart of ECAP. Titanium samples and the pressing mold are initially put into a continuous furnace to heat up 425 °C, and then they are taken to the pressing machine and the pressing process is conducted. After completing pressing, the titanium samples are brought back to the temperature of 425 °C, and then pressing is conducted again. This process is constantly carried out. The result of the titanium grain size is around 160 nanometers (nm) when the titanium samples are pressed 12 times. However, the results of the ECAP process contain insufficient properties for implants. Therefore, researchers face the problem of how to take advantage of ECAP to produce the nano-titanium that can be used in surgical implants. In order to solve this problem, the Teoriya Resheniya Izobreatatelskih Zadatch (TRIZ) method is applied to improve the production process of nano-titanium [

10].

This research has two major purposes. The first purpose is to apply TRIZ to create nano-titanium with a grain size of around 100 nanometers and good mechanical properties (or high tensile strength). Because the nano-titanium is used for knee replacements, the grain size and mechanical properties are highly important for achieving biocompatible implants. The second purpose is to apply TRIZ to reduce time and energy consumption during the ECAP process to reduce the production cost.

The remainder of this paper is organized as follows.

Section 2 proposes the approach of this study and the improvement analysis of this research. Materials and the experiment method are depicted in

Section 3. Experimental results based on realistic data are shown in

Section 4. Finally, conclusions are in conducted in

Section 5 with future research directions.

2. Research Method and Problem Solving

TRIZ is a problem-solving method based on logic and data, not intuition, which accelerates the project team’s ability to solve these problems creatively. TRIZ also provides repeatability, predictability, and reliability due to its structure and algorithmic approach. Altshuller and his colleagues developed the method between 1946 and 1985 [

10]. By reviewing over 300,000 patents, Altshuller ended up with a concept of ideality of a system and leveraged other theoretical and practical approaches. TRIZ offers a systematic creativity process built primarily on the concept of abstraction. TRIZ is aimed at creating an algorithmic approach in the invention of new systems and the refinement of old systems.

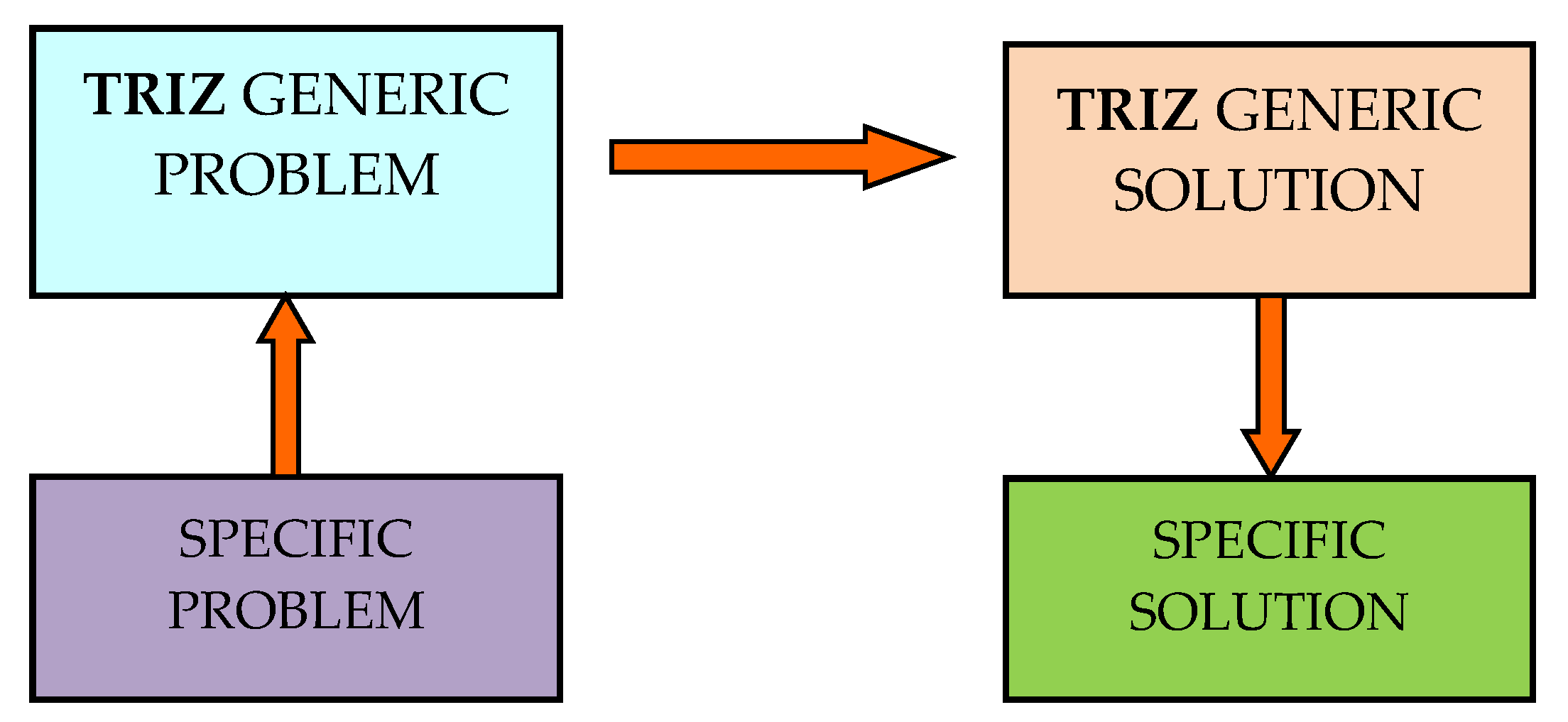

TRIZ researchers have enclosed the principles of good inventive practice and a generic model for a TRIZ problem-solving framework, as shown in

Figure 3 [

11]. The general process, in which the TRIZ method avoids the trial and error approach for idea generation and the psychological inertia barrier, starts from the specific problem to an analogous TRIZ generic problem. Then, through the comparison of the generic TRIZ problem to find the generic TRIZ solution from the solutions of 40 principles, or from the knowledge database from scientific effects, or from patents research, it allows the researchers to generate the solutions for the specific problem. TRIZ helps to avoid an inefficient route for problem solving, and provides a systematic and efficient way to solve the problem. Hence, it is a reliable process that results in systematic innovation [

12].

Altshuller discovered that technical systems normally follow certain regularities in their development. These regularities were translated into patterns of evolution and are beneficial for developing good solutions to problems and predicting how systems evolve [

13].

Series of TRIZ tools are used from the problem identification step to the problem-solving step. However, the contradiction matrix is a very important part of TRIZ for newcomers to be exposed to. Altshuller found that inventors usually had problems with technical contradictions and physical contradictions in the engineering constructions of the problem [

14]. The core of TRIZ consists of 40 principles and the contradiction matrix. When facing an engineering problem, the contradiction matrix is used to select pairs of parameters in conflict from 39 parameters and then 40 inventive principles are used to find out the possible technical combinations. How users actually use the contradiction matrix mainly depends on preferred ways of working. Some peoples prefer to just use the inventive principles; others like the idea that the contradiction matrix will reduce the number of possible principles to be examined.

Effective TRIZ demands a good definition of the contradiction. This definition is usually conducted in a number of separate stages. There are five steps of practical application using the contradiction matrix and principles [

11], which are included as follows:

Step 1: Define the problem:

Step 2: Analyze the problem:

Step 3: Select parameters:

Step 4: Find invention principles:

Step 5: Develop and evaluate the feasible solutions:

In this study, the titanium properties are implemented by applying the ECAP process. However, there are some issues when applying the ECAP process to produce nano-titanium. The contradiction matrix and 40 principles are selected to generate solutions to improve the manufacturing of nano-titanium.

Firstly, the contradiction matrix is applied. Basically, the contradiction matrix and inventive principles must be simultaneously conducted during the problem solving of TRIZ, because the consideration of improving parameters and conflicting parameters in the contradiction matrix will provide the corresponding inventive principles. Hence, from the conflict matrix, the improving process can select some solution directions. Applying these to the research system, improving parameters and conflicting parameters are listed in

Table 1.

After defining the improving parameters and conflicting parameters, the inventive principles are chosen from the contradiction matrix.

Table 2 shows the improving and conflicting parameters, as well as the inventive principles in relationship with improving the process.

All of 40 principles are proposed from the matrix. After reviewing for all related principles, some related ones are considered to apply in

Table 2. Those are numbers three, 10, 20, 28, 34, and 35 from the principles. The contents of six principles are shown in

Table 3 [

11].

Following the hints of the above principles, some important solution directions are taken out from the six principles. Specific solution directions for the research are proposed as below:

- (1)

Enable each part of the system to meet optimal conditions

- (2)

Pre-arrange the object or system at the most convenient time and place

- (3)

Make all parts of an object or system work at full load

- (4)

Introduce electric, magnetic fields to interact with an object or system

- (5)

Restore consumable or degradable parts of an object or system during operation

- (6)

Change the degree of flexibility

Combining these solution directions, specific solution directions for the research are proposed as below:

- (1)

The electric field with the pressing mold can remove the harmful interaction between the pressing mold and the continuous furnace, and excessive interaction between the continuous furnace and the titanium. The solution is to put the pressing mold heating resistance wires into the furnace and then simultaneously heat the pressing mold and the titanium samples.

- (2)

Changing the degree of flexibility in the process, the ECAP process uses cold rolling to achieve the refined grain structure and high mechanical properties for the Titanium.

In order to solve the wasted energy and thermal problems of the continuous furnace, the solution is to add a new field (power) and a new substance (heating resistance wire) to the original mold. The new pressing mold is called a heating mold. The additions make the original become a heating mold with good heating ability and less energy. On the other hand, the insufficient nano-titanium problem from the ECAP process is also solved by adding a new field (cold rolling) and a new substance (rolling mill). When the cold rolling process is added shortly after the ECAP process, the final nano-titanium product is improved in terms of mechanical properties. Solutions are specifically conducted. The improvement steps are shown below.

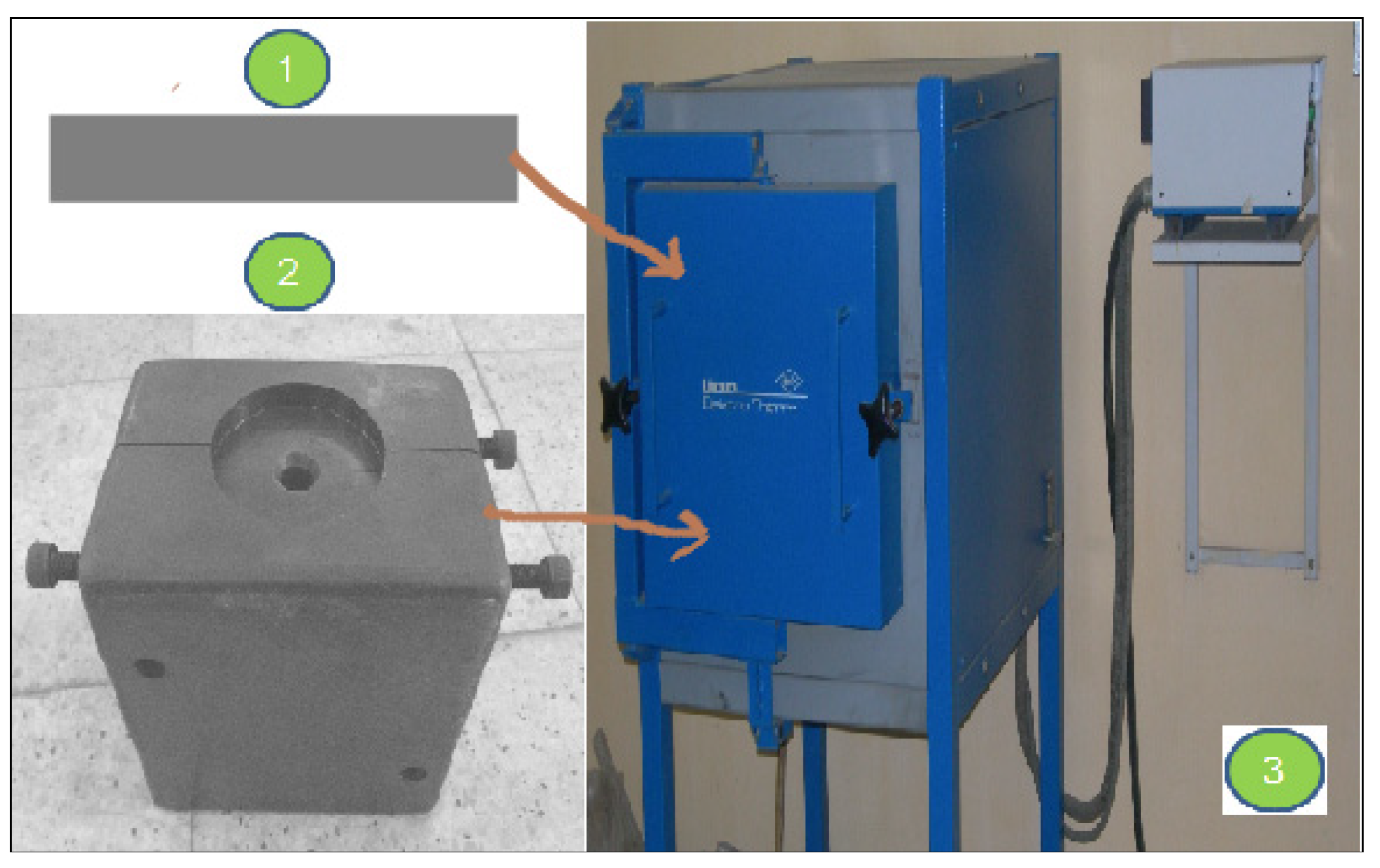

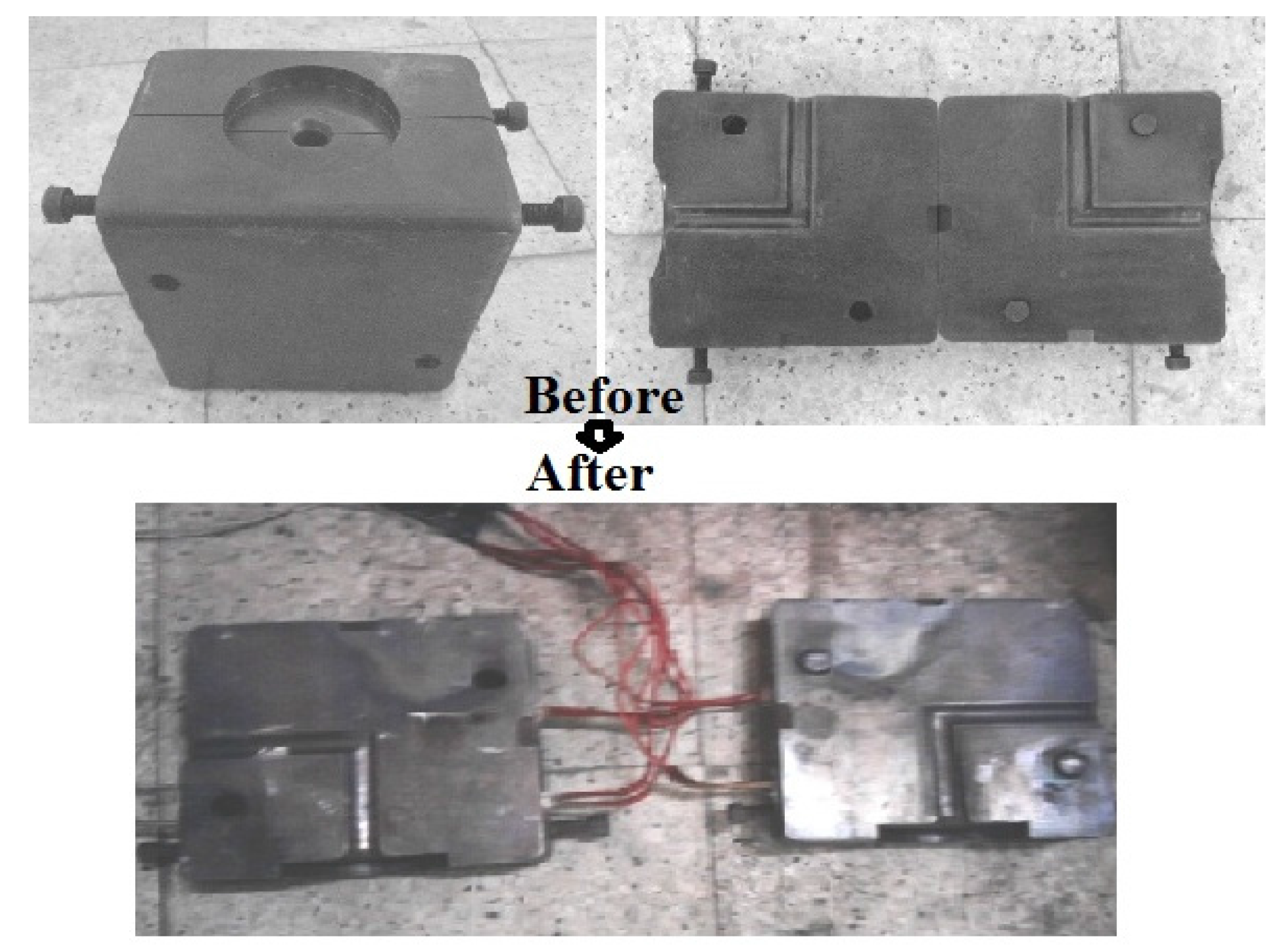

The original mold is processed as follows. The baking temperature applied to baked titanium samples and the mold is 425 °C for the pressing process, but the continuous furnace operates at a maximum temperature up to 1200 °C and consumes electrical energy up to 13.5 kW/h. These indicate that using a continuous furnace causes wasted heating and energy. In addition, the titanium samples are taken to the pressing machine to press after they are baked in the continuous furnace as shown in

Figure 4. The transportation of the mold and samples causes loss of heating which also affects the pressing process and results of the nano-titanium. Thus, the improved mold is created to address these issues.

The original pressing mold should have four heating resistance wires added to become a multifunction mold. The heating resistance wires generate a maximum thermal up to 550 °C for the pressing mold; each wire consumes about 600 kW/h of energy. The addition of the heating resistance wires creates a new mold as shown in

Figure 5.

The heating mold creates thermal stability during the ECAP process and saves energy. The pressing process continuously operates when the heating mold is used. Because the step of bringing the pressing mold and titanium samples to the pressing process is removed, the pressing process is time-saving. Hence, creating the heating mold solves issues in terms of wasted energy and time, and it maintains thermal stability in the process.

Secondly, it is necessary to improve the mechanical properties of the nano-titanium after the ECAP process. Although the titanium pressing process is conducted several times, the mechanical properties of nano-titanium after the ECAP process are still not good enough for implants in the body. Therefore, the addition of cold rolling after the ECAP process is conducted. Because cold rolling (at 25 °C) is also known as a method of improving mechanical properties, cold rolling is selected to solve the above issue.

Finally, nano-titanium products that are obtained after the ECAP and cold rolling processes indicate increased tensile strength and a better refined grain size. The increased tensile strength of nano-titanium improves its shape memory properties, and also enhances implant longevity. More refined grain size will increase the biocompatible property of nano-titanium. Thus, a new process, which includes the ECAP and cold rolling processes, creates good nano-titanium for implants.

3. Materials and Experiment Method

The major focus of this study is to improve the manufacturing of nano-titanium, not its material characteristics. Therefore, this study only examines four factors. They are reducing the process time, saving power, and changing the grain size and tensile strength. The first two factors examine improving the manufacturing process and the last two items are for mechanical testing of the characteristics. The material used in the experiment is pure titanium (99.9%) and both the original mode and heating mode tested 60 samples. The samples with a 2 mm gage length × 2 mm width × 0.1 mm thickness are used in the experiment.

For the tests of reducing process time and saving energy, both the original mode and heating mode are tested. For the original mode (ECAP process), titanium samples and the pressing mold are initially put into a continuous furnace to heat up to 425 °C, and then they are taken to the pressing machine and the pressing process is conducted. After completing the pressing, the titanium samples are brought back to heat up to 425 °C, but the continuous furnace operates at a maximum temperature up to 1200 °C and consumes electrical energy up to 13.5 kW/h. All samples are pressed 12 times. For the heating mode, the original pressing mold should have four heating resistance wires added to become a multifunction mold. The heating resistance wires generate a maximum thermal temperature up to 550 °C for the pressing mold; each wire consumes about 600 kW/h of energy. The addition of the heating resistance wires creates the heating mold. All samples are pressed 12 times as well. This study records all the processing time and energy consumption of the original mode and heating mode.

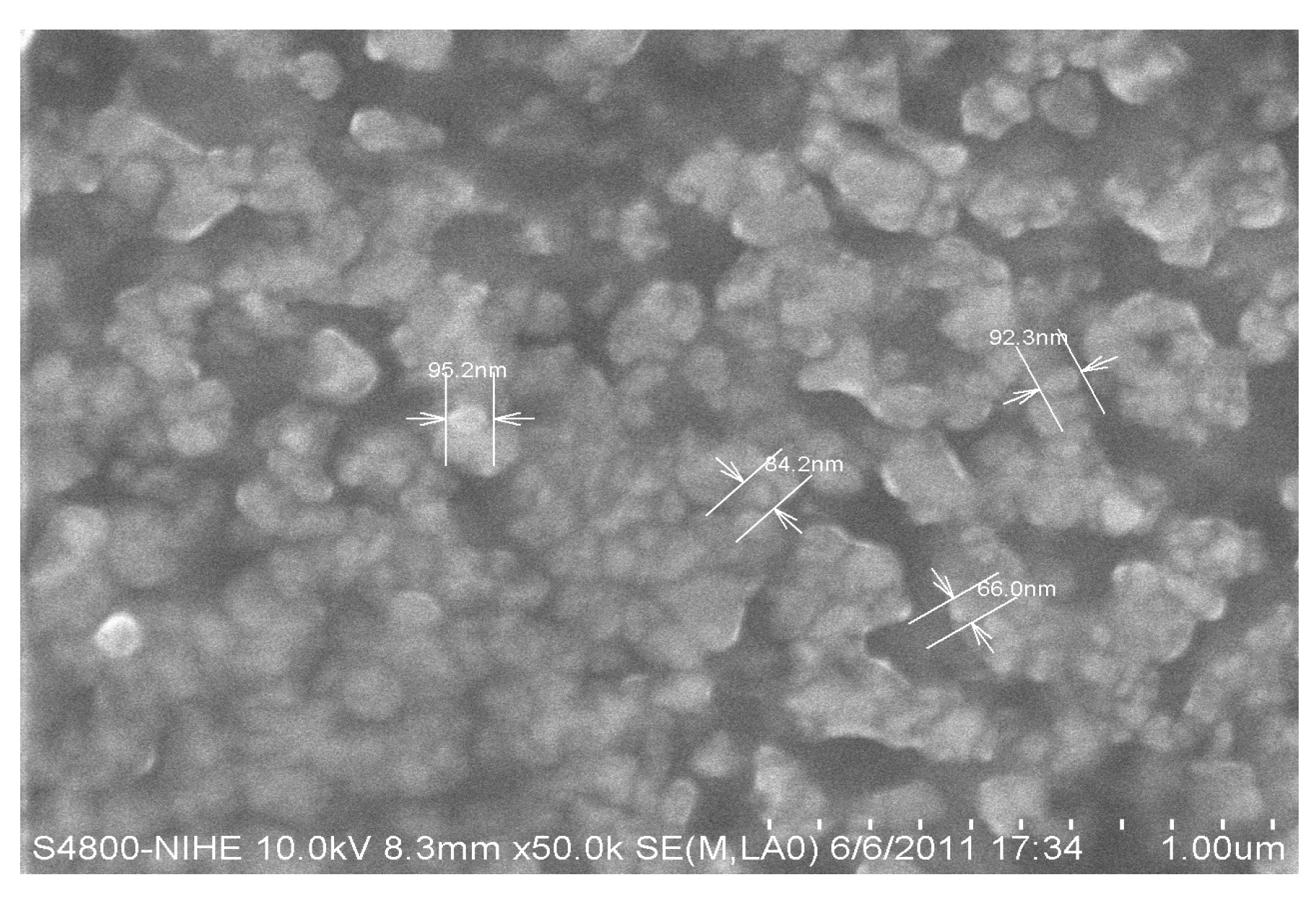

For the test of changing the grain size, the study uses the scanning electron microscope (SEM), which is known as a high accuracy device, to check the results. The SEM model is S-4800 and it is operated at 10 kV to check the grain sizes of samples for both the original mode and heating mode.

For the test of tensile strength, both the original mode and heating mode are tested. A constant strain rate tensile (CSRT) test machine was applied to measure the stress-strain relation. The tensile tests were performed on a custom-built computer to control the CSRT test machine with a displacement resolution of 10 μm and a load resolution of 0.1 N, and the strain rate is 10−3 s−1. The experimental data of each mold specimens were tested five times at 24 °C to obtain an average. The temperature of the original mold and heating mold on the mechanical result during tensile test is 24 °C as well.

4. Experiment Results

The results are sound. Sixty samples are tested. The process capacity is significantly increased when the press molding is improved and the continuous furnace is removed from the ECAP process. The new mold design appreciably improves time and energy consumption.

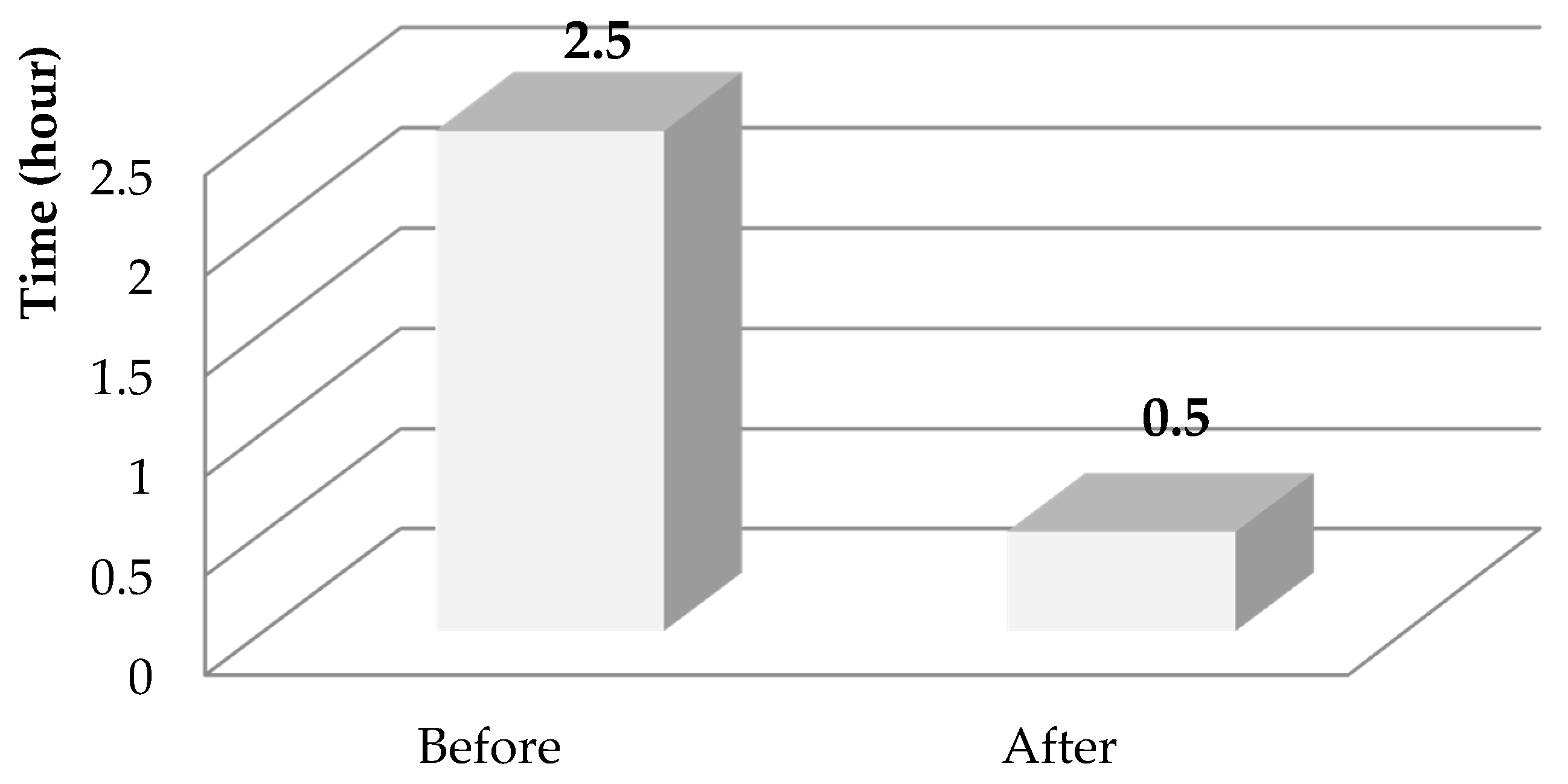

Figure 6 indicates that the heating mold saves much time for the whole ECAP process compared to the original mold. It takes 150 hours to press 60 titanium samples through 12 passes (12 pressing times) as compared to using the original mold (2.5 hours per sample). However, the heating mold only takes 30 hours to press the same 60 samples, each of which also passes 12 pressings (0.5 hours per sample). The process time has an 80% reduction.

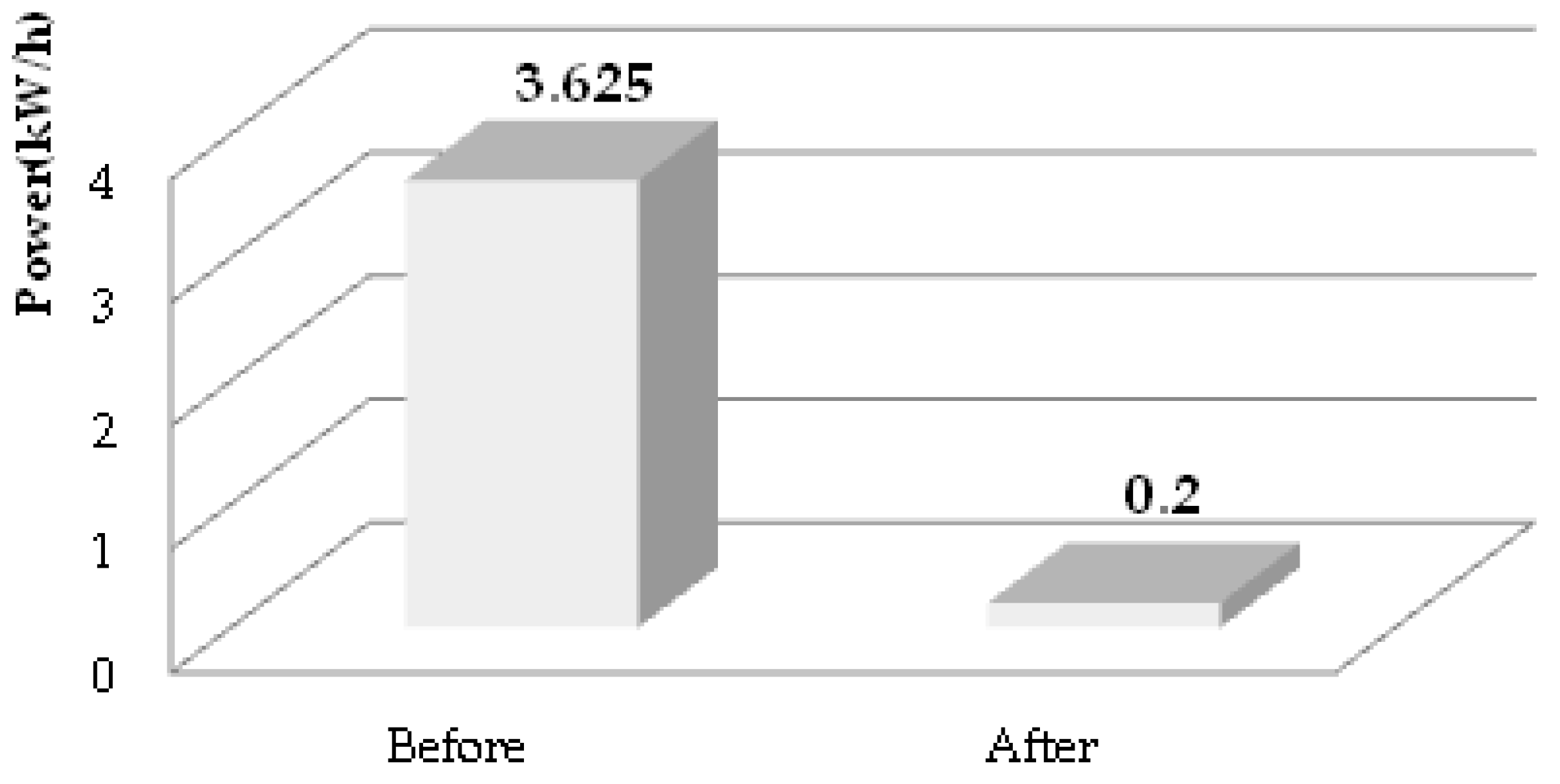

The application of the heating mold also saves more energy for the process (see

Figure 7). The consumed electrical energy of 60 samples is a total 202.5 kW/h (3.625 kW/h for each resistive wire) with the continuous furnace that wastes too much energy for the original pressing mold. The original pressing mold is improved to become a heating mold with 12 kW/h for 60 samples (0.2 kW/h for each resistive wire) consumption. This saves 94% of the energy and also creates much more uniform heating. In addition, the heating mold also accelerates the titanium pressing process.

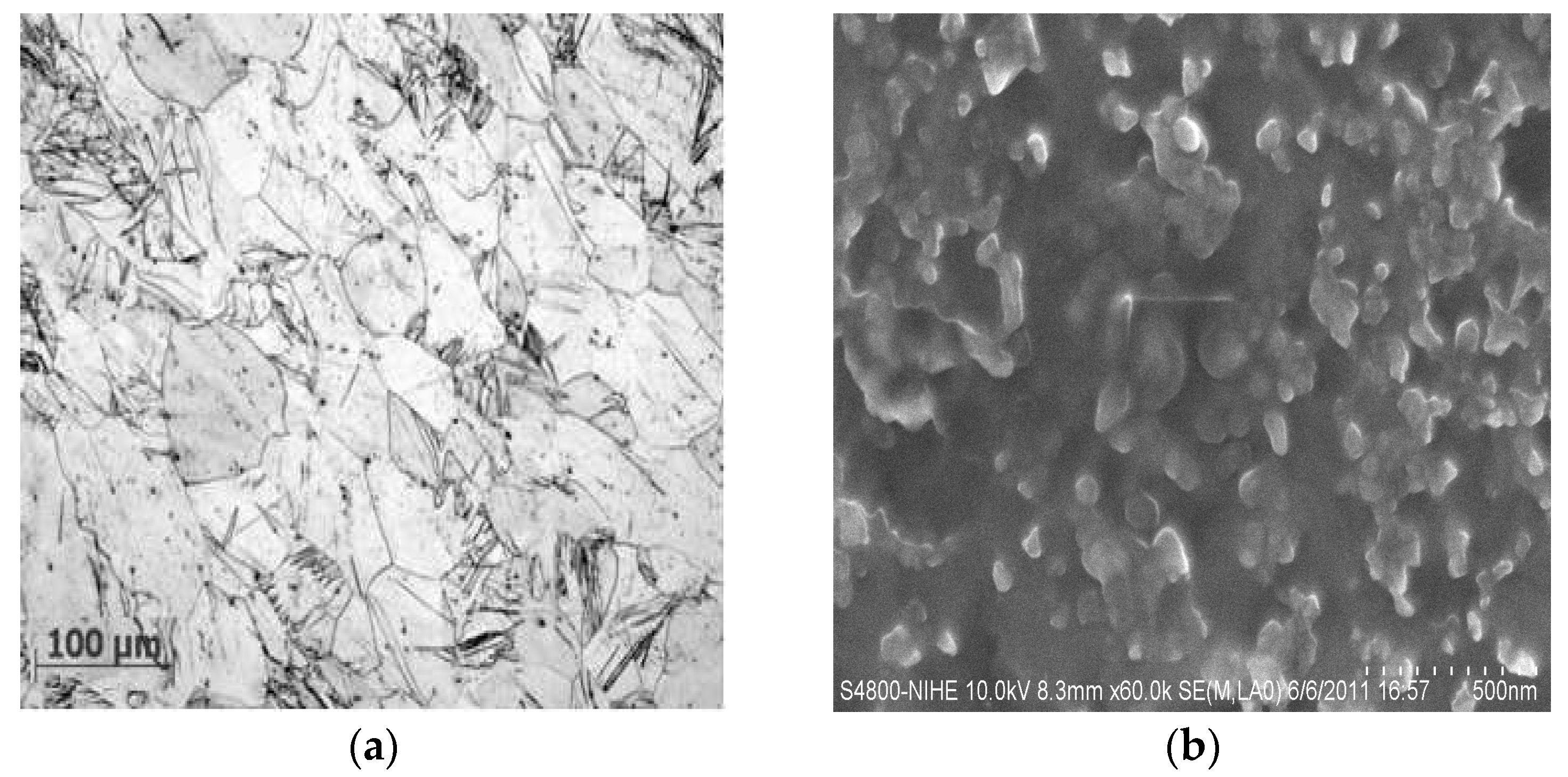

By applying the ECAP process, nano-titanium approaches 160 nm (12 passes sample in the ECAP process) in grain size. The grain structure of titanium is refined much more after the ECAP process. The titanium structure transfers from rough to fine. However, the best result (160 nm) obtained from the ECAP process is not good enough when it is implanted as a knee replacement into the body due to low biocompatibility.

In

Table 4, the results of adding cold rolling are also much better than those of the original ECAP process. That result shows an 80 nm grain size of titanium after the ECAP with the cold rolling process.

Figure 8 shows the structures of the initial titanium grain structure and the grain structure of titanium ECAP with added cold rolling. The results are a 50% reduction of the diameter and an increase of 700% in volume.

In this study, this nano-titanium structure is the best result because the ECAP process only is pressed up to 12 times for titanium samples. If the samples are pressed over 12 times, they will cause destruction deformation in the internal titanium structure. In addition, cold rolling is a good approach to strain deformation up to 75%, because rollers always exit residual deformation. Thus, titanium samples are not deformed when the strain deformation is over 75%. In summary, this ultrafine grain size of titanium demonstrates good biocompatibility when it is used in an implant due to this grain structure similarity of the nano-titanium with the knee replacement structure.

Figure 9 presents the nano-titanium structure after the ECAP (12 passes) and cold rolling (75% of strain) processes.

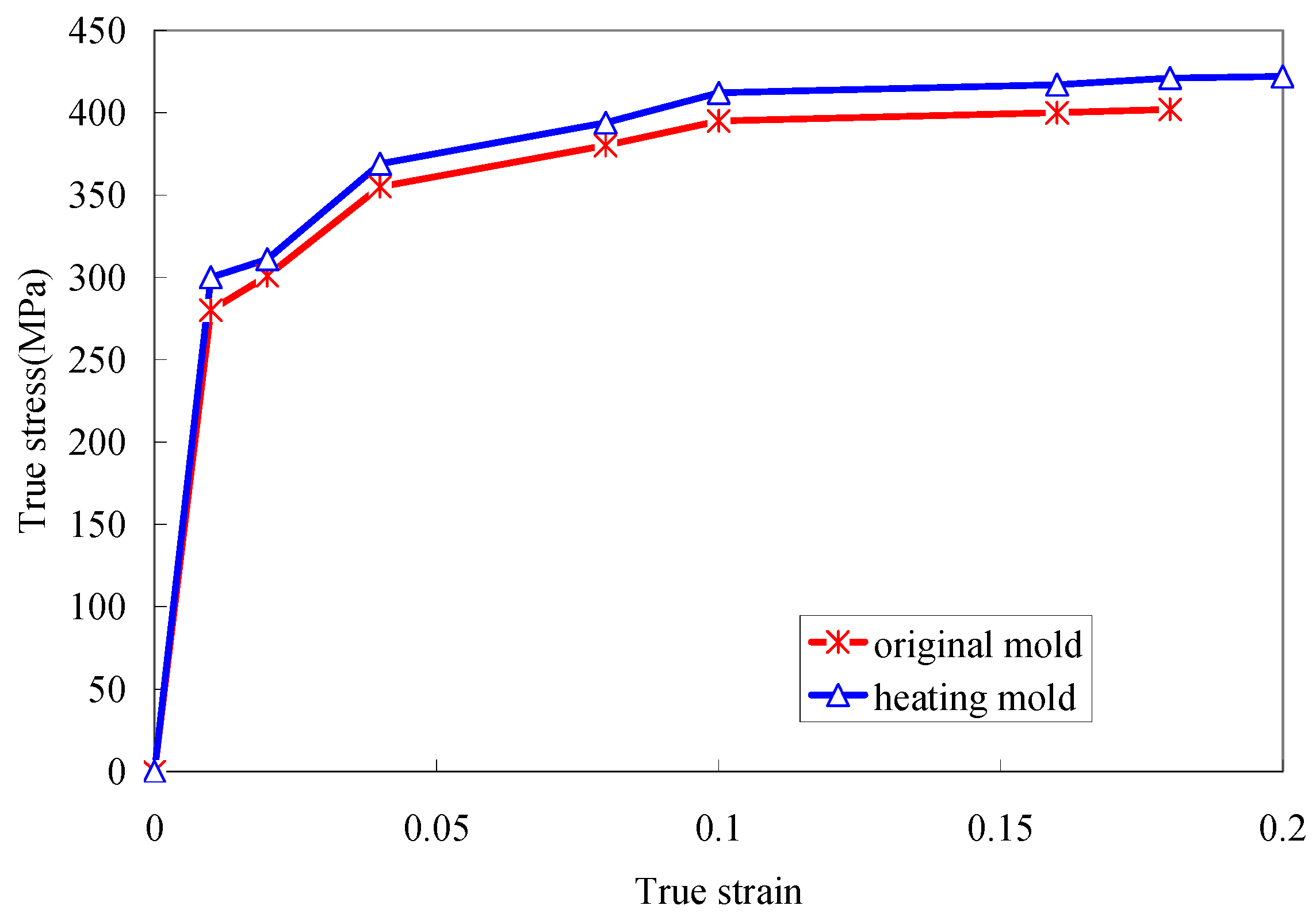

The behavior of the original mold and heating mold on the mechanical result during the tensile test at room temperature is shown in

Figure 10. It is obvious that the heating mold specimen leads to a significant increase in tensile strength. For example, when the stain rate is 0.1, the stresses of the original mode and heating mode are 390 and 410, respectively. The heating mode is around 5% superior to the original mode.

The summary of test results of the four manufacturing and mechanical factors are demonstrated in

Table 5.

5. Conclusions

In this research, improving the nano-titanium manufacturing process is performed using the pressing mold. The original pressing mold is replaced by a heating mold. This study achieves significant improvement in the mechanical properties of nano-titanium material. This improvement is implemented by adding the cold rolling process after the pressing process of the nano-titanium. The titanium material, after adding the cold rolling process, shows significant improvement in mechanical properties and grain size. Research results show that the process time is reduced by 80%, and 94% of the energy saved. Results of the structure analysis taken by SEM show the ultrafine grain size of nano-titanium, which has changed from 160 nm to 80 nm. The results are a 50% reduction of the diameter and a 75% improvement in volume. These enhance the biocompatibility of nano-titanium for implants.

The research shows an improved process for producing nano-titanium for knee replacements. The combination between the ECAP and the cold rolling processes can be applied to produce many other nanomaterials for other purposes in which it is necessary to have a nano-scale grain structure for the material. For example, the proposed method can be applied to produce nano-copper for the electricity industry, or nano-aluminum for the food industry, etc. Based on this research, nanomaterial production is becoming easier and simpler.

The research results achieve satisfaction of the production status. However, it is necessary for future studies to consider the level of biocompatibility and the biological elimination time of implanted material into the body. The combination of the computer simulation and real experiments can be applied to reduce the biological elimination time of the nano-titanium product. Moreover, the new set-up of the production line could be a real challenge. Furthermore, experiments indicate the high applicability of nano-titanium. Thus, future research should execute mechanical tests to verify the performance of material characteristics and approach more commercial production to create products with various sizes, high implant longevity, and reasonable price.