How to Deliver Open Sustainable Innovation: An Integrated Approach for a Sustainable Marketable Product

Abstract

:1. Introduction

2. Experimental Context: Mobile Forensics

3. A New Integrated Approach for Product Development

3.1. Hardware Prototype

3.1.1. Case Design and Production

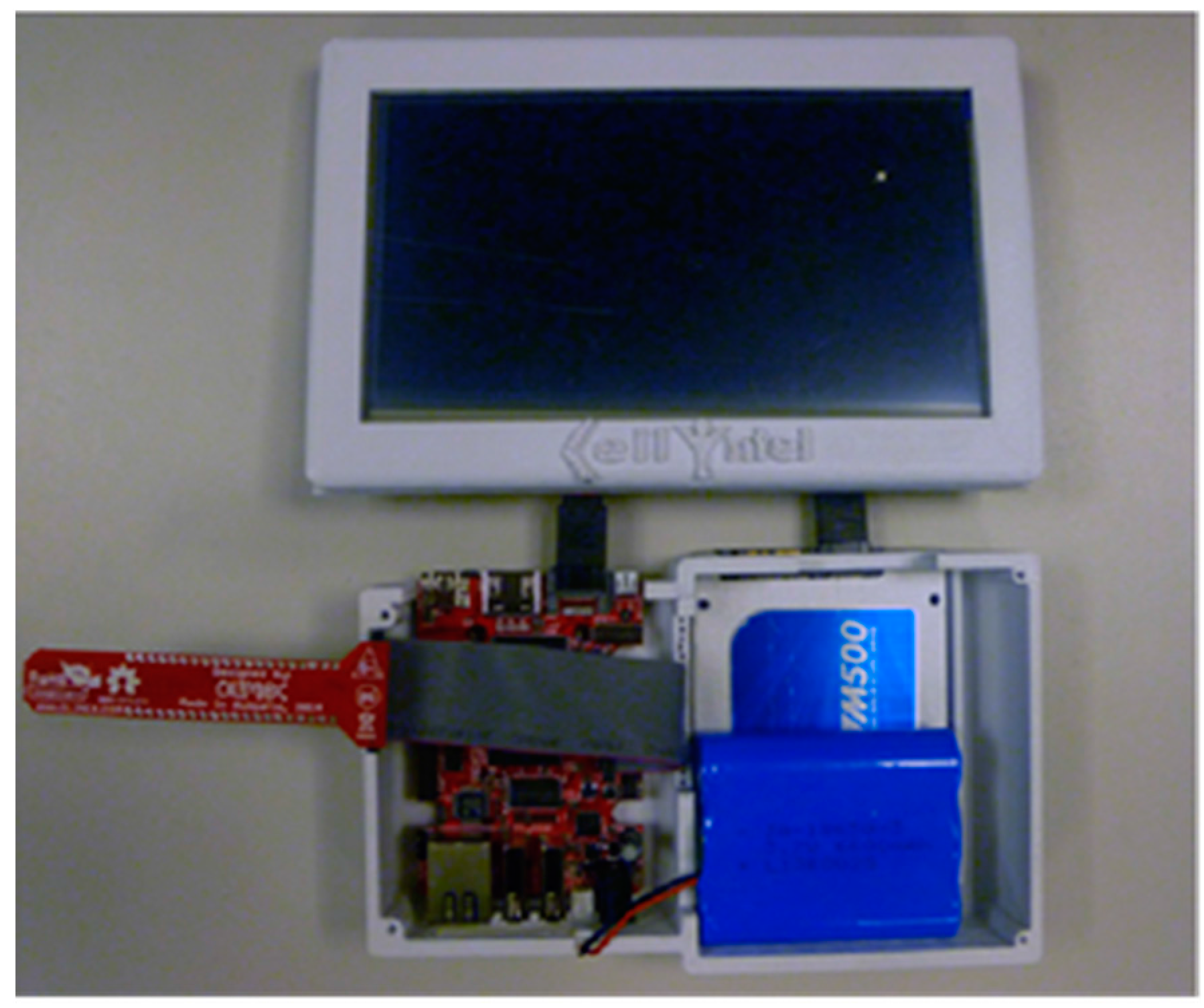

3.1.2. Prototype Electronics

3.2. Software Prototype

3.3. Sustainability Implications

4. Empirical Testing

5. Economic Analysis

6. Limitations

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gershenfeld, N. How to Make Almost Anything. Foreign Aff. 2012, 91, 43–57. [Google Scholar]

- Parvin, A. Architecture (and the other 99%): Open-Source Architecture and Design Commons. Arch. Des. 2013, 83, 90–95. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Antikainen, M.; Mäkipää, M.; Ahonen, M. Motivating and supporting collaboration in open innovation. Eur. J. Innov. Manag. 2010, 13, 100–119. [Google Scholar] [CrossRef]

- Carlsson, S.; Corvello, V.; Schroll, A.; Mild, A. Open innovation modes and the role of internal R&D: An empirical study on open innovation adoption in Europe. Eur. J. Innov. Manag. 2011, 14, 475–495. [Google Scholar]

- Enkel, E.; Gassmann, O.; Chesbrough, H. Open R&D and open innovation: Exploring the phenomenon. R&D Manag. 2009, 39, 311–316. [Google Scholar]

- Helfat, C.E. Open Innovation: The new imperative for creating and profiting from technology. Acad. Manag. Perspect. 2006, 20, 86–88. [Google Scholar] [CrossRef]

- Chesbrough, H.W. The Era of Open Innovation. MIT Sloan Manag. Rev. 2003, 44, 35–41. [Google Scholar]

- Schwerdtner, W.; Siebert, R.; Busse, M.; Freisinger, U. Regional open innovation roadmapping: A new framework for innovation-based regional development. Sustainability 2015, 7, 2301–2321. [Google Scholar] [CrossRef]

- Michelino, F.; Cammarano, A.; Lamberti, E.; Caputo, M. Knowledge domains, technological strategies and open innovation. J. Technol. Manag. Innov. 2015, 10, 50–78. [Google Scholar] [CrossRef]

- West, J.; Salter, A.; Vanhaverbeke, W.; Chesbrough, H. Open innovation: The next decade. Res. Policy 2014, 43, 805–811. [Google Scholar] [CrossRef]

- Cammarano, A.; Caputo, M.; Lamberti, E.; Michelino, F. R&D collaboration strategies for innovation: An empirical study through social network analysis. Int. J. Innov. Technol. Manag. 2016, 14, 1740001. [Google Scholar]

- Belderbos, R.; Carree, M.; Lokshin, B. Cooperative R&D and firm performance. Res. Policy 2004, 33, 1477–1492. [Google Scholar]

- Schemmann, B.; Herrmann, A.M.; Chappin, M.M.H.; Heimeriks, G.J. Crowdsourcing ideas: Involving ordinary users in the ideation phase of new product development. Res. Policy 2016, 45, 1145–1154. [Google Scholar] [CrossRef]

- Cappa, F.; Laut, J.; Nov, O.; Giustiniano, L.; Porfiri, M. Activating social strategies: Face-to-face interaction in technology-mediated citizen science. J. Environ. Manag. 2016, 182, 374–384. [Google Scholar] [CrossRef] [PubMed]

- Felin, T. Cosmologies of capability, markets and wisdom of crowds: Introduction and comparative agenda. Manag. Decis. Econ. 2012, 33, 283–294. [Google Scholar] [CrossRef]

- Surowiecki, J. The Wisdom of Crowds. Am. J. Phys. 2005, 75, 336. [Google Scholar] [CrossRef]

- Garcia Martinez, M.; Walton, B. The wisdom of crowds: The potential of online communities as a tool for data analysis. Technovation 2014, 34, 203–214. [Google Scholar] [CrossRef]

- Sassenberg, K.; Moskowitz, G.B. Don’t stereotype, think different! Overcoming automatic stereotype activation by mindset priming. J. Exp. Soc. Psychol. 2005, 41, 506–514. [Google Scholar] [CrossRef]

- Acar, O.A.; van den Ende, J. Knowledge Distance, Cognitive-Search Processes, and Creativity: The Making of Winning Solutions in Science Contests. Psychol. Sci. 2016, 27, 692–699. [Google Scholar] [CrossRef] [PubMed]

- Koch, C. Innovation networking between stability and political dynamics. Technovation 2004, 24, 729–739. [Google Scholar] [CrossRef]

- Vujovic, S.; Ulhøi, J.P. Online innovation: The case of open source software development. Eur. J. Innov. Manag. 2008, 11, 142–156. [Google Scholar] [CrossRef]

- Grimaldi, M.; Cricelli, L.; Rogo, F. A methodology to assess value creation in communities of innovation. J. Intellect. Cap. 2012, 13, 305–330. [Google Scholar] [CrossRef]

- Moilanen, J.; Vadén, T. 3D printing community and emerging practices of peer production. First Monday 2013, 18, 8. [Google Scholar] [CrossRef]

- Von Hippel, E. Democratizing innovation. J. Betr. 2005, 55, 63–78. [Google Scholar]

- Von Hippel, E. Open user innovation. Handb. Econ. Innov. 2010, 1, 411–427. [Google Scholar]

- Bonaccorsi, A.; Rossi, C. Why Open Source software can succeed. Res. Policy 2003, 32, 1243–1258. [Google Scholar] [CrossRef]

- Benkler, Y.; Nissenbaum, H. Commons-based peer production and virtue. J. Political Philos. 2006, 14, 394–419. [Google Scholar] [CrossRef]

- Kostakis, V.; Papachristou, M. Commons-based peer production and digital fabrication: The case of a RepRap-based, Lego-built 3D printing-milling machine. Telemat. Inform. 2014, 31, 434–443. [Google Scholar] [CrossRef]

- Espalin, D.; Muse, D.W.; MacDonald, E.; Wicker, R.B. 3D Printing multifunctionality: Structures with electronics. Int. J. Adv. Manuf. Technol. 2014, 72, 963–978. [Google Scholar] [CrossRef]

- Mertz, L. New World of 3-D Printing Offers “Completely New Ways of Thinking”. IEEE Pulse 2013, 4, 12–14. [Google Scholar] [PubMed]

- Matias, E.; Rao, B. 3D printing: On its historical evolution and the implications for business. In Proceedings of the 2015 Portland International Conference on Management of Engineering and Technology (PICMET), Portland, OR, USA, 2–6 August 2015; pp. 551–558.

- Ratto, M.; Ree, R. Materializing information: 3D printing and social change. First Monday 2012, 17. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Gebler, M.; Schoot Uiterkamp, A.J.M.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Wohlers, T. Wohlers Report 2014. 3D Printing and Additive Manufacturing State of the Industry; Wohlers Associate: Fort Collins, CO, USA, 2014. [Google Scholar]

- Cho, C.; Lee, S. How firms can get ideas from users for sustainable business innovation. Sustainability 2015, 7, 16039–16059. [Google Scholar] [CrossRef]

- Pinelli, M.; Maiolini, R. Strategies for Sustainable Development: Organizational Motivations, Stakeholders’ Expectations and Sustainability Agendas. Sustain. Dev. 2016, in press. [Google Scholar] [CrossRef]

- Maxwell, D.; Van der Vorst, R. Developing sustainable products and services. J. Clean. Prod. 2003, 11, 883–895. [Google Scholar] [CrossRef]

- Lubin, D.A.; Esty, D.C. Bridging the Sustainability Gap. MIT Sloan Manag. Rev. 2012, 55, 18–21. [Google Scholar]

- Lubin, D.A.; Esty, D.C. The sustainability imperative. Harv. Bus. Rev. 2010, 88, 42–50. [Google Scholar]

- Morelli, J. Environmental Sustainability: A Definition for Environmental Professionals. J. Environ. Sustain. 2011, 1, 1–27. [Google Scholar] [CrossRef]

- Moreno, M.; Charnley, F. Can Re-Distributed Manufacturing and Digital Intelligence Enable a Regenerative Economy? An Integrative Literature Review; Springer: Berlin, Germany, 2016; pp. 563–575. [Google Scholar]

- Boons, F.; Montalvo, C.; Quist, J.; Wagner, M. Sustainable innovation, business models and economic performance: An overview. J. Clean. Prod. 2013, 45, 1–8. [Google Scholar] [CrossRef]

- Arcese, G.; Flammini, S.; Lucchetti, M.C.; Martucci, O. Open Sustainability Innovation in the Food Sector. World Sustain. Forum 2014, 7, 8067–8090. [Google Scholar]

- Pearce, J.M. Quantifying the Value of Open Source Hard-ware Development. Mod. Econ. 2015, 6, 1–11. [Google Scholar] [CrossRef]

- Arthur, C. Smartphone Explosion in 2014 Will See Ownership in India Pass US. The Guardian. 2014. Available online: https://www.theguardian.com/technology/2014/jan/13/smartphone-explosion-2014-india-us-china-firefoxos-android (accessed on 7 December 2015).

- eMarketer Smartphone Users Worldwide. Available online: http://www.emarketer.com/Article/Smartphone-Users-Worldwide-Will-Total-175-Billion-2014/1010536 (accessed on 7 December 2015).

- Hayes, D. A Practical Guide to Computer Forensics Investigations; Pearson: London, UK, 2014. [Google Scholar]

- Farjamfar, A.; Abdullah, M.T.; Mahmod, R.; Udzir, N.I. A review on mobile device’s digital forensic process models. Res. J. Appl. Sci. Eng. Technol. 2014, 8, 358–366. [Google Scholar]

- Jang, Y.-J.; Kwak, J. Digital forensics investigation methodology applicable for social network services. Multimed. Tools Appl. 2015, 74, 5029–5040. [Google Scholar] [CrossRef]

- Ferrara, E.; De Meo, P.; Catanese, S.; Fiumara, G. Detecting criminal organizations in mobile phone networks. Expert Syst. Appl. 2014, 41, 5733–5750. [Google Scholar] [CrossRef]

- Palmer, G. A Road Map for Digital Forensic Research. In Proceedings of the 2001 Digital Forensics Research Workshop (DFRWS 2004), Orlando, FL, USA, 11–13 August 2004.

- Paraben Paraben. Available online: https://www.paraben.com/device-seizure.html (accessed on 7 December 2015).

- Oxygen Oxygen Forensics. Available online: http://www.oxygen-forensic.com/en/ (accessed on 7 December 2015).

- Cellebrite Mobile Foresics—Delivering Mobile Expertise. Available online: http://www.cellebrite.com/Mobile-Forensics (accessed on 7 December 2015).

- Knight, R. National Security or Consumer Privacy? A Question Even Siri Couldn’t Answer. Univ. Cin. Intell. Prop. Comput. Law J. 2016, 1, 1–13. [Google Scholar]

- Howe, J. The Rise of Crowdsourcing. Wired Mag. 2006, 14, 1–5. [Google Scholar]

- Kantar Smarphone OS Market Share. Available online: http://www.kantarworldpanel.com/global/smartphone-os-market-share/intro (accessed on 7 December 2015).

- Laplume, A.; Anzalone, G.C.; Pearce, J.M. Open-source, self-replicating 3-D printer factory for small-business manufacturing. Int. J. Adv. Manuf. Technol. 2016, 85, 633–642. [Google Scholar] [CrossRef]

- Stratasys FDM Technology, About Fused Deposition Modeling Stratasys. Available online: http://www.stratasys.com/3d-printers/technologies/fdm-technology (accessed on 7 December 2015).

- Masood, S.H. Intelligent rapid prototyping with fused deposition modelling. Rapid Prototyp. J. 1996, 2, 24–33. [Google Scholar] [CrossRef]

- GitHub. Available online: https://github.com/ (accessed on 11 May 2016).

- The World Commission on Environment and Development. Our Common Future; Oxford University Press: Oxford, UK, 1987; Volume 154. [Google Scholar]

- Liu, L. Sustainability: Living within one’s own ecological means. Sustainability 2009, 1, 1412–1430. [Google Scholar] [CrossRef]

- Ljungberg, L.Y. Materials selection and design for development of sustainable products. Mater. Des. 2007, 28, 466–479. [Google Scholar] [CrossRef]

- Nozick, L.K.; Turnquist, M.A. Inventory, transportation, service quality and the location of distribution centers. Eur. J. Oper. Res. 2001, 129, 362–371. [Google Scholar] [CrossRef]

- Paris Climate Change Conference—November 2015. Available online: http://unfccc.int/meetings/paris_nov_2015/meeting/8926.php (accessed on 7 July 2016).

- International Energy Agency. World Energy Outlook 2013; International Energy Agency: Paris, France, 2013. [Google Scholar]

- Pisello, A.L.; Castaldo, V.L.; Rosso, F.; Piselli, C.; Ferrero, M.; Cotana, F. Traditional and Innovative Materials for Energy Efficiency in Buildings. Key Eng. Mater. 2016, 678, 14–34. [Google Scholar] [CrossRef]

- Haines, A.; Kovats, R.S.; Campbell-Lendrum, D.; Corvalan, C. Climate change and human health: Impacts, vulnerability and public health. Public Health 2006, 120, 585–596. [Google Scholar] [CrossRef] [PubMed]

- Boons, F.; Lüdeke-Freund, F. Business models for sustainable innovation: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2013, 45, 9–19. [Google Scholar] [CrossRef]

- Remer, D.S.; Nieto, A.P. A compendium and comparison of 25 project evaluation techniques. Part 1: Net present value and rate of return methods. Int. J. Prod. Econ. 1995, 42, 79–96. [Google Scholar] [CrossRef]

- Ferrin, B.G.; Plank, R.E. Total Cost of Ownership Models: An Exploratory Study. J. Supply Chain Manag. 2002, 38, 18–29. [Google Scholar] [CrossRef]

- Shaikh, M.; Cornford, T. Framing the Conundrum of Total Cost of Ownership of Open Source Software. Open Source Syst. Grounding Res. 2011. [Google Scholar] [CrossRef]

- Shaikh, M.; Cornford, T. Total Cost of Ownership of Open Source Software: A Report for the UK Cabinet Office Supported by OpenForum Europe; London School of Economics and Political Science: London, UK, 2011. [Google Scholar]

- Makerbot 3D Printing Resources and Tools MakerBot. Available online: http://www.makerbot.com/ (accessed on 7 December 2015).

- TierTime. Available online: http://www.tiertime.com/en/ (accessed on 7 December 2015).

- Cappa, F.; Facci, A.L.; Ubertini, S. Proton exchange membrane fuel cell for cooperating households: A convenient combined heat and power solution for residential applications. Energy 2015, 90, 1229–1238. [Google Scholar] [CrossRef]

- Zadeh, S.; Hunt, D.; Lombardi, D.; Rogers, C. Shared Urban Greywater Recycling Systems: Water Resource Savings and Economic Investment. Sustainability 2013, 5, 2887–2912. [Google Scholar] [CrossRef]

- Damodaran, A. Investment Valuation: Tools and Techniques for Determining the Value of Any Asset; John Wiley & Sons: Hoboken, NJ, USA, 2012; Volume 666. [Google Scholar]

- Willassen, S. Forensic analysis of mobile phone internal memory. In Advances in Digital Forensics; Springer: Berlin, Germany, 2005; pp. 191–204. [Google Scholar]

- Chun, W.-S.; Park, D.-W. A study on the forensic data extraction method for sms, photo and mobile image of google android and windows mobile smart phone. In Convergence and Hybrid Information Technology; Springer: Berlin, Germany, 2012; pp. 654–663. [Google Scholar]

- Grispos, G.; Storer, T.; Glisson, W.B. A comparison of forensic evidence recovery techniques for a windows mobile smart phone. Digit. Investig. 2011, 8, 23–36. [Google Scholar] [CrossRef]

- Schaltegger, S.; Freund, F.L.; Hansen, E.G. Business cases for sustainability: The role of business model innovation for corporate sustainability. Int. J. Innov. Sustain. Dev. 2012, 6, 95. [Google Scholar] [CrossRef]

- Arcese, G.; Lucchetti, M.; Merli, R. Social Life Cycle Assessment as a Management Tool: Methodology for Application in Tourism. Sustainability 2013, 5, 3275–3287. [Google Scholar] [CrossRef]

| Components | Mass | Production Time | Cost |

|---|---|---|---|

| Electronic box | 17 g | 4 h, 12 m | $3.40 |

| LCD Screen box | 21.8 g | 2 h, 38 m | $2.56 |

| Top of the box | 16.4 g | 2 h, 10 m | $2.14 |

| Electricity costs | 55.2 g | $0.03 | |

| Total | 55.2 g | 9 h | $8.13 |

| Components | Cost |

|---|---|

| LCD screen | $55.99 |

| Solid state drive (SSD) 2.5” | $85.99 |

| Motherboard | $49.89 |

| 3D printed casing | $8.13 |

| Total | $200 |

| Units | 68 | |||

|---|---|---|---|---|

| Cost of capital | 7.64% | |||

| Taxes | 40% | |||

| Price | $999 | |||

| Cost | $200 | |||

| Year | 0 | 1st | 2nd | 3rd |

| Revenues | $67,932 | $67,932 | $67,932 | |

| Cost of unit sold | $(13,600) | $(13,600) | $(13,600) | |

| Salary costs | $(50,000) | $(50,000) | $(50,000) | |

| Depreciation | $(3333.33) | $(3333.33) | $(3333.33) | |

| Earnings Before taxes | $998.66 | $998.66 | $998.66 | |

| Taxes | $(399.33) | $(399.33) | $(399.33) | |

| Depreciation added back | $3333.33 | $3333.33 | $3333.33 | |

| Initial capital expenditure | ($10,000) | |||

| Free cash flow to operations | ($10,000) | $3932.53 | $3932.53 | $3932.53 |

| Net Present Value | $200.71 | |||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cappa, F.; Del Sette, F.; Hayes, D.; Rosso, F. How to Deliver Open Sustainable Innovation: An Integrated Approach for a Sustainable Marketable Product. Sustainability 2016, 8, 1341. https://doi.org/10.3390/su8121341

Cappa F, Del Sette F, Hayes D, Rosso F. How to Deliver Open Sustainable Innovation: An Integrated Approach for a Sustainable Marketable Product. Sustainability. 2016; 8(12):1341. https://doi.org/10.3390/su8121341

Chicago/Turabian StyleCappa, Francesco, Fausto Del Sette, Darren Hayes, and Federica Rosso. 2016. "How to Deliver Open Sustainable Innovation: An Integrated Approach for a Sustainable Marketable Product" Sustainability 8, no. 12: 1341. https://doi.org/10.3390/su8121341

APA StyleCappa, F., Del Sette, F., Hayes, D., & Rosso, F. (2016). How to Deliver Open Sustainable Innovation: An Integrated Approach for a Sustainable Marketable Product. Sustainability, 8(12), 1341. https://doi.org/10.3390/su8121341