Outcomes on the Spray Profiles Produced by the Feasible Adjustments of Commonly Used Sprayers in “Tendone” Vineyards of Apulia (Southern Italy)

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Sprayers

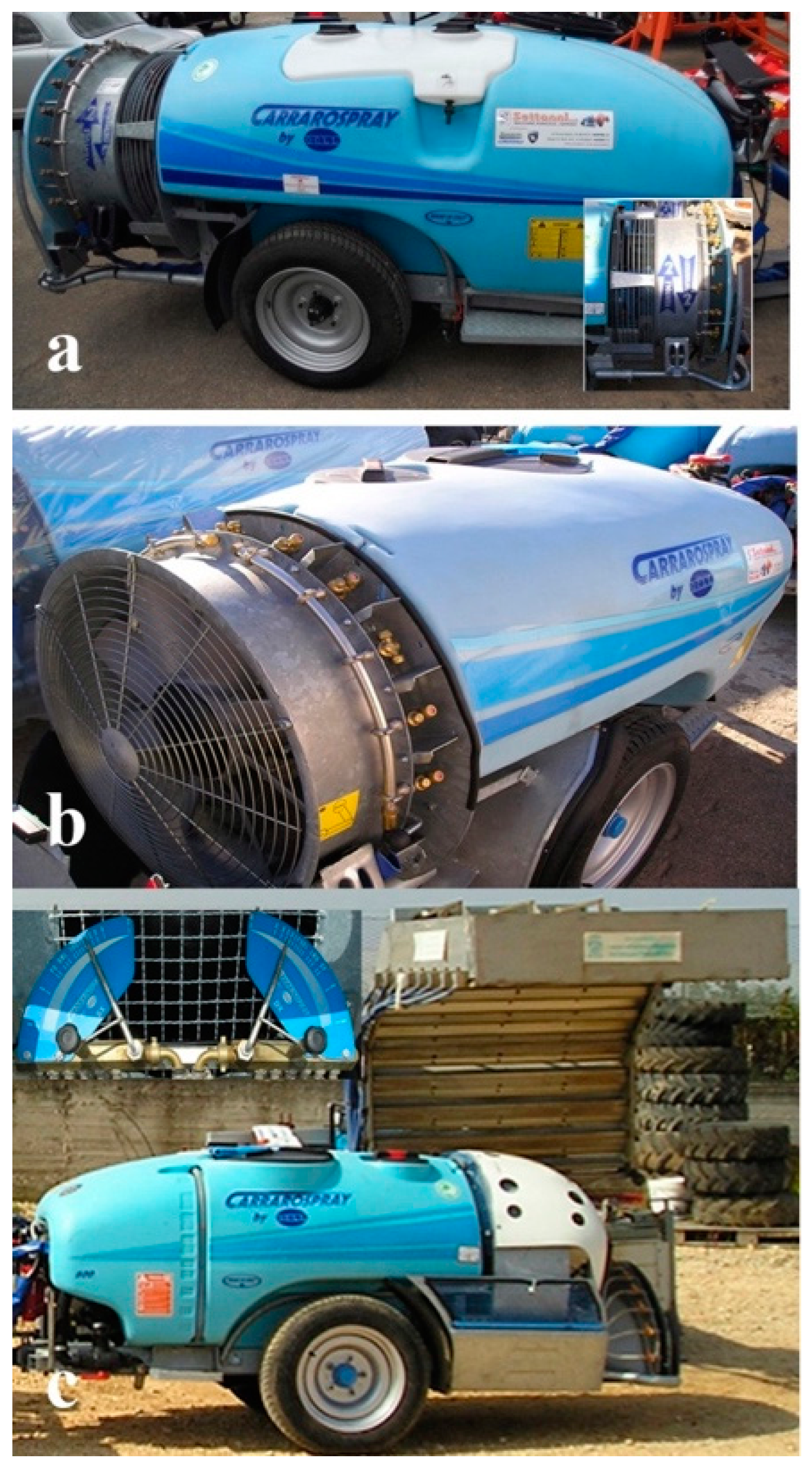

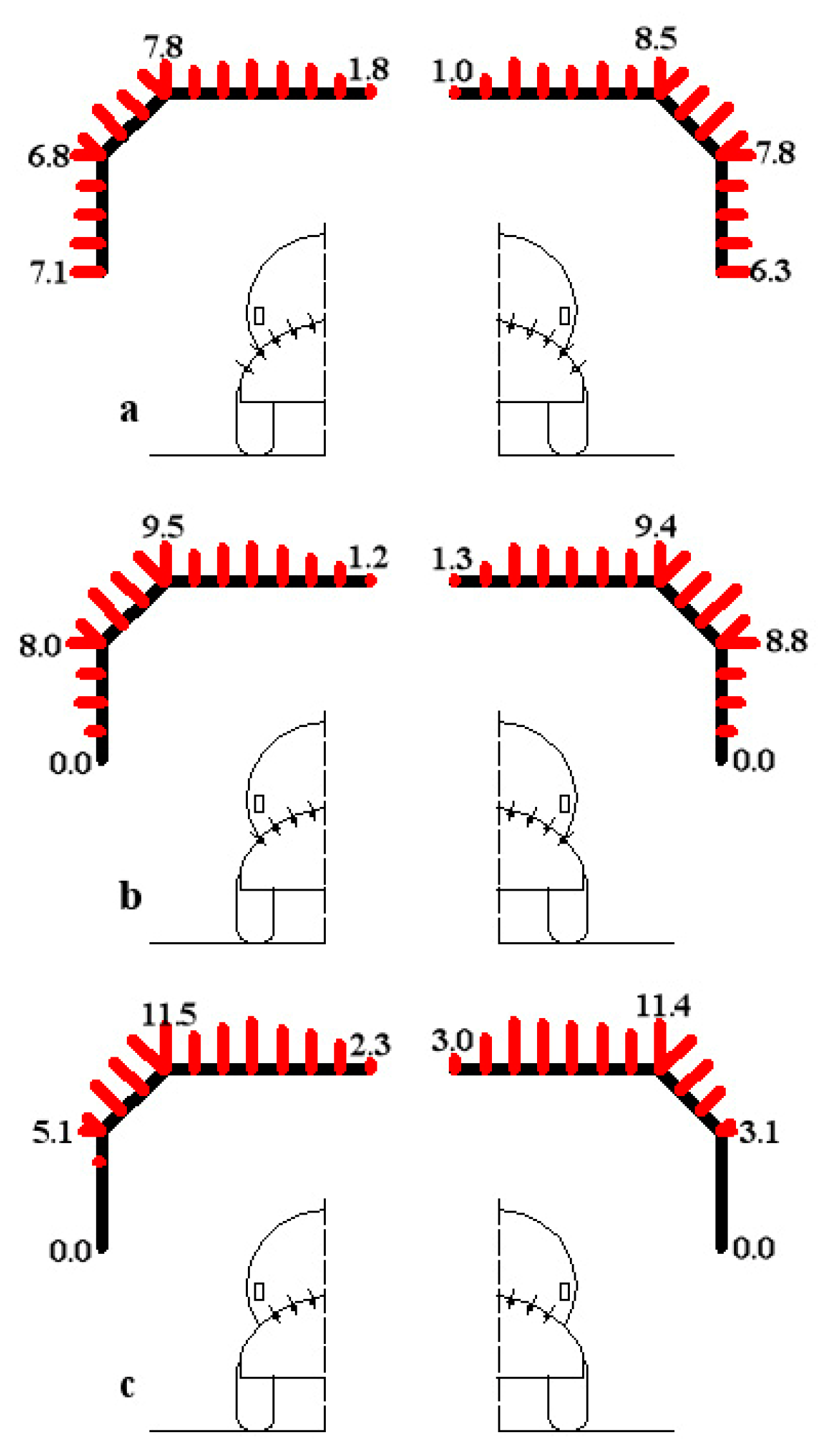

- Carrarospray ATD800 (Figure 1a), equipped with a 600 L main tank and two counter-rotating axial fans (diameter 700 mm, fans axis height above the ground 730 mm) with an anterior intake. The first fan is counter-clockwise rotating, whereas the second one is clockwise-rotating. At 57 rad/s rotation speed of the tractor power take-off (PTO), beyond the idle position, the air flow rate was 54,000 m3/h at the highest gearbox ratio of the fans, and 42,260 m3/h as the lowest.

- Carrarospray ATP800 (Figure 1b), equipped with a 600 L main tank and single axial fan (diameter 700 mm, counter-clockwise rotation, the fan axis height above the ground is 740 mm) with a rear intake. Air deflectors were mounted onto the output section of the fan, each one placed at the middle between two adjacent nozzles. The same gearbox ratios were available and at the 57 rad/s rotation speed of the PTO, the air flow rates were, respectively, 54,000 m3/h and 42,260 m3/h, beyond the idle position.

- Carrarospray NTF600 (Figure 1c), equipped with a 600 L main tank and centrifugal fan (diameter 500 mm, counter clockwise rotation, the fan axis height above the ground is 740 mm); two adjacent spray head diffusers both having about 90° arch shape, each with six deflection nozzles (φ = 1.8 mm) in place. At the 57 rad/s rotation speed of the PTO, beyond the idle position, the air flow rate was 32,000 m3/h with the highest gearbox ratio of the fan, and 23,600 m3/h with the lowest. Furthermore, the overall flow rates discharged by the six simultaneously switched-on nozzles of each diffuser at the operative pressure of 0.3 MPa changed within the range 85–989 L/min and this adjustment took place by means of a control system constituted by a flow rate valve fitted with a wheel closely connected to a metal pointer moving on a graduated scale. Two separate control systems then allow the independent adjustment of the nozzle flow rates discharged by the two diffusers.

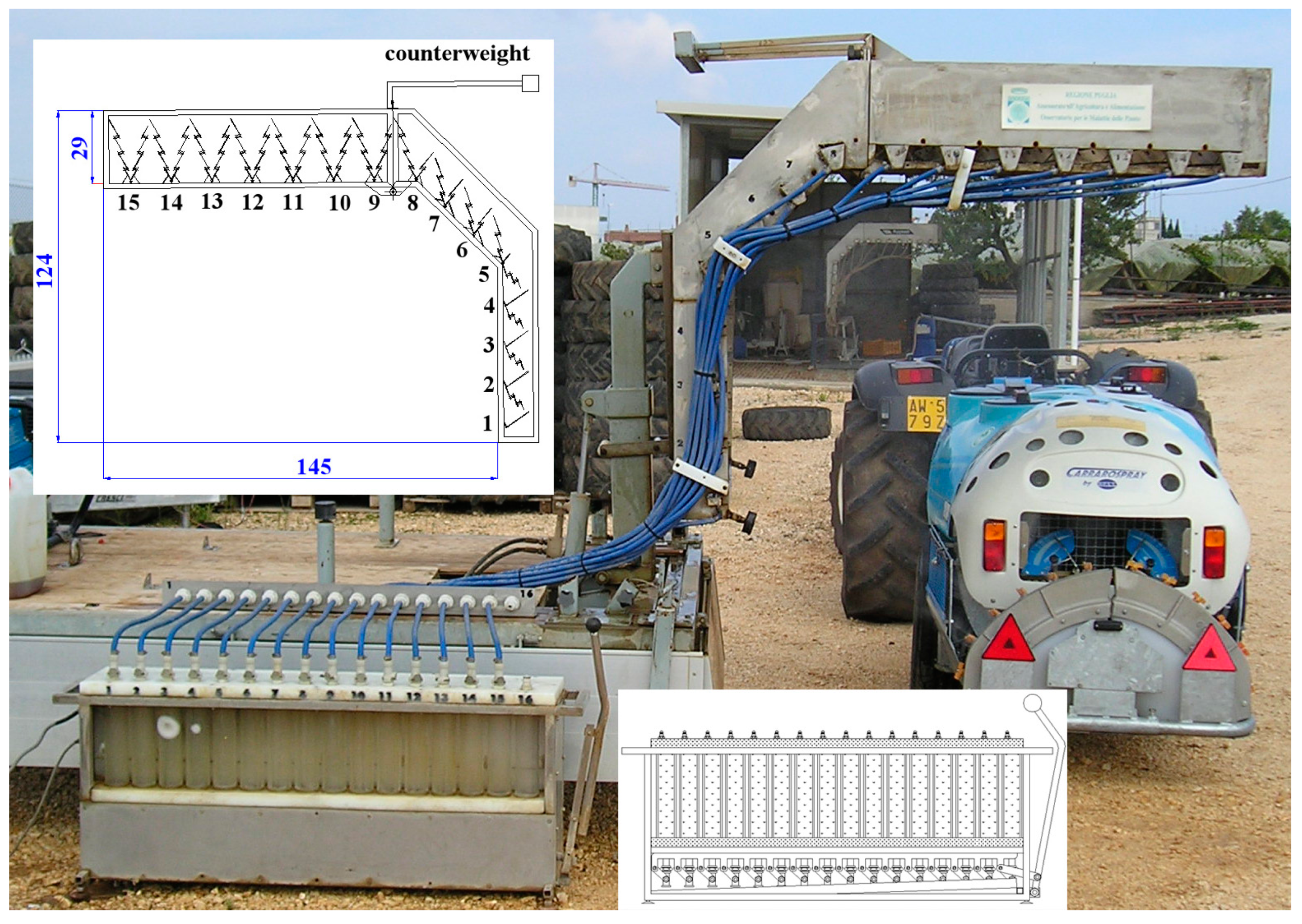

2.2. The Test Bench Used for the Assessment of the Spray Distribution Profiles

2.3. The Experimental Design

- Two spray tips:

- φ 0.8 mm tip and blank core;

- φ 1.2 mm tip and blank core;

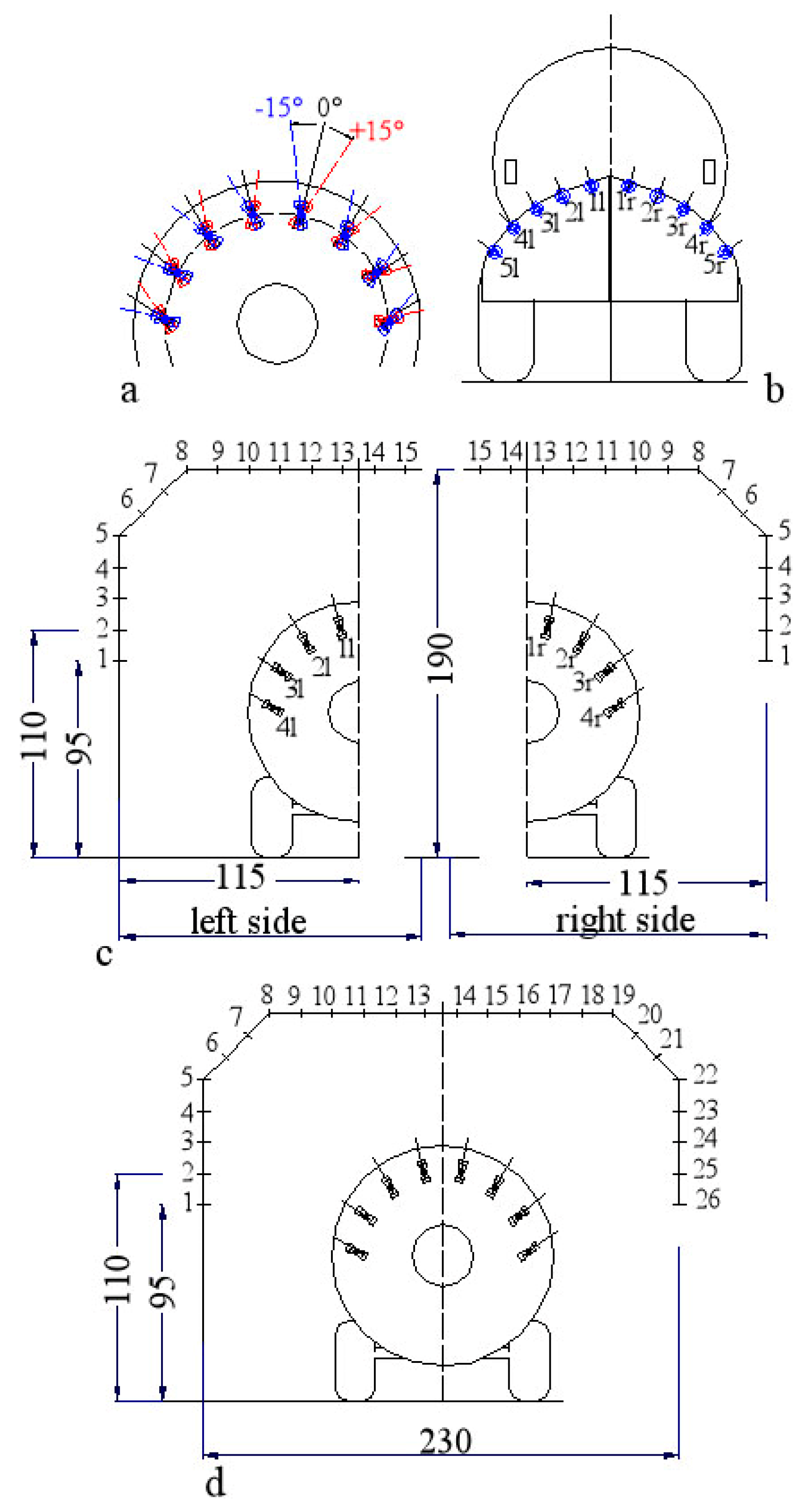

- Three angular positions of spray tips with 4 + 4 nozzles simultaneously switched on:

- A: central position (0°);

- B: counter-clockwise rotation (−15°) of the four nozzle bodies placed on the right side and clockwise rotation (+15°) of the four nozzle bodies placed on the left side;

- C: clockwise rotation (+15°) of the four nozzle bodies placed on the right side and counter-clockwise rotation (−15°) of the four nozzle bodies placed on the left side (Figure 3a);

- Three air flow rates:

- 0 m3/h (idle fan);

- 42,120 m3/h (fan first speed);

- 54,000 m3/h (fan second speed).

- Two spray tips:

- φ 0.8 mm tip and blank core;

- φ 1.2 mm tip and blank core;

- Two angular positions of spray tips with 4 + 4 nozzles simultaneously switched on:

- B: counter-clockwise rotation (−15°) of the four nozzle bodies placed on the right side and clockwise rotation (+15°) of the four nozzle bodies placed on the left side;

- C: clockwise rotation (+15°) of the four nozzle bodies placed on the right side and counter-clockwise rotation (−15°) of the four nozzle bodies placed on the left side (Figure 4a);

- Two air flow rates:

- 0 m3/h (idle fan);

- 54,000 m3/h (fan, second speed).

- each spray tip, one by one switched on; and

- the spray tips placed on each side of the machine simultaneously switched on.

- Two air flow rates:

- 23,600 m3/h (fan first speed);

- 32,000 m3/h (fan second speed).

- Two nozzle flow rates on the average discharged by both the diffusers:

- 4.10 L/min (Qmb1);

- 9.20 L/min (Qmb2).

- each nozzle, one by one switched on; and

- the nozzles placed on each side simultaneously switched on.

3. Results and Discussion

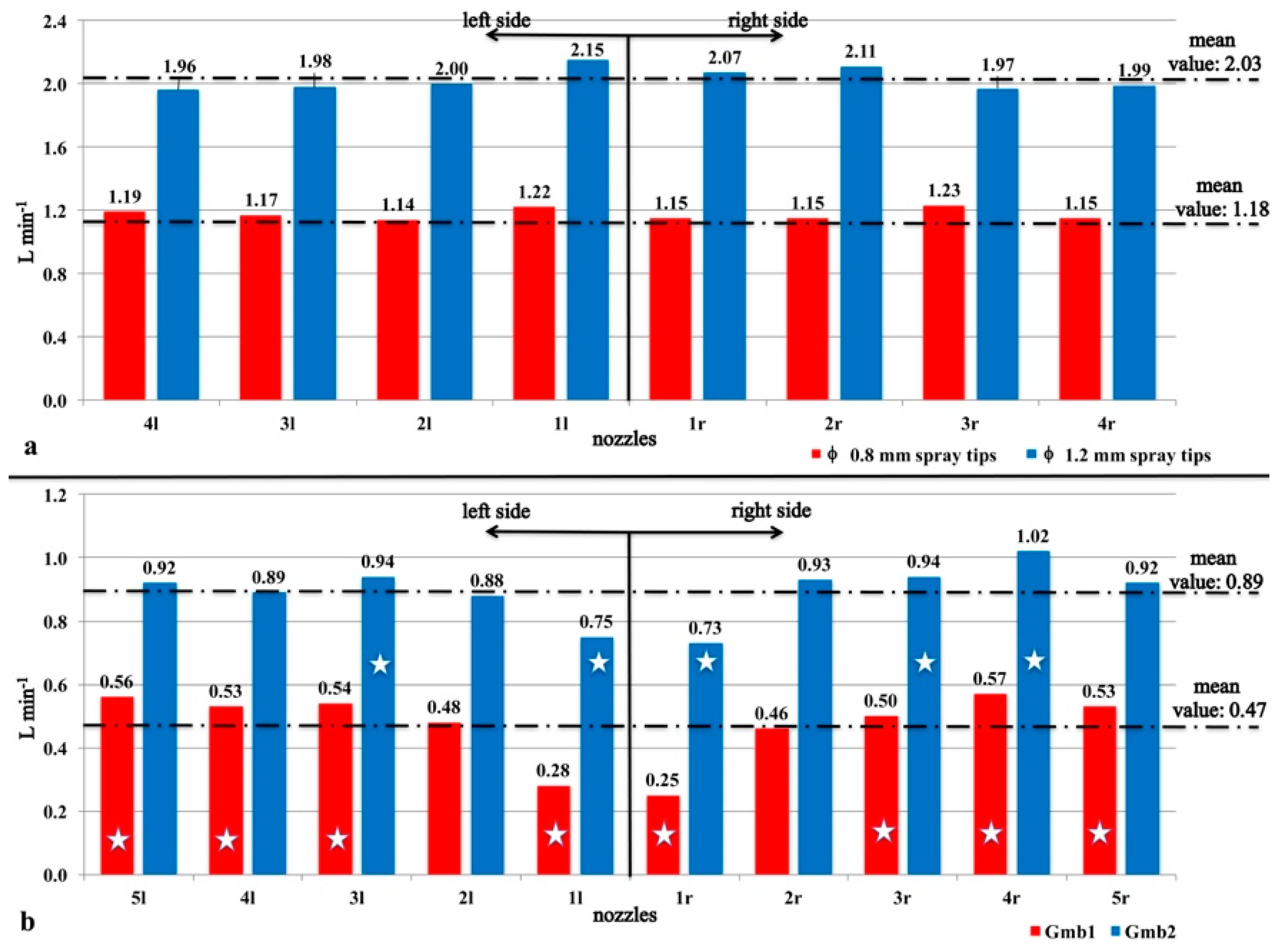

3.1. Measure of the Nozzle Flow Rate

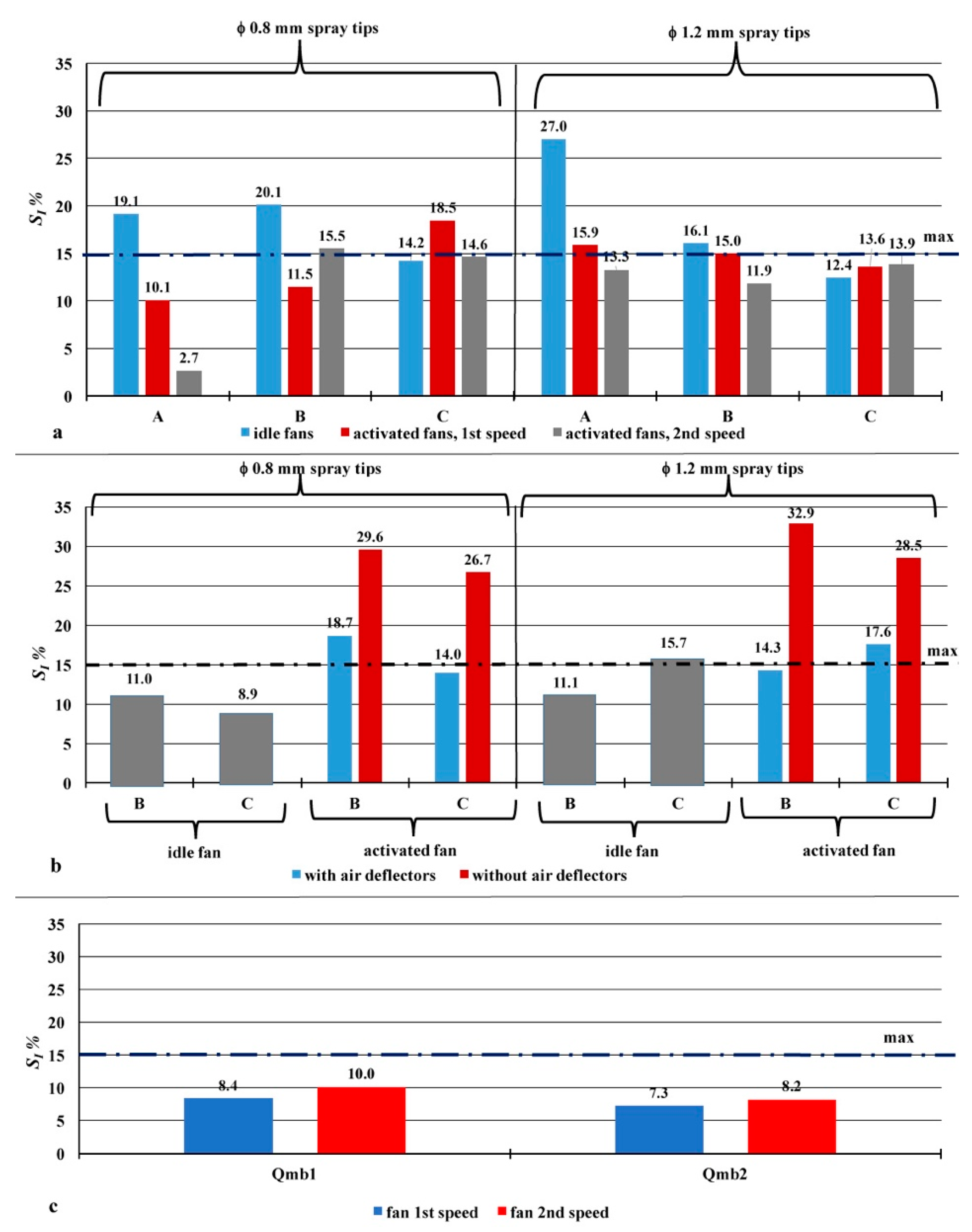

3.2. Symmetry Index of Distribution Diagrams

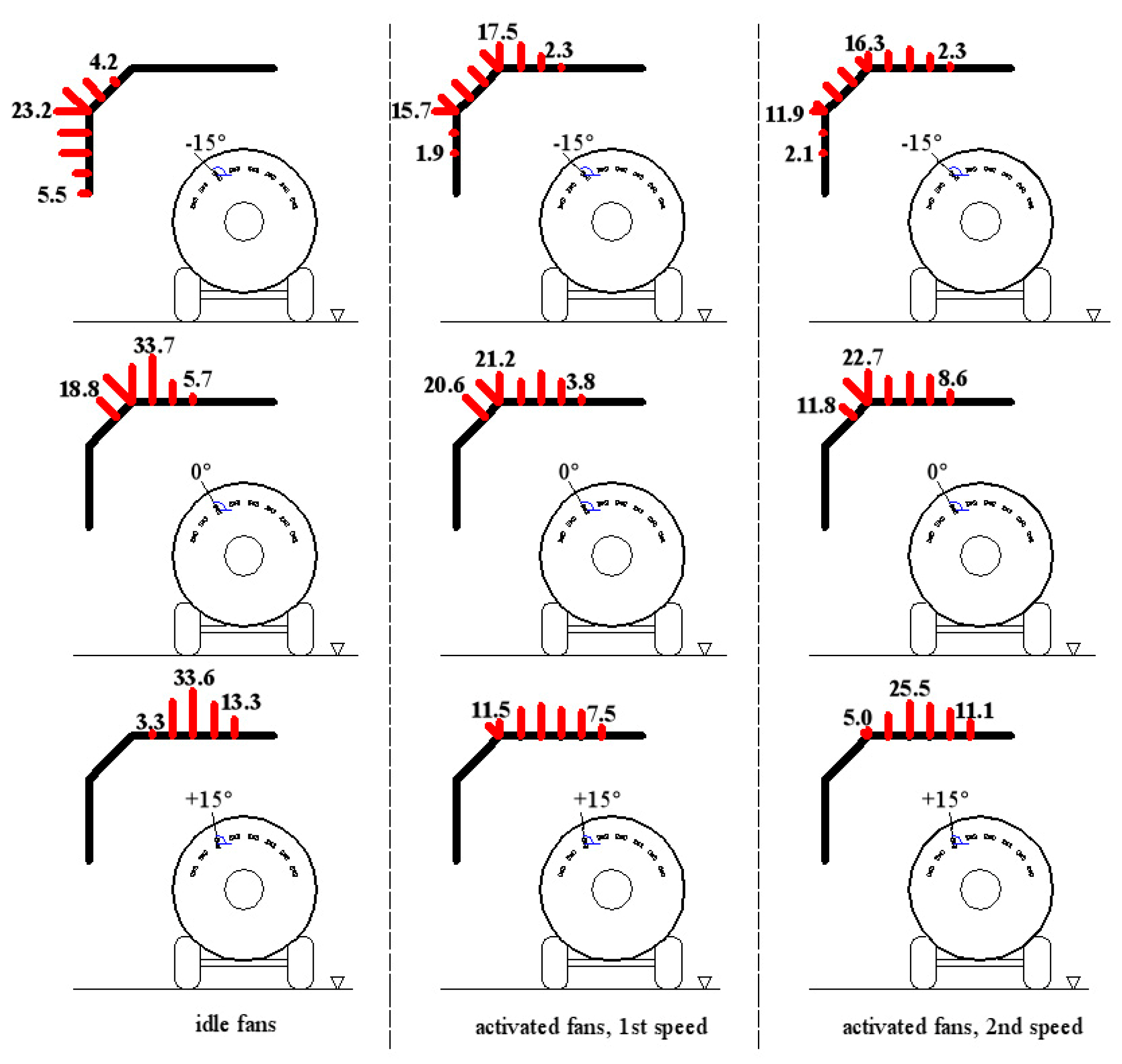

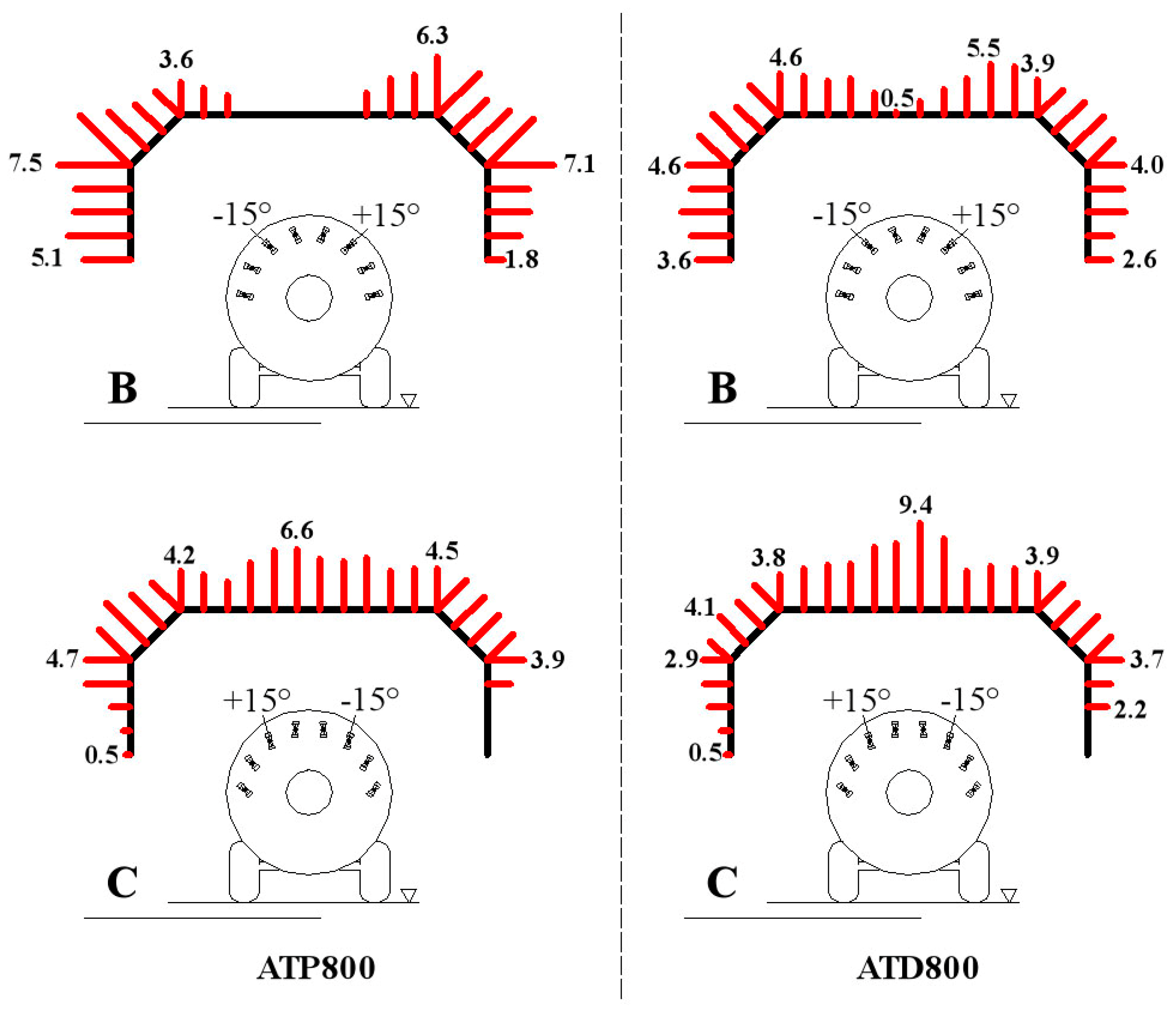

3.3. Outcomes on the Spray Profile Due to Angular Positions of Nozzles and Their Placement on the Boom

4. Conclusions

- compared with the mist blower model, have a better chance to match the spray pattern with the canopy profile of the “tendone” vines;

- the left-right asymmetry of the spray profile is reduced only in the case of sprayers with two counter-rotating fans, operating at high speed, under certain operating conditions;

- the symmetry index is influenced by the hole size of the nozzles and their angular positioning;

- the symmetry index worsens with the activation of the single fan either with or without the air deflectors even if, in this last case, the deterioration produced by the turning effect of the air stream is very marked;

- regardless of the interference of the sprays, the two lower-positioned nozzles, when rotated outward, would be potentially responsible for the off-target losses; and

- the optimum air blast sprayer for treatments to “tendone” vineyards should include two counter-rotating fans and 3 + 3 simultaneously switched-on nozzles, mounted on arc-shaped booms having a higher radius of curvature.

- it develops lower drawbacks, in terms of left-right asymmetry of the spray profile;

- the high “stiffness” of the spray profile, which cannot be corrected because there are no devices for quick and easy adjustments, making this sprayer not particularly suitable to the changing needs of the canopy of the “tendone” vineyards;

- the use of 5 + 5 simultaneously switched on nozzles— the currently adopted solution—increases the “off target” losses caused, in particular, by the outer nozzle (left and right); and

- the optimum mist blower sprayer for treatments to “tendone” vines should include the possibility to adjust the spray profile.

Acknowledgments

Conflicts of Interest

References

- Establishing a Framework for Community Action to Achieve the Sustainable Use of Pesticides. Available online: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:309:0071:0086:en:PDF (accessed on 8 December 2016).

- Herbst, A. SPISE Guidelines on How to Make Sprayer Adjustment at the Workshop as an Addition to the Functional Inspection of the Field Crop Sprayers. In Proceedings of the Fifth European Workshop on Standardised Prodedure for the Inspection of Sprayers (SPISE 5), Montpellier, France, 15–17 October 2014.

- Balsari, P.; Oggero, G.; Marucco, P. Proposal of a Guide for Sprayers Calibration. In Proceedings of the Second European Workshop on Standardised Prodedure for the Inspection of Sprayers (SPISE 2), Straelen, Germany, 10–12 April 2007.

- Brown, D.L.; Giles, D.K.; Oliver, M.N.; Klassen, P. Targeted spray technology to reduce pesticide in runoff from dormant orchards. Crop Prot. 2008, 27, 545–552. [Google Scholar] [CrossRef]

- Andersen, P.G.; Jørgensen, M.K. Calibration of Sprayers. In Proceedings of the Second European Workshop on Standardised Prodedure for the Inspection of Sprayers (SPISE 3), Brno, Czech Republic, 22–24 September 2009.

- Gil, E.; Arnó, J.; Llorens, J.; Sanz, R.; Llop, J.; Rosell-Polo, J.R.; Gallart, M.; Escolà, A. Advanced technologies for the improvement of spray application techniques in Spanish viticulture: An overview. Sensors 2014, 14, 691–708. [Google Scholar] [CrossRef] [PubMed]

- Salyani, M.; Serdynski, J.W. A device and method for sprayer calibration. Appl. Eng. Agric. 1993, 9, 29–32. [Google Scholar] [CrossRef]

- Cross, J.V.; Walklate, P.J.; Murray, R.A.; Richardson, G.M. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: 2. Effects of spray quality. Crop Prot. 2001, 20, 333–343. [Google Scholar] [CrossRef]

- A System for Adjusting the Spray Application to the Target Characteristics. Available online: http://www.cigrjournal.org/index.php/Ejounral/article/view/1237 (accessed on 8 December 2016).

- Wachowiak, M.; Kierzek, R. Economic aspects of application of plant protection techniques. Prog. Plant Prot. 2009, 49, 1668–1675. [Google Scholar]

- Pergher, G. Recovery rate of tracer dyes used for deposit assessment. Trans. ASAE 2001. [Google Scholar] [CrossRef]

- Baldoin, C.; Balsari, P.; Cerruto, E.; Pascuzzi, S.; Raffaelli, M. Improvement in pesticide application on greenhouse crops: Results of a survey about greenhouse structures in Italy. Acta Hort. 2008, 801, 609–614. [Google Scholar] [CrossRef]

- Walklate, P.J.; Cross, J.V.; Richardson, G.M.; Murray, R.A.; Baker, D.E. Comparison of different spray volume deposition models using LIDAR measurements of apple orchards. Biosyst. Eng. 2002, 82, 253–267. [Google Scholar] [CrossRef]

- Solanelles, F.; Escolà, A.; Planas, S.; Rosell, J.R.; Camp, F.; Gràcia, F. An electronic control system for pesticide application proportional to the canopy width of tree crops. Biosyst. Eng. 2006, 4, 473–481. [Google Scholar] [CrossRef]

- Gil, E.; Escolà, A.; Rosell, J.R.; Planas, S.; Val, L. Variable rate application of plant protection products in vineyard using ultrasonic sensors. Crop Prot. 2007, 26, 1287–1297. [Google Scholar] [CrossRef]

- Siegfried, W.; Viret, O.; Huber, B.; Wohlhauser, R. Dosage of plant protection products adapted to leaf area index in viticulture. Crop Prot. 2007, 26, 73–82. [Google Scholar] [CrossRef]

- Cerruto, E. Influence of airflow rate and forward speed on the spray deposit in vineyards. J. Agric. Eng. 2007, 1, 7–14. [Google Scholar] [CrossRef]

- Cerruto, E. Further studies on the variation of spray deposits in vineyards with airflow rate and volume rate. J. Agric. Eng. 2007, 1, 31–38. [Google Scholar] [CrossRef]

- Llorens, J.; Gil, E.; Llop, J.; Escolà, A. Variable rate dosing in precision viticulture: Use of electronic devices to improve application efficiency. Crop Prot. 2010, 29, 239–248. [Google Scholar] [CrossRef]

- Duga, A.T.; Ruysen, K.; Dekeyser, D.; Nuyttens, D.; Bylemans, D.; Nicolai, B.M.; Verboven, P. Spray deposition profiles in pome fruit trees: Effects of sprayer design, training system and tree canopy characteristics. Crop Prot. 2015, 67, 200–213. [Google Scholar] [CrossRef]

- Biocca, M.; Gallo, P. Comparison between horizontal and vertical lamellate patternators for air-blast sprayers. Open Agric. J. 2014, 8, 12–17. [Google Scholar] [CrossRef]

- Pergher, G. Field evaluation of a calibration method for air-assisted sprayers involving the use of a vertical patternator. Crop Prot. 2004, 23, 437–446. [Google Scholar] [CrossRef]

- Sarghini, F.; Pergher, G. Numerical and experimental analysis of vertical spray control patternators. J. Agric. Eng. 2013, 4, 368–372. [Google Scholar] [CrossRef]

- International Organization of Standardization (ISO). ISO 16122-3:2015 Agricultural and Forestry Machinery—Inspection of Sprayers in Use—Part 3: Sprayers for Bush and Tree Crops; International Organization for Standardization Publications: Geneva, Switzerland, 2015. [Google Scholar]

- Guarella, P.; Pascuzzi, S. Test bench for calibration of spraying machines used in “tendone” trained vines. Design and operation aspects. Riv. Ing. Agrar. 2000, 1, 18–23. (In Italian) [Google Scholar]

- Guarella, P.; Pascuzzi, S. Computer-aided measurement system for checking and calibrating pesticide spraying machines. Riv. Ing. Agrar. 2001, 4, 1–8. (In Italian) [Google Scholar]

- ISTAT (Italian Central Statistics Institute). Table C26—Area (Hectares) and Production (Quintals): Table Grapes, Wine Grapes, Wine. Data by Province–Year 2012. Available online: http://agri.istat.it/jsp/dawinci.jsp?q=plC260000030000173200&an=2012&ig=1&ct=604&id=21A%7C15A%7C73A (accessed on 8 December 2016).

- Pascuzzi, S. A multibody approach applied to the study of driver injures due to a narrow-track wheeled tractor rollover. J. Agric. Eng. 2015. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E. Spray deposition in “tendone” vineyards when using a pneumatic electrostatic sprayer. Crop Prot. 2015. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E. An innovative pneumatic electrostatic sprayer useful for tendone vineyards. J. Agric. Eng. 2015. [Google Scholar] [CrossRef]

- Cerruto, E.; Emma, G.; Manetto, G. Study of a new model of sprayer for applications in “tendone” vineyards. J. Agric. Eng. 2008, 1, 41–48. [Google Scholar]

- Pascuzzi, S. The effects of the forward speed and air volume of an air-assisted sprayer on spray deposition in “tendone” trained vineyards. J. Agric. Eng. 2013. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E.; Manetto, G. Foliar spray deposition in a “tendone” vineyard as affected by airflow rate, volume rate and vegetative development. Crop Prot. 2017. [Google Scholar] [CrossRef]

- Cory, W. Fans and Ventilation. A Practical Guide; Elsevier Science: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Blanco, I.; Anifantis, A.S.; Pascuzzi, S.; Scarascia Mugnozza, G. Hydrogen and renewable energy sources integrated system for greenhouse heating. J. Agric. Eng. 2013, 44, 226–230. [Google Scholar] [CrossRef]

- International Organization of Standardization (ISO). ISO 5682-2:1997 Equipment for Crop Protection—Spraying Equipment—Part 2: Test Methods for Hydraulic Sprayers; International Organization for Standardization Publications: Geneva, Switzerland, 1997. [Google Scholar]

- ENAMA (Italian Body Supporting the Agro-Mechanical Industry). Guidelines for the Employment of Test Bench within the Inspections of the Sprayers in Use for Tree Crops. 2016. Available online: http://www.enama.it (accessed on 8 December 2016). (In Italian)

| New Numbering | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| left side | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| right side | 15 | 14 | |||||||||||

| New Numbering | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 |

| left side | 14 | 15 | |||||||||||

| right side | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 |

| Air Blast Sprayer | Tip Hole φ | Mean Flow Rate | Overall Flow Rate |

|---|---|---|---|

| mm | L/min | L/min | |

| Carrarospray ATD800 | 0.8 | 1.18 | 9.40 |

| 1.2 | 2.03 | 16.23 | |

| Carrarospray ATP800 | 0.8 | 1.20 | 9.60 |

| 1.2 | 2.03 | 16.21 |

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pascuzzi, S. Outcomes on the Spray Profiles Produced by the Feasible Adjustments of Commonly Used Sprayers in “Tendone” Vineyards of Apulia (Southern Italy). Sustainability 2016, 8, 1307. https://doi.org/10.3390/su8121307

Pascuzzi S. Outcomes on the Spray Profiles Produced by the Feasible Adjustments of Commonly Used Sprayers in “Tendone” Vineyards of Apulia (Southern Italy). Sustainability. 2016; 8(12):1307. https://doi.org/10.3390/su8121307

Chicago/Turabian StylePascuzzi, Simone. 2016. "Outcomes on the Spray Profiles Produced by the Feasible Adjustments of Commonly Used Sprayers in “Tendone” Vineyards of Apulia (Southern Italy)" Sustainability 8, no. 12: 1307. https://doi.org/10.3390/su8121307

APA StylePascuzzi, S. (2016). Outcomes on the Spray Profiles Produced by the Feasible Adjustments of Commonly Used Sprayers in “Tendone” Vineyards of Apulia (Southern Italy). Sustainability, 8(12), 1307. https://doi.org/10.3390/su8121307