Superiority of Filtered Tailings Storage Facility to Conventional Tailings Impoundment in Southern Rainy Regions of China

Abstract

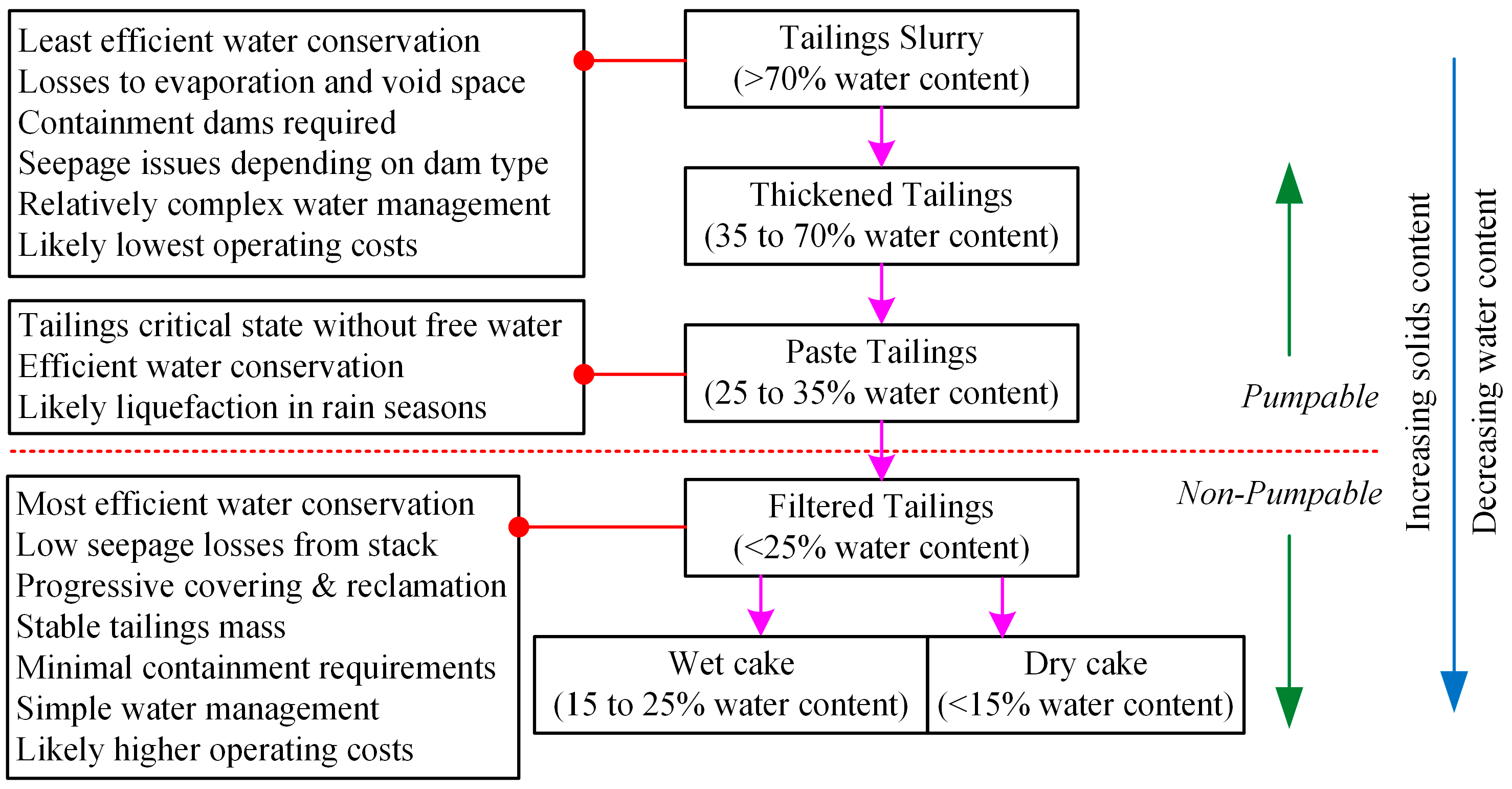

:1. Introduction

2. Accident Analysis and Liquefaction Evaluation

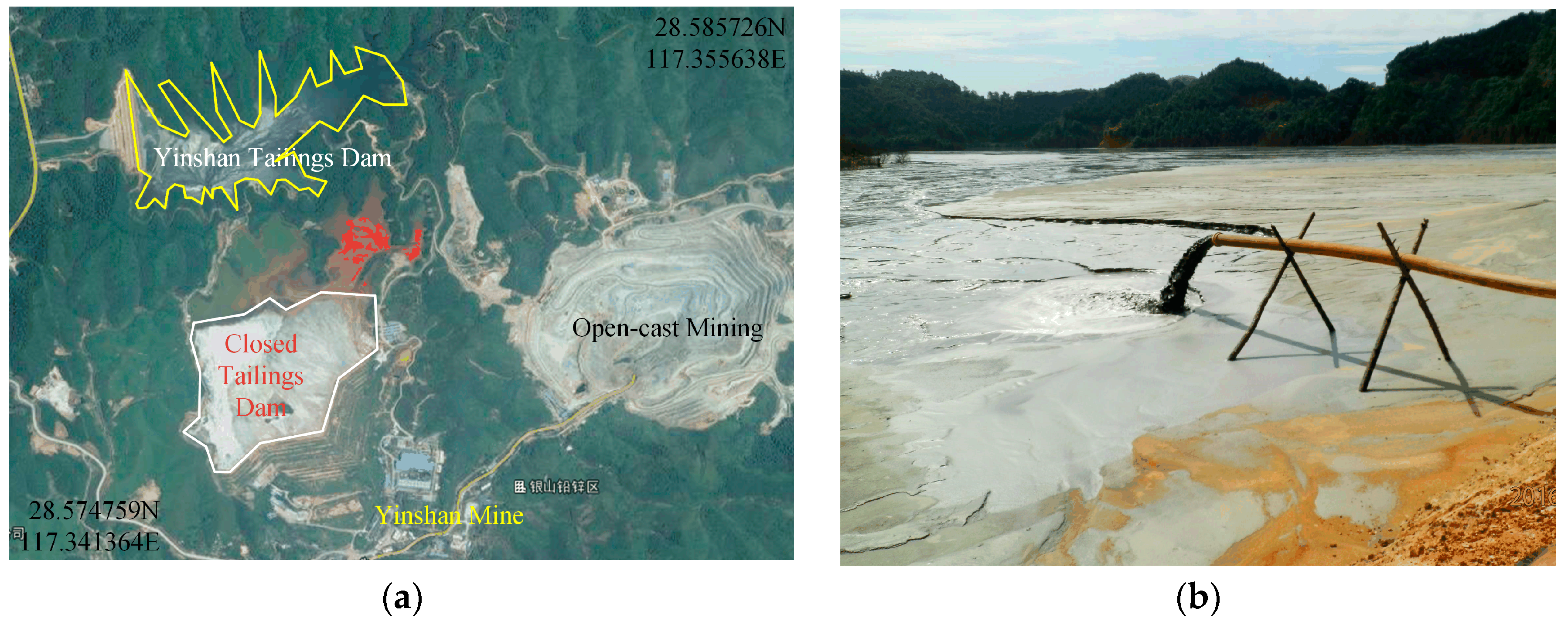

2.1. Accident Analysis of the WTD of Yinshan

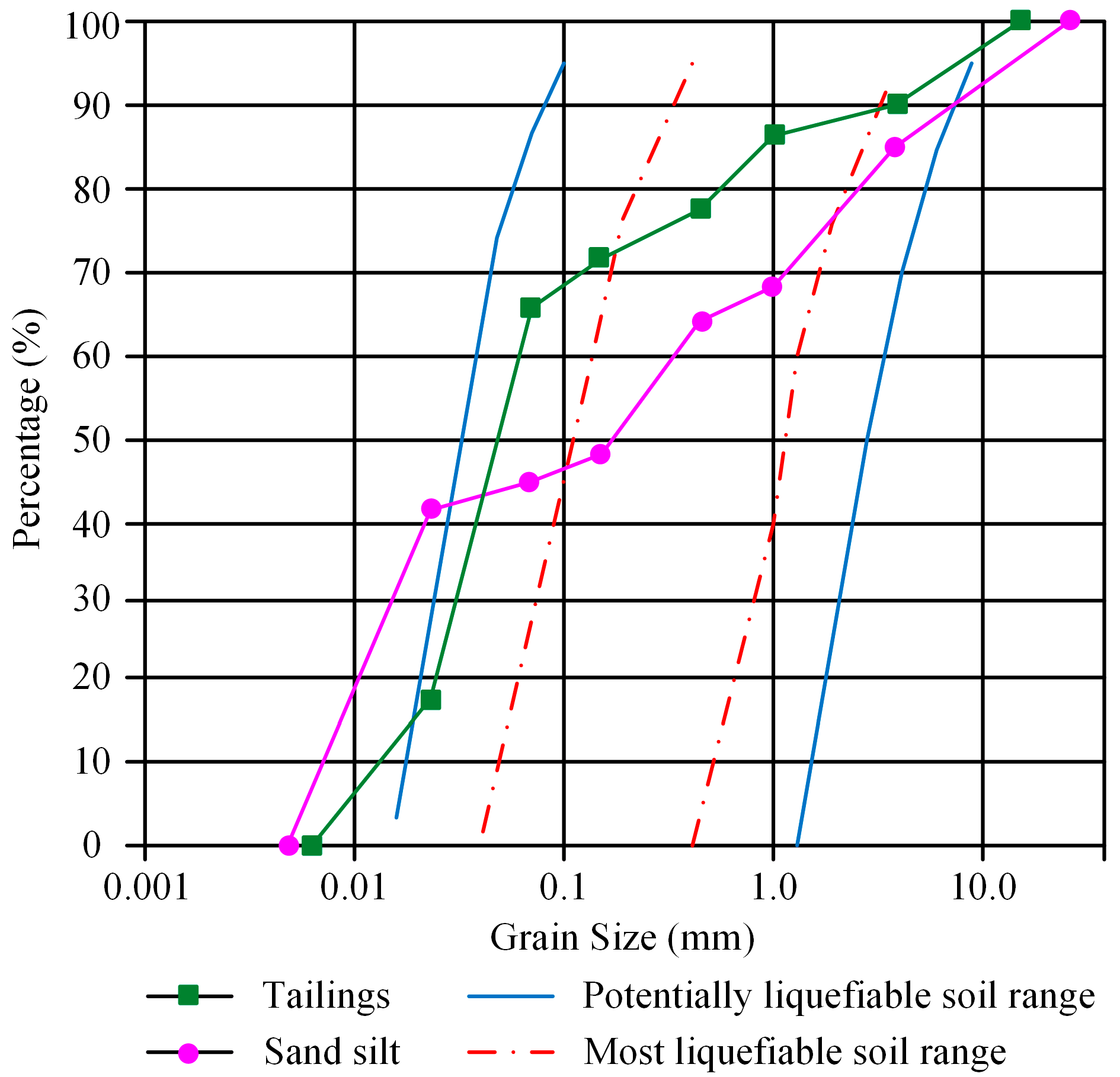

2.2. Evaluation of Tailings Liquefaction

3. Slope Stability Analysis

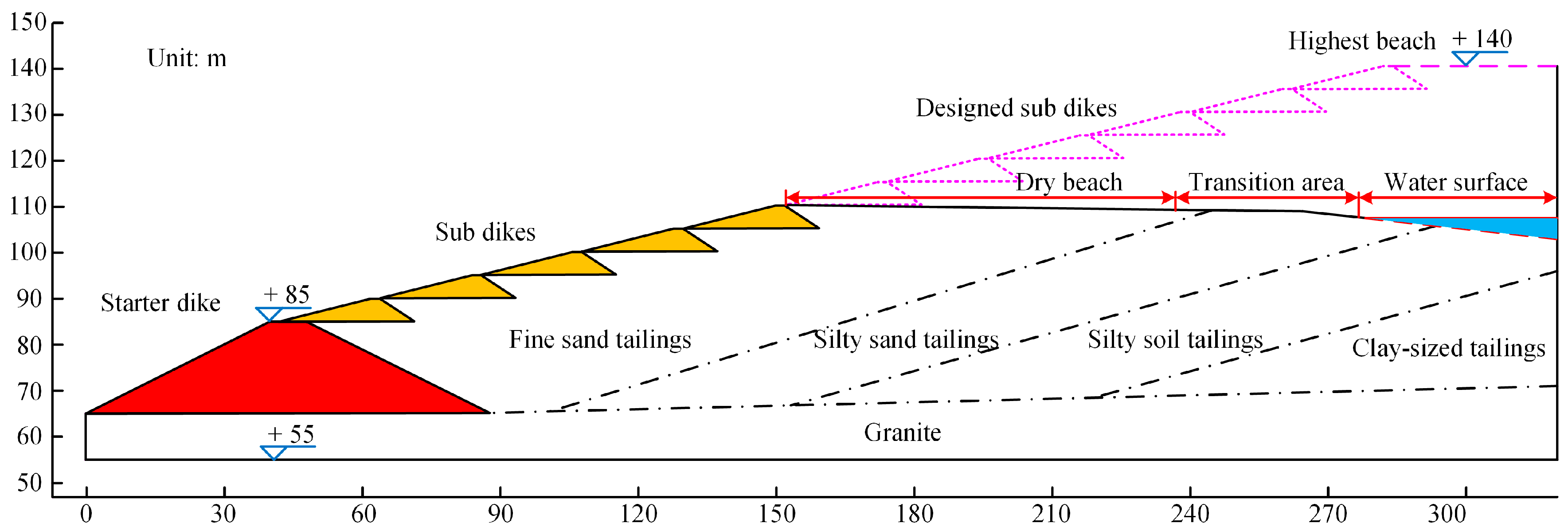

3.1. Dam Section and Tailings Properties

3.2. Saturation Line Calculation

3.3. Slope Stability Analysis for Normal Operation

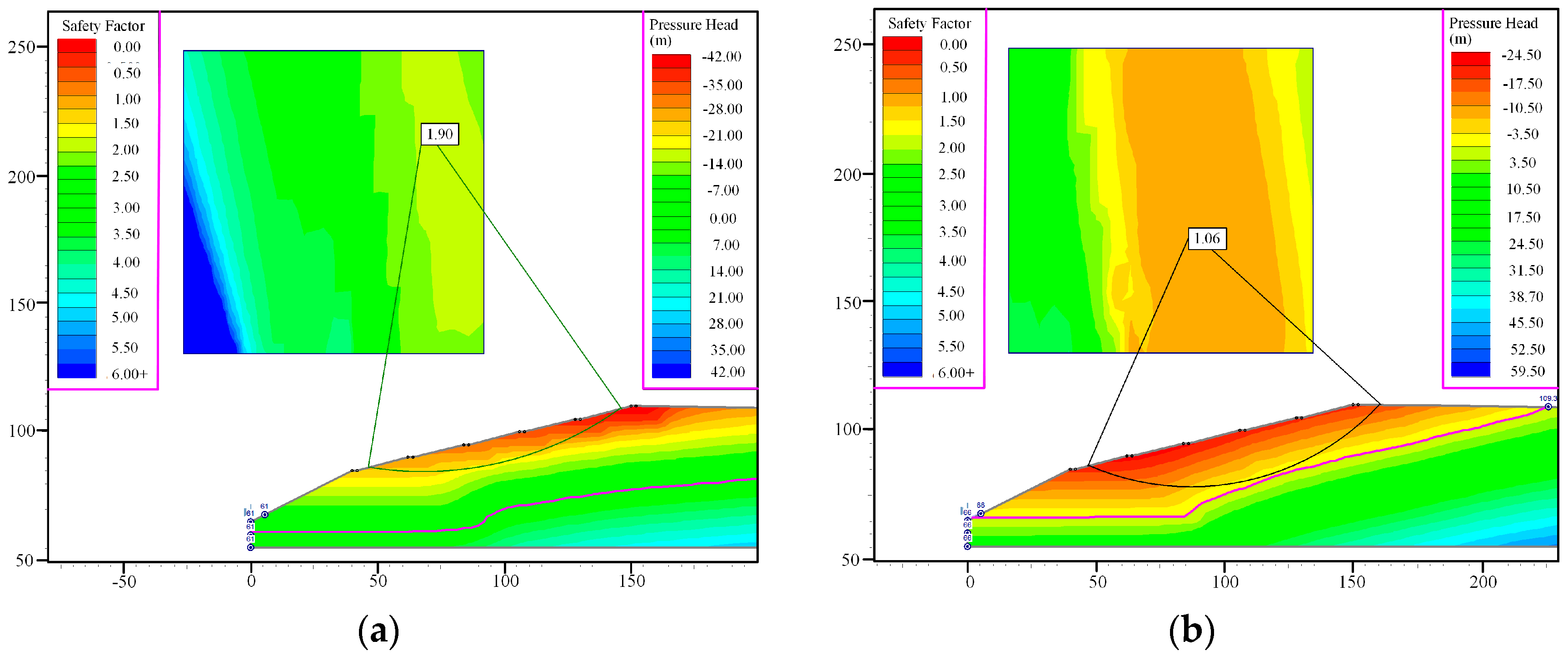

3.4. Slope Stability Analysis under Flood Conditions

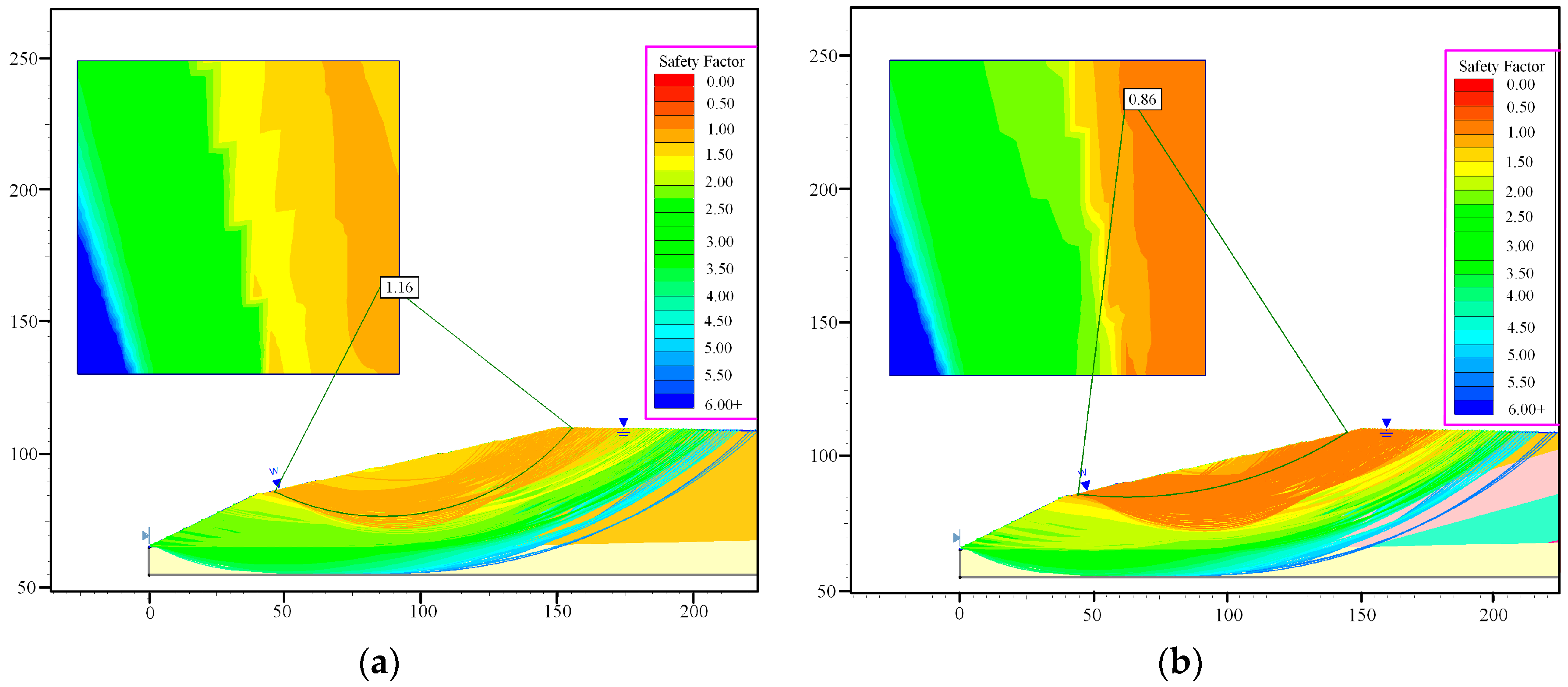

3.5. Slope Stability Analysis for Continuous Rainfall

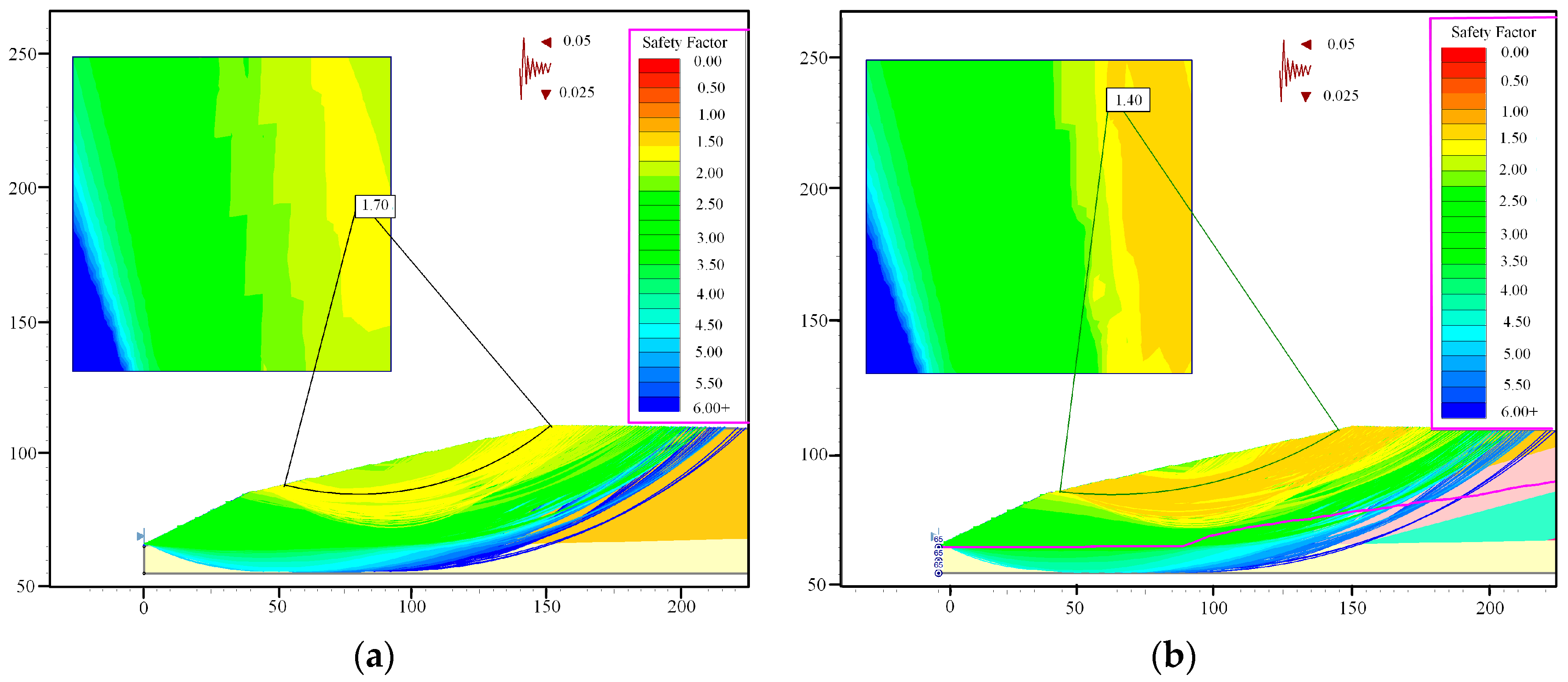

3.6. Seismic Slope Stability Analysis

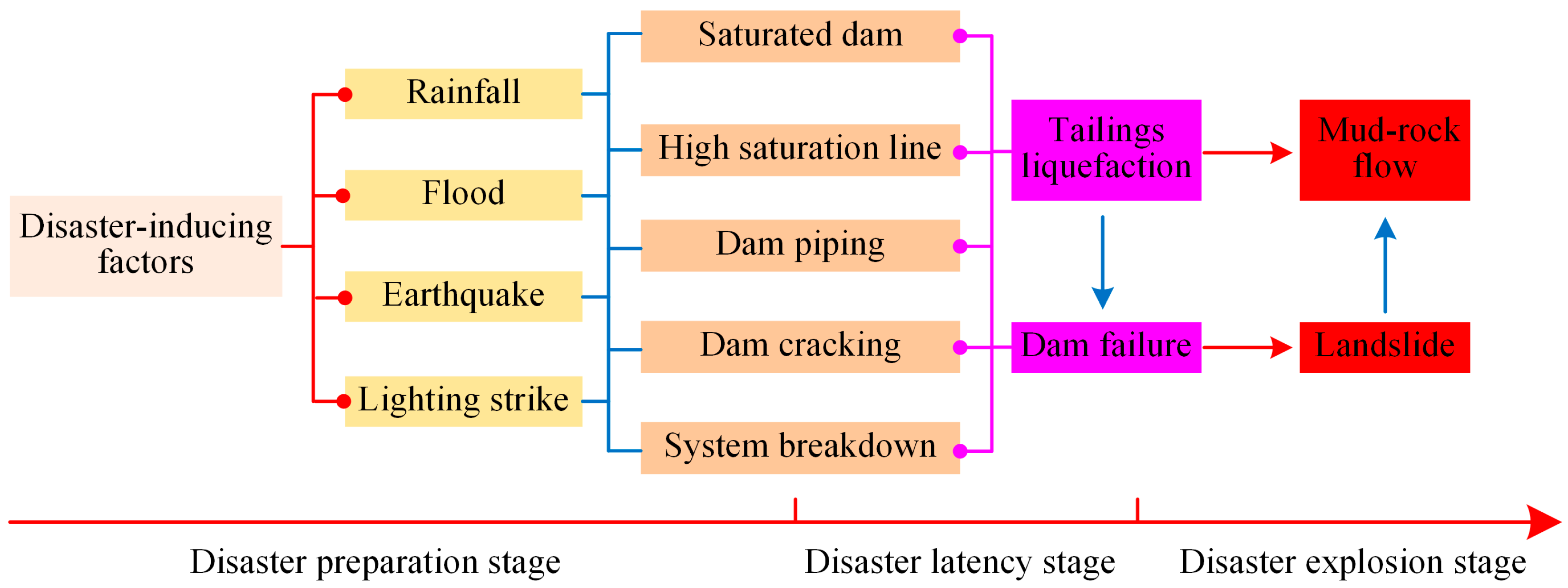

4. Disaster Chains and Chain-Cutting Disaster Mitigation Technology

4.1. Disaster Chains

4.2. Chain-Cutting Disaster Mitigation Technology

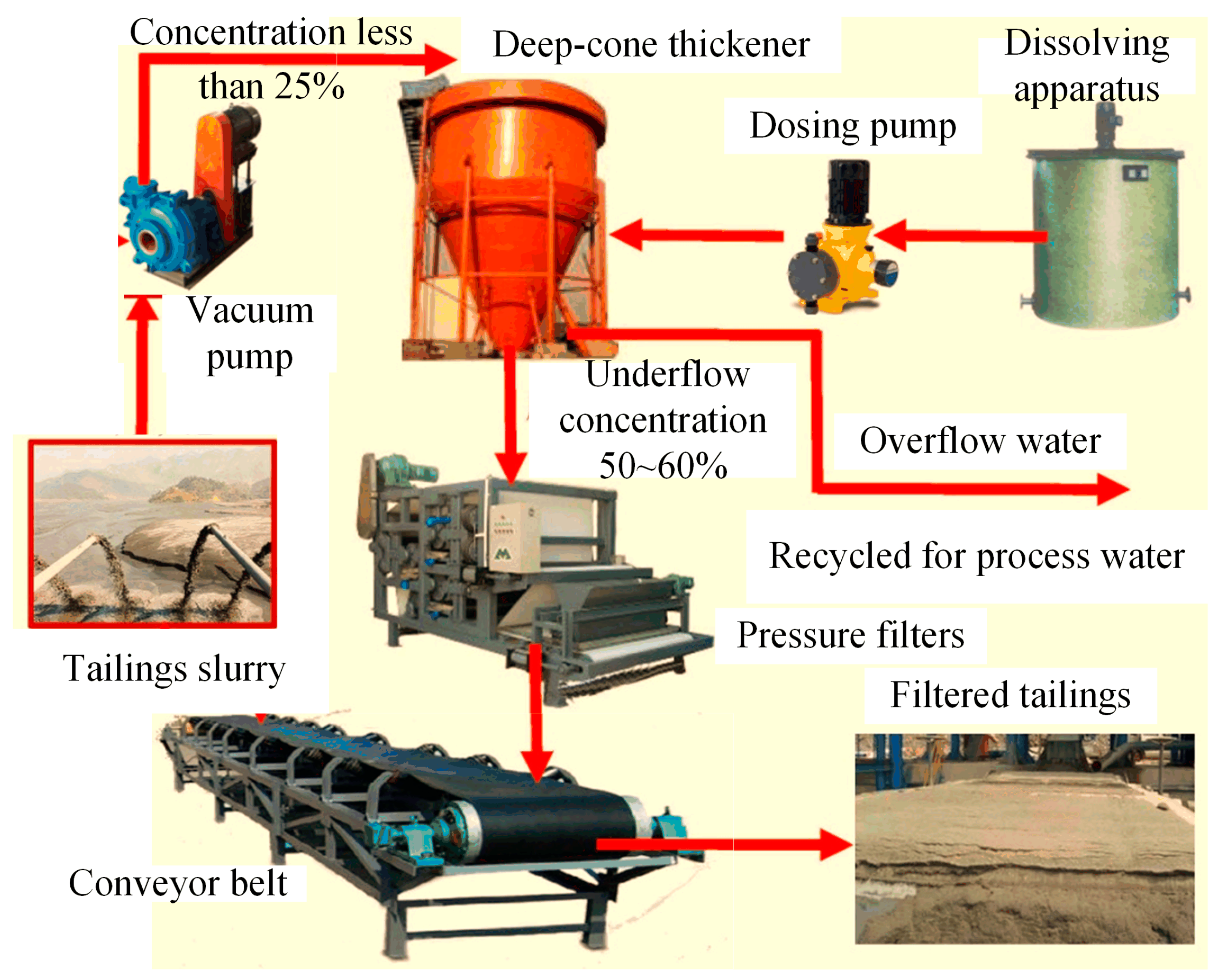

5. Application

6. Conclusions

- (1)

- Field research and laboratory tests have indicated that the WTD of Yinshan is not safe, and the tailings are susceptible to liquefaction, especially in rainy days.

- (2)

- The FTSF has less chance of seepage, lower failure probability, and limited potential destructiveness than the WTD with average slope safety factors of 2.120 for normal operation, 1.919 for flooding, 1.204 for continuous rainfall, and 1.724 for a magnitude-6.0 earthquake.

- (3)

- The failures type of the WTD of Yinshan is consistent with the bursting and slippage disaster chain. As the most safe and effective active prevention measure in rainy regions, the FTDT has the advantages of improving the dam stability in rainfall and flood situations and reducing the dam failure probability and potential losses.

- (4)

- The FTDT in Yinshan has obvious benefits for improving the storage capacity and service life, reducing land expropriation and dam maintenance costs, saving water, and protecting the environment, while showing a high application promotion value in SRRC.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ozcan, N.T.; Ulusay, R.; Isik, N.S. A study on geotechnical characterization and stability of downstream slope of a tailings dam to improve its storage capacity (Turkey). Environ. Earth. Sci. Environ. Earth. Sci. 2013, 69, 1871–1890. [Google Scholar] [CrossRef]

- Yin, G.; Li, G.; Wei, Z.; Wan, L.; Shui, G.; Jing, X. Stability analysis of a copper tailings dam via laboratory model tests: A Chinese case study. Miner. Eng. 2011, 24, 122–130. [Google Scholar] [CrossRef]

- Rico, M.; Benito, G.; Salgueiro, A.R.; Díez-Herrero, A.; Pereira, H.G. Reported tailings dam failures. J. Hazard. Mater. 2008, 152, 846–852. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.; Liu, C.; Zhang, L.; Wan, J.; Li, D.; Yue, Q.; Guo, Y. Adaptive governance to typhoon disasters for coastal sustainability: A case study in Guangdong, China. Environ. Sci. Policy 2015, 54, 281–286. [Google Scholar] [CrossRef]

- Kwak, M.; James, D.F.; Klein, K.A. Flow behaviour of tailings paste for surface disposal. Int. J. Miner. Process. 2005, 77, 139–153. [Google Scholar] [CrossRef]

- Schoenberger, E. Environmentally sustainable mining: The case of tailings storage facilities. Resour. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- Brackebusch, G.A. Paste tailings disposal in the Coeur d’Alene Mining District. Miner. Eng. 2014, 66, 52–56. [Google Scholar]

- Fourie, A. Paste and thickened tailings: Has the promise been fulfilled. Proc. Geol. Assoc. 2012. [Google Scholar] [CrossRef]

- Power, G.; Gräfe, M.; Klauber, C. Bauxite residue issues: I. Current management, disposal and storage practices. Hydrometallurgy 2011, 108, 33–45. [Google Scholar] [CrossRef]

- Davies, M.P. Filtered dry stack tailings—the fundamentals. In Proceedings of the Tailings and Mine Waste 2011, Vancouver, BC, Canada, 6–9 November 2011.

- Davies, M.P.; Rice, S. An alternative to conventional tailings management—“Dry stack” filtered tailings. In Proceeding of the Tailings and Mine Waste 2001, Fort Collins, CO, USA, 15–18 January 2001.

- Johnson, J.L.; Slottee, J.S. Paste technology: Success is in the approach. In Tailings and Mine Waste’04, Proceedings of the Eleventh Tailings and Mine Waste Conference, Vail, CO, USA, 10–13 October 2004.

- Jewell, R.J.; Fourie, A.B. Paste and Thickened Tailings: A Guide, 2nd ed.; Australian Centre for Geomechanics: Perth, Australia, 2006. [Google Scholar]

- Davies, M.P.; Lupo, J.; Martin, T.; McRoberts, E.; Musse, M.; Ritchie, D. Dewatered tailings practice–trends and observations. In Proceedings of the Tailings and Mine Waste 2010, Vail, CO, USA, 17–20 October 2010.

- Williams, D.J. Selection of shear strength profile for desiccated tailings to support an upstream raise. In Proceedings of the Tailings and Mine Waste 2015, Vancouver, BC, Canada, 26–28 October 2015.

- Peng, H.; Liu, S.; Zhang, Q. Research on dry piling process of tailings in Yunnan Zhenyuan Gold Mine. Yunnan Metall. 2010, 6, 54–57. (In Chinese) [Google Scholar]

- Xu, M.; Wang, Z.; Qi, L.; Liu, L.; Zhang, K. Disaster chains initiated by the Wenchuan earthquake. Environ. Earth. Sci. 2012, 65, 975–985. [Google Scholar] [CrossRef]

- Peng, J.B.; Sun, X.H.; Wang, W.; Sun, G.C. Characteristics of land subsidence, earth fissures and related disaster chain effects with respect to urban hazards in Xi’an, China. Environ. Earth. Sci. 2016, 75, 1190. [Google Scholar] [CrossRef]

- Gao, F.; Zhou, K.P.; Chen, X.Y.; Luo, X.W. Disaster chains induced by mining and chain-cutting disaster mitigation Technology. Disaster Adv. 2012, 5, 971–975. [Google Scholar]

- Tsuchida, H. Prediction and counter measure against the liquefaction in sand deposits. In Proceedings of the Seminar of the Port and Harbour Research Institute, Yokosuka, Japan, 1970; pp. 1–3.

- Wala, M.; Mehta, P.; Patel, R. Study of stability of fly ash dam using slide software. Int. Edu. Res. J. 2016, 2, 125–126. [Google Scholar]

- Saeidi, A.; Maazallahi, V.; Rouleau, A. Locating Pre-Slide Topography using Site Investigation Data, Case Study of the Maskun Landslide, Iran. In Proceedings of the 13th ISRM International Congress of Rock Mechanics 2015, Montréal, QC, Canada, 10–13 May 2015.

- Xu, B.; Wang, Y. Stability analysis of the Lingshan gold mine tailings dam under conditions of a raised dam height. Bull. Eng. Geol. Environ. 2015, 74, 151–161. [Google Scholar] [CrossRef]

- Tongle, X.; Yingbo, W.; Kang, C. Tailings saturation line prediction based on genetic algorithm and BP neural network. J. Intell. Fuzzy Syst. 2016, 30, 1947–1955. [Google Scholar] [CrossRef]

- Xu, X.; Xue, D.; Li, Y.; Hu, P.; Chen, N. Neoproterozoic sequences along the Dexing–Huangshan fault zone in the eastern Jiangnan orogen, South China: Geochronological and geochemical constrains. Gondwana Res. 2014, 25, 368–382. [Google Scholar] [CrossRef]

- Lakshmi, M.R.; Kumar, V.D. Anthropogenic hazard and disaster relief operations: A case study of GAIL pipeline blaze in east godavari of A.P. Procedia Soc. Behav. Sci. 2015, 189, 198–207. [Google Scholar] [CrossRef]

- Wang, J.; Gu, X.; Huang, T. Using Bayesian networks in analyzing powerful earthquake disaster chains. Nat. Hazards 2013, 68, 509–527. [Google Scholar] [CrossRef]

| Failure Date | Name | Province | Failure Consequences |

|---|---|---|---|

| 26 September 1962 | Huogudu dam, Yunan Tin Group Co. | Yunnan | 171 killed, 20 million CNY losses |

| 13 July 1997 | Longjiaoshan, Daye Nonferrous Metals Co. | Hubei | 28 killed, 55 million CNY losses |

| 18 October 2000 | Dachang, Nandan Tin Mine | Guangxi | 28 killed, 34 million CNY losses |

| 25 November 2009 | Yinshan Mine, Jiangxi Copper Co. | Jiangxi | Leakage 30,000 m3, pollution sweep 3 km |

| 21 September 2010 | Gaoqiling dam, Zijin Mining Co. | Guangdong | 22 killed, 460 million CNY losses |

| Materials | Volume-Weight (kN·m−3) | Adhesion Stress (kPa) | Internal Friction Angle (°) | Osmotic Coefficient (cm·s−1) | ||||

|---|---|---|---|---|---|---|---|---|

| Nature γ | Saturation γsat | Normal c | Earthquake c′ | Normal ϕ | Earthquake ϕ′ | Horizontal K1 | Vertical K2 | |

| Granite | 25.5 | 25.8 | 257 | 188 | 50.2 | 44 | 6.35 × 10−7 | 5.22 × 10−7 |

| Starter dike | 24.1 | 24.5 | 128 | 25 | 36.7 | 26.2 | 8.65 × 10−2 | 7.53 × 10−2 |

| Sub dikes | 20.2 | 20.8 | 1 | 0 | 26.5 | 16.8 | 5.06 × 10−4 | 4.16 × 10−4 |

| Fine sand | 20.5 | 21.0 | 0 | 0 | 27.5 | 17.1 | 5.68 × 10−4 | 4.72 × 10−4 |

| Sility sand | 19.8 | 20.5 | 3 | 0 | 25.2 | 16.7 | 3.44 × 10−4 | 2.81 × 10−4 |

| Sility soil | 19.2 | 20.1 | 5 | 0 | 23.6 | 15.6 | 9.58 × 10−5 | 8.38 × 10−5 |

| Clay-sized tailings | 18.7 | 19.8 | 10 | 0 | 21.9 | 15.4 | 6.80 × 10−5 | 5.52 × 10−5 |

| Filtered tailings | 20.5 | 21.2 | 13 | 0 | 20.8 | 18.3 | 3.66 × 10−5 | 2.90 × 10−5 |

| Situtations | WTD | FTD | Standard | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Bishop | Fellenuius | Janbu | Average | Bishop | Fellenuius | Janbu | Average | ||

| Normal operation | 1.76 | 1.72 | 1.72 | 1.73 | 2.17 | 2.10 | 2.09 | 2.12 | 1.30 |

| Flood conditions | 1.09 | 1.06 | 1.06 | 1.07 | 1.95 | 1.90 | 1.90 | 1.92 | 1.20 |

| Continuous rainfall | 0.88 | 0.90 | 0.86 | 0.88 | 1.24 | 1.22 | 1.16 | 1.20 | 1.20 |

| Earthquake | 1.43 | 1.40 | 1.40 | 1.41 | 1.77 | 1.71 | 1.70 | 1.72 | 1.10 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Chen, Q.; Wang, X. Superiority of Filtered Tailings Storage Facility to Conventional Tailings Impoundment in Southern Rainy Regions of China. Sustainability 2016, 8, 1130. https://doi.org/10.3390/su8111130

Li S, Chen Q, Wang X. Superiority of Filtered Tailings Storage Facility to Conventional Tailings Impoundment in Southern Rainy Regions of China. Sustainability. 2016; 8(11):1130. https://doi.org/10.3390/su8111130

Chicago/Turabian StyleLi, Shuai, Qiusong Chen, and Xinmin Wang. 2016. "Superiority of Filtered Tailings Storage Facility to Conventional Tailings Impoundment in Southern Rainy Regions of China" Sustainability 8, no. 11: 1130. https://doi.org/10.3390/su8111130

APA StyleLi, S., Chen, Q., & Wang, X. (2016). Superiority of Filtered Tailings Storage Facility to Conventional Tailings Impoundment in Southern Rainy Regions of China. Sustainability, 8(11), 1130. https://doi.org/10.3390/su8111130