Advanced Manufacturing Technologies and Green Innovation: The Role of Internal Environmental Collaboration

Abstract

:1. Introduction

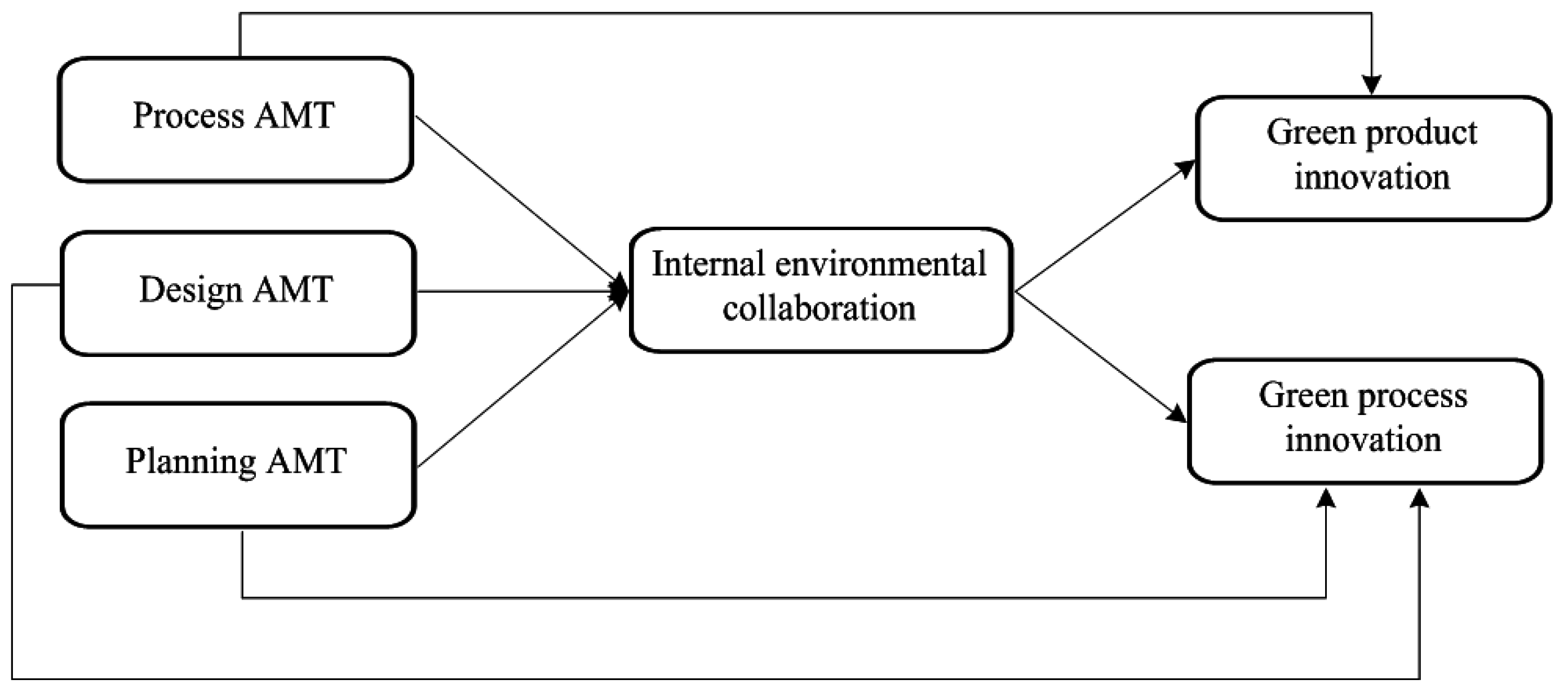

2. Theoretical Background and Research Hypotheses

2.1. AMT and Green Product Innovation

2.2. AMT and Green Process Innovation

2.3. The Mediating Effect of Internal Environmental Collaboration

3. Research Methods

3.1. Sampling and Data Collection

3.2. Variables and Measures

3.3. Reliability and Validity

4. Analysis and Results

5. Discussion and Managerial Implications

5.1. Discussion

5.2. Managerial Implications

6. Conclusions and Limitations

6.1. Research Contributions

6.2. Limitations and Future Research

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Item | Loading |

|---|---|

| Process AMT (α = 0.821) | |

| PAMT1: Computer-aided manufacturing (CAM) technology practice is applied. | 0.711 |

| PAMT2: Robotics is used. | 0.874 |

| PAMT3: Flexible manufacturing systems (FMS) technology practice is applied. | 0.727 |

| PAMT4: Environmental control systems are applied. | 0.770 |

| Design AMT (α = 0.874) | |

| DAMT1: Computer-aided process planning (CAPP) technology practice is applied. | 0.831 |

| DAMT2: Computer-aided design (CAD) technology practice is applied. | 0.905 |

| DAMT3: Product data management (PDM) systems are used. | - |

| DAMT4: Computer-aided engineering (CAE) technology practice is applied. | 0.719 |

| DAMT5: Rapid prototyping (e.g., stereolithography) technology practice is applied. | 0.754 |

| Planning AMT (α = 0.881) | |

| PAMT1: Enterprise resource planning system (ERP) is used. | 0.871 |

| PAMT2: Advanced MRPⅡsystem is used. | 0.767 |

| PAMT3: Activity-based accounting (ABC) is used. | 0.800 |

| PAMT4: Decision support systems (DSS) are applied. | 0.798 |

| Internal environmental collaboration (α = 0.927) | |

| IEC1: Achieving environmental goals collectively. | - |

| IEC2: Developing a mutual understanding of responsibilities regarding environmental performance. | 0.908 |

| IEC3: Working together to reduce the environmental impact of our activities. | 0.895 |

| IEC4: Conducting joint planning to anticipate and resolve environment-related problems. | 0.931 |

| IEC5: Making joint decisions about ways to reduce the environmental impact of our products/services. | 0.854 |

| Green product innovation (α = 0.929) | |

| GPDI1: The new products reduce the consumption of materials/energy. | 0.777 |

| GPDI2: The new products reuse, recycle, and recover materials and component parts. | 0.887 |

| GPDI3: The new products reduce resource consumption and waste generation in product usage. | 0.920 |

| GPDI4: The new products reduce the environmental impact of product disposal. | 0.902 |

| Green process innovation (α = 0.919) | |

| GPCI1: The manufacturing process uses clean technology/equipment. | - |

| GPCI2: The manufacturing process installs energy-efficient equipment. | 0.915 |

| GPCI3: The manufacturing process installs pollution control technologies. | 0.943 |

| GPCI4: Production planning and control during the manufacturing process focused on reducing waste and optimizing materials. | 0.872 |

References

- Porter, M.E.; Linde, C.V.D. Green and competitive: Ending the stalemate. Harv. Bus. Rev. 1995, 73, 128–129. [Google Scholar]

- Sharma, S. Managerial Interpretations and Organizational Context as Predictors of Corporate Choice of Environmental Strategy. Acad. Manag. J. 2000, 43, 681–697. [Google Scholar] [CrossRef]

- Schiederig, T.; Tietze, F.; Herstatt, C. Green innovation in technology and innovation management—An exploratory literature review. RD Manag. 2012, 42, 180–192. [Google Scholar] [CrossRef]

- Swink, M.; Nair, A. Capturing the competitive advantages of AMT: Design-manufacturing integration as a complementary asset. J. Oper. Manag. 2007, 25, 736–754. [Google Scholar] [CrossRef]

- Kotha, S.; Swamidass, P.M. Strategy, advanced manufacturing technology and performance: Empirical evidence from US manufacturing firms. J. Oper. Manag. 2000, 18, 257–277. [Google Scholar] [CrossRef]

- Wemmerlöv, U.; Hyer, N.L. Cellular manufacturing in the U.S. industry: A survey of users. Int. J. Prod. Res. 1989, 27, 1511–1530. [Google Scholar] [CrossRef]

- Swamidass, P.M.; Kotha, S. Explaining manufacturing technology use, firm size and performance using a multidimensional view of technology. J. Oper. Manag. 1998, 17, 23–37. [Google Scholar] [CrossRef]

- Lei, D.; Hitt, M.A.; Goldhar, J.D. Advanced Manufacturing Technology: Organizational Design and Strategic Flexibility. Organ. Stud. 1996, 17, 501–523. [Google Scholar] [CrossRef]

- Tracey, M.; Vonderembse, M.A.; Lim, J.S. Manufacturing technology and strategy formulation: Keys to enhancing competitiveness and improving performance. J. Oper. Manag. 1999, 17, 411–428. [Google Scholar] [CrossRef]

- Hofmann, C.; Orr, S. Advanced manufacturing technology adoption—The German experience. Technovation 2005, 25, 711–724. [Google Scholar] [CrossRef]

- Cagliano, R.; Spina, G. Advanced manufacturing technologies and strategically flexible production. J. Oper. Manag. 2000, 18, 169–190. [Google Scholar] [CrossRef]

- Santamaría, L.; Nieto, M.J.; Barge-Gil, A. Beyond formal R&D: Taking advantage of other sources of innovation in low-and medium-technology industries. Res. Policy 2009, 38, 507–517. [Google Scholar]

- Trifilova, A.; Bartlett, D. Green technology and eco-innovation: Seven case—Studies from a Russian manufacturing context. J. Manuf. Technol. Manag. 2010, 21, 910–929. [Google Scholar]

- Small, M.H.; Yasin, M.M. Advanced manufacturing technology: Implementation policy and performance. J. Oper. Manag. 1997, 15, 349–370. [Google Scholar] [CrossRef]

- Nair, A.; Swink, M. Linking internal process technology development and the use of AMT with manufacturing plant performance—An examination of complementarities and redundancies. IEEE Trans. Eng. Manag. 2007, 54, 742–755. [Google Scholar] [CrossRef]

- Klassen, R.D.; Whybark, D.C. Environmental Management in Operations: The Selection of Environmental Technologies. Decision Sci. 1999, 30, 601–631. [Google Scholar] [CrossRef]

- Tseng, M.L.; Wang, R.; Chiu, A.S.F.; Geng, Y.; Lin, Y.H. Improving performance of green innovation practices under uncertainty. J. Clean. Prod. 2013, 40, 71–82. [Google Scholar] [CrossRef]

- Weng, H.H.; Chen, J.S.; Chen, P.C. Effects of Green Innovation on Environmental and Corporate Performance: A Stakeholder Perspective. Sustainability 2015, 7, 209–214. [Google Scholar] [CrossRef]

- Sohal, A.; Sarros, J.; Schroder, R.; O’neill, P. Adoption framework for advanced manufacturing technologies. Int. J. Prod. Res. 2006, 44, 5225–5246. [Google Scholar] [CrossRef]

- Udo, G.J.; Ehie, I.C. Advanced manufacturing technologies: Determinants of implementation success. Int. J. Oper. Prod. Manag. 1996, 16, 6–26. [Google Scholar] [CrossRef]

- Burcher, P.; Lee, G.; Sohal, A. Lessons for implementing AMT: Some case experiences with CNC in Australia, Britain and Canada. Int. J. Oper. Prod. Manag. 1999, 19, 515–527. [Google Scholar] [CrossRef]

- Das, A.; Jayaram, J. Relative importance of contingency variables for advanced manufacturing technology. Int. J. Prod. Res. 2003, 41, 4429–4452. [Google Scholar] [CrossRef]

- Boyer, K.K.; Leong, G.K.; Ward, P.T.; Krajewski, L.J. Unlocking the potential of advanced manufacturing technologies. J. Oper. Manag. 1997, 15, 331–347. [Google Scholar] [CrossRef]

- Zhang, Q.; Vonderembse, M.A.; Cao, M. Achieving flexible manufacturing competence: The roles of advanced manufacturing technology and operations improvement practices. Int. J. Oper. Prod. Manag. 2006, 26, 580–599. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lai, S.B.; Wen, C.T. The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Ethics 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Chen, Y.S. The driver of green innovation and green image - green core competence. J. Bus. Ethics 2008, 81, 531–543. [Google Scholar] [CrossRef]

- Orsato, R.J. Competitive Environmental Strategies: When does it pay to be green? Calif. Manag. Rev. 2006, 48, 127–143. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Wagner, H.T.; Morton, S.C.; Dainty, A.R.J.; Burns, N.D. Path dependent constraints on innovation programmes in production and operations management. Int. J. Prod. Res. 2011, 49, 3069–3085. [Google Scholar] [CrossRef]

- Cooper, R.G.; Kleinschmidt, E.J. New products: What separates winners from losers? J. Prod. Innov. Manag. 1987, 4, 169–184. [Google Scholar] [CrossRef]

- Kumar, V.; Murphy, S.A.; Loo, S.C.K. An investment decision process: The case of advanced manufacturing technologies in Canadian manufacturing firms. Int. J. Prod. Res. 1996, 34, 947–958. [Google Scholar] [CrossRef]

- Khazanchi, S.; Lewis, M.W.; Boyer, K.K. Innovation-supportive culture: The impact of organizational values on process innovation. J. Oper. Manag. 2007, 25, 871–884. [Google Scholar] [CrossRef]

- Subramaniam, M.; Youndt, M.A. The Influence of Intellectual Capital on the Types of Innovative Capabilities. Acad. Manag. J. 2005, 48, 450–463. [Google Scholar] [CrossRef]

- Cohen, W.M.; Levinthal, D.A. Absorptive Capacity: A New Perspective on Learning and Innovation. Admin. Sci. Quart. 1990, 35, 128–152. [Google Scholar] [CrossRef]

- Piening, E.P.; Salge, T.O. Understanding the Antecedents, Contingencies, and Performance Implications of Process Innovation: A Dynamic Capabilities Perspective. J. Prod. Innov. Manag. 2015, 32, 80–97. [Google Scholar] [CrossRef]

- Noci, G.; Verganti, R. Managing ‘green’ product innovation in small firms. R D Manag. 1998, 29, 3–15. [Google Scholar]

- Moyanofuentes, J.; Sacristándíaz, M.; Garridovega, P. Improving supply chain responsiveness through Advanced Manufacturing Technology: The mediating role of internal and external integration. Prod. Plan. Control 2016, 27, 686–697. [Google Scholar] [CrossRef]

- Kogut, B.; Zander, U. Knowledge of the Firm, Combinative Capabilities, and the Replication of Technology. Organ. Sci. 1992, 3, 17–35. [Google Scholar] [CrossRef]

- Chen, C.J.; Huang, J.W. Strategic human resource practices and innovation performance—The mediating role of knowledge management capacity. J. Bus. Res. 2009, 62, 104–114. [Google Scholar] [CrossRef]

- Rodan, S.; Galunic, C. More than network structure: How knowledge heterogeneity influences managerial performance and innovativeness. Strateg. Manag. J. 2004, 25, 541–562. [Google Scholar] [CrossRef]

- Fleming, L. Recombinant Uncertainty in Technological Search. Manag. Sci. 2001, 47, 117–132. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lin, Y.H.; Lin, C.Y.; Chang, C.W. Enhancing Green Absorptive Capacity, Green Dynamic Capacities and Green Service Innovation to Improve Firm Performance: An Analysis of Structural Equation Modeling (SEM). Sustainability 2015, 7, 15674–15692. [Google Scholar] [CrossRef]

- Berkel, R.V. Eco-Innovation: Opportunities for advancing waste prevention. Int. J. Environ. Technol. Manag. 2007, 7, 527–550. [Google Scholar] [CrossRef]

- Machiba, T. Eco-innovation for enabling resource efficiency and green growth: Development of an analytical framework and preliminary analysis of industry and policy practices. Int. Econ. Econ. Policy 2010, 7, 357–370. [Google Scholar] [CrossRef]

- Zairi, M. Measuring success in AMT implementation using customer-supplier interaction criteria. Int. J. Oper. Prod. Manag. 1992, 12, 34–55. [Google Scholar] [CrossRef]

- Turkulainen, V.; Ketokivi, M. Cross-functional integration and performance: What are the real benefits? Int. J. Oper. Prod. Mang. 2012, 32, 447–467. [Google Scholar] [CrossRef]

- Lewis, M.W.; Boyer, K.K. Factors impacting AMT implementation: An integrative and controlled study. J. Eng. Technol. Manag. 2002, 19, 111–130. [Google Scholar] [CrossRef]

- Zammuto, R.F.; O’Connor, E.J. Gaining advanced manufacutring technologies' benifits: The roles of organization design and culture. Acad. Manag. Rev. 1992, 17, 701–728. [Google Scholar]

- Horbach, J. Determinants of environmental innovation—New evidence from German panel data sources. Res. Policy 2008, 37, 163–173. [Google Scholar] [CrossRef]

- Adler, P.S. CAD/CAM: Managerial challenges and research issues. IEEE Trans. Eng. Manag. 1989, 36, 202–215. [Google Scholar] [CrossRef]

- Hart, S.L. A natural resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar]

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar] [CrossRef]

- Ryszko, A. Proactive Environmental Strategy, Technological Eco-Innovation and Firm Performance—Case of Poland. Sustainability 2016, 8, 156. [Google Scholar] [CrossRef]

- Ram, N.; Prahalad, C.K.; Rangaswami, M.R. Why sustainbility is now the key driver of innovation. Harv. Bus. Rev. 2009, 87, 57–64. [Google Scholar]

- Zhao, H.; Co, H.C. Adoption and implementation of advanced manufacturing technology in Singapore. Int. J. Prod. Econ. 1997, 48, 7–19. [Google Scholar] [CrossRef]

- Li, J.J.; Poppo, L.; Zhou, K.Z. Relational mechanisms, formal contracts, and local knowledge acquisition by international subsidiaries. Strateg. Manag. J. 2010, 31, 349–370. [Google Scholar] [CrossRef]

- Vachon, S. Green supply chain practices and the selection of environmental technologies. Int. J. Prod. Res. 2007, 45, 4357–4379. [Google Scholar] [CrossRef]

- Geffen, C.A.; Rothenberg, S. Suppliers and environmental innovation: The automotive paint process. Int. J. Oper. Prod. Manag. 2000, 20, 166–186. [Google Scholar] [CrossRef]

- Frohlich, M.T. Techniques for improving response rates in OM survey research. J. Oper. Manag. 2002, 20, 53–62. [Google Scholar] [CrossRef]

- Armstrong, J.; Overton, T. Estimating nonresponse bias in mail surveys. J. Mark. Res. 1977, 14, 396–402. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Podsakoff, P.M.; Organ, D.W. Self-reports in organizational research: Problems and prospects. J. Manag. 1986, 12, 531–544. [Google Scholar] [CrossRef]

- Sanchez, J.I.; Brock, P. Outcomes of perceived discrimination among hispanic employees: Is diversity management a luxury or a necessity? Acad. Manag. J. 1996, 39, 704–719. [Google Scholar] [CrossRef]

- Banerjee, S.B.; Kashyap, R.K. Corporate Environmentalism: Antecedents and Influence of Industry Type. J. Mark. 2003, 67, 106–122. [Google Scholar] [CrossRef]

- Prajogo, D.; Tang, A.K.Y.; Lai, K.-H. The diffusion of environmental management system and its effect on environmental management practices. Int. J. Oper. Prod. Manag. 2014, 34, 565–585. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Sroufe, R. Effects of environmental management systems on environmental management practices and operations. Prod. Oper. Manag. 2003, 12, 416–431. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- O’Leary-Kelly, S.W.; Vokurka, R.J. The empirical assessment of construct validity. J. Oper. Manag. 1998, 16, 387–405. [Google Scholar] [CrossRef]

- Hu, L.-T.; Bentler, P.M. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Model. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Anderson, J.C. An approach for confirmatory measurement and structural equation modeling of organizational properties. Manag. Sci. 1987, 33, 525–541. [Google Scholar] [CrossRef]

- Baron, R.M.; Kenny, D.A. The moderator-mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Pers. Soc. Psychol. 1986, 51, 1173–1182. [Google Scholar] [CrossRef] [PubMed]

- Adler, P.S. Interdepartmental interdependence and coordination: The case of the design/manufacturing interface. Organ. Sci. 1995, 6, 147–167. [Google Scholar] [CrossRef]

- Zhang, K.M.; Wen, Z.G. Review and challenges of policies of environmental protection and sustainable development in China. J. Environ. Manag. 2008, 88, 1249–1261. [Google Scholar] [CrossRef] [PubMed]

- Feng, T.; Wang, D. The influence of environmental management systems on financial performance: A moderated-mediation analysis. J. Bus. Ethics 2016, 135, 265–278. [Google Scholar] [CrossRef]

- Feng, T.; Cai, D.; Wang, D.; Zhang, X. Environmental management systems and financial performance: The joint effect of switching cost and competitive intensity. J. Clean. Prod. 2016, 113, 781–791. [Google Scholar] [CrossRef]

- Peng, M.W.; Heath, P.S. The growth of the firm in planned economies in transition: Institutions, organizations, and strategic choice. Acad. Manag. Rev. 1996, 21, 492–528. [Google Scholar]

| Characteristics of Firms | Frequency | Percentage (%) |

|---|---|---|

| Environmental strategy [64] | ||

| Level of environmental corporate strategy | ||

| Lower than industry average | 24 | 12.12 |

| Industry average | 24 | 12.12 |

| Higher than industry average | 150 | 75.76 |

| Level of environmental marketing strategy | ||

| Lower than industry average | 30 | 15.15 |

| Industry average | 16 | 8.08 |

| Higher than industry average | 152 | 76.77 |

| Industry | ||

| Metal products | 19 | 9.6 |

| Machinery and engineering | 21 | 10.61 |

| Electrical machinery and equipment | 25 | 12.63 |

| Communication and computers related equipment | 32 | 16.16 |

| Instruments and related products | 18 | 9.09 |

| others | 83 | 41.92 |

| Number of employees | ||

| Large size (2000 or more) | 34 | 17.17 |

| Medium size (300–2000) | 47 | 23.74 |

| Small size (<300) | 117 | 59.09 |

| Annual sales (million RMB) | ||

| Large size (100 or more) | 60 | 30.3 |

| Medium size (10–100) | 59 | 29.8 |

| Small size (<10) | 79 | 39.9 |

| Ownership | ||

| State-owned | 72 | 36.36 |

| Private-owned | 96 | 48.48 |

| foreign-owned | 30 | 15.15 |

| Mean | S.D. | PAMT | PLAMT | DAMT | IEC | GPDI | GPCI | |

|---|---|---|---|---|---|---|---|---|

| Process AMT (PAMT) | 5.047 | 1.101 | 0.598 | |||||

| Design AMT (DAMT) | 4.855 | 1.069 | 0.498 | 0.645 | ||||

| Planning AMT (PLAMT) | 5.343 | 1.068 | 0.534 | 0.494 | 0.656 | |||

| Internal environmental collaboration (IEC) | 5.149 | 1.098 | 0.428 | 0.424 | 0.496 | 0.805 | ||

| Green product innovation (GPDI) | 5.024 | 1.133 | 0.345 | 0.368 | 0.312 | 0.438 | 0.763 | |

| Green process innovation (GPCI) | 5.217 | 1.178 | 0.440 | 0.445 | 0.392 | 0.629 | 0.607 | 0.829 |

| IEC | GPDI | GPCI | |||||

|---|---|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | Model 7 | |

| Control variables | |||||||

| Firm age | −0.165 (−1.147) | 0.363 (2.151) * | 0.515 (3.237) ** | 0.442 (2.857) ** | 0.038 (0.235) | 0.226 (1.651) | 0.147 (1.121) |

| Firm size | −0.101 (−1.249) | 0.101 (1.063) | 0.179 (1.994) * | 0.149 (1.716) + | 0.070 (0.769) | 0.168 (2.171) * | 0.136 (1.850) + |

| Ownership | 0.184 (1.322) | −0.072 (−0.440) | −0.238 (−1.583) | −0.160 (−1.070) | 0.152 (0.974) | −0.065 (−0.500) | 0.031 (0.240) |

| Main effects | |||||||

| Process AMT | 0.223 (2.664) ** | 0.205 (2.089) * | 0.098 (1.070) | 0.313 (3.340) ** | 0.166 (2.146) * | ||

| Design AMT | 0.430 (5.823) *** | 0.231 (2.668) ** | 0.024 (0.281) | 0.268 (3.242) ** | −0.016 (−0.215) | ||

| Planning AMT | 0.195 (2.294) * | 0.308 (3.090) ** | 0.214 (2.319) * | 0.297 (3.110) ** | 0.168 (2.141) * | ||

| Mediation | |||||||

| IEC | 0.697 (13.089) *** | 0.480 (6.200) *** | 0.865 (18.855) *** | 0.661 (10.054) *** | |||

| R2 | 0.568 | 0.444 | 0.494 | 0.538 | 0.528 | 0.652 | 0.692 |

| Adjusted R2 | 0.554 | 0.427 | 0.483 | 0.521 | 0.514 | 0.645 | 0.681 |

| F-value | 41.842 *** | 25.468 *** | 47.015 *** | 31.598 *** | 35.672 *** | 90.341 *** | 61.035 *** |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, T.; Feng, T.; Ye, C. Advanced Manufacturing Technologies and Green Innovation: The Role of Internal Environmental Collaboration. Sustainability 2016, 8, 1056. https://doi.org/10.3390/su8101056

Kong T, Feng T, Ye C. Advanced Manufacturing Technologies and Green Innovation: The Role of Internal Environmental Collaboration. Sustainability. 2016; 8(10):1056. https://doi.org/10.3390/su8101056

Chicago/Turabian StyleKong, Ting, Taiwen Feng, and Chunming Ye. 2016. "Advanced Manufacturing Technologies and Green Innovation: The Role of Internal Environmental Collaboration" Sustainability 8, no. 10: 1056. https://doi.org/10.3390/su8101056

APA StyleKong, T., Feng, T., & Ye, C. (2016). Advanced Manufacturing Technologies and Green Innovation: The Role of Internal Environmental Collaboration. Sustainability, 8(10), 1056. https://doi.org/10.3390/su8101056