Development of Manufacturing Sustainability Assessment Using Systems Thinking

Abstract

:1. Introduction

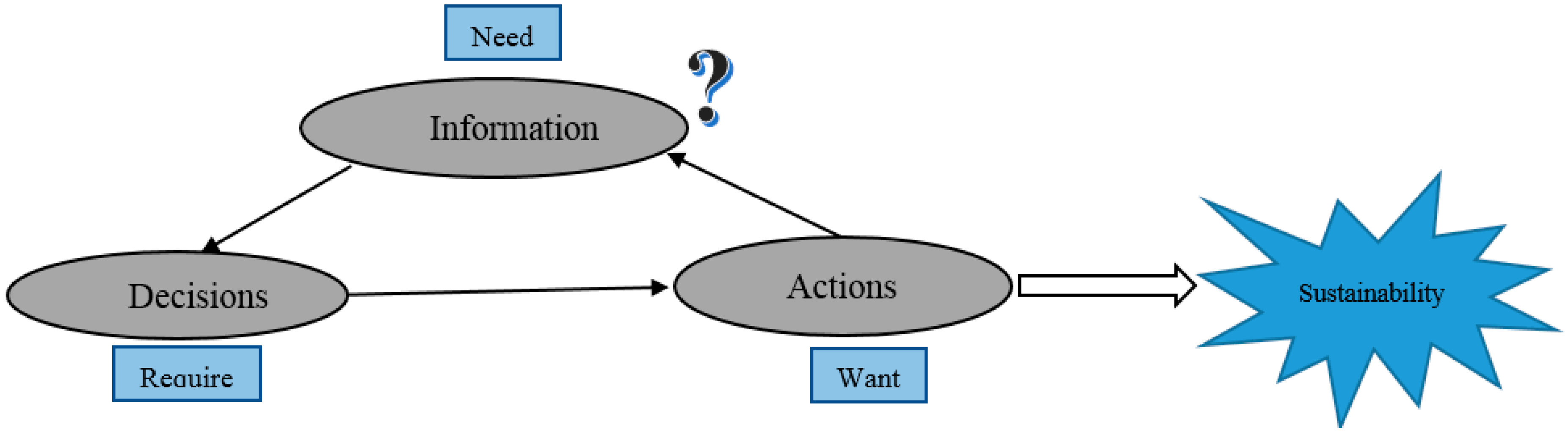

2. Sustainability Assessment

- “the process that directs decision-making towards sustainability” [27];

- “a process that aims to integrate sustainability issues into decision-making by identifying sustainability impacts, but also by fostering sustainability objectives to be achieved” [28];

- “an important tool to aid in the shift towards sustainability… and a process by which the implications of an initiative on sustainability are evaluated, where the initiative can be a proposed or existing policy, plan, programme, project, piece of legislation, or a current practice or activity” [6];

- “a tool that can help decision-makers and policy-makers decide what actions they should take and should not take in an attempt to make society more sustainable” [29];

- “the tool that can help decision and policymakers select which actions are to be taken to make society more sustainable” [30].

| Paper | Categorization Dimensions | Approaches to Sustainability Assessment |

|---|---|---|

| Ness et al. [5] |

|

|

| Pope et al. [6] |

| |

| Pope et al. [1] based on [6] |

| |

| Videira et al. [7] based on [6] |

| |

| Wiek and Binder [31] |

| |

| Pope et al. [1] |

| |

| Huge et al. [32] |

| |

| Hacking and Guthrie [33] |

|

- Information generation for decision-making;

- Operationalization and forum for participation, debate and deliberation;

- Social learning;

- Structuring complexity.

3. The Need for a New Sustainability Assessment Tool

3.1. Shortcomings: Methodology behind a Tool

3.2. Shortcomings: Implementation of a Tool

3.3. Lessons Learned

4. Systems Thinking and Sustainability Assessment

4.1. Defining Thinking

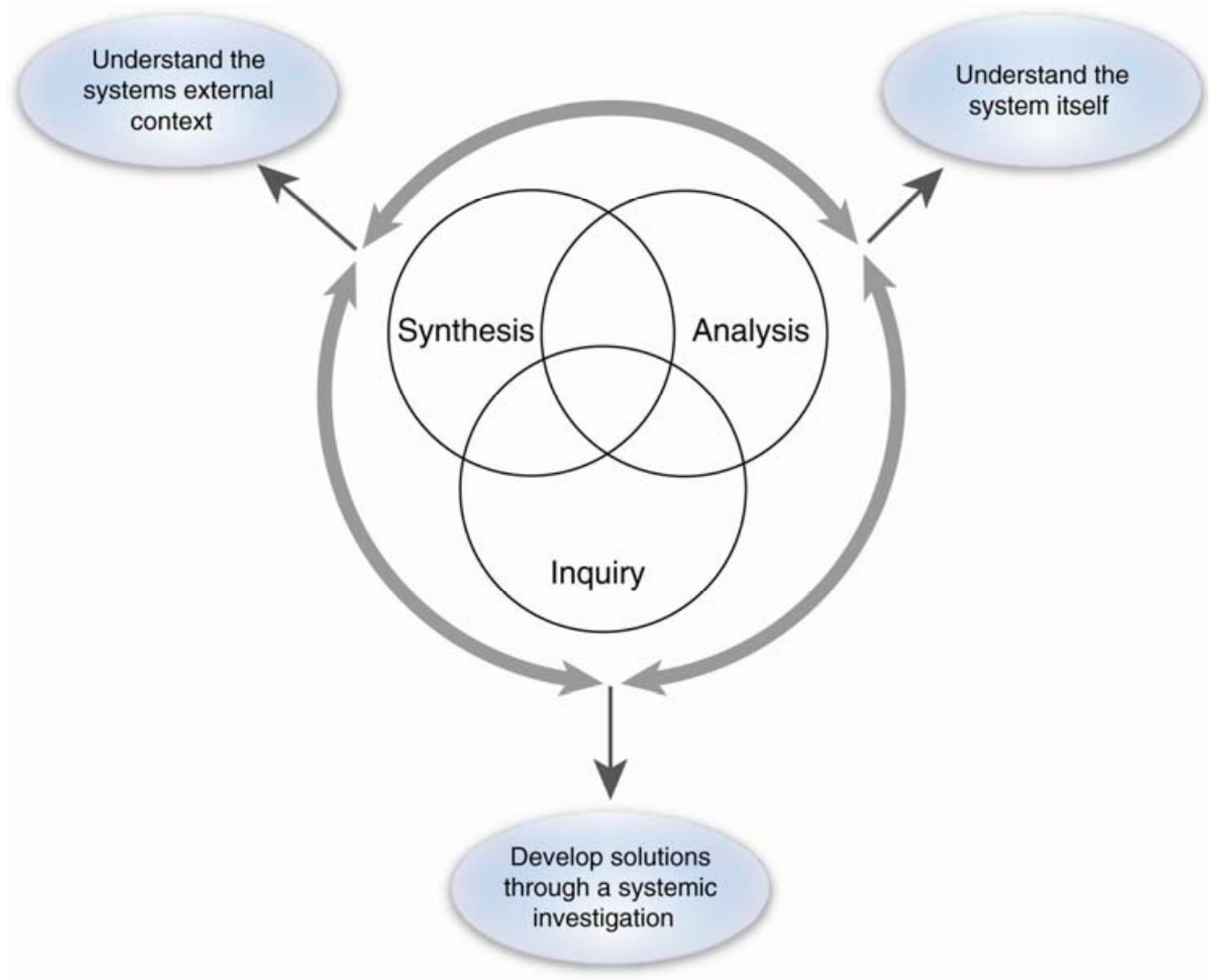

4.2. Applying Systems Thinking to Sustainability Assessment

- Overly identify “enduring well-being” as the sustainability objective;

- Contextualize the role of the proposed actions in terms of the necessary transition to sustainability at the focal and global scale;

- Identify the causal relationships, feedback and delay that determine the dynamics of the focal socio-ecological system in the absence of the proposed action;

- Use this understanding to formulate alternative approaches to achieving the objectives of the proposed action;

- Identify the possible consequences of the alternatives;

- Formulate the preferred solution based on the enhanced understanding of system behavior;

- Guide the development of an adaptive management approach whereby system changes are monitored, the model is refined, and actions are revised in response.

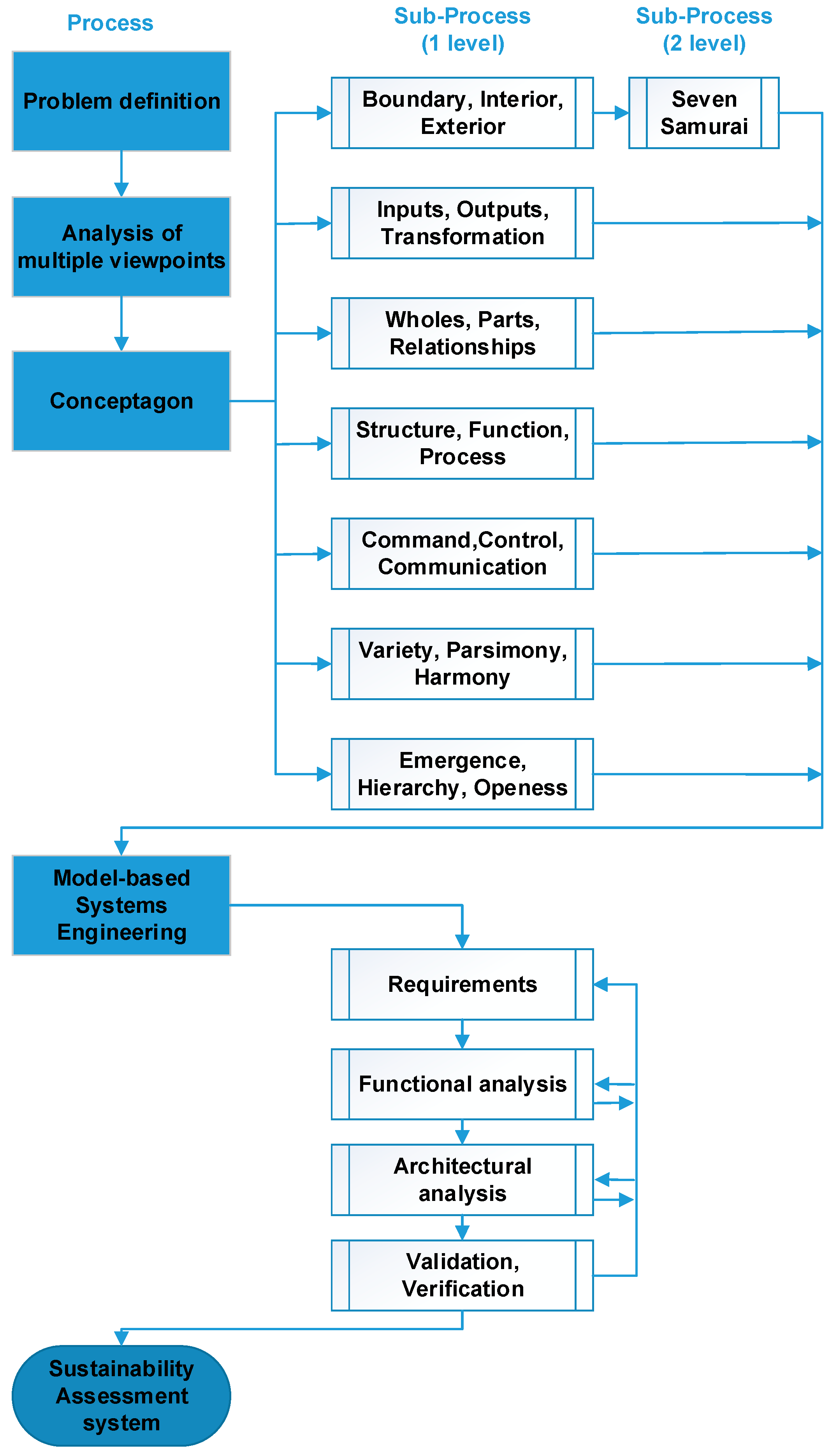

5. Development of Sustainability Assessment System Using the Systems Thinking

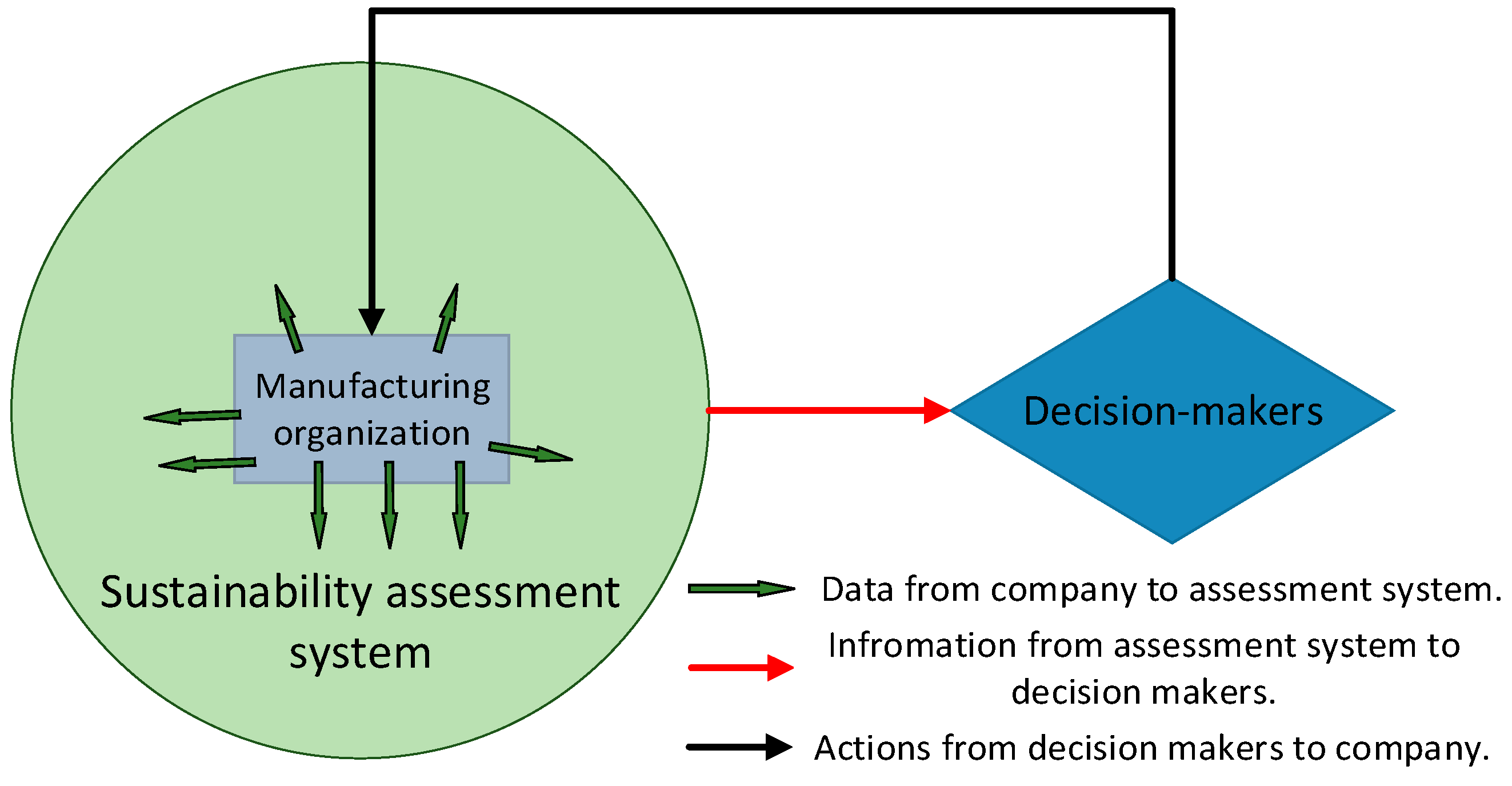

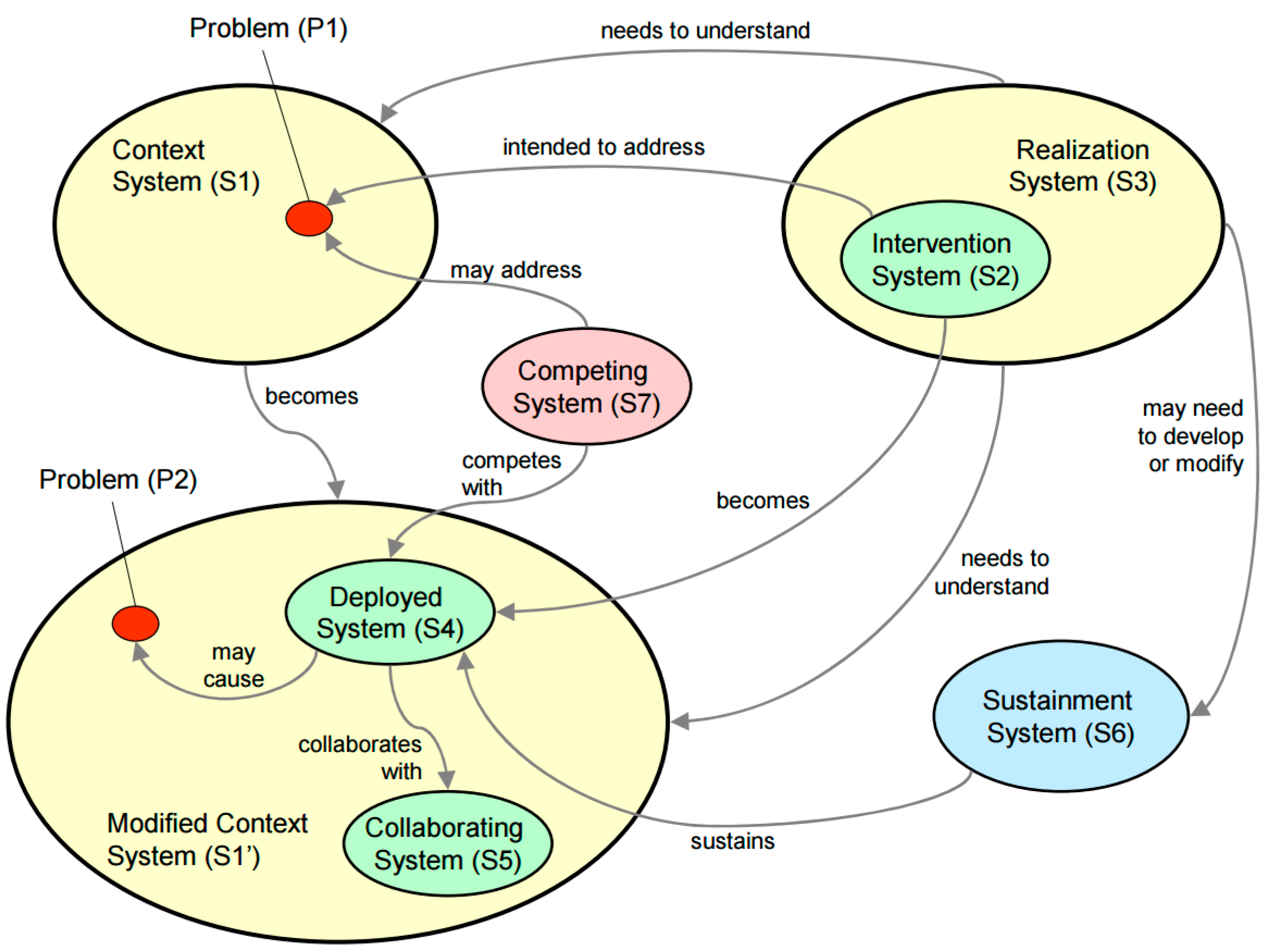

5.1. Problem Definition

5.2. Analysis of Multiple Viewpoints

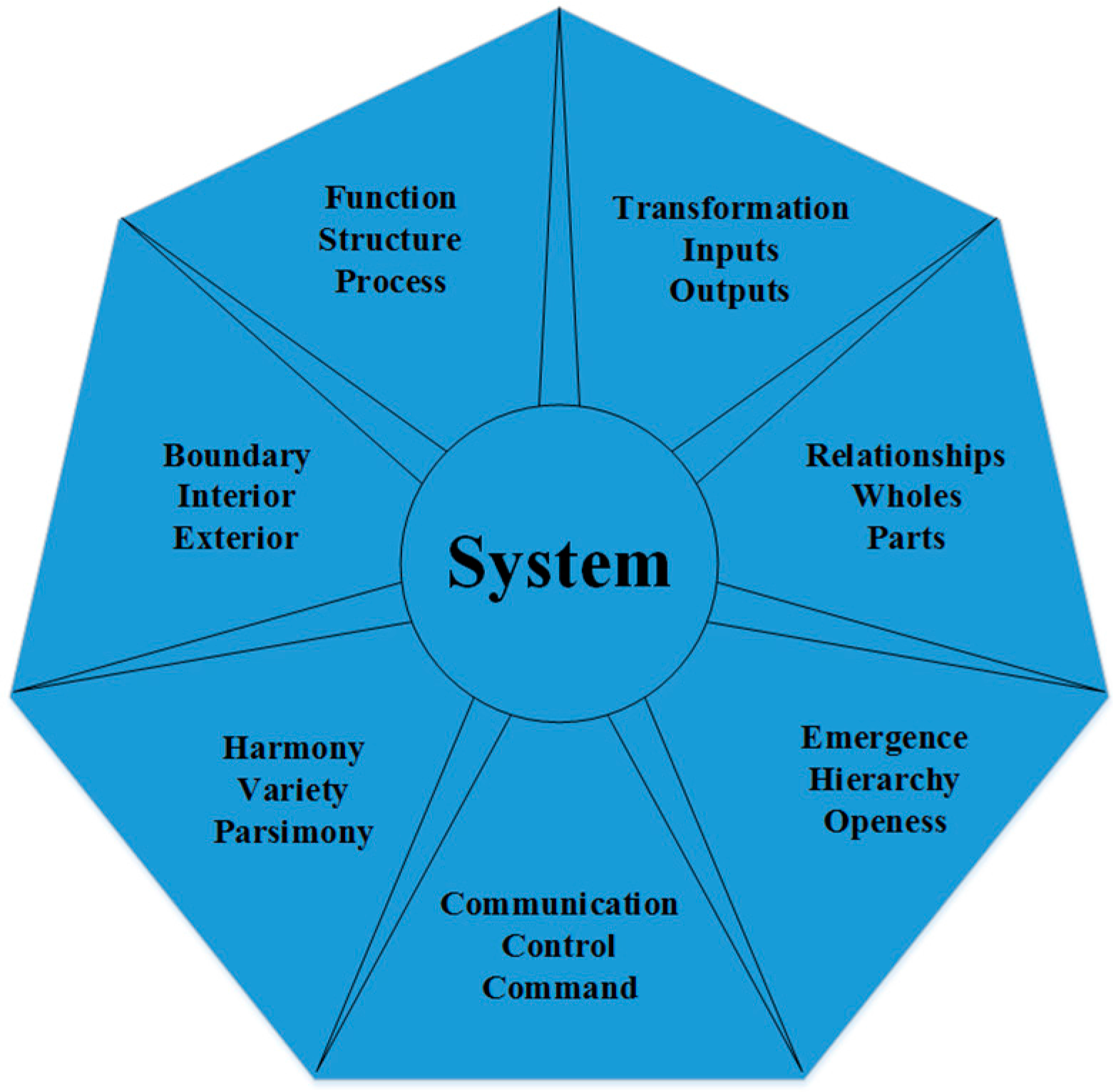

5.3. Conceptagon

5.3.1. Boundary, Interior, Exterior

5.3.2. Inputs, Outputs, Transformation

5.3.3. Wholes, Parts, Relationships

5.3.4. Structure, Function, Process

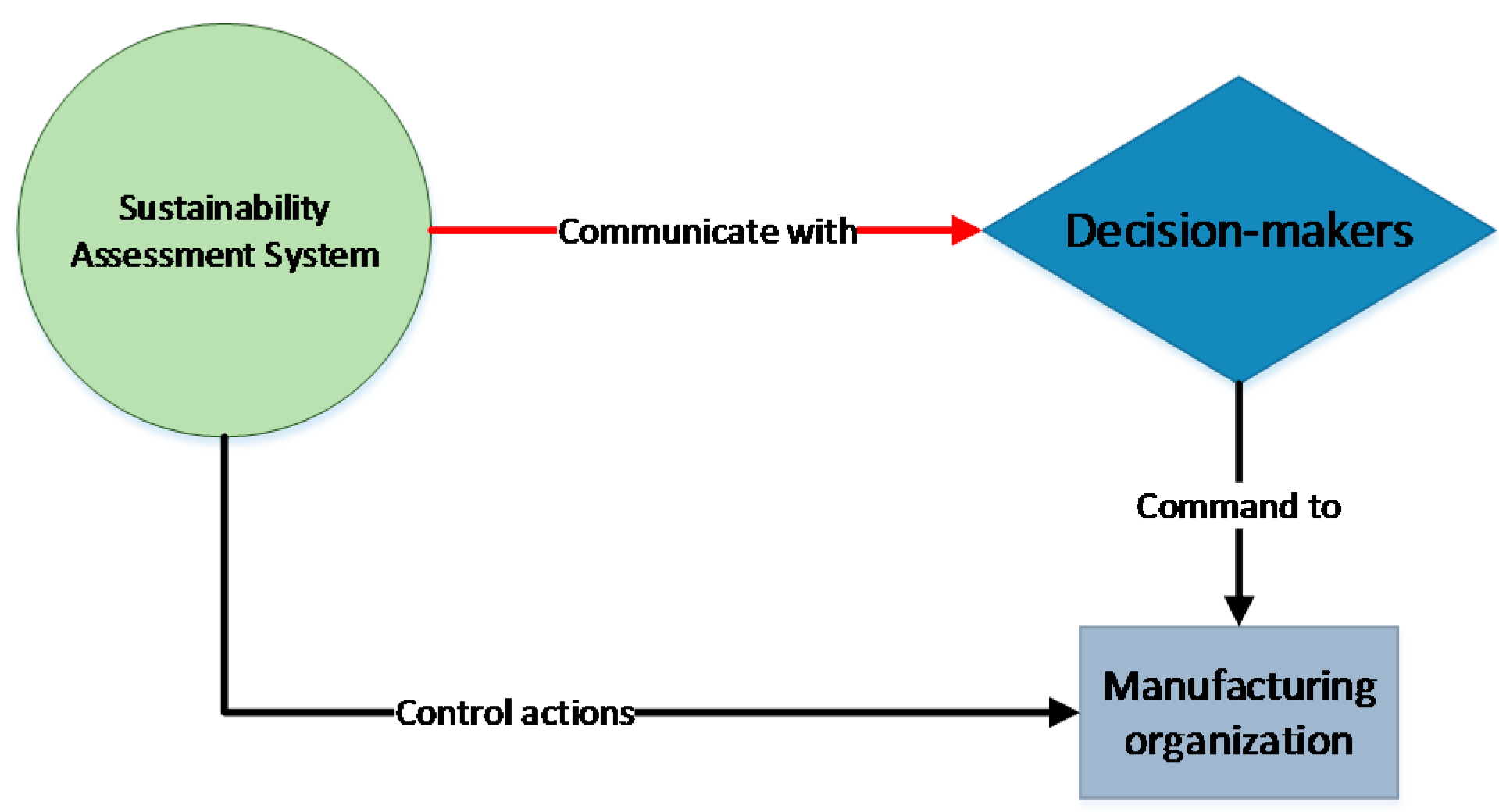

5.3.5. Command, Control, Communication

5.3.6. Variety, Parsimony, Harmony

5.3.7. Emergence, Hierarchy, Openness

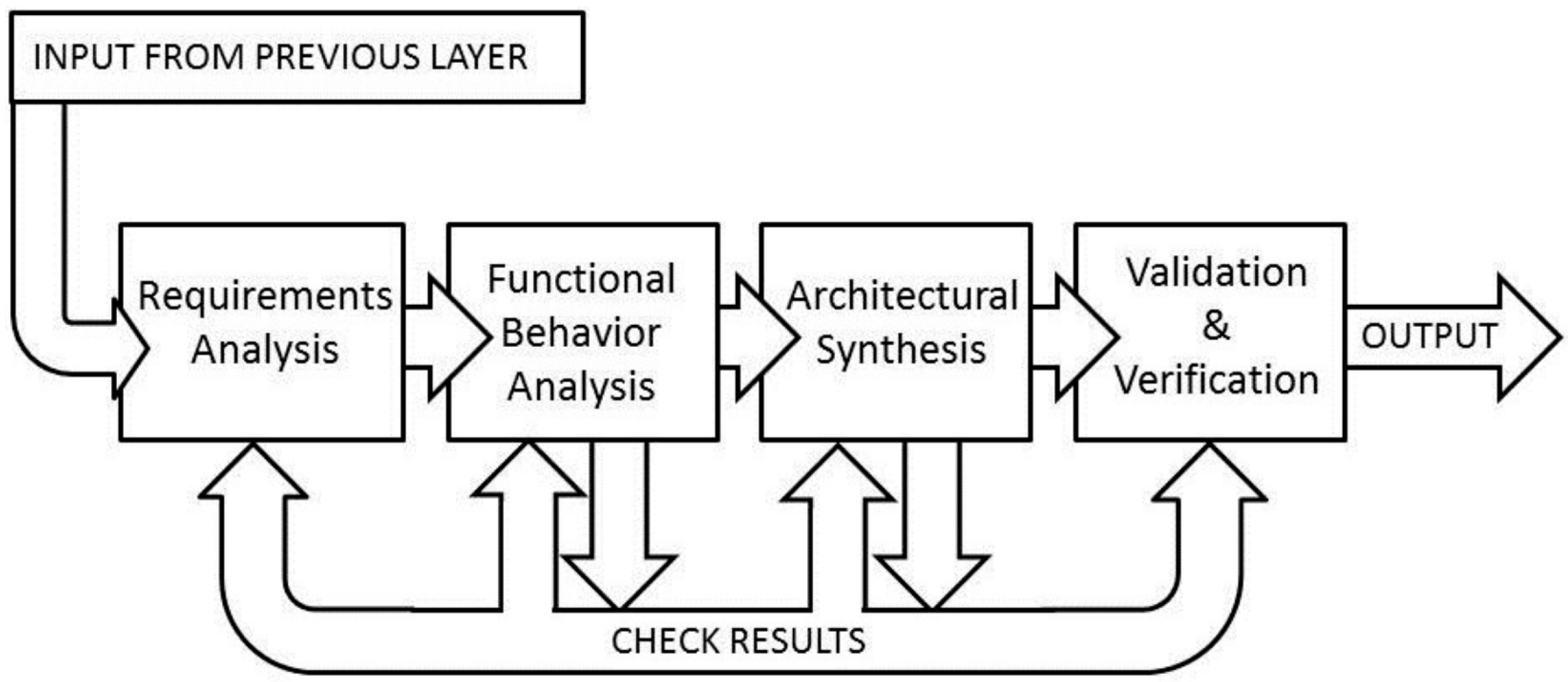

5.4. Model-Based Systems Engineering

5.4.1. Requirements Analysis

- Operational requirements—what is the purpose of the sustainability assessment system? (e.g., to provide information about issues which require improvements);

- Functional requirements—what should the system do? (e.g., address social aspect, address manufacturing processes, and address information flow);

- Interface requirements—how should the tool interact with external systems? (e.g., receive data from ERP automatically). This is addressed partly by Seven Samurai tool;

- Adaptability requirements—potential extensions and growth, e.g., ability to include additional sustainability criteria for assessment. This type of requirements refers to one of the conceptagon triple—openness, hierarchy, and emergence;

- Logistical requirements—sustainment, e.g., training of people.

| What to consider during the assessment: |

| Address intergenerational equity |

| Address intragenerational equity |

| Address geographical equity |

| Address interspecies equity |

| Address procedural equity |

| Assess the system as a whole, including it parts and their interactions |

| Assess the system considering the different sustainability objectives together (integration) |

| Assess dynamics and interactions between trends and drivers of change |

| Adopt appropriate time horizon (short, medium, and long term) and (geographical) scope |

| Consider the normative nature of sustainability |

| Assessment of sustainability impacts and alternatives for decision-making, including synergies and trade-offs |

| Assessment is based on a conceptual sustainability framework and its indicators |

| Adapted to and integrated into the institutional context |

| Relations to global sustainability |

| Address socio-ecological system integrity |

| Address livelihood sufficiency and opportunity |

| Address resource maintenance and efficiency |

| Address socio-ecological civility and democratic governance |

| Address precaution and adaptation |

| Address immediate and long-term integration |

| Address resources consumption versus value creation |

| Triple bottom line consideration |

| Consider each product life cycle stage |

| How to do assessment: |

| Establish formal and transparent synergy/trade-off rules |

| Be responsive to change, including uncertainties and risks (dynamism) |

| Avoid irreversible risks and favors a precautionary approach |

| Mix of qualitative and quantitative metrics |

| Broad participation of stakeholders, including experts, while providing active leadership to the process |

| Develop and maintain adequate capacity |

| Continuous learning and improvement |

| Transparency regarding data (sources, methods), indicators, results, choices, assumptions, uncertainties, funding bodies and potential conflicts of interest |

| Ensure effective communications (clear language, fair and objective, visualization tools and graphics, make data appropriately available) |

| Iterative assessment process, starting at the onset of the decision-making process |

| Mix of leading and lagging indicators |

| Mix of absolute and relative metrics |

| Tradeoffs between external and internal performance measures |

| Integration of indicators across different policy arena |

| Reference values for indicators |

| Avoid “data drivenness” |

| Address interlinkages (socio-economic, socio-environmental, environmental-economic) |

5.4.2. Functional Behavior Analysis

5.4.3. Architectural Synthesis

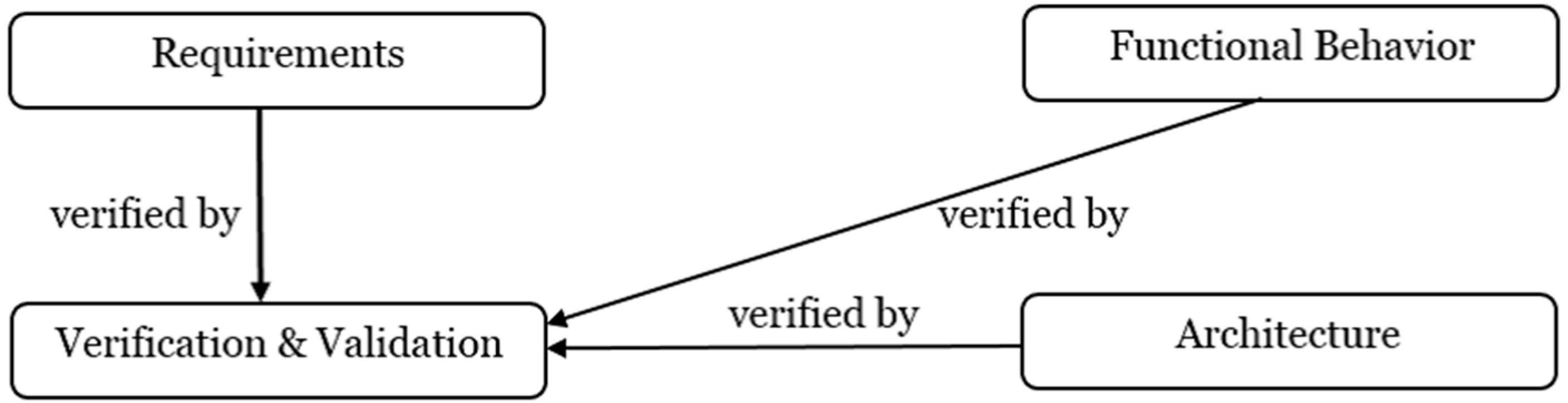

5.4.4. Validation and Verification

6. Conclusions

- Analysis of multiple viewpoints incorporates the idea of systems thinking of existence of multiple views on any system. In addition, analysis enables incorporation of pluralism into sustainability assessment.

- The conceptagon provides a structured and organized way to ensure that all significant aspects of the system are addressed e.g., emergence, relationships, boundaries, function, structure, purpose.

- Seven Samurai highlights interfaces between the sustainability assessment system and exterior, enriching a development process and may enhance the applicability of sustainability assessment.

- Model-based systems engineering assists the development process by helping to deal with complexity. The requirements analysis ensures that plurality of sustainability assessment is addressed. The functional analysis ensure that the focus is on the purpose of the assessment instead of on the means of it. The architectural analysis based on the system dynamics modeling can ensure that the ideas of systems thinking, which address the manufacturing dynamics, will be incorporated into sustainability assessment of a manufacturing organization.

- A clear definition of the problem that a particular sustainability assessment tends to address have to be given in the beginning of every development process.

- More attention should be paid to analysis of multiple viewpoints as a measure to overcome the gap between researchers and manufacturing and to address pluralism of sustainability assessment.

- A focus on the sustainability assessment system and its connections with exterior systems may increase applicability of the sustainability assessment in manufacturing.

- A clear understanding of the purpose and, thus, the output of sustainability assessment can enhance development of the architecture of the sustainability assessment and the choice of criteria for assessment.

- Sustainability assessment that captures dynamics of manufacturing can address situations that manufacturing may experience e.g., shift of a problem, sub-optimization, or solution that become a problem.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pope, J.; Bond, A.; Morrison-Saunders, A. A conceptual framework for sustainability assessment. In Handbook of Sustainability Assessment; Morrison-Saunders, A., Pope, J., Bond, A., Eds.; Edward Elgar: Northampton, UK, 2015; pp. 20–42. [Google Scholar]

- Bell, S.; Morse, S. Sustainability Indicators: Measuring the Immeasurable? Earthscan: Oxford, UK, 2008. [Google Scholar]

- Hopwood, B.; Mellor, M.; O’Brien, G. Sustainable development: Mapping different approaches. Sustain. Dev. 2005, 13, 38–52. [Google Scholar] [CrossRef]

- Bond, A.; Morrison-Saunders, A.; Howitt, R. Framework for comparing and evaluating sustainability assessment practice. In Sustainability Assessment: Pluralism, Practice and Progress; Routledge: London, UK, 2013; pp. 117–131. [Google Scholar]

- Ness, B.; Urbel-Piirsalu, E.; Anderberg, S.; Olsson, L. Categorising tools for sustainability assessment. Ecol. Econ. 2007, 60, 498–508. [Google Scholar] [CrossRef]

- Pope, J.; Annandale, D.; Morrison-Saunders, A. Conceptualising sustainability assessment. Environ. Impact Assess. Rev. 2004, 24, 595–616. [Google Scholar] [CrossRef]

- Videira, N.; Antunes, P.; Santos, R.; Lopes, R. A participatory modelling approach to support integrated sustainability assessment processes. Syst. Res. Behav. Sci. 2010, 27, 446–460. [Google Scholar] [CrossRef]

- Faulkner, W.; Badurdeen, F. Sustainable value stream mapping (sus-vsm): Methodology to visualize and assess manufacturing sustainability performance. J. Clean. Prod. 2014, 85, 8–18. [Google Scholar] [CrossRef]

- Singh, S.; Olugu, E.; Fallahpour, A. Fuzzy-based sustainable manufacturing assessment model for smes. Clean Technol. Environ. Policy 2014, 16, 847–860. [Google Scholar] [CrossRef]

- Zhang, H.; Haapala, K.R. Integrating sustainable manufacturing assessment into decision making for a production work cell. J. Clean. Prod. 2014, 105, 52–63. [Google Scholar] [CrossRef]

- Chen, D.; Thiede, S.; Schudeleit, T.; Herrmann, C. A holistic and rapid sustainability assessment tool for manufacturing smes. CIRP Ann.—Manuf. Technol. 2014, 63, 437–440. [Google Scholar] [CrossRef]

- Chen, D.; Schudeleit, T.; Posselt, G.; Thiede, S. A state-of-the-art review and evaluation of tools for factory sustainability assessment. Procedia CIRP 2013, 9, 85–90. [Google Scholar] [CrossRef]

- Rosen, M.A.; Kishawy, H.A. Sustainable manufacturing and design: Concepts, practices and needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

- Paju, M.; Heilala, J.; Hentula, M.; Heikkil, A.; Johansson, B.; Leong, S.; Lyons, K. Framework and Indicators for a Sustainable Manufacturing Mapping Methodology. In Proceedings of the 2010 Winter Simulation Conference, Baltimore, Maryland, 5–8 December 2010; pp. 3411–3422.

- Hasna, A.M. A review of sustainability assessment methods in engineering. Int. J. Environ. Cult. Econ. Social Sustain. 2008, 5, 161–176. [Google Scholar]

- Moneim, A.F.A.; Galal, N.M.; Shakwy, M.E. Sustainable Manufacturing Indicators. In Proceedings of the Global Climate Change: Biodiversity and Sustainability, Alexandria, Egypt, 15–18 April 2013.

- Feng, S.C.; Joung, C.B. An Overview of a Proposed Measurement Infrastructure for Sustainable Manufacturing. In Proeedings of the 7th Global Conference on Sustainable Manufacturing, Chennai, India, 2–4 December 2009; p. 12.

- Poveda, C.A.; Lipsett, M.G. A review of sustainability assessment and sustainability/environmental rating systems and credit weighting tools. J. Sustain. Dev. 2011, 4, 36–55. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2012, 15, 281–299. [Google Scholar] [CrossRef]

- Ioppolo, G.; Cucurachi, S.; Salomone, R.; Saija, G.; Ciraolo, L. Industrial ecology and environmental lean management: Lights and shadows. Sustainability 2014, 6, 6362–6376. [Google Scholar] [CrossRef]

- Deutz, P.; Ioppolo, G. From theory to practice: Enhancing the potential policy impact of industrial ecology. Sustainability 2015, 7, 2259–2273. [Google Scholar] [CrossRef]

- Moldavska, A.; Welo, T. On the applicability of sustainability assessment tools in manufacturing. Procedia CIRP 2015, 29, 621–626. [Google Scholar] [CrossRef]

- Grace, W.; Pope, J. A systems approach to sustainability assessment. In Handbook of Sustainability Assessment; Morrison-Saunders, A., Pope, J., Bond, A., Eds.; Edward Elgar: Northampton, UK, 2015; pp. 285–320. [Google Scholar]

- Cashmore, M.A.; Kørnøv, L. The changing theory of impact assessment. In Sustainability Assessment: Pluralism, Practice and Progress; Bond, A., Morrison-Saunders, A., Howitt, R., Eds.; Routledge: London, UK, 2013; pp. 18–33. [Google Scholar]

- Bond, A.; Pope, J.; Morrison-Saunders, A. Introducing the roots, evolution and effectiveness of sustainability assessment. In Handbook of Sustainability Assessment; Morrison-Saunders, A., Pope, J., Bond, A., Eds.; Edward Elgar: Northampton, UK, 2015; pp. 3–19. [Google Scholar]

- Marsden, G.; Kimble, M.; Nellthorp, J.; Kelly, C. Sustainability assessment: The definition deficit. Int. J. Sustain. Transp. 2010, 4, 189–211. [Google Scholar] [CrossRef]

- Bond, A.J.; Morrison-Saunders, A. Re-evaluating sustainability assessment: Aligning the vision and the practice. Environ. Impact Assess. Rev. 2011, 31, 1–7. [Google Scholar] [CrossRef]

- Hugé, J.; Waas, T.; Eggermont, G.; Verbruggen, A. Impact assessment for a sustainable energy future—Reflections and practical experiences. Energy Policy 2011, 39, 6243–6253. [Google Scholar] [CrossRef]

- Devuyst, D.; Hens, L.; de Lannoy, W. How Green is the City?: Sustainability Assessment and the Management of Urban Environments; Columbia University Press: New York, NY, USA, 2001; p. 457. [Google Scholar]

- Langeveld, H.; Sanders, J.; Meeusen, M. The Biobased Economy: Biofuels, Materials and Chemicals in the Post-Oil Era; Routledge: London, UK, 2012. [Google Scholar]

- Wiek, A.; Binder, C. Solution spaces for decision-making—A sustainability assessment tool for city-regions. Environ. Impact Assess. Rev. 2005, 25, 589–608. [Google Scholar] [CrossRef]

- Hugé, J.; Waas, T.; Dahdouh-Guebas, F.; Koedam, N.; Block, T. A discourse-analytical perspective on sustainability assessment: Interpreting sustainable development in practice. Sustain. Sci. 2013, 8, 187–198. [Google Scholar] [CrossRef]

- Hacking, T.; Guthrie, P. A framework for clarifying the meaning of triple bottom-line, integrated, and sustainability assessment. Environ. Impact Assess. Rev. 2008, 28, 73–89. [Google Scholar] [CrossRef]

- Waas, T.; Hugé, J.; Block, T.; Wright, T.; Benitez-Capistros, F.; Verbruggen, A. Sustainability assessment and indicators: Tools in a decision-making strategy for sustainable development. Sustainability 2014, 6, 5512–5534. [Google Scholar] [CrossRef]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Fan, C.; Carrell, J.D.; Zhang, H.-C. An Investigation of Indicators for Measuring Sustainable Manufacturing. In Proceedings of the 2010 IEEE International Symposium on Sustainable Systems and Technology (ISSST), Arlington, VA, USA, 17–19 May 2010; pp. 1–5.

- Veleva, V.; Ellenbecker, M. Indicators of sustainable production: Framework and methodology. J. Clean. Prod. 2001, 9, 519–549. [Google Scholar] [CrossRef]

- NIST. Sustainable manufacturing indicators repository. Available online: http://www.mel.nist.gov/msid/SMIR/ (accessed on 26 December 2015).

- Taisch, M.; Sadr, V.; May, G.; Stahl, B. Sustainability assessment tools—State of research and gap analysis. In Advances in Production Management Systems. Sustainable Production and Service supply Chains; Prabhu, V., Taisch, M., Kiritsis, D., Eds.; Springer: Berlin, Germany, 2013; Volume 415, pp. 426–434. [Google Scholar]

- Sikdar, S.K. Sustainable development and sustainability metrics. AIChE J. 2003, 49, 1928–1932. [Google Scholar] [CrossRef]

- Clancy, G.; Fröling, M.; Svanström, M. Insights from guiding material development towards more sustainable products. Int. J. Sustain. Des. 2013, 2, 149–166. [Google Scholar] [CrossRef]

- Ameta, G.; Rachuri, S.; Fiorentini, X.; Mani, M.; Fenves, S.; Lyons, K.; Sriram, R. Extending the notion of quality from physical metrology to information and sustainability. J. Intell. Manuf. 2011, 22, 737–750. [Google Scholar] [CrossRef]

- Brown, A.; Amundson, J.; Badurdeen, F. Sustainable value stream mapping (sus-vsm) in different manufacturing system configurations: Application case studies. J. Clean. Prod. 2014, 85, 164–179. [Google Scholar] [CrossRef]

- Lanz, M.; Järvenpää, E.; Nylund, H.; Tuokko, R.; Torvinen, S.; Georgoulias, K. Sustainability and performance indicators landscape. In Proceedings of the 24th International Conference on Flexible Automation and Intelligent Manufacturing, San Antonio, TX, USA, 20–23 May 2014; p. 8.

- Spitzer, D.R. Transforming Performance Measurement: Rethinking the Way We Measure and Drive Organizational Success; American Management Association: New York, NY, USA, 2007. [Google Scholar]

- Hák, T.; Moldan, B.; Dahl, A.L. Sustainability Indicators: A scientific Assessment; Island Press: Washington, DC, USA, 2012. [Google Scholar]

- Fantini, P.; Palasciano, C.; Taisch, M. Back to intuition: Proposal for a performance indicators framework to facilitate eco-factories management and benchmarking. Procedia CIRP 2015, 26, 1–6. [Google Scholar] [CrossRef]

- Snodgrass, D. A Note on Indicators of Sustainability for Value Chain Projects; United States Agency for International Development: Washing, DC, USA, 2012. [Google Scholar]

- Andrews, E.S.; Barthel, L.-P.; Beck, T.; Benoît, C.; Ciroth, A.; Cucuzzella, C.; Gensch, C.-O.; Hébert, J.; Lesage, P.; Manhart, A.; et al. Guidelines for Social Life Cycle Assessment of Products; UNEP: Nairobi, Kenya, 2009; p. 104. [Google Scholar]

- Gibson, R.B. Beyond the pillars: Sustainability assessment as a framework for effective integration of social, economic and ecological considerations in significant decision-making. J. Environ. Assess. Policy Manag. 2006, 8, 259–280. [Google Scholar] [CrossRef]

- Fischer, J.; Weinert, N.; Herrmann, C. Method for selecting improvement measures for discrete production environments using an extended energy value stream model. Procedia CIRP 2015, 26, 133–138. [Google Scholar] [CrossRef]

- Despeisse, M.; Oates, M.R.; Ball, P.D. Sustainable manufacturing tactics and cross-functional factory modelling. J. Clean. Prod. 2013, 42, 31–41. [Google Scholar] [CrossRef]

- Despeisse, M.; Ball, P.D.; Evans, S.; Levers, A. Industrial ecology at factory level—A conceptual model. J. Clean. Prod. 2012, 31, 30–39. [Google Scholar] [CrossRef]

- Richmond, B. Systems thinking/system dynamics: Let’s just get on with it. Syst. Dyn. Rev. 1994, 10, 135–157. [Google Scholar] [CrossRef]

- Senge, P.M. The Fifth Discipline: The Art and Practice of the Learning Organization; Doubleday/Currency: New York, NY, USA, 1990. [Google Scholar]

- Klir, G. Facets of Systems Science; Springer US: New York, NY, USA, 2013. [Google Scholar]

- Edson, R. Systems Thinking. Applied. A Primer; Applied Systems Thinking (ASYST) Institute, Analytic Services Inc.: Arlington, VA, USA, 2008. [Google Scholar]

- Gharajedaghi, J. Systems Thinking: Managing Chaos and Complexity: A platform for Designing Business Architecture; Elsevier Science: Philadelphia, PA, USA, 2011. [Google Scholar]

- Sterman, J. Business Dynamics: Systems Thinking and Modeling for a Complex World; Irwin/McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Saha, P. A Systemic Perspective to Managing Complexity with Enterprise Architecture; IGI Global: Hershey, PA, USA, 2013. [Google Scholar]

- Kelly, K.L. A systems approach to identifying decisive information for sustainable development. Eur. J. Oper. Res. 1998, 109, 452–464. [Google Scholar] [CrossRef]

- Skaržauskienė, A. Managing complexity: Systems thinking as a catalyst of the organization performance. Meas. Bus. Excell. 2010, 14, 49–64. [Google Scholar]

- Halog, A.; Manik, Y. Advancing integrated systems modelling framework for life cycle sustainability assessment. Sustainability 2011, 3, 469. [Google Scholar] [CrossRef]

- Zhang, H.; Calvo-Amodio, J.; Haapala, K.R. A systems thinking approach for modeling sustainable manufacturing problems in enterprises. In Proceedings of the International Annual Conference (IAC) of the American Society for Engineering Management (ASEM), Minneapolis, MI, USA, 3–5 October 2013.

- Uphoff, N. Systems thinking on intensification and sustainability: Systems boundaries, processes and dimensions. Curr. Opin. Environ. Sustain. 2014, 8, 89–100. [Google Scholar] [CrossRef]

- Halog, A.; Awuah, N. The Need for Integrated Life Cycle Sustainability Analysis of Biofuel Supply Chains; INTECH Open Access Publisher: Rijeka, Croatia, 2013. [Google Scholar]

- Byomkesh, T.; Blay-Palmer, A. Incorporating system thinking in assessments of food and agriculture system sustainability. In Graduate Student Workshop of Waterloo Food Issues Group; WatFIG: Waterloo, ON, Canada, 2013. [Google Scholar]

- Tejeda, J.; Ferreira, S. Applying systems thinking to analyze wind energy sustainability. Procedia Comput. Sci. 2014, 28, 213–220. [Google Scholar] [CrossRef]

- Gibson, R.B.; Hassan, S. Sustainability Assessment: Criteria and Processes; Earthscan: Oxford, UK, 2005; p. 254. [Google Scholar]

- Gaudreau, K.; Gibson, R.B. Illustrating integrated sustainability and resilience based assessments: A small-scale biodiesel project in barbados. Impact Assess. Proj. Apprais. 2010, 28, 233–243. [Google Scholar] [CrossRef]

- Meadows, D.; Wright, D. Thinking in Systems: A Primer; Chelsea Green Publishing: Hartford, VT, USA, 2008. [Google Scholar]

- Boardman, J.; Sauser, B.; John, L.; Edson, R. The Conceptagon: A Framework for Systems Thinking and Systems Practice. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics, Antonio, TX, USA, 11–14 October 2009; pp. 3299–3304.

- Nooteboom, S. Impact assessment procedures for sustainable development: A complexity theory perspective. Environ. Impact Assess. Rev. 2007, 27, 645–665. [Google Scholar] [CrossRef]

- Mitchell, R.K.; Agle, B.R.; Wood, D.J. Toward a theory of stakeholder identification and salience: Defining the principle of who and what really counts. Acad. Manag. Rev. 1997, 22, 853–886. [Google Scholar]

- Freeman, R.E. Strategic Management: A Stakeholder Approach; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Lützkendorf, T.; Hájek, P.; Lupíšek, A.; Immendörfer, A.; Nibel, S.; Häkkinen, T. New trends in sustainability assessment systems—Based on top-down approach and stakeholders needs. Int. J. Sustain. Build. Technol. Urban Dev. 2012, 3, 256–269. [Google Scholar] [CrossRef]

- Mathur, V.N.; Price, A.D.F.; Austin, S.A.; Moobela, C. Defining, Identifying and Mapping Stakeholders in the Assessment of Urban Sustainability. In Proceedings of the SUE-MOT International Conference on Whole Life Urban Sustainability and Its Assessment, Glasgow, Scotland, 27–29 June 2007; Horner, M., Hardcastle, C., Price, A., Bebbington, J., Eds.; p. 18.

- Triste, L.; Marchand, F.; Debruyne, L.; Meul, M.; Lauwers, L. Reflection on the development process of a sustainability assessment tool: Learning from a flemish case. Ecol. Soc. 2014, 19. Article 47. [Google Scholar] [CrossRef]

- Whitmarsh, L.; Nykvist, B. Integrated sustainability assessment of mobility transitions: Simulating stakeholders’ visions of and pathways to sustainable land-based mobility. Int. J. Innov. Sustain. Dev. 2008, 3, 115–127. [Google Scholar] [CrossRef]

- Berardi, U. Chapter 15—Sustainability assessments of buildings, communities, and cities. In Assessing and Measuring Environmental Impact and Sustainability; Klemeš, J.J., Ed.; Butterworth-Heinemann: Oxford, UK, 2015; pp. 497–545. [Google Scholar]

- Lützkendorf, T.; Balouktsi, M.; Immendörfer, A.; Nibel, S.; Bosdevigie, B.; Lebert, A.; Fies, B.; Iñarra, P.H.; Lupíšek, A.; Hajek, P.; et al. Sustainability and Performance Assessment and Benchmarking of Buildings; VTT: Espoo, Finland, 2012. [Google Scholar]

- Driscoll, C.; Starik, M. The primordial stakeholder: Advancing the conceptual consideration of stakeholder status for the natural environment. J. Bus. Ethics 2004, 49, 55–73. [Google Scholar] [CrossRef]

- McGee, S.; Edson, R. Extending the conceptagon as an analytic framework: A case study of public preparedness in israel. In Proceedings of the 8th Conference on Systems Engineering Research, Hoboken, NJ, USA, 17–19 March 2010.

- McGee, S.; Joel, M.; Edson, R. Mexico’s Cartel Problem: A Systems Thinking Perspective; Applied Systems Thinking Institute, Analytic Services, Inc.: Arlington, VA, USA, 2011. [Google Scholar]

- Martin, J.N. The seven samurai of systems engineering: Dealing with the complexity of 7 interrelated systems. In Proceedings of the INCOSE International Symposium, Toulouse, France, 20–24 June 2004; Volume 14, pp. 459–470.

- Boardman, J.; Sauser, B. Systems Thinking: Coping with 21st Century Problems; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Long, D.; Scott, Z. A Primer for Model-Based Systems Engineering; Vitech Company: Blacksburg, VA, USA, 2011. [Google Scholar]

- Fiksel, J.; McDaniel, J.; Mendenhall, C. Measuring Progress towards Sustainability Principles, Process, and Best Practices. In Proceedings of the Greening of Industry Network Conference Best Practice Proceedings, Chapell Hill, NC, USA, 14–17 November 1999.

- Ahi, P.; Searcy, C. An analysis of metrics used to measure performance in green and sustainable supply chains. J. Clean. Prod. 2015, 86, 360–377. [Google Scholar] [CrossRef]

- Meyer, M.W. Rethinking Performance Measurement: Beyond the Balanced Scorecard; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Pintér, L.; Hardi, P.; Martinuzzi, A.; Hall, J. Bellagio stamp: Principles for sustainability assessment and measurement. Ecol. Indic. 2012, 17, 20–28. [Google Scholar] [CrossRef]

- Hjorth, P.; Bagheri, A. Navigating towards sustainable development: A system dynamics approach. Futures 2006, 38, 74–92. [Google Scholar] [CrossRef]

- Estefan, J.A. Survey of Model-Based Systems Engineering (MBSE) Methodologies; Incose MBSE Focus Group: Pasadena, CA, USA, 2007; p. 47. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moldavska, A.; Welo, T. Development of Manufacturing Sustainability Assessment Using Systems Thinking. Sustainability 2016, 8, 5. https://doi.org/10.3390/su8010005

Moldavska A, Welo T. Development of Manufacturing Sustainability Assessment Using Systems Thinking. Sustainability. 2016; 8(1):5. https://doi.org/10.3390/su8010005

Chicago/Turabian StyleMoldavska, Anastasiia, and Torgeir Welo. 2016. "Development of Manufacturing Sustainability Assessment Using Systems Thinking" Sustainability 8, no. 1: 5. https://doi.org/10.3390/su8010005

APA StyleMoldavska, A., & Welo, T. (2016). Development of Manufacturing Sustainability Assessment Using Systems Thinking. Sustainability, 8(1), 5. https://doi.org/10.3390/su8010005