1. Introduction

Modern food supply systems (production and distribution) are heavily dependent on fossil energy [

1] and other non-renewable resources [

2]. The global environmental crisis [

3,

4] and foreseeable constraints on the supply of energy [

5] and fertilizer [

6,

7] clearly show that there is a need to develop food supply systems that conserve biodiversity and natural systems and rely less on non-renewable resources. A similar conclusion is drawn in a report initiated by the Food and Agriculture Organization of the United Nations (FAO) and The World Bank. It emphasizes the need to maintain productivity, while conserving natural resources by improving nutrient, energy, water and land use efficiency, increasing farm diversification, and supporting agro-ecological systems that take advantage of and conserve biodiversity at both field and landscape scale [

8].

It has been shown that the food industry in the UK is responsible for 14% of national energy consumption and for 25% of heavy goods vehicle kilometers [

9]. The structural development of the food supply system over the past 60 years means that most goods are now distributed through regional distribution centers before being transported to increasingly centralized and concentrated out-of-town supermarkets. This also means that more shopping trips are done by private cars which make up approximately half of the total food vehicle kilometers [

10]. In 2002, 9% of UK’s total consumption of petroleum products was used for transportation of food [

10]. This clearly shows that if the environmental impacts of the food supply system are to be significantly reduced, then it is necessary to view the production and distribution of food together. Direct marketing and local selling of products offers a way for farms to by-pass the energy intensive mass distribution system. Such distribution systems are particularly appropriate for vegetables, which have a relative short lifetime and are most attractive to consumers when they are fresh. On the other hand, depending on the distance travelled and the mode of transport, the local system may be more energy consuming than the mass distribution system [

11,

12].

The development in food supply systems has also resulted in a push towards producers being more specialized and production being in larger, uniform units [

10]. These changes tend to imply reductions in crop diversity at the farm level, which in the long run may cause problems for society. For example, the biodiversity loss associated with these systems has been shown to result in decreased productivity and stability of ecosystems due to loss of ecosystem services [

13]. Specifically, biodiversity at the farm level has been shown often to have many ecological benefits (ecosystem services) like supporting pollination, pest and disease control. Therefore, it has been suggested that it is time for a paradigm shift in agriculture by embracing complexity through diversity at all levels, including soil, crops, and consumers [

14]. However, high levels of crop diversity may be rather difficult to combine with the supermarket mass distribution system, which at present sell 85% of food in the UK [

10]. On the contrary, local based direct marketing has been identified as a driving force for increasing on-farm biodiversity [

15].

The sustainability aspects of resource use and environmental impacts of food supply systems can be assessed by Life Cycle Assessment (LCA) [

16,

17] or emergy assessment [

18,

19]. Emergy accounting and LCA are largely based on the same type of inventory (

i.e., accounting for energy and material flows) but apply different theories of values and system boundaries [

20]. In emergy accounting, all flows of energy and materials are added based on the total available energy (exergy) directly and indirectly required to produce the flow. Emergy accounting is particularly suited for assessing agricultural systems since the method accounts for use of freely available natural resources (sun, rain, wind and geothermal heat) as well as purchased resources from the society [

18]. LCA draws system boundaries around human dominated processes (resource extraction, refining, transportation,

etc.) and includes indirect resources used throughout the supply chain, such as the transport of inputs supplied into the production system. Unlike emergy accounting, LCA disregards energy used by nature and normally also labor. LCA on the other hand considers emissions to the environment in addition to resource use. Due to the differences in system boundaries and scope of analysis, emergy and LCA are complementary methods [

21].

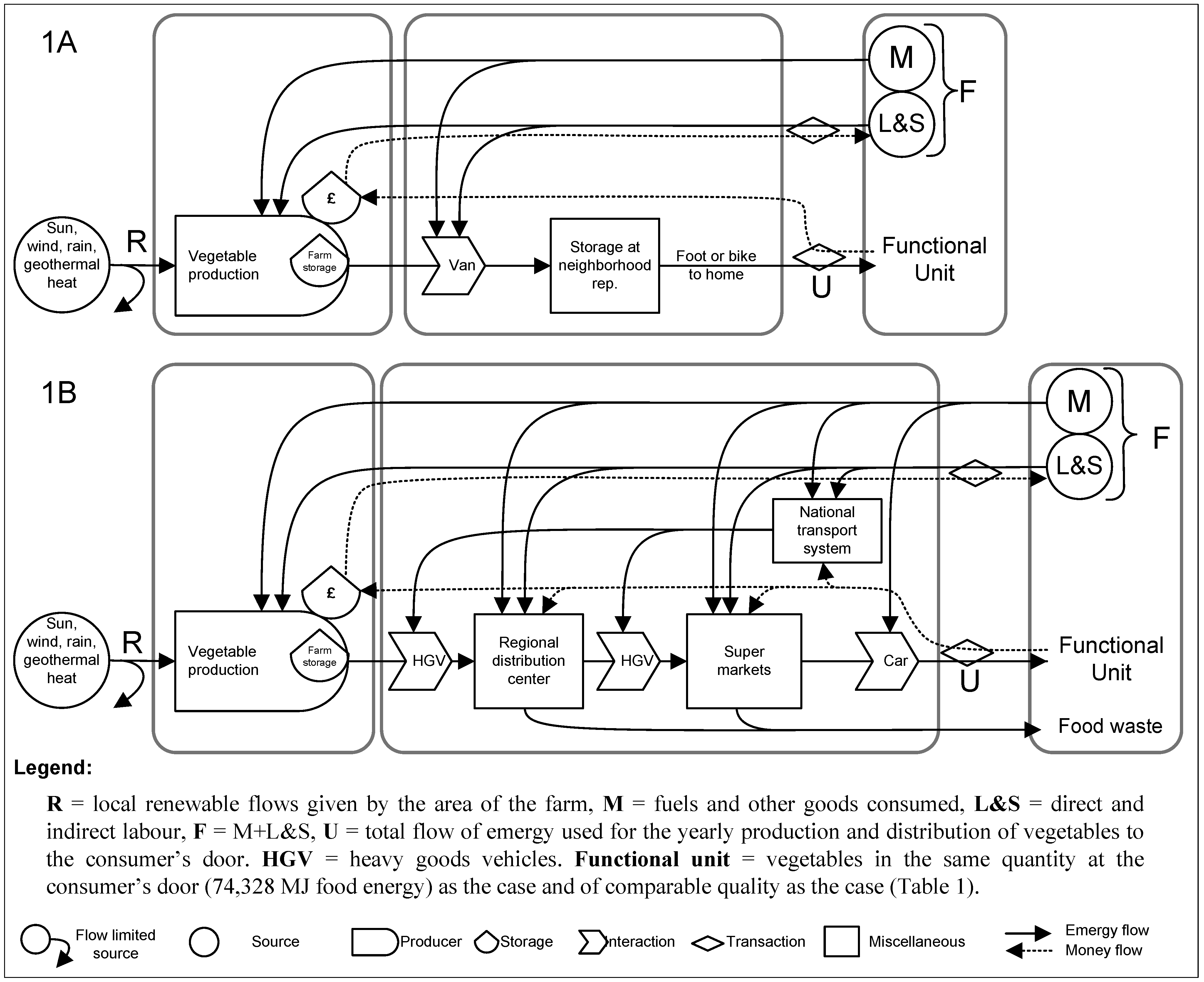

We studied the sustainability of a small-scale low-input organic vegetable food supply system by evaluating empirical data on resource use and emissions resulting from production and distribution of vegetables in a box-scheme. This specific case was chosen because the farm is managed with a strong preference to increase crop diversity and to close the production system with regard to external inputs. Combined with the box-scheme distribution system it thus represents a fundamentally different way of producing and distributing food compared to the dominating supermarket based systems. Our hypothesis was that the food supply system of the case study uses fewer resources (especially fewer non-renewable resources) when compared to standard practices. To test this we developed two organic vegetable food supply model systems, low and high yielding. Each system provided the same amount of food as the case study system, and the food produced was distributed via supermarkets rather than through a box-scheme. The case supply system is benchmarked against these model systems based on a combined emergy and LCA evaluation. Therefore, within this study we aimed to evaluate whether it is possible to perform better than the dominating systems with respect to resource use including labor and environmental impacts, and at the same time increase resilience.

2. Farm and Food Distribution System—Empirical Data

The case study farm is a small stockless organic unit of 6.36 ha of which 5.58 ha are cropped and a total of 0.78 ha is used for field margins, parking area and buildings. The box-scheme distribution system supplies vegetables to 200–300 customers on a weekly basis.

Data for 2009 and 2010 were collected by two one-day visits at the farm and follow up contacts in the period 2011 to 2013. Data included all purchased goods for crop production and distribution, as well as a complete list of machineries and buildings. The vegetable production was estimated based on sales records of vegetables delivered to consumers for each week during 2009 and 2010 and subsequently averaged to give an average annual production (

Table A1). For the years studied, about 20% of the produce was sold to wholesalers. In our analyses, this share was included in the box-scheme sales.

2.1. Production Systems

Forty-eight different crops of vegetables are produced (

Table A1) and several different varieties are grown for each crop. Crops are grown in three different systems: open field, intensive managed garden and polytunnels, and greenhouses. The open fields are managed with a 7-year crop rotation and make up 5.09 ha of cropping area. The fields are characterized by a low-fertility soil with a shallow top soil and high stone content. The garden is managed with a 9-year crop rotation and the cropped area is 0.38 ha. In the garden only, walk-behind tractors and hand tools are used for the cultivation. The greenhouse and poly-tunnels make up 0.10 ha.

The farm is managed according to the Stockfree Organic Standard [

22], which means that no animals are included in the production system and the farm uses no animal manure. The farm is in general designed and managed with a strong focus on reducing external inputs (e.g., fuel and fertilizers). An example of this is that the fertility is maintained by the use of green manures. The only fertility building input comes from woodchips composted on the farm and small amounts of lime and vermiculite, which are used to produce potting compost for the on-farm production of seedlings. All seed is purchased except for 30% of the seed potatoes, which are farm saved.

2.2. Distribution System

The distribution is done by weekly round-trips of 70 km, where multiple bags are delivered to neighborhood representatives. Other customers may then come to the representatives’ collection points to collect the bags. Customers are encouraged to collect the bag on foot or on bike, and the bags are designed to make this easier (i.e., a wooden box is more difficult to carry). Potential customers are rejected if they live in a location from where they would need to drive by car to pick up their bags, even though they offer to pick up the bags themselves and pay the same price. The neighborhood representatives have some administrative tasks and are paid by getting boxes for free.

3. Assessment Methods—Emergy and LCA

The system boundary in this study is the farm and its distribution system. Cooking, consumption, human excretion and wastewater treatment are excluded from the scope of the analysis. The functional unit, which defines the service that is provided, is baskets of vegetables produced during one year and delivered at consumer’s door as average of the years 2009 and 2010. Resource consumption and environmental impacts associated with consumers’ transport is included except for transport by foot or bike, which was assumed negligible.

3.1. Emergy Accounting

Emergy accounting quantifies direct input of energy and materials to the system and multiplies these with suitable conversion factors for the solar equivalent joules required per unit input. These are called unit emergy values (UEV) and given in seJ/unit, e.g., seJ/g or seJ/J. Emergy used by a system is divided into different categories [

23] and in the following we describe how they are applied in this study.

Local renewable resources (R). The term “R” includes flows of sun, rain, wind and geothermal heat and is the freely available energy flows that an agricultural system captures and transforms into societal useful products. We include the effect of rainfall as evapotranspiration. To avoid double counting only the largest flow of sun, rain and wind is included.

Local non-renewable recourses (N). This includes all stocks of energy and materials within the system boundaries that are subject to depletion. In agricultural systems, this is typically soil carbon and soil nutrients. In this study we assume that these stocks are maintained.

Feedback from the economy (F) consists of purchased materials (M) and purchased labor and services (L&S) [

23]. M includes all materials and assets such as machinery and buildings. Assets are worn down over a number of years and the emergy use takes into account the actual age and expected lifetime of each asset. The materials come with a service or indirect labor component. This represents the emergy used to support the labor needed in the bigger economy to make the products and services available for the studied system. It is reflected in the price of purchased goods.

Labor and service (L&S). In this study, the L&S component is accounted for based on monetary expenses calculated from the sales price of the vegetables. This approach rests on the assumption that all money going into the system is used to pay labor and services (including the services provided in return for government taxes or insurances). This revenue is multiplied with the emergy money ratio, designated em£-ratio (seJ/£), which is the total emergy used by the UK society divided by the gross domestic product (GDP). Thus the em£-ratio is the average emergy used per £ of economic activity. To avoid counting the service component twice, UEVs assigned to purchased materials (M) are without the L&S component.

Total emergy use (U). The sum of all inputs is designated “U”. We use three emergy indicators to reveal the characteristics of the food supply system: (1) Emergy Yield Ratio (U/F), a measure of how much the system takes advantage of local resources (in this study only R) for each investment from the society in emergy terms (F), (2) Renewability (R/U), a measure of the share of the total emergy use that comes from local renewable resources, and (3) Unit Emergy Value, UEV (U/output from system) [

23].

3.2. Life Cycle Assessment (LCA)

The LCA approach quantifies the environmental impacts associated with a product, service or activity throughout its life cycle [

24]. The method looks at the impact of the whole system on the global environment by tracing all material flows from their point of extraction from nature through the technosphere and up to the moment of their release into the environment as emissions. LCA takes into account all direct and indirect manmade inputs to the system and all outputs from the system and quantifies the associated impacts on the environment.

Impact categories that are relevant and representative for the assessment of agricultural systems [

16] were considered: non-renewable resource use as derived from fossil and nuclear resources [

25], Global Warming Potential over 100 years according to the IPCC method [

26] and a selection of other impacts from CML01 methods [

27] and EDIP2003 [

28], (

i.e., eutrophication potential to aquatic and terrestrial ecosystems, acidification, terrestrial and aquatic ecotoxicity potentials, human toxicity potential). In addition the use of fossil phosphorus was assessed.

The inventories for the LCA were constructed with the use of Swiss Agricultural Life Cycle Assessment (SALCA) models [

28], Simapro V 7.3.3 [

29] and the Ecoinvent database v2.2 [

30]. The following inputs and emissions were based on other studies: life cycle inventory for vegetable seedlings [

31]; biomulch [

32]; nitrous oxide and methane emissions from open field woodchip composting on the case study farm [

33]. The Life Cycle Inventory for irrigation pipeline from ecoinvent was adjusted to reflect the irrigation system of the case farm and the Swiss inventory for irrigation was adjusted to reflect the British electricity mix.

The analysis was carried out from cradle to the consumer’s door with respect to the ISO14040 [

24] and ISO14044 [

34] standards for environmental Life Cycle Assessment. Upstream environmental impacts related to the production of woodchips or manure were not considered. This is following a cut-off approach that makes a clear division between the system that produces a by-product or waste and the system using it. The emissions from livestock farming (associated with the production of manure used in the models of standard practice) are fully assigned to the livestock farmer and the gardener is responsible for the production of woodchips. However, environmental impacts from the transport of both type of inputs to the farm, their storage and composting at the farm and all the emissions to soil, air and water that arise from their application were considered in this study. The results of the impact category non-renewable resource use were investigated in more detail by looking at the relative contribution of particular processes to the overall resource use, because of some similarities with the emergy assessment.

4. Models for Standard Practice of Vegetable Supply System

The overall aim of developing these models is to assess the resource use and environmental impacts of providing the same service as the case system but in the dominating supermarket based system. The two model systems, M-Low and M-High, express the range of standard practice for organic vegetable production as defined from the Organic Farm Management Handbook [

35]. Since the information in this handbook is independent of scale,

i.e., all numbers are given per ha or per kg, then the model systems are also independent of scale. Both model systems provide vegetables in the same quantity at the consumer’s door (in food energy) and of comparable quality as the case study. The mix of vegetables provided is identical to the case system for the eight crops (two types of potatoes, carrots, parsnips, beetroots, onions, leeks and squash) constituting 75% of the food energy provided (

Table 1). For the remaining 25% representing 40 crops at the case farm, four crops (white cabbage, cauliflower, zucchini and lettuce) have been chosen based on the assumption that they provide a similar utility for the consumer.

Table 1.

Characteristics of vegetables produced annually in the case system and their counterparts in the model systems.

Table 1.

Characteristics of vegetables produced annually in the case system and their counterparts in the model systems.

| Case farm crops | Model farm crops | Food energy at consumers (MJ) | Share of total food energy |

|---|

| Storable crops | | | |

| Potatoes, main crop | Potatoes, main crop | 25,597 | 34.4% |

| Potatoes, early | Potatoes, early | 8532 | 11.5% |

| Carrots (stored and fresh) | Carrots | 4635 | 6.2% |

| Beetroots (stored and fresh) | Beetroots | 4271 | 5.7% |

| Onions (stored, fresh and spring) | Onions | 3688 | 5.0% |

| Parsnips | Parsnips | 3555 | 4.8% |

| Leeks | Leeks | 2902 | 3.9% |

| Squash | Squash | 2697 | 3.6% |

| Cabbages (red-, black-, green-, sprouts, kale, pak choi) | Cabbages, white | 5390 | 7.3% |

| Cauliflower, broccoli and minor crops (celeriac, fennel, turnips, kohlrabi, rutabaga, daikon, garlic) | Cauliflower | 3344 | 4.5% |

| Storable crops, total | | 64,610 | 86.9% |

| Fresh crops | | | |

| 18 different crops (see Table A1 for list of crops) | 50% Courgettes | 4859 | 6.5% |

| 50% Lettuce | 4859 | 6.5% |

| Fresh crops, total | | 9717 | 13.1% |

| All crops, total (functional unit) | | 74,328 | 100.0% |

4.2. Model Distribution System

The model distribution system from farm gate to consumer’s door was modeled on a crop by crop basis based on published LCA reports for supermarket based food distribution chains [

40,

41,

42] (

Table 3). The chain is thus assumed to consist of 200 km transport to and storage for 5 days at regional distribution center (RDC), 50 km transport to and storage for 2 days at retailers and 6.4 km transport from the retailer to the customer’s home [

40] (see Supplementary Material for detailed assumptions.) Transportation from the farm to the RDC is assumed to be in a chilled 32 t truck with an energy consumption of 22.9 mL diesel per euro pallet kilometer [

41]. Throughout the system, food waste is taken into account for each crop [

42].

The total expenses to labor, service and materials throughout the supply system were estimated based on 12 month average supermarket prices (from March 2012 to March 2013) for each of the vegetables [

43]. The prices were adjusted for inflation to reflect average 2009–2010 prices according to the price index for vegetables including potatoes and tubers [

44].

6. Discussion

6.1. LCA versus Emergy Assessment—Handling of Co-Products

The assessment of sustainability of the organic low-input vegetable supply system using emergy accounting and LCA has shown that the two methods lead to the same conclusion regarding the supply chain but differ to some extent in the assessment of the production systems. The sometimes contradictory results of the emergy and LCA results are to a large part due to differences in how co-products, e.g., manure, are accounted for. In emergy accounting, the focus is on the provision of resources, and a key principle in emergy algebra is that all emergy used in a process should be assigned to all co-products as long as they are considered in separate analyses [

23]. As manure cannot be produced without producing meat and milk, the entire input to livestock production should be assigned to each of the three products. We have used this approach despite its disadvantages when comparing systems with or without inputs of manure [

58]. As a proxy for the UEV of manure, we have combined the UEVs of mineral N, P and K. In the LCA approach, all environmental impacts from animal production were assigned to the main products of animal production being meat and milk. As a result, only emissions associated with transportation, storage and application are considered and the principle of no import of manure in the case system is only partially reflected in the LCA results. Further, this approach has lead to the counter-intuitive result that M-Low has higher phosphorus use than M-High (

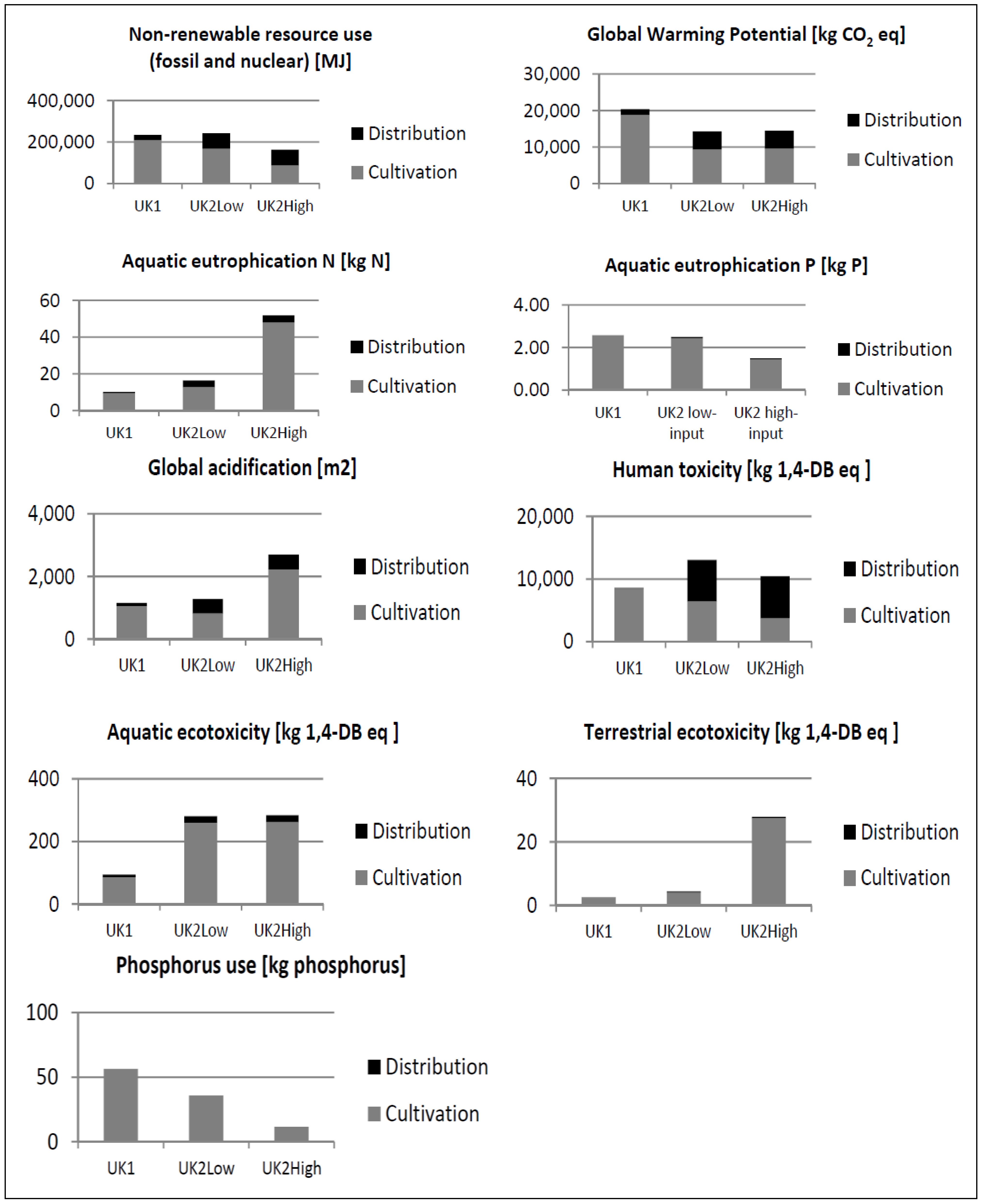

Figure 2) even though the latter system imports twice as much phosphorus as the former (

Table A2). The assumption that manure is a waste may not reflect the actual situation for many organic growers who experience that the supply of N is often a limiting factor for maintaining productivity [

59].

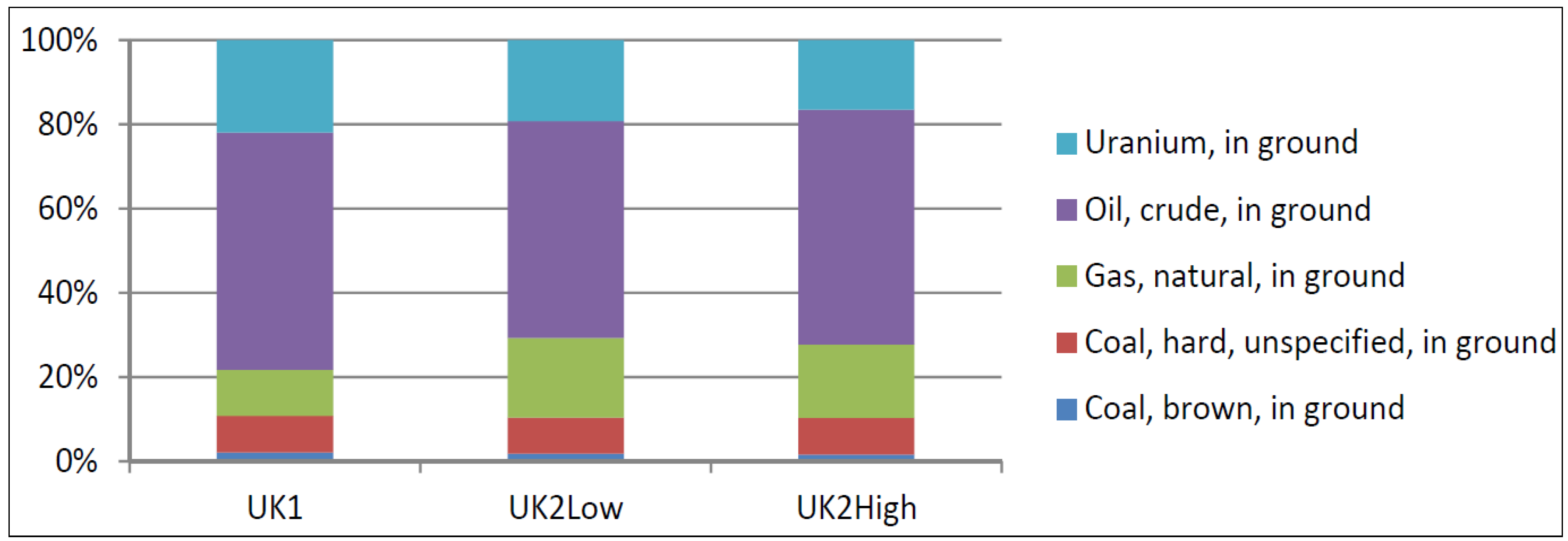

6.2. Potentials for Reducing Resource Use in the Case System

Even though the case has a strong focus on minimizing use of purchased resources (M), their contribution is still more than six times larger than the contribution from local renewable resources (R) (

Table 4). Disregarding L&S, then the largest potential for improving percentage of renewability is to reduce the amount of used fuels (

Figure 2). However, to substitute fossil fuelled machinery with more labor intensive practices such as draft animals or manual labor, would under current socio-economic conditions increase overall resource consumption due to the high emergy flow associated with labor. In addition, draft animals would require that a considerable amount of land should be used for feed production.

Ground and tap water used for irrigation constitutes 17% of the total emergy use. Due to the differences in UEV between tap and ground water, the emergy use could be substantially reduced by using only ground water. Producing the woodchips, which accounts for 10% of the total emergy used, within the geographical boundaries of the farm would improve renewability. Currently they are residuals supplied from a local gardener who prunes and trims local gardens. In a larger perspective, there are, thus, few environmental benefits from becoming self-sufficient with wood chips in the case system. According to the LCA analysis, the composting process accounts for 30% of greenhouse gas emissions, and using less wood chip compost would reduce the overall global warming potential.

Electricity, which is primarily used for heating and lighting in the production of seedlings, constitutes 11% of the emergy used. It is no doubt convenient to use electricity for heating, but substituting the electricity with a firewood based system would largely reduce the emergy. Alternatively, it may be worthwhile to consider harvesting excess heat from the composting process to heat the green house.

As for the distribution phase, the case has the potential for decimating fossil fuel consumption by replacing the current customers with some of the many households located within few kilometers of the farm. This could dramatically reduce the 70 km round trip each week. The current way of organizing the distribution, however, is extremely efficient when compared to the alternative where customers would go by car each week and pick up the produce. The latter solution would require up to 1,000,000 car-km per year based on the case farmer’s calculation. With a fuel efficiency of 15 km/L this translates to 66,666 liter of fuel. This is almost 40 times the fuel consumption for the model system (1737 L).

6.3. Outlook for Emergy Use for L&S

In a foreseeable future with increasing constraints on the non-renewable resources [

6,

60], which currently are powering the society with very high EYR-values [

23], it is desirable or even necessary that agricultural systems become net-emergy providers,

i.e., that more emergy is returned to society from local renewable resources than the society has invested in the production [

61]. This requirement means that the contribution from R has to be bigger than F. Bearing in mind that R cannot be increased as the local renewable flows are flow limited, then achieving this can alone be achieved by reducing the emergy currently invested from society, F (3808.2 × 10

14 seJ) to less than R (54.8 × 10

14 seJ),

i.e., by a factor of 70. Such an improvement seems out of reach without transforming the food supply system. Some improvements can be made on the farm as indicated, but the largest change will need to be in the society which determines the emergy use per unit labor. It is important to note that for the standard practices represented by the model system much larger reduction would be required.

Emergy used for L&S accounts for 89% of total emergy flow and constitutes by far the biggest potential for improvements. The L&S-component reflects the emergy used to support people directly employed on the farm and people employed in the bigger economy to manufacture and provide the purchased inputs. Due to the high average material living standard in UK with emergy use per capita being 8.99 × 10

16 seJ/year [

50], labor is highly resource intensive.

Emergy used for L&S can be reduced by reducing the revenue, but this is highly undesirable. Nevertheless, the employees already have a relatively low salary, which they accept because of the benefits enjoyed, e.g., free access to vegetables, cheap accommodation on the farm perimeter and in their opinion a meaningful job close to nature. Thus, the case system attracts people with a Spartan lifestyle with few expenses and thus below average emergy use.

In future, it is almost certain that the nation-wide emergy use per capita will be reduced. A likely future scenario for the UK is that the indigenous extraction of non-renewable resources continues to decline (down 23% from 2.4 × 10

24 seJ in 2000 to 1.8 × 10

24 seJ in 2008 [

50]). This is a result of the oil extraction plunging from 2.6 to 1.5 million barrels per day (mbd) from 2000 to 2008 (in 2010 further down to 1.1 mbd) [

62]. In the same period the extraction of natural gas dropped from 97.5 to 62.7 million tonnes oil equivalent (and to 40.7 by 2010) [

62]. This decline has been compensated by increasing imports of fuels from 57 × 10

22 seJ in 2000 to 95 × 10

22 seJ by 2008 [

50]. The UK has been able to maintain a high level of emergy use per capita by gradually substituting the decline in oil and gas production with imported fuels and services. Such a substitution may continue for some years, but in a longer time perspective a decline in global production of oil, gas and other non-renewable resource is inevitable. Coupled with an increased competition from a growing global population increasing in affluence, it is likely that the import of such resources will eventually decline for the UK as well as other industrialized nations [

63].

Such a future scenario imply that the resource consumption per capita will be reduced and thereby that the emergy needed for supporting labor is reduced. However, it may also bring along transformations that are more substantial in the organization of the national economy and all its sub-systems, not least the mass food supply system, which at present uses 9% of UK’s petroleum products. In this perspective, the capacity of a system to adapt to changes is a crucial part of its sustainability, and this characteristic is not directly reflected in the quantitative indicators of emergy assessment and LCA.

6.4. Local Based Box-Scheme versus National-Wide Supermarket Distribution—Resilience

The supermarket based distribution system has during the previous decades been redesigned according to principles of Just-In-Time delivery (JIT). These principles aim at reducing the storage need and storage capacity at every link in a production chain, such that a minimum of capital investment is idle or in excess at any time. Less idle capital means fewer costs and fewer environmental impacts. While JIT may decrease environmental impacts per unit of produce for the particular system, as long as everything is running smoothly, it may compromise the system’s resilience as it becomes more vulnerable to disturbance and systemic risks. Systemic risks include disruption in infrastructure supplying money, energy, fuel, power, communications and IT or transport as well as pandemics and climate change [

64,

65,

66]. As can be imagined any disturbance caused by such events may quickly spread throughout the tightly connected network [

65,

67]. A loss of IT and communication would make it impossible for a national-wide JIT supply system to coordinate supplies [

64]. A loss of money would make it impossible to conduct transactions with customers. A loss of fuel for transportation would results in large bulks of produce being stranded. A loss of power in the RDC would stop the entire chain and retailers would run out of products in a few days.

When benchmarking the case-study against the national wide supermarket system, the former may be more resilient than the latter as it is in a better position to handle infrastructure failures. Due to the higher degree of autonomy and fewer actors involved, the case system would be able to work around many events, which could bring the supermarket-based system to a halt. For instance, a loss of money supply could be handled by delaying payments until the system recovers. Loss of fuel would be difficult to overcome, but produce could still be collected on bike or by public transport.

However, from the consumer’s point of view, the risks have a different nature. Consumers in the case system are vulnerable to a poor or failed harvest (e.g., caused by flooding, unusual weather conditions or pests). The supermarket supply system would be unaffected by a failed harvest at a single farm because of the large number of producers feeding into the system. However, the crop diversity of the case-study minimizes the risk of a complete harvest failure.

6.5. Limitations of Study—Validity of Model Systems

The vegetables produced from the case-study farm have determined the design of the cultivation phase of the two model systems. It is very likely that other model systems would be developed if the systems were optimized for producing any mix of vegetables of certain food energy content but such analyses are outside the scope of this study. However, as the model systems are scale independent the results can be considered as representing the production from larger areas where different farms are producing different crops. Although in many cases the yields will vary from those presented, the high and low yield scenario should capture the range of possible outcomes.

For both emergy assessment and LCA the on-farm use of fuel and irrigation resulted in higher impacts for the case-study than for the model systems. This is to a large part due that the model systems are based on standard data for field operations and that annual variation in rainfall is not reflected. This implies that any additional driving of tractors and machinery, that may occur for various reasons in a real farming system are not included. This may result in an underestimation of the actual resource consumption, which real UK organic farms would have needed in the same years under the same conditions.

7. Conclusions

The results of the emergy analysis showed that the case study is more resource efficient than the modeled standard practices, and with the identified potential for further reducing the emergy use, the case-study farm can become substantially better. This is especially true when also considering emergy used to support labor and service. The results of the LCA for the cultivation phase were less conclusive as the case had neither consistently more nor consistently less environmental impacts compared to the model systems. However, for the distribution phase, both the emergy assessment and LCA evaluated the case to perform substantially better than model systems. In addition, we have argued that the case may be in a better position to cope with likely future scenario of reduced access to domestic and imported fossil fuels and other non-renewable resources.

The real value of the case study is that it points out that there are alternative ways of organizing the production and distribution of organic vegetables, which are more resource efficient and potentially more resilient. The case-study shows that it is possible to efficiently manage a highly diverse organic vegetable production system independently of external input of nutrients through animal manure, whilst remaining economically competitive. The success of the case system is to a large part due to management based on a clear vision of bringing down external inputs. This vision is generic but the specific practices of the case-study may not always be the most appropriate for a farm to improve its resource efficiency and resilience. For systems in other societal contexts, e.g., farms with livestock and crop production or farms in remote locations, other strategies will be needed.