Energy Analysis of a Biomass Co-firing Based Pulverized Coal Power Generation System

Abstract

:Nomenclature

| A | Ash fraction in fuel |

| Molar flow rate, kmol/s |

| Cp | Specific heat at constant pressure, kJ/kg.K |

| Energy rate, MW |

| F | Mass fraction of fixed carbon in fuel |

| h | Specific enthalpy, kJ/kg |

| Molar specific enthalpy, kJ/kmol |

| Enthalpy of formation, kJ/kmol |

| HHV | Higher heating value, kJ/kg |

| k | Coefficients for correlation for specific heat capacity of ash, kJ/kmol |

| LHV | Lower heating value, kJ/kg |

| M | Molecular weight, kg/kmol |

| Mass flow rate, kg/s |

| Number of moles, kmol |

| P | Co-firing ratio |

| p | Pressure, bar |

| Heat interaction rate, MW |

| T | Temperature, K |

| V1 | Mass fraction of primary volatile matter in fuel, on dry ash-free basis |

| V2 | Mass fraction of secondary volatile matter in fuel, on dry ash-free basis |

| Work rate, MW |

| W | Weight percent |

Greek Letters

| 𝜂 | Energy efficiency, % |

Subscripts

| b | Biomass |

| C | Carbon |

| c | Coal |

| H | Hydrogen |

| 𝑖 | Identifies the constituent of a mixture |

| in | Inlet |

| O | Oxygen |

| p | Products |

| R | Reactants |

| out | Outlet |

| S | Sulphur |

| V1 | Primary volatile matter |

| V2 | Secondary volatile matter |

Superscripts

| o | Standard environment state |

Acronyms

| BFP | Boiler feed pump |

| B/CL | Bituminous coal/chicken litter blend |

| B/RFD | Bituminous coal/refuse derived fuel blend |

| B/RH | Bituminous coal/rice husk blend |

| B/SD | Bituminous coal/saw dust blend |

| CP | Condensate pump |

| FG | Flue gases |

| FWH | Feedwater heater |

| LPT | Low pressure turbine |

| HPT | High pressure turbine |

| L/CL | Lignite/chicken litter blend |

| L/RFD | Lignite/refuse derived fuel blend |

| L/RH | Lignite/rice husk blend |

| L/SD | Lignite/saw dust blend |

| M | Moisture |

1. Introduction

2. Characteristics of Fuels

(1)

(1) (2)

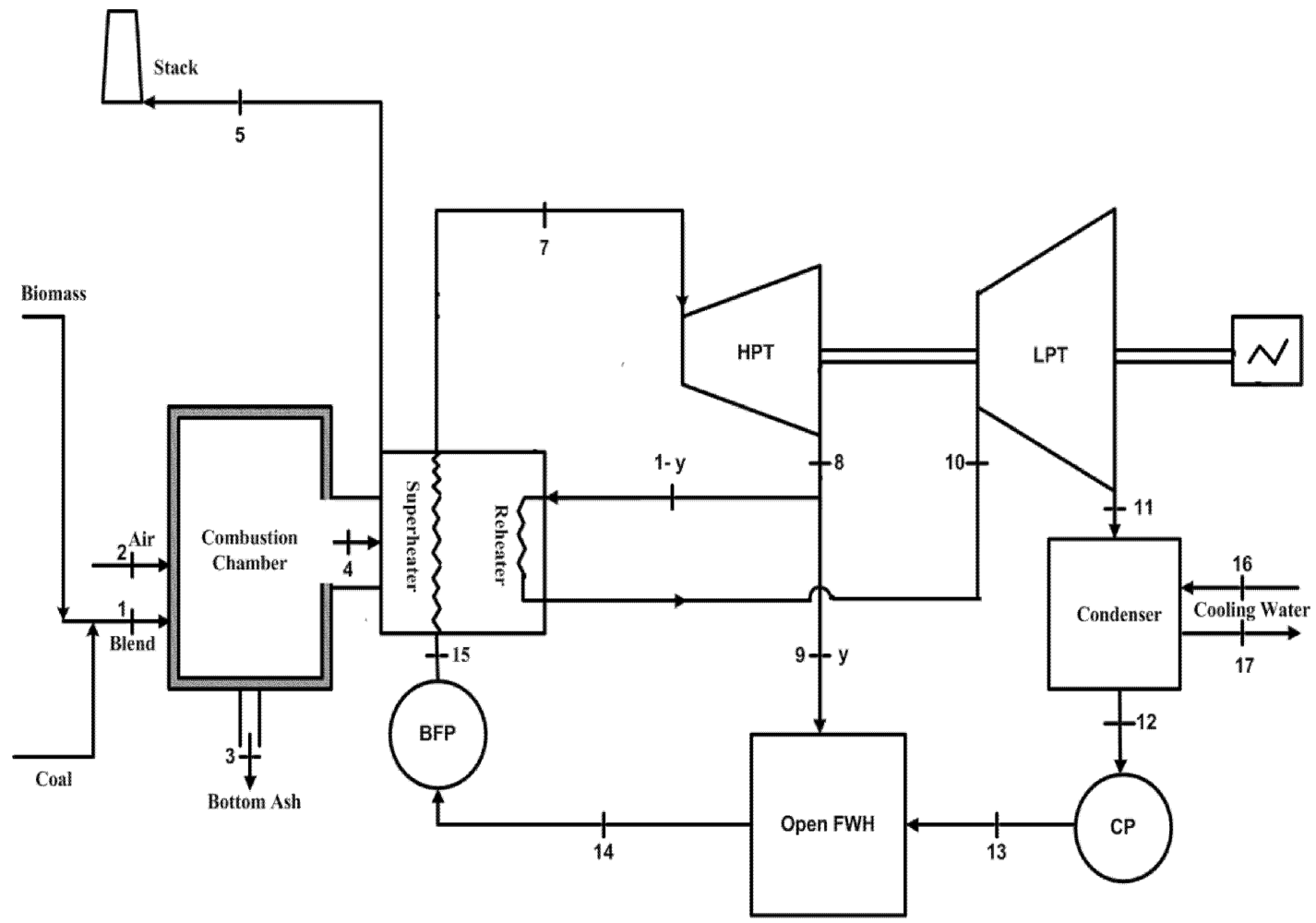

(2)3. System Configurations

| Parameter | Chicken litter1 | Pine sawdust1 | Refuse derived fuel1 | Rice husk2 | Bituminous coal3 | Lignite3 | ||

|---|---|---|---|---|---|---|---|---|

| Proximate analysis (wt%) | ||||||||

| Fixed carbon | 13.1 | 14.2 | 0.5 | 20.1 | 53.9 | 35.0 | ||

| Volatile matter | 43.0 | 70.4 | 70.3 | 55.6 | 28.2 | 44.5 | ||

| Moisture | 9.3 | 15.3 | 4.2 | 10.3 | 7.8 | 12.4 | ||

| Ash | 34.3 | 0.1 | 25.0 | 14.0 | 10.1 | 8.1 | ||

| Ultimate analysis (wt%) | ||||||||

| Hydrogen | 3.8 | 5.0 | 5.5 | 4.5 | 3.9 | 4.1 | ||

| Carbon | 34.1 | 43.2 | 38.1 | 38.0 | 70.3 | 51.0 | ||

| Oxygen | 14.4 | 36.3 | 26.1 | 32.4 | 6.4 | 23.8 | ||

| Nitrogen | 3.50 | 0.08 | 0.78 | 0.69 | 1.07 | 0.4 | ||

| Sulphur | 0.67 | - | 0.33 | 0.06 | 0.41 | 0.16 | ||

| Ash analysis (wt%) | ||||||||

| SiO2 | 5.77 | 9.71 | 38.67 | 94.48 | 51.67 | 46.15 | ||

| Al2O3 | 1.01 | 2.34 | 14.54 | 0.24 | 29.15 | 20.91 | ||

| Fe2O3 | 0.45 | 0.10 | 6.26 | 0.22 | 10.73 | 6.77 | ||

| CaO | 56.85 | 46.88 | 26.81 | 0.97 | 3.72 | 12.54 | ||

| SO3 | 3.59 | 2.22 | 3.01 | 0.92 | 1.47 | 8.00 | ||

| MgO | 4.11 | 13.80 | 6.45 | 0.19 | 1.41 | 2.35 | ||

| K2O | 12.19 | 14.38 | 0.23 | 2.29 | 0.29 | 1.49 | ||

| TiO2 | 0.03 | 0.14 | 1.90 | 0.02 | 1.24 | 0.77 | ||

| Na2O | 0.60 | 0.35 | 1.36 | 0.16 | 0.31 | 0.73 | ||

| P2O5 | 15.40 | 6.08 | 0.77 | 0.54 | - | 0.29 | ||

| Heating value (kJ/kg) | ||||||||

| Higher heating value | 14,240 | 17,280 | 16,620 | 14,980 | 28,330 | 20,070 | ||

| Lower heating value | 13,410 | 16,180 | 15,410 | 13,990 | 27,340 | 19,070 | ||

| Stream | Bituminous coal | Lignite | ||||||

|---|---|---|---|---|---|---|---|---|

|  |  |  |  |  |  |  | |

| (kg/s) | (K) | (bar) | (MW) | (kg/s) | (K) | (bar) | (MW) | |

| 1 | 1.00 | 281.15 | 1.01 | 28.33 | 1.00 | 281.15 | 1.01 | 20.07 |

| 2 | 2.31 | 281.15 | 1.01 | 0.00 | 2.31 | 281.15 | 1.01 | 0.00 |

| 3 | 0.002 | 873.15 | 1.01 | 0.01 | 0.001 | 873.15 | 1.01 | 0.009 |

| 4 | 11.87 | 2159.15 | 1.01 | 26.22 | 8.40 | 2007.15 | 1.01 | 18.12 |

| 5 | 11.87 | 423.15 | 1.01 | 2.867 | 8.40 | 423.15 | 1.01 | 3.086 |

| 62 | 0.08 | 423.15 | 1.01 | 0.009 | 0.06 | 423.15 | 1.01 | 0.007 |

| 7 | 8.44 | 873.15 | 120.00 | 30.46 | 5.82 | 873.15 | 120.00 | 21.00 |

| 8 | 8.44 | 669.05 | 30.00 | 27.20 | 5.82 | 669.05 | 30.00 | 18.75 |

| 9 | 2.35 | 669.05 | 30.00 | 7.57 | 1.62 | 669.05 | 30.00 | 5.22 |

| 10 | 6.09 | 873.15 | 30.00 | 22.44 | 4.24 | 873.15 | 30.00 | 15.47 |

| 11 | 6.09 | 309.32 | 0.06 | 15.35 | 4.24 | 309.32 | 0.06 | 10.58 |

| 12 | 6.09 | 309.32 | 0.06 | 0.92 | 4.24 | 309.32 | 0.06 | 0.64 |

| 13 | 6.09 | 309.5 | 3.00 | 0.94 | 4.24 | 309.5 | 3.00 | 0.65 |

| 14 | 8.44 | 507.05 | 3.00 | 8.51 | 5.82 | 507.05 | 3.00 | 5.87 |

| 15 | 8.44 | 509.35 | 120.00 | 8.62 | 5.82 | 509.35 | 120.00 | 5.94 |

| 16 | 596.40 | 281.15 | 1.01 | 20.10 | 411.3 | 281.15 | 1.01 | 13.86 |

| 17 | 596.40 | 289.15 | 1.01 | 40.07 | 411.3 | 289.15 | 1.01 | 27.63 |

,

,  ,

,  , and

, and  denote respectively mass flow rate, temperature, pressure, and energy rate.2Stream 6 (not shown in Figure 1) represents fly ash carried with flue gases through stack.

denote respectively mass flow rate, temperature, pressure, and energy rate.2Stream 6 (not shown in Figure 1) represents fly ash carried with flue gases through stack.4. Analysis

4.1. Assumptions

- All components operate at steady state.

- All gases are ideal.

- Kinetic and potential energy effects are neglected.

- Ambient air is 79% nitrogen and 21% oxygen on a volume basis.

- The temperature and pressure of the reference environment are 8 ˚C and 1.013 bar respectively.

- 80% of the ash in the combusted fuel exits as fly ash, and the remainder is collected as bottom ash [40], which is inert.

- The bottom ash temperature is 600 °C, based on values reported for pulverized boilers with dry bottoms [38].

- The formation of NO takes place through three paths: fuel bound nitrogen conversion, thermal fixation of atmospheric nitrogen at elevated temperatures (typically greater than 1500° C), and due to prompt formation resulting from the fast reactions within the flame zone involving nitrogen and fuel bound hydrocarbon radicals. Fuel, thermal, and prompt NO constitute 80%, 16%, and 4% respectively of total NO formed [41,43].

- Flue gases leave the stack at 150 °C [38].

- All the components of the steam cycle have adiabatic boundaries.

- The isentropic efficiency for each steam turbine is 85% and for each pump is 88% [40].

4.2. Governing Equations

(3)

(3) (4)

(4)4.2.1. Energy Analysis of Boiler

(5)

(5) ,

,  ,

,  ,

,  , and

, and  are the molar flow rate of reactants, molar flow rate of products, molar specific enthalpy of reactants, molar specific enthalpy of the products, and heat loss from the combustor or boiler, respectively.

are the molar flow rate of reactants, molar flow rate of products, molar specific enthalpy of reactants, molar specific enthalpy of the products, and heat loss from the combustor or boiler, respectively. (6)

(6) (7)

(7) (8)

(8) is the molar flow rate of reactant i. Subscripts c and b denote coal and biomass, while the letters P, M, m, and W respectively represent the percent share of co-firing, molecular weight, mass, and weight percent of the respective element, found from ultimate analysis.

is the molar flow rate of reactant i. Subscripts c and b denote coal and biomass, while the letters P, M, m, and W respectively represent the percent share of co-firing, molecular weight, mass, and weight percent of the respective element, found from ultimate analysis.  (9)

(9) (10)

(10) is found as:

is found as: (11)

(11) (12)

(12) (13)

(13) (14)

(14) denotes specific heat at constant pressure of fuel (kJ/kg), while F, V1, and V2 are mass fractions of fixed carbon, primary volatile matter, and secondary volatile matter on dry ash free basis, respectively. Fixed carbon is taken from proximate analysis of the fuel. Primary volatile matter is taken to be the amount in excess of 10% on a dry, ash-free basis. The secondary volatile matter is taken to be 10% if the total volatile matter content is greater than 10%. Expressions for the specific heats of fixed carbon, primary volatile matter, and secondary volatile matter follow:

denotes specific heat at constant pressure of fuel (kJ/kg), while F, V1, and V2 are mass fractions of fixed carbon, primary volatile matter, and secondary volatile matter on dry ash free basis, respectively. Fixed carbon is taken from proximate analysis of the fuel. Primary volatile matter is taken to be the amount in excess of 10% on a dry, ash-free basis. The secondary volatile matter is taken to be 10% if the total volatile matter content is greater than 10%. Expressions for the specific heats of fixed carbon, primary volatile matter, and secondary volatile matter follow: (15)

(15) (16)

(16) (17)

(17)| Constituent | Molecular weight (kg/kmol) | Standard enthalpy (MJ/kmol) |

|---|---|---|

| Silica (SiO2) | 60 | –911.3 |

| Aluminum Oxide (Al2O3) | 102 | –1674.4 |

| Ferric Oxide (Fe2O3) | 160 | –825.9 |

| Calcium Oxide (CaO) | 56 | –634.6 |

| Magnesium Oxide (MgO) | 40 | –601.5 |

| Titanium Oxide (TiO2) | 80 | –945.2 |

| Alkalies (Na2O + K2O) | 62 | –418.2 |

| Sulphur Trioxide (SO3) | 80 | –437.9 |

| Phosphorus Pentaoxide (P2O5)1 | 142 | –1505.99 |

(18)

(18)| Constituent | K0 | K1 × 10-2 | K2 × 10-5 | K3 × 10-7 |

|---|---|---|---|---|

| SiO2 | 80.01 | –2.403 | –35.47 | 49.16 |

| Al2O3 | 155.02 | –8.28 | –38.61 | 40.91 |

| Fe2O3 | 146.86 | 0 | –55.77 | 52.56 |

| CaO | 58.79 | –1.34 | –11.47 | 10.30 |

| MgO | 58.179 | –1.61 | –14.05 | 11.27 |

| TiO2 | 77.84 | 0 | –33.68 | 40.29 |

| Na2O | 95.148 | 0 | –51.04 | 83.36 |

| K2O | 105.40 | –5.77 | 0 | 0 |

(19)

(19) ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  and y denote respectively molar flow rate of flue gases leaving the furnace, molar enthalpy of flue gases leaving the furnace, mass flow rate of fly ash, enthalpy change of fly ash, the heat loss associated with incombustibles in the fly ash exiting the stack, molar flow rate of flue gases leaving through stack, enthalpy of flue gases leaving through stack, mass flow rate of steam produced, specific enthalpy of feedwater entering superheater, specific enthalpy of steam leaving superheater, specific enthalpy of steam entering reheater, specific enthalpy of steam leaving reheater, and fraction of steam diverted towards open feedwater heater.

and y denote respectively molar flow rate of flue gases leaving the furnace, molar enthalpy of flue gases leaving the furnace, mass flow rate of fly ash, enthalpy change of fly ash, the heat loss associated with incombustibles in the fly ash exiting the stack, molar flow rate of flue gases leaving through stack, enthalpy of flue gases leaving through stack, mass flow rate of steam produced, specific enthalpy of feedwater entering superheater, specific enthalpy of steam leaving superheater, specific enthalpy of steam entering reheater, specific enthalpy of steam leaving reheater, and fraction of steam diverted towards open feedwater heater.4.2.2. Energy Analysis of Steam Cycle Components

(20)

(20) (21)

(21)| Control volume | Balances | |

|---|---|---|

| Mass | Energy | |

| High Pressure Turbine |  |  |

| Low Pressure Turbine |  |  |

| Condenser |  |  |

| ||

| Condensate Pump |  |  |

| Boiler Feed Pump |  |  |

| Open Feedwater Heater |  |  |

and y are mass flow of cooling water and fraction of the steam extracted, respectively.

and y are mass flow of cooling water and fraction of the steam extracted, respectively.5. Results and Discussion

(22)

(22) (23)

(23)5.1. Effect of Co-firing on Overall System Performance

| Fuel blend1 | Fuel flow rate | Co-firing share | Input | Output | ||||

|---|---|---|---|---|---|---|---|---|

|  | Pc | Pb(%) | Air (mol/s) |  |  |  | |

| (kg/s) | (kg/s) | (%) | (MW) | (MW) | (MW) | |||

| Base | 1.00 | 0.00 | 100 | 0 | 79.86 | 28.33 | 24.65 | 9.92 |

| B/RH | 0.95 | 0.05 | 95 | 5 | 77.85 | 27.66 | 24.04 | 9.67 |

| 0.90 | 0.10 | 90 | 10 | 75.83 | 27.00 | 23.42 | 9.43 | |

| 0.85 | 0.15 | 85 | 15 | 73.81 | 26.33 | 22.80 | 9.18 | |

| 0.80 | 0.20 | 80 | 20 | 71.79 | 25.66 | 22.18 | 8.93 | |

| 0.75 | 0.25 | 75 | 25 | 69.77 | 24.99 | 21.56 | 8.68 | |

| 0.70 | 0.30 | 70 | 30 | 67.76 | 24.33 | 20.95 | 8.43 | |

| B/SD | 0.95 | 0.05 | 95 | 5 | 78.10 | 27.78 | 24.14 | 9.71 |

| 0.90 | 0.10 | 90 | 10 | 76.34 | 27.23 | 23.62 | 9.51 | |

| 0.85 | 0.15 | 85 | 15 | 74.58 | 26.67 | 23.10 | 9.30 | |

| 0.80 | 0.20 | 80 | 20 | 72.81 | 26.12 | 22.58 | 9.09 | |

| 0.75 | 0.25 | 75 | 25 | 71.05 | 25.57 | 22.06 | 8.88 | |

| 0.70 | 0.30 | 70 | 30 | 69.29 | 25.02 | 21.54 | 8.67 | |

| B/CL | 0.95 | 0.05 | 95 | 5 | 77.91 | 27.63 | 24.00 | 9.66 |

| 0.90 | 0.10 | 90 | 10 | 75.99 | 26.92 | 23.35 | 9.40 | |

| 0.85 | 0.15 | 85 | 15 | 74.03 | 26.22 | 22.69 | 9.14 | |

| 0.80 | 0.20 | 80 | 20 | 72.10 | 25.51 | 22.04 | 8.87 | |

| 0.75 | 0.25 | 75 | 25 | 70.13 | 24.81 | 21.39 | 8.61 | |

| 0.70 | 0.30 | 70 | 30 | 68.19 | 24.10 | 20.74 | 8.34 | |

| B/RFD | 0.95 | 0.05 | 95 | 5 | 77.92 | 27.75 | 24.11 | 9.70 |

| 0.90 | 0.10 | 90 | 10 | 75.98 | 27.16 | 23.56 | 9.49 | |

| 0.85 | 0.15 | 85 | 15 | 74.02 | 26.57 | 23.02 | 9.27 | |

| 0.80 | 0.20 | 80 | 20 | 72.09 | 25.99 | 22.48 | 9.05 | |

| 0.75 | 0.25 | 75 | 25 | 70.14 | 25.40 | 21.93 | 8.83 | |

| 0.70 | 0.30 | 70 | 30 | 68.20 | 24.82 | 21.39 | 8.61 | |

,

,  , Pc, Pb,

, Pc, Pb,  ,

,  , and

, and  , denote respectively mass flow rate of coal, mass flow rate of biomass, percent co-firing share of coal, percent co-firing share of biomass or co-firing ratio, energy input rate, useful heat inputs to steam cycle, and net power output of the plant.2B/RH, B/SD, B/CL, and B/RFD denote respectively bituminous coal/rice husk, bituminous coal/sawdust, bituminous coal/chicken litter, and bituminous coal/refuse derived fuel.

, denote respectively mass flow rate of coal, mass flow rate of biomass, percent co-firing share of coal, percent co-firing share of biomass or co-firing ratio, energy input rate, useful heat inputs to steam cycle, and net power output of the plant.2B/RH, B/SD, B/CL, and B/RFD denote respectively bituminous coal/rice husk, bituminous coal/sawdust, bituminous coal/chicken litter, and bituminous coal/refuse derived fuel. | Fuel blend1 | Fuel flow rate | Co-firing share | Input | Output | ||||

|---|---|---|---|---|---|---|---|---|

|  | Pc | Pb(%) | Air (mol/s) |  |  |  | |

| (kg/s) | (kg/s) | (%) | (MW) | (MW) | (MW) | |||

| Base | 1.00 | 0.00 | 100 | 0 | 54.53 | 20.07 | 17.00 | 6.84 |

| L/RH | 0.95 | 0.05 | 95 | 5 | 53.75 | 19.82 | 16.76 | 6.75 |

| 0.90 | 0.10 | 90 | 10 | 53.00 | 19.56 | 16.53 | 6.65 | |

| 0.85 | 0.15 | 85 | 15 | 52.25 | 19.31 | 16.29 | 6.56 | |

| 0.80 | 0.20 | 80 | 20 | 51.50 | 19.05 | 16.06 | 6.46 | |

| 0.75 | 0.25 | 75 | 25 | 50.75 | 18.80 | 15.82 | 6.37 | |

| 0.70 | 0.30 | 70 | 30 | 50.00 | 18.54 | 15.59 | 6.27 | |

| L/SD | 0.95 | 0.05 | 95 | 5 | 54.01 | 19.93 | 16.85 | 6.79 |

| 0.90 | 0.10 | 90 | 10 | 53.51 | 19.79 | 16.73 | 6.73 | |

| 0.85 | 0.15 | 85 | 15 | 53.02 | 19.65 | 16.58 | 6.67 | |

| 0.80 | 0.20 | 80 | 20 | 52.52 | 19.51 | 16.44 | 6.62 | |

| 0.75 | 0.25 | 75 | 25 | 52.03 | 19.37 | 16.29 | 6.56 | |

| 0.70 | 0.30 | 70 | 30 | 51.53 | 19.23 | 16.18 | 6.51 | |

| L/CL | 0.95 | 0.05 | 95 | 5 | 53.82 | 19.78 | 16.73 | 6.73 |

| 0.90 | 0.10 | 90 | 10 | 53.14 | 19.49 | 16.47 | 6.63 | |

| 0.85 | 0.15 | 85 | 15 | 52.47 | 19.20 | 16.20 | 6.52 | |

| 0.80 | 0.20 | 80 | 20 | 51.79 | 18.90 | 15.94 | 6.41 | |

| 0.75 | 0.25 | 75 | 25 | 51.12 | 18.61 | 15.65 | 6.31 | |

| 0.70 | 0.30 | 70 | 30 | 50.44 | 18.32 | 15.39 | 6.19 | |

| L/RFD | 0.95 | 0.05 | 95 | 5 | 53.83 | 19.90 | 16.85 | 6.78 |

| 0.90 | 0.10 | 90 | 10 | 53.15 | 19.73 | 16.67 | 6.71 | |

| 0.85 | 0.15 | 85 | 15 | 52.48 | 19.55 | 16.53 | 6.65 | |

| 0.80 | 0.20 | 80 | 20 | 51.80 | 19.38 | 16.35 | 6.58 | |

| 0.75 | 0.25 | 75 | 25 | 51.13 | 19.21 | 16.20 | 6.52 | |

| 0.70 | 0.30 | 70 | 30 | 50.45 | 19.04 | 16.03 | 6.45 | |

| Fuel blend | Fuel flow rate | Co-firing share | Input | Output | ||||

|---|---|---|---|---|---|---|---|---|

|  | Pc | Pb (%) | Air (mol/s) |  |  |  | |

| (kg/s) | (kg/s) | (%) | (MW) | (MW) | (MW) | |||

| Base | 1.00 | 0.00 | 100 | 0 | 79.86 | 28.30 | 24.65 | 9.92 |

| B/RH | 0.95 | 0.10 | 90.45 | 9.55 | 79.80 | 28.40 | 24.65 | 9.92 |

| 0.90 | 0.20 | 81.77 | 18.23 | 79.80 | 28.49 | 24.65 | 9.92 | |

| 0.85 | 0.30 | 73.85 | 26.15 | 79.70 | 28.58 | 24.65 | 9.92 | |

| 0.80 | 0.40 | 66.59 | 33.41 | 79.70 | 28.66 | 24.65 | 9.92 | |

| 0.75 | 0.50 | 59.91 | 40.09 | 79.70 | 28.75 | 24.65 | 9.92 | |

| 0.70 | 0.60 | 53.76 | 46.24 | 79.70 | 28.84 | 24.65 | 9.92 | |

| B/SD | 0.95 | 0.09 | 91.63 | 8.37 | 79.70 | 28.40 | 24.65 | 9.92 |

| 0.90 | 0.17 | 83.84 | 16.16 | 79.60 | 28.48 | 24.65 | 9.92 | |

| 0.85 | 0.26 | 76.56 | 23.44 | 79.50 | 28.57 | 24.65 | 9.92 | |

| 0.80 | 0.35 | 69.74 | 30.26 | 79.30 | 28.65 | 24.65 | 9.92 | |

| 0.75 | 0.43 | 63.36 | 36.64 | 79.20 | 28.73 | 24.65 | 9.92 | |

| 0.70 | 0.52 | 57.35 | 42.65 | 79.10 | 28.81 | 24.65 | 9.92 | |

| B/CL | 0.95 | 0.11 | 89.97 | 10.03 | 80.20 | 28.41 | 24.65 | 9.92 |

| 0.90 | 0.21 | 80.95 | 19.05 | 80.50 | 28.50 | 24.65 | 9.92 | |

| 0.85 | 0.32 | 72.79 | 27.21 | 80.90 | 28.59 | 24.65 | 9.92 | |

| 0.80 | 0.42 | 65.37 | 34.63 | 81.20 | 28.68 | 24.65 | 9.92 | |

| 0.75 | 0.53 | 58.60 | 41.40 | 81.60 | 28.78 | 24.65 | 9.92 | |

| 0.70 | 0.64 | 52.40 | 47.60 | 82.00 | 28.87 | 24.65 | 9.92 | |

| B/RFD | 0.95 | 0.09 | 91.38 | 8.62 | 79.50 | 28.39 | 24.65 | 9.92 |

| 0.90 | 0.18 | 83.40 | 16.60 | 79.20 | 28.46 | 24.65 | 9.92 | |

| 0.85 | 0.27 | 75.97 | 24.03 | 78.90 | 28.54 | 24.65 | 9.92 | |

| 0.80 | 0.36 | 69.05 | 30.95 | 78.60 | 28.61 | 24.65 | 9.92 | |

| 0.75 | 0.45 | 62.59 | 37.41 | 78.20 | 28.68 | 24.65 | 9.92 | |

| 0.70 | 0.54 | 56.55 | 43.45 | 77.90 | 28.76 | 24.65 | 9.92 | |

| Fuel blend | Fuel flow rate | Co-firing share | Input | Output | ||||

|---|---|---|---|---|---|---|---|---|

|  | Pc | Pb(%) | Air (mol/s) |  |  |  | |

| (kg/s) | (kg/s) | (%) | (MW) | (MW) | (MW) | |||

| Base | 1.00 | 0.00 | 100 | 0 | 54.53 | 20.07 | 17.00 | 6.84 |

| L/RH | 0.95 | 0.07 | 93.27 | 6.73 | 54.51 | 20.10 | 17.00 | 6.84 |

| 0.90 | 0.14 | 86.74 | 13.26 | 54.49 | 20.13 | 17.00 | 6.84 | |

| 0.85 | 0.21 | 80.44 | 19.56 | 54.48 | 20.16 | 17.00 | 6.84 | |

| 0.80 | 0.28 | 74.36 | 25.64 | 54. 47 | 20.19 | 17.00 | 6.84 | |

| 0.75 | 0.34 | 68.50 | 31.50 | 54.46 | 20.22 | 17.00 | 6.84 | |

| 0.70 | 0.41 | 62.84 | 37.16 | 54.45 | 20.26 | 17.00 | 6.84 | |

| L/SD | 0.95 | 0.06 | 94.12 | 5.88 | 54.42 | 20.09 | 17.00 | 6.84 |

| 0.90 | 0.12 | 88.31 | 11.69 | 54.36 | 20.12 | 17.00 | 6.84 | |

| 0.85 | 0.18 | 82.62 | 17.38 | 54.30 | 20.15 | 17.00 | 6.84 | |

| 0.80 | 0.24 | 77.03 | 22.97 | 54.25 | 20.18 | 17.00 | 6.84 | |

| 0.75 | 0.30 | 71.54 | 28.46 | 54.19 | 20.21 | 17.00 | 6.84 | |

| 0.70 | 0.36 | 66.16 | 33.84 | 54.13 | 20.24 | 17.00 | 6.84 | |

| L/CL | 0.95 | 0.07 | 92.92 | 7.08 | 54.74 | 20.10 | 17.00 | 6.84 |

| 0.90 | 0.15 | 86.10 | 13.90 | 55.01 | 20.13 | 17.00 | 6.84 | |

| 0.85 | 0.22 | 79.57 | 20.43 | 55.28 | 20.17 | 17.00 | 6.84 | |

| 0.80 | 0.29 | 73.31 | 26.69 | 55.54 | 20.21 | 17.00 | 6.84 | |

| 0.75 | 0.36 | 67.32 | 32.68 | 55.81 | 20.24 | 17.00 | 6.84 | |

| 0.70 | 0.44 | 61.56 | 38.44 | 56.08 | 20.28 | 17.00 | 6.84 | |

| L/RFD | 0.95 | 0.06 | 93.95 | 6.05 | 54.29 | 20.09 | 17.00 | 6.84 |

| 0.90 | 0.12 | 87.99 | 12.01 | 54.09 | 20.11 | 17.00 | 6.84 | |

| 0.85 | 0.18 | 82.16 | 17.84 | 53.89 | 20.13 | 17.00 | 6.84 | |

| 0.80 | 0.25 | 76.46 | 23.54 | 53.70 | 20.15 | 17.00 | 6.84 | |

| 0.75 | 0.31 | 70.89 | 29.11 | 53.50 | 20.18 | 17.00 | 6.84 | |

| 0.70 | 0.37 | 65.44 | 34.56 | 53.30 | 20.20 | 17.00 | 6.84 | |

5.2. Effect of Co-firing on Energy Losses

| Fuel blend | Co-firing share (%) | Energy loss rate (MW) | |||||

|---|---|---|---|---|---|---|---|

| Pc | Pb | M | FG | Ash |  |  | |

| Base | 100 | 0 | 1.237 | 1.630 | 0.021 | 0.850 | 14.52 |

| B/RH | 95 | 5 | 1.257 | 1.590 | 0.022 | 0.830 | 14.16 |

| 90 | 10 | 1.277 | 1.549 | 0.022 | 0.810 | 13.80 | |

| 85 | 15 | 1.297 | 1.509 | 0.023 | 0.790 | 13.44 | |

| 80 | 20 | 1.316 | 1.468 | 0.023 | 0.770 | 13.08 | |

| 75 | 25 | 1.336 | 1.428 | 0.024 | 0.750 | 12.71 | |

| 70 | 30 | 1.356 | 1.388 | 0.024 | 0.730 | 12.34 | |

| B/SD | 95 | 5 | 1.297 | 1.595 | 0.020 | 0.833 | 14.23 |

| 90 | 10 | 1.356 | 1.560 | 0.019 | 0.817 | 13.92 | |

| 85 | 15 | 1.416 | 1.525 | 0.018 | 0.800 | 13.61 | |

| 80 | 20 | 1.475 | 1.490 | 0.017 | 0.784 | 13.30 | |

| 75 | 25 | 1.534 | 1.454 | 0.016 | 0.767 | 12.99 | |

| 70 | 30 | 1.594 | 1.419 | 0.015 | 0.750 | 12.68 | |

| B/CL | 95 | 5 | 1.249 | 1.590 | 0.024 | 0.829 | 14.14 |

| 90 | 10 | 1.261 | 1.551 | 0.026 | 0.808 | 13.76 | |

| 85 | 15 | 1.273 | 1.511 | 0.028 | 0.787 | 13.39 | |

| 80 | 20 | 1.285 | 1.471 | 0.030 | 0.765 | 12.99 | |

| 75 | 25 | 1.297 | 1.431 | 0.033 | 0.744 | 12.61 | |

| 70 | 30 | 1.308 | 1.392 | 0.035 | 0.723 | 12.23 | |

| B/RDF | 95 | 5 | 1.209 | 1.591 | 0.023 | 0.832 | 14.21 |

| 90 | 10 | 1.180 | 1.552 | 0.024 | 0.815 | 13.88 | |

| 85 | 15 | 1.151 | 1.513 | 0.026 | 0.797 | 13.56 | |

| 80 | 20 | 1.123 | 1.473 | 0.028 | 0.780 | 13.25 | |

| 75 | 25 | 1.094 | 1.434 | 0.029 | 0.762 | 12.92 | |

| 70 | 30 | 1.066 | 1.395 | 0.031 | 0.745 | 12.61 | |

, and

, and  represent respectively energy loss rate due to moisture, energy loss rate due to exit flue gases, heat loss due to unburned combustibles and radiation and convection from the exterior surface of boiler, and energy loss in condenser.

represent respectively energy loss rate due to moisture, energy loss rate due to exit flue gases, heat loss due to unburned combustibles and radiation and convection from the exterior surface of boiler, and energy loss in condenser.| Fuel blend | Co-firing share (%) | Energy loss rate (MW) | |||||

|---|---|---|---|---|---|---|---|

| Pc | Pb | M | FG | Ash |  |  | |

| Base | 100 | 0 | 1.967 | 1.126 | 0.017 | 0.602 | 10.01 |

| L/RH | 95 | 5 | 1.950 | 1.111 | 0.018 | 0.595 | 9.88 |

| 90 | 10 | 1.933 | 1.095 | 0.018 | 0.587 | 9.74 | |

| 85 | 15 | 1.917 | 1.080 | 0.019 | 0.579 | 9.60 | |

| 80 | 20 | 1.900 | 1.065 | 0.020 | 0.572 | 9.46 | |

| 75 | 25 | 1.883 | 1.050 | 0.021 | 0.564 | 9.33 | |

| 70 | 30 | 1.867 | 1.035 | 0.021 | 0.556 | 9.19 | |

| L/SD | 95 | 5 | 1.990 | 1.116 | 0.016 | 0.598 | 9.93 |

| 90 | 10 | 2.013 | 1.106 | 0.015 | 0.594 | 9.86 | |

| 85 | 15 | 2.036 | 1.096 | 0.014 | 0.590 | 9.77 | |

| 80 | 20 | 2.059 | 1.086 | 0.014 | 0.585 | 9.69 | |

| 75 | 25 | 2.082 | 1.076 | 0.013 | 0.581 | 9.60 | |

| 70 | 30 | 2.105 | 1.066 | 0.012 | 0.577 | 9.53 | |

| L/CL | 95 | 5 | 1.942 | 1.111 | 0.020 | 0.593 | 9.86 |

| 90 | 10 | 1.918 | 1.097 | 0.022 | 0.585 | 9.70 | |

| 85 | 15 | 1.893 | 1.082 | 0.025 | 0.576 | 9.55 | |

| 80 | 20 | 1.868 | 1.068 | 0.027 | 0.567 | 9.39 | |

| 75 | 25 | 1.844 | 1.053 | 0.030 | 0.558 | 9.22 | |

| 70 | 30 | 1.819 | 1.039 | 0.032 | 0.550 | 9.07 | |

| L/RFD | 95 | 5 | 1.902 | 1.112 | 0.019 | 0.597 | 9.93 |

| 90 | 10 | 1.837 | 1.098 | 0.021 | 0.592 | 9.82 | |

| 85 | 15 | 1.772 | 1.084 | 0.022 | 0.587 | 9.74 | |

| 80 | 20 | 1.707 | 1.070 | 0.024 | 0.581 | 9.64 | |

| 75 | 25 | 1.642 | 1.056 | 0.026 | 0.576 | 9.55 | |

| 70 | 30 | 1.577 | 1.042 | 0.028 | 0.571 | 9.45 | |

| Fuel blend | Co-firing share (%) | Energy loss rate (MW) | |||||

|---|---|---|---|---|---|---|---|

| Pc | Pb | M | FG | Ash |  |  | |

| Base | 100.00 | 0.00 | 1.237 | 1.630 | 0.021 | 0.850 | 14.52 |

| B/RH | 90.45 | 9.55 | 1.338 | 1.631 | 0.024 | 0.852 | 14.52 |

| 81.77 | 18.23 | 1.44 | 1.632 | 0.028 | 0.855 | 14.52 | |

| 73.85 | 26.15 | 1.542 | 1.633 | 0.032 | 0.857 | 14.52 | |

| 66.59 | 33.41 | 1.644 | 1.634 | 0.035 | 0.860 | 14.52 | |

| 59.91 | 40.09 | 1.746 | 1.635 | 0.039 | 0.863 | 14.52 | |

| 53.76 | 46.24 | 1.848 | 1.636 | 0.044 | 0.865 | 14.52 | |

| B/SD | 91.63 | 8.37 | 1.384 | 1.628 | 0.021 | 0.852 | 14.52 |

| 83.84 | 16.16 | 1.533 | 1.627 | 0.020 | 0.855 | 14.52 | |

| 76.56 | 23.44 | 1.681 | 1.626 | 0.020 | 0.857 | 14.52 | |

| 69.74 | 30.26 | 1.83 | 1.625 | 0.019 | 0.859 | 14.52 | |

| 63.36 | 36.64 | 1.979 | 1.624 | 0.019 | 0.862 | 14.52 | |

| 57.35 | 42.65 | 2.127 | 1.623 | 0.018 | 0.864 | 14.52 | |

| B/CL | 89.97 | 10.03 | 1.330 | 1.636 | 0.029 | 0.852 | 14.52 |

| 80.95 | 19.05 | 1.424 | 1.643 | 0.037 | 0.855 | 14.52 | |

| 72.79 | 27.21 | 1.519 | 1.650 | 0.046 | 0.858 | 14.52 | |

| 65.37 | 34.63 | 1.613 | 1.657 | 0.055 | 0.861 | 14.52 | |

| 58.60 | 41.40 | 1.708 | 1.664 | 0.065 | 0.863 | 14.52 | |

| 52.40 | 47.60 | 1.803 | 1.671 | 0.075 | 0.866 | 14.52 | |

| B/RDF | 91.38 | 8.62 | 1.234 | 1.624 | 0.026 | 0.852 | 14.52 |

| 83.40 | 16.60 | 1.232 | 1.618 | 0.031 | 0.854 | 14.52 | |

| 75.97 | 24.03 | 1.23 | 1.613 | 0.036 | 0.856 | 14.52 | |

| 69.05 | 30.95 | 1.228 | 1.607 | 0.041 | 0.858 | 14.52 | |

| 62.59 | 37.41 | 1.226 | 1.601 | 0.047 | 0.861 | 14.52 | |

| 56.55 | 43.45 | 1.224 | 1.596 | 0.053 | 0.863 | 14.52 | |

| Fuel blend | Co-firing share (%) | Energy loss rate (MW) | |||||

|---|---|---|---|---|---|---|---|

| Pc | Pb | M | FG | Ash |  |  | |

| Base | 100.00 | 0.00 | 1.967 | 1.126 | 0.017 | 0.602 | 10.01 |

| L/RH | 93.27 | 6.73 | 1.980 | 1.127 | 0.019 | 0.603 | 10.01 |

| 86.74 | 13.26 | 1.995 | 1.128 | 0.020 | 0.604 | 10.01 | |

| 80.44 | 19.56 | 2.010 | 1.129 | 0.022 | 0.605 | 10.01 | |

| 74.36 | 25.64 | 2.024 | 1.130 | 0.024 | 0.606 | 10.01 | |

| 68.50 | 31.50 | 2.039 | 1.131 | 0.026 | 0.607 | 10.01 | |

| 62.84 | 37.16 | 2.054 | 1.132 | 0.028 | 0.608 | 10.01 | |

| L/SD | 94.12 | 5.88 | 2.012 | 1.125 | 0.016 | 0.603 | 10.01 |

| 88.31 | 11.69 | 2.059 | 1.124 | 0.016 | 0.604 | 10.01 | |

| 82.62 | 17.38 | 2.106 | 1.123 | 0.015 | 0.605 | 10.01 | |

| 77.03 | 22.97 | 2.153 | 1.122 | 0.014 | 0.606 | 10.01 | |

| 71.54 | 28.46 | 2.200 | 1.121 | 0.013 | 0.606 | 10.01 | |

| 66.16 | 33.84 | 2.246 | 1.120 | 0.013 | 0.607 | 10.01 | |

| L/CL | 92.92 | 7.08 | 1.975 | 1.130 | 0.022 | 0.603 | 10.01 |

| 86.10 | 13.90 | 1.984 | 1.135 | 0.026 | 0.604 | 10.01 | |

| 79.57 | 20.43 | 1.994 | 1.139 | 0.031 | 0.605 | 10.01 | |

| 73.31 | 26.69 | 2.003 | 1.144 | 0.036 | 0.606 | 10.01 | |

| 67.32 | 32.68 | 2.012 | 1.149 | 0.041 | 0.607 | 10.01 | |

| 61.56 | 38.44 | 2.022 | 1.153 | 0.047 | 0.608 | 10.01 | |

| L/RFD | 93.95 | 6.05 | 1.909 | 1.121 | 0.020 | 0.603 | 10.01 |

| 87.99 | 12.01 | 1.852 | 1.117 | 0.022 | 0.603 | 10.01 | |

| 82.16 | 17.84 | 1.795 | 1.113 | 0.025 | 0.604 | 10.01 | |

| 76.46 | 23.54 | 1.738 | 1.109 | 0.028 | 0.605 | 10.01 | |

| 70.89 | 29.11 | 1.680 | 1.105 | 0.031 | 0.605 | 10.01 | |

| 65.44 | 34.56 | 1.623 | 1.101 | 0.034 | 0.606 | 10.01 | |

5.3. Effect of Co-firing on Efficiencies

6. Conclusions

Acknowledgments

References

- International Energy Agency. Publications: CO2 Emissions from Fuel Combustion 2010 – Highlights. Available online: http://www.iea.org/co2highlights/CO2highlights.pdf (accessed on 16 February 2011).

- World Coal Association. Where is Coal Found. Available online: http://www.worldcoal.org/coal/what-is-coal/ (accessed on 27 January 2011).

- World Coal Association. Coal and Electricity. Available online: http://www.worldcoal.org/coal/uses-of-coal/coal-electricity/ (accessed on 27 January 2011).

- Demirbas, A. Sustainable Co-firing of Biomass with Coal. Energ. Convers. Manage. 2003, 44, 1465–1479. [Google Scholar]

- Savolainen, K. Co-firing of Biomass in Coal-fired Utility Boilers. Appl. Energ. 2003, 74, 369–381. [Google Scholar]

- Pronobis, M. The Influence of Biomass Co-Combustion on Boiler Fouling and Efficiency. Fuel 2006, 85, 474–480. [Google Scholar]

- Spliethoff, H.; Hein, K.R.G. Effect of Co-combustion of Biomass on Emissions in Pulverized Fuel Furnaces. Fuel Process. Technol. 1998, 54, 189–205. [Google Scholar]

- Skodras, G.; Grammelis, P.; Samaras, P.; Vourliotis, P.; Kakaras, E.; Sakellaropoulos, G.P. Emissions Monitoring during Coal Waste Wood Co-combustion in an Industrial Steam Boiler. Fuel 2002, 81, 547–554. [Google Scholar]

- Ye, T.H.; Azevedo, J.; Costa, M.; Semiao, V. Co-combustion of Pulverized Coal, Pine Shells, and Textile Wastes in a Propane-Fired Furnace: Measurements and Predictions. Combust. Sci. Technol. 2004, 176, 2071–2104. [Google Scholar]

- Gani, A.; Morishita, K.; Nishikawa, K.; Naruse, I. Characteristics of Co-combustion of Low-Rank Coal with Biomass. Energ. Fuel. 2005, 19, 1652–1659. [Google Scholar]

- Kruczek, H.; Raczka, P.; Tatarek, A. The Effect of Biomass on Pollutant Emission and Burnout in Co-combustion with Coal. Combust. Sci. Technol. 2006, 178, 1511–1539. [Google Scholar]

- Chao, C.Y.H.; Kwong, P.C.W.; Wang, J.H.; Cheung, C.W.; Kendall, G. Co-firing Coal with Rice Husk and Bamboo and the Impact on Particulate Matters and Associated Polycyclic Aromatic Hydrocarbon Emissions. Bioresoure Technol. 2008, 99, 83–93. [Google Scholar]

- Kwong, P.C.W.; Chao, C.Y.H.; Wang, J.H.; Cheung, C.W.; Kendall, G. Co-combustion Performance of Coal with Rice Husks and Bamboo. Atmos. Environ. 2007, 41, 7462–7472. [Google Scholar]

- Casaca, C.; Costa, M. Co-combustion of Biomass in a Natural Gas-fired Furnace. Combust. Sci. Technol. 2003, 175, 1953–1977. [Google Scholar]

- Lawrence, B.; Annamalai, K.; Sweeten, J.M.; Heflin, K. Co-firing Coal and Dairy Biomass in a 29 kWt Furnace. Appl. Energ. 2009, 86, 2359–2372. [Google Scholar]

- Patumsawad, S.; Cliffe, K.R. Experimental Study on Fludized Bed Combustion of High Moisture Municipal Solid Waste. Energ. Convers. Manage. 2002, 43, 2329–2340. [Google Scholar]

- Demirbas, A. Co-firing Coal and Municipal Solid Waste. Energ. Source. Part A 2008, 30, 361–369. [Google Scholar]

- Abbas, T.; Costen, P.; Kandamby, N.H.; Lockwood, F.C. The Influence of Burner Injection Mode on Pulverized Coal and Biomass Co-fired Flames. Combust.Flame 1994, 99, 617–625. [Google Scholar]

- Backreedy, R.I.; Fletcher, L.M.; Jones, J.M.; Ma, L.; Pourkashanian, M.; Williams, A. Co-firing Pulverized Coal and Biomass: A Modelling Approach. P. Combust. Inst. 2005, 30, 2955–2964. [Google Scholar]

- Doshi, V.; Vuthaluru, H.B.; Korbee, R.; Kiel, J.H.A. Development of Modeling Approach to Predict Ash Formation during Co-firing of Coal and Biomass. Fuel Process. Technol. 2009, 90, 1148–1156. [Google Scholar]

- Ghenai, C.; Janajreh, I. CFD Analysis of the Effects of Co-firing Biomass with Coal. Energ. Convers. Manage. 2010, 51, 1694–1701. [Google Scholar]

- Dong, C.; Yang, Y.; Yang, R.; Zhang, J. Numerical Modeling of the Gasification based Co-firing in a 600 MW Pulverized Coal Boiler. Appl. Energ. 2010, 87, 2838–2834. [Google Scholar]

- De, S.; Assadi, M. Impact of Biomass Co-firing with Coal in Power Plants: A Techno-economic Assessment. Biomass Bioenerg. 2009, 33, 283–293. [Google Scholar]

- Basu, P.; Butler, J.; Leon, M.A. Biomass Co-firing Options on the Emissions Reduction and Electricity Generation Costs in Coal-fired Power Plants. Renew. Energ. 2011, 36, 282–288. [Google Scholar]

- Wang, X.; Tan, H.; Niu, Y.; Pourkashanian, M.; Ma, L.; Chen, E.; Liu, Y.; Liu, Z.; Xu, T. Experimental Investigation on Biomass Co-firing in a 300 MW Pulverized Coal-fired Utility Furnace in China. P. Combust. Inst. 2011, 33, 2725–2733. [Google Scholar]

- Otero, M.; Sánchez, M.E.; Gómez, X. Co-firing of Coal and Manure Biomass: A TG–MS Approach. Bioresoure Technol. 2011, 102, 8304–8309. [Google Scholar]

- Teixeira, P.; Lopes, H.; Gulyurtlu, I.; Lapa, N.; Abelha, P. Evaluation of Slagging and Fouling Tendency during Biomass Co-firing with Coal in a Fluidized Bed. Biomass Bioenerg. 2012, 39, 192–203. [Google Scholar]

- Li, X.J.; Wang, Y.Z.; Yue, M.Z. Experimental Study on the Corrosion Characteristics during Co-firing of Cornstalk and Lean Coal. Adv. Mat. Res. 2012, 347-357, 2622–2625. [Google Scholar]

- Zuwala, J.; Sciazko, M. Full Scale Co-firing Tests of Sawdust and Bio-waste in Pulverized Coal-fired 230t/h Steam Boiler. Biomass Bioenerg. 2010, 34, 1165–1174. [Google Scholar]

- Huang, Y.; Wright, D.M.; Rezvani, S.; Wang, Y.D.; Hewitt, N.; Williams, B.C. Biomass Co-firing in a Pressurized Fluidized Bed Combustion (PFBC) Combined Cycle Power Plant: A Techno-Environmental Assessment based on Computational Simulations. Fuel Process. Technol. 2006, 87, 927–934. [Google Scholar]

- The Handbook of Biomass Combustion and Co-firirng; Loo, S.V.; Koppejan, J. (Eds.) Earthscan: London, UK, 2008.

- Ghamarian, A.; Cambel, A.B. Biomass Exergy Analysis of Illinois No. 6 Coal. Energy 1982, 7, 483–488. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar]

- Madhiyanon, T.; Sathitruangsak, P.; Soponronnarit, S. Co-combustion of Rice Husk with Coal in a Cyclonic Fluidized-bed Combustor (ψ-FBC). Fuel 2009, 88, 132–138. [Google Scholar]

- Vassilev, S.V.; Vassileva, C.G. A New Approach for the Combined Chemical and Mineral Classification of the Inorganic Matter in Coal. 1. Chemical and Mineral Classification Systems. Fuel 2009, 88, 235–245. [Google Scholar] [CrossRef]

- Al-Mansour, F.; Zuwala, J. An Evaluation of Biomass Co-firing in Europe. Biomass Bioenerg. 2010, 34, 620–629. [Google Scholar]

- Maciejewska, A.; Veringa, H.; Sanders, J.; Peteves, S.D. Co-firing Biomass with Coal: Constraints and Role of Biomass Pre-treatment. JRC's Institute for Energy. 2006. Available online: http://library.wur.nl/way/bestanden/clc/1880856.pdf (accessed on 27 January 2011).

- Basu, P.; Kefa, C.; Jestin, L. Boilers and Burners: Design and Theory; Springer: New York, NY, USA, 2000. [Google Scholar]

- Thumann, A.; Williams, J.; Younger, T.N. Handbook of Energy Audits, 8th ed; The Fairmont Press Inc: Lilburn, GA, USA, 2009. [Google Scholar]

- Power Plant Engineering; Drbal, L.F.; Boston, P.G.; Westra, K.L. (Eds.) Springer: New Yok, NY, USA, 1996.

- Bellhouse, G.M.; Whittington, H.W. Simulation of Gaseous Emissions from Electricity Generation Plant. Int. Elect. Power 1996, 18, 501–507. [Google Scholar]

- Sarofim, A.; Flagan, R.C. NOx Control for Stationary Combustion Sources. Prog. Energ. Combust. 1976, 2, 1–25. [Google Scholar]

- Phong-Anant, D.; Wibberley, L.J.; Wall, T.F. Nitrogen Oxide Formation from Canadian Coals. Combust. Flame 1985, 62, 21–30. [Google Scholar]

- Miller, A.; Bowman, C.T. Mechanism and Modeling of Nitrogen Chemistry in Combustion. Prog. Energ. Combust. 1989, 15, 287–238. [Google Scholar]

- Grass, S.W.; Jenkins, B.M. Biomass Fluidized-bed Combustion: Atmospheric Emissions, Emissions Control Devices and Environmental Regulations. Biomass Bioenerg. 1994, 6, 243–260. [Google Scholar]

- De Souza-Santos, M.L. Solid Fuels Combustion and Gasification: Modeling, Simulation, and Equipment Operations, 2nd ed; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Tsatsaronis, G.; Winhold, M. Exergoeconomic Analysis and Evaluation of Energy-Conversion Plants—II. Analysis of a Coal-fired Steam Power Plant. Energy 1985, 10, 81–94. [Google Scholar] [CrossRef]

- Aljundi, I.H. Energy and Exergy Analysis of a Steam Power Plant in Jordan. Appl. Therm. Eng. 2009, 29, 324–328. [Google Scholar]

- Suresh, M.V.J.J.; Reddy, K.S.; Kolar, A.K. 3-E Analysis of Advanced Power Plants based on High Ash Coal. Int. J. Energ. Res. 2010, 34, 716–735. [Google Scholar]

- Dincer, I.; Rosen, M.A. Exergy: Energy, Environment and Sustainable Development; Elsevier: Oxford, UK, 2007. [Google Scholar]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics, 7th ed; John Wiley & Sons Inc: Hoboken, NJ, USA, 2011. [Google Scholar]

- Eisermann, W.; Johnson, P.; Conger, W.L. Estimating Thermodynamic Properties of Coal, Char, Tar and Ash. Fuel Process. Technol. 1980, 3, 39–53. [Google Scholar]

- Woods, T.L.; Garrels, R.M. The Exergoecology Portal, 1987. Available online: http://www.exergoecology.com (accessed on 10 February 2011).

- National Institute of Standards and Technology (NIST). Standard Reference Data, 1965. Available online: http://webbook.nist.gov/cgi/cbook.cgi?ID=C7446119&Units=SI&Mask=1&Type=JANAFG&Plot=on#JANAFG (accessed on 31 January 2011).

- Berman, R.G.; Brown, T.H. Heat Capacity of Minerals in the System Na2O-K2O-CaO-MgO-FeO-Fe2O3-A12O3-SiO2-TiO2-H2O-CO2: Representation, Estimation, and High Temperature Extrapolation. Contrib. Mineral. Petrol. 1985, 89, 168–163. [Google Scholar]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Mehmood, S.; Reddy, B.V.; Rosen, M.A. Energy Analysis of a Biomass Co-firing Based Pulverized Coal Power Generation System . Sustainability 2012, 4, 462-490. https://doi.org/10.3390/su4040462

Mehmood S, Reddy BV, Rosen MA. Energy Analysis of a Biomass Co-firing Based Pulverized Coal Power Generation System . Sustainability. 2012; 4(4):462-490. https://doi.org/10.3390/su4040462

Chicago/Turabian StyleMehmood, Shoaib, Bale V. Reddy, and Marc A. Rosen. 2012. "Energy Analysis of a Biomass Co-firing Based Pulverized Coal Power Generation System " Sustainability 4, no. 4: 462-490. https://doi.org/10.3390/su4040462

APA StyleMehmood, S., Reddy, B. V., & Rosen, M. A. (2012). Energy Analysis of a Biomass Co-firing Based Pulverized Coal Power Generation System . Sustainability, 4(4), 462-490. https://doi.org/10.3390/su4040462