3.2. Remaining Subjects of Molten-Salt Reactor

Though there are many advantages in the concept of molten-salt reactors, there are still some remaining many subjects which have to be cleared before its commercialization. For example, MSBR focused on enabling high conversion ratio. MSBR is a thermal neutron reactor thus MSBR was designed to have small leakage of neutron from reactor core. MSBR adopted graphite as moderator. As a result, internal region of reactor vessel is filled with moderator graphite. Volume of solid graphite does not expand significantly when temperatures increase, thus the ability of moderation of neutron is not lost. On the other hand, volume of liquid fuel can expand against temperature rise. This contributes to coarse ability of moderation of neutron. However, in the case of MSBR which has large volumetric ratio of solid phase by graphite, total temperature reactivity coefficient can be positive. Original evaluation carried out by ORNL indicated that temperature reactivity coefficient becomes negative but the value has been recalculated in 2005 to have a positive value [

23]. In the explanation of molten-salt reactor in Wikipedia, a conceptual illustration is shown which indicates the use of graphite moderator [

24]. This illustration is originally made for generation IV international forum (GIF). In contrast to this, the web site of GIF apparently claims that present concept of GIF’s molten-salt reactor does not use graphite moderator by showing a large red cross [

25].

Furukawa pointed out the difficultness of online reprocessing unit considered in the design of MSBR and proposed a molten-salt reactor named “FUJI series” which enables conversion ratio to be 1, even by eliminating the online reprocessing unit [

15]. Designing policy of FUJI series is simple: (1) no use of online reprocessing; (2) thermal spectrum reactor; and (3) reduce leakage of neutron from reactor core. As a result, volumetric ratio of solid graphite moderator was kept high in reactor core for achieving the conversion ratio of 1. Furukawa revealed that FUJI has negative temperature reactivity coefficient [

15] but Hirose implied that the value would be positive [

26].

The question of temperature reactivity coefficient can be solved by taking other criteria of designing molten-salt reactor. For example, the value will become small if neutron leakage from reactor core is increased. In this case, conversion ratio will be somewhat small. Selecting fast spectrum neutron instead of thermal spectrum will be another possibility. This can be done by eliminating graphite moderator from the core. French MSFR [

27] and Russian MOSART [

28] correspond to this approach.

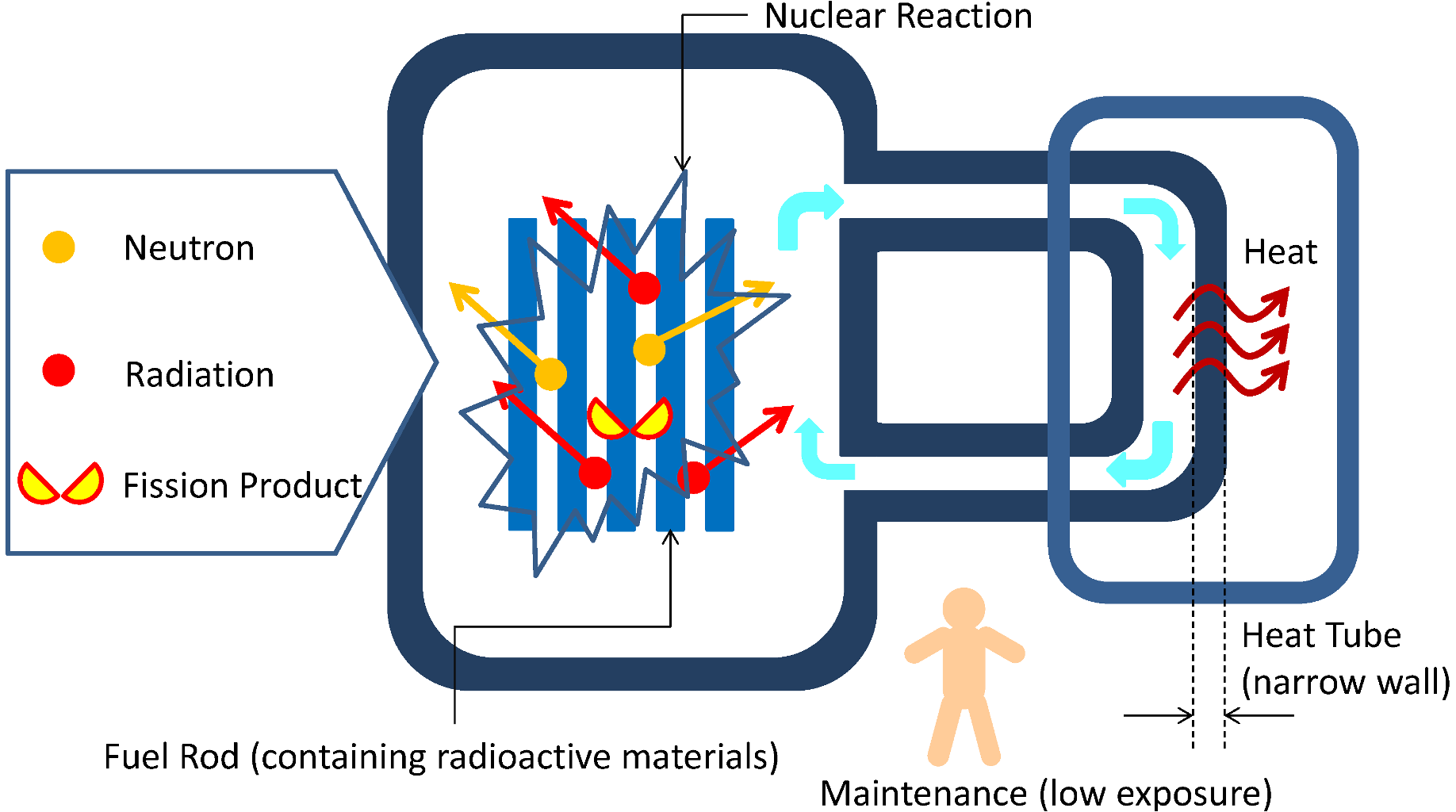

Most of the proposed designs of molten-salt reactor are targeted to be a large capacity power reactor. Though there were several detailed differences in reactor core designs, the basic configurations as a power system were the same. That is to say: (1) fission reaction happens in the core; (2) generated thermal energy heats up the surrounding molten-salt fuel; (3) hot liquid fuel is transferred from reactor core to intermediate heat exchanger through external pipe; (4) thermal energy is transferred to secondary coolant via thin wall of intermediate heat exchanger; (5) cooled molten-salt fuel is pumped back to go into the reactor core again. The path where molten-salt fuel goes around is called the primary circuit. Most of the other remaining subjects relating to molten-salt reactor are caused by this basic configuration. That is to say, these subjects are caused by the radioactive materials including fission products leaving the reactor core and circulating in the primary circuit. For example, the main subjects are: (1) increase of radiation background around primary circuit; (2) loss of delayed neutrons due to the flowing out of precursor toward external pipe; (3) erosion of thin thickness external pipe by direct contact of molten-salt containing many different kind of fission products especially in the region of intermediate heat exchanger; (4) transportation of tritium generated by neutron capture of lithium-6 from molten-salt fuel to secondary coolant because it is easy for tritium going through metal material; and (5) uncertainty of availability of containing fission product inside of primary circuit where there are pumps. Though many other small problems are solved, the safety of the molten-salt reactor will never be achieved unless at least these main problems are solved. In order to help understanding of these difficulties of molten-salt reactor, the technical way involved in the present light water reactor taking care of similar questions will be shown in

Figure 2.

Figure 2.

Nuclear reactions and radioactive materials contained in light water reactor.

Figure 2.

Nuclear reactions and radioactive materials contained in light water reactor.

As shown in

Figure 2, nuclear fuel exists only in the center of reactor core and nuclear reaction also happens in this region in the case of the light water reactor. Newly generated radioactive materials are also kept in this region namely inside the nuclear fuel rod. Though high radiation occurs, it is limited around the reactor vessel. Thus, theoretically, radiation background around primary circuit does not become high. The delayed neutrons, which play an important safety role, occur only in the reactor core because precursors are kept in the nuclear fuel pellets. Thermal heat generated in the reactor core is transferred via thin wall of steam generator (in the case of pressurized water reactor) to a secondary loop. Though often a small pinhole is shaped on this thin wall of steam generator, basically no radioactive materials are contained in the coolant of primary circuit. Tritium is also produced in light water reactor but the amount is much smaller than in the case of the molten-salt reactor which utilizes lithium as a medium.

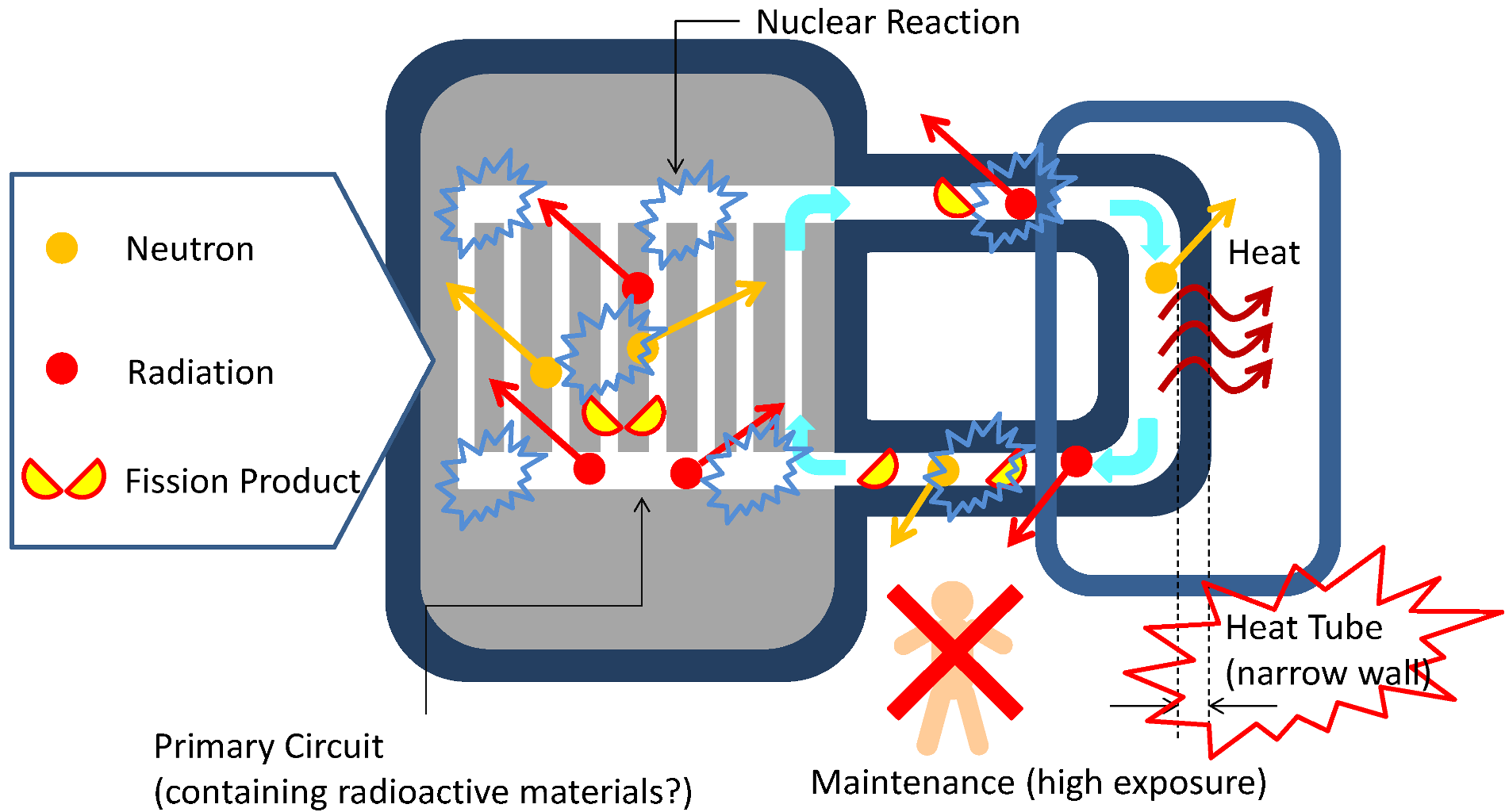

Subjects relating to molten-salt reactor are illustrated in

Figure 3. Whereas, in the case of light water reactor, nuclear reactions including decay happen not only inside reactor core but also in pipes of primary circuit. Thallium-208 goes through pipes of primary circuit and thus radiation around these pipes increases. Exposure to radiation will be greater than in the case of light water reactor. Though this tendency depends on the length of pipes, many delayed neutrons are lost outside of reactor core and the safety margin of nuclear reaction control is decreased. Of course, these lost neutrons are not used for converting thorium to uranium-233. Even though a modified Hastelloy N has been developed as material of molten-salt reactor which improved resistivity of erosion by tellurium as fission product, its reliability under operational conditions has to be confirmed, especially for a thin wall instrument such as intermediate heat exchanger. These problems are common in previously proposed molten-salt reactors such as FUJI.

Figure 3.

Nuclear reactions and radioactive materials contained in molten-salt reactor.

Figure 3.

Nuclear reactions and radioactive materials contained in molten-salt reactor.

3.3. Development of “Internal Circulating and Surface Heat Transferring Molten-Salt Reactor”

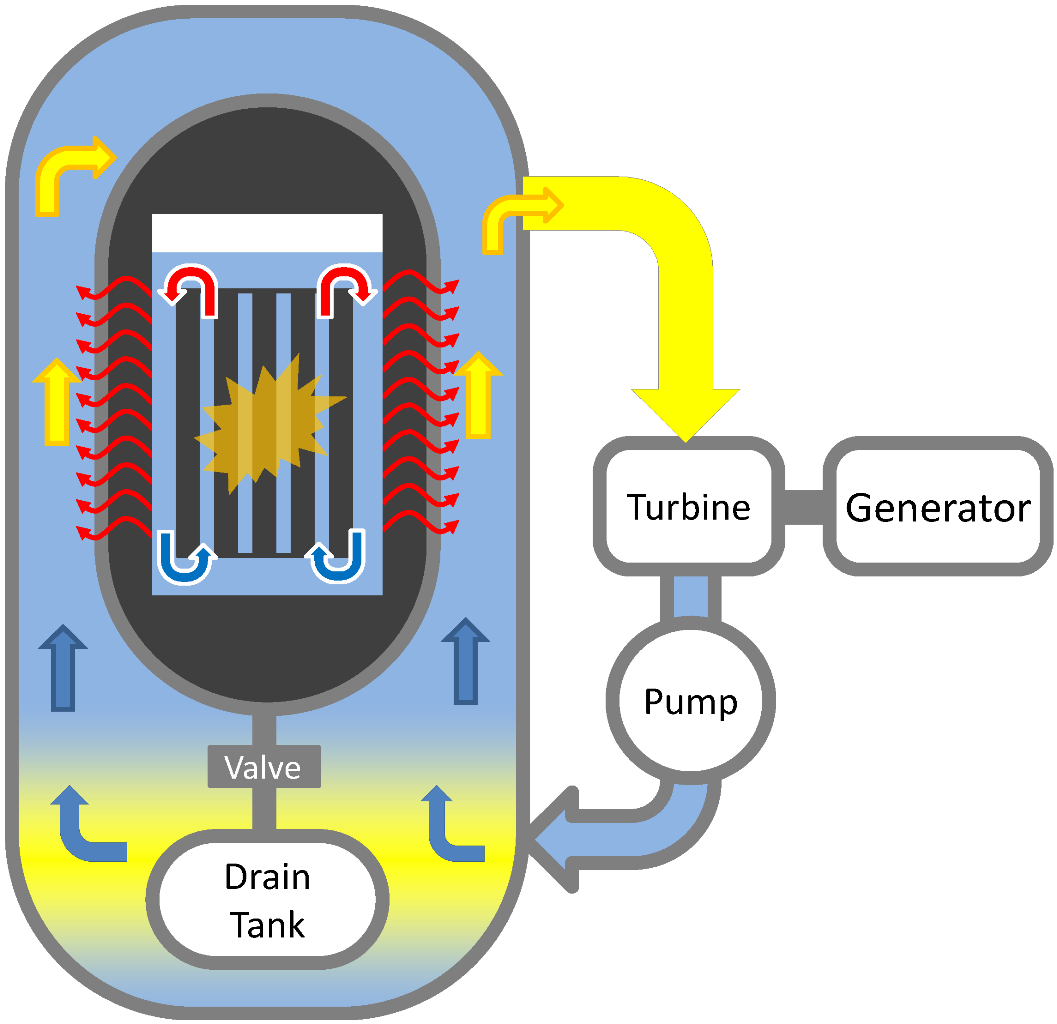

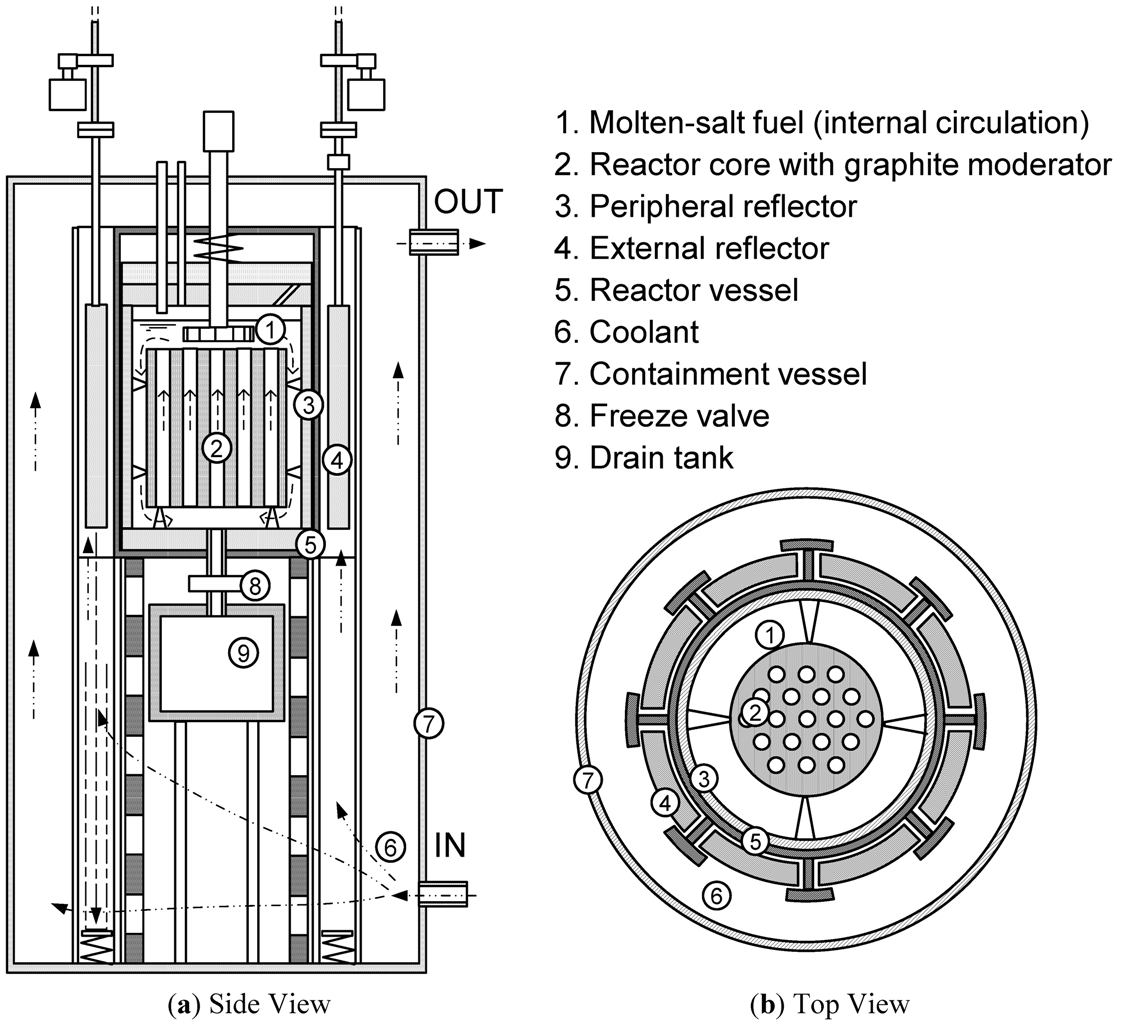

Requirements of nuclear power from the view of sustainability can be summarized as follows. They are: (1) reduction of waste including radioactive materials; (2) enhancement of nuclear non-proliferation; (3) high safety; and (4) availability of small capacity with enough high economy. In addition (5) availability of load-following operation and (6) eliminating bottle neck of supply chain such as Japan Steel Works having more than an 80% share of pressure vessel production have to be satisfied. Small capacity reactor can be of course done in a scheme of light water reactor but economy is not necessarily high because of the production and exchange of fuel rods. For satisfying requirement (1), thorium was selected as fertile material and basic concept of molten-salt reactor was chosen. Concept of molten-salt reactor also enables to have small size of the reactor with acceptable economy. Bottleneck in supply chain of producing large-scale light water reactor can be eliminated by adopting molten-salt reactor which has low inner pressure. Since the reactor size is small, there may be relatively small efficiency of neutron usage or large amount of neutron loss. It means that small molten-salt reactor tends to have a small conversion ratio. Thus, the value of conversion ratio is not considered to have high priority in this study. Even though molten-salt reactor is adopted as fundamental concept, the previously proposed design using primary circuit for heat transfer such as FUJI does not solve molten-salt reactor’s engineering problems mentioned above. That is to say, the heat generated in reactor core is transferred to external heat exchanger via primary circuit by using fuel salt. Therefore, the author is developing a new concept of molten-salt reactor to overcome these subjects by eliminating the function of heat transfer via primary circuit. The concept’s structural features are illustrated in

Figure 4. A patent for this design of “internal circulating and surface heat transferring molten-salt reactor” is in process (Request number 2012-122679 in Japan).

Figure 4.

Conceptual design of internal circulating and surface heat transferring molten-salt reactor.

Figure 4.

Conceptual design of internal circulating and surface heat transferring molten-salt reactor.

In this new concept, thermal energy generated in the core is transferred by fuel salt itself. The fuel salt flows upward in the core and then moves in a peripheral direction at the top of the core. It goes into the gap formed by graphite moderator and peripheral reflector. The fuel salt transfers its heat to peripheral reflector while it goes down this gap. The transferred heat moves by thermal conduction within both the peripheral reflector and its surrounding reactor vessel. Finally, the heat is moved by coolant which flows outside of the reactor vessel. Namely, the fuel salt does not go out of reactor vessel via narrow tubes having thin wall thickness optimized for high efficiency of heat transfer.

Graphite is used in the core as moderator. Thus, this concept is a thermal reactor. Temperature reactivity coefficient can be negative by the limiting small size of the reactor. It is estimated that leakage of neutrons will be increased due to such a small reactor resulting neutron radiation outside of reactor vessel and essentially low efficiency of neutron. Therefore, external reflector is equipped outside of the reactor vessel to reduce neutron loss as shown in

Figure 5. This external reflector is movable toward axial direction. Thus, it enables to actively control the ratio of neutron reflection. This keeps temperature reactivity coefficient to be negative value. In contrast to the previously proposed molten-salt reactors which lose delayed neutrons in pipes of primary circuit because of no reflection around pipes, this new conceptual design can keep the delayed neutron within the reactor vessel. Molten-salt reactor has an ability of load following but its time-constant is more than 10 minutes [

29]. This value must be much shorter if the small molten-salt reactor proposed here is used in a small-scale grid. It is expected that this function of active control of neutron reflection will improve the ability of load following operation.

Figure 5.

Schematic diagram of internal circulating and surface heat transferring molten-salt reactor.

Figure 5.

Schematic diagram of internal circulating and surface heat transferring molten-salt reactor.

Ceiling and bottom of the reactor core are also covered by neutron reflectors, therefore fuel salt does not directly contact with reactor vessel. This non-direct contact of fuel salt with reactor vessel enables avoiding the mass-transfer phenomena caused by solubility difference of metallic components to salt at hot part and cold part. It is also expected that most of tritium produced in a reaction between lithium-6 and neutron will be kept inside the reactor vessel because there is little contact of fuel salt and vessel. Noble gases such as xenon which act as neutron poison do not dissolve in the fuel salt and are kept in the upper space of reactor vessel. From these features, this conceptual design can be expressed as an “internal circulating and surface heat transferring” molten-salt reactor. This design can equip high safety by eliminating pipes of primary circuit.

Generally speaking, the purpose of the primary circuit is only heat transfer and thus it has a large enough capacity for heat removal. It is imagined that the capacity of thermal generation in the proposed design with no primary pipes, will be small. Although this design does not require a large capacity because the motivation of this study is to realize a small reactor with high safety yet remaining economical, it is necessary to evaluate upper limit of thermal generation from an engineering point of view. Neutronics behavior of this design has been confirmed in a preliminary stage of discussion and now its detailed study is being carried out. The results will be reported in the near future. In this paper, upper limit of thermal capacity of this reactor is demonstrated as below.

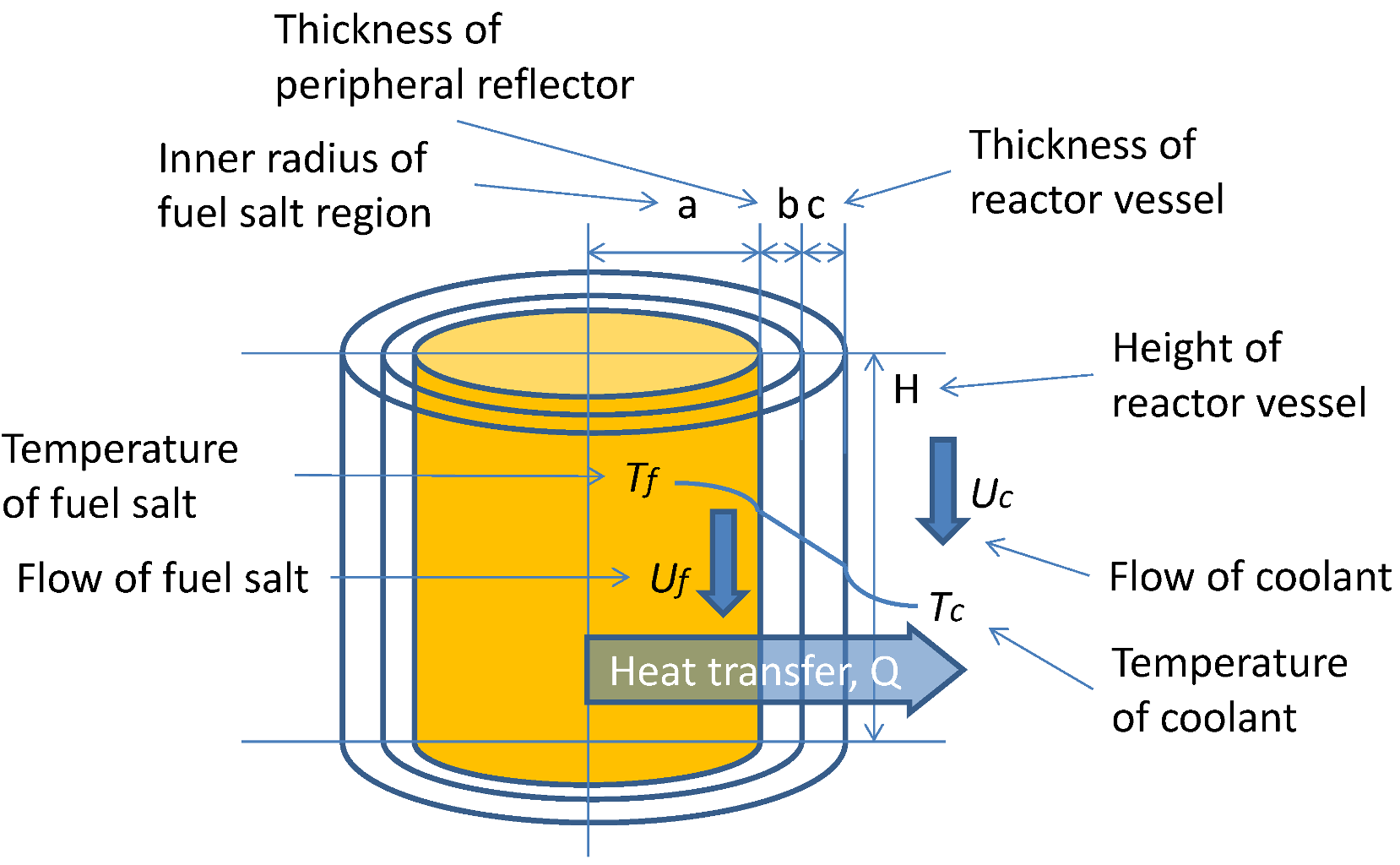

In this design, there is a molten-salt as hot fluid in the center of reactor vessel and solid peripheral reflector and reactor vessel surround the fuel salt as cylinders. Cold working fluid flows outside of reactor vessel removes heat. Though there is a solid moderator made of graphite in the fuel salt, it is assumed that the core is filled with homogeneous fuel salt. Then the system can be treated simply as a multi-layered cylinder. Calculation model of heat transfer is illustrated in

Figure 6.

Figure 6.

Calculation model of heat transfer.

Figure 6.

Calculation model of heat transfer.

Amount of heat transfer Q from multi-layered cylinder can be expressed as Equation (1).

here, R is total thermal resistance, Tf is temperature of fuel salt, Tc is temperature of coolant. R can be expressed by using thermal resistance of fuel salt (Rf), that of peripheral reflector (Rr), that of reactor vessel (Rv) and that of coolant (Rc) as shown in Equation (2).

Each thermal resistance can be expressed as Equations (3–6).

here, a, b and c are radius from center of reactor to peripheral reflector, thickness of this reflector and thickness of reactor vessel, respectively. H is height of reactor vessel. kr and kv are thermal conductivity of peripheral reflector and reactor vessel. hf and hc are heat transfer coefficient of fuel salt and coolant. hf and hc can be expressed as Equations (7,8).

here, L is representative length and Nu is Nusselt number. In this study, it is assumed that the reactor vessel has large diameter and the surface can be treated as flat plate. Nu is determined by condition of flow. Condition of fuel salt can be evaluated by using Equation (9).

here,

Re is Reynolds number.

Uf is superficial fuel salt velocity.

ν is kinematic viscosity of fuel salt. In this study, Flibe (LiF – BeF

2 – ThF

4 – UF

4: 71.76, 16, 12, 0.24 mol%) is considered as fuel salt. Hastelloy N is used as reactor vessel’s structural material. Characteristics of these materials are summarized in

Table 1.

Table 1.

Characteristics of materials considered in this study.

Table 1.

Characteristics of materials considered in this study.

| Item | Value |

|---|

| ρ (Flibe) | 2,270 kg/m3 |

| kf (Flibe) | 1.2 W/mK |

| Cp (Flibe) | 2,383 J/kgK |

| ν (Flibe) | 1.15×10−5 m2/s |

| kr (Graphite) | 100 W/mK |

| kv (Hastelloy N) | 18 W/mK |

Re of fuel salt becomes 8696 from Equation (9) by considering that the representative length L is 1 m corresponding to height of reactor vessel and superficial velocity Uf is 0.1 m/s. The condition of fuel salt on a flat plate is laminar flow because above Re is smaller than 3 × 105. The flow is forced convection. Then Equation (10) can be used to obtain Nu for fuel salt.

Here Pr is Prandtl number and determined by Equation (11). Its value becomes 52.

Then Nu becomes 228 and hf becomes 273.

There are many candidates of coolant such as water, liquid metal, molten-salt and gaseous medium. In our present studies, helium is considered because this concept is aimed at realising a small and compact reactor. Characteristics of helium depend strongly on pressure and temperature. Density of helium can be obtained by Equations (12–14). Thermal conductivity of helium can be obtained by Equations (15,16). Viscosity of helium can be obtained by Equations (17,18).

R is gas constant being 2.07723 × 10−3 MPa/kgK. Pressure and temperature of coolant are 4 MPa and 873 K, respectively. Then density of helium becomes 2.2 kg/m3, thermal conductivity becomes 0.33 W/mK and viscosity becomes 4.06 × 10−5 kg/ms. Kinematic viscosity can be obtained by Equation (19) and the value is 1.85 × 10−5 m2/s.

Specific heat capacity of helium is 5192 and then Pr of helium becomes 0.64. Re of coolant helium becomes 5.4 × 105 for its superficial velocity being 10 m/s. Flow condition of coolant is turbulent flow because above Re is larger than critical value between laminar flow and turbulent flow being 3 × 105. Nu of coolant helium can be obtained by Equation (20). This equation is also for a flow on flat plate but the flow is turbulent. In this case, the value is 1231.

Heat transfer coefficient of helium can be calculated to be 405 from Equation (8). Each thermal resistance can be obtained as below by assuming that reactor vessel’s outer radius is 0.5 m, thickness of peripheral reflector is 0.1 m, thickness of reactor vessel is 0.01 m and height of reactor vessel is 1 m.

It can be seen from the result that the governing factor of heat transfer in this newly proposed reactor is mainly by thermal resistance of fuel salt. Then thermal resistance of helium coolant and that of peripheral reflector are large. Thermal resistance of reactor vessel can be improved by reducing its thickness but it should not be small from a mechanical intensity point of view. It is not necessary to seriously consider this value as far as it is smaller than other resistances.

It is not necessary to improve thermal resistance of peripheral reflector because it is smaller than that of helium coolant, too. Thickness of peripheral reflector affects neutron behavior. If this thickness is small, the amount of neutrons going through the vessel will be increased. Even though these neutrons can be returned to reactor by external reflector, neutron radiation of reactor vessel will be enlarged. Therefore, thickness of peripheral reflector must be evaluated from both considerations of heat transfer and neutronics. Detailed discussion of this will be reported in the near future.

Fuel salt existing in the reactor core has a possibility of phase change. Thus, temperature of fuel salt has to be kept lower than boiling point of the fuel, i.e., 1703 K. Thermal power corresponding to above conditions is 289 kW. Melting point of graphite being 3823 K is large enough compared to boiling point of fuel salt.

Thermal resistance depends on surface area of heat transfer. Therefore, thermal resistance can be small for large radius and height of reactor vessel. Several examples of thermal resistances for different radius and height of reactors are summarized in

Table 2.

Table 2.

Calculation results of thermal resistance and maximum thermal power.

Table 2.

Calculation results of thermal resistance and maximum thermal power.

| Uf | 0.1 m/s | 1 m/s | 2.8 m/s |

|---|

| a + b + c, H | 0.5 m, 1 m | 1 m, 1 m | 0.5 m, 2 m | 1 m, 2 m | 1 m, 2 m | 0.7 m, 1.6 m |

|---|

| Rf | 1493 × 10−6 | 654 × 10−6 | 1056 × 10−6 | 463 × 10−6 | 146 × 10−6 | 56 × 10−6 |

| Rr | 408 × 10−6 | 179 × 10−6 | 204 × 10−6 | 89 × 10−6 | 89 × 10−6 | 169 × 10−6 |

| Rv | 181 × 10−6 | 89 × 10−6 | 90 × 10−6 | 45 × 10−6 | 45 × 10−6 | 80 × 10−6 |

| Rc | 786 × 10−6 | 393 × 10−6 | 452 × 10−6 | 226 × 10−6 | 226 × 10−6 | 386 × 10−6 |

| Qmax | 289 kW | 630 kW | 460 kW | 1008 kW | 1639 kW | 1202 kW |

Qmax is the maximum thermal power of the reactor satisfying temperature of fuel salt smaller than its melting point at each condition. Thickness of peripheral reflector and reactor vessel are kept the same at 0.1 m and 0.01 m, respectively.

Thermal resistance of fuel salt depends on its heat transfer coefficient. The value is determined by Nu and it increases by superficial velocity. Thus, thermal resistance is evaluated for a large superficial velocity of fuel salt. Qmax for a 1 m radius, 2 m height of reactor vessel and 1 m/s of superficial fuel salt velocity becomes 1639 kW (1.6 MW). Qmax for a 0.7 m radius, 1.6 m height of reactor vessel and 2.8 m/s of superficial fuel salt velocity is 1.2 MW. These values are of MSRE which operated at ORNL in 1960’s. It can be seen that the upper limit of thermal power of presently proposed reactor is small compared to the MSRE’s thermal output designed to be 10 MW.

This design’s policy is to achieve smallness of capacity and ease in manufacturing. Though theoretically the economy of molten-salt reactor is excellent, it has to be confirmed for our new design including additional requirements for fuel preparation, reprocessing and so on.