Abstract

The article reviews the literature on the potential utilization of decommissioned wind turbine blade waste (WTBW) in construction materials, including geopolymers, which are rarely discussed. The review indicates that only the mechanical processing of WTBW creates prerequisites for its possible use as fillers in construction materials; however, adjustments to the composition of binding materials are necessary. Wind turbine blades (WTBs) are usually made from strong and durable composite materials, thus posing serious recycling and environmental challenges. Thermal process methods are promising approaches for recovering glass fibers from thermosets of WTBW through pyrolysis or converting WTBW into fibers via plasma processing. Preliminary durability studies of such recovered and recycled glass fibers have demonstrated their potential application in geopolymers or cement-based materials. Implementing these technologies would expand the waste management system, completing recycling and reuse solutions. To successfully adopt more environmentally friendly solutions, further development of geopolymer production processes and sustainable fiber recovery is recommended.

1. Introduction

Wind energy is one of the cleanest and most sustainable methods of generating electricity. It helps reduce greenhouse gas emissions and decreases our reliance on fossil fuels. However, despite these advantages, environmental challenges are associated with the waste management of wind turbine components, particularly the blades.

The growing accumulation of waste from WTBs has become a significant concern in recent years. It is predicted that by 2050, the world will generate approximately 43 million tons of this waste unless more efficient recycling solutions are implemented [1]. Several countries in the European Union, including Germany, the Netherlands, Austria, and Finland, are already banning the landfilling of wind turbine blades and encouraging the development of alternative solutions.

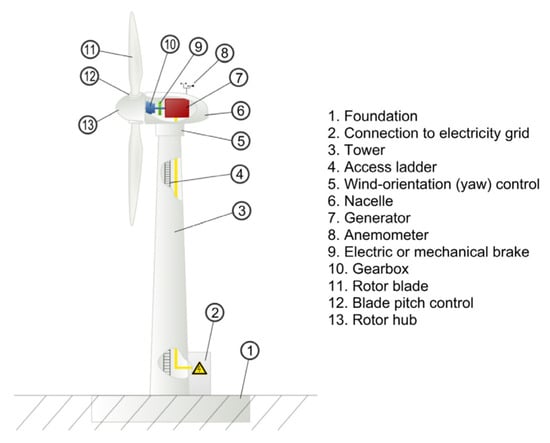

Numerous excellent reviews have been published in scientific journals dealing with challenges associated with wind turbine (WT) waste management [1,2,3], recycling, and upcycling [2,3,4,5,6]. According to the hierarchy proposed by D. Jasinska and M. Dutkiewicz [5], waste management starts with reuse, followed by recycling and recovery, and finishes with disposal, where the last one should be the least expected procedure. However, the construction of wind turbines limits the complete recycling or reuse of all their components. The review by S. T. Tayebi et al. [7] presents a detailed description of the main construction elements of WT and their functions (Figure 1). Materials, such as steel, copper, cast iron, and aluminum, are used in the production of towers, rotors, gearboxes, generators, nacelle, and foundations, whereas glass- or carbon fiber-reinforced polymers, foam, and wood are used for wind turbine blade (WTB) production [7].

Figure 1.

Standard figure of upwind three-bladed WT. Reprinted from Ref. [7], 2024, MDPI.

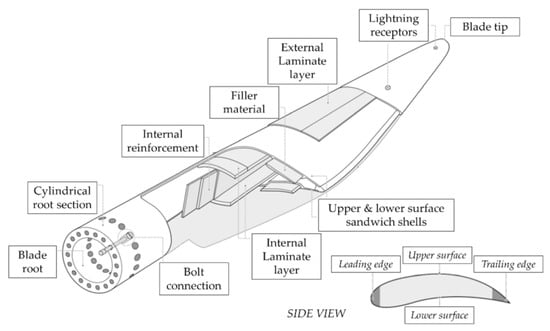

The repurposing and reuse of WTBs is the target of most studies discussed in numerous reviews [3,4,5,6,8]. Repurposing involves redesigning WTBs by incorporating their elements in new structures [6]; however, difficulty in establishing the materials’ properties limits their wider adaptation. The main components of WTBs include balsa wood, polyurethane, and a thermoset polymeric matrix composite. This composite typically contains over 50 wt% of fibers and is known as carbon fiber-reinforced polymer (CFRP) or glass fiber-reinforced polymer (GFRP). These materials are generally the target for recycling or recovery (Figure 2).

Figure 2.

Main components of a typical WTB. Reprinted from Ref. [7], 2024, MDPI.

The literature widely discusses the application of various methods for GFRP recycling [7]. Recycling usually defines the conversion of waste into a new product that can be used as a standard for other applications [7]. The most common recycling methods for GFRP utilization are chemical, thermal, and mechanical recycling [3,4,5,6]. A detailed overview of each technique, along with its strengths and limitations, can be found in the review by J. Quereshi [6].

Mechanical recycling is a cost-efficient and straightforward process; however, it demonstrates a low fiber recovery, leading to the generation of up to 40% waste material [3,6]. Chemical recycling methods, such as high- and low-temperature solvolysis, are applied for clean, mainly carbon fiber recovery. However, solvolysis is costly and consumes aggressive chemical reagents that may negatively impact the environment [3,6]. Alongside mechanical recycling, thermal recycling has become a commercially successful technique as it generally provides higher recycling and fiber recovery rates, even though it may generate harmful gases and slag [2]. As with the solvolysis method, clean fibers without char deposits are recovered by fluidized bed combustion of GFRP, which is one of the thermal recycling methods [3,6]. Since the strength of thermally recycled fibers is reduced by up to 25%, the hot alkali treatment was proposed recently by K. Pender and L. Yang [9]. A microwave-based thermal recycling method [10,11,12] preserves carbon fibers from degradation, particularly when performed in an argon atmosphere. In contrast, treatment in an oxygen atmosphere results in defects on the fiber surface [13]. The conventional pyrolysis method minimizes carbon fiber degradation [2]. However, the thermal decomposition of epoxy thermosets requires higher temperatures and an oxidizing atmosphere, which can negatively affect the strength of the recovered fibers [3,6,13].

Pyrolysis, fluidized bed, and microwave methods are commonly recognized as thermal WTBW recycling techniques, whereas plasma technology is less frequently mentioned. Additionally, there is a notable lack of literature specifically reviewing the application of wind turbine blade waste (WTBW or WTB waste) in geopolymers or the durability aspects of recovered or recycled glass fibers. This short review addresses the management and sustainability challenges associated with these issues and the aforementioned aspects of recycled glass fiber.

2. Management Aspects of Wind Turbine Blade Waste (WTBW)

A wind turbine blade (WTB) is typically made from glass fiber, which primarily contains silicon dioxide (SiO2), calcium oxide (CaO), and aluminum oxide (Al2O3) or carbon fiber-reinforced composites bonded with epoxy resin [14]. The epoxy resin contains primary epoxy rings and hydroxyl functional groups. Additionally, polyester and, less commonly, vinyl ester resin are also used. The glass fiber-reinforced composite polymers (GFRPs) provide the necessary strength, lightweight characteristics, and resistance to environmental factors, making the blades exceptionally durable. However, this durability poses a significant challenge during the recovery phase, as these materials are difficult to recycle due to their unique structure, which traditional recycling methods struggle to address [15].

There are currently several methods for managing blade waste [3,4,16,17,18]. One of the most common is landfilling; however, this option is increasingly restricted due to stricter environmental regulations [19]. Another method is incineration for energy recovery, but because of the glass fiber composition, this process is inefficient and can lead to additional pollution. A proposed method involves incinerating GFRP for material recovery in the wind sector, utilizing the waste material in the cement industry [20]. In this process, the non-combustible GFRP can be used as a substitute for limestone fillers and clay in concrete [21]. However, this method is generally not favored due to technological and economic challenges, as cement kilns are not designed for incinerating waste blade materials.

One of the most promising, circular, and low-carbon solutions is chemical recycling, where resins are broken down into primary raw materials that can be used to manufacture new blades [22]. However, this process requires specialized equipment, and concerns arise regarding the high solvent content and toxic gas emissions associated with solvolysis [23]. Additionally, biodegradable resins are being developed to facilitate the production of more easily recyclable composite components [24,25].

Moreover, projects are being developed in some countries to reuse dismantled blades, such as in the construction sector, where they can be adapted as structural elements for small architecture, bridges, or buildings [6].

Currently, no technology is entirely feasible or promising, and a structured market for products made from recycled materials has yet to be established. Mechanical recycling is the most advanced method, which has attained a Technology Readiness Level (TRL) of 9 [26]. This method involves crushing blades and using them as filler in construction materials; however, it is still not widely adopted due to its low economic value, technological limitations, and the absence of life cycle assessments (LCAs), which require additional data. This review will discuss the application of a mechanical method to wind turbine blade waste recycling.

3. Sustainability Challenges in the Construction Industry

The cement industry is one of the world’s largest and most polluting industries. Although cement plays an essential role in construction, as it is a key raw material used in producing concrete, the production process of cement is associated with extremely high carbon dioxide (CO2) emissions, significant energy consumption, and various negative environmental impacts.

Rapid urbanization and infrastructure development continue to drive a high demand for cement, which presents serious sustainability challenges. Global cement production exceeds 4 billion tons each year, making the industry responsible for 12–15% of the total industrial energy consumption [27] and about 7% of the global anthropogenic CO2 emissions [28], which is equivalent to the emissions produced by the entire transport sector. The primary source of these emissions is the clinker production process, where limestone is heated to around 1450 °C. This process emits vast amounts of CO2 from the fossil fuels used in combustion and the chemical reactions involved.

To address these challenges, the Global Cement and Concrete Association (GCCA) has set ambitious targets: to reduce the carbon footprint by 40% by 2030 and to achieve zero emissions from cement production by 2050 [29].

In addition to CO2 emissions, cement production also causes other environmental problems. The process requires many natural resources, in particular limestone, clay, and sand, and the extraction of these can lead to the destruction of ecosystems and loss of biodiversity. Cement factories also consume large amounts of water, and the dust emitted during production and transport can have a negative impact on the health of local communities.

To address the sustainability challenges of the cement industry, cement producers and scientists are looking for different ways to reduce emissions and energy consumption. Achieving sustainability in cement production requires fewer virgin materials, more recycled materials, and renewable resources, with an increasing focus on lower carbon footprint alternatives. One way to reduce CO2 emissions is to use clinker substitutes, such as bottom ash from municipal solid waste incinerators, fly ash from coal power plants, and gypsum from the desulfurization plants used in power plants [30,31], which reduces the energy and carbon footprint of cement production. New technologies, including carbon capture and sequestration (CCS) and low-carbon cement grades, are being developed, which could significantly reduce the industrial impact on the climate.

The cement industry faces challenges in utilizing alternative raw materials, particularly those derived from other sectors considered by-products or waste [31]. Recently, a growing amount of research has focused on solutions for disposing of wind turbine blades at the end of their service lives. Some of these studies investigate the potential use of GFRP waste from wind turbine blades in concrete production.

4. Valorization of Wind Turbine Blade Waste (WTBW)

Integrating waste from WTBs into concrete production is an innovative approach to addressing waste management issues. Researchers and industry professionals are becoming increasingly interested in this technology’s economic and environmental benefits. Incorporating WTBW into concrete can offer several advantages, including promoting sustainable waste recycling, creating greener and more durable building materials, and reducing landfill loads. One of the primary benefits is that using WTBW significantly lowers carbon dioxide emissions by reducing the reliance on cement [32]. Research indicates that concrete containing WTBW has a lower global warming potential (GWP) than traditional fiber-reinforced concrete [33]. For instance, incorporating 1% WTBW by volume can reduce the GWP by 51.48% compared to concrete that utilizes steel fibers.

A. Tyurkay et al. [3] emphasized that material passports are essential for the sustainable use of end-of-life (EoL) WTB materials. However, most manufacturers rarely disclose their exact compositions due to the confidentiality that persists in the wind industry. Additionally, the composition of WTBs can vary widely among manufacturers, and the lack of composition passports makes it challenging to compare results. Even a small quantity of additives can significantly impact the properties of cement. Therefore, we have chosen to focus this review exclusively on articles concerning the use of WTBW, excluding the literature related to other by-products.

4.1. Thermal Methods for Glass Fiber Recycling and Recovery

4.1.1. Pyrolysis Process in Fiber Recovery from GFRP

Pyrolysis is a thermal method in which thermal treatment occurs at a relatively low temperature (below 800 °C) in an inert atmosphere. During the process, thermosets decompose while solid products remain [3,6,7,34,35,36,37]. The output of pyrolysis is fibers and fillers together with oil products, such as toluene, benzene, phenol, benzene, and others [2,3,36]. The liquid products can be used as an energy resource for the process, while fibrous material is contaminated by char. The application of the one-step pyrolysis process requires a post-pyrolysis step in an oxidizing atmosphere to remove the residual carbon remaining on the fibrous material [38,39]. It consumes additional energy and increases operational costs. Therefore, the recovered oil and gas after the pyrolysis of WTBs is returned to the process, thus increasing the operational flexibility [38].

The increasing operational temperature negatively affects the properties of the recovered fibers, making them more brittle [13,36,37,40]. The pyrolysis atmosphere (nitrogen or air) has little effect on the tensile strength of the recovered fiber until the temperature is below 480 °C [37,41] (Table 1). A high pyrolysis temperature (above 500 °C) is required for the complete decomposition of epoxy resins; however, it induces the diffusion of surface flow over the glass fiber [23,39]. M. X. Xu et al. [39] investigated the impact of H2O and CO2 on the mechanical properties of recovered glass fibers. It was found that H2O facilitated the oxidation of char, though it caused the thermal–oxidative diffusion of the surface flows, reducing the strength of the recovered fibers up to 6%. The same group of researchers [42] proposed the introduction of acetic acid to co-pyrolysis, while L. Li et al. [40] used coal-fired glue gas single-step processing to reduce the recovered fibers’ surface defects, thus improving tensile strength.

Table 1.

Summary of the recovered fibers’ properties.

They studied the impact of CO2 and O2 gases on the degradation mechanism of the recovered glass fiber and found that the concentration of gas and the processing stage are crucial parameters [40]. Mild oxidation promotes the growth of defects on the surface of the fiber, increasing Si dangling bonds or oxygen vacancies [40]. Moreover, during the oxidation stage, water generated from oxidation products may diffuse through pitting or cracks and react with SiO2, developing a larger amount of Si-OH, and reducing fiber strength. However, the damaging effect of Si-OH may be significantly reduced with the incorporation of 15% of CO2 gas volume [40].

G. Cheng et al. [41] investigated the pyrolysis process of WTBs in coal-fired flue gas. The impact of process parameters, such as temperature and time, on the tensile strength of glass fiber was studied. They found that the optimal temperature should be in the 420–450 °C range to obtain fiber comparable to virgin fiber’s strength. However, the pyrolysis duration, even at low (450 °C) temperature, still negatively affects the strength of the fiber [41]. On the other hand, R. S. Ginder [34] investigated the impact of two-temperature step pyrolysis on the mechanical strength of recovered glass fiber. The process consisted of 30 and 10 min exposure at 350 °C and 450 °C, respectively. The results revealed that the multistep process was less damaging than the single higher-temperature pyrolysis, improving the fiber’s tensile strength by up to 19%. The authors also concluded that the higher strength was likely a result of the reduced growth rate of the pre-existing surface flows in the fiber [34].

The mechanical properties of a single fiber recovered after thermal and mechanical extraction from end-of-life (EoL) scrap turbine blades were analyzed by A. Rahimizadeh et al. [43]. The mechanical treatment was simple grinding of the blades, while the thermal method consisted of two steps: pyrolysis in a nitrogen atmosphere at 550 °C for 45 min with subsequent oxidation in air at 550 °C for 10 min. The remaining epoxy was still visible after mechanical grinding, while the surface of the fibers was nearly smooth, with a small content of impurities after two-step thermal treatment. It was shown that the pyrolyzed fibers possessed higher stiffness than the ground ones. However, their tensile strength was lower, possibly caused by the silica network compaction in the fiber, implying the damage arising due to the pyrolysis process [43]. A summary of process parameters and their impact on fiber properties is provided in Table 1.

4.1.2. Plasma Method in WTBW Recycling

A. Bosmans et al. [44] reviewed the potential and suitability of thermochemical technologies for the energetic valorization of landfilling wastes. It was pointed out that plasma-based systems are relatively new technologies for solid waste treatment by reducing their volume through melting or immobilization in a vitrified, non-leachable slag [44]. However, it is worth mentioning that plasma technologies have long been used for waste processing due to their ability to reach extremely high temperatures and efficiently break down complex materials [45,46,47]. These technologies operate by utilizing the plasma state, in which gases become ionized and reach temperatures unattainable by conventional methods [48], thus enabling the treatment of both organic and inorganic materials. This allows for the recycling of various industrial and household wastes, including plastics, metals, and other difficult-to-process components.

Like other thermochemical conversion methods, such as pyrolysis, gasification, and combustion, plasma treatment converts waste into high-calorific fuel gases and an inert solid slag; however, this occurs at substantially higher temperatures, 1200–2000 °C [44]. Due to high heat and reactant transferring rates, high-temperature materials can be melted in the plasma process. When exposed to a high-temperature plasma flow, organic polymer matrices are decomposed into smaller carbon and hydrogen compounds. This process results in lower CO2 emissions than traditional methods such as pyrolysis or incineration. Additionally, the process aims to produce methane or syngas from the carbon oxides generated during plasma treatment through various chemical reactions [44,49,50]. The generation of valuable products, such as syngas or hydrogen, may compensate for the actual costs related to electricity consumption, which is the primary energy source in the plasma process [44].

Plasma technology also holds significant potential for recycling wind turbine blades. Since blades are typically made of composite materials, such as glass or carbon fibers combined with highly resistant polymers, plasma-based methods can effectively break down these complex structures and separate valuable components.

The plasma recycling process produces only the target product without generating additional harmful substances or residues, making it environmentally friendly and non-polluting. As mentioned previously, fibers derived from mechanically grounded WTBs contain organic contaminations such as wood, which negatively impacts the final material’s properties [51]. Mechanical separation from wood requires additional energy. However, in a plasma–chemical reactor, wood can act as an energy source during recycling, potentially eliminating the need for separation.

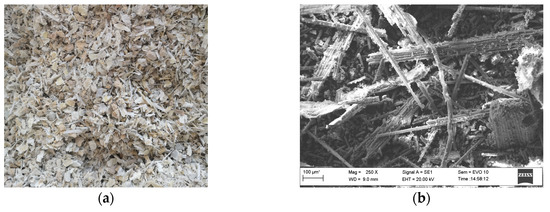

It is worth mentioning that mechanical processing is necessary to recycle materials using plasma. Notably, the cost of shredding raw WTBs is approximately 40% lower than the energy cost associated with extracting natural aggregates, highlighting the sustainability and efficiency of this method [52]. Figure 3 shows the shredded WTB waste, whose particles are too big to supply into the reactor. Therefore, the grinding step is needed to achieve a uniform particle size of 50–300 µm. This uniformity ensures a consistent bulk density of the raw material, which facilitates a steady supply to the plasma–chemical reactor via a screw feeder.

Figure 3.

Shredded (a) and ground (b) WTBW (data of this study).

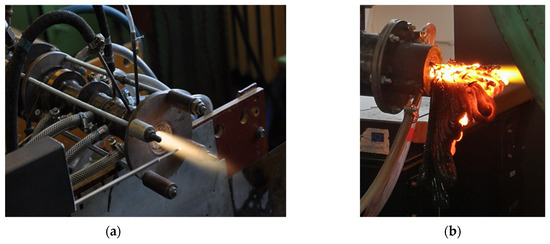

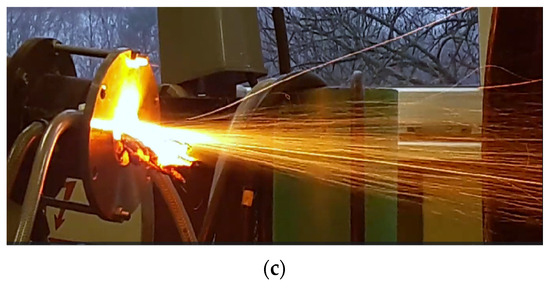

Material recycling, including WTBW, can be performed in specially designed plasma–chemical equipment with a flow reactor and a linear DC plasma torch with a power capacity of up to 100 kW [53,54,55], presented in Figure 4. Once the plasma torch is activated, the system operates in a steady-state mode. The reactor is designed with multiple sections to enhance the velocity of the jet outflow and thus increase the effectiveness of the melting process of WTB waste. When crushed WTBW is introduced into the plasma field (2000–3000 °C), the composite materials, such as temperature-resistant thermosets, rapidly heat up, melt, and undergo complete decomposition at the molecular level along with various chemical and physical transformations resulting in high-purity secondary products [53,56]. The inorganic material exiting the reactor is rapidly cooled and solidified, forming fused slags and/or fibers.

Figure 4.

Plasma processing: (a) without material, (b) melted slag, (c) fiber flow (data of this study).

The fiber (Figure 4a) or/and slag, as the resulting material of the plasma process, is collected after reaching the optimal process parameters. Therefore, the monitoring of the process temperature, the flow rates of air, auxiliary gases, water, and raw materials, as well as the operational parameters of the plasma generator, are required [44,50,53,54].

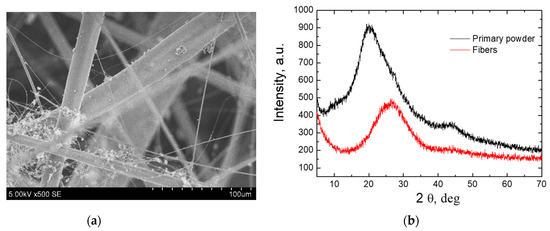

Kavaliauskas et al. [53] used a thermochemical plasma process [54] to convert WTB powdered waste into fibers with a diameter of 40–50 µm (Figure 5). The ground WTBW (Figure 5b) has an amorphous non-crystalline phase, as well as the fiber obtained after WTBW recycling in the thermal plasma process (Figure 5b). The peak of ground WTBW powder is shifted to a lower diffraction angle, indicating the presence of organic compounds. Meanwhile, the peak of the recycled fiber is situated between the 2θ angle of 20–30° (Figure 5b), characteristic of the crystalline SiO2. The nearly doubled amount of SiO2 in the resulting fiber measured by X-ray fluorescence (XRF) analysis confirms the glass fiber formation [53].

Figure 5.

Reprinted from the reference [53], 2023, MDPI: (a) iber produced from WTBW; (b) XRD patterns of the ground WTBW powder and recycled glass fiber.

A comparison of Fourier-transform infrared spectroscopy (FTIR) spectra shows that virgin WTBW contains many chemical bonds typical of organic compounds [53]. Meanwhile, the carbon content of the resulting fiber after WTBW plasma flow treatment is up to seven times lower than that of the raw material [53]. A very high 2300 °C temperature of the process resulted in a substantial reduction in the carbon-containing functional peaks responsible for the degradation of most organic compounds in GFRP. As a result, the peaks associated with epoxy resins such as O-H, C-H, C-O, C=O, and C=C are significantly reduced or disappear in the FTIR spectra of fiber [53].

If the appropriate plasma-based systems with optimal parameters are selected, plasma technology may offer an innovative, sustainable solution for the production of recycled glass fibers from GFRP or WTBW, thereby enhancing their recyclability and potential for reuse [44].

4.2. Application of Recovered or Recycled Glass Fiber

4.2.1. Mechanically Treated Glass Fiber-Reinforced Polymer (GFRP) in Concrete

One effective way to minimize the environmental impact associated with the use of glass fiber-reinforced plastic (GFRP) is through recycling, specifically by creating products suitable for civil engineering applications. For instance, waste materials from WTBW can be utilized as cement replacements, fine and coarse aggregates, fillers, or reinforcing fiber in concrete [8,52,57]. The literature presents a variety of applications for WTBW. Some studies have been carried out on raw-crushed WTB, where the material is crushed non-selectively without separating its constituents. The final product contains fiberglass, composite fibers, polyurethane, and balsa wood particles and was tested for reuse as a raw material for concrete [32,58].

Some studies have investigated the recycling of GFRP from wind turbine blades and its incorporation into concrete as “needles” to enhance the material’s mechanical properties. All the researchers found that adding GFRP needles can improve concrete’s specific properties; however, the effectiveness of this enhancement depends on factors such as the quantity, size, and surface texture of the needles. A study by A. Yazdanbakhsh et al. [59] found that incorporating 5% and 10 wt% GFRP needles into concrete did not negatively affect its stability, workability, or mechanical properties. In fact, 10 wt% needle content significantly enhanced the energy absorption capacity of the concrete. However, T. Yu et al. [60] indicated that while 40 mm and 60 mm long needles improved the compressive strength of concrete by up to 37.1%, the use of 80 mm fibers led to a reduction in compressive strength by 13.98%, suggesting that excessively long fibers can impair concrete performance. In the study by L. Abdo et al. [61], GFRP needles were utilized as a partial substitute for natural aggregates, making up 2.5% of the total volume. The results indicated an increase in the split tensile strength of the concrete, although the compressive strength showed a slight decrease. This suggests that using a small amount of GFRP needles can enhance tensile properties, but it does not necessarily improve compressive strength. A study conducted by A. Yazdanbakhsh et al. [62] found that cutting WTBW GFRP into short cylindrical shapes resulted in a more significant reduction in concrete strength than using a needle form. This decrease in strength occurred because the rounded sections lacked sharp edges, which led to weaker bonding with the cementitious matrix and poorer interlocking with coarse aggregates. Additionally, research by D. Baturkin et al. [51] emphasized that the surface texture and roughness of GFRP aggregates enhance bonding through mechanical interlocking and an increased overall surface area. This improvement leads to better adhesion and higher compressive strength than GFR aggregates with smooth surfaces. All the studies agree that appropriately selected GFRP needles can enhance concrete’s fracture resistance and tensile properties. However, their effect on compressive strength varies depending on factors, such as fiber length, quantity, and surface roughness. Longer or smoother needles may negatively impact mechanical performance, while optimally sized and textured needles can significantly improve concrete’s structural integrity and load-bearing capacity.

Since GFRP contains durable resins that essentially do not show good compatibility with cementitious materials, mainly glass or carbon fibers are used to partially replace virgin fibers or filler materials [51]. All the fiber-reinforced thermoset materials, including GFRP, can be recycled using mechanical recycling techniques. However, achieving properties similar to those of recycled fibers (RFs) compared to virgin fibers (VFs) is quite challenging. Despite this, RFs can be reused, which helps reduce the demand for natural resources, energy consumption, and negative environmental impacts.

D. Baturkin et al. [51] researched the effects of converting WTB waste glass fiber-reinforced polymer materials (as a powder, aggregate, or fiber) into concrete. The findings demonstrated that the mechanical properties of these materials are comparable to those of conventional concrete. When RFs from WTBW are incorporated into concrete, the flexural capacity increases by up to 15%, with no noticeable reduction in compressive strength. However, the use of powder (10–30 wt% replacement for cement) with unremoved wood and the use of coarse aggregate (33–100 wt% replacement of limestone) significantly reduced the mechanical properties of the concrete due to the presence of organic admixtures, and the weak bond between the GFRP aggregate and the cementitious matrix, respectively. A summary of the mechanical properties of cementitious composites with WTBW incorporation is provided in Table 2.

Table 2.

Summary of the mechanical properties of cementitious composites with WTBW.

4.2.2. WTBW in Geopolymers

The strategy to reduce cement consumption forced researchers to focus on producing cement-free materials. One of them is geopolymers, invented by J. Davidovits in early 1979 [72]. He developed amorphous or semi-crystalline three-dimensional silico-aluminate materials or mineral polymers resulting from geochemistry, thus calling them geopolymers [72]. The geopolymer preparation process involves several steps, such as preparation of binder, incorporation of reactive components, and then filler materials and additives. In most studies, alkaline-based binders, such as sodium or potassium, rather than phosphate-based binders, are used for geopolymer production [73]. The reactive components are minerals of the kaolinite group, volcanic tuff, and industrial by-products such as blast furnace slag, fly ash, rice husk ash, and others rich in alumina and silica [72,73,74]. Fillers can be either inert or reactive materials, though the latter is more appropriate since it may generate a chemical bond with the geopolymer binder itself.

Geopolymers possess high mechanical strength and resistance to fire, freeze-thawing, and chemical attack, though they may suffer from brittleness [73,74]. Therefore, their reinforcement with fibrous materials may overcome this problem [73,75,76].

Waste can be generated i) during the turbine blades production stage and ii) at the end of the wind turbine lifecycle. Therefore, waste can be non-contaminated fibrous material or a powdered mixture of fibers, epoxy, plastic, or wood [75]. Since WTB waste does not contain reactive components, it may serve as reinforcement or filler material in geopolymer composites (Table 3). For example, B. Figiela et al. [77] incorporated 25 to 75 wt% powdered WTB production GFRP waste as a filler material to produce geopolymer with coal gangue waste and sodium-based binder. They found that a high content of aluminum oxide, present in both waste materials, results in a porosity increase and, thus, strength reduction. They indicated that the higher molarity of the binding solution may result in better performance of geopolymers with WTBW powder incorporation.

Table 3.

Summary of WTBW application in geopolymers.

K. Plawecka et al. [78] studied the use of waste from different parts of wind turbine rotor production as a partial replacement of filler materials in geopolymer. The milled waste was oxidized in the furnace at 600 °C for 12 h to reduce the organic matter content. After firing, the length of the fiber varied from 0.05 to 1 mm, while the main components were aluminum, silicon, and sodium. The authors concluded that the mechanical properties of modified alkaline-based geopolymers were reduced, and more significantly at the highest content of waste filler (30 wt%), although the adsorbability was improved [78].

L. Senff et al. [79] investigated the performance of geopolymer foam reinforced with pure fibrous material from wind turbine blade production cut into uniform fibers 6 mm in length and nearly 18 µm in diameter. The fiber dosage at 1 and 2 wt% was effective since the mechanical strength of the foam geopolymer was enhanced, though the impact on thermal properties was minor [79]. The same production waste material, cut in fibers of 6 and 20 mm in length, was used by R.M. Novais et al. [80] for an alkaline-based geopolymer composite. The proportion of added fiber varied from very low (0.1 and 0.2%) to medium (1.0, 2.0, and 3.0%). The results revealed that the length of fibers has no impact on strength at low fiber dosages, while at higher dosages, the performance of geopolymers substantially increases when shorter fibers are used [80]. Shorter fibers (1.45–4.75 mm) obtained after the crushing and sieving of decommissioned wind turbine blades were used by M. Zhang et al. [81] for foamed sodium-based geopolymer and lightweight geopolymer mortar production. Three dosages of fibers (2, 4, and 6%) were investigated to determine their impact on workability, density, thermal conductivity, and porosity. According to the results, the best performance of fiber-reinforced geopolymers depends on the dual effect of fiber and foaming agents. However, a higher dosage of fiber creates the tensile-transfer bridging effect, decreasing the drying shrinkage of porous lightweight geopolymers [81].

D.S. Cousins et al. [82] applied the dissolution technique to recover glass fibers from thermoplastic components since the dissolution method is impossible for thermosets. They compared the mass-normalized force at the brake and load displacement of the recovered and virgin fiber. The results revealed that the tensile strength of the recovered fiber was nearly the same as the virgin, while stiffness was reduced by up to 12% thus implying that the dissolution method is more advantageous than the pyrolysis one [82].

A new approach for recovered fiber application in geopolymers was suggested by Yuan et al. [83]. They proposed a new method of reusing end-of-life WTB by converting them into binding material. The discarded WTB were calcined at 650 °C for 2 h to obtain pure fibers that were milled-up powdered material with a fiber length of less than 100 µm. The impact of the particle size of the milled glass fibers on the sodium activator’s parameters, such as modulus, sodium content to the binder, and water–binder ratio, was investigated. They found that the most significant parameter was the activator’s modulus influencing gel quantity and the structure of reaction products. XRD, FTIR, and SEM-EDS analysis confirmed the geopolymerization reaction between ground fiber powder and alkali activator. A high Si/Al ratio was assumed to influence the geopolymerization and polycondensation processes [83]. Although the microstructure and micromechanical properties were considered, the long-term durability of recycled fibers remained undiscussed.

4.3. Durability of Recovered or Recycled Glass Fiber

4.3.1. Durability of Glass Fiber Recovered by Pyrolysis

The durability of recovered glass fibers within the geopolymer matrix is a critical concern, as fiber degradation could undermine the composite’s long-term performance. According to previous authors’ study [84], the recovered glass fibers derived from the pyrolysis of WTB withstand up to 90 days of soaking in the alkaline solution (pH~14), showing no damaging effect on fibers.

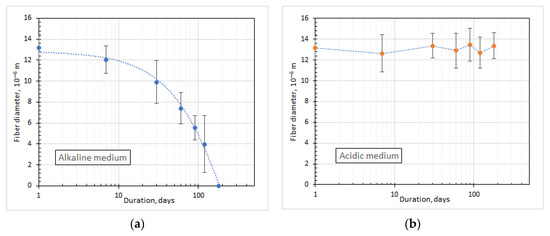

The literature review revealed a lack of studies on the durability of such recovered fibers in geopolymer binder solutions. Therefore, glass fibers obtained after pyrolysis [84] were exposed to aggressive alkaline (molar ratio 2.8) and acidic (13 M) solutions at room temperature for up to 180 days [85]. The low resistance of glass fiber to alkaline medium is known, and therefore, the dissolution of fiber was expected. However, the results reveal that the dissolution starts after 7 days, with an increase in rate after 30 days until the complete dissolution after six months of exposure (Figure 6a). Contrary, the diameter of the recovered glass fiber remained nearly constant in the acidic medium up to half of the year (Figure 6b). The elemental composition of the fiber before and after 120 days of exposure to different solutions does not change significantly; however, a slight increase in Na and P content indicates a possible chemical interaction between the solution and fiber (Table 4).

Figure 6.

Fiber diameter versus exposure duration in (a) alkaline medium and (b) acidic medium (data of this study).

Table 4.

EDS data of fiber before and after exposure in alkaline and acidic medium (data of this study).

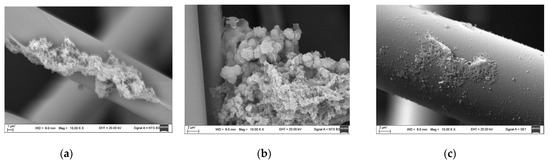

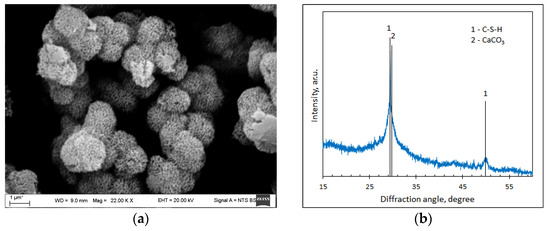

Dissolution of the recovered glass fiber created sediments on the surface of the fibers or near them in both solutions, although the amount and shape differed greatly (Figure 7). The coral-like sediments formed after the dissolution of the recovered fiber in the alkaline solution (Figure 8) are very similar to those obtained during the synthesis of calcium silicate hydrates from cetyltrimethylammonium bromide dissolved in 0.01 M Na2SiO3 with the dissolution of Ca(OH)2 [86].

Figure 7.

Sediments on (near) the fibers after 120 days exposure in (a,b) alkaline medium and (c) acidic medium (data of this study).

Figure 8.

Sediments formed after 180 days in alkaline medium: (a) SEM image; (b) X-ray pattern (data of this study).

The X-ray analysis of the coral-like shape sediments confirmed the formation of calcium silicate hydrates, though a peak of calcium carbonates was also detected (Figure 8).

The chemical composition of the recovered fiber and sediments is summarized in Table 5. The data show that sediments in alkaline solution contain mainly SiO2 and CaO oxides, while P2O3, CaO, Al2O3, and SiO2 are present in the sediments exposed to an acidic medium.

Table 5.

Chemical composition of recovered glass fiber and sediments found after long-term exposure of fibers in acidic and alkaline solutions (data of this study).

Various calcium phosphate compounds can be formed depending on the Ca/P molar ratio [87,88]. Since the sediment content in the acidic medium was too low, it was hard to identify which compound prevailed. However, as the fiber contains alumina, insoluble aluminum orthophosphates were probably formed together with calcium phosphates or apatites [87]. Nonetheless, the significant reduction in CaO and Al2O3 with increased P2O3 confirms the chemical interaction between the fiber and solution. The obtained results infer the feasibility of reusing recovered fiber in geopolymeric compositions, as fiber can be involved in polymerization reactions.

4.3.2. Durability of Recycled Fiber Derived from Plasma Processing

The slag derived from thermal processes, including plasma, gasification, and incineration, has found its potential utilization in the construction industry [89,90,91,92]. However, the application of fibrous materials from the plasma process has been studied in a fragmented way [53,93,94], and a more profound analysis of fibers from WTBW recycling is lacking.

According to a study [53], the fiber derived from the plasma–chemical reactor is mainly an amorphous material containing calcium, aluminum, and silicon oxides (Table 6). Compared with commercial basalt fiber [95], which is less resistant to alkaline medium [95], the recycled WTBW fiber contains more calcium oxide, which suggests the possibility of using it in cement-based materials. However, it is worth mentioning that the content of SiO2 and CaO is much lower in the fiber recycled by plasma processing than recovered from GFRP waste by pyrolysis (Table 5).

Table 6.

Chemical composition of fibers obtained after WTBW plasma processing [53] and commercial basalt fiber [95].

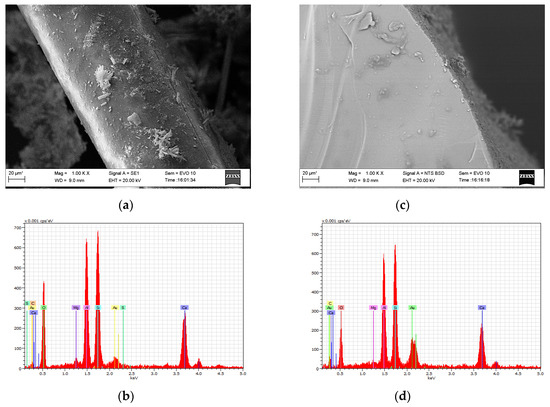

The applicability of fibers depends on their resistance to alkaline medium, which is created during cement hydration. Therefore, the fibers obtained after WTBW treatment in a plasma–chemical reactor [53] were tested for long-term durability in cement extraction [84]. Contrary to the previous study [84], containers filled with water and cement instead of cement extraction were used for the fibers’ durability test. This ensured the continuous supply of calcium ions to the solution from the cement reaction with water [96]. It is known that the chemical composition of fiber, alkali concentration of the medium, soaking time, and temperature significantly contribute to the corrosion rate of the fiber [97,98]. Therefore, fibers were left in containers for one and a half years. Then, they were taken from the solution, washed with distilled water, and analyzed by SEM-EDS.

It is known that the degradation of fiber in an alkaline medium may arise due to alkali ions leaching out from the surface of glass fiber and the breaking of the Si-O-Si structure by hydroxyl ions [96,97,98,99]. Chemical reactions and their products cause fibers to be brittle.

Figure 9 shows that the fiber’s outer surface is rough and covered by non-washed crystals of various shapes. The cross-section analysis from the outer surface to the center of the fiber reveals no sign of cracking or morphological–structural changes after such long-term exposure. These data correlate well with Meng Li et al. observations [98], where no degradation of fiber was obtained for basalt fiber after immersion in Ca(OH)2 extraction. On the contrary, C. Scheffler et al. [68] observed the formation of holes (~250 nm in diameter) on the surface of different types of fibers after one week of storage in cement solution at 40–80 °C.

Figure 9.

SEM micrograph and EDS spectra of the surface (a,b) and cross-section (c,d) of the fiber after 550 days in an alkaline medium (data of this study).

The degradation mechanism of basalt fibers in an alkaline medium was studied by others [95,96,98]. It was pointed out that the Ca-Si structures formed during exposure to calcium hydroxide extraction prevent or delay the degradation of fibers [98]. Meanwhile, the KOH or NaOH medium initiates the dissolution of Si-O (-Al-O) bonds, thus boosting the leaching of Fe and Mg ions from the fiber and resulting in the lowering of Al and Si content in the fiber [96,98].

The EDS spectra in Figure 9 show that the elemental composition of the fiber’s cross-sectional and outer surface is nearly the same. Before exposure, the calculated oxide ratios of Al2O3 to SiO2 and SiO2 to CaO were 0.86 and 1.67, respectively; after exposure, these values were 0.84 and 1.66, respectively (Table 6). This implies that WTBW recycling by the plasma process results in the formation of fibers of dense, impermeable structure possessing higher resistivity to alkaline Ca(OH)2 medium.

Alongside the durability test, the pozzolanic activity of fiberglass was evaluated to determine its potential as a supplementary cementitious material [100]. Pozzolanic activity indicates the waste material’s ability to react with lime or calcium hydroxide at ambient temperature and form hydration products.

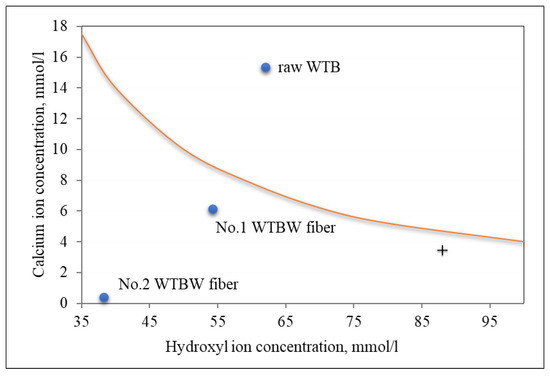

The pozzolanic test was conducted in several stages following the EN 196-5 standard procedure [101]. Ground samples of raw WTB (denoted as raw WTB) and two fibrous materials obtained at different plasma operational conditions (denoted as No.1 WTBW fiber and No.2 WTBW fiber) were selected for the pozzolanic activity test. First, raw WTBW and fibers were ground up to a powdered state similar to the size of Portland cement particles. Portland cement was mixed with each ground sample at a ratio of 4:1. Each mixture was placed in a flask filled with 100 mL of distilled water, and immediately placed in a furnace at 40 °C. Each day, the mixtures were shaken to ensure uniform mixing. After 28 days, samples were removed from the furnace for the titration procedure. For the titration procedure, three solutions were used: a 0.1 l/mol hydrochloric acid (HCl) solution, a Trilon B (EDTA) solution, and a 10% sodium hydroxide (NaOH) solution.

The calculated concentrations of calcium and hydroxyl ions in each sample are plotted in Figure 10. The curve in the plot represents the saturation of calcium oxide. The points below the saturation curve satisfy the pozzolanic activity (marked by “+” in the plot), while points above the curve fail. As expected, the WTB waste is an inert material and does not show any pozzolanic activity (point above the curve) (Figure 10). Contrarily, both samples with finely ground plasma-recycled glass fiber are characterized as pozzolanic materials, implying its possible application in cementitious materials, though more detailed studies are needed to draw definitive conclusions.

Figure 10.

Diagram for assessing pozzolanicity (data of this study).

The results show that plasma–chemical treatment technology is an excellent tool for recycling wind turbine blade waste and producing a clean by-product, slag or fiberglass, which can be used as a pozzolanic additive for concrete production. Nevertheless, further research is needed to determine the optimal plasma conditions (temperature, pressure, and gas composition) for different WTB material compositions. This will improve the efficiency and quality of the recycling process.

5. Concluding Remarks

The future management of wind turbine blade waste (WTBW) relies significantly on advancing new recycling technologies and adopting more sustainable materials. Given the stringent environmental regulations and the projected growth of the wind energy sector, it is essential to develop innovative and sustainable solutions for the disposal and utilization of wind turbine blades. By integrating economic principles throughout the entire life cycle of wind turbines, it will be possible to ensure that this renewable energy source remains efficient and ecological. The sustainability of the cement industry remains a critical challenge as urbanization and infrastructure development continue, keeping the construction sector heavily dependent on cement. Transitioning to low-carbon production technologies and implementing circular economic principles are crucial to decreasing the cement industry’s environmental impact and supporting global climate change mitigation efforts.

Wind turbine blade waste (WTBW) presents significant environmental concerns due to its non-degradable nature and end-of-life disposal challenges. Thermal recycling methods, such as pyrolysis and plasma processing, show the potential for recovering fibers from GFRP or converting WTBW into fibrous materials. However, the quality of recovered and recycled fibers depends on thermal process parameters, highlighting the need to optimize recycling techniques to obtain fibers with the desired properties. A literature review suggests that recovered or recycled fibers have potential applications in civil engineering as reinforcement or filler materials, while efforts to convert them into binding agents also appear promising. Further research is needed to assess the long-term performance of cementitious and non-cementitious composites incorporating recovered or recycled fibers obtained from GFRP and WTBW, respectively.

Incorporating WTBW into construction materials provides multiple benefits, including sustainable waste management, developing more durable and environmentally friendly building materials, and reducing landfill waste. However, further research is needed to evaluate its environmental impact quantitatively. Life cycle assessment (LCA) and cost–benefit analyses of WTBW utilization in concrete and geopolymer production are crucial for advancing its practical implementation in the construction industry.

Author Contributions

Conceptualization, methodology, validation, investigation, writing—original draft preparation, writing—review and editing: R.K.-D. and V.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data will be available upon request.

Acknowledgments

The authors express their sincere gratitude to Jūratė Čėsnienė for her valuable contributions to the fiber durability analysis and insightful discussions. R. Kriūkienė and A. Baltušnikas are acknowledged for their assistance with SEM images and XRD analysis.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Yu, H.; Yin, B.; Akbar, A.; Liew, K.M. Sustainable transformation of end-of-life wind turbine blades: Advancing clean energy solutions in civil engineering through recycling and upcycling. J. Clean. Prod. 2023, 426, 139184. [Google Scholar] [CrossRef]

- Tyurkay, A.; Kirkelund, G.M.; Lima, A.T.M. State-of-the-art circular economy practices for end-of-life wind turbine blades for use in the construction industry. Sustain. Prod. Consum. 2024, 47, 17–36. [Google Scholar] [CrossRef]

- Podara, C.; Termine, S.; Modestou, M.; Semitekolos, D.; Tsirogiannis, C.; Karamitrou, M.; Trompeta, A.F.; Milickovic, T.K.; Charitidis, C. Recent Trends of Recycling and Upcycling of Polymers and Composites: A Comprehensive Review. Recycling 2024, 9, 37. [Google Scholar] [CrossRef]

- Jasińska, D.; Dutkiewicz, M. Waste Management of Wind Turbine Blades—A Review of Recycling Methods and Applications in Cementitious Composites. Sustainability 2025, 17, 805. [Google Scholar] [CrossRef]

- Qureshi, J. A Review of Recycling Methods for Fibre Reinforced Polymer Composites. Sustainability 2022, 14, 16855. [Google Scholar] [CrossRef]

- Tayebi, S.T.; Sambucci, M.; Valente, M. Waste Management of Wind Turbine Blades: A Comprehensive Review on Available Recycling Technologies with A Focus on Overcoming Potential Environmental Hazards Caused by Microplastic Production. Sustainability 2024, 16, 4517. [Google Scholar] [CrossRef]

- Liu, T.; Paraskevoulakos, C.; Mughal, U.A.; Tyurkay, A.; Lushnikova, N.; Song, H.; Duyal, C.; Karnick, S.T.; Gauvin, F.; Lima, A.T. Mechanisms and applications of wind turbine blade waste in cementitious composites: A review. Mater. Des. 2025, 251, 113732. [Google Scholar] [CrossRef]

- Pender, K.; Yang, L. Regenerating performance of glass fibre recycled from wind turbine blade. Compos. Part B Eng. 2020, 198, 108230. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. Development of sustainable microwave-based approach to recover glass fibers for wind turbine blades composite waste. Resour. Conserv. Recycl. 2022, 179, 106107. [Google Scholar] [CrossRef]

- Obunai, K.; Fukuta, T.; Ozaki, K. Carbon fiber extraction from waste CFRP by microwave irradiation. Compos. Part A Appl. Sci. Manuf. 2015, 78, 160–165. [Google Scholar] [CrossRef]

- Deng, J.; Xu, L.; Zhang, L.; Peng, J.; Guo, S.; Liu, J.; Koppala, S. Recycling of carbon fibers from CFRP waste by microwave thermolysis. Processes 2019, 7, 207. [Google Scholar] [CrossRef]

- Zhao, X.; Long, Y.; Xu, S.; Liu, X.; Chen, L.; Wang, Y.Z. Recovery of epoxy thermosets and their composites. Mater. Today 2023, 64, 72–97. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Tan, H.; Xiong, X. Pollutant emission during pyrolysis of waste wind turbine blades: Nitrogen-containing components and polycyclic aromatic hydrocarbons. J. Environ. Manag. 2024, 371, 123159. [Google Scholar] [CrossRef]

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Nazari, Z.; Yang, B.; Ceylan, H.; Kim, S. A comprehensive review of sustainable solutions for reusing wind turbine blade waste materials. J. Environ. Manag. 2024, 366, 121735. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Hossain, M.; Umer, R. Recycling of wind turbine blades through modern recycling technologies: A road to zero waste. Renew. Energy Focus 2023, 44, 373–389. [Google Scholar] [CrossRef]

- Leon, M.J. Recycling of wind turbine blades: Recent developments. Curr. Opin. Green Sustain. Chem. 2023, 39, 100746. [Google Scholar] [CrossRef]

- Trivyza, N.L.; Tuni, A.; Rentizelas, A. Towards circularity in the wind industry: Optimal reverse supply network design under various policy scenarios. Waste Manag. 2025, 191, 294–307. [Google Scholar] [CrossRef]

- Schindler, A.K.; Duke, S.R.; Galloway, W.B. Co-processing of end-of-life wind turbine blades in portland cement production. Waste Manag. 2024, 182, 207–214. [Google Scholar] [CrossRef] [PubMed]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite material recycling technology—State-of-the-art and sustainable development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Diez-Cañamero, B.; Mendoza, J.M.F. Circular economy performance and carbon footprint of wind turbine blade waste management alternatives. Waste Manag. 2023, 164, 94–105. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.-X.; Ji, H.-W.; Wu, Y.-C.; Meng, X.-X.; Di, J.-Y.; Yang, J.; Lu, Q. Recovering glass fibers from waste wind turbine blades: Recycling methods, fiber properties, and potential utilization. Renew. Sustain. Energy Rev. 2024, 202, 114690. [Google Scholar] [CrossRef]

- Beauson, J.; Laurent, A.; Rudolph, D.P.; Pagh Jensen, J. The complex end-of-life of wind turbine blades: A review of the European context. Renew. Sustain. Energy Rev. 2022, 155, 111847. [Google Scholar] [CrossRef]

- Han, N.; Baran, I.; Zanjani, J.S.M.; Yuksel, O.; An, L.L.; Akkerman, R. Experimental and computational analysis of the polymerization overheating in thick glass/Elium® acrylic thermoplastic resin composites. Compos. Part B Eng. 2020, 202, 108430. [Google Scholar] [CrossRef]

- Paulsen, E.B.; Enevoldsen, P. A multidisciplinary review of recycling methods for end-of-life wind turbine blades. Energies 2021, 14, 4247. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Hossain, M.S.; Rahim, N.A. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Supriya; Chaudhury, R.; Sharma, U.; Thapliyal, P.C.; Singh, L.P. Low-CO2 emission strategies to achieve net zero target in cement sector. J. Clean. Prod. 2023, 417, 137466. [Google Scholar] [CrossRef]

- GCCA. Cement Industry Net Zero Progress Report; Global Cement and Concrete Association: London, UK, 2023. [Google Scholar]

- Liu, F.; Ding, W.; Qiao, Y. Experimental investigation on the tensile behavior of hybrid steel-PVA fiber reinforced concrete containing fly ash and slag powder. Constr. Build. Mater. 2020, 241, 118000. [Google Scholar] [CrossRef]

- Mikulčić, H.; Klemeš, J.J.; Vujanović, M.; Urbaniec, K.; Duić, N. Reducing greenhouse gasses emissions by fostering the deployment of alternative raw materials and energy sources in the cleaner cement manufacturing process. J. Clean. Prod. 2016, 136, 119–132. [Google Scholar] [CrossRef]

- Ortega-López, V.; Faleschini, F.; Hurtado-Alonso, N.; Manso-Morato, J.; Revilla-Cuesta, V. Analysis of raw-crushed wind-turbine blade as an overall concrete addition: Stress–strain and deflection performance effects. Compos. Struct. 2024, 340, 118170. [Google Scholar] [CrossRef]

- Manso-Morato, J.; Hurtado-Alonso, N.; Revilla-Cuesta, V.; Skaf, M.; Ortega-López, V. Fiber-Reinforced concrete and its life cycle assessment: A systematic review. J. Build. Eng. 2024, 94, 110062. [Google Scholar] [CrossRef]

- Ginder, R.S.; Ozcan, S. Recycling of commercial E-glass reinforced thermoset composites via two temperature step pyrolysis to improve recovered fiber tensile strength and failure strain. Recycling 2019, 4, 24. [Google Scholar] [CrossRef]

- Deeney, P.; Leahy, P.G.; Campbell, K.; Ducourtieux, C.; Mullally, G.; Dunphy, N.P. End-of-life wind turbine blades and paths to a circular economy. Renew. Sustain. Energy Rev. 2025, 212, 115418. [Google Scholar] [CrossRef]

- Yousef, S.; Eimontas, J.; Zakarauskas, K.; Striūgas, N. Recovery of styrene-rich oil and glass fibres from fibres-reinforced unsaturated polyester resin end-of-life wind turbine blades using pyrolysis technology. J. Anal. Appl. Pyrolysis 2023, 173, 106100. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, S.; Yang, Z.; Liu, W.; Wu, B.; Huang, M.; Liu, B. Pyrolysis process and products characteristics of glass fiber reinforced epoxy resin from waste wind turbine blades. Compos. Part B Eng. 2024, 287, 111803. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Ma, W.; Chen, P.; Bai, B.; Li, L.; Lai, Y.; Wang, X. Pyrolysis and oxidation characteristics and energy self-sustaining process design of retired wind turbine blades. J. Anal. Appl. Pyrolysis 2025, 185, 106872. [Google Scholar] [CrossRef]

- Xu, M.-X.; Ji, H.-W.; Wu, Y.-C.; Di, J.-Y.; Meng, X.-X.; Jiang, H.; Lu, Q. The pyrolysis of end-of-life wind turbine blades under different atmospheres and their effects on the recovered glass fibers. Compos. Part B Eng. 2023, 251, 110493. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Wang, M.; Tan, H.; Xiong, X. Collaborative disposal of exhaust gas and waste wind turbine blades: Mechanical properties of recycled glass fibres and economic analysis. J. Clean. Prod. 2024, 471, 143351. [Google Scholar] [CrossRef]

- Cheng, G.; Yang, S.; Wang, X.; Guo, Z.; Cai, M. Study on the recycling of waste wind turbine blades. J. Eng. Res. 2023, 11, 13–17. [Google Scholar] [CrossRef]

- Xu, M.; Yang, J.; Ji, H.; Wu, Y.; Li, J.; Di, J.; Meng, X.; Jiang, H.; Lu, Q. Recovering high-quality glass fibers from end-of-life wind turbine blades through swelling-assisted low-temperature pyrolysis. Waste Manag. 2024, 187, 179–187. [Google Scholar] [CrossRef] [PubMed]

- Rahimizadeh, A.; Tahir, M.; Fayazbakhsh, K.; Lessard, L. Tensile properties and interfacial shear strength of recycled fibers from wind turbine waste. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105786. [Google Scholar] [CrossRef]

- Bosmans, A.; Vanderreydt, I.; Geysen, D.; Helsen, L. The crucial role of Waste-to-Energy technologies in enhanced landfill mining: A technology review. J. Clean. Prod. 2013, 55, 10–23. [Google Scholar] [CrossRef]

- Solis, M.; Silveira, S. Technologies for chemical recycling of household plastics—A technical review and TRL assessment. Waste Manag. 2020, 105, 128–138. [Google Scholar] [CrossRef]

- Mazzoni, L.; Janajreh, I.; Elagroudy, S.; Ghenai, C. Modeling of plasma and entrained flow co-gasification of MSW and petroleum sludge. Energy 2020, 196, 117001. [Google Scholar] [CrossRef]

- Samal, S. Thermal plasma technology: The prospective future in material processing. J. Clean. Prod. 2017, 142, 3131–3150. [Google Scholar] [CrossRef]

- Boulos, M.I.; Fauchais, P.L.; Pfender, E. Handbook of Thermal Plasmas; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Gimžauskaitė, D.; Tamošiūnas, A.; Aikas, M.; Uscila, R. Thermal plasma potential to remediate soil contaminated with diesel. Environ. Res. 2023, 229, 115976. [Google Scholar] [CrossRef] [PubMed]

- Striūgas, N.; Tamošiūnas, A.; Marcinauskas, L.; Paulauskas, R.; Zakarauskas, K.; Skvorčinskienė, R. A sustainable approach for plasma reforming of tail biogas for onsite syngas production during lean combustion operation. Energy Convers. Manag. 2020, 209, 112617. [Google Scholar] [CrossRef]

- Baturkin, D.; Hisseine, O.A.; Masmoudi, R.; Tagnit-Hamou, A.; Massicotte, L. Valorization of recycled FRP materials from wind turbine blades in concrete. Resour. Conserv. Recycl. 2021, 174, 105807. [Google Scholar] [CrossRef]

- Manso-Morato, J.; Hurtado-Alonso, N.; Revilla-Cuesta, V.; Ortega-López, V. Management of wind-turbine blade waste as high-content concrete addition: Mechanical performance evaluation and life cycle assessment. J. Environ. Manag. 2025, 373, 123995. [Google Scholar] [CrossRef]

- Kavaliauskas, Ž.; Kėželis, R.; Grigaitienė, V.; Marcinauskas, L.; Milieška, M.; Valinčius, V.; Uscila, R.; Snapkauskienė, V.; Gimžauskaitė, D.; Baltušnikas, A. Recycling of Wind Turbine Blades into Microfiber Using Plasma Technology. Materials 2023, 16, 3089. [Google Scholar] [CrossRef] [PubMed]

- Grigaitienė, V.; Uscila, R.; Valinčius, V.; Kėželis, R.; Milieška, M.; Gimžauskaitė, D.; Snapkauskienė, V.; Kavaliauskas, Ž. Possibility of recycling wind turbine blades using plasma technology. WIT Trans. Ecol. Environ. 2022, 257, 65–71. [Google Scholar] [CrossRef]

- Gimžauskaitė, D.; Tamošiūnas, A.; Eimontas, J.; Aikas, M.; Uscila, R.; Snapkauskienė, V. Bituminous Soil Remediation in the Thermal Plasma Environment. Sustainability 2024, 16, 4855. [Google Scholar] [CrossRef]

- Grigaitienė, V.; Kėželis, R.; Valinčius, V.; Valatkevičius, P.; Milieška, M. Numerical and experimental images of multiphase plasma jet during plasma processing of dispersed materials. In Proceedings of the V European Conference on Computational Fluid Dynamics, Lisbon, Portugal, 14–17 June 2010; Available online: https://api.semanticscholar.org/CorpusID:138813350 (accessed on 1 September 2010).

- Tao, Y.; Hadigheh, S.A.; Wei, Y. Recycling of glass fibre reinforced polymer (GFRP) composite wastes in concrete: A critical review and cost benefit analysis. Structures 2023, 53, 1540–1556. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Ortega-López, V.; Manso, J.M. Raw-crushed wind-turbine blade: Waste characterization and suitability for use in concrete production. Resour. Conserv. Recycl. 2023, 198, 107160. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C.; Chen, C.; Tian, Y. FRP-Needles as Discrete Reinforcement in Concrete. J. Mater. Civ. Eng. 2017, 29, 04017175. [Google Scholar] [CrossRef]

- Yu, T.; Zhou, C.; Cao, L.; Zhang, Y.; Cao, P.; Shi, F. Effect of GFRP fibres recovered from decommissioned wind turbine blades on the fracture properties of concrete. Constr. Build. Mater. 2025, 463, 140121. [Google Scholar] [CrossRef]

- Abdo, M.; Toumpanaki, E.; Diambra, A.; Comandini, G.; Bank, L. Evaluation of mechanical properties of concrete with recycled FRP wind blade waste material. In Proceedings of the 11th International Conference on Fiber-Reinforced Polymer (FRP) Composites in Civil Engineering, Rio de Janeiro, Brazil, 23–26 July 2023. [Google Scholar]

- Yazdanbakhsh, A.; Bank, L.C.; Tian, Y. Mechanical processing of GFRP waste into large-sized pieces for use in concrete. Recycling 2018, 3, 8. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Manso-Morato, J.; Hurtado-Alonso, N.; Skaf, M.; Ortega-López, V. Mechanical and environmental advantages of the revaluation of raw-crushed wind-turbine blades as a concrete component. J. Build. Eng. 2024, 82, 108383. [Google Scholar] [CrossRef]

- Xu, G.T.; Liu, M.J.; Xiang, Y.; Fu, B. Valorization of macro fibers recycled from decommissioned turbine blades as discrete reinforcement in concrete. J. Clean. Prod. 2022, 379, 134550. [Google Scholar] [CrossRef]

- Fu, B.; Liu, K.C.; Chen, J.F.; Teng, J.G. Concrete reinforced with macro fibres recycled from waste GFRP. Constr. Build. Mater. 2021, 310, 125063. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C.; Rieder, K.A.; Tian, Y.; Chen, C. Concrete with discrete slender elements from mechanically recycled wind turbine blades. Resour. Conserv. Recycl. 2018, 128, 11–21. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C.; Chen, C. Use of recycled FRP reinforcing bar in concrete as coarse aggregate and its impact on the mechanical properties of concrete. Constr. Build. Mater. 2016, 121, 278–284. [Google Scholar] [CrossRef]

- Sorathiya, S.; Patel, P.N.R.; Pitroda, J. A Techno Economical Study on Wind Turbine Blade Waste as Replacement of Natural Coarse Aggregates in Concrete. Int. J. Constr. Res. Civ. Eng. 2017, 3, 26–32. [Google Scholar] [CrossRef]

- Farinha, C.B.; de Brito, J.; Veiga, R. Assessment of glass fibre reinforced polymer waste reuse as filler in mortars. J. Clean. Prod. 2019, 210, 1579–1594. [Google Scholar] [CrossRef]

- Oliveira, P.S.; Antunes, M.L.P.; da Cruz, N.C.; Rangel, E.C.; de Azevedo, A.R.G.; Durrant, S.F. Use of waste collected from wind turbine blade production as an eco-friendly ingredient in mortars for civil construction. J. Clean. Prod. 2020, 274, 122948. [Google Scholar] [CrossRef]

- Rodin, H.; Nassiri, S.; Englund, K.; Fakron, O.; Li, H. Recycled glass fiber reinforced polymer composites incorporated in mortar for improved mechanical performance. Constr. Build. Mater. 2018, 187, 738–751. [Google Scholar] [CrossRef]

- Walkley, B. Geopolymers. In Encyclopedia of Engineering Geology; Encyclopedia of Earth Sciences Series; Springer: Cham, Switzerland, 2018; Volume 37, pp. 1–2. [Google Scholar] [CrossRef]

- Zhao, J.; Tong, L.; Li, B.; Chen, T.; Wang, C.; Yang, G.; Zheng, Y. Eco-friendly geopolymer materials: A review of performance improvement, potential application and sustainability assessment. J. Clean. Prod. 2021, 307, 127085. [Google Scholar] [CrossRef]

- Souza Junior, F.G. de Geopolymer: A Review of Structure, Applications and Properties of Fiber Reinforced Composites. Res. Dev. Mater. Sci. 2018, 7, 752–759. [Google Scholar] [CrossRef]

- Abbas, A.-G.N.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Huseien, G.F. A state-of-the-art review on fibre-reinforced geopolymer composites. Constr. Build. Mater. 2022, 330, 127187. [Google Scholar] [CrossRef]

- Sambucci, M.; Sibai, A.; Valente, M. Recent Advances in Geopolymer Technology. A Potential Eco-Friendly Solution in the Construction Materials Industry: A Review. J. Compos. Sci. 2021, 5, 109. [Google Scholar] [CrossRef]

- Figiela, B.; Korniejenko, K.; Łach, M.; Azzopardi, B. A study on geopolymer composites based on waste from wind turbine blades. Materwiss. Werksttech. 2022, 53, 467–478. [Google Scholar] [CrossRef]

- Pławecka, K.; Przybyła, J.; Korniejenko, K.; Lin, W.T.; Cheng, A.; Łach, M. Recycling of mechanically ground wind turbine blades as filler in geopolymer composite. Materials 2021, 14, 6539. [Google Scholar] [CrossRef] [PubMed]

- Senff, L.; Novais, R.M.; Carvalheiras, J.; Labrincha, J.A. Eco-friendly approach to enhance the mechanical performance of geopolymer foams: Using glass fibre waste coming from wind blade production. Constr. Build. Mater. 2020, 239, 117805. [Google Scholar] [CrossRef]

- Novais, R.M.; Carvalheiras, J.; Seabra, M.P.; Pullar, R.C.; Labrincha, J.A. Effective mechanical reinforcement of inorganic polymers using glass fibre waste. J. Clean. Prod. 2017, 166, 343–349. [Google Scholar] [CrossRef]

- Zhang, M.; Qiu, X.; Shen, S.; Wang, L.; Zang, Y. Mechanical and Thermal Insulation Properties of rGFRP Fiber-Reinforced Lightweight Fly-Ash-Slag-Based Geopolymer Mortar. Sustainability 2023, 15, 7200. [Google Scholar] [CrossRef]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Yuan, Y.; Ge, Y.; Yan, J.; Peng, H.; Zhang, B. Synthesis of geopolymer using glass fiber powder from retired wind blades: A new attempt to recycle solid waste in wind power industries. J. Build. Eng. 2024, 95, 110130. [Google Scholar] [CrossRef]

- Yousef, S.; Kalpokaitė-Dičkuvienė, R. Sustainable mortar reinforced with recycled glass fiber derived from pyrolysis of wind turbine blade waste. J. Mater. Res. Technol. 2024, 31, 879–887. [Google Scholar] [CrossRef]

- Kalpokaitė-Dičkuvienė, R.; Čėsnienė, J.; Kriūkienė, R.; Anastasiia, S. Toward sustainable material use: Fiber durability in geopolymer hardening solutions. In Proceedings of the 5th International Conference: Strategies Toward Green Deal Implementation: Water, Raw Materials & Energy in Green Transition: Abstract Book, Krakow, Poland, 27–29 November 2024; Volume 97. Available online: https://files.cdn-files-a.com/uploads/6569390/normal_676555a4b76f6.pdf (accessed on 1 December 2024).

- Zhang, M.; Chang, J. Surfactant-assisted sonochemical synthesis of hollow calcium silicate hydrate (CSH) microspheres for drug delivery. Ultrason. Sonochem. 2010, 17, 789–792. [Google Scholar] [CrossRef]

- Lin, K.; Wu, C.; Chang, J. Advances in synthesis of calcium phosphate crystals with controlled size and shape. Acta Biomater. 2014, 10, 4071–4102. [Google Scholar] [CrossRef]

- Katoh, Y.; Suzuki, M.; Kato, C.; Shinkai, K.; Ogawa, M.; Yamauchi, J. Observation of calcium phosphate powder mixed with an adhesive monomer experimentally developed for direct pulp capping and as a bonding agent. Dent. Mater. J. 2010, 29, 15–24. [Google Scholar] [CrossRef] [PubMed]

- He, P.; Zhang, X.; Chen, H.; Zhang, Y. Waste-to-resource strategies for the use of circulating fluidized bed fly ash in construction materials: A mini review. Powder Technol. 2021, 393, 773–785. [Google Scholar] [CrossRef]

- Pitak, I.; Baltušnikas, A.; Kalpokaitė-Dičkuvienė, R.; Kriukiene, R.; Denafas, G. Experimental study effect of bottom ash and temperature of firing on the properties, microstructure and pore size distribution of clay bricks: A Lithuania point of view. Case Stud. Constr. Mater. 2022, 17, e01230. [Google Scholar] [CrossRef]

- Kalpokaitė-Dičkuvienė, R.; Pitak, I.; Baltušnikas, A.; Čėsnienė, J.; Kriūkienė, R.; Lukošiūtė, S.I. Functional and microstructural alterations in hydrated and freeze–thawed cement-oil shale ash composites. Case Stud. Constr. Mater. 2023, 19, e02302. [Google Scholar] [CrossRef]

- Elahi, M.M.A.; Shearer, C.R.; Naser Rashid Reza, A.; Saha, A.K.; Khan, M.N.N.; Hossain, M.M.; Sarker, P.K. Improving the sulfate attack resistance of concrete by using supplementary cementitious materials (SCMs): A review. Constr. Build. Mater. 2021, 281, 122628. [Google Scholar] [CrossRef]

- Kalpokaite-Dickuviene, R.; Brinkiene, K.; Cesniene, J. Application of Fiber Produced by Plasma Spray Method in Cementitious Complex Binder. Adv. Sci. Technol. 2010, 71, 133–137. [Google Scholar] [CrossRef]

- Kalpokaite-Dičkuviene, R.; Keželis, R.; Česniene, J.; Brinkiene, K.; Baltušnikas, A.; Milieška, M. Microstructure analysis of fibrous material manufactured by plasma spray method. Medziagotyra 2009, 15, 262–265. [Google Scholar]

- Scheffler, C.; Förster, T.; Mäder, E.; Heinrich, G.; Hempel, S.; Mechtcherine, V. Aging of alkali-resistant glass and basalt fibers in alkaline solutions: Evaluation of the failure stress by Weibull distribution function. J. Non. Cryst. Solids 2009, 355, 2588–2595. [Google Scholar] [CrossRef]

- Wei, C.; Zhou, Q.; Deng, K.; Lin, Y.; Wang, L.; Luo, Y.; Zhang, Y.; Zhou, H. Alkali resistance prediction and degradation mechanism of basalt fiber: Integrated with artificial neural network machine learning model. J. Build. Eng. 2024, 86, 108850. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; He, Y.; Huang, G.; Li, J.; Niu, Z.; Gao, B. A review on durability of basalt fiber reinforced concrete. Compos. Sci. Technol. 2022, 225, 109519. [Google Scholar] [CrossRef]

- Li, M.; Xing, D.; Zheng, Q.B.; Li, H.; Hao, B.; Ma, P.C. Variation on the morphology and tensile strength of basalt fiber processed in alkali solutions. Constr. Build. Mater. 2022, 335, 127512. [Google Scholar] [CrossRef]

- Liu, M.Y.; Zhu, H.G.; Siddiqui, N.A.; Leung, C.K.Y.; Kim, J.K. Glass fibers with clay nanocomposite coating: Improved barrier resistance in alkaline environment. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2051–2059. [Google Scholar] [CrossRef]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- EN 196-5:2011; Methods of Testing Cement—Part 5: Pozzolanicity Test for Pozzolanic Cement. CEN (European Committee for Standardization): Brussel, Belgium, 2011.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).