Development of KF-Rated Face Mask Using Biodegradable and Functional Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Overview

2.2. Development of Mask Materials

2.3. Function Processing of Nonwovens

2.4. Biodegradability Testing

2.5. KF 94 Rating Test

2.6. Bacterial Filtration Efficiency

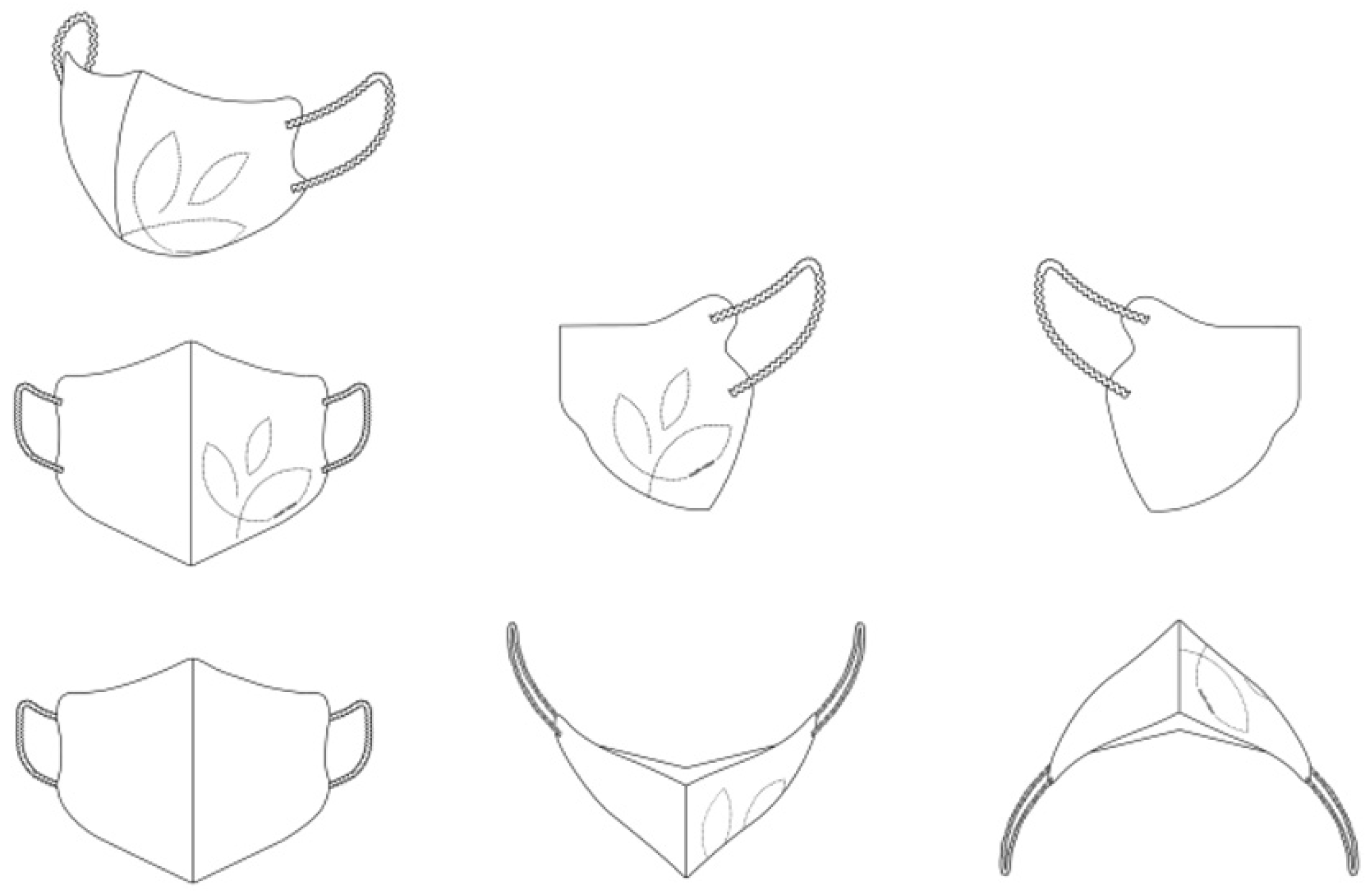

2.7. Prototype Development

2.8. Prototype Wearability Evaluation

3. Results

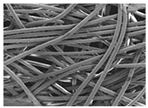

3.1. Nonwoven Production for Biodegradable Material Applications

3.2. Antibacterial Properties and Odor Resistance of Nonwovens

3.3. Functional Evaluation

3.4. Prototype Evaluaion

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MB | Melt-blown |

| MFDA | Ministry of Food and Drug Safety |

| SB | Spunbond |

| KF | Korean filter |

| PP | Polypropylene |

| PLA | Polylactic acid |

| PBS | Polybutylene succinate |

References

- Chang, H.W.; Yim, S.V. Masks in the Era of COVID-19: Medical Masks and the Ecosystem of Masks. Comp. Kor. Stu. 2022, 30, 43–69. [Google Scholar] [CrossRef]

- Kim, Y.K. A Study on Legal Policy for Improving the Disposable Mask System—Focusing on Reviewing the Measures for Expanding the Permission Scope of Quasi-Drugs. J. Law Polit. Res. 2021, 21, 291–322. [Google Scholar]

- Yoon, C.S.; Go, S.B.; Park, J.H. Comparisons of Certification Standards for Mask and Review on Filtration Efficiency for Viruses. J. Korean Soc. Occup. Environ. Hyg. 2020, 30, 109–123. [Google Scholar]

- Choi, H.J. Trends in the development of antibacterial mask technology to protect against respiratory diseases. KOSEN Report 2020.

- Chosun Ilbo. 20 Million Waste Masks Are Used Every Day, 450 of Which Rot. 21 April 2021. Available online: https://www.chosun.com/national/national_general/2021/04/26/UDKKJTJQ2JFSTLFRFBJFNPWDHI/?utm_source (accessed on 2 January 2025).

- Seoul Ilbo. Masks that Are Used Only Once and Then Thrown Away, If Recycled. 1 April 2021. Available online: https://www.seoul.co.kr/news/newsView.php?id=20210401500096&utm_source (accessed on 2 January 2025).

- Yonhap News. Korea Research Institute of Chemical Technology Develops N95 Eco-Friendly Mask Filter that 100% Decomposes in Soil. 22 March 2021. Available online: https://www.yna.co.kr/view/AKR20210322073800063 (accessed on 2 January 2025).

- Moreira, J.; Lopes, C.; Arias, M.L.; Silva, J.; Curto, J. Development of Biodegradable, Cellulose-Based, Essential Oil and Chitosan Drug Delivery Systems for Cosmetic Mask Applications. KnE Mater. Sci. 2022, 22, 63–71. [Google Scholar] [CrossRef]

- Patel, S. Disposable Mask Made From Bioplastic Resins. U.S. Patent US20150075532A1, 19 March 2015. [Google Scholar]

- Krucińska, I.; Strzembosz, W.; Majchrzycka, K.; Brochocka, A.; Sulak, K. Biodegradable particle filtering half masks for respiratory protection. Fibres Text. East. Eur. 2012, 20, 77–83. [Google Scholar]

- Lee, K.D.; Kim, J.K.; Lee, K.D.; Zun, H.D.; Kim, C.G.; Yoon, K.B. Study on the biodegradable PLA sheet with multiple functionalities. J. Converg. Cult. Technol. 2019, 5, 341–346. [Google Scholar]

- Kang, G.S. Research and Development Status of Biodegradable PLA High Polymers in Korea and Abroad; Chemical Materials Information Bank: Seongnam-si, Republic of Korea, 2020; pp. 1–18. [Google Scholar]

- Moon, J.Y.; Kim, M.H.; Lee, Y.T.; Lee, H.H.; Noh, Y.H. Study on the Biodegradable ability of Biodegradable Plastics PLA(Polylactic acid) by composting. J. Korea Acad.-Ind. Coop. Soc. 2016, 17, 596–605. [Google Scholar] [CrossRef]

- Lindsley, W.G.; Noti, J.D.; Blachere, F.M.; Szalajda, J.V.; Beezhold, D.H. Efficacy of face shields against cough aerosol droplets from a cough simulator. J. Occup. Environ. Hyg. 2014, 11, 509–518. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.E. Analysis of Contamination Patterns and Sources in Used Masks. Int. Next-Gener. Converg. Technol. Assoc. 2017, 8, 2108–2116. [Google Scholar]

- Dubinskaitė, K.; Rubežienė, V.; Sankauskaitė, A.; Skurkytė-Papievienė., V. Development of Technology for Providing Antimicrobial Properties to Medical Disposable Masks. Polymers 2024, 16, 3005. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.J.; Jeon, H.Y.; Jang, M.; Kim, H.R.; Shin, G.Y.; Koo, J.M.; Lee, M.K.; Sung, H.K.; Eom, Y.G.; Yang, H.S.; et al. Biodegradable, efficient, and breathable multi-use face mask filter. Adv. Sci. 2021, 8, 2003155. [Google Scholar] [CrossRef] [PubMed]

- Park, J.Y.; Kim, H.S. Safety regulation of quasi-drug products and its the perspective of legal policy. J. Law Polit. Res. 2020, 20, 39–64. [Google Scholar]

- Notice of the Ministry of Trade, Industry and Energy; Ministry of Trade, Industry and Energy: Sejong-si, Republic of Korea, 2020.

- NIFDS (National Institute of Food and Drug Safety Evaluation). Guidelines for Standard Specifications of Health Masks (Civil Complaint Guide); NIFDS: Cheongju-si, Republic of Korea, 2019.

- Ham, S.H.; Choi, W.J.; Lee, W.H.; Kang, S.K. Characteristics of Health Masks Certified by the Ministry of Food and Drug Safety. J. Environ. Health Sci. 2019, 45, 134–141. [Google Scholar]

- Ministry of Food and Drug Safety. Guideline on Standards and Specifications For Filtering Respirators. 16 June 2020. Available online: https://www.mfds.go.kr/eng/brd/m_65/view.do?seq=6 (accessed on 2 January 2025).

- Chen, L.; Han, C.; Du, B.; Zhang, X.; He, G. Jade powder: Characterization, cytocompatibility, and bactericidal effect. J. Test. Eval. 2023, 51, 20220477. [Google Scholar] [CrossRef]

- Kim, H.C. A study of the physical properties on human-friendly natural non-woven fabric for mask use. In Proceedings of the International Conference on Next-Generation Convergence Technology, Pune, India, 7–9 April 2022; pp. 73–75. [Google Scholar]

- Rashidi, L. Standards and guidelines for testing biodegradability of bioplastic. In Biodegradable Polymer-Based Food Packaging; Springer Nature Singapore: Singapore, 2022; pp. 297–325. [Google Scholar]

- KSK 0693; Test Method for Antibacterial Activity of Textile Materials. Korean Standards Association: Seoul, Republic of Korea, 2022. Available online: https://www.kssn.net/search/stddetail.do?itemNo=K001010140415 (accessed on 20 February 2025).

- Japan Textile Evaluation Technology Council (JTETC). Gas Detector Tube Method for Textile Testing; JTETC: Tokyo, Japan, 2021; Available online: https://nissenken.or.jp/pdf/english/functionality_deodorant_test_en.pdf?202107 (accessed on 20 February 2025).

- ISO Standard 14855-1:2023; Determination of the Ultimate Aerobic Biodegradability of Plastic Materials Under Controlled Composting Conditions—Method by Analysis of Evolved Carbon Dioxide—Part 1: General Method. International Organization for Standardization: Geneva, Switzerland, 2023.

- ASTM Standard D5338-15(2021); Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials Under Controlled Composting Conditions, Incorporating Thermophilic Temperatures. ASTM International: West Conshehoken, PA, USA, 2021. Available online: https://www.astm.org/standards/d5338 (accessed on 2 January 2025).

- Notification 2022-45; Regulations on the Safety Standards of Food Additives. Korea Food & Drug Administration: Cheongju-si, Republic of Korea, 2022. Available online: http://www.kfda.go.kr/notification/2022-45 (accessed on 2 January 2025).

- Notification 2021-03; Guidelines for Reference Standards for Respirators. Ministry of Food and Drug Safety: Cheongju, Republic of Korea, 2021. Available online: https://www.mfds.go.kr/eng/brd/m_15/view.do?seq=72435 (accessed on 2 January 2025).

- Notification 2022-05; Guidelines for Reference Standards for Respirators. Ministry of Food and Drug Safety: Cheongju, Republic of Korea, 2022. Available online: https://www.mfds.go.kr/brd/m_1060/view.do?seq=15008&srchFr=&srchTo=&srchWord=%EC%9D%98%EB%A3%8C%EA%B8%B0%EA%B8%B0&srchTp=0&itm_seq_1=0&itm_seq_2=0&multi_itm_seq=0&company_cd=&company_nm=&Data_stts_gubun=C9999&page=4 (accessed on 2 January 2025).

- Park, Y.H.; Bae, H.S. Development of susceptible functional fiber through chitosan finishing treatment of tencel blended fabrics (Part I)—Surface structure analysis and hand value assessment. J. Korean Soc. Cloth. Text. 2005, 29, 987–996. [Google Scholar]

- Seo, H.; Kang, B.K.; Kwon, Y.I. Fit testing for domestic N95 medical masks. J. Korean Soc. Occup. Environ. Hyg. 2020, 30, 124–133. [Google Scholar]

| Rating | Criteria | Usage Examples | ||

|---|---|---|---|---|

| Dust Collection Efficiency | Facial Intake Resistance | Facial Leakage Rate | ||

| KF80 | 80.0%+ blockage of average particle size 0.6 μm (Sodium chloride test) | 6.2 mmH2O or less or 60 Pa or less | 25.0% or less | For sulfur |

| KF94 | >94% of average particle size of 0.4 μm (Sodium chloride and paraffin oil test) | 7.2 mmH2O or less or 70 Pa or less | 11.0% or less | For sulfur, For quarantine |

| KF99 | >99% of average particle size 0.4 μm (Sodium chloride and paraffin oil test) | 10.3 mmH2O or less or 100 Pa or less | 5.0% or less | |

| Classification | Materials | Manufacturing Method | Weight (g/m2) | |

|---|---|---|---|---|

| KF 94 | Outer layer | PLA/Cotton | Water punching | 50 |

| Interlayer (filter) | PLA MB | Melt blown | 30 | |

| Inner layer | Cotton/Tencel | Water punching | 40 | |

| Physical Properties | |

|---|---|

| Insularity (dtex) | 1.5 |

| Strength (cN/tex) | 32–36 |

| Elongation (%) | 50–60 |

| Moisture content (%) | 0.4–0.6 |

| Number of crimps ea/10 cm | 30–35 |

| Sectional shapes | Circle |

| Surface Characteristics | Smooth |

| Density (g/cm3) | 1.25 |

| Melting point (°C) | 170 |

|  |  |  |  |

| Water weighing | Jade weighing | Binder addition and mixing | Immersion | Drying |

| Set natural Content (g) | Sample After Machining | ||

|---|---|---|---|

| Jade | Water | Binders | |

| 50 | 180 | 10 |  |

| Metric |  | ||

| 1 | Weight | ||

| 2 | Thickness | ||

| 3 | Length (folded in half) | Width | |

| 4 | Height | ||

| 5 | Ear band (elastic) | Length | |

| 6 | Width | ||

| 7 | Between band ends | ||

| 8 | Position of nose wire | From the top edge | |

| 9 | Width | ||

| 10 | Length | ||

| 2-Stage Vertical Folding | ||

|---|---|---|

| 1 (Everfresh®) | 2 (Flow®) | 3 (Exploration®) |

|  |  |

| 4 (Polytechnic®) | 5 (Safe®) | 6 (Line Story®) |

|  |  |

| Measurement | ① Weight (g) | ② Thickness (mm) | Length (mm) | |||||||

| Type | ③ Width | ④ Height | ||||||||

| 2-level portrait Folding | 1 | 4.22 | 1.08 | 22.80 | 14.80 | |||||

| 2 | 4.78 | 0.99 | 23.50 | 15.60 | ||||||

| 3 | 4.65 | 1.05 | 21.40 | 16.10 | ||||||

| 4 | 4.49 | 0.98 | 21.60 | 14.30 | ||||||

| 5 | 5.07 | 1.21 | 18.20 | 14.60 | ||||||

| 6 | 5.11 | 0.89 | 24.10 | 15.90 | ||||||

| Mean | 4.72 | 1.03 | 21.93 | 15.22 | ||||||

| S.D | 0.342 | 0.109 | 2.109 | 0.747 | ||||||

| Z | −1.746 | −2.529 * | −2.443 * | −3.013 * | ||||||

| Measurement | Elastic band (mm) | Position of nose wire (mm) | ||||||||

| Type | ⑤ Length | ⑥ Width | ⑦ Between band ends | ⑧ From the top edge | ⑨ Width | ⑩ Height | ||||

| 2-level portrait Folding | 1 | 16.10 | 0.40 | 4.60 | 0.90 | 9.30 | 0.50 | |||

| 2 | 15.50 | 0.40 | 5.10 | 1.00 | 10.70 | 0.50 | ||||

| 3 | 14.80 | 0.30 | 5.50 | 1.00 | 12.10 | 0.40 | ||||

| 4 | 13.60 | 0.30 | 5.30 | 0.90 | 8.90 | 0.35 | ||||

| 5 | 16.00 | 0.50 | 5.00 | 0.70 | 11.60 | 0.40 | ||||

| 6 | 14.50 | 0.30 | 4.80 | 0.80 | 12.30 | 0.40 | ||||

| Mean | 15.08 | 0.37 | 5.05 | 0.88 | 10.82 | 0.43 | ||||

| S.D | 0.882 | 0.075 | 0.327 | 0.107 | 1.320 | 0.056 | ||||

| Z | −1.651 | −1.658 | −2.228 * | −2.443 * | −1.747 | −2.888 * | ||||

| Development Design | |

|---|---|

|  |

|  |

| Item | Subjects | Average Size for a Woman in Her 30s |

|---|---|---|

| Mean (S.D.) | Mean (S.D.) | |

| Head circumference | 54.5 (1.3) | 55.4 (1.6) |

| Head height | 19.1 (1.8) | 22.4 (1.0) |

| Head width | 15.3 (0.2) | 16.0 (0.6) |

| Nose width | 3.5 (0.1) | 3.1 (0.3) |

| Nose height | 1.6 (0.1) | 1.3 (0.2) |

| Item | Categorization | Weight (g) | Thickness (mm) | Inhalation Resistance (Pa) | Total Inward Leakage (%) | Size | Layer |

|---|---|---|---|---|---|---|---|

| M0 | Commercial product | 4.60 | 1.08 | 8.8 | 9 | L | 4 |

| M1 | Development (raw) | 4.70 | 1.11 | 6.7 | 9 | L | 3 |

| M2 | Development (Jade) | 4.70 | 1.12 | 7.0 | 9 | L | 3 |

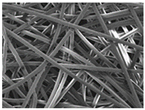

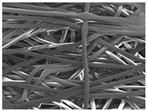

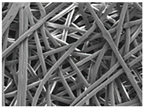

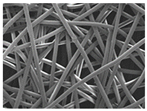

| NO. | Purpose | Mixing Rate | X150 |

|---|---|---|---|

| 1 | Outer layer | Cotton + PLA (90:10) |  |

| 2 | Cotton + PLA (80:20) |  | |

| 3 | Filter | PLA 100 |  |

| 4 | Inner layer | Cotton + Tencel (90:10) |  |

| 5 | Cotton + Tencel (70:30) |  | |

| 6 | Cotton + Tencel (50:50) |  |

| Category | Conventional KF-Rated Mask (PP/PE-Based) | Developed Biodegradable Mask (PLA/Natural Fiber-Based) | Superior Performance |

|---|---|---|---|

| Material Type | Polypropylene (PP), Polyethylene (PE) | PLA fiber, Cotton, Tencel (natural fiber blend) | Developed Mask |

| Biodegradability | Very low (takes over 450 years to degrade) | Over 70% biodegradation (decomposes within 45 days in compost) | Developed Mask |

| Antibacterial Properties | None or only temporary sterilization | Long-lasting antibacterial properties through jade coating (over 99.8%) | Developed Mask |

| Odor Resistance | None or limited | Excellent (over 80% deodorization rate) | Developed Mask |

| Surface Comfort (Softness) | Slightly rough | Softer touch (cotton + Tencel blending) | Developed Mask |

| Environmental Impact | Significant carbon and toxic gas emissions from landfilling or incineration | Reduced carbon emissions and landfill burden via biodegradable materials | Developed Mask |

| Filtration Efficiency (KF94) | ≥94% | ≥94% | Equivalent |

| Item | M0 | M1 | M2 | X2 | |

|---|---|---|---|---|---|

| Mean (S.D.) | Mean (S.D.) | Mean (S.D.) | |||

| Wear for 15 min | Thermal sensation | 5.0 (1.2) | 4.4 (1.8) | 4.4 (0.8) | 1.462 |

| Wetness | 3.0 (1.7) | 4.4 (1.8) | 4.4 (0.7) | 1.152 | |

| Comfort | 4.8 (1.0) | 4.6 (1.6) | 4.6 (1.5) | 1.956 | |

| Frustration | 4.8 (1.6) | 4.8 (1.7) | 5.0 (1.2) | 2.812 | |

| Hygiene | 3.8 (1.1) | 4.0 (1.3) | 4.1 (1.3) | 1.887 | |

| Wear for 30 min | Thermal sensation | 5.4 (1.3) | 3.2 (0.9) | 3.4 (1.1) | 5.438 ** |

| Wetness | 4.4 (1.6) | 2.2 (1.1) | 2.4 (0.8) | 4.371 * | |

| Comfort | 4.8 (1.3) | 5.6 (0.8) | 5.3 (0.6) | 1.294 | |

| Frustration | 4.2 (1.2) | 2.8 (0.6) | 2.7 (0.8) | 4.459 * | |

| Hygiene | 3.4 (0.8) | 6.1 (0.4) | 6.3 (0.5) | 5.792 ** | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Kim, H. Development of KF-Rated Face Mask Using Biodegradable and Functional Materials. Sustainability 2025, 17, 4161. https://doi.org/10.3390/su17094161

Kim H, Kim H. Development of KF-Rated Face Mask Using Biodegradable and Functional Materials. Sustainability. 2025; 17(9):4161. https://doi.org/10.3390/su17094161

Chicago/Turabian StyleKim, Hyunchel, and Hyunah Kim. 2025. "Development of KF-Rated Face Mask Using Biodegradable and Functional Materials" Sustainability 17, no. 9: 4161. https://doi.org/10.3390/su17094161

APA StyleKim, H., & Kim, H. (2025). Development of KF-Rated Face Mask Using Biodegradable and Functional Materials. Sustainability, 17(9), 4161. https://doi.org/10.3390/su17094161