AI-Driven Waste Management in Innovating Space Exploration

Abstract

1. Introduction

2. Methodology

Complete Sterilisation of Biological Waste Measures

3. Traditional Waste Management Practices in Space

3.1. Ground-Based Simulations and Testing

3.2. Limited Storage Hampers Resource Recovery

4. Smart Waste Management Technologies for Space

4.1. Strategies for Waste Management

4.2. Waste Conversion

4.3. Smart Waste Management and Enhances Mission Sustainability

5. Challenges and Considerations

5.1. Practical Constraints and Implementation Realities

5.2. Economic Implications and Environmental Impacts

5.3. Summarise the Challenge

6. International Collaboration and Policy

6.1. Actionable Stakeholder Roadmap

6.2. Private Companies, International Policy, and Global Cooperation Need

6.3. Future Research and Recommendations

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abdallah, M.; Abu Talib, M.; Feroz, S.; Nasir, Q.; Abdalla, H.; Mahfood, B. Artificial intelligence applications in solid waste management: A systematic research review. Waste Manag. 2020, 109, 231–246. [Google Scholar] [CrossRef] [PubMed]

- Abi-Fadel, M.; Harbi, M.; Chafen, M. Leveraging additive manufacturing to enable deep space crewed missions. In Proceedings of the International Astronautical Congress, IAC, Washington, DC, USA, 21–25 October 2019. [Google Scholar]

- Jin, Y.; Lu, G.; Sun, W. Genuine multipartite entanglement from a thermodynamic perspective. Phys. Res. A 2024, 109, 042422. [Google Scholar] [CrossRef]

- Aglietti, G.S. From Space Debris to NEO, Some of the Major Challenges for the Space Sector. Front. Space Technol. 2020, 1, 2. [Google Scholar] [CrossRef]

- Amalfitano, S.; Levantesi, C.; Copetti, D.; Stefani, F.; Locantore, I.; Guarnieri, V.; Lobascio, C.; Bersani, F.; Giacosa, D.; Detsis, E.; et al. Water and microbial monitoring technologies towards the near future space exploration. Water Res. 2020, 177, 115787. [Google Scholar] [CrossRef]

- Xiao, G.; Xiao, Z.; Zhou, P.; Jia, X.; Wang, N.; Zhao, D.; Wei, H. PPP based on factor graph optimisation. Meas. Sci. Technol. 2024, 35, 116307. [Google Scholar] [CrossRef]

- Azami, M.; Kazemi, Z.; Moazen, S.; Dubé, M.; Potvin, M.-J.; Skonieczny, K. A Comprehensive Review of Lunar-based Manufacturing and Construction. Prog. Aerosp. Sci. 2024, 150, 101045. [Google Scholar] [CrossRef]

- Jiang, W.; Yang, L.; Bu, Y. Research on the Identification and Classification of Marine Debris Based on Improved YOLOv8. J. Mar. Sci. Eng. 2024, 12, 1748. [Google Scholar] [CrossRef]

- Bernardo, P.; Iulianelli, A.; Macedonio, F.; Drioli, E. Membrane technologies for space engineering. J. Membr. Sci. 2021, 626, 119177. [Google Scholar] [CrossRef]

- Bhatt, K.P.; Patel, S.; Upadhyay, D.S.; Patel, R.N. A critical research on solid waste treatment using plasma pyrolysis technology. Chem. Eng. Process.—Process Intensif. 2022, 177, 108989. [Google Scholar] [CrossRef]

- Wu, S.; Cao, J.; Shao, Q. How to select remanufacturing mode: End-of-life or used product? Environ. Dev. Sustain. 2024, 1–21. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, Y.; Hu, F.; Zhou, H. Can the energy conservation and emission reduction demonstration city policy enhance urban domestic waste control? Evidence from 283 cities in China. Cities 2024, 154, 105323. [Google Scholar] [CrossRef]

- Bushnell, D.M. Futures of Deep Space Exploration, Commercialization, and Colonization: The Frontiers of the Responsibly Imaginable. NTRS—NASA Technical Reports Server. 2021. Available online: https://ntrs.nasa.gov/citations/20210009988 (accessed on 30 January 2025).

- Xu, X.; Fu, X.; Zhao, H.; Liu, M.; Xu, A.; Ma, Y. Three-Dimensional Reconstruction and Geometric Morphology Analysis of Lunar Small Craters within the Patrol Range of the Yutu-2 Rover. Remote Sens. 2023, 15, 4251. [Google Scholar] [CrossRef]

- Ciurans, C.; Bazmohammadi, N.; Vasquez, J.C.; Dussap, G.; Guerrero, J.M.; Godia, F. Hierarchical Control of Space Closed Ecosystems: Expanding Microgrid Concepts to Bioastronautics. IEEE Ind. Electron. Mag. 2021, 15, 16–27. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, Y.; Song, J.; Zhou, Q.; Rasol, J.; Ma, L. Planet Craters Detection Based on Unsupervised Domain Adaptation. IEEE Trans. Aerosp. Electron. Syst. 2023, 59, 7140–7152. [Google Scholar] [CrossRef]

- Creech, S.; Guidi, J.; Elburn, D. Artemis: An Overview of NASA’s Activities to Return Humans to the Moon. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 5–12 March 2022. [Google Scholar] [CrossRef]

- Peng, L.; Liang, Y.; He, X. Transfers to Earth-Moon triangular libration points by Sun-perturbed dynamics. Adv. Space Res. 2025, 75, 2837–2855. [Google Scholar] [CrossRef]

- Doboš, B. Outer Space as a Socioeconomic Field. In Geopolitics of the Outer Space; Contributions to Political Science; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Dolyna, L.F.; Nahorna, O.; Zhdan, Y.; Dolyna, D. Waste water treatment technology in space. Ukr. J. Civ. Eng. Archit. 2021, 3, 76–84. [Google Scholar] [CrossRef]

- He, L.; Zhang, Y.; Qu, Z.; Wu, L. An Accurate Method for the Global Ionospheric TEC Estimation Using Multi-GNSS Observations. IEEE Trans. Geosci. Remote Sens. 2025, 63, 5800315. [Google Scholar] [CrossRef]

- Elitzur, S.; Rosenband, V.; Gany, A. Combined energy production and waste management in manned spacecraft utilising on-demand hydrogen production and fuel cells. Acta Astronaut. 2016, 128, 580–583. [Google Scholar] [CrossRef]

- Ellery, A. Sustainable in-situ resource utilisation on the moon. Planet. Space Sci. 2020, 184, 104870. [Google Scholar] [CrossRef]

- Ellery, A. Supplementing closed ecological life support systems with in-situ resources on the moon. Lifelife 2021, 11, 770. [Google Scholar] [CrossRef]

- Zou, Z.; Yang, S.; Zhao, L. Dual-loop control and state prediction analysis of QUAV trajectory tracking based on biological swarm intelligent optimisation algorithm. Sci. Rep. 2024, 14, 19091. [Google Scholar] [CrossRef] [PubMed]

- Erkinay Ozdemir, M.; Ali, Z.; Subeshan, B.; Asmatulu, E. Applying machine learning approach in recycling. J. Mater. Cycles Waste Manag. 2021, 23, 855–871. [Google Scholar] [CrossRef]

- Espinosa-Ortiz, E.J.; Rene, E.R.; Gerlach, R. Potential use of fungal-bacterial co-cultures for the removal of organic pollutants. Crit. Res. Biotechnol. 2022, 42, 361–383. [Google Scholar] [CrossRef]

- Li, T.; Yu, L.; Ma, Y.; Duan, T.; Huang, W.; Zhou, Y.; Jiang, T. Carbon emissions of 5G mobile networks in China. Nat. Sustain. 2023, 6, 1620–1631. [Google Scholar] [CrossRef]

- Gul, M.M.; Ahmad, K.S. Bioelectrochemical systems: Sustainable bio-energy powerhouses. Biosens. Bioelectron. 2019, 142, 111576. [Google Scholar] [CrossRef]

- Gupta, B.; Sinha Roy, R. Sustainability of Outer Space: Facing the Challenge of Space Debris. Environ. Policy Law 2018, 48, 3–7. [Google Scholar] [CrossRef]

- Li, T.; Li, Y. Artificial intelligence for reducing the carbon emissions of 5G networks in China. Nat. Sustain. 2023, 6, 1522–1523. [Google Scholar] [CrossRef]

- Heldmann, J.L.; Marinova, M.M.; Lim, D.S.; Wilson, D.; Carrato, P.; Kennedy, K.; Esbeck, A.; Colaprete, T.A.; Elphic, R.C.; Captain, J.; et al. Mission Architecture Using the SpaceX Starship Vehicle to Enable a Sustained Human Presence on Mars. New Space 2022, 10, 259–273. [Google Scholar] [CrossRef] [PubMed]

- Hoey, W.A.; Martin, M.G.; A Steagall, C.; Soares, C.E.; Shallcross, G.S.; Worthy, E.S. A predictive model of Lunar Gateway molecular outgassing and plume-induced contamination. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1287, 012002. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, M.; Bhandari, B.; Cao, P. Current processing and packing technology for space foods: A research. Crit. Res. Food Sci. Nutr. 2020, 60, 3573–3588. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, J.; Song, Y.; Li, X.; Xu, W. Fusing Visual Quantified Features for Heterogeneous Traffic Flow Prediction. Promet—TrafficTransp. 2024, 36, 1068–1077. [Google Scholar] [CrossRef]

- Liao, M.; Yao, Y. Applications of artificial intelligence-based modeling for bioenergy systems: A research. GCB Bioenergy 2021, 13, 774–802. [Google Scholar] [CrossRef]

- Lim, S.; Prabhu, V.L.; Anand, M.; Taylor, L.A. Extra-terrestrial construction processes—Advancements, opportunities and challenges. Adv. Space Res. 2017, 60, 1413–1429. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, Y.; Yang, Z.; Zhang, Q.; He, X.; Song, Y.; Wu, H. Improving aerobic digestion of food waste by adding a personalised microbial inoculum. Curr. Microbiol. 2024, 81, 277. [Google Scholar] [CrossRef] [PubMed]

- Linne, D.L.; Palaszewski, B.A.; Gokoglu, S.A.; Balasubramaniam, B.; Hegde, U.G.; Gallo, C. Waste management options for long-duration space missions: When to reject, reuse, or recycle. In Proceedings of the 7th Symposium on Space Resource Utilization, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar] [CrossRef]

- Maddela, N.R.; Aransiola, S.A.; Ezugwu, C.I.; Eller, L.K.W.; Scalvenzi, L.; Meng, F. Microbial Biotechnology for Bioenergy; Elsevier: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Yu, S.; Guan, D.; Gu, Z.; Guo, J.; Liu, Z.; Liu, Y. Radar Target Complex High-Resolution Range Profile Modulation by External Time Coding Metasurface. IEEE Trans. Microw. Theory Tech. 2024, 72, 6083–6093. [Google Scholar] [CrossRef]

- Maiwald, V.; Schubert, D.; Quantius, D.; Zabel, P. From space back to Earth: Supporting sustainable development with spaceflight technologies. Sustain. Earth 2021, 4, 3. [Google Scholar] [CrossRef]

- Manna, S.; Pratim, G.P.; Kumar, S.A.; Chatterjee, P.K. Waste management using plasma treatment. In Handbook of Advanced Approaches Towards Pollution Prevention and Control; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Mao, C.; Mao, Y.; Zhu, X.; Chen, G.; Feng, C. Synthetic biology-based bioreactor and its application in biochemical analysis. Crit. Res. Anal. Chem. 2023, 54, 2467–2484. [Google Scholar] [CrossRef]

- Kabashkin, I.; Glukhikh, S. Closed biotechnological cycles for transport life support systems in deep space exploration. Proc. E3S Web Conf. 2023, 389, 05028. [Google Scholar] [CrossRef]

- Keller, R.; Goli, K.; Porter, W.; Alrabaa, A.; Jones, J.A. Cyanobacteria and Algal-Based Biological Life Support System (BLSS) and Planetary Surface Atmospheric Revitalizing Bioreactor Brief Concept Research. Life 2023, 13, 816. [Google Scholar] [CrossRef]

- Kim, D.-H. Proposal of Establishing a New International Space Agency for Mining the Natural Resources in the Moon, Mars and Other Celestial Bodies. Korean J. Air Space Law Policy 2020, 35, 313–374. [Google Scholar] [CrossRef]

- Koehle, A.P.; Brumwell, S.L.; Seto, E.P.; Lynch, A.M.; Urbaniak, C. Microbial applications for sustainable space exploration beyond low Earth orbit. Npj Microgravity 2023, 9, 47. [Google Scholar] [CrossRef] [PubMed]

- Kokkinakis, I.W.; Drikakis, D. Atmospheric pollution from rockets. Phys. Fluids 2022, 34, 056107. [Google Scholar] [CrossRef]

- Kshirsagar, P.R.; Kumar, N.; Almulihi, A.H.; Alassery, F.; Khan, A.I.; Islam, S.; Rothe, J.P.; Jagannadham, D.B.V.; Dekeba, K. Artificial Intelligence-Based Robotic Technique for Reusable Waste Materials. Comput. Intell. Neurosci. 2022, 2022, 2073482. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K. Space Exploration Technologies Corporation aka SpaceX’s Amazing Accomplishments: A complete Analysis. Int. J. Sci. Res. Eng. Manag. 2023, 7, 1–6. [Google Scholar] [CrossRef]

- Martin, A.S.; Freeland, S. Back to the Moon and Beyond: Strengthening the Legal Framework for Protection of the Space Environment. Air Space Law 2021, 46, 415–446. [Google Scholar] [CrossRef]

- Martinez, P.; Jankowitsch, P.; Schrogl, K.-U.; Di Pippo, S.; Okumura, Y. Reflections on the 50th Anniversary of the Outer Space Treaty, UNISPACE+50, and Prospects for the Future of Global Space Governance. Space Policy 2019, 47, 28–33. [Google Scholar] [CrossRef]

- Glukhikh, S. Bacteria in the biosynthesis of animal nutrition components for crews of autonomous transport systems. Proc. E3S Web Conf. 2023, 431, 01019. [Google Scholar] [CrossRef]

- Gómez-Gast, N.; Cuellar, M.D.R.L.; Vergara-Porras, B.; Vieyra, H. Biopackaging Potential Alternatives: Bioplastic Composites of Polyhydroxyalkanoates and Vegetal Fibers. Polymers 2022, 14, 1114. [Google Scholar] [CrossRef]

- Gorman, A. Space Junk. In Earth 2020: An Insider’s Guide to a Rapidly Changing Planet; Open Book Publishers: Cambridge, UK, 2020. [Google Scholar] [CrossRef]

- Goutam Mukherjee, A.; Wanjari, U.R.; Chakraborty, R.; Renu, K.; Vellingiri, B.; George, A.; CR, S.R.; Gopalakrishnan, A.V. A research on modern and smart technologies for efficient waste disposal and management. J. Environ. Manag. 2021, 297, 113347. [Google Scholar] [CrossRef]

- Granata, T.; Rattenbacher, B.; John, G. Micro-Bioreactors in Space: Case Study of a Yeast (Saccharomyces cerevisiae) Bioreactor With a Non-Invasive Monitoring Method. Front. Space Technol. 2022, 2, 773814. [Google Scholar] [CrossRef]

- Greenbaum, D. Space debris puts exploration at risk. Science 2020, 370, 922. [Google Scholar] [CrossRef] [PubMed]

- Johnson, N.; Ewert, M.K.; Trieu, S.; Young, J.; Pace, G.S.; Martin, K.R.; Richardson, T.M.J.; Lee, J.M.; Sepka, S.A. A Research of Existing Policies Affecting the Jettison of Waste in Low Earth Orbit and Deep Space. In Proceedings of the 50th International Conference on Environmental Systems, Virtual, 12–15 July 2021. [Google Scholar]

- Jones, H.W.; Pace, G.S.; Fisher, J.W. Managing spacecraft waste using the Heat Melt Compactor (HMC). In Proceedings of the 43rd International Conference on Environmental Systems, Vail, CO, USA, 14–18 July 2013. [Google Scholar] [CrossRef]

- Doyle, R.; Kubota, T.; Picard, M.; Sommer, B.; Ueno, H.; Visentin, G.; Volpe, R. Recent research and development activities on space robotics and AI. Adv. Robot. 2021, 35, 1244–1264. [Google Scholar] [CrossRef]

- Duri, L.G.; Caporale, A.G.; Rouphael, Y.; Vingiani, S.; Palladino, M.; De Pascale, S.; Adamo, P. The Potential for Lunar and Martian Regolith Simulants to Sustain Plant Growth: A Multidisciplinary Overview. Front. Astron. Space Sci. 2022, 8, 747821. [Google Scholar] [CrossRef]

- Ewert, M.K.; Kubota, T.; Picard, M.; Sommer, B.; Ueno, H.; Visentin, G.; Volpe, R. Comparing trash disposal and reuse options for deep space gateway and mars missions. In Proceedings of the AIAA SPACE and Astronautics Forum and Exposition, SPACE, Orlando, FL, USA, 12–14 September 2017. [Google Scholar] [CrossRef]

- Ewert, M.K.; Broyan, J.L. Improving logistics and waste management for deep space human exploration. In Proceedings of the 2018 AIAA SPACE and Astronautics Forum and Exposition, Orlando, FL, USA, 17–19 September 2018. [Google Scholar] [CrossRef]

- Fahrion, J.; Mastroleo, F.; Dussap, C.-G.; Leys, N. Use of Photobioreactors in Regenerative Life Support Systems for Human Space Exploration. Front. Microbiol. 2021, 12, 699525. [Google Scholar] [CrossRef]

- Ferretti, S.; Imhof, B.; Balogh, W. Future Space Technologies for Sustainability on Earth. Stud. Space Policy 2020, 2020, 265–280. [Google Scholar] [CrossRef]

- Di Foggia, G.; Beccarello, M. An Overview of Packaging Waste Models in Some European Countries. Recycling 2022, 7, 38. [Google Scholar] [CrossRef]

- De Freitas Bart, R.; Duda, K.R.; Hoffman, J. Estimating the Cost to Transition a Space System from Expendable to Reusable. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 4–11 March 2023. [Google Scholar] [CrossRef]

- Ghodke, P.K.; Sharma, A.K.; Pandey, J.; Chen, W.-H.; Patel, A.; Ashokkumar, V. Pyrolysis of sewage sludge for sustainable biofuels and value-added biochar production. J. Environ. Manag. 2021, 298, 113450. [Google Scholar] [CrossRef] [PubMed]

- Matsushita, Y.; Yoshimura, Y.; Hanada, T.; Itaya, Y.; Fukushima, T. Risk Assessment of a Large Constellation of Satellites in Low-Earth Orbit’Orbit. Trans. Jpn. Soc. Aeronaut. Space Sci. Aerosp. Technol. Jpn. 2022, 20, 10–15. [Google Scholar] [CrossRef]

- Sarc, R.; Curtis, A.; Kandlbauer, L.; Khodier, K.; Lorber, K.E.; Pomberger, R. Digitalisation and intelligent robotics in value chain of circular economy oriented waste management—A research. Waste Manag. 2019, 95, 476–492. [Google Scholar] [CrossRef]

- Cheah, C.G.; Chia, W.Y.; Lai, S.F.; Chew, K.W.; Chia, S.R.; Show, P.L. Innovation designs of industry 4.0 based solid waste management: Machinery and digital circular economy. Environ. Res. 2022, 213, 113619. [Google Scholar] [CrossRef]

- Schneider, W.F.; Meyer, C.E. NASA advanced exploration systems: 2018 advancements in life support systems. In Proceedings of the International Astronautical Congress, IAC, Washington, DC, USA, 21–25 October 2019. [Google Scholar]

- Mattia, O.; Claire, J.; Marit, U. Space Technology Transfers and Their Commercialisation; OECD Publishing: Paris, France, 2021; p. 116. Available online: https://www.proquest.com/openview/54c190cbbb6d5d37c18a1fff4803f0da/1?cbl=6245952&pq-origsite=gscholar (accessed on 30 January 2025).

- Seedhouse, E. International Space Station Life Support System. Life Support Syst. Hum. Space 2020, 2020, 151–179. [Google Scholar] [CrossRef]

- Seidel, A.; Teicher, U.; Ihlenfeldt, S.; Sauer, K.; Morczinek, F.; Dix, M.; Niebergall, R.; Durschang, B.; Linke, S. Towards Lunar In-Situ Resource Utilization Based Subtractive Manufacturing. Appl. Sci. 2024, 14, 18. [Google Scholar] [CrossRef]

- Selvan, A.T.; Durai, R. Artificial Intelligence in the Helm of Space Exploration and Discovery; VIT Vellore: Vellore, India, 2024. [Google Scholar]

- Shen, R. Utilising Artificial Intelligence and Machine Learning to Facilitate Achieving Carbon Neutrality. Sci. Technol. Eng. Chem. Environ. Prot. 2023, 1, 11–14. [Google Scholar] [CrossRef]

- Sheng, T.J.; Islam, M.S.; Misran, N.; Baharuddin, M.H.; Arshad, H.; Islam, R.; Chowdhury, M.E.H.; Rmili, H. An Internet of Things Based Smart Waste Management System Using LoRa and Tensorflow Deep Learning Model. IEEE Access 2020, 8, 148793–148811. [Google Scholar] [CrossRef]

- Shi, R.; Zhang, Z.Y.; Zhang, F.S. An efficient approach for spaceflight solid waste treatment: Co-disposal with hazardous medicine by hydrothermal oxidation process. Chem. Eng. J. 2018, 349, 204–213. [Google Scholar] [CrossRef]

- Sinha, S. A Study on Management of Solid Waste using Plasma Arc Technology. Int. J. Res. Appl. Sci. Eng. Technol. 2019, 7, 35–45. [Google Scholar] [CrossRef]

- Sylvestrea, H.; Ramakrishna Parama, V.R. Space debris: Reasons, types, impacts and management. Indian J. Radio Space Phys. 2017, 46, 20–26. [Google Scholar]

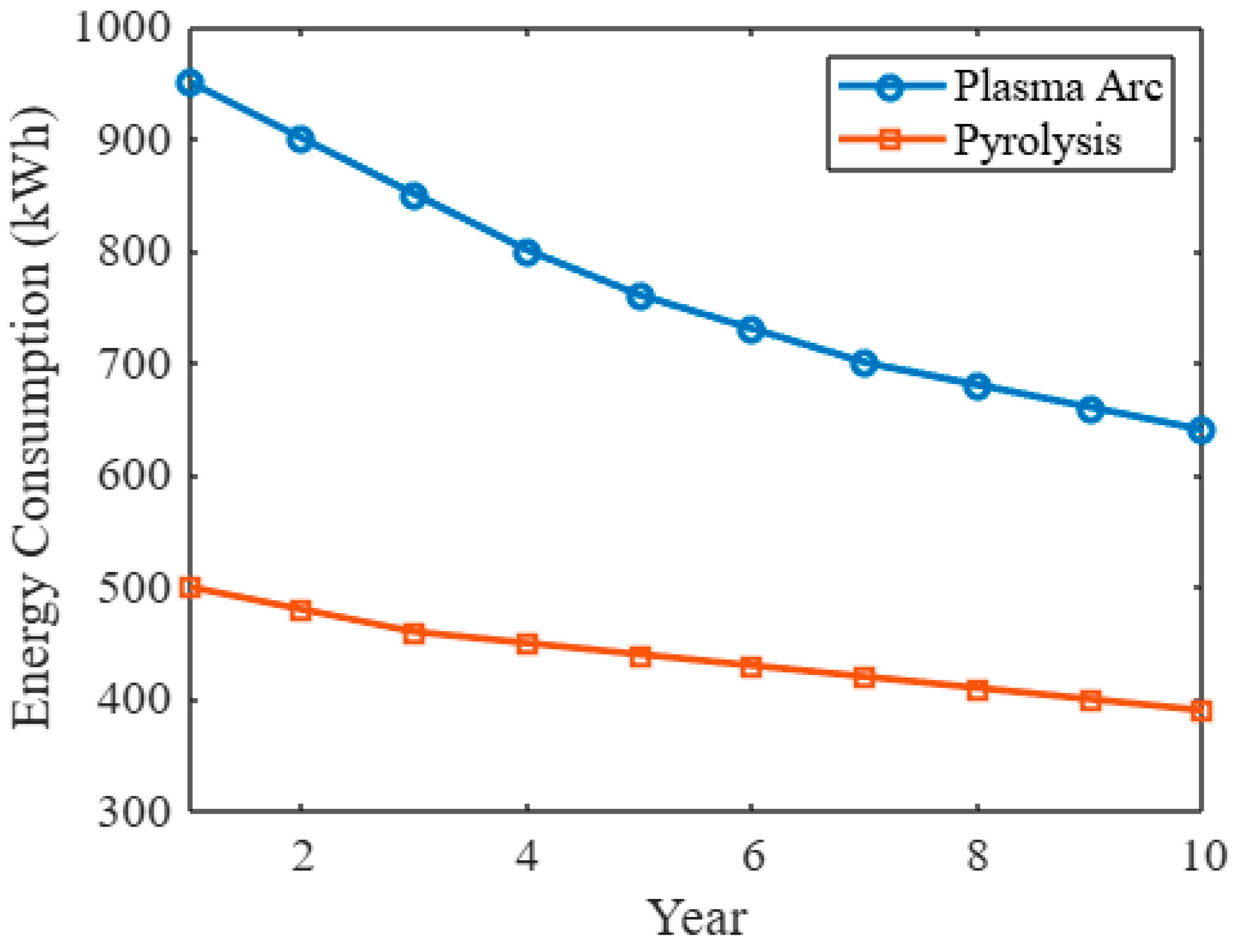

| Waste Processing Technology | Energy Requirements (kWh per ton) |

|---|---|

| Plasma Arc | 500–1000 |

| Pyrolysis | 200–500 |

| Bioreactors | 50–150 |

| Mechanical Compaction | 10–50 |

| Incineration | 300–600 |

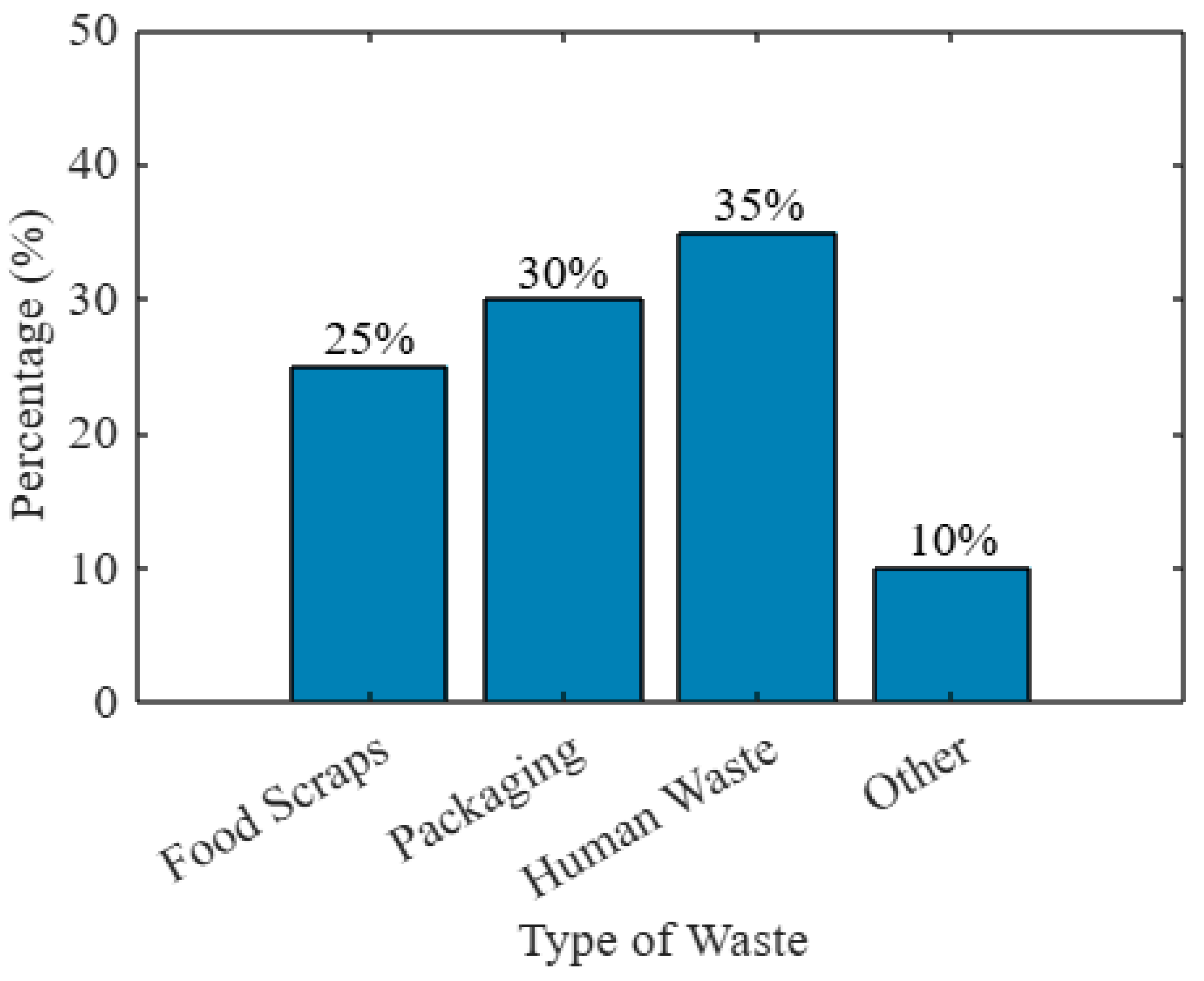

| Waste Type and Corresponding Management Techniques | |

| Waste Type | Management Techniques |

| Organic Waste | Bioreactors, Composting |

| Inorganic Waste | Mechanical Compaction, Pyrolysis |

| Packaging Waste | Mechanical Compaction, Plasma Arc |

| Human Waste | Bioreactors, Advanced Filtration Systems |

| Chemical Waste | Incineration, Chemical Neutralization |

| Electronic Waste | Recycling, Plasma Arc |

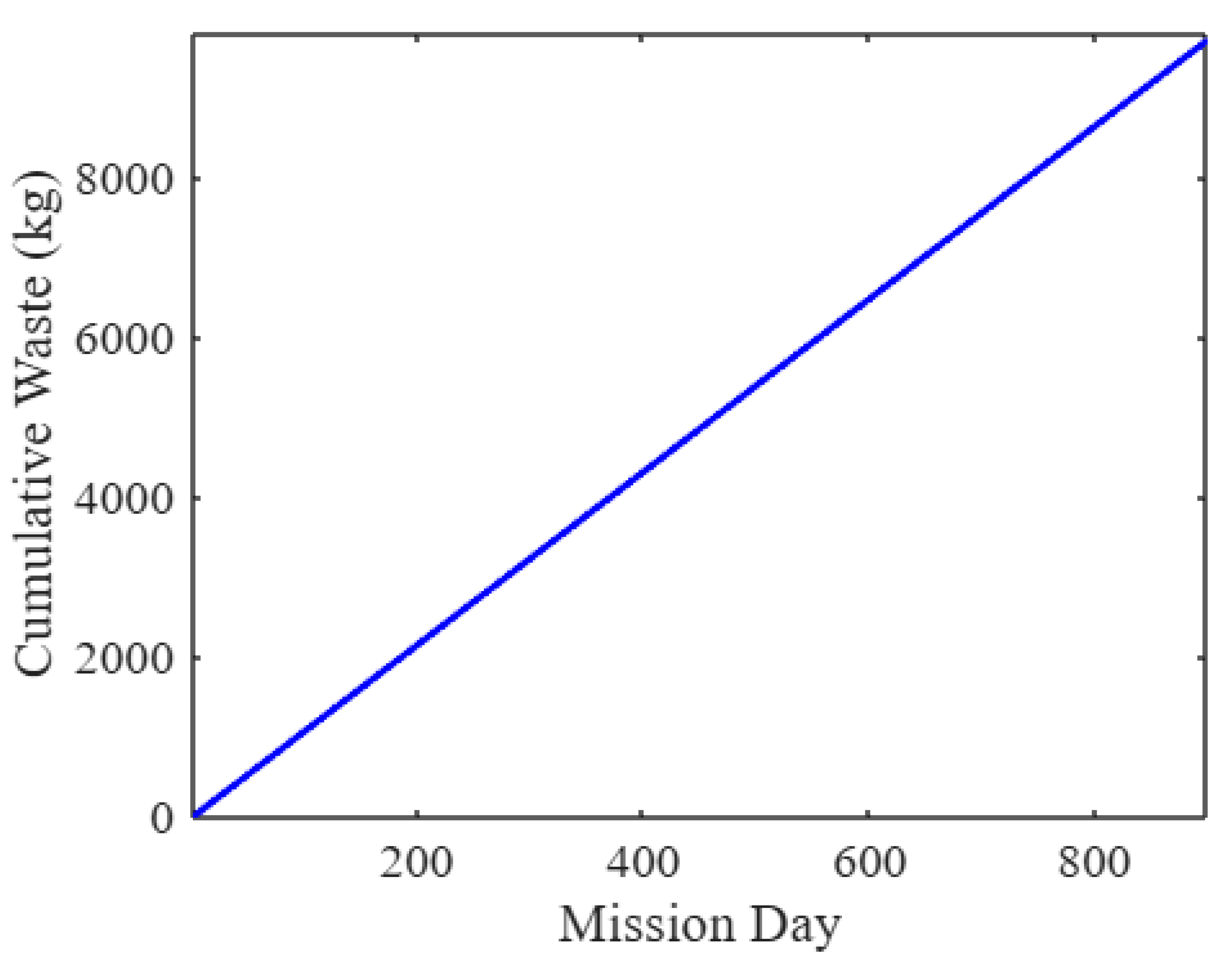

| Mission Type | Average Waste/Day (kg) | Total Waste per Mission (kg) | Mission Duration (Days) |

|---|---|---|---|

| International Space Station (ISS) | 1.5 per crew member | Variable (based on crew size and duration) | Variable |

| Lunar Missions | 2.0 per crew member | Calculated based on mission duration and crew size | 10–30 |

| Mars Missions | 1.8 per crew member | Calculated based on mission duration and crew size | 180–500 |

| Waste Management System | Initial Setup Cost | Operating Cost/Year | Savings from Reduced Resupply (USD/year) |

| Plasma Arc | USD 500,000 | USD 50,000 | USD 200,000 |

| Pyrolysis | USD 300,000 | USD 40,000 | USD 150,000 |

| Bioreactors | USD 250,000 | USD 30,000 | USD 180,000 |

| Mechanical Compaction | USD 100,000 | USD 10,000 | USD 50,000 |

| Incineration | USD 400,000 | USD 45,000 | USD 120,000 |

| Feature | Terrestrial Systems | Space Systems |

|---|---|---|

| Gravity Dependence | High | Negligible (Microgravity) |

| Microbial Risks | Naturally manageable | High, requires sterilisation |

| Resource Recycling | Variable, optional | Essential |

| Storage and Logistics | Extensive space available | Highly limited storage space |

| System Integration | Separate systems acceptable | Fully integrated with life-support |

| Efficiency Metrics of Current vs. Enhanced Recycling Systems | ||

|---|---|---|

| System | Current Recycling Efficiency (%) | Enhanced Recycling Efficiency (%) |

| Water Recycling | 90 | 98 |

| Air Recycling | 75 | 85 |

| Solid Waste Recycling | 30 | 50 |

| International Standards for Space Waste Management | ||

| Standard/Organisation | Key Guidelines | Focus Area |

| Space Systems—Debris Mitigation | Limit debris released during normal operations | Debris Management |

| COSPAR Planetary Protection Policy | Avoid biological contamination of celestial bodies | Environmental Protection |

| NASA Procedural Requirements 8715.6B | Waste disposal for spacecraft and associated hardware | Waste Disposal and Processing |

| UN Office for Outer Space Affairs | Long-term sustainability of outer space activities | Sustainable Space Exploration |

| Inventory of Waste Management Equipment on the ISS | ||

| Equipment | Manufacturer | Capacity |

| Closed-Loop System | Boeing (Washington, DC, USA) | Processes 6 kg/day |

| O2 Generation System | Airbus (Blagnac, France) | 2 kg O2/day |

| Urine Processor Assembly | Lockheed Martin (Bethesda, MD, USA) | 1.5 L/day |

| Solid Waste Compactor | Thales Alenia Space (Cannes, France) | 50 kg of waste |

| Water Recovery System | Hamilton Sundstrand (Windsor Locks, CT, USA) | 6 L/day |

| Technology | Processing | Energy (kWh/ton) | Suitability for Space Use | By-Product Utilization |

|---|---|---|---|---|

| Plasma Arc | High volume reduction | 500–1000 | High (requires significant power) | Syngas for energy |

| Pyrolysis | Moderate volume reduction produces biochar, oil, and syngas | 200–500 | Moderate (less energy than plasma but still significant) | Biochar for soil enhancement, syngas for energy |

| Bioreactors | Organic waste to biogas and compost | 50–150 | High (low energy, valuable by-products) | Compost for growing food, biogas for energy |

| Mechanical Compaction | Compacts solid waste to reduce volume | 10–50 | Very High (low energy, simple technology) | None (reduces storage space only) |

| Incineration | High volume reduction, sterilisation of waste | 300–600 | Moderate (efficient but requires energy for high heat) | Heat can be used for energy |

| Projected Waste Volumes for Future Deep-Space Missions | ||||

| Mission Type | days | Crew Size | Daily Waste/Crew | Total Waste |

| Mars | 900 | 6 | 1.8 kg | 9720 kg |

| Asteroid Mining | 180 | 4 | 1.5 kg | 1080 kg |

| Lunar Habitat | 365 | 5 | 1.5 kg | 2738 kg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olawade, D.B.; Wada, O.Z.; Popoola, T.T.; Egbon, E.; Ijiwade, J.O.; Oladapo, B.I. AI-Driven Waste Management in Innovating Space Exploration. Sustainability 2025, 17, 4088. https://doi.org/10.3390/su17094088

Olawade DB, Wada OZ, Popoola TT, Egbon E, Ijiwade JO, Oladapo BI. AI-Driven Waste Management in Innovating Space Exploration. Sustainability. 2025; 17(9):4088. https://doi.org/10.3390/su17094088

Chicago/Turabian StyleOlawade, David Bamidele, Ojima Zechariah Wada, Tunbosun Theophilus Popoola, Eghosasere Egbon, James O. Ijiwade, and B. I. Oladapo. 2025. "AI-Driven Waste Management in Innovating Space Exploration" Sustainability 17, no. 9: 4088. https://doi.org/10.3390/su17094088

APA StyleOlawade, D. B., Wada, O. Z., Popoola, T. T., Egbon, E., Ijiwade, J. O., & Oladapo, B. I. (2025). AI-Driven Waste Management in Innovating Space Exploration. Sustainability, 17(9), 4088. https://doi.org/10.3390/su17094088