Abstract

In the context of the global carbon neutrality process intertwined with the digital technology revolution, firms are facing unprecedented opportunities and challenges in green process innovation (GPI). Therefore, achieving GPI has become a critical issue for academics and industry practitioners. To deepen the understanding of the driving factors of GPI, this study explores how technology orientation can effectively promote GPI, considering the mediating role of digital capability and the moderating effect of innovation-oriented leadership. Utilizing a two-stage lagged data collection approach, we gathered information from a sample of 291 manufacturing firms in China. The findings reveal that technology orientation has a direct positive effect on GPI and also exerts an indirect influence through digital capability. Furthermore, innovation-oriented leadership significantly strengthens the positive impact of technology orientation on digital capability. This research contributes to the existing literature by providing a comprehensive theoretical framework that integrates technology orientation, digital capability, and leadership dynamics while focusing on the specific context of Chinese manufacturing. It offers practical insights for firms in China seeking to bridge the gap between technological advantages and environmental benefits in the pursuit of carbon neutrality, ultimately guiding them in effectively leveraging technology for sustainable development.

1. Introduction

With the profound restructuring of the global energy system and the ongoing tightening of environmental regulations, manufacturing firms are facing the dual challenges of green transformation and high-quality development. To achieve a more fundamental and systematic upgrade, GPI has become increasingly urgent. According to the United Nations Industrial Development Organization (UNIDO), manufacturing accounts for approximately 37% of global carbon emissions, while GPI can unlock up to 50–70% in reduction potential, equivalent to an annual decrease of 2.6 billion tons of CO₂. As a vital pathway for reducing environmental burdens and enhancing resource efficiency, GPI is gradually becoming a core strategy for building a green competitive advantage. Cases such as Midea Group’s “Sustainable Lighthouse” and LONGi Green Energy’s green supply chain exemplify the practical significance of GPI. Against this backdrop, exploring the driving factors of GPI not only enriches the theoretical landscape but also offers actionable guidance for firms engaging in sustainable development.

GPI essentially involves the adaptive adjustment and dynamic optimization of existing production processes, based on the continuous accumulation of green technologies and their organizational embedding, to achieve lower environmental impact and resource consumption than conventional alternatives. As a system-wide transformation grounded in technological reconfiguration, GPI encompasses the allocation, application, and renewal of key technological resources [1]. Prior research based on the resource-based view (RBV) has explored how firms initiate green innovation through the reorganization of static technological assets and the enhancement of organizational agility [2]. Other studies, drawing on dynamic capabilities theory, emphasize the importance of synergistically improving environmental adaptability and technological innovation capacity [1]. However, the existing literature largely overlooks the directional guiding role of technology within the process embedding stage, and fails to address the critical strategic question: how can firms activate technological resources to effectively realize their environmental value? Between 2020 and 2023, the number of green patents held by European firms rose by 85%, yet fewer than 30% achieved above-average reductions in carbon intensity. This phenomenon of “patent dormancy” reveals a core paradox in the traditional innovation paradigm—static technological accumulation does not necessarily yield dynamic environmental benefits [3]. In practice, the contribution of technology orientation to GPI lies not only in sustained investment in green technology, but also in the efficient transformation of patent outputs into practical applications. For instance, Spinnova has long focused on green fiber technologies and actively built a patent-centered process system, integrating experimental breakthroughs into production lines. This has significantly enhanced both the resource efficiency and environmental performance of fiber manufacturing. Clearly, technology orientation not only provides critical technical support for GPI but also enables the strategic allocation of dynamic resources. On this basis, this study investigates the effects of digital orientation on GPI, aiming to expand and refine existing theoretical frameworks.

By placing technological innovation at the strategic core, technology orientation offers essential resource foundations and directional guidance for GPI. However, despite continued technological accumulation, a growing disconnection persists between technology orientation and environmental performance [4]. Within green innovation contexts, process innovation exhibits strong problem orientation and systemic dependency, characterized by a high degree of tacit knowledge and extended validation cycles. Traditional models of “trial–verification–optimization” now face critical efficiency and cost bottlenecks. McKinsey reports that although 72% of manufacturing firms possess above-average technological resources, only 35% can effectively convert these into emission reduction outcomes. This suggests that the mechanism for translating technology orientation into environmental performance remains ambiguous, potentially due to overlooked capability factors. The rise of digital capabilities presents new theoretical opportunities for addressing this gap [5]. Digital capabilities extend beyond technical tool adoption to encompass cross-departmental collaboration, data-driven decision-making, and algorithmic transformation [6]. Through real-time data collection and modeling of process activities, firms can overcome the inefficiencies of trial-and-error approaches, accelerate the codification and reuse of technical knowledge, and construct a high-efficiency transformation pathway linking “technology–data–emission reduction” [7]. Accordingly, this paper introduces digital capability as a mediating variable to explore its bridging role in the pathway from technology orientation to GPI, and to uncover the dynamic transmission mechanism among “resources–capabilities–performance”.

Technology orientation holds substantial promise for acquiring technical resources and fostering digital capabilities to drive GPI. Nevertheless, the “digital transformation gap” remains a pressing challenge. Prior studies have highlighted that misaligned organizational cognition and a lack of change momentum, especially the absence of critical actors during strategy execution, can significantly weaken the effect of digital enablement. During the process of leveraging technology orientation to build digital capability, innovation-oriented leadership—defined by technological sensitivity, risk tolerance, and integrative capacity across domains—plays a pivotal role. Such leadership not only facilitates the identification of core issues in green transformation under a technology-oriented paradigm but also shapes cross-functional collaboration and an innovation-driven organizational climate. For instance, Alibaba’s policy of granting “three rounds of trial-and-error rights” in constructing green data centers reflects an innovation-oriented leadership style that acknowledges the iterative nature of green technology conversion and the need to transcend short-term financial indicators. While existing studies and practices recognize the critical role of leadership in resource reconfiguration [8], current strategic leadership research remains largely focused on macro-level strategy formulation, neglecting the specific micro-level mechanisms through which leaders facilitate technological transformation [9,10]. Transformational leadership theory, although emphasizing employee motivation, falls short in addressing the organizational context for digital technology adoption [11,12]. This theoretical fragmentation obscures the key moderating mechanism and creates a gap that warrants further investigation: in the context of pronounced path dependence in production processes, how can leaders reshape technological priorities and drive knowledge integration through cognitive intervention [13]?

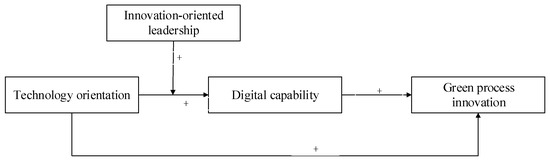

To address these research gaps, this study integrates insights from dynamic capabilities theory, digital transformation literature, and strategic leadership research to construct a theoretical framework linking technology orientation, digital capability, and GPI. Innovation-oriented leadership is introduced as a moderating variable. The study centers on two core questions: (1) how does technology orientation drive GPI through the mediating role of digital capability, and (2) how does innovation-oriented leadership moderate the relationship between technology orientation and digital capability? Addressing these questions yields three theoretical contributions: First, it reconstructs the interaction paradigm between technological innovation and environmental constraints by demonstrating how technology orientation embeds environmental standards into decision-making processes, transforming green innovation from passive compliance to proactive adaptation. Second, it proposes a new theoretical model incorporating digital capability as a mediator, thereby extending traditional RBV and dynamic capabilities perspectives on the transformation of technological resources. Third, by identifying the moderating role of innovation-oriented leadership, it introduces a dynamic co-evolutionary model of technology: digital synergy, which offers a renewed understanding of strategic leadership’s role in achieving sustainable competitive advantage.

2. Theoretical Background and Hypotheses Development

2.1. Theoretical Background

Green innovation is defined as a set of diversified transformation activities undertaken by firms to achieve the integration of environmental and economic benefits [14]. GPI, more specifically, refers to dynamic, holistic, and directional changes made to existing production processes through the adoption of advanced manufacturing technologies [15]. Against the backdrop of the global push for carbon neutrality and the digital technology revolution, firms are increasingly inclined to optimize organizational processes to enhance environmental performance [16]. In this context, existing research grounded in the resource-based view (RBV) considers the accumulation of resources as a necessary condition for promoting GPI, confirming the pivotal roles of financial capital, technological patents, and human resources in driving innovation [17]. Other studies, based on dynamic capabilities theory, have constructed a “sensing–seizing–reconfiguring” pathway of technological realization, enabling firms to advance ongoing green innovation practices by sensing external opportunities, seizing critical resources, and reconfiguring internal capabilities [16,18]. Within the framework of GPI, such capabilities are reflected in the efficiency with which technological reserves are converted into iterative, low-carbon production systems. Scholars have further incorporated organizational learning theory, suggesting that firms must continuously accumulate knowledge through learning to sustain the dynamic evolution of innovation [19]. In addition, extant research has consistently emphasized key contextual factors influencing the use of technology to drive green innovation. For instance, intense market competition encourages firms to actively pursue green innovation to maintain a competitive edge, while stringent environmental regulations compel firms to adopt green technological solutions to meet compliance requirements [20,21]. Although current studies have explored multiple dimensions, such as technology, environment, and resources, and enriched our understanding of the antecedents of GPI, limitations persist in explaining how technological achievements are translated into practice. In particular, the conversion of tacit technological knowledge into tangible emissions-reduction outcomes typically requires a period of 18 to 24 months, which stands in stark contrast to the time sensitivity demanded by carbon neutrality targets, thereby highlighting the urgency for theoretical breakthroughs [18].

Existing studies emphasize that technology—as both a core driver and necessary condition of GPI—has its integration and utilization outcomes directly determining the effectiveness of a firm’s green innovation efforts. Within innovation contexts, technology orientation is defined as a firm’s strategic inclination to prioritize the development and application of new technologies, encompassing both technology exploration and integration dimensions [22,23]. Existing research demonstrates that technology orientation not only enables firms to identify and capture green technology opportunities through exploration, but also facilitates the efficient integration of diverse technology resources to accumulate the necessary assets for innovation [24]. By integrating digital transformation theory and leadership theory, this study adopts a strategic orientation perspective to systematically analyze the realization mechanisms of GPI, thereby offering a potential approach to addressing the unresolved issue of the “patent conversion gap” in the literature. Bharadwaj’s framework of digital capabilities emphasizes that data-driven decision-making is reshaping the paradigm of knowledge generation [20].

Knowledge management theory further posits that digital capabilities can accelerate knowledge transformation through three mechanisms: first, data standardization breaks down knowledge silos; second, algorithmic modeling facilitates the explicit articulation of tacit knowledge; third, real-time feedback loops foster continuous improvement cycles [21,22]. Hambrick’s upper echelons theory suggests that managerial cognitive frameworks shape the pathways of organizational change [23]. Innovation-oriented leadership can strengthen the synergy between technology orientation and digital capability by establishing a long-term vision to counteract short-termism, creating a tolerance mechanism to support technological iteration, and reshaping organizational structures to enhance knowledge flow [24,25]. By constructing an integrated analytical framework centered on “technology orientation–digital capability–GPI” and introducing innovation-oriented leadership as a moderator, this study enables the formation of a multidimensional theoretical explanation system and provides a concrete theoretical response to the practical challenge of the “technology-to-performance gap” observed in firms’ innovation practice.

2.2. Hypotheses Development

2.2.1. Technology Orientation and GPI

As a process-oriented innovation that emphasizes the integration of environmental performance and systemic reconfiguration of operations, GPI is characterized by the low-carbon transformation of production factors, the systemic optimization of process structures, and the embedded integration of environmental objectives [26,27,28]. This type of innovation not only highlights the dynamic coordination between resources and the environment under technological drive but also requires firms to restructure their process governance systems through cross-functional collaboration [29]. Technology orientation, by placing technological configuration and integration at the strategic core of the enterprise, enables organizations to develop systematic advantages in identifying, deploying, and transforming green technologies, thereby offering stable strategic support for GPI [30].

First, technology orientation facilitates the development of a dynamic adaptation mechanism for responding to green technological change, thereby providing a flexible technological foundation for GPI. According to dynamic capability theory, firms operating in highly uncertain technological environments must integrate external opportunities through the stages of sensing, seizing, and reconfiguring [31]. Technology-oriented firms are more likely to establish technical sensing mechanisms and forward-looking technology evaluation procedures to proactively identify clean technologies, energy-saving processes, and pathways for intelligent transformation [32]. On this basis, they adopt process simulation, scenario modeling, and technology-matching mechanisms to capture green solutions that can be embedded into existing process systems, and employ modular design and flexible configuration to rapidly reconfigure technological systems [33,34]. By doing so, GPI is no longer a reaction to external regulation, but a natural outcome of the firm’s self-evolving technical systems.

Second, technology orientation strengthens the firm’s cross-functional knowledge integration mechanisms, enhancing the cognitive foundation for GPI. GPI often involves highly heterogeneous knowledge domains such as environmental regulations, process parameters, and system simulations, which are fragmented in semantics and difficult to coordinate [35]. According to the knowledge-based view, the ability of an organization to convert heterogeneous knowledge into systemic understanding is a prerequisite for innovation [36,37]. Technology-oriented firms tend to exhibit stronger tendencies for knowledge reconstruction. By implementing unified coding rules, performance metrics, and data platforms, they convert environmental requirements into technical specifications and embed experiential process knowledge into iterative parameters, thus improving the shareability and operability of knowledge. Moreover, with the aid of intelligent tools such as digital twins and machine learning, firms can externalize tacit experience, embed environmental standards into process systems, and establish a direct translation channel “from knowledge to process”. In this way, technology orientation helps firms transcend traditional knowledge silos, achieving cognitive synergy in green process design and knowledge-driven process optimization.

Third, technology orientation promotes deep integration between resource allocation and process governance mechanisms, providing institutional safeguards and sustained incentives for GPI. GPI is not an isolated event, but a systematic endeavor built upon continuous resource investment and institutional coordination [15]. Technology-oriented firms are more inclined to strategically allocate resources toward green infrastructure, smart equipment, and carbon monitoring platforms. They also develop standardized green process templates and dynamic energy efficiency evaluation mechanisms to ensure real-time responsiveness and ongoing optimization of green performance at the process level [34]. At the institutional level, technology orientation also facilitates the formation of green process operational standards, including integrating green performance into process design approvals, incorporating carbon emission metrics into KPI systems, and establishing dedicated teams for green process improvement [30,32]. This organizational and institutional restructuring not only enhances the execution of GPI, but also embeds green orientation into the logic of process governance, forming a closed-loop system for green management that spans process motivation, evaluation, and iteration. Accordingly, the following hypothesis is proposed:

H1.

Technology orientation positively influences a firm’s GPI.

2.2.2. Technology Orientation and Digital Capability

As digital technologies become deeply embedded in the value creation processes of firms, digital capability has increasingly been recognized as a critical foundation for achieving organizational agility, real-time optimization, and systemic evolution [19]. Given the inherently cross-platform, modular, and evolutionary characteristics of digital technologies, building sustainable digital capabilities requires firms to develop strategic foresight in technology integration, as well as systematic mechanisms for identifying, absorbing, and reconfiguring technologies at the strategic level [38]. Accordingly, technology orientation—representing a firm’s strategic commitment and behavioral investment in technological resources—serves as a critical starting point for the development of digital capabilities.

First, technology orientation builds a strategic accumulation mechanism of technological resources, providing essential inputs for the foundation of digital capabilities. According to the RBV, a firm’s competitive advantage originates from its ability to control and combine rare and inimitable resources [36]. Technology-oriented firms consistently channel R&D investment, capital, and organizational attention toward frontier technologies with strategic potential, such as big data architectures, Internet of Things (IoT) systems, and artificial intelligence (AI) algorithms [5]. This focused investment leads to the formation of distinctive digital asset portfolios, including proprietary data platforms, customized modeling capabilities, and process algorithm libraries [6].

Second, technology orientation enhances organizational agility and modular integration capacity, accelerating the dynamic evolution of digital capabilities. According to dynamic capability theory, capability development depends not only on resource possession but also on whether firms can rapidly absorb, reconfigure, and integrate emerging technologies [39]. Technology-oriented firms often embed technology monitoring mechanisms into their strategic scanning systems and establish experimental innovation structures [5], such as agile development teams, rapid prototyping labs, and cross-functional task forces, to facilitate fast technology adoption and internal transformation. When digital technologies reach the stage of mature diffusion, technology-oriented firms can quickly integrate new functional modules—such as edge computing nodes, automated decision units, and real-time data processing interfaces—through modular architectures, significantly shortening technology deployment cycles [7].

Third, technology orientation promotes digital restructuring of organizational systems and management processes, expanding the embeddedness and organizational boundaries of digital capabilities. The realization of digital capabilities involves more than just technological access; it also requires full integration into daily workflows and decision-making frameworks. Technology-oriented firms tend to adopt data-driven architectures such as open middle platforms, low-code development environments, and programmable interface systems when building process platforms, thereby enabling large-scale integration of digital tools across the organization [22]. At the same time, technology orientation drives institutional updates in management processes; for example, incorporating algorithmic recommendations into process improvement approvals, embedding data metrics into performance evaluation systems, and transitioning from a “human-led, tech-assisted” to a “tech-led, human-coordinated” decision-making paradigm [23]. These institutional and organizational reforms centered on technology orientation effectively expand the adaptive scope and evolutionary resilience of digital capabilities [5], making them suitable not only for static process optimization, but also for restructuring in response to dynamic strategic scenarios. Accordingly, the following hypothesis is proposed:

H2.

Technology orientation positively influence a firm’s digital capability.

2.2.3. Digital Capability and GPI

Unlike traditional linear improvement models, GPI increasingly relies on firms’ ability to perceive environmental dynamics in real time, allocate complex resources, and orchestrate cross-functional process governance. In this transformation, digital capability functions as a key organizational competence that connects technological systems to environmental objectives, playing an important role in stimulating GPI.

First, digital capability improves firms’ granularity of environmental sensing and responsiveness, reconstructing the closed loop of sensing–decision–execution in GPI [40]. In traditional process systems, environmental data is often delayed, fragmented, and low frequency, making it inadequate for supporting high-precision, real-time green decision-making during process execution [38]. Firms with high digital capability are able to deploy real-time sensing mechanisms around critical process nodes to monitor green factors, such as carbon intensity, energy consumption fluctuations, and pollutant levels, across the entire process. On this basis, digital capability enables horizontal connectivity and vertical updating of data, embedding green performance objectives into every stage of process execution, thereby enabling data-driven green regulation logic. Furthermore, digital capability facilitates vertical feedback between strategic and operational levels, reducing the discrepancy between top-level green goals and frontline process behavior.

Second, digital capability strengthens firms’ ability to map cross-system knowledge and formalize green logic, providing cognitive and structural support for GPI [41]. GPI is an inherently knowledge-intensive process that involves the integration of technical, environmental, procedural, and managerial knowledge systems [42]. Digital capability empowers firms to integrate heterogeneous knowledge across functional domains through structured representations and modeling tools, allowing logical relations among different knowledge systems to be quantified, abstracted, and transferred. More importantly, digital capability allows firms to establish dynamic mapping mechanisms for green knowledge across process units, enabling green design logic to cross functional boundaries and enter process configuration, resource allocation, and control nodes. This forms a transmission chain from standard setting to execution, following a “knowledge–rule–behavior” logic [30]. In addition, digital capability facilitates the transformation of knowledge from experience to models and from tacit to explicit, enabling green norms to be embedded as rule-based process modules, thereby promoting the standardization and normalization of GPI.

Third, digital capability reshapes resource allocation logic and process governance models, establishing a data-driven, platform-based, and institutionally embedded integrated execution structure for GPI. In traditional production systems, resource allocation is typically based on static planning, and process governance relies on linear management chains—an approach ill-suited for the dynamic coordination and real-time feedback required by GPI [19]. In firms with advanced digital capabilities, the organization of process resources undergoes a fundamental shift: resources are no longer isolated functional units, but are transformed into callable, composable, and optimizable functional components through data-mediated linkages, enabling the flexible coupling of resources to green objectives [33]. At the same time, digital capability drives governance transformation from closed control to open feedback, and from ex-ante settings to real-time coordination. For example, firms can configure rule engines to define green response logic in processes and use monitoring mechanisms to continuously assess performance against green indicators, thereby adjusting execution parameters dynamically. This drives the transition from linear to cyclical governance models and enhances organizational responsiveness under uncertainty [43]. Such data-embedded process governance not only improves the transparency and consistency of green execution, but also combines rule-driven logic with algorithmic feedback to institutionalize and expand GPI [41]. Accordingly, we propose the following hypothesis:

H3.

Digital capabilities positively influence a firm’s GPI.

2.2.4. The Mediating Role of Digital Capability

Based on the analyses above, digital capability can be regarded as a key organizational mechanism linking strategic orientation and process transformation, serving as the critical pathway through which technology orientation affects GPI [44,45].

First, digital capability transforms the resource configurations driven by technology orientation into technically operable platforms for process systems, thus bridging the gap between “strategic focus” and “organizational usability” [46]. Technology-oriented firms often accumulate a wide array of green-related technical resources, such as energy-efficient equipment, simulation algorithms, and process databases, but in the absence of sufficient digital capability, these resources may remain “silent”—unable to contribute to green process transformation due to incompatible interfaces, inaccessible modules, or uncontrollable process links [44]. However, firms with digital capability can integrate these resources through platform consolidation, data modeling, and standardized process interfaces, enabling them to be invoked and programmed as part of process restructuring efforts [47]. In other words, digital capability converts the static stock of green technologies embedded in technology orientation into dynamic increments, thereby laying the executional foundation for GPI [48].

Second, digital capability facilitates the decoupling of knowledge and the reconstruction of cross-system logic in green process design, translating the organizational cognition triggered by technology orientation into process rules and structural optimization [2]. Green process optimization often requires firms to convert environmental metrics into technical specifications and map experiential knowledge into standardized parameters. In this context, digital capability plays a mediating role in knowledge orchestration and structural mapping [43]. By leveraging unified indicator systems, cross-process data interfaces, and algorithm-based knowledge frameworks, digital capability integrates previously fragmented green knowledge scattered across departments and process units and projects it into technical systems, enabling consistent articulation of green goals at the process level [49]. This mechanism bridges the gap between the cognitive front-end of technology orientation and the actual operation of process systems, transforming green process design from experience-based judgments to rule-based modeling, and forming a green process logic that is both executable and iterative [39].

Third, digital capability reconstructs the execution and feedback mechanisms of green processes, enabling feedback loops and iterative updates within technology-oriented process transformations [50]. GPI is not a one-off optimization activity, but a continuous, adaptive, and iterative process [38]. While technology orientation can endow firms with acute insights into green technologies, the lack of feedback systems and adaptive mechanisms may hinder the formation of closed-loop optimization. Digital capability enables real-time monitoring, process visualization, and carbon emission traceability, equipping green processes with dynamic adjustment capabilities during execution [39]. Furthermore, firms can leverage algorithmic models to simulate process changes, conduct impact analyses, and evaluate benefits, thereby establishing a closed-loop management cycle from “technology identification—process transformation—environmental feedback—technology iteration.” This process ultimately converts the strategic potential embedded in technology orientation into a sustainable capability for ongoing process renewal [2]. Accordingly, the following hypothesis is proposed:

H4.

Digital capabilities mediate the relationship between technology orientation and GPI.

2.2.5. The Moderating Role of Innovation-Oriented Leadership

In the process of organizational transformation and capability reconstruction, leaders’ strategic intent, institutional arrangements, and organizational advocacy often amplify or weaken the path through which strategic orientation is translated into capabilities. Innovation-oriented leadership emphasizes leaders’ preference for innovation and their guiding role in promoting organizational learning, institutional relaxation, resource integration, and cross-boundary collaboration [10,11,12]. Compared to traditional structural leadership, innovation-oriented leaders are more inclined to foster organizational agility, encourage experimentation, and restructure coordination mechanisms, thereby breaking existing capability boundaries and accelerating the transformation of resources into capabilities [51,52]. While technology orientation serves as a strategic driver in the construction of digital capabilities, its effectiveness largely depends on whether top management possesses innovation-oriented governance capacity.

First, innovation-oriented leadership institutionalizes and operationalizes technology-oriented behavior by reconstructing the strategic framework, thus enhancing the directive force of technology orientation in digital capability development [53]. Although technology-oriented firms may have both the intent and capacity to acquire digital technologies, without top-level strategic planning and systematic resource allocation mechanisms, these technological resources may remain confined to isolated pilot projects, failing to form a cohesive digital capability system [54,55]. Innovation-oriented leaders are often able to embed technology strategies into the broader organizational agenda, incorporate digital capability development into long-term corporate goals, and design the top-level architecture linking data assets, technology modules, and capability components. Furthermore, they ensure that the strategic blueprint is effectively implemented through institutional arrangements [56]. This enhanced strategic coherence reduces path dependence in resource allocation and improves coordination efficiency in digital capability development [48].

Second, innovation-oriented leadership enhances structural flexibility in the transformation process from technology orientation to digital capability by promoting cross-boundary experimentation and organizational restructuring [52]. Under the impetus of technology orientation, firms continuously introduce new tools and systems, but their effective integration is often constrained by organizational inertia and rigid process structures [57]. Innovation-oriented leaders tend to foster flat collaborative networks, task-based teams, or cross-departmental innovation groups to break down communication barriers between technology, process management, and IT departments in experimental settings. This enhances the organizational adaptability of digital system integration [55]. At the same time, such leaders value iterative learning and encourage “learning by doing”, allowing teams to accumulate experiential knowledge through trial and error, thus laying the institutional and cognitive foundation for the stable operation of new systems [2].

Third, innovation-oriented leadership improves organizational awareness and behavioral engagement in the digital capability development process, strengthening the behavioral translation path of technology orientation. During the development of digital capabilities, it is essential for organizational members to reach a shared understanding of the objectives and internalize them into voluntary actions [58]. Innovation-oriented leaders typically use vision-building, semantic framing, and value reinforcement to translate abstract strategic goals into actionable guidance that frontline employees can perceive and follow. For instance, during the early stages of digital system implementation, leaders may highlight the “green objectives” of technological application, establish aligned behavioral incentive systems, and build feedback and evaluation mechanisms [59]. These efforts enhance employee participation, continuity, and identification during capability transformation processes [56,60]. This cognitive empowerment process reinforces the psychological linkage between strategic orientation and capability development and lays the foundation for embedding and scaling digital capabilities within the organization [61,62]. Accordingly, the following hypothesis is proposed:

H5.

Innovation-oriented leadership positively moderates the relationship between technology orientation and digital capability.

3. Methodology

3.1. Research Setting

Chinese manufacturing firms provide a suitable research environment for this study for several reasons. First, the industry is currently under pressure to undergo transformation and upgrade, necessitating a shift from traditional production models to greener and more sustainable practices. Exploring how technology orientation and digital capabilities can promote GPI can offer practical guidance and strategies for this transformation. Second, with the Chinese government’s strong push for the development of the digital economy, manufacturing firms are increasingly exploring and practicing digital transformation. This trend provides a wealth of data to support research on how digital capabilities influence GPI. Furthermore, the government has introduced a series of policies aimed at promoting green development, encouraging firms to engage in green innovation and digital transformation. This supportive policy environment enhances the relevance and applicability of the research findings. Third, within Chinese firms, leadership styles vary significantly, with innovation-oriented leadership styles gradually emerging in some firms. This diversity allows for an exploration of how different leadership styles influence the relationship between technology orientation and digital capabilities, and how they subsequently affect the outcomes of green innovation.

3.2. Sampling and Data Collection

This study employed a questionnaire survey method for data collection. To ensure content validity, the original items were derived from established English scales published in reputable journals. We utilized a back-translation method to convert the scales, first translating all items into Chinese and then translating them back into English for comparison with the original items. This approach helped ensure that the semantic meaning remained consistent throughout the translation process [63]. To assess the equivalence of the items in both languages, we invited other scholars in the field to analyze the Chinese and English items, making adjustments based on their feedback to maintain the core essence of the original variables while ensuring cultural relevance for Chinese respondents.

Prior to the formal survey, a pilot test was conducted in Hubei Province, China, where experienced researchers contacted senior managers to collect preliminary questionnaire data. Feedback from participants indicated that some original questions were too ambiguous for accurate responses. Consequently, we revised the questionnaire to enhance its reliability and validity, rephrasing or simplifying items to facilitate easier completion. The adjusted questionnaire was then used for the formal survey.

During the formal research phase, we ensured that the selected sample of firms met the study requirements by covering five provinces in the Yangtze River Delta and the Pearl River Delta, including cities like Shanghai, Suzhou, Nanjing, Wuxi, Guangzhou, Shenzhen, and Zhuhai. We conducted two rounds of questionnaire distribution and collection, staggering the measurement of independent and dependent variables to minimize common method bias [64]. The survey period is from May 2023 to September 2024. In the first round (T1), researchers randomly selected 3000 firms from regional business directories, with an average of 600 firms from each province. With the help of professional survey agencies, we sent invitations and introductory letters to these firms, assuring confidentiality and anonymity, and stating that the data would be used solely for academic research. As a result, 1126 firms that had engaged in GPI over the past three years agreed to participate. Researchers then successfully established contact with the senior managers of these firms and scheduled in-person meetings for the survey.

To facilitate data collection, we collaborated with professional data collection agencies and conducted a two-wave survey targeting Chinese manufacturing firms. We utilized two versions of the questionnaire (A and B), dividing the measurement items into two sections, with two managers from each company completing the questionnaires. This approach aimed to minimize common method bias by employing multiple informants [64,65]. To ensure that respondents were well-informed about their firm’s strategic direction and internal activities, we targeted mid- to senior-level decision-makers or department heads [66], assigning different items to different management levels to enhance data quality [67,68]. In the Tl phase, senior managers answered questions regarding technology orientation and innovation-oriented leadership, while middle managers addressed issues related to the company’s digital capabilities. For firms unable to participate in the in-person survey, we also mailed questionnaires to complete the data collection. This phase aimed to ensure that our sample was as representative as possible, resulting in a total of 732 valid paired questionnaires.

One year later, we re-surveyed the managers who participated in the first round, inviting senior managers to respond to questions about GPI while middle managers provided control variables and demographic information to enrich our dataset. After organizing and filtering the completed questionnaires to remove any with missing data or invalid information, we ultimately collected valid paired responses from 291 firms across 32 cities, encompassing various industries such as automotive, IT, petrochemicals, and electronics.

To address potential non-response bias, we conducted t-tests. The results indicated no significant differences in key characteristics (such as company size, development stage, geographic location, and ownership type) between responding and non-responding firms [69]. Furthermore, we compared the initial sample of 1126 firms with the final sample of 291, finding that the final sample remained representative in terms of industry type, company size, and geographic location. Last, we also compared early and late responses for the aforementioned variables, with no significant differences. These checks suggest that non-response bias did not have a significant impact on this study.

3.3. Variables and Measurement

With the exception of some control variables, all items used a 7-point Likert scale, ranging from 1 (strongly disagree) to 7 (strongly agree), to reflect varying degrees of agreement among respondents. Detailed measurement items and the results of reliability and validity tests are provided in Appendix A.

Technology Orientation. The measure for technology orientation was adapted from the works of Gatignon and Xuereb and Zhou et al. [70,71], focusing on a firm’s proactive use of cutting-edge technologies in new product development.

GPI. The measurements of GPI were adapted from Huang and Li [14], with four items developed to assess aspects of GPI, including energy savings, pollution prevention, waste recycling, and reduced toxicity in manufacturing processes.

Digital Capability. For digital capability, this study adapted measures from Khin and Ho [5]. Five items were included to assess the respondent firm’s capabilities related to the application of digital technology.

Innovation-Oriented Leadership. Innovation-oriented leadership was measured using scales from Stock et al. [72], which evaluate how leaders influence innovative outcomes.

Control variables. To mitigate the potential impact of other variables, this study includes several control variables, including geographic location, firm size, firm age, development stage, ownership, industry type, and external environmental turbulence.

3.4. Reliability and Validity

We conducted a series of analyses to assess the reliability and validity of the data. The reliability analysis results indicated that the Cronbach’s α values for all variables were above 0.8, and the composite reliability (CR) also exceeded 0.8, demonstrating high reliability for the scales [73]. The items were derived from established scales validated in reputable journals, translated into Chinese using a back-translation method, and revised based on expert feedback before the formal survey, ensuring high content validity. Moreover, the confirmatory factor analysis results showed that the fit indices met the required criteria (χ2/df = 2.245; IFI = 0.976; TLI = 0.948; CFI = 0.982; GFI = 0.918; RMSEA = 0.037), indicating a good fit of the data. Additionally, all factor loadings for the corresponding items were above 0.7 [74], and the average variance extracted (AVE) for each variable was greater than 0.5.

To assess the discriminant validity of the scales, we employed Fornell and Larcker’s [73] method to compare the intercorrelations among constructs with the square roots of their average variances extracted (AVEs), as outlined in Table 1. The findings revealed that the intercorrelations were lower than the square roots of the AVEs, indicating good discriminant validity for the scales. Next, we compared the fit indices among different measurement models, finding that the four-factor model (χ2/df = 2.245; IFI = 0.976; TLI = 0.948; CFI = 0.982; GFI = 0.918; RMSEA = 0.037) provided a better fit than the three-factor, two-factor, and one-factor models. Finally, we utilized the Heterotrait–Monotrait Ratio (HTMT) method as a reference indicator to further examine the scales’ discriminant validity; the calculations in Table 2 showed that the HTMT values for key variables were all below the threshold of 0.85 [75], further confirming the scales’ strong discriminant validity.

Table 1.

Correlations and descriptive statistics.

Table 2.

HTMT tests for discriminant validity.

3.5. Common Method Variance (CMV)

The results of this study are derived from questionnaire survey data, which may be influenced by common method bias (CMB) [76]. To address this concern, we implemented several strategies to minimize the potential impact of CMB.

Following the recommendations of Podsakoff et al. [64], we gathered data on key variables from two managers within each participating firm. This strategy aimed to minimize the potential for CMB by obtaining insights from multiple perspectives within the firm. Additionally, during the formal survey, we assured participants that their responses would be used solely for academic purposes and that their personal information would remain confidential, thereby reinforcing the anonymity of the survey.

To further assess the influence of CMB on our findings, we employed three statistical methods for post-hoc testing. First, the Harman’s single-factor test indicated that the first factor explained only 25.42% of the total variance. This suggests that there is no single dominant factor that accounts for most of the shared variation among the measures. Second, we used the marker variable (MV) method to examine common method bias [77]. The MV was chosen to be theoretically unrelated to at least one key variable in this study, and the institutional environment was chosen as the MV, which was measured by a four-item scale. As shown in Table 1, the MV exhibited a minimal positive correlation of only 0.002 with the latent variable, innovation-oriented leadership. After adjusting for the marker variable, the correlation coefficients remained unchanged, indicating that CMB was not present in this study. Third, we applied the common latent factor (CLF) method to further investigate CMB. A new measurement item representing the CLF was included in the measurement model, which pointed to all variables. By comparing the standardized factor loadings of the models with and without the CLF, we found that the differences in factor loadings were well below 0.1, indicating that the impact of common method bias on our findings was minimal.

4. Analyses and Results

4.1. Hypothesis Tests

We tested our hypotheses using hierarchical regression models. To address potential multi-collinearity, we mean-centered all variables involved in the interaction term [78]. As shown in Table 3, the Variance Inflation Factor (VIF) values ranged from 1.338 to 1.349, which is well below the threshold of 10, indicating that multi-collinearity is not a significant concern in this study.

Table 3.

Results of hierarchical regression.

The results from Model 5 demonstrate a significant positive relationship between technology orientation and GPI (β = 0.276, p < 0.001), thus supporting H1. Similarly, results in Model 6 support Hypothesis 3. H2 proposes that technology orientation has a positive effect on digital capability. Results in Model 2 suggest that the regression coefficients of technology orientation and digital capability are positive and statistically significant (β = 0.294, p < 0.001), thereby supporting H3. Results in Table 4 further confirm these three hypotheses.

Table 4.

Results of mediation analysis.

Hypothesis 4 suggests that digital capability acts as a mediator in the relationship between technology orientation and GPI. To test this mediation effect, we utilized the bootstrapping method in IBM SPSS Statistics 29 which produced a 95% bias-corrected confidence interval based on 5000 iterations. The findings of this mediation analysis are presented in Table 4. Since both the mediated effect (a × b) and the direct effect c are significant and consistent in direction, this supports the notion of a complementary mediation effect of organizational unlearning [79]. Therefore, we find support for Hypothesis 4.

Hypothesis 5 posits that innovation-oriented leadership enhances the positive effect of technology orientation on digital capability. In Model 3, the interaction of technology orientation and innovation-oriented leadership is significantly positively related to digital capability (β = 0.222, p < 0.001), thereby supporting H5. To further test this hypothesis, we conducted a bootstrapping analysis [80] to further examine the moderating effect of innovation-oriented leadership. The results in Table 5 further validate H5.

Table 5.

Results of moderation analysis.

4.2. Robust Tests

In exploring the impact of technology orientation on GPI, we recognized potential endogeneity issues linked to factors such as omitted variables, bidirectional causality, and measurement errors. These concerns could compromise the consistency and unbiasedness of our parameter estimates, highlighting the need for endogeneity tests to ensure the reliability of our findings. To address this, we employed a Gaussian copula approach [81], which is particularly effective for handling endogeneity issues, including measurement errors [82].

We first assessed whether the endogenous constructs—technology orientation and digital capability—followed non-normal distributions. The Kolmogorov–Smirnov and Shapiro–Wilk tests, detailed in Table 6, confirmed their non-normality. This result necessitated the use of the Gaussian copula method to effectively tackle the potential endogeneity associated with these constructs [83]. We conducted our analysis using SmartPLS software (version 4.1.0.9), with bootstrapping set at 5000 samples. The results, shown in Table 7, indicated that none of the Gaussian copulas across various model configurations were statistically significant (p > 0.05), suggesting that endogeneity is unlikely to be a concern in our analysis. This finding enhances the reliability of our conclusions regarding the relationships among the constructs.

Table 6.

The results of Kolmogorov–Smirnov and Shapiro–Wilk tests.

Table 7.

Result of Gaussian copula analysis.

5. Discussion

Under the drive of the “dual carbon” goals, exploring how technology orientation can address the challenges of transforming GPI is of significant theoretical and practical importance. Currently, firms face bottlenecks in green innovation due to high costs of technological iteration, organizational inertia, and difficulties in converting environmental benefits. Our study presents a comprehensive theoretical framework that connects technology orientation with GPI in the context of Chinese firms, while also highlighting the mediating role of digital capability and the contingent role of innovation-oriented leadership, as depicted in Figure 1. Evidence from 291 Chinese manufacturing firms demonstrates that technology orientation has a direct and positive impact on GPI. Additionally, our research identifies that this impact is mediated by digital capability, and that innovation-oriented leadership enhances the effect of technology orientation on digital capability. Taken together, these empirical findings strongly support our research model.

Figure 1.

The direction of the relationship between variables.

5.1. Theoretical Contributions

This study makes three significant theoretical contributions to existing studies. First, by highlighting the theoretical importance of technology orientation in advancing GPI, this study addresses limitations inherent in existing strategic perspectives. The traditional resource-based view conceptualizes technology primarily as a static resource [36], inadequately accounting for the adaptive adjustments required under dynamic environmental regulations. Meanwhile, although dynamic capabilities theory emphasizes the flexible adaptation of technological systems [31], it fails to sufficiently explain the strategic-level constraints imposed by environmental factors on technological evolution. This study demonstrates that technology orientation enables firms to internalize environmental standards within technological decision-making, transforming green innovation from a passive compliance response into an active ecological adaptation process [84], thus offering a new perspective on the interplay between technological innovation and environmental constraints. Additionally, this research extends Grant’s knowledge integration framework [37] by transcending the binary opposition between “environment” and “technology”, thereby expanding the applicability of technology orientation within cross-domain knowledge transformation. Whereas the traditional framework emphasizes internal synergies within technological systems [37], it overlooks how technology orientation facilitates embedding eco-compliance knowledge into innovation systems [4,60,85]. Therefore, this study proposes a technology-driven theoretical framework for green innovation, emphasizing the role of technology orientation in redefining environmental constraints from mere peripheral conditions to benchmarks guiding technological design [86], thereby providing a novel theoretical basis for future research. Unlike previous studies that portray technological innovation and environmental constraints as inherently conflicting, the present research shows that upgraded environmental standards can serve as catalysts for technological iteration under a technology-oriented approach, shifting green innovation from a “compliance cost” paradigm toward a proactive framework of “technological competitive advantage”. This finding not only refines Winter’s classical argument regarding the stability of organizational routines [87], but also affirms the applicability of Nonaka’s knowledge spiral model [88] in the context of ecology–technology interactions, thereby advancing knowledge creation theory into the realm of sustainable innovation and offering a new analytical lens for sustainable competitive advantage theory [89].

Second, this study develops a theoretical model incorporating digital capability as a mediating variable, thereby providing a novel and comprehensive explanatory logic for how firms achieve GPI in the digital era. Although the resource-based view [36] and dynamic capabilities theory [31] offer explanations for technology-driven green innovation, the former primarily highlights the heterogeneous value of technological resources, while the latter stresses the dynamic adaptation of organizational routines; neither sufficiently addresses the mechanisms through which digital technologies foster sustainable competitive advantage. This research identifies that technology orientation can activate digital capability to convert static resources, such as patent portfolios, into environmental adaptability [90,91], thereby challenging the resource-based view’s conventional assumption regarding the “stock value” of technological assets [36], and enhancing the explanatory scope of dynamic capabilities theory within the context of green digital transformation. Furthermore, the study emphasizes that digital capability can encode environmental knowledge into actionable technical parameters, enabling firms to reframe environmental constraints as strategic tools for reshaping technological niches [92]. This transformation allows GPI to move beyond traditional cost–benefit frameworks, establishing a new micro-foundation for sustainable competitive advantage [86]. Consequently, these findings not only alleviate the tension between environmental objectives and technological capabilities in the “green paradox”, but also propel strategic management research towards a new paradigm emphasizing the synergy between ecological imperatives and technological trajectories.

Third, this study elucidates how innovation-oriented leadership positively moderates the relationship between technology orientation and digital capability through dual pathways of strategic framework reconstruction and organizational routine transformation, offering novel and robust insights into the interdisciplinary field linking strategic leadership and technological capability evolution. Although existing strategic leadership research primarily focuses on macro-level strategy formulation, it often overlooks the specific roles leaders play in micro-level technological transformation processes [9,10,93]. By identifying innovation-oriented leadership as a critical moderating factor, this study develops a dynamic adjustment model of technology–digital capability co-evolution, explicating how particular leadership styles facilitate the formation of sustainable competitive advantages. Diverging from traditional knowledge governance approaches reliant on voluntary sharing, this research positions innovation-oriented leadership as a moderating link between strategic orientation and digital capability, highlighting both the moderating influence of senior executives’ attributes in the technology–digital co-evolution and the catalytic role of structural power in digitally encoding tacit knowledge. Consequently, this work addresses previous gaps concerning how firms leverage senior leaders’ innovative characteristics to effectively operationalize technology orientation [13], thus enriching the theoretical framework connecting strategic orientation to innovation performance.

5.2. Practical Implications

This study reveals the synergistic mechanism of technology orientation, digital capability, and innovation-oriented leadership in facilitating GPI, providing actionable managerial insights for firms pursuing systematic green transformations.

First, firms should deeply embed technology orientation into their green innovation strategies and actively explore dynamically adapted pathways for technology resource transformation. Managers may prioritize integrating green technology accumulation and process optimization into strategic planning, acquiring advanced green technology knowledge by setting targeted R&D funds, encouraging employee participation in green technology projects, and enhancing collaboration with external research institutions and universities. Firms can further establish a strategic roadmap for green technology accumulation: short-term goals should focus on assimilating existing mature green technologies; mid-term efforts can intensify independent R&D in key technological domains to establish proprietary green technology systems; and in the long term, firms should aim to develop open innovation platforms, integrating internal and external resources to continuously innovate and upgrade green technologies, thereby solidifying foundations for GPI.

Second, firms need to emphasize cultivating digital capability as a pivotal mediator in technology-driven GPI. By proactively investing in digital infrastructure, such as deploying advanced sensor networks and data analytics systems, firms can achieve real-time data collection and precise modeling of production processes. Firms should implement structured roadmaps for digital capability enhancement: initially, establishing cross-departmental digital collaboration teams to overcome departmental barriers; subsequently, investing in employee training programs to build data literacy and analytical skills; and ultimately, embedding digital capability deeply into corporate decision-making and innovation processes. These measures effectively leverage technological resources for environmental value, address the “patent dormancy” issue, enable rapid encoding and reuse of technical knowledge, and build efficient technology–data–emission reduction pathways, thus enhancing the efficiency and efficacy of GPI.

Third, firms must harness the moderating influence of innovation-oriented leadership to bridge technology orientation and digital capability. Firms should identify and cultivate leaders with strong technological acumen, risk tolerance, and cross-domain integration skills, granting them sufficient decision-making authority and resource allocation power to drive green innovation initiatives. Leadership interventions can recalibrate technological priorities, channel resources toward key green technology innovation areas, mitigate “digital transformation gaps”, and promote synergy between technological orientation and digital capability, ultimately fostering robust GPI and sustainable competitive advantage.

6. Limitations and Future Research

This study has several limitations and offers opportunities for future research. First, this study primarily focuses on China’s manufacturing sector, and limited sample diversity may constrain the generalizability of our findings. Although manufacturing represents a crucial domain for green digital transformation, digitization levels and market conditions vary considerably across countries and industries, and this research may not fully capture the differential role mechanisms of technology orientation in sectors such as services or agriculture. Additionally, the current analysis relies on static data, thus inadequately addressing the dynamic interplay between technology iteration and digital capability accumulation. Future research should establish cross-industry longitudinal datasets, integrate enterprise lifecycle theory, and utilize panel data models to explore the dynamic coupling between intergenerational technological leaps and digital capability maturation trajectories. This approach would enhance the applicability of findings across diverse contexts.

Second, our study does not sufficiently deconstruct the boundary conditions imposed by external environments, such as policy regulations and regional digital infrastructure, on the transformation of technology orientation into digital capabilities. This oversight limits the precision of practical guidance. Future research could create a three-dimensional analytical framework combining “institutional, technological, and organizational” factors. By employing spatial econometric models, researchers can quantify the interaction effects of regional digital policy intensity and industrial chain collaboration. Furthermore, developing a policy simulation system based on digital twin technology could help forecast the digital empowerment efficiency of corporate technology investments under various carbon pricing mechanisms, providing dynamic decision-making support for both governments and firms.

Third, the present study does not adequately explain the nonlinear patterns driven by digital capabilities in green innovation, such as critical adoption points and human-machine collaboration thresholds. The impact of emerging technologies like generative AI and quantum computing on the conceptualization of digital capabilities has also not been considered. Future research should incorporate computational experimental methods to identify critical effectiveness thresholds for core indicators, such as the penetration rate of industrial internet platforms and the assetization rate of environmental data. Moreover, exploring new scenarios involving brain–computer interface-enhanced decision-making and blockchain-enabled green intellectual property transactions could lead to the development of a theoretical extension model linking “disruptive technologies, digital capabilities, and sustainable innovation,” thereby shifting the research paradigm from linear relationships to complex system evolution.

Author Contributions

Conceptualization, Q.X.; Software, Z.L.; Formal analysis, Z.L. and J.Z.; Investigation, Q.X. and J.D.; Resources, J.D.; Data curation, J.D.; Writing – original draft, Q.X. and Z.L.; Visualization, J.Z.; Supervision, Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets presented in this article are not readily available because they contain sensitive information. Requests to access the datasets should be directed to the corresponding author at zhiyuanl@163.com.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Measurement of Variables

Technology orientation (α = 0.879; AVE = 0.697; CR = 0.902)

In your company:

- You use sophisticated technologies in our new product development. (0.758)

- Your new products always involve state-of-the-art technology. (0.824)

- You actively solicit and develop technologically advanced new products. (0.867)

- Technical innovation, based on research results, is readily accepted at this organization. (0.884)

Digital capability (α = 0.912; AVE = 0.705; CR = 0.923)

Please indicate the level of your company’s capabilities in following areas:

- Acquiring important digital technologies. (0.878)

- Identifying new digital opportunities. (0.825)

- Responding to digital transformation. (0.887)

- Mastering the state-of-the-art digital technologies. (0.834)

- Developing innovative products/service/process using digital technology. (0.768)

GPI (α = 0.886; AVE = 0.698; CR = 0.902)

Has your company ever taken the following action in the production process:

- Low energy consumption such as water, electricity, gas and petrol during production/use/disposal. (0.887)

- Use of cleaner technology to make savings and prevent pollution (such as energy, water and waste). (0.824)

- Recycle, reuse and remanufacture material. (0.768)

- Less or no toxicity in manufacturing process. (0.859)

Innovation-oriented leadership (α = 0.904; AVE = 0.683; CR = 0.928)

The leaders in your company:

- Encourage activities that foster innovations. (0.872)

- Express appreciation for innovation-oriented attitudes of their employees. (0.769)

- Criticize employees’ behaviours that are not innovation-oriented. (0.746)

- Support innovation-oriented employees in particular. (0.815)

- Demonstrate an innovation orientation in their own behaviour. (0.886)

- Set the goals of their employees in order to promote a high innovation orientation. (0.862)

Environment uncertainty (α = 0.918; AVE = 0.709; CR = 0.936)

In the past 3 years:

- The technology in our industry is changing rapidly (0.863)

- Technological changes provide big opportunities in our industry (0.829)

- Technological developments in our industry are rather major (0.853)

- In our kind of business, customers’ product preferences change quite a bit over time. (0.878)

- Our customers tend to look for new products all the time (0.834)

- New customers tend to have product-related needs that are different from those of our existing customers (0.793)

Note: AVE—average variance extracted; CR—composite reliability.

References

- Weaven, S.; Quach, S.; Thaichon, P.; Frazer, L.; Billot, K.; Grace, D. Surviving an economic downturn: Dynamic capabilities of SMEs. J. Bus. Res. 2021, 128, 109–123. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strat. Manag. J. 1997, 187, 509–533. [Google Scholar] [CrossRef]

- Fang, L.; Li, Z. Corporate digitalization and green innovation: Evidence from textual analysis of firm annual reports and corporate green patent data in China. Bus. Strategy Environ. 2024, 335, 3936–3964. [Google Scholar] [CrossRef]

- Shehzad, M.U.; Jianhua, Z.; Naveed, K.; Zia, U.; Sherani, M. Sustainable transformation: An interaction of green entrepreneurship, green innovation, and green absorptive capacity to redefine green competitive advantage. Bus. Strategy Environ. 2024, 337, 7041–7059. [Google Scholar] [CrossRef]

- Khin, S.; Ho, T.C. Digital technology, digital capability and organizational performance: A mediating role of digital innovation. Int. J. Innov. Sci. 2019, 112, 177–195. [Google Scholar] [CrossRef]

- Nambisan, S. Digital entrepreneurship: Toward a digital technology perspective of entrepreneurship. Entrep. Theory Pract. 2017, 416, 1029–1055. [Google Scholar] [CrossRef]

- Ge, Y.; Xia, Y.; Wang, T. Digital economy, data resources and enterprise green technology innovation: Evidence from A-listed Chinese Firms. Resour. Policy 2024, 92, 105035. [Google Scholar] [CrossRef]

- Teece, D.J. The foundations of enterprise performance: Dynamic and ordinary capabilities in an economic theory of firms. Acad. Manag. Perspect. 2014, 284, 328–352. [Google Scholar] [CrossRef]

- Samimi, M.; Cortes, A.F.; Anderson, M.H.; Herrmann, P. What is strategic leadership? Developing a framework for future research. Leadersh. Q. 2022, 333, 101353. [Google Scholar] [CrossRef]

- Thys, K.; Vandekerkhof, P.; Steijvers, T.; Corten, M. Top management team and board of directors as the strategic leadership system: The effect of behavioral integration on strategic decision-making quality. Eur. Manag. J. 2024, 425, 721–734. [Google Scholar] [CrossRef]

- Lin, Q. Transformational leadership and innovative work behavior: The role of identification, voice and innovation climate. Int. J. Hosp. Manag. 2023, 113, 103521. [Google Scholar] [CrossRef]

- Lyubykh, Z.; Gulseren, D.; Turner, N.; Barling, J.; Seifert, M. Shared transformational leadership and safety behaviours of employees, leaders, and teams: A multilevel investigation. J. Occup. Organ. Psychol. 2022, 952, 431–458. [Google Scholar] [CrossRef]

- Goswami, A.K.; Agrawal, R.K. It’sa knowledge centric world! Does ethical leadership promote knowledge sharing and knowledge creation? Psychological capital as mediator and shared goals as moderator. J. Knowl. Manag. 2023, 273, 584–612. [Google Scholar] [CrossRef]

- Huang, J.W.; Li, Y.H. Green innovation and performance: The view of organizational capability and social reciprocity. J. Bus. Ethics 2017, 145, 309–324. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, G.; Jin, J.; Xie, Q.; Li, J. CEO s’ transformational leadership and product innovation performance: The roles of corporate entrepreneurship and technology orientation. J. Prod. Innov. Manag. 2014, 31, 2–17. [Google Scholar] [CrossRef]

- Yuan, B.; Cao, X. Do corporate social responsibility practices contribute to green innovation? The mediating role of green dynamic capability. Technol. Soc. 2022, 68, 101868. [Google Scholar] [CrossRef]

- Vogel, R.; Güttel, W.H. The dynamic capability view in strategic management: A bibliometric review. Int. J. Manag. Rev. 2013, 154, 426–446. [Google Scholar] [CrossRef]

- Wang, X.; Ma, C.; Yao, Z. The double-edged sword effect of digital capability on green innovation: Evidence from Chinese listed industrial firms. Econ. Anal. Policy 2024, 82, 321–339. [Google Scholar] [CrossRef]

- Ghosh, S.; Hughes, M.; Hodgkinson, I.; Hughes, P. Digital transformation of industrial businesses: A dynamic capability approach. Technovation 2022, 113, 102414. [Google Scholar] [CrossRef]

- Bharadwaj, A.; El Sawy, O.A.; Pavlou, P.A.; Venkatraman, N.V. Digital business strategy: Toward a next generation of insights. MIS Q. 2013, 37, 471–482. [Google Scholar] [CrossRef]

- Di Vaio, A.; Palladino, R.; Pezzi, A.; Kalisz, D.E. The role of digital innovation in knowledge management systems: A sytematic literature review. J. Bus. Res. 2021, 123, 220–231. [Google Scholar] [CrossRef]

- Cheng, J.; Singh, H.S.M.; Zhang, Y.C.; Wang, S.Y. The impact of business intelligence, big data analytics capability, and green knowledge management on sustainability performance. J. Clean. Prod. 2023, 429, 139410. [Google Scholar] [CrossRef]

- Hambrick, D.C.; Mason, P.A. Upper Echelons: The Organization as a Reflection of Its Top Managers. Acad. Manag. Rev. 1984, 92, 193–206. [Google Scholar] [CrossRef]

- Arici, H.E.; Uysal, M. Leadership, green innovation, and green creativity: A systematic review. Serv. Ind. J. 2022, 42, 280–320. [Google Scholar] [CrossRef]

- Colovic, A. Leadership and business model innovation in late internationalizing SMEs. Long Range Plann. 2022, 551, 102083. [Google Scholar] [CrossRef]

- Zhuo, C.; Chen, J. Can digital transformation overcome the enterprise innovation dilemma: Effect, mechanism and effective boundary. Technol. Forecast. Soc. Change 2023, 190, 122378. [Google Scholar] [CrossRef]

- Chang, C.H. The determinants of green product innovation performance. Corp. Soc. Responsib. Environ. Manag. 2016, 23, 65–76. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pujari, D. Mainstreaming green product innovation: Why and how companies integrate environmental sustainability. J. Bus. Ethics. 2010, 95, 471–486. [Google Scholar] [CrossRef]

- Zailani, S.; Govindan, K.; Iranmanesh, M.; Shaharudin, M.R.; Sia Chong, Y. Green innovation adoption in automotive supply chain: The Malaysian case. J. Clean. Prod. 2015, 108, 1115–1122. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Vilkas, M.; Grybauskas, A.; Amran, A. Drivers and barriers of Industry 4.0 technology adoption among manufacturing SMEs: A systematic review and transformation roadmap. J. Manuf. Technol. Manag. 2022, 336, 1029–1058. [Google Scholar] [CrossRef]

- Teece, D.J. Business models and dynamic capabilities. Long Range Plann. 2018, 511, 40–49. [Google Scholar] [CrossRef]

- Li, L.; Tong, Y.; Wei, L.; Yang, S. Digital technology-enabled dynamic capabilities and their impacts on firm performance: Evidence from the COVID-19 pandemic. Inf. Manag. 2022, 598, 103689. [Google Scholar] [CrossRef]

- Liu, X.; Liu, F.; Ren, X. Firms’ digitalization in manufacturing and the structure and direction of green innovation. J. Environ. Manag. 2023, 335, 117525. [Google Scholar] [CrossRef]

- Schiederig, T.; Tietze, F.; Herstatt, C. Green innovation in technology and innovation management–an exploratory literature review. R D Manag. 2012, 422, 180–192. [Google Scholar] [CrossRef]

- Shahzad, M.; Qu, Y.; Zafar, A.U.; Appolloni, A. Does the interaction between the knowledge management process and sustainable development practices boost corporate green innovation? Bus. Strategy Environ. 2021, 308, 4206–4222. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 171, 99–120. [Google Scholar] [CrossRef]

- Grant, R.M. Toward a Knowledge-Based Theory of the Firm. Strat. Manag. J. 1996, 17, 109–122. [Google Scholar] [CrossRef]

- Luo, S.; Yimamu, N.; Li, Y.; Wu, H.; Irfan, M.; Hao, Y. Digitalization and sustainable development: How could digital economy development improve green innovation in China? Bus. Strategy Environ. 2023, 324, 1847–1871. [Google Scholar] [CrossRef]

- Teece, D.; Peteraf, M.; Leih, S. Dynamic capabilities and organizational agility: Risk, uncertainty, and strategy in the innovation economy. Calif. Manag. Rev. 2016, 584, 13–35. [Google Scholar] [CrossRef]

- Cui, R.; Wang, J.; Xue, Y.; Liang, H. Interorganizational learning, green knowledge integration capability and green innovation. Eur. J. Innov. Manag. 2021, 244, 1292–1314. [Google Scholar] [CrossRef]

- Yang, S.; Hussain, M.; Maqsood, U.S.; Younas, M.W.; Zahid, R.A. How digital orientation drives green innovation: Financial constraints as a mediator in Chinese A-share firms. Balt. J. Manag. 2025, ahead-of-print. [Google Scholar] [CrossRef]

- Tian, H.; Li, Y.; Zhang, Y. Digital and intelligent empowerment: Can big data capability drive green process innovation of manufacturing enterprises? J. Clean. Prod. 2022, 377, 134261. [Google Scholar] [CrossRef]

- AlNuaimi, B.K.; Singh, S.K.; Harney, B. Unpacking the role of innovation capability: Exploring the impact of leadership style on green procurement via a natural resource-based perspective. J. Bus. Res. 2021, 134, 78–88. [Google Scholar] [CrossRef]

- Majchrzak, A.; Markus, M.L.; Wareham, J. Designing for digital transformation. MIS Q. 2016, 402, 267–278. [Google Scholar] [CrossRef]

- Haug, A.; Adsbøll Wickstrøm, K.; Stentoft, J.; Philipsen, K. The impact of information technology on product innovation in SMEs: The role of technological orientation. J. Small Bus. Manag. 2023, 612, 384–410. [Google Scholar] [CrossRef]

- Baiyere, A.; Salmela, H.; Nieminen, H.; Kankainen, T. Assessing digital capabilities for digital transformation—The MIND framework. Inf. Syst. J. 2025, 351, 6–38. [Google Scholar] [CrossRef]

- Nasiri, M.; Saunila, M.; Ukko, J.; Rantala, T.; Rantanen, H. Shaping digital innovation via digital-related capabilities. Inf. Syst. Front. 2023, 253, 1063–1080. [Google Scholar] [CrossRef]

- Sirmacek, D.G.; Hitt, G.T.; Irland, R.D. Managing firm resources in dynamic environments to create value: Looking inside the black box. Acad. Manag. Rev. 2007, 321, 273–292. [Google Scholar]