Integrating Noise into Life Cycle Assessment for Sustainable High-Rise Construction: A Comparative Study of Concrete, Timber, and Steel Frames in Australia

Abstract

1. Introduction

2. Material and Method

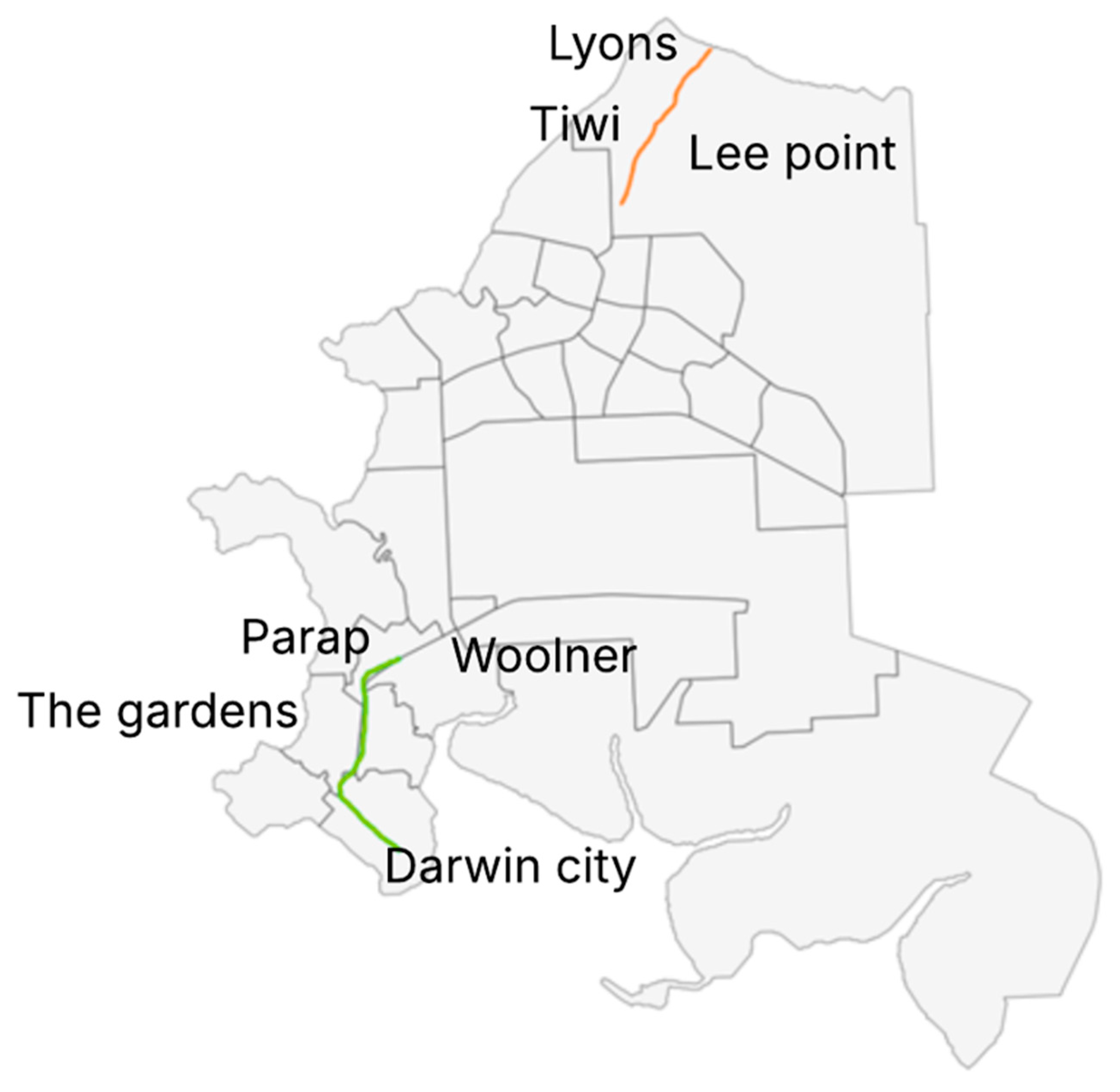

2.1. Goal and Scope Definition

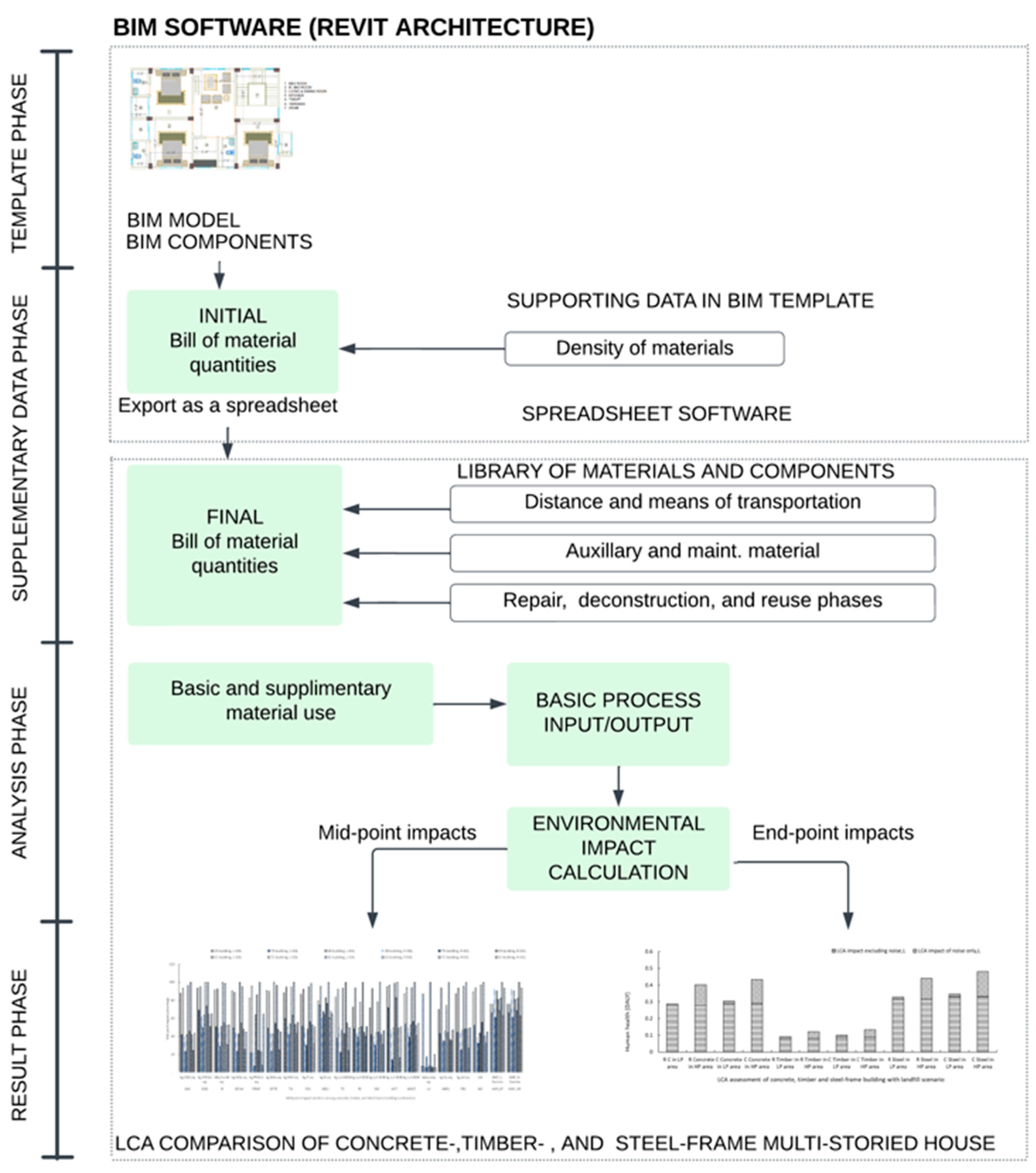

2.2. Life Cycle Inventory (LCI)

2.3. Life Cycle Impact Assessment

2.3.1. Traditional LCA Method

2.3.2. Noise Integration in LCA Method

- Human Health (measured in Disability-Adjusted Life Years, DALY).

- Ecosystem Quality (measured in species lost per year).

- Resource Scarcity (measured in USD increase in extraction cost).

3. Result and Discussion

3.1. LCA of Six-Story Concrete-, Timber-, and Steel-Frame Houses

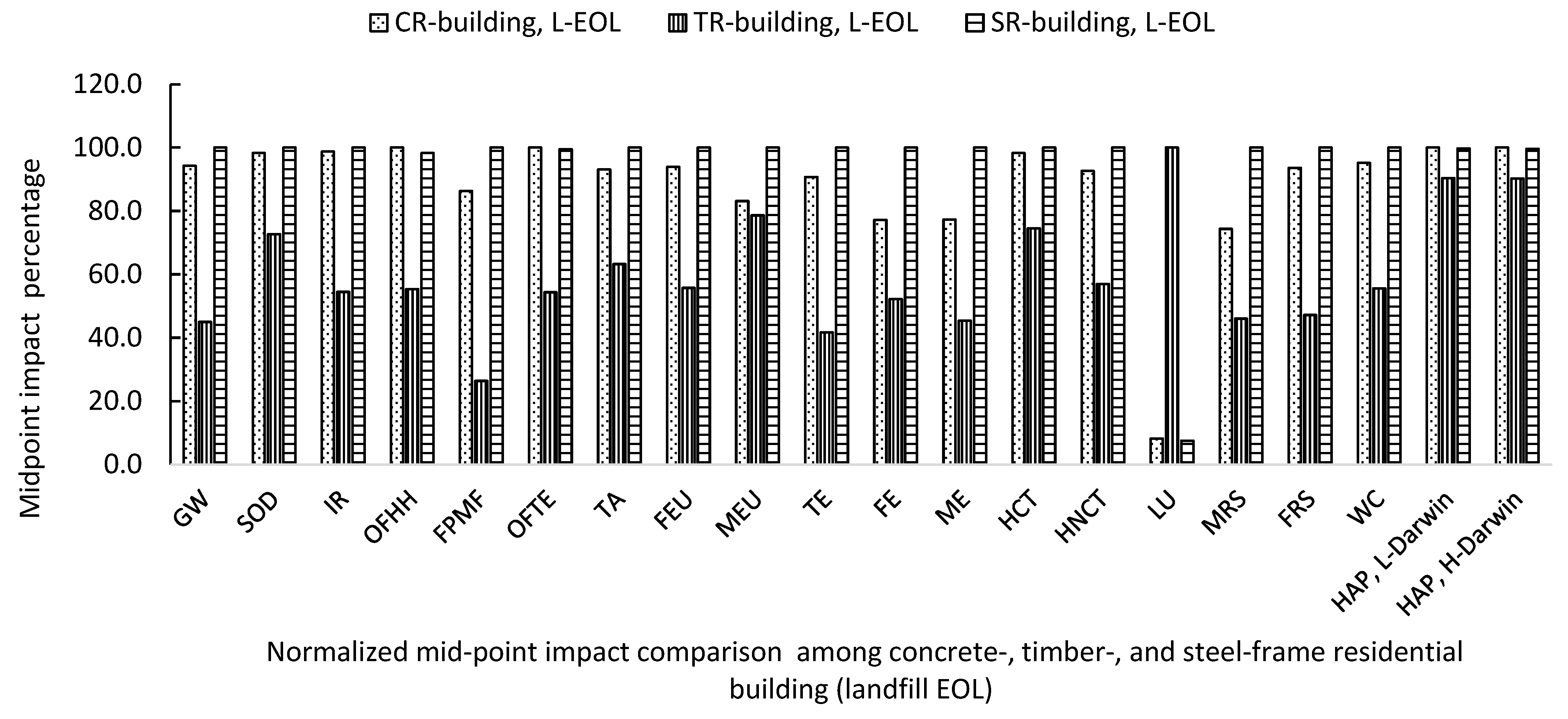

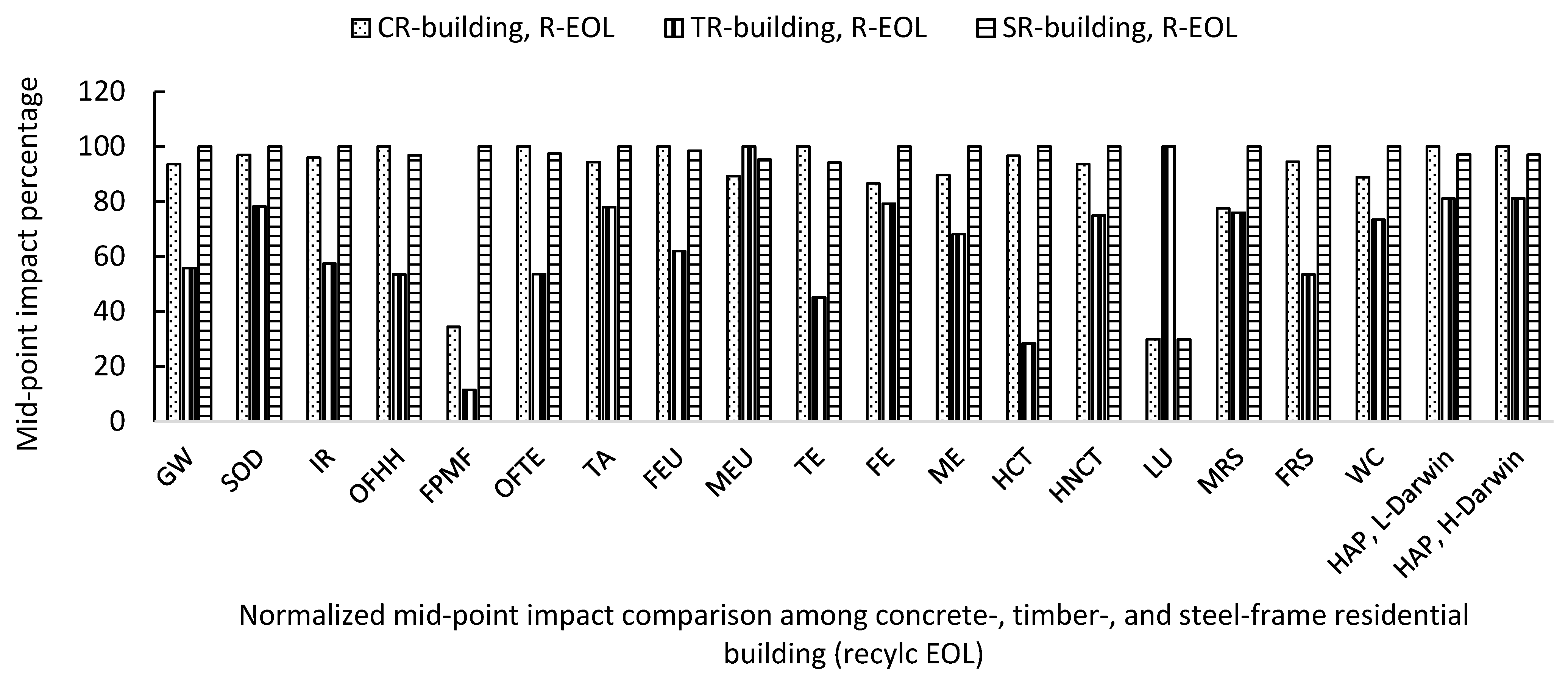

3.1.1. Midpoint Impact Assessment

- Residential buildings using landfill EOL.

- Residential buildings using recycled EOL.

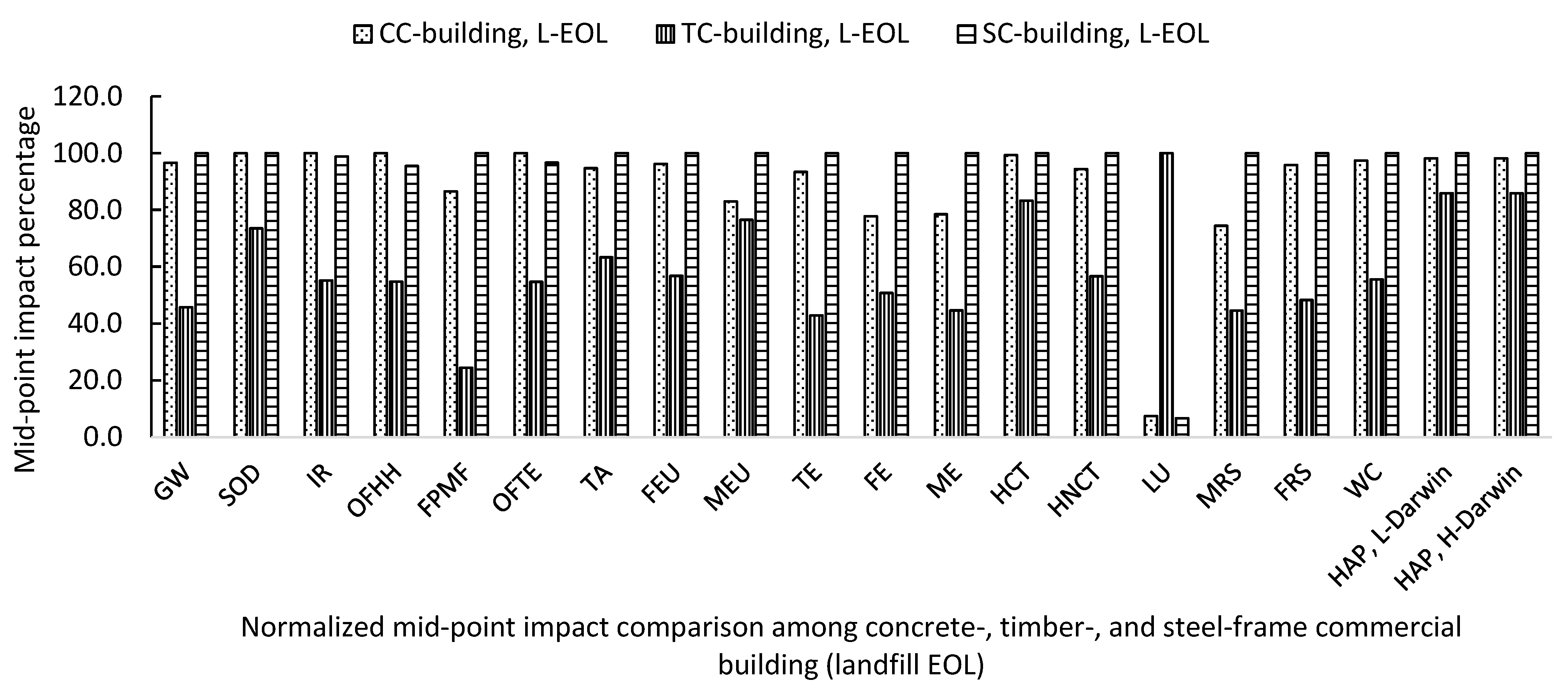

- Commercial buildings using landfill EOL.

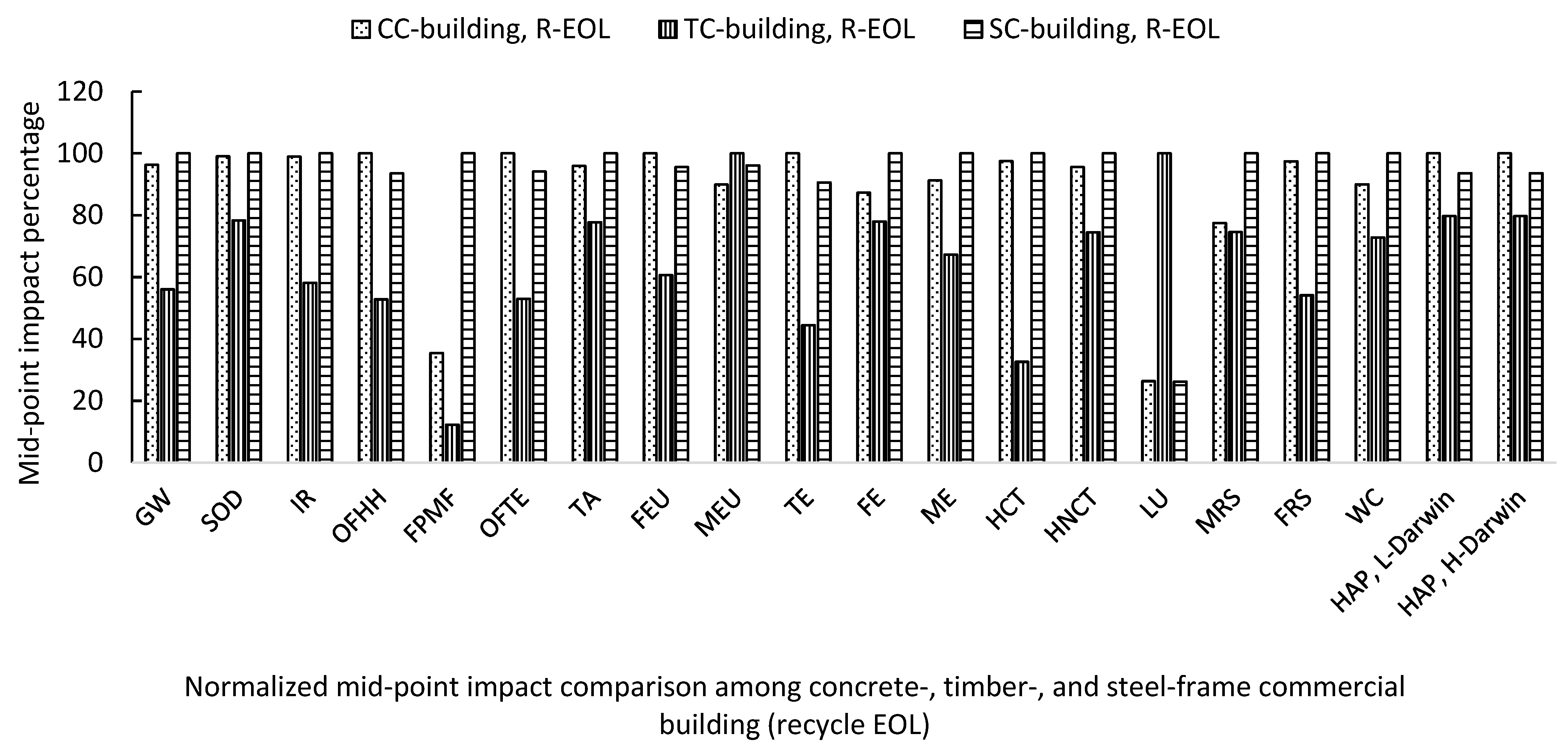

- Commercial buildings using recycled EOL.

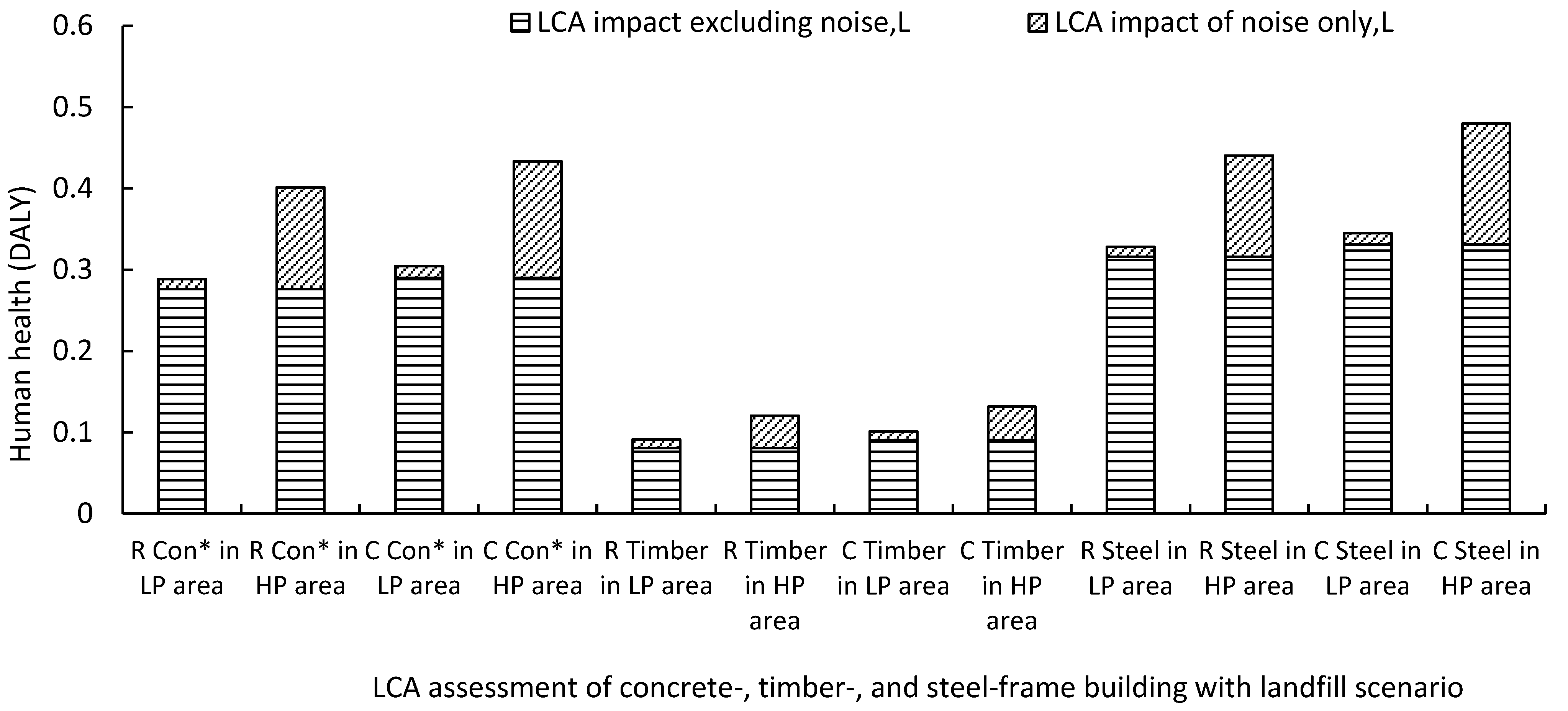

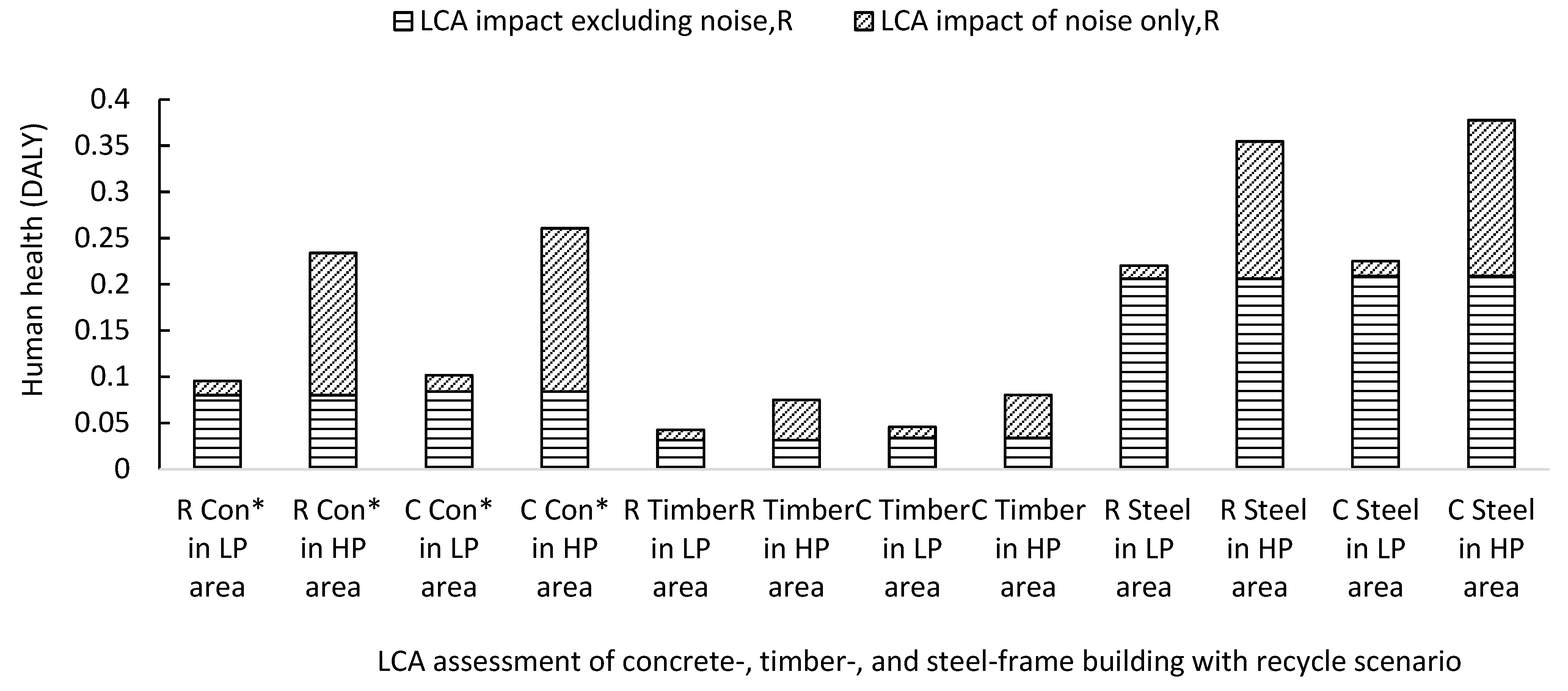

3.1.2. EndPoint Impact Assessment

4. Limitation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| LCA | life cycle assessment |

| LCIA | life cycle impact assessment |

| DALY | disability-adjusted life years |

| BIM | building information modelling |

| CF | characterisation factor |

| DW | disability weight |

| HAP | highly annoyed person |

| HSDP | highly sleep-deprived person |

References

- Fufa, S.M.; Skaar, C.; Gradeci, K.; Labonnote, N. Assessment of greenhouse gas emissions of ventilated timber wall constructions based on parametric LCA. J. Clean. Prod. 2018, 197, 34–46. [Google Scholar] [CrossRef]

- Giama, E.; Papadopoulos, A.M. Assessment tools for the environmental evaluation of concrete, plaster and brick elements production. J. Clean. Prod. 2015, 99, 75–85. [Google Scholar] [CrossRef]

- Yang, Q.; Kong, L.; Tong, H.; Wang, X. Evaluation model of environmental impacts of insulation building envelopes. Sustainability 2020, 12, 2258. [Google Scholar] [CrossRef]

- Ahn, Y.H.; Jung, C.W.; Suh, M.; Jeon, M.H. Integrated Construction Process for Green Building. Procedia Eng. 2016, 145, 670–676. [Google Scholar] [CrossRef]

- Glavinich, T.E. Contractor’s Guide to Green Building Construction: Management, Project Delivery, Documentation, and Risk Reduction; John Wiley: Hoboken, NJ, USA, 2008; ISBN 9780470056219. [Google Scholar]

- Vierra, S. Green Building Standards and Certification System. 2018. Available online: https://globalgbc.org/wp-content/uploads/2022/07/034_green-building-standards-and-certification-system.pdf (accessed on 12 March 2025).

- Hwang, B.G.; Shan, M.; Tan, E.K. Investigating Reworks in Green Building Construction Projects: Magnitude, Influential Factors, and Solutions. Int. J. Environ. Res 2016, 10, 499–510. [Google Scholar]

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-cycle assessment and the environmental impact of buildings: A review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Reeder, L. Guide to Rating Green Buildings; Wiley: Hoboken, NJ, USA, 2010; ISBN 9780470401941. [Google Scholar]

- Amoruso, F.M.; Schuetze, T. Life cycle assessment and costing of carbon neutral hybrid-timber building renovation systems: Three applications in the Republic of Korea. Build. Environ. 2022, 222, 109395. [Google Scholar] [CrossRef]

- Russell, D.J.F.; Hastie, G.D.; Thompson, D.; Janik, V.M.; Hammond, P.S.; Scott-Hayward, L.A.S.; Matthiopoulos, J.; Jones, E.L.; McConnell, B.J. Avoidance of wind farms by harbour seals is limited to pile driving activities. J. Appl. Ecol. 2016, 53, 1642–1652. [Google Scholar] [CrossRef]

- Periodica, P. Acoustical Aspects of the Reconstruction of a Historical Building with a Closed Courtyard. Pollack Period. 2020, 15, 197–208. [Google Scholar] [CrossRef]

- Felicioni, L.; Gaspari, J.; Veselka, J.; Malík, Z. A comparative cradle-to-grave life cycle approach for addressing construction design choices: An applicative case study for a residential tower in Aalborg, Denmark. Energy Build. 2023, 298, 113557. [Google Scholar] [CrossRef]

- Duan, Z.; Huang, Q.; Sun, Q.; Zhang, Q. Comparative life cycle assessment of a reinforced concrete residential building with equivalent cross laminated timber alternatives in China. J. Build. Eng. 2022, 62, 105357. [Google Scholar] [CrossRef]

- Allan, K.; Phillips, A.R. Comparative cradle-to-grave life cycle assessment of low and mid-rise mass timber buildings with equivalent structural steel alternatives. Sustainability 2021, 13, 3401. [Google Scholar] [CrossRef]

- Kerr, J.; Rayburg, S.; Neave, M.; Rodwell, J. Comparative Analysis of the Global Warming Potential (GWP) of Structural Stone, Concrete and Steel Construction Materials. Sustainability 2022, 14, 9019. [Google Scholar] [CrossRef]

- Hart, J.; D’Amico, B.; Pomponi, F. Whole-life embodied carbon in multistory buildings: Steel, concrete and timber structures. J. Ind. Ecol. 2021, 25, 403–418. [Google Scholar] [CrossRef]

- Hegeir, O.A.; Kvande, T.; Stamatopoulos, H.; Bohne, R.A. Comparative Life Cycle Analysis of Timber, Steel and Reinforced Concrete Portal Frames: A Theoretical Study on a Norwegian Industrial Building. Buildings 2022, 12, 573. [Google Scholar] [CrossRef]

- de Souza, D.M.; Lafontaine, M.; Charron-Doucet, F.; Bengoa, X.; Chappert, B.; Duarte, F.; Lima, L. Comparative Life Cycle Assessment of ceramic versus concrete roof tiles in the Brazilian context. J. Clean. Prod. 2015, 89, 165–173. [Google Scholar] [CrossRef]

- Kern, A.P.; Amor, L.V.; Angulo, S.C.; Montelongo, A. Factors influencing temporary wood waste generation in high-rise building construction. Waste Manag. 2018, 78, 446–455. [Google Scholar] [CrossRef]

- Iuorio, O.; Gigante, A.; De Masi, R.F. Life Cycle Analysis of Innovative Technologies: Cold Formed Steel System and Cross Laminated Timber. Energies 2023, 16, 586. [Google Scholar] [CrossRef]

- Tighnavard Balasbaneh, A.; Ramli, M.Z. A comparative life cycle assessment (LCA) of concrete and steel-prefabricated prefinished volumetric construction structures in Malaysia. Environ. Sci. Pollut. Res. 2020, 27, 43186–43201. [Google Scholar] [CrossRef]

- Vares, S.; Hradil, P.; Sansom, M.; Ungureanu, V. Economic potential and environmental impacts of reused steel structures. Struct. Infrastruct. Eng. 2020, 16, 750–761. [Google Scholar] [CrossRef]

- Li, X.; Song, Z.; Wang, T.; Zheng, Y.; Ning, X. Health impacts of construction noise on workers: A quantitative assessment model based on exposure measurement. J. Clean. Prod. 2016, 135, 721–731. [Google Scholar] [CrossRef]

- Shi, J.; Hu, J.; Ma, M.; Wang, H. An environmental impact analysis method of machine-tool cutting units based on LCA. J. Eng. Des. Technol. 2021, 19, 1192–1206. [Google Scholar] [CrossRef]

- Miiller-wenk, R. A Method to Include in LCA Road Traffic Noise and its Health Effects. Int. J. Life Cycle Assess. 2004, 9, 76–85. [Google Scholar] [CrossRef]

- Esmeray, E.; Eren, S. GIS—Based mapping and assessment of noise pollution. Environ. Dev. Sustain. 2021, 23, 15413–15431. [Google Scholar] [CrossRef] [PubMed]

- Ongel, A. Inclusion of Noise in Environmental Assessment of Road Transportation. Environ. Model. Assess. 2016, 21, 181–192. [Google Scholar] [CrossRef]

- Alwan, Z.; Jones, P. The importance of embodied energy in carbon footprint assessment. Struct. Surv. 2014, 32, 49–60. [Google Scholar] [CrossRef]

- Mukkavaara, J.; Sandberg, M.; Sandberg, K.; Pousette, A.; Norén, J. Sustainability evaluation of timber dwellings in the north of Sweden based on environmental impact and optimization of energy and cost. Procedia Manuf. 2020, 44, 76–83. [Google Scholar] [CrossRef]

- Röck, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. Build. Environ. 2018, 140, 153–161. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Development of a BIM-based environmental and economic life cycle assessment tool. J. Clean. Prod. 2020, 265, 121705. [Google Scholar] [CrossRef]

- Barclay, M.; Kang, J.; Sharples, S. Combining noise mapping and ventilation performance for non-domestic buildings in an urban area. Build. Environ. 2012, 52, 68–76. [Google Scholar] [CrossRef]

- Alawode, A.; Rajagopalan, P. Feasibility of net zero energy high rise apartment buildings in Australia. Sol. Energy 2022, 231, 158–174. [Google Scholar] [CrossRef]

- Daly, D.; Cooper, P.; Ma, Z. Understanding the risks and uncertainties introduced by common assumptions in energy simulations for Australian commercial buildings. Energy Build. 2014, 75, 382–393. [Google Scholar] [CrossRef]

- Budig, M.; Heckmann, O.; Hudert, M.; Boon Ng, A.Q. Next Generation Residential High-Rise: Evaluating and comparing the Global Warming Potential of different structural systems and materials. In Proceedings of the IASS Annual Symposia, Barcelona, Spain, 7–10 October 2019; International Association for Shell and Spatial Structures (IASS): Madrid, Spain, 2019; Volume 2019, pp. 1–8. [Google Scholar]

- Najjar, M.; Figueiredo, K.; Palumbo, M.; Haddad, A.; Hammad, A.W.A.; Haddad, A.; Su, S.; Wang, Q.; Han, L.; Hong, J.; et al. Integrated optimization with building information modeling and life cycle assessment for generating energy efficient buildings. Appl. Energy 2019, 250, 1366–1382. [Google Scholar] [CrossRef]

- Wang, J.; Wu, H.; Duan, H.; Zillante, G.; Zuo, J.; Yuan, H. Combining life cycle assessment and Building Information Modelling to account for carbon emission of building demolition waste: A case study. J. Clean. Prod. 2018, 172, 3154–3166. [Google Scholar] [CrossRef]

- Wang, J.; Wu, H.; Duan, H.; Zillante, G.; Zuo, J.; Yuan, H.; Su, S.; Wang, Q.; Han, L.; Hong, J.; et al. Calculation of a building’s life cycle carbon emissions based on Ecotect and building information modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- Zou, C.; Zhu, R.; Tao, Z.; Ouyang, D.; Chen, Y. Evaluation of building construction-induced noise and vibration impact on residents. Sustainability 2020, 12, 1579. [Google Scholar] [CrossRef]

- Marcinkowski, A.; Kopania, J. Environmental performance of noise reduction system in cogeneration plants—A life cycle assessment study. Energies 2021, 14, 1324. [Google Scholar] [CrossRef]

- Goretti, M.; Cotana, F. Footprint analysis concerning noise: Approaches, tools and opportunities. In Proceedings of the INTERNOISE 2014—43rd International Congress and Exposition on Noise Control Engineering, Fort Lauderdale, FL, USA, 8–10 September 2014; pp. 1–10. [Google Scholar]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Varun Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Janjua, S.Y.; Sarker, P.K.; Biswas, W.K. Sustainability assessment of a residential building using a life cycle assessment approach. Chem. Eng. Trans. 2019, 72, 19–24. [Google Scholar] [CrossRef]

- AS 3600. Available online: https://research-repository.griffith.edu.au/server/api/core/bitstreams/1d352b3a-8d66-4b97-bfb2-e4d86e4959f2/content (accessed on 2 April 2025).

- AS 4100. Available online: https://www.standards.org.au/standards-catalogue/standard-details?designation=AS-4100-2020 (accessed on 2 April 2025).

- AS 1684. Available online: https://www.scribd.com/document/515288316/AS1684-1-Residential-timber-frame-construction (accessed on 2 April 2025).

- Roy, K.; Dani, A.A.; Ichhpuni, H.; Fang, Z.; Lim, J.B.P. Improving Sustainability of Steel Roofs: Life Cycle Assessment of a Case Study Roof. Appl. Sci. 2022, 12, 5943. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Fnais, A.; Rezgui, Y.; Petri, I.; Beach, T.; Yeung, J.; Ghoroghi, A.; Kubicki, S. The application of life cycle assessment in buildings: Challenges, and directions for future research. Int. J. Life Cycle Assess. 2022, 27, 627–654. [Google Scholar] [CrossRef]

- Rajendran, P.; Seow, T.W.; Goh, K.C. Bulding Information Modeling (BIM) in Design Stage to Assist in Time, Cost and Quality in Construction Innovation. Int. J. Concept. Manag. Soc. Sci. 2014, 2, 52–55. [Google Scholar]

- Bueno, C.; Pereira, L.M.; Fabricio, M.M. Life cycle assessment and environmental-based choices at the early design stages: An application using building information modelling. Archit. Eng. Des. Manag. 2018, 14, 332–346. [Google Scholar] [CrossRef]

- Sultana, R.; Rashedi, A.; Khanam, T.; Jeong, B.; Hosseinzadeh-Bandbafha, H.; Hussain, M. Life Cycle Environmental Sustainability and Energy Assessment of Timber Wall Construction: A Comprehensive Overview. Sustainability 2022, 14, 4161. [Google Scholar] [CrossRef]

- Khanam, T.; Khalid, F.; Manzoor, W.; Id, A.R.; Hadi, R.; Ullah, F.; Rehman, F.; Akhtar, A.; Karthik Babu, N.B.; Hussainid, M. Environmental sustainability assessment of biodiesel production from Jatropha curcas L. seeds oil in Pakistan. PLoS ONE 2021, 16, e0258409. [Google Scholar] [CrossRef]

- Rashedi, A.; Khanam, T.; Jonkman, M. On reduced consumption of fossil fuels in 2020 and its consequences in global environment and exergy demand. Energies 2020, 13, 6048. [Google Scholar] [CrossRef]

- Rashedi, A.; Khanam, T. Life cycle assessment of most widely adopted solar photovoltaic energy technologies by mid-point and end-point indicators of ReCiPe method. Environ. Sci. Pollut. Res. 2020, 27, 29075–29090. [Google Scholar] [CrossRef]

- Lavandier, C.; Meyer, R.; Benetto, E. Characterization of damages from road traf fi c noise in life cycle impact assessment: A method based on emission and propagation models. J. Clean. Prod. 2019, 231, 121–131. [Google Scholar] [CrossRef]

- Cucurachi, S.; Heijungs, R. Characterisation factors for life cycle impact assessment of sound emissions. Sci. Total Environ. 2014, 468–469, 280–291. [Google Scholar] [CrossRef] [PubMed]

- Cucurachi, S.; Hellweg, S.; Schiess, S.; Froemelt, A. Noise footprint from personal land-based mobility. J. Ind. Ecol. 2019, 23, 1028–1038. [Google Scholar] [CrossRef] [PubMed]

- Meyer, R.; Meyer, R. Analysis of the different techniques to include noise damage in life cycle assessment. A case study for car tires. Int. J. Life Cycle Assess. 2017, 22, 744–757. [Google Scholar] [CrossRef]

- Tokairin, T.; Kitada, T. Study on the Effect of Porous Fence on Air Quality and Traffic Noise Level Around a Double-Decked Road Structure. Environ. Monit. Assess. 2005, 105, 121–143. [Google Scholar] [CrossRef]

- Licitra, G.; Ascari, E.; Brambilla, G. Comparative analysis of methods to evaluate urban noise exposure. In Proceedings of the 39th International Congress on Noise Control Engineering 2010, INTER-NOISE 2010, Baltimore, MD, USA, 19–21 April 2010; Volume 3, pp. 2137–2143. [Google Scholar]

- ISO 1996-2:1987; Acoustics—Description and Measurement of Environmental Noise—Part 2: Acquisition of Data Pertinent to Land Use. International Organization for Standardization: Geneva, Switzerland, 1987.

- Miedema, H.M.E.; Oudshoorn, C.G.M. Annoyance from Transportation Noise: Relationships with Exposure Metrics DNL and DENL and Their Confidence Intervals. Environ. Health Perspect. 2001, 109, 409–416. [Google Scholar] [CrossRef]

- Zuo, J.; Pullen, S.; Rameezdeen, R.; Bennetts, H.; Wang, Y.; Mao, G.; Zhou, Z.; Du, H.; Duan, H.; Röck, M.; et al. Green building evaluation from a life-cycle perspective in Australia: A critical review. Renew. Sustain. Energy Rev. 2017, 70, 358–368. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Peters, G.M.; Ashbolt, N.J.; Shiels, S.; Khan, S.J. Science of the Total Environment Assessing burden of disease as disability adjusted life years in life cycle assessment. Sci. Total Environ. 2015, 530–531, 120–128. [Google Scholar] [CrossRef]

- Garraín, D.; Vidal, R.; Garraín, D.; Franco, V.; Vidal, R.; Moliner, E.; Casanova, S. The Noise Impact Category in Life Cycle Assessment. 2009. Available online: https://www.researchgate.net/publication/47745426 (accessed on 12 March 2025).

- Jung, S.; Kang, H.; Choi, J.; Hong, T.; Park, H.S.; Lee, D.E. Quantitative health impact assessment of construction noise exposure on the nearby region for noise barrier optimization. Build. Environ. 2020, 176, 106869. [Google Scholar] [CrossRef]

- National Academy of Sciences. Eutrophication: Causes, Consequences, Correctives; Proceedings of a Symposium; National Academy of Sciences: Washington, DC, USA, 1969; pp. 1–661. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sultana, R.; Khanam, T.; Rashedi, A.; Rajabipour, A. Integrating Noise into Life Cycle Assessment for Sustainable High-Rise Construction: A Comparative Study of Concrete, Timber, and Steel Frames in Australia. Sustainability 2025, 17, 4040. https://doi.org/10.3390/su17094040

Sultana R, Khanam T, Rashedi A, Rajabipour A. Integrating Noise into Life Cycle Assessment for Sustainable High-Rise Construction: A Comparative Study of Concrete, Timber, and Steel Frames in Australia. Sustainability. 2025; 17(9):4040. https://doi.org/10.3390/su17094040

Chicago/Turabian StyleSultana, Rabaka, Taslima Khanam, Ahmad Rashedi, and Ali Rajabipour. 2025. "Integrating Noise into Life Cycle Assessment for Sustainable High-Rise Construction: A Comparative Study of Concrete, Timber, and Steel Frames in Australia" Sustainability 17, no. 9: 4040. https://doi.org/10.3390/su17094040

APA StyleSultana, R., Khanam, T., Rashedi, A., & Rajabipour, A. (2025). Integrating Noise into Life Cycle Assessment for Sustainable High-Rise Construction: A Comparative Study of Concrete, Timber, and Steel Frames in Australia. Sustainability, 17(9), 4040. https://doi.org/10.3390/su17094040