1. Introduction

In the context of the rapid development of intelligent transportation systems, coupled with the ongoing advancement of global economic integration and the expansion of international trade, ports—critical hubs for cargo transportation—are playing an increasingly prominent role within the broader intelligent transportation ecosystem. The increasing prevalence of large-scale vessels has significantly heightened the operational pressure on ports, presenting considerable challenges to both their operational efficiency and service quality during the process of digital transformation. One of the key strategies for effectively managing port operations is the optimization of berth and QC schedules, as these are among the most essential yet limited resources within the port system. From a sustainability perspective, inefficient utilization of core port resources results in prolonged vessel idle time, excessive energy consumption, and exacerbated greenhouse gas emissions—factors that collectively compromise both the environmental and economic sustainability of port operations. Consequently, the development of intelligent and adaptive scheduling frameworks is essential not only for enhancing operational efficiency but also for minimizing environmental impact and advancing green transformation of seaports.

Moreover, seaport operations should not be viewed in isolation. As highlighted in recent research [

1], maritime transport forms an integral part of intermodal logistics systems, where seamless coordination with inland transport modes—such as rail and road—is essential. Optimizing berth and quay crane scheduling at ports not only improves port-side efficiency but also facilitates smoother cargo transfers across the entire supply chain, ultimately benefiting manufacturers, distributors, sellers, and customers.

In the Berth Allocation and Quay Crane Assignment Problem, QC assignment can be categorized into two types: time-invariant QC assignment and time-variant QC assignment. Time-invariant QC assignment refers to a scenario in which a fixed number of QCs serve a vessel throughout its entire operational process. The BACAP, considering time-invariant QC assignment, has received significant attention in the literature. Imai et al. [

2] introduced a formulation for BACAP with time-invariant QC assignment and proposed two novel models: a 0–1 integer linear programming (ILP) model for the BACAP and a mixed-integer linear programming (MILP) model. Building on the model developed by Meisel and Bierwirth [

3], Iris et al. [

4] introduced a generalized set partitioning approach to address the BACAP, which incorporates two QC assignment strategies. Wang et al. [

5] investigated the time-invariant Berth Allocation and Quay Crane Assignment Scheduling Problem (BACASP) within the context of carbon emission tax policies, incorporating both single and segmented tax rates. They developed an optimization model and proposed several equivalent or relaxed models to enhance computational efficiency. Wang, Miao et al. [

6] introduced a two-stage robust optimization model for time-invariant BACAP under uncertain conditions, achieving a comprehensive solution with enhanced robustness. Sharifi et al. [

7] developed an integrated BACAP model with time-invariant QC assignment, considering vessel emission and speed optimization. Cheimanoff et al. [

8] proposed a new MILP model to solve the time-invariant BACAP, considering continuous terminal topology and dynamic ship arrivals. Correcher et al. [

9] proposed a novel MILP model for the continuous BACAP and demonstrated its capability to solve instances involving up to 50 vessels. Ji et al. [

10] investigated time-invariant BACAPs under stochastic vessel arrivals and formulated a MILP model, aimed at minimizing the total port time of vessels. They employed a Multi-Objective Constrained Handling (MOCH) strategy and proposed an Enhanced Non-dominated Sorting Genetic Algorithm II (ENSGA-II) to solve the problem. Bouzekri et al. [

11] addressed the integrated problem of the Laycan Allocation Problem, the dynamic continuous Berth Allocation Problem (BAP), and the time-invariant QC Assignment Problem in tidal ports. Xiang et al. [

12] redefined the discrete berth allocation and time-invariant QC assignment problem as a constraint-limited resource scheduling problem. Then, a branch-and-cut algorithm was proposed to solve the redefined problem efficiently. Ji et al. [

13] studied a dynamic Berth Allocation and time-invariant QC Assignment specific problem when unscheduled vessels arrive at the port (UBACASP), considering factors such as dynamic vessel arrivals and non-crossing constraints between quay cranes. Building upon their previous research [

14], Song et al. [

15] integrated time-invariant QC Assignment into the Multi-port Berth Allocation Problem (MBACAP) for the first time, constructing a MILP model. In comparison to previous studies on the Multi-port Berth Allocation Problem (MBAP), this model considers the impact of specific QC assignments on vessel handling time and incorporates additional constraints to reflect a more realistic scheduling scenario.

While time-invariant QC assignment reduces the computational complexity of the model, it also limits the practical applicability of the solution. In contrast, time-variant QC assignment not only maximizes QC utilization but also more accurately reflects real-world operations. This approach offers greater flexibility by allowing the number of QCs allocated to a vessel to change throughout its operational period. As a result, numerous studies have been conducted on time-variant QC assignment.

Park and Kim [

16] developed a MILP model to schedule both berths and QCs. Meisel and Bierwirth [

3] critiqued Park and Kim’s linear relationship between vessel handling time and the number of QCs, proposing an alternative model that accounts for interference between QCs and the deviation from the optimal berthing position, which influences handling time. Raa et al. [

17] introduced a MILP model that considers vessel priorities, berthing preferences, and handling times influenced by container volume and quay crane availability. This model was solved using a hybrid heuristic and validated with real-world data. Li et al. [

18] extended the BACAP by incorporating quay crane coverage constraints, formulating a nonlinear mixed-integer programming model based on continuous berth and quay crane coverage constraints. Wang, Hu et al. [

19] incorporated onshore power supply (OPS) allocation into time-variant BACAP to support carbon emission reduction policies. Guo et al. [

20] integrated time-variant BACAP with Yard Allocation Problem (YAP) and formulated a mixed-integer nonlinear programming (MINLP) model. Xiang and Liu [

21] developed an almost robust model for time-variant BACAP, considering uncertainties in the late arrival of ships and inflation of container quantity. They also proposed a decomposition method to solve this complex problem. Li et al. [

22] proposed a bi-objective optimization model for BACAP, aiming to minimize both the total vessel turnaround time and the penalty costs associated with quay crane maintenance earliness and tardiness. Xu et al. [

23] developed a comprehensive mathematical model for the C/T-V (Continuous and Time-variant) BACAP and proposed a memetic algorithm with a heuristic decoding strategy, capable of efficiently solving large-scale instances involving up to 60 vessels. Zou et al. [

24] developed a swarm optimization algorithm with intra- and inter-hierarchical competition (I2HCSO) for solving large-scale BACAP. Ran et al. [

25] incorporated quay crane movement energy consumption for the first time, where a MILP model was formulated to minimize the maximum completion time of all vessels and total energy consumption. Thanos et al. [

26] addressed QC working range constraints and developed a model to minimize container trans-shipment distances within the terminal yard. They proposed a heuristic algorithm based on fast local search to solve the BACAP. Malekahmadi et al. [

27] considered safe distances between quay cranes and non-crossing constraints. They formulated an integer programming model for the integrated continuous berth allocation, time-variant QC assignment, and QC scheduling problem.

However, within the planning horizon, frequent quay crane exchanges are not always optimal, as they incur time and cost penalties. As a result, several studies have imposed constraints on QC exchanges to mitigate these drawbacks. Zhang et al. [

28] argued that frequent changes in QC allocation led to substantial relocation costs. To address this, they introduced limitations on the number of QC changes during vessel service, taking into account the length of each QC and the berthing range it can serve. Türkoğulları et al. [

29] integrated QC relocation costs into their model, incorporating both fixed and distance-dependent variable costs. In a subsequent study [

30], the same team strengthened the constraints on QC changes, stipulating that once a QC is assigned to a vessel, it can only be reassigned upon the completion of the vessel’s loading/unloading operations.

Giallombardo et al. [

31] introduced the definition of QC profiles to effectively balance quay crane utilization and the frequency of QC exchanges. Each QC profile contains information on the number of work shifts and the number of QCs assigned to each work shift. The QC profile transforms the time-invariant QC assignment into a time-variant assignment by varying the number of QCs between work shifts, thus improving QC utilization and aligning the model more closely with real-world operations. By limiting the difference in the number of QCs between shifts to no more than two, the non-crossing constraint between QCs can be addressed. Additionally, by restricting QCs to move only between shifts, the number of QC exchanges during a vessel’s service can be controlled. Vacca et al. [

32] explored the time-variant BACAP in seaport container terminals, building upon the BAP defined by Giallombardo et al. [

31], and introduced a column generation (CG) algorithm to solve the problem. Xie et al. [

33] further developed the BACAP based on QC profiles, aiming at minimizing berth and time deviations. This problem was solved using a branch-and-price algorithm within the Dantzig–Wolfe decomposition framework. Tang et al. [

34] were the first to incorporate QC efficiency uncertainty into the BACAP with QC profiles, considering tidal time windows. They formulated a MILP model to minimize the total cost of vessel delay in berthing and departure, solving it using a column generation algorithm. Xiang et al. [

35] investigated automated trans-shipment hubs and introduced a multi-objective optimization model that simultaneously addresses berth allocation, quay crane assignment, and yard allocation by incorporating QC profiles. They proposed an efficient adaptive dynamic scheduling strategy to balance the trade-offs among multiple objectives adaptively.

To summarize, existing studies have made significant progress in modeling the BACAP under both time-invariant and time-variant quay crane assignments. However, most models are constrained by computational scalability and heavily rely on exact solution methods. Heuristic methods for BACAP incorporating QC profiles, particularly for large-scale instances, remain underexplored. Moreover, the BACAP has been proven to be NP-hard [

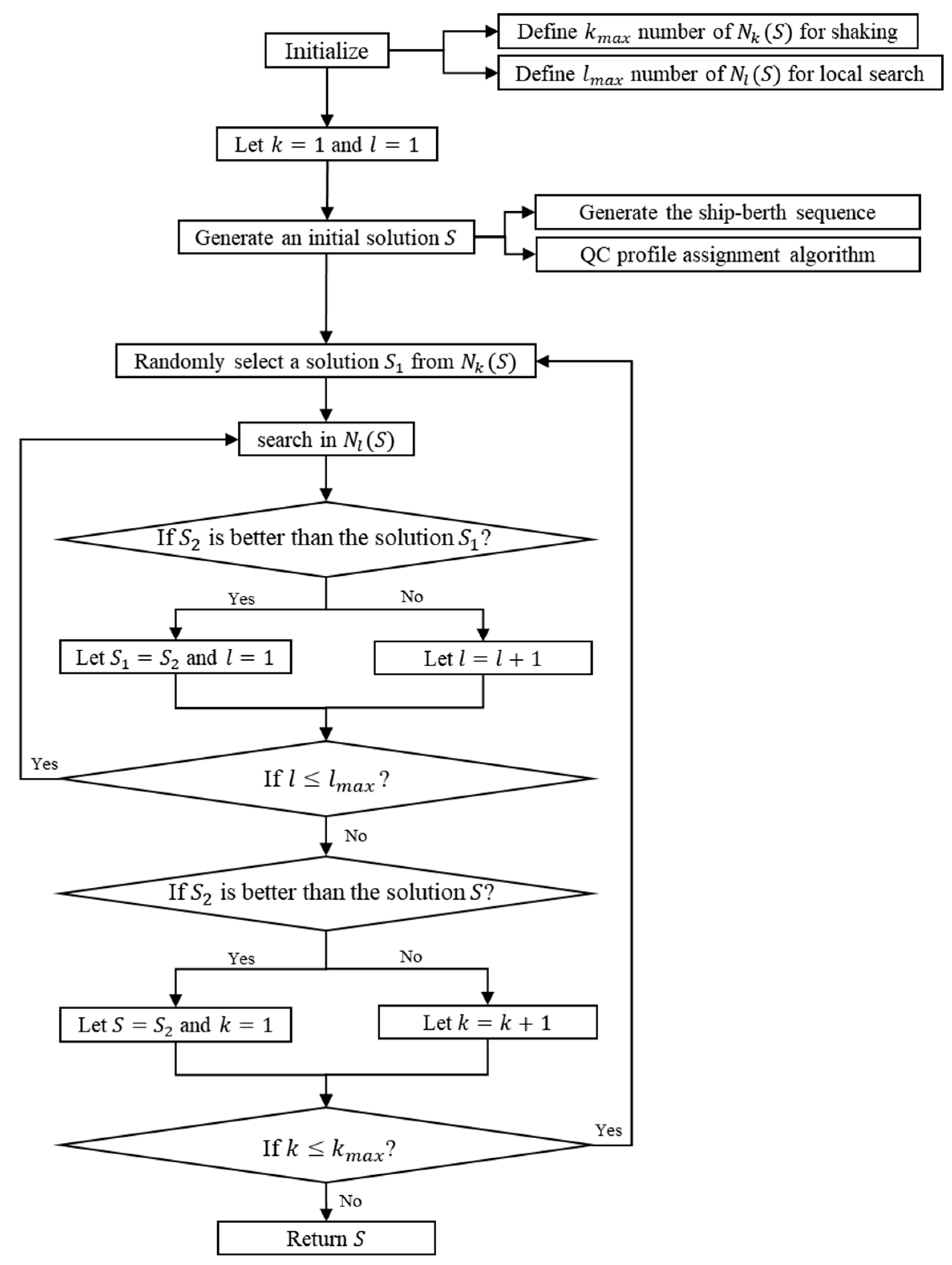

16], and as the scale of the problem rises, these exact algorithms face significant challenges related to excessive computation time and memory consumption. To address these challenges, this paper proposes an effective VNS algorithm to solve the proposed MILP model of the BACAP. The effectiveness and superiority of the VNS algorithm are demonstrated through a comparative analysis with other algorithms. The results of this research provide theoretical support and practical guidance for port operation management, offering significant theoretical and practical value.

The BACAP exhibits typical characteristics of multi-resource allocation, multi-task scheduling, and time window constraints. It shares significant similarities with the flexible job shop scheduling problem (FJSP) and the Vehicle Routing Problem with Time Windows (VRPTW). For the FJSP, Yang et al. [

36] addressed distributed heterogeneous assembly flexible job shop scheduling problems and proposed a Q-learning-based improved multi-objective genetic algorithm. Zhang et al. [

37] formulated a MILP model for the dual-resource flexible job shop scheduling problem in production line reconfiguration scenarios (DRFJSP-PLR) and proposed a rule-guided exemplar learning genetic algorithm with neighborhood search (RgELGA_NS). Shao et al. [

38] developed a multi-objective optimal scheduling method for variable sublot flexible shops, incorporating switching time and operator constraints, and proposed an adaptive job scheduling NSGA-II (AJS-NSGAII) algorithm. For the VRPTW, Liu et al. [

39] proposed an improved genetic algorithm based on clustering methods and the longest common substring (LCS) between elite and inferior individuals. Su et al. [

40] introduced a lightweight genetic algorithm with variable neighborhood search (LGAVNS), combining GA as the upper-level algorithm and VNS as the local search method, to solve a multi-depot green VRPTW considering customer satisfaction (MDGVRPTW-CS). In conclusion, heuristic and metaheuristic algorithms have become prominent research topics in complex scheduling problems.

This paper investigates the BACAP within a VNS framework, leveraging its multi-resource collaborative scheduling feature. The design of solution and neighborhood structures in this study provides valuable insights for solving FJSP and VRPTW problems.

The main contributions of this study are as follows:

- (1)

A MILP model is formulated for the discrete and time-variant BACAP based on QC profiles, aiming to minimize the costs of vessel waiting and delayed departures while considering berth time windows and spatiotemporal non-overlapping constraints among vessels.

- (2)

A VNS algorithm is developed for the BACAP with QC profiles, in which a tailored solution structure is designed, and multiple neighborhood structures are incorporated to enhance the search efficiency and effectiveness. The algorithm can calculate instances of 40 ships.

- (3)

The effectiveness of the proposed model and algorithm is validated through two sets of computational experiments, and sensitivity analysis on the weights of waiting and delay costs provides valuable managerial insights for port operations.

The remainder of this paper is organized as follows:

Section 2 presents the problem statement,

Section 3 formulates the MILP model for the BACAP,

Section 4 elaborates on the VNS algorithm designed according to the characteristics of the BACAP, and

Section 5 provides the numerical experiments that include two sets of instances.

Section 6 presents the conclusion.

2. Problem Statement

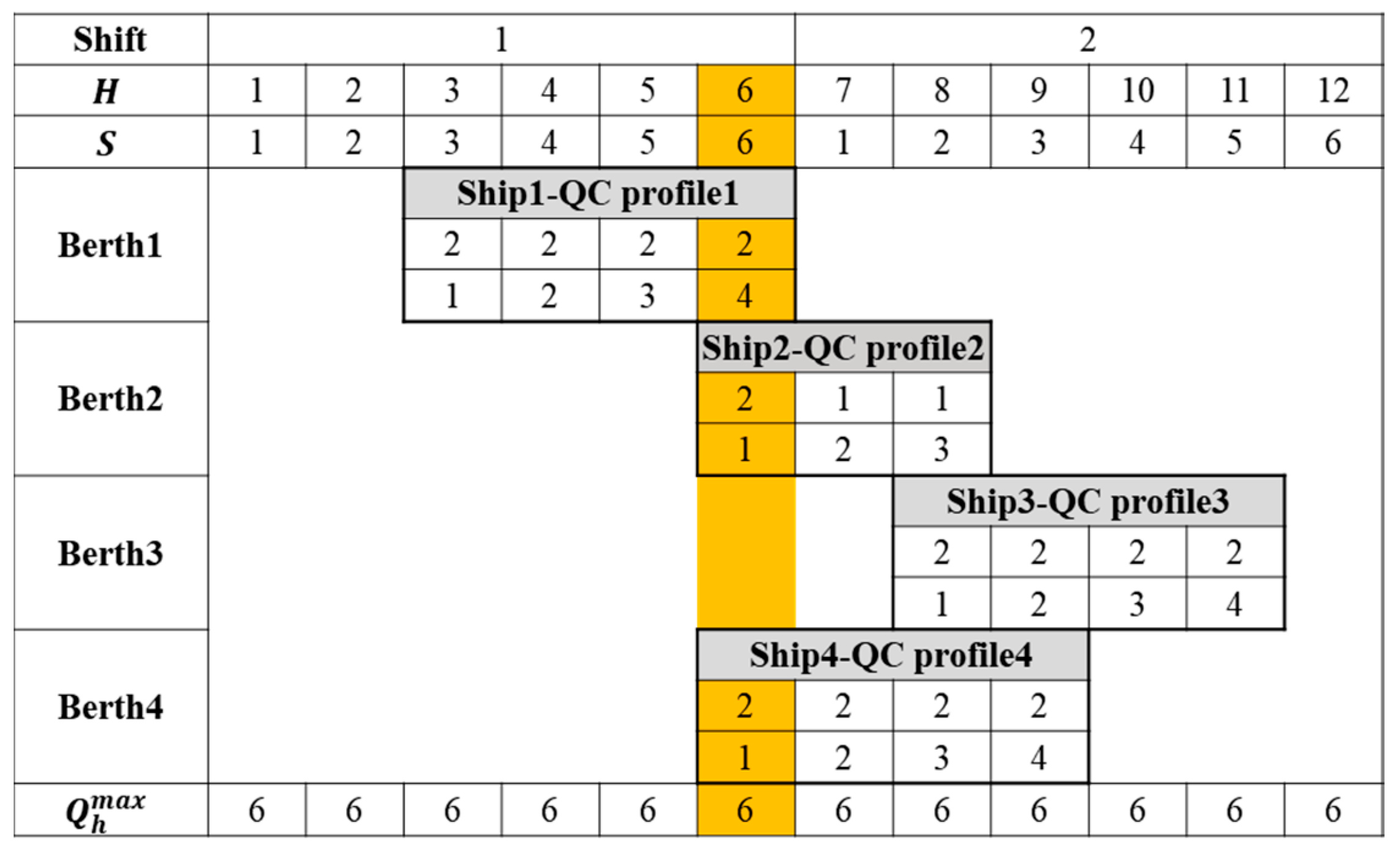

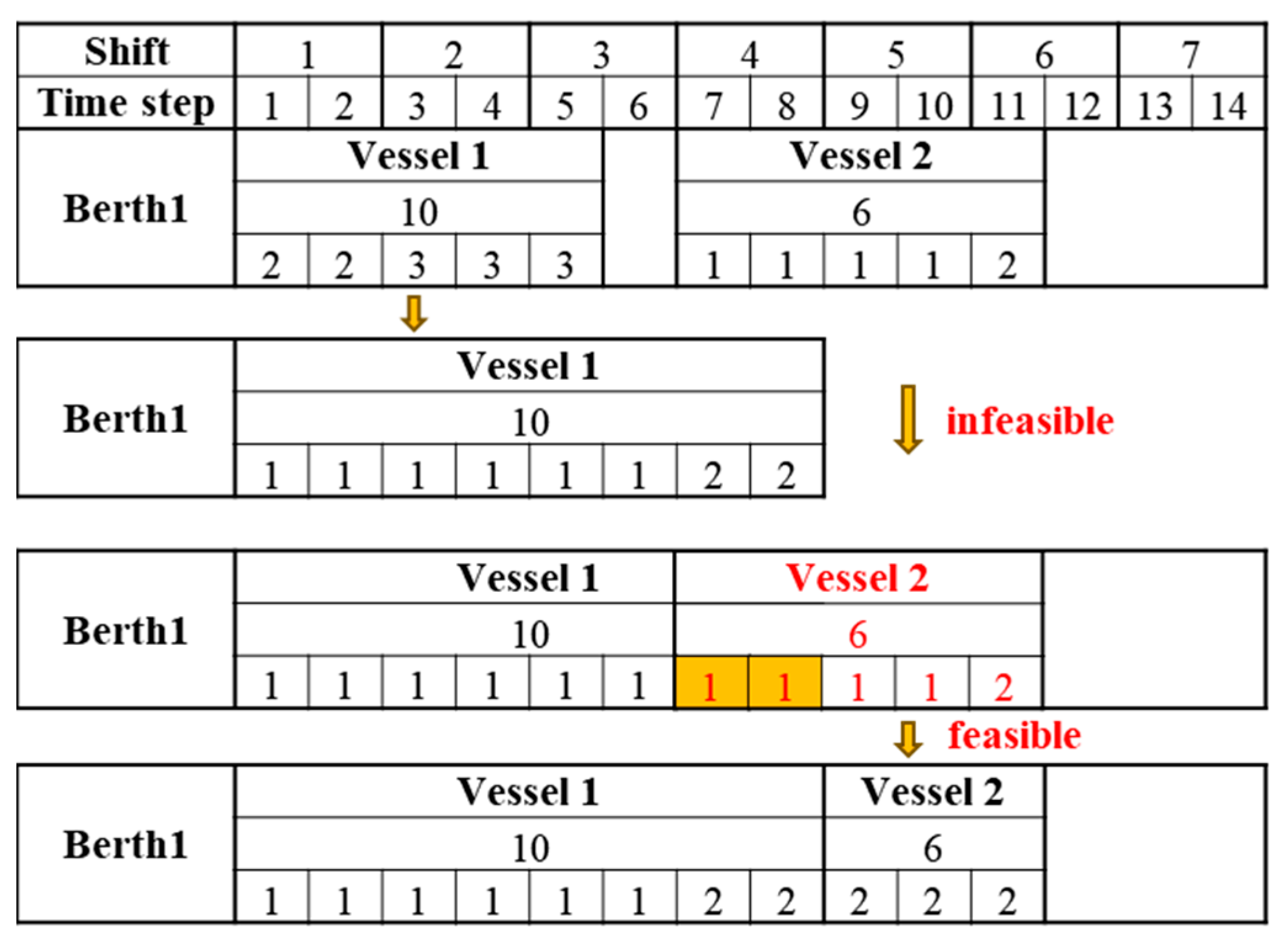

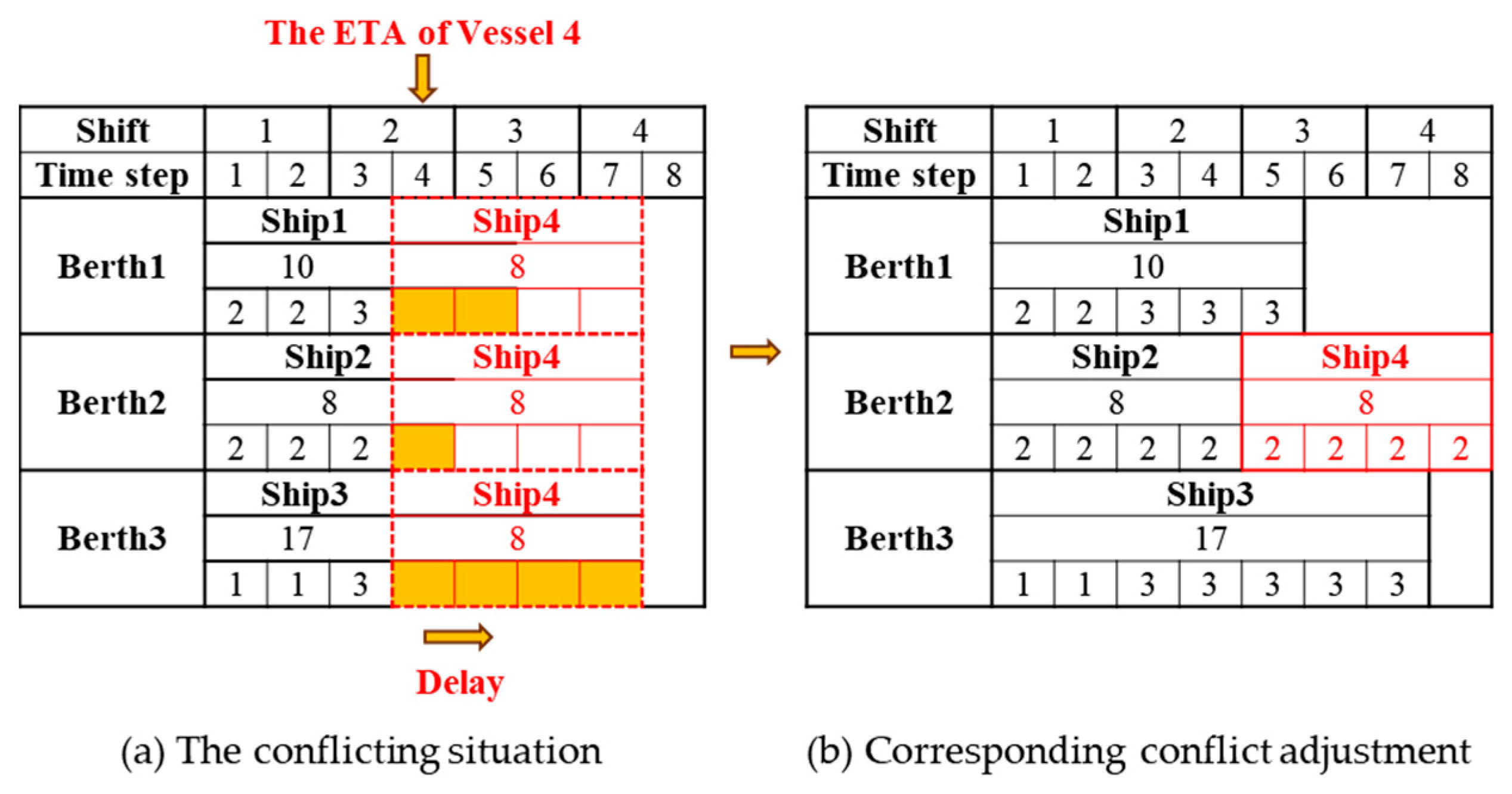

Prior to the arrival of vessels, relevant information—such as the vessel type, estimated time of arrival (ETA), estimated time of departure (ETD), and the number of containers to be handled—is collected by the port of call. The port then assigns berths, berthing time steps, and a reliable QC profile to vessels arriving within a given planning horizon. The QC profile, introduced by Giallombardo et al. [

31], represents a combination of time duration and the assigned number of QCs at each time step. This definition is based on the end-of-shift assumption, which means that QCs can be moved during a vessel’s service, but they cannot be reassigned until the end of a work shift.

The handling time for each vessel is determined precisely by the assigned QC profile, rather than by a predefined constant. For further details on the QC profile definition, readers are referred to Giallombardo et al. [

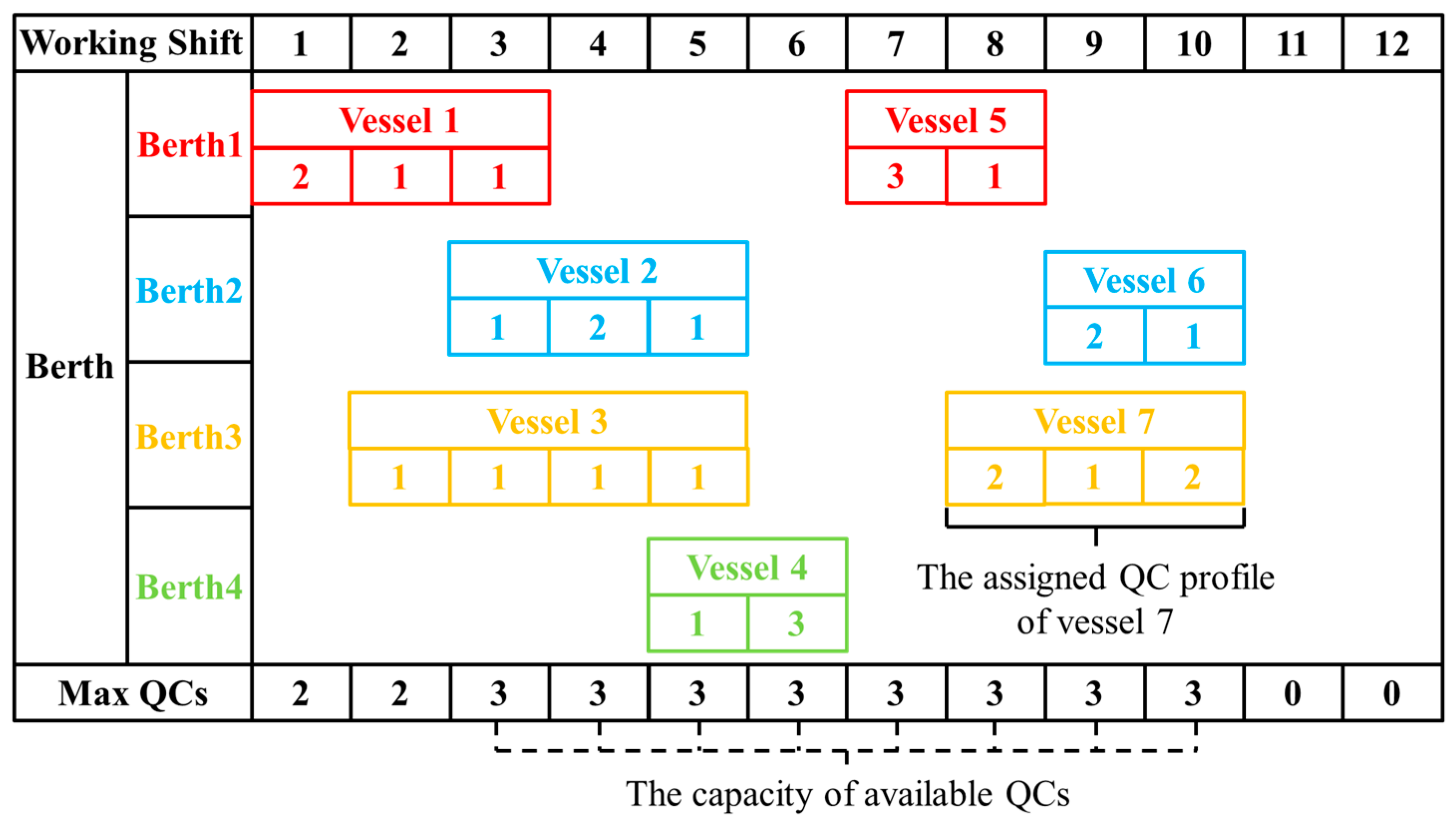

31]. The port can assign a QC profile to determine the number of QCs allocated to a specific vessel at each time step during the vessel’s service. To better understand the BACAP and the QC profile, a berthing plan for five vessels at three berths over 12 work shifts is illustrated in

Figure 1. In this figure, one work shift is equivalent to one step. In the figure, vessel 1 begins berthing in work shift 1, berths for three work shifts, and departs in work shift 3. Based on the assigned QC profile, the number of QCs servicing the vessel in each time step is known. For vessel 1, two QCs are allocated in work shift 1, and one QC is allocated in both work shifts 2 and 3.

In this paper, a MILP model for the BACAP is developed for discrete berths, considering the non-overlapping constraints of vessels, the available time windows for ships and berths, and the constraints associated with the QC profile.

The objective is to minimize the total cost of delayed berthing and the total cost of delayed departures. In the existing literature on the BACAP, various objectives have been explored to reflect different operational priorities. For instance, Wang et al. [

41] developed a model for minimizing the total terminal scheduling cost, which includes berth deviation cost, delayed start delay cost, and delayed departure cost. Li et al. [

42] extended the total terminal scheduling cost proposed by Wang et al. [

41] by further incorporating the loading and unloading costs of vessels. These objective functions capture diverse optimization goals in port operations. In this study, we focus on two critical and practical objectives:

- (1)

Minimizing the delayed berthing time, which captures the cost associated with vessels failing to berth at their expected times;

- (2)

Minimizing the delayed departure time, which accounts for the penalties incurred when vessels leave the port later than scheduled.

These objectives are highly relevant to real-world port operations. By reducing vessel waiting and departure delays, this objective contributes to lowering fuel consumption, mitigating greenhouse gas emissions, and improving the overall sustainability of port operations.

The formulation is based on the following assumptions:

- (1)

The estimated time of vessel arrival (ETA) and the estimated time of vessel departure (ETD) are discrete and known.

- (2)

The container quantity to be handled for each vessel is known.

- (3)

The set of available QC profiles for each vessel is known.

- (4)

Vessels can only be berthed after their arrival.

- (5)

QCs operate on rails and cannot pass each other.

- (6)

The number of QCs allocated to a vessel can only be changed between shifts.

5. Numerical Results

The experimental data in this paper consists of two components: QC profile data and vessel arrival data. Two sets of BACAP instances, A1 and A2, are used in the experiments. Instance A1 is based on the QC profile information and time settings used by Ilaria Vacca et al. [

32], combined with the vessel information provided by Zhang et al. [

28]. Instance A2 is generated following the rules outlined by Tang et al. [

34] for the QC profile and vessel arrival data.

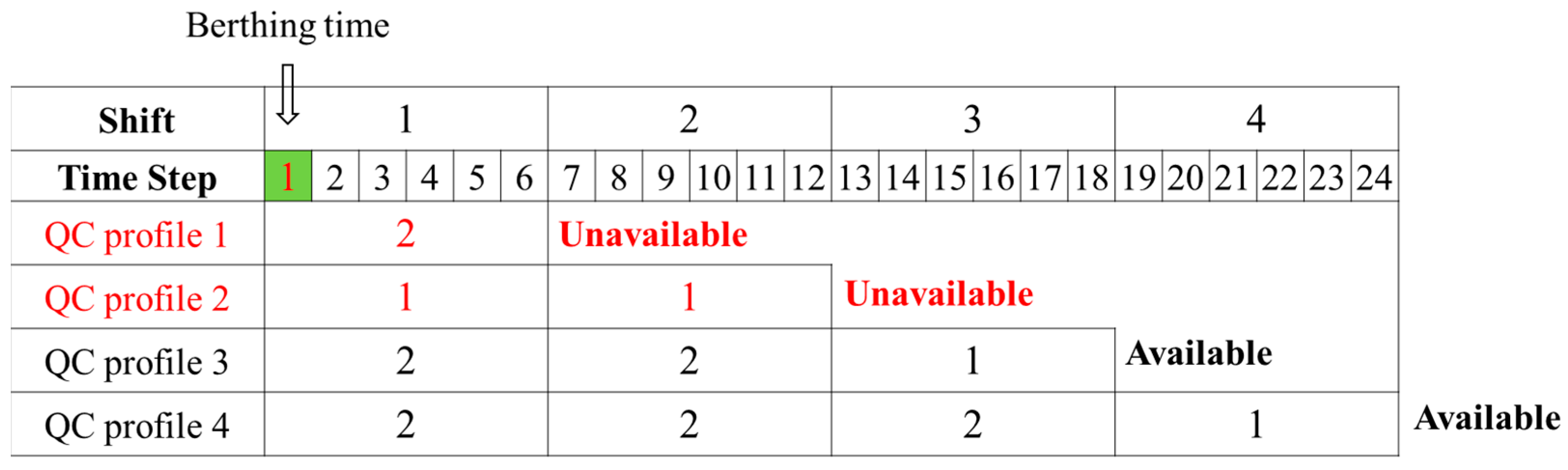

In instance A1, the sets of feasible profiles, as shown in

Table 2, were synthetically generated according to the operational rules presented by Giallombardo et al. [

31]. As shown in

Table 2, a profile must comply with a fixed set of parameters to be considered feasible. Maximum and minimum QC amount limit the number of QCs allocated to each QC profile at each work shift, and maximum and minimum handling time limit the number of shifts covered by each QC profile.

In instance A1, the specific vessel information shown in

Table 3 is adopted from Zhang et al. [

28]—such as the estimated arrival time, the estimated departure time and the minimum required QC time based on the number of containers. These data are based on real-world information from a terminal at the Tianjin seaport in China.

In instance A1, the planned period is set to a time horizon of 168 h, or one week. Each work shift contains 6 h, and the available berth time window spans the entire observation period, i.e., [0, 167]. According to the study by Xie et al. [

33], the unit idle time cost

—due to vessel waiting for all vessels and the unit delay time cost

—due to late vessel departure for all vessels, are both set to 1000.

Instance A1 is classified into three scales based on the number of vessels and is further divided into three categories according to the number of QC profiles. For each combination, five sets of randomly generated experiments are conducted. The parameters for each A1 instance are presented in

Table 4.

In instance A2, the QC profile data are generated according to the rules proposed by Tang et al. [

34], which assume that arriving vessels can be classified into different types. The probabilities of occurrence of these vessel types are presented in

Table 5. In

Table 5,

and

represent the container capacity and operating hours, respectively. According to the parameters in

Table 5, the available QC profile set

for vessel

and the corresponding number of QCs

at each time step can be generated following the steps proposed in [

34], and we recommend that readers refer to their study for further details.

In instance A2, the arrival vessel information required includes the ETA, the ETD, and the handling time required by each vessel. The ETA, denoted as

, is generated from the uniform distribution

, where

. The ETD is generated according to the rule

, where

. The handling time required by the vessels is generated based on the handling time corresponding to different vessel types, as presented in

Table 5. According to the study by Tang et al. [

34], since vessel delays often lead to a series of chain reactions such as subsequent vessels failing to berth in the estimated time, we set the unit delayed berthing time to be larger in instance A2. The unit idle time cost due to vessel waiting

is generated from a uniform distribution

, and the unit delay cost due to late vessel departure

, is generated from the distribution

.

In instance A2, the planned period is also set to a time horizon of 168 h. Unlike instance A1, each shift in A2 consists of a single step, i.e., hour per step. The available time window for the berth spans the entire observation period. The scale of instance A2 is determined by the number of vessels

, the number of berths

, and the maximum number of QCs

. For each vessel, 2 to 10 QC profiles are generated and subsequently incorporated into the overall QC profile scheme of the port. Consequently, the number of QC profiles

ranges from

to

. Data from four different problem scales is provided, denoted as G1, G2, G3 and G4. Label G1-1 refers to the first instance of the G1 problem scale. The specific parameters for each instance are presented in

Table 6.

Finally, performance comparison between the VNS algorithm and Gurobi is conducted using the generated set of BACAP instances. The VNS algorithm, as described previously, is implemented in Python using PyCharm Community Edition 2024.2.1, while the formulated MILP model is solved through the commercial optimization software Gurobi 12.0.0. After conducting the experiments and considering both the solution efficiency and solution quality of the algorithms, in the VNS algorithm process, the number of vessels disturbed during the shaking step, , is set to , and the number of vessels selected to destroy–repair during the local search step, , is set to . In addition, the total number of iterations for the entire algorithm is limited to 1000, while the total number of iterations for each neighborhood structure in the local search step is limited to 100. Each run records the objective value and the solution time of the output solution. To maximize the likelihood of finding the optimal solution within a limited time while still allowing for practical decision-making, the commercial solver Gurobi is restricted to a maximum solution time of 1 h. For each run, the objective value of the output solution , the gap between the optimal solution and the return time are recorded. All numerical experiments are conducted on a Windows PC with an Intel(R) Core (TM) i5-8500 CPU (Intel Corporation, Santa Clara, CA, USA) and 8.00 GB of RAM.

5.1. Experimental Comparisons

All generated BACAP instances are addressed using both the proposed VNS algorithm and the commercial solver Gurobi. The detailed comparison results are presented in

Table 7 and

Table 8. In these tables,

represents the objective value obtained by Gurobi within 1 h, and

denotes the gap between the Gurobi solution and the optimal solution.

is the objective value obtained by VNS, while

indicates the gap between the best solution found by VNS and the solution returned by Gurobi, as calculated according to Equation (40).

As presented in

Table 7 for the A1 instance set, for small-scale instances (S_01–S_03), the objective values obtained by VNS and Gurobi are identical; however, VNS demonstrates a significant advantage in solution time. For the first sub-instance of S_01, Gurobi takes 10.36 s, while VNS requires only 1.23 s. In another sub-instance of S_01, the solution time of VNS is at most one-tenth that of Gurobi. For medium-scale instances (M_01–M_03), when the objective values are the same, VNS further outperforms Gurobi in terms of solution time. For example, in the first sub-instance of M_02, Gurobi requires 123.46 s, while VNS completes the solution in just 2.45 s. In larger instances, the VNS algorithm demonstrates clear performance benefits, not only outperforming Gurobi in solution quality but also achieving results within 30 s. Thus, the proposed VNS algorithm is well-suited for small- and medium-scale BACAP instances and demonstrates superior performance over Gurobi in large-scale cases.

As shown in

Table 8, the results for the A2 instance indicate that VNS achieves the same objective value as Gurobi for some sub-instances of the G1 and G2 instances. Although there are some sub-instances within both the G1 and G2 instances where the objective value obtained by VNS differs slightly from that of Gurobi, the gap is small (for example, the first sub-instance of G1 has a

of 2.41). At the same time, in all G1 and G2 instances, the solution time of the VNS algorithm is consistently better than that of Gurobi. For the G3 instances, VNS demonstrates a more significant advantage, as the solution time of Gurobi reaches 3600 s, whereas VNS requires substantially less time. Furthermore, VNS yields better objective values in several sub-instances. For example, in the first sub-instance of G3, the

is 12.03, while the

is −4.56, indicating that the objective value computed by VNS is closer to the optimal solution. For all sub-instances of G4, Gurobi fails to reach optimality within the time limit, resulting in high

values (e.g., 22.43, 28.38, and 31.09), while VNS not only solves each sub-instance in under 40 s but also achieves significantly better objective values. The negative

values (e.g., −12.56, −19.08, and −20.77) further suggest that VNS delivers higher-quality solutions under stringent computational constraints. Therefore, the results from the A2 instance set provide additional evidence that the proposed VNS algorithm is both efficient and stable in solving large-scale BACAP instances.

In summary, after analyzing the A1 and A2 instance sets, the VNS algorithm for solving the BACAP proves to be effective for small- and medium-scale instances. For large-scale instances, VNS demonstrates a significant advantage over Gurobi in terms of solution time, while maintaining comparable or even superior solution quality. Therefore, the VNS algorithm exhibits the capability to efficiently and reliably solve large-scale BACAP instances.

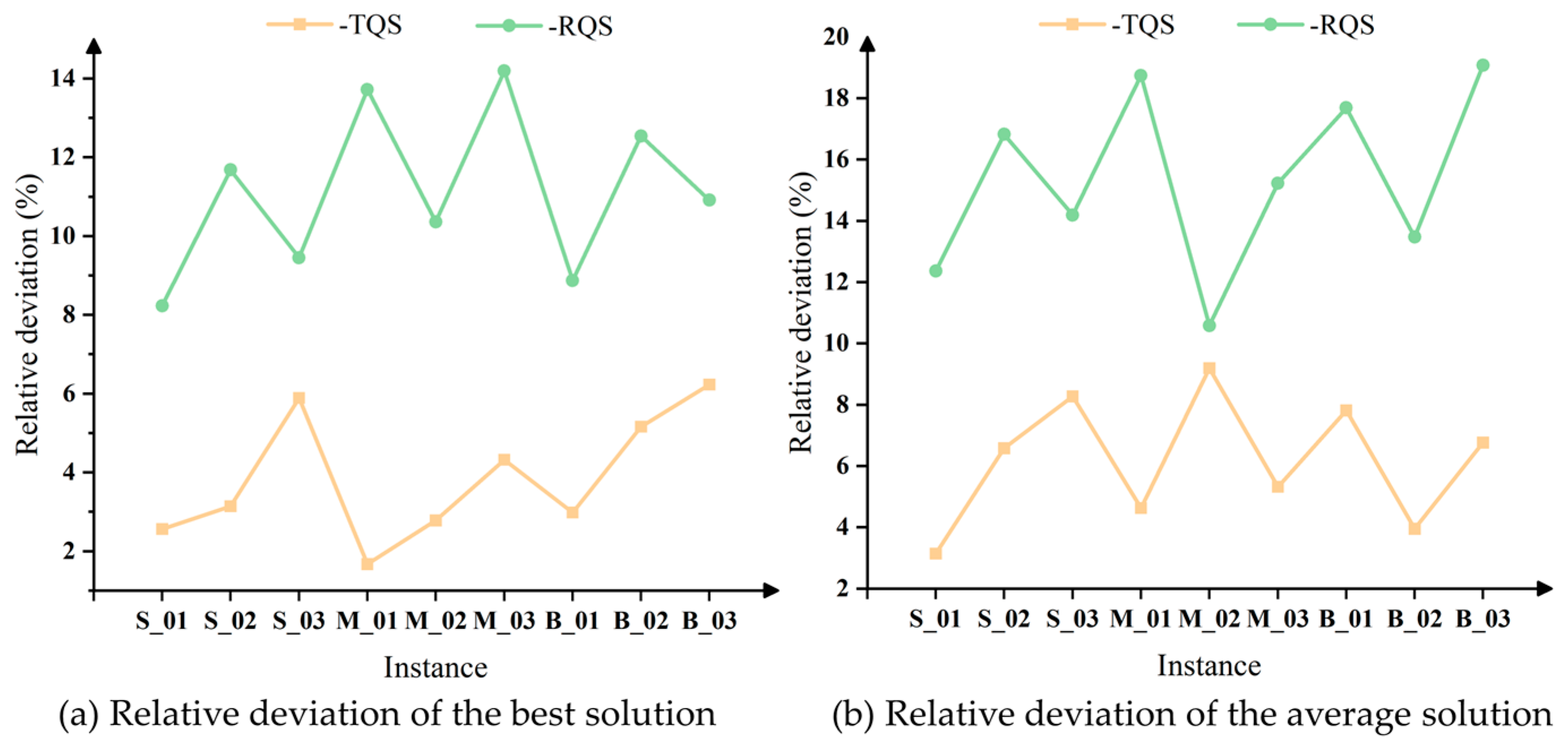

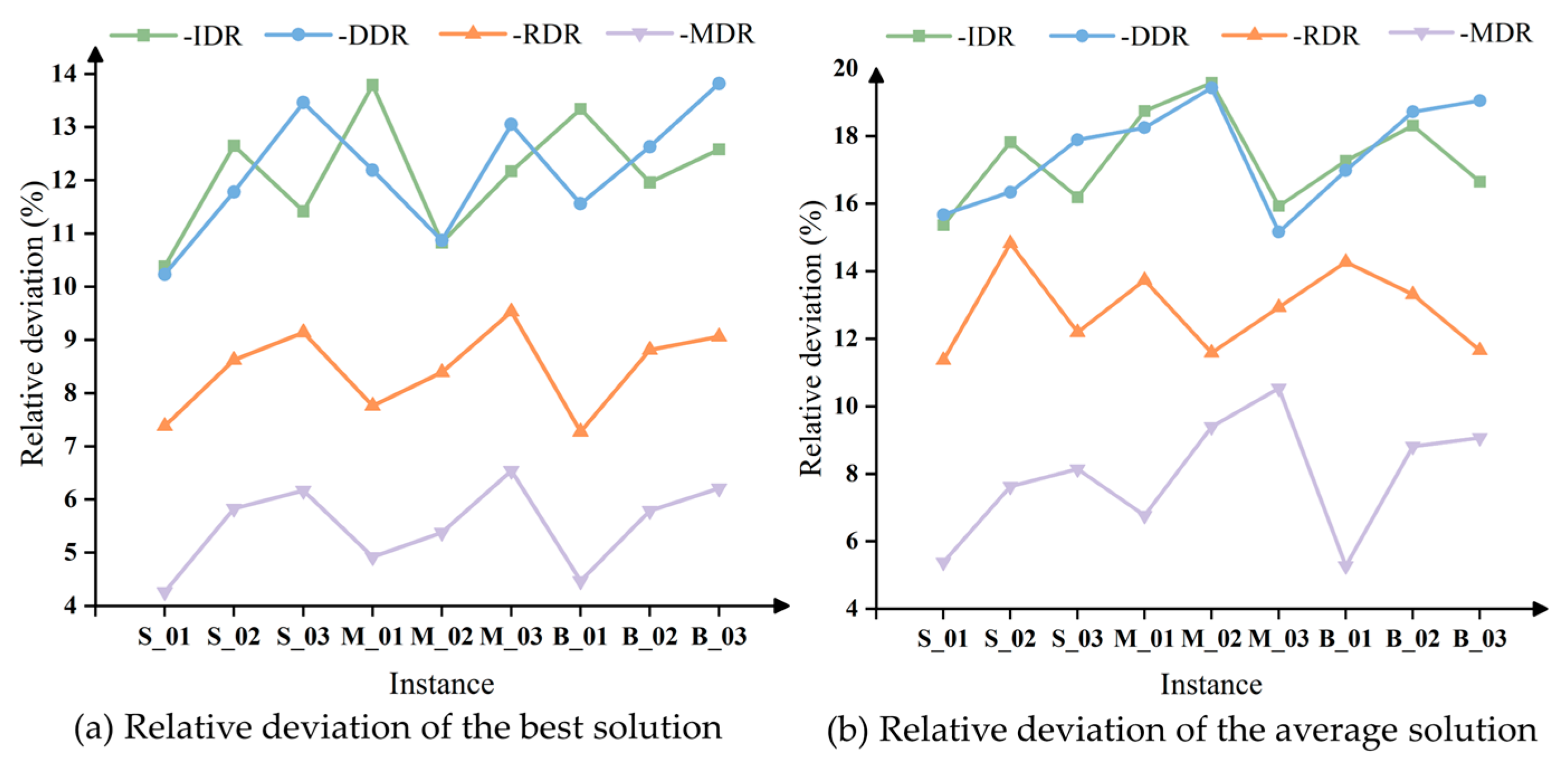

Furthermore, in order to verify the validity of the neighborhood structures designed in the shaking step and the local search step, we carried out the following experiments. Sequentially, the neighborhood structures of the corresponding steps are removed in the VNS algorithm, and then 20 experiments are carried out, respectively, and the best solution, denoted as

, and the average solution, denoted as

, are recorded. Their relative deviations, denoted as

, from the results in

Table 7 are calculated using Equation (41). The experiment selects the first instance from each scale within the A1 set. The results are presented in

Figure 7 and

Figure 8, where ‘-’ represents the removal of the corresponding neighborhood structure.

The results in

Figure 7 and

Figure 8 visualize the role played by the neighborhood structure during shaking steps and local search steps in the VNS algorithm process. In the shaking step, the Random QC Profile (RQS) neighborhood structure exerts the greatest impact, with the Time-Increased QC Profile (TQS) structure following. This is because the RQS structure can escape local optima and has a notable effect on improving the solution, while most vessels tend to serve with shorter handling times to minimize the risk of delayed departures. Although the effect of the TQS neighborhood structure is less pronounced than that of the RQS, it still contributes positively to the improvement of the solution. Regarding the local search neighborhood structures, the Idle Destroy–Repair (IDR) and Delay Destroy–Repair (DDR) structures exhibit the most significant and comparable effects, followed by the Random Destroy–Repair (RDR), with the Max-QC Destroy–Repair (MDR) structure having the least impact.

Therefore, in the actual scheduling process, special attention should be given to ships with delays and longer waiting times. Additionally, it is undesirable to select a QC profile with longer handling times solely to meet the maximum number of QC limitation, as this may lead to delayed departures, resulting in higher costs due to delayed times.

In addition, when allocating QC profiles based on the ship–berth sequence discussed in

Section 4.3, we introduced a QC profile sorting algorithm. The following presents a comparison of the algorithmic effects of applying versus not applying this QC profile sorting algorithm. When the sorting algorithm is not applied, the first QC profile from the provided set is selected for allocation to the corresponding ship, which significantly increases the randomness in the selection of QC profiles. For the experiment, the first instance from each scale in the A1 set is selected.

Specifically, the QC profile sorting algorithm is removed initially, and then the VNS algorithm, without the sorting component, is executed 20 times to record both the average solution and the average solution time. The results are presented in

Table 9. In

Table 9, “VNS+” refers to VNS with the QC profile sorting algorithm, while “VNS-” denotes VNS without the QC profile sorting algorithm.

As shown in

Table 9, for each instance, the objective value remains the same regardless of whether the QC profile sorting algorithm is applied. However, the running time of VNS with the QC profile sorting algorithm is significantly shorter than that of VNS without it, indicating that the QC profile sorting algorithm effectively improves computational efficiency and significantly reduces the required computation time. In conclusion, the application of the QC profile sorting algorithm does not affect the final solution’s value but can significantly reduce the running time. Thus, the use of the QC profile sorting algorithm enhances computational efficiency and reduces time costs in practical applications.

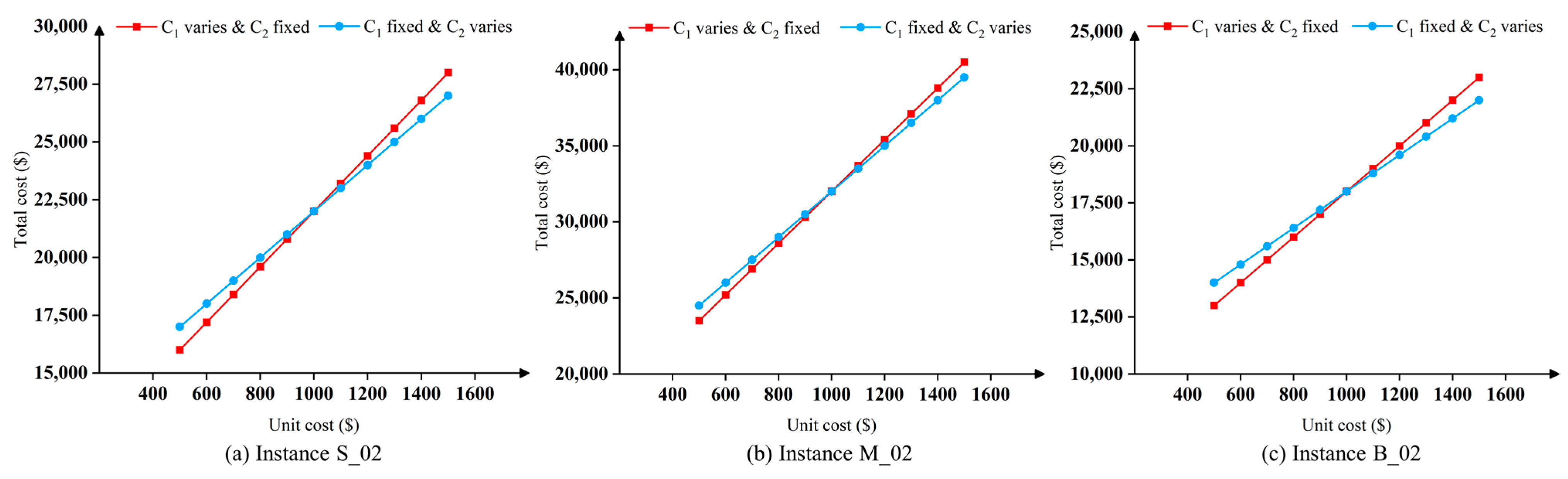

5.2. Sensitivity Analysis of Idle Cost and Delay Cost

In the BACAP model, the unit idle time cost due to vessel waiting

and the unit delay time cost due to late vessel departures

are important factors. In this section, a sensitivity analysis is conducted to examine the influence of these costs on the BACAP. The experiment selects the S_02, M_02, and B_02 instances from A1, with the results for these instances presented in

Figure 9a–c. In this experiment,

is first fixed at 1000, and

is varied by conducting 10 experiments in steps of 100 within the interval [500, 1500]. Then,

is fixed at 1000, and

is varied similarly, as well as in steps of 100 within the same interval.

Figure 9 illustrates the average total of vessel idle time costs and delay time costs, according to the best solution from 20 runs of the VNS.

The sensitivity analysis results in

Figure 9 indicate that with the same step size of cost change, as

increases, the total cost for each instance (S_02, M_02, and B_02) rises by a larger magnitude and exhibits a steeper slope. In contrast, the increase in total cost when

is varied is relatively small, with a flatter slope.

The underlying reason for this trend is that, under the data of the A1 instances, the disturbance to the overall operation caused by delayed vessel berthing is greater than that caused by delayed vessel departures. This may be due to the relatively high frequency of delayed vessel berthing, which results in the cost incurred by delayed berthing accounting for a larger portion of the total cost per-unit time. As a result, any change in its cost per unit of time has a significant impact on the total cost. In contrast, delayed vessel departures cause relatively mild disruptions to the overall operation, or occur less frequently, leading to a weaker impact on the total cost from changes in the unit time cost.

Based on the above analysis, in practical management, emphasis should be placed on monitoring the unit time cost associated with delayed berthing. The risk of delayed berthing can be mitigated by training crew members to improve operational skills, upgrading equipment to enhance reliability, and addressing error-causing factors in the berthing process. Optimizing the berthing process, improving the scheduling system, and strengthening communication and collaboration among all parties can further reduce the likelihood of delayed berthing. Additionally, it is crucial to establish a dynamic cost evaluation mechanism to adjust operational strategies and budgets based on real-time cost fluctuations, thereby ensuring maximum economic benefits.

6. Conclusions

This paper investigates the Berth Allocation and Quay Crane Assignment Problem from the perspective of QC profiles, as proposed by Giallombardo et al. [

19]. QC profiles offer new insights into the BACAP at the tactical level, with the goal of dealing with existing challenges and improving maritime transportation efficiency. Drawing on previous studies [

19,

21], we propose a MILP model for the BACAP, with the objective of minimizing the sum of idle time cost due to vessel waiting and delay time cost resulting from late vessel departures. Furthermore, we introduce a VNS algorithm designed to address the BACAP with both stability and effectiveness, particularly suitable for large-scale and complex scheduling problems. Both the model and the algorithm focus on the variable number of QCs in actual terminal operations, providing better applicability for real-world scenarios.

Numerical experiments conducted on the A1 and A2 instance sets validate the stability and efficiency of the proposed VNS algorithm across different problem scales. Specifically, the VNS algorithm outperforms the commercial solver Gurobi in terms of both solution quality and computational time on large-scale instances, achieving high-quality solutions within significantly shorter times. Additionally, the evaluation of the VNS neighborhood structures reveals that different neighborhood structures play distinct roles in the optimization process, and the proposed QC profile sorting algorithm significantly improves the computational efficiency of the VNS without compromising the solution quality. Sensitivity analysis of the per-unit time costs for delayed berthing and delayed departure shows that changes in the unit time cost for delayed berthing have a more pronounced impact on the total cost, highlighting the critical importance of minimizing vessel waiting times in practical port management. Based on this analysis, it is recommended that port operation management prioritize the cost of delayed berthing unit time, mitigate the risk of delayed berthing through crew training and equipment upgrades, optimize the berthing process, and implement a dynamic cost assessment mechanism to adjust operational strategies and budgets in response to cost fluctuations.

In conclusion, this study demonstrates the effectiveness of the VNS algorithm in solving the BACAP. By minimizing vessel idle times and reducing inefficient quay crane reallocations, the proposed framework helps lower energy consumption and emissions, thereby contributing to greener and more sustainable port operations. However, port operations continuously face challenges and developmental bottlenecks. It should be noted that the proposed model is tailored for container terminals, as quay crane operation time is determined by the vessel’s handling volume and the unit-time handling efficiency of a single quay crane. This implies an approximate linear relationship between handling volume and operation time, which is more applicable to container terminals. As a result, the applicability of the current model is limited to container ports.

Future research will explore more generalized and flexible relationships between handling volume and handling time, aiming to extend the model to other types of ports. In the future, we will further consider equipment maintenance strategies in the scheduling model to enhance its practical applicability. Future research can also explore the integration of additional port resources, such as yards and transport trucks, into the BACAP for integrated scheduling from the perspective of the QC profile. Furthermore, extending the BACAP to the coordinated scheduling of multiple ports by considering the cooperation of port groups is a promising research direction. Incorporating sustainability metrics, such as carbon emissions and energy efficiency, into future BACAP formulations will be essential for aligning port operations with global environmental goals. Additionally, incorporating vessel emissions in port operations aligns with the growing emphasis on environmentally sustainably shipping. Lastly, the continuous development of more efficient solution algorithms to address increasingly complex port scheduling problems will remain a key research topic.