Optimizing Reverse Logistics Network for Waste Electric Vehicle Batteries: The Impact Analysis of Chinese Government Subsidies and Penalties

Abstract

1. Introduction

- (1)

- Diverging from existing studies, this study establishes a RLN optimization model for electric vehicle batteries that concurrently integrates subsidy and penalty policies through a policy combination perspective. By conducting comparative analyses of implementation outcomes between single policy and combined policy, this study provides decision-making support for governments formulating battery recycling policies.

- (2)

- Meanwhile, this study takes into account the differences between hydrometallurgy and pyrometallurgy in terms of cost and carbon emissions, significantly improving the practical relevance of the findings.

- (3)

- Furthermore, this study incorporates dual-aspect uncertainties in quantity and quality characteristics of multi-variant waste electric vehicle batteries into the modeling framework, the proposed model demonstrates superior applicability in addressing real-world recycling complexities.

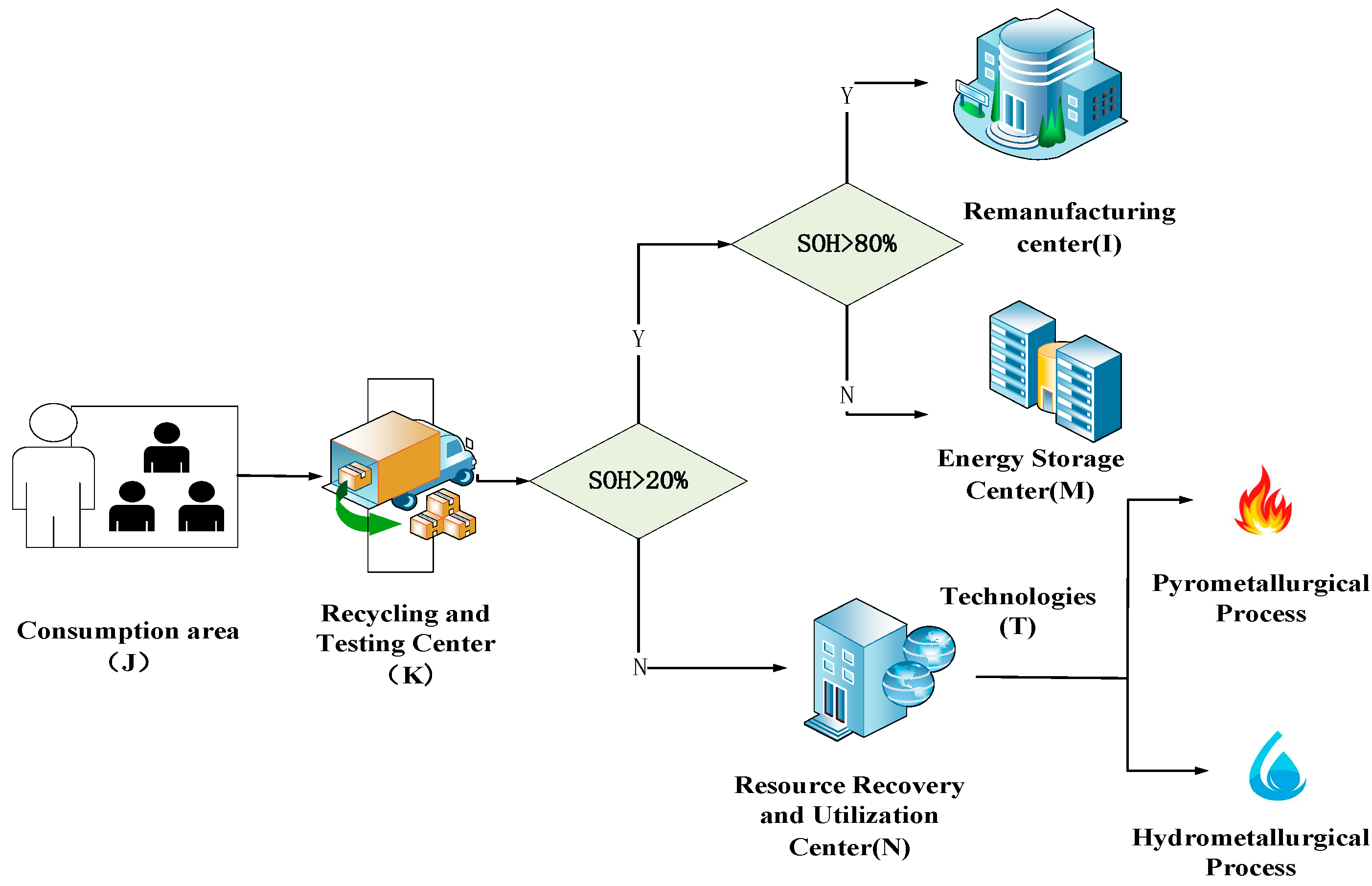

2. Problem Description and Proposed Model

2.1. Assumptions

- (1)

- The candidate locations and capacities of each facility are known.

- (2)

- There is only a single mode of transportation.

- (3)

- Facility capacities of all potential facilities are limited and known in advance.

- (4)

- The transportation costs at each stage are related to the type of electric vehicle batteries being transported, the transportation cost, and the quantity of transportation.

- (5)

- The alternative locations and capacities of the recycling and testing center, remanufacturing center, energy storage center, and resource recovery and utilization center are known.

- (6)

- The recovery rate of waste electric vehicle batteries at the recycling and testing center is correlated with subsidies. Based on practical experience, a higher subsidy leads to a higher recovery rate. Drawing inspiration from reference [38], the recovery rate is set as shown in Equation (1) and represents the recovery rate for the consumption area; denotes the base recovery rate; and is the subsidy coefficient.

2.2. Notations

2.3. Model Construction

2.4. The Solution of the Model

2.4.1. The Equivalent Auxiliary Crisp Model

2.4.2. The Proposed Method

3. Case Study

3.1. Input Data

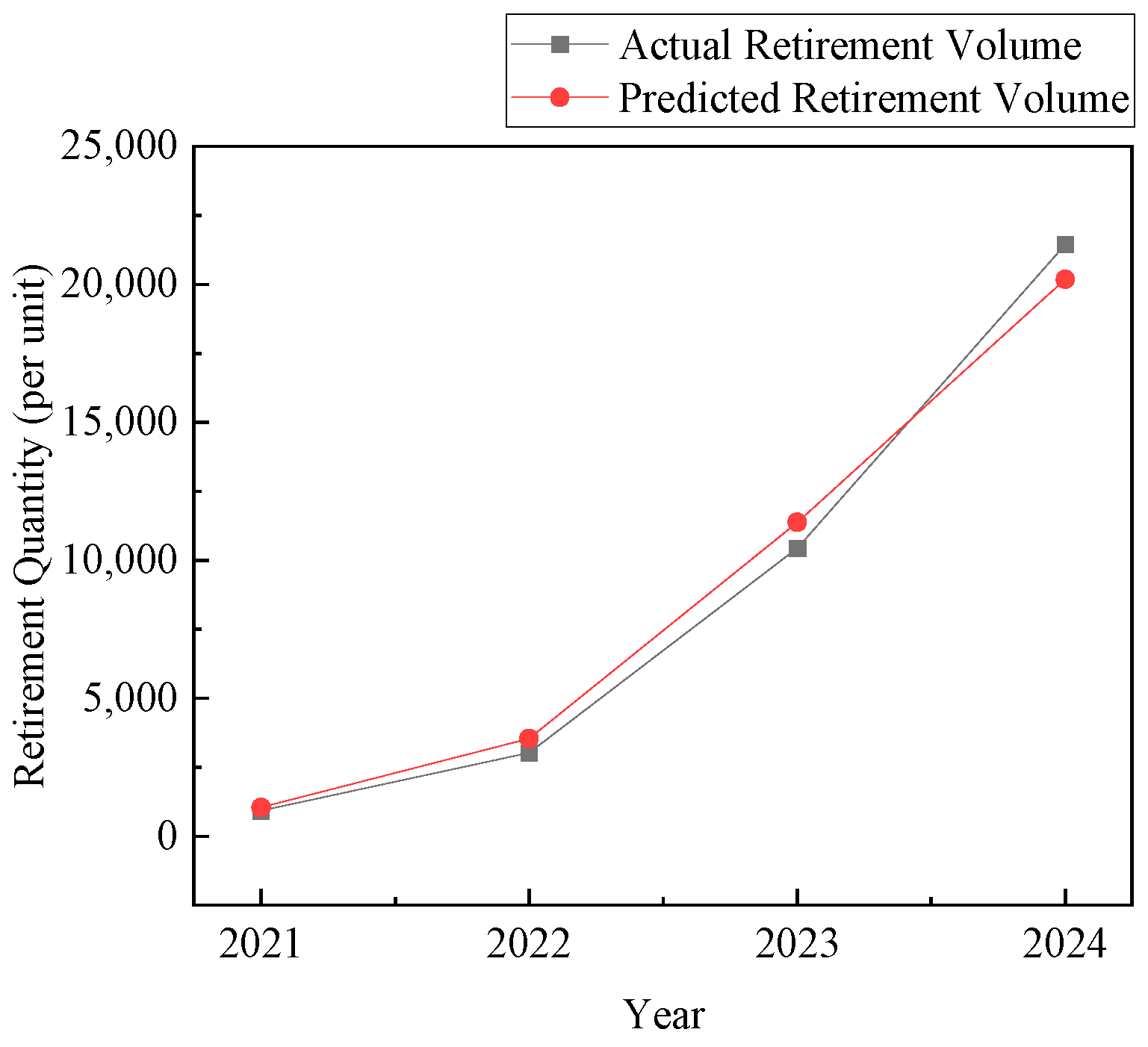

3.1.1. Prediction of Recycling Volume

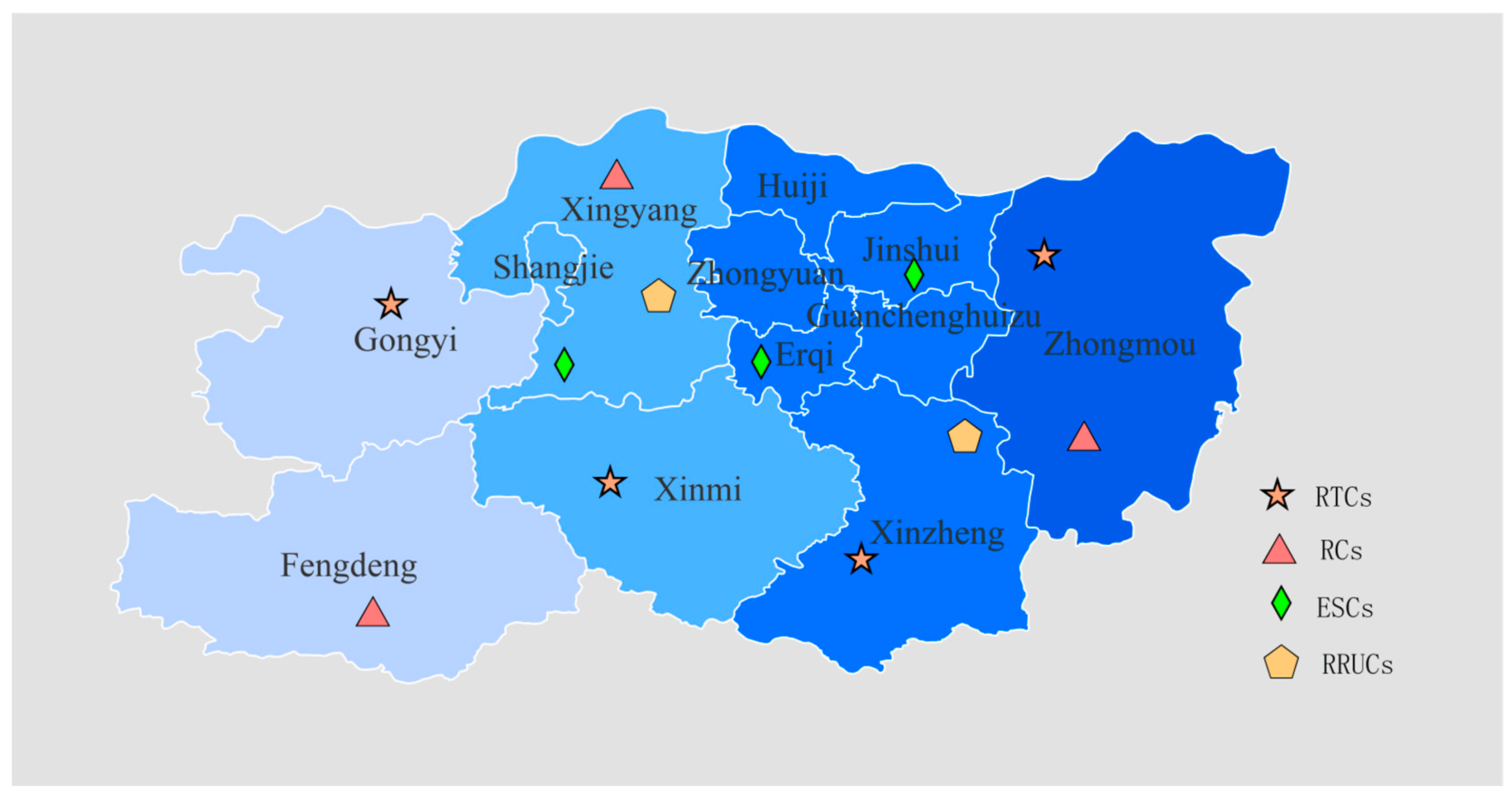

3.1.2. Network Layout and Parameter Settings

3.2. Results Presentation and Sensitivity Analysis

3.2.1. Results

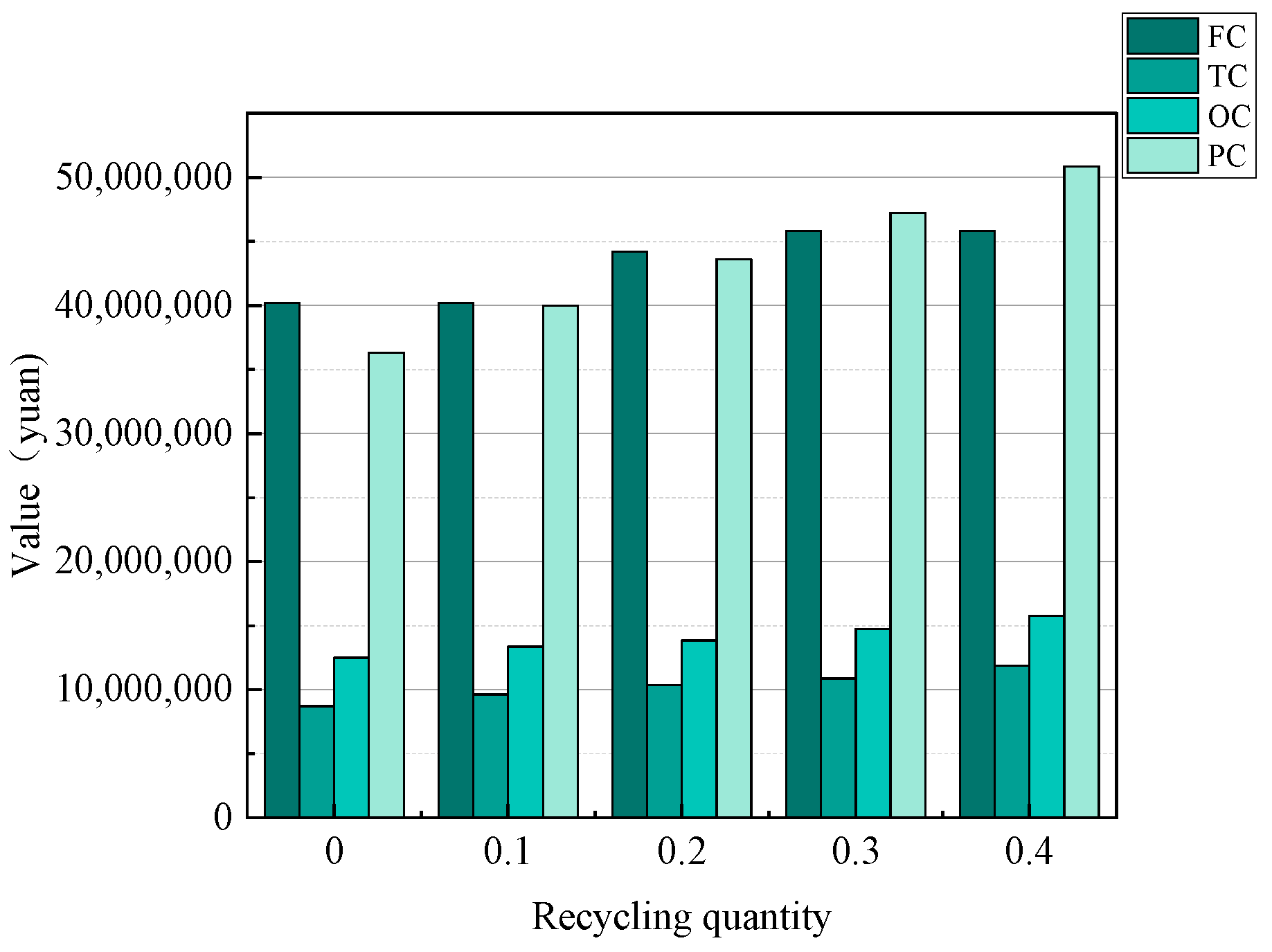

3.2.2. Sensitivity Analysis of Recycling Quantity

3.2.3. Sensitivity Analysis of Recycling Quality

3.3. Analysis of the Implementation Effect of Policies

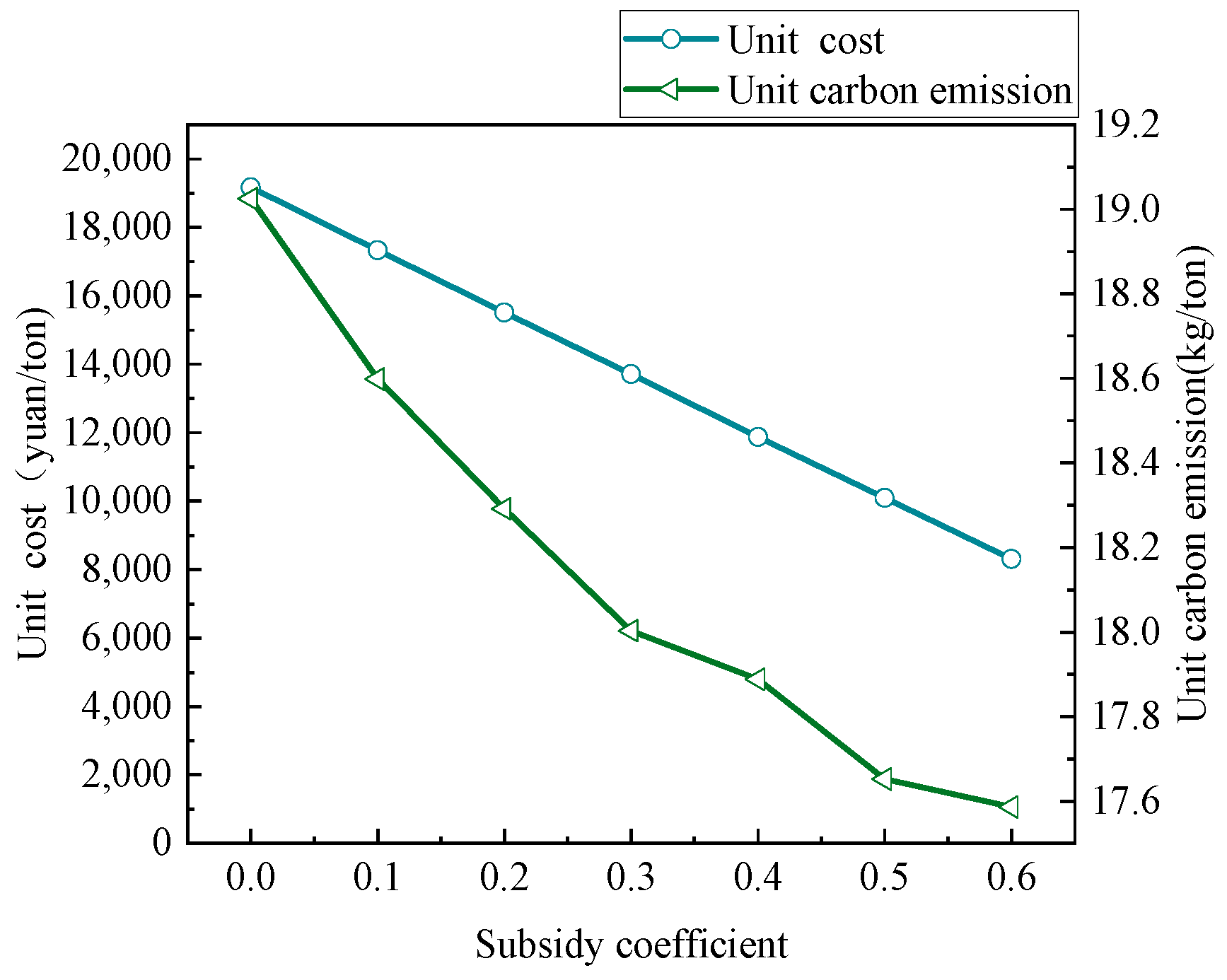

3.3.1. Scenario 1: Analysis of Subsidy Policy (Including the Scenario Without Subsidy Policy)

3.3.2. Scenario 2: Analysis of Penalty Policy (Including the Scenario Without Penalty Policy)

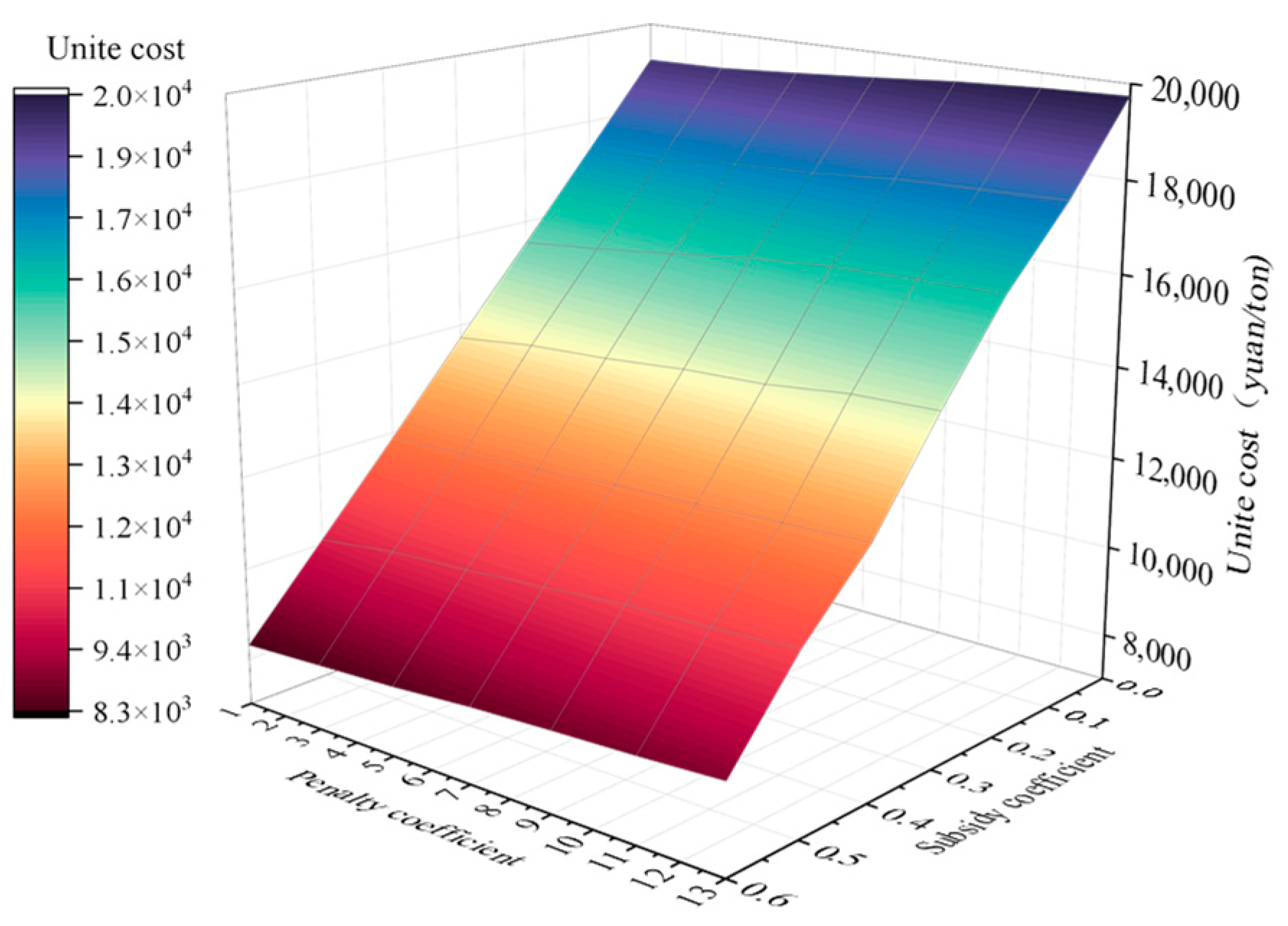

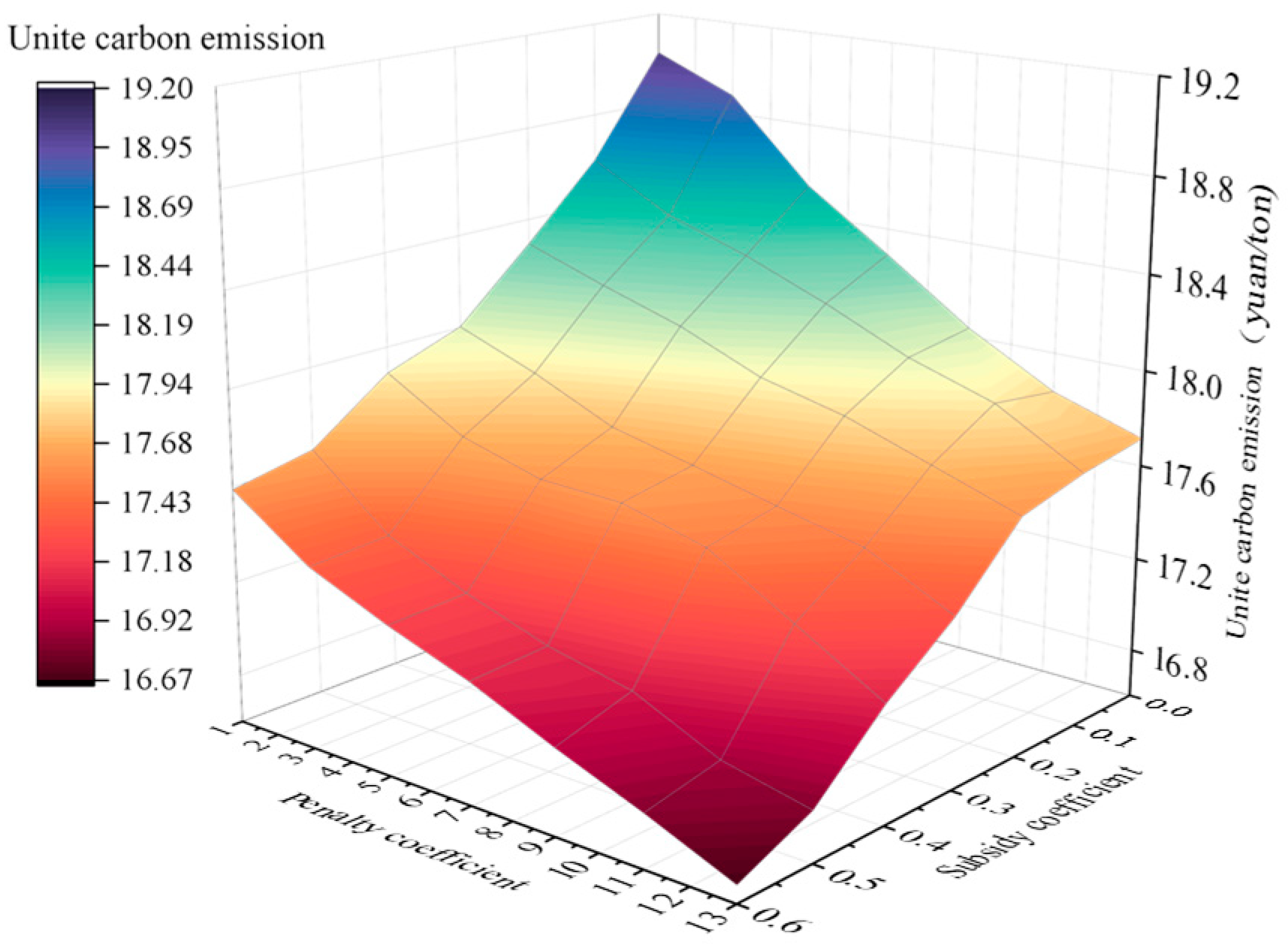

3.3.3. Scenario 3: Analysis of Combined Subsidy–Penalty Policy

3.3.4. Comparison of Solution Methods

4. Conclusions and Suggestions

- As demonstrated in Section 3.2.1, the RLN design for electric vehicle batteries should abandon the singular pursuit of cost minimization and instead adopt a multi-objective model balancing cost and environmental factors, thus achieving a balanced approach that considers economic and environmental benefits can facilitate more effective carbon emission reduction with minimal economic impact and promoting sustainable development.

- The findings presented in Section 3.2.2 and Section 3.2.3 suggest that decision-makers should strategically invest in facilities that align with prevailing industry trends, such as the escalating volume of battery recycling, which is driven by advancements in the new energy vehicle sector. Proactive planning for higher-capacity facilities or reserving expansion space can address growing recycling demands, enhance resource utilization efficiency, and reduce waste. In addition, decision-makers should emphasize the quality assessment of waste electric vehicle batteries and make informed decisions on whether to direct them to cascade utilization facilities or recycling treatment facilities based on evaluation results. Continuous improvement in detection technologies can reduce the number of batteries requiring recycling treatment, thereby lowering total costs and emissions while achieving dual environmental and economic benefits.

- As demonstrated in Section 3.3.1 and Section 3.3.2, governments should leverage subsidy policies by appropriately increasing financial incentives to alleviate economic pressures on recycling enterprises, enhance their operational enthusiasm, and channel more waste electric vehicle batteries to formal processing channels. This approach has the potential to enhance the overall recycling rates within the industry and to contribute to the improvement of environmental conditions. While the implementation of penalty policies has the potential to promote the development of environmentally friendly network nodes and regulate carbon emissions, it may also result in economic trade-offs. Consequently, governments should strive to balance economic and environmental concerns when implementing penalties, establishing reasonable standards that achieve environmental objectives without imposing corporate burdens.

- According to Section 3.3.3, it is recommended that governments implement a combination of subsidy and penalty policies to achieve synergistic effects. Despite the potential for short-term increases in unit cost resulting from the implementation of combined subsidy–penalty policies, these strategies have been demonstrated to yield substantial long-term benefits. These benefits include the enhancement of total recycling volumes, the reduction in unit costs, the mitigation of emission growth, the optimization of the balance between economic and environmental benefits, and the promotion of the effective management of reverse logistics for waste electric vehicle batteries.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sets | Definitions |

|---|---|

| Index of waste electric vehicle batteries, ∈ {1, 2, …, E}; | |

| Index of consumption area (CA), ∈ {1, 2, …, J}; | |

| K | Index of recycling and testing center (RTC), ∈ {1, 2, …, K}; |

| Index of remanufacturing center (RC), ∈ {1, 2, …, L}; | |

| Index of energy storage center (ESC), ∈ {1, 2, …, M}; | |

| Index of resource recovery and utilization center (RRUC), ∈ {1, 2, …, N}; | |

| Index of technology used in the resource recovery and utilization center, ∈ {1, 2, …, T} | |

| Parameters | Definitions |

| Fixed construction cost of the RTC; | |

| Fixed construction cost of RC; | |

| Fixed construction cost of ESC; | |

| Fixed construction cost of RRUC with t-technology; | |

| Operating cost per unit e-kind of waste electric vehicle battery at the RTC; | |

| Operating cost per unit e-kind of waste electric vehicle battery at the RC; | |

| Operating cost per unit e-kind of waste electric vehicle battery at the ESC; | |

| Operating cost per unit e-kind of waste electric vehicle battery at the RRUC with t-technology; | |

| Maximum processing capacity of the RTC; | |

| Maximum processing capacity of the RC; | |

| Maximum processing capacity of the ESC; | |

| Maximum processing capacity of the RRUC with t-technology; | |

| Carbon emission from building a RTC; | |

| Carbon emission from building a RC; | |

| Carbon emission from building an ESC; | |

| Carbon emission from building a RRUC with t-technology; | |

| Carbon emissions from processing unit e-kind of waste electric vehicle battery in RTC; | |

| Carbon emissions from processing unit e-kind of waste electric vehicle battery in RC; | |

| Carbon emissions from processing unit e-kind of waste electric vehicle battery in ESC; | |

| Carbon emissions from processing unit e-kind of waste electric vehicle battery in RRUCs with t-technology; | |

| Transportation cost per unit e-kind of waste electric vehicle battery from consumption area to RTC; | |

| Transportation cost per unit e-kind of waste electric vehicle battery from RTC to RC; | |

| Transportation cost per unit e-kind of waste electric vehicle battery from RTC to ESC; | |

| Transportation cost per unit e-kind of waste electric vehicle battery from RTC to RRUC with t-technology; | |

| Carbon emissions during the transportation of per unit e-kind of waste electric vehicle battery from the consumption area to the RTC ; | |

| Carbon emissions during the transportation of per unit e-kind of waste electric vehicle battery from the RTC to the RC; | |

| Carbon emissions during the transportation of per unit e-kind of waste electric vehicle battery from the RTC to the ESC; | |

| Carbon emissions during the transportation of per unit e-kind of waste electric vehicle battery from RTC to RRUC with t-technology; | |

| Number of waste electric vehicle batteries generated by consumption area; | |

| Recycling price per unit e-kind of waste electric vehicle batteries at the RTC; | |

| Proportion of e-kind of waste electric vehicle batteries used for cascade utilization; | |

| Proportion of the number of e-kind of waste electric vehicle batteries to RCs to the number of e-kind of waste electric vehicle batteries for cascade utilization; | |

| The carbon emissions allowed by the government for companies to generate, i.e., the rated carbon emission allowance; | |

| The penalty coefficient set by the government for exceeding the rated carbon emissions. | |

| Variables | Definitions |

| Binary variable equal to 1 if the RTC is opened, and 0 otherwise; | |

| Binary variable equal to 1 if the RC is opened, and 0 otherwise; | |

| Binary variable equal to 1 if the ESC is opened, and 0 otherwise; | |

| Binary variable equal to 1 if RRUC with t-technology is opened, and 0 otherwise; | |

| Integer variable indicating the number of e-kind of waste electric vehicle batteries shipped from the CA to the RTC ; | |

| Integer variable indicating the number of e-kind of waste electric vehicle batteries shipped from the RTC to the RC ; | |

| Integer variable indicating the number of e-kind of waste electric vehicle batteries shipped from the RTC to the ESC ; | |

| Integer variable indicating the number of e-kind of waste electric vehicle batteries that can undergo cascade utilization from the RTC ; | |

| Integer variable representing the quantity of e-kind of waste electric vehicle batteries transported from the RTC to the RRUC utilizing technology with t-technology. |

References

- Sun, S.; Jin, C.; He, W.; Li, G.; Zhu, H.; Huang, J. Management Status of Waste Lithium-Ion Batteries in China and a Complete Closed-Circuit Recycling Process. Sci. Total Environ. 2021, 776, 145913. [Google Scholar] [CrossRef] [PubMed]

- Notter, D.A.; Gauch, M.; Widmer, R.; Wäger, P.; Stamp, A.; Zah, R.; Althaus, H.-J. Contribution of Li-Ion Batteries to the Environmental Impact of Electric Vehicles. Environ. Sci. Technol. 2010, 44, 6550–6556. [Google Scholar] [CrossRef] [PubMed]

- Kilic, H.S.; Kalender, Z.T.; Solmaz, B.; Iseri, D. A Two-Stage MCDM Model for Reverse Logistics Network Design of Waste Batteries in Turkey. Appl. Soft Comput. 2023, 143, 110373. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Li, X.; Zhang, B.; Song, H. Collaborative Decision-Making Based on Effort Level: Power Battery Recycling Alliance. Procedia Comput. Sci. 2023, 221, 1155–1161. [Google Scholar] [CrossRef]

- Lyu, X.; Xu, Y.; Sun, D. An Evolutionary Game Research on Cooperation Mode of the NEV Power Battery Recycling and Gradient Utilization Alliance in the Context of China’s NEV Power Battery Retired Tide. Sustainability 2021, 13, 4165. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, W.; Song, Y. Study on the Impact of Government Policies on Power Battery Recycling under Different Recycling Models. J. Clean. Prod. 2023, 413, 137492. [Google Scholar] [CrossRef]

- Zhu, X.; Li, W. The Pricing Strategy of Dual Recycling Channels for Power Batteries of New Energy Vehicles under Government Subsidies. Complexity 2020, 2020, 1–16. [Google Scholar] [CrossRef]

- Li, J.; Xu, Y.; Jiao, J.; Yang, R.; Zha, J. Do Recycling Channels Affect Young Consumers’ Choices for Formal Power Battery Recycling? J. Clean. Prod. 2023, 425, 138766. [Google Scholar] [CrossRef]

- Pappu, S.; Muduli, S.; Katchala, N.; Tata, N.R.; Bulusu, S.; Martha, S.K. Easy and Scalable Synthesis of NiMnCo-Oxalate Electrode Material for Supercapacitors from Spent Li-Ion Batteries: Power Source for Electrochromic Devices. Energy Fuels 2022, 36, 13398–13407. [Google Scholar] [CrossRef]

- Fan, J.; Teng, H.; Wang, Y. Research on Recycling Strategies for New Energy Vehicle Waste Power Batteries Based on Consumer Responsibility Awareness. Sustainability 2022, 14, 10016. [Google Scholar] [CrossRef]

- Wang, C.; Feng, X.; Woo, S.; Wood, J.; Yu, S. The Optimization of an EV Decommissioned Battery Recycling Network: A Third-Party Approach. J. Environ. Manag. 2023, 348, 119299. [Google Scholar] [CrossRef]

- Rosenberg, S.; Glöser-Chahoud, S.; Huster, S.; Schultmann, F. A Dynamic Network Design Model with Capacity Expansions for EoL Traction Battery Recycling–A Case Study of an OEM in Germany. Waste Manag. 2023, 160, 12–22. [Google Scholar] [CrossRef]

- Mu, N.; Wang, Y.; Chen, Z.-S.; Xin, P.; Deveci, M.; Pedrycz, W. Multi-Objective Combinatorial Optimization Analysis of the Recycling of Retired New Energy Electric Vehicle Power Batteries in a Sustainable Dynamic Reverse Logistics Network. Environ. Sci. Pollut. Res. 2023, 30, 47580–47601. [Google Scholar] [CrossRef] [PubMed]

- Saeedi, M.; Parhazeh, S.; Tavakkoli-Moghaddam, R.; Khalili-Fard, A. Designing a Two-Stage Model for a Sustainable Closed-Loop Electric Vehicle Battery Supply Chain Network: A Scenario-Based Stochastic Programming Approach. Comput. Ind. Eng. 2024, 190, 110036. [Google Scholar] [CrossRef]

- Kamyabi, E.; Moazzez, H.; Husseinzadeh Kashan, A. A Hybrid System Dynamics and Two-Stage Mixed Integer Stochastic Programming Approach for Closed-Loop Battery Supply Chain Optimization. Appl. Math. Model. 2022, 106, 770–798. [Google Scholar] [CrossRef]

- Lin, J.; Li, X.; Zhao, Y.; Chen, W.; Wang, M. Design a Reverse Logistics Network for End-of-Life Power Batteries: A Case Study of Chengdu in China. Sustain. Cities Soc. 2023, 98, 104807. [Google Scholar] [CrossRef]

- Hao, H.; Sun, Y.; Mei, X.; Zhou, Y. Reverse Logistics Network Design of Electric Vehicle Batteries Considering Recall Risk. Math. Probl. Eng. 2021, 2021, 5518049. [Google Scholar] [CrossRef]

- Yang, Y.; Guan, Q.; Yu, Y.; Lin, M. Sustainable Reverse Logistics Network Optimization Model Based on Dual-Channel Power Battery Recycling Mode. Comput. Integr. Manuf. Syst. 2023, 29, 2461–2473. [Google Scholar] [CrossRef]

- Tosarkani, B.M.; Amin, S.H. A Possibilistic Solution to Configure a Battery Closed-Loop Supply Chain: Multi-Objective Approach. Expert. Syst. Appl. 2018, 92, 12–26. [Google Scholar] [CrossRef]

- Saha, A.K. Stochastic Optimization of Value Recovery Network for Li-Ion Batteries in the United States under Price and Return Volume Uncertainties. Resour. Conserv. Recycl. 2024, 206, 107623. [Google Scholar] [CrossRef]

- He, M.; Li, Q.; Wu, X.; Izui, K. Designing a Multi-Level Reverse Logistics Network for Waste Batteries of Electric Vehicles under Uncertainty—A Case Study in the Yangtze River Delta Urban Agglomerations of China. J. Clean. Prod. 2024, 472, 143418. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Yang, W. Optimal Design of Electric Vehicle Battery Recycling Network–From the Perspective of Electric Vehicle Manufacturers. Appl. Energy 2020, 275, 115328. [Google Scholar] [CrossRef]

- General Office of Shanghai Municipal People’s Government. Interim Measures for Encouraging the Purchase and Use of New Energy Vehicles in Shanghai. Available online: https://czj.sh.gov.cn/zys_8908/zcfg_8983/zcfb_8985/qy_9027/qtqyfczc/20140529/0017-156685.html (accessed on 2 April 2025).

- Shanghai Municipal People’s Government. Shanghai Municipal Carbon Emission Management Measures. Available online: https://www.shanghai.gov.cn/nw12344/20250314/d7f358a1242d4b7e91884fed6a967d3b.html (accessed on 2 April 2025).

- Hefei Municipal Bureau of Industry and Information Technology. Notice on Applying for 2024 Hefei New Energy Vehicle Financial Subsidy Funds. Available online: https://gxj.hefei.gov.cn/tzgg/18768287.html (accessed on 2 April 2025).

- Hefei Municipal People’s Government. Notice on Issuing the Implementation Plan for Energy Conservation and Emission Reduction in Hefei During the 14th Five-Year Plan Period; Hefei Municipal People’s Government: Hefei, China, 2022.

- Guangxi Zhuang Autonomous Region Development and Reform Commission. Notice on Issuing the Implementation Rules for Fiscal Subsidies of the Three-Year Action Plan for New Energy Vehicle Promotion and Application in Guangxi Zhuang Autonomous Region. fgw.gxzf.gov.cn. Available online: http://fgw.gxzf.gov.cn/zfxxgkzl/wjzx/zyzc/zdyj/t11266170.shtml (accessed on 2 April 2025).

- Department of Ecology and Environment of Guangxi Zhuang Autonomous Region. Announcement on Three Typical Cases of Failure to Fully Surrender Carbon Emission Allowances on Time. Available online: http://sthjt.gxzf.gov.cn/zfxxgk/zfxxgkgl/fdzdgknr/xzsysf/zfgs/t12906268.shtml (accessed on 2 April 2025).

- Fujian Provincial People’s Government. Fujian Province Provides Incentives and Subsidies to Enterprises for Recycling Waste Power Batteries from New Energy Vehicle. Available online: https://www.fujian.gov.cn/xwdt/fjyw/202404/t20240414_6428212.htm (accessed on 2 April 2025).

- Fujian Provincial People’s Government. Notice of Fujian Provincial People’s Government on Issuing the Implementation Plan for Energy Conservation and Emission Reduction During the 14th Five-Year Plan Period in Fujian Province. Available online: https://www.fujian.gov.cn/zwgk/zxwj/szfwj/202206/t20220617_5932061.htm (accessed on 2 April 2025).

- Chengdu Municipal People’s Government. Notice on Organizing Applications for 2024 Subsidy Projects Supporting the Recycling, Cascade Utilization, and Regeneration of Waste Power Batteries from New Energy Vehicles in Chengdu; Chengdu Municipal People’s Government: Chengdu, China, 2024.

- Chengdu Municipal People’s Government. Notice of Chengdu Municipal People’s Government on Issuing the Implementation Plan for Carbon Peaking in Chengdu. Available online: https://cds.sczwfw.gov.cn/art/2024/3/20/art_15398_252241.html?areaCode=510100000000 (accessed on 2 April 2025).

- Dong, H.; Hu, Q.; Li, D.; Li, Z. Predictive Battery Thermal and Energy Management for Connected and Automated Electric Vehicles. IEEE Trans. Intell. Transp. Syst. 2025, 26, 2144–2156. [Google Scholar] [CrossRef]

- Wang, C.; Yuan, Z.; Wang, Y.; Cao, W.; Jiang, F. Overview of Key Technologies for Cascade Utilization of Retired Power Batteries. Adv. New Renew Energy 2021, 9, 327–341. [Google Scholar]

- Kastanaki, E.; Giannis, A. Dynamic Estimation of End-of-Life Electric Vehicle Batteries in the EU-27 Considering Reuse, Remanufacturing and Recycling Options. J. Clean. Prod. 2023, 393, 136349. [Google Scholar] [CrossRef]

- Jena, K.K.; AlFantazi, A.; Mayyas, A.T. Comprehensive Review on Concept and Recycling Evolution of Lithium-Ion Batteries (LIBs). Energy Fuels 2021, 35, 18257–18284. [Google Scholar] [CrossRef]

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. A Critical Review and Analysis on the Recycling of Spent Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2018, 6, 1504–1521. [Google Scholar] [CrossRef]

- Zhou, Z.; Yang, B.; Xu, B.; Zhu, X. Optimization Design of End-of-Life Vehicle Reverse Logistics Network Under Government Guidance. Mod. Manuf. Eng. 2015, 12, 113–120, 125. [Google Scholar] [CrossRef]

- Liu, B.; Peng, J. Uncertainty Theory Tutorial; Tsinghua University Press: Beijing, China, 2025. [Google Scholar]

- Jimenez, M.; Arenas, M.; Bilbao, A.; Rodriguez, M.V. Linear Programming with Fuzzy Parameters: An Interactive Method Resolution. Eur. J. Oper. Res. 2007, 177, 1599–1609. [Google Scholar] [CrossRef]

- Kumar, P. Analyzing Challenges for Sustainable Supply Chain of Electric Vehicle Batteries Using a Hybrid Approach of Delphi and Best-Worst Method. Resour. Conserv. Recycl. 2021, 175, 105879. [Google Scholar] [CrossRef]

- Wenzhu Liao, G.H.; Luo, X. Collaborative Reverse Logistics Network for Electric Vehicle Batteries Management from Sustainable Perspective. J. Environ. Manag. 2022, 324, 116352. [Google Scholar] [CrossRef] [PubMed]

- Hendrickson, T.P.; Kavvada, O.; Shah, N.; Sathre, R.; Scown, C.D. Life-Cycle Implications and Supply Chain Logistics of Electric Vehicle Battery Recycling in California. Environ. Res. Lett. 2015, 10, 014011. [Google Scholar] [CrossRef]

- Selim, H.; Ozkarahan, I. A Supply Chain Distribution Network Design Model: An Interactive Fuzzy Goal Programming-Based Solution Approach. Int. J. Adv. Manuf. Technol. 2008, 36, 401–418. [Google Scholar] [CrossRef]

| Region | Subsidy Policy | Penalty Policy |

|---|---|---|

| Shanghai City | A subsidy of RMB 1000 is granted for each set of electric vehicle batteries recycled [23]. | A comprehensive carbon emission allowance management system has been established, synchronized with the dual-control mechanism governing total emission volumes and intensity thresholds [24]. |

| Hefei City | Battery and vehicle manufacturers receive capacity-based incentives of RMB 10/kWh for establishing functional recycling systems for end-of-life power batteries [25]. | Sector-specific decarbonization measures are enforced, including green transformation initiatives for key industries, the implementation of energy-efficient building standards, and emission reduction protocols for transportation systems [26]. |

| Guangxi Zhuang Autonomous Region | The subsidy framework combines operational support (RMB 20/kWh based on actual battery recovery volumes) with capital subsidies covering up to 30% of recycling facility construction costs [27]. | Regulatory authorities impose fines ranging from RMB 20,000 to 30,000 on entities failing to meet carbon quota obligations, accompanied by mandatory corrective orders issued through municipal-level ecological environment departments [28]. |

| Fujian Province | Enterprises meeting industry standards qualify for a one-time RMB 200,000 reward, while large-scale recycling operations processing ≥10,000 tons annually (or achieving ≥5000 tons/750,000 kWh in renewable utilization) receive tiered subsidies up to RMB 10 million (calculated at RMB 1000/ton or RMB 6.6/kWh) [29]. | Enhanced enforcement mechanisms combine the strict implementation of energy conservation laws with upgraded industrial emission controls, including the intensified monitoring of production processes and the systematic reinforcement of energy efficiency targets [30]. |

| Chengdu City | Recycling enterprises receive a weight-based compensation of RMB 500/metric ton for processed batteries, subject to an annual cap of RMB 1 million per entity [31]. | The implementation of industrial carbon reduction and supply chain enhancement initiatives, and the establishment of incentive mechanisms for emissions reduction [32]. |

| Technology | Advantage | Disadvantage |

|---|---|---|

| Hydrometallurgy [36] | Low carbon emissions, low environmental pressure | Complex process, high costs |

| Pyrometallurgy [37] | Simple process, low costs | High carbon emissions, high environmental pressure |

| Studies | Multiple Recycling Technologies | Policy Consideration | Battery Type | Fuzzy Parameters | Objective | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Yes | No | Single | Multi | Quantity | Quality | Single | Multi | |||

| Subsidy Policies | Penalty Policies | |||||||||

| Wang [11] | √ | √ | √ | |||||||

| Rosenberg [12] | √ | √ | √ | |||||||

| Mu [13] | √ | √ | √ | |||||||

| Saeedi [14] | √ | √ | √ | |||||||

| Kamyabi [15] | √ | √ | √ | |||||||

| Lin [16] | √ | √ | √ | √ | √ | |||||

| Hao [17] | √ | √ | √ | |||||||

| Yang [18] | √ | √ | √ | |||||||

| Tosarkani [19] | √ | √ | √ | |||||||

| Saha [20] | √ | √ | √ | √ | ||||||

| He [21] | √ | √ | √ | √ | √ | |||||

| Wang [22] | √ | √ | √ | |||||||

| This study | √ | √ | √ | √ | √ | √ | √ | |||

| Year | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 |

| Sales volume | 552 | 921 | 1326 | 3350 | 16,785 | 36,009 | 19,614 | 29,548 | 77,968 | 109,207 | 183,896 | 278,523 |

| RTCs | ||

|---|---|---|

| 1 | (392.76, 436.4, 480.04) | (419.58, 466.2, 512.82) |

| 2 | (450.81, 500.9, 550.99) | (481.59, 535.1, 588.61) |

| 3 | (1597.68, 1775.2, 1952.72) | (1706.67, 1896.3, 2085.03) |

| 4 | (181.26, 201.4, 221.54) | (193.68, 215.2, 236.72) |

| Parameters | Distribution Function/Value | Parameters | Distribution Function/Value | Parameters | Distribution Function/Value |

|---|---|---|---|---|---|

| U(4,000,000, 6,000,000) | U(1000, 5000) | U(500, 2000) | |||

| U(4,000,000, 7,000,000) | U(1000, 5000) | U(500, 2000) | |||

| U(5000000, 700,000) | U(2000, 6000) | U(500, 2000) | |||

| U(5,000,000, 7,000,000) | U(2000, 6000) | U(500, 2000) | |||

| U(500, 2000) | U(2500, 6000) | U(10, 30) | |||

| U(500, 2000) | U(2500, 6000) | U(10, 30) | |||

| U(500, 2000) | U(0, 100) | U(10, 30) | |||

| U(1000, 2500) | U(0, 100) | U(10, 30) | |||

| U(1000, 6000) | U(0, 100) | U(0.1, 0.7) | |||

| U(500, 2000) | U(10, 200) | U(0.1, 0.7) |

| Cost | Carbon Emissions | RTCs | RCs | ESCs | RRUCs | Technology | |

|---|---|---|---|---|---|---|---|

| Cost of single- objective model | 94,184,340 | 879,949.4 | 1, 2 | 1 | 1, 2 | 1, 2 | 1, 1 |

| Controlled quantity of carbon emissions in single-objective model | 103,225,500 | 647,462.7 | 3, 4 | 3 | 2, 3 | 1, 2 | 2, 2 |

| Multi-objective model | 97,767,470 | 700,579.5 | 1, 4 | 1 | 1, 3 | 1, 2 | 2, 1 |

| Cost | Carbon Emissions | RTCs | RCs | ESCs | RRUCs | Technology | |

|---|---|---|---|---|---|---|---|

| 0 | 97,767,470 | 700,579.5 | 1, 4 | 1 | 1, 3 | 1, 2 | 2, 1 |

| 10% | 103,159,000 | 780,503.7 | 2, 4 | 1 | 1, 3 | 1, 2 | 1, 2 |

| 20% | 112,012,600 | 911,751.3 | 1, 2, 4 | 1, | 1, 3 | 1, 2 | 1, 2 |

| 30% | 118,661,400 | 987,876.7 | 1, 2, 4 | 2 | 1, 3 | 1, 2 | 1, 2 |

| 40% | 123,129,300 | 1,054,716 | 1, 2, 4 | 2 | 1, 3 | 1, 2 | 1, 2 |

| Cost | Carbon Emissions | RTCs | RCs | ESCs | RRUCs | Technology | |

|---|---|---|---|---|---|---|---|

| −20% | 100,767,503 | 765,490.6 | 1, 2, 4 | 1 | 1, 2 | 1, 2 | 2, 1 |

| −10% | 98,467,509 | 723,424 | 1, 2, 4 | 1 | 1, 2 | 1, 2 | 2, 1 |

| 0 | 97,767,502 | 700,579.5 | 1, 2, 4 | 1 | 1, 3 | 1, 2 | 2, 1 |

| 10% | 97,567,509 | 656,834 | 1, 2, 4 | 2 | 1, 3 | 1, 2 | 2, 1 |

| 20% | 95,767,499 | 606,453.7 | 1, 2, 4 | 2 | 2, 3 | 1, 2 | 2, 1 |

| The Proposed Method | LP-Metric Method | |||||

| DI | DI | |||||

| 1 | 98,747,390 | 955,749.3 | 0.03 | 98,747,390 | 955,749.3 | 0.03 |

| 0.9 | 98,751,470 | 951,750.6 | 0.03 | 100,124,600 | 836,851.6 | 0.15 |

| 0.8 | 98,765,830 | 950,141.7 | 0.03 | 101,015,200 | 802,361.6 | 0.25 |

| 0.7 | 100,124,600 | 836,851.6 | 0.15 | 102,770,200 | 753,735.7 | 0.44 |

| 0.6 | 100,315,400 | 827,781.2 | 0.17 | 104,600,800 | 730,693 | 0.64 |

| 0.5 | 102,770,200 | 753,735.7 | 0.44 | 104,600,800 | 730,693 | 0.64 |

| 0.4 | 102,770,200 | 753,735.7 | 0.44 | 105,506,800 | 724,659.5 | 0.74 |

| 0.3 | 104,600,800 | 730,693 | 0.64 | 107,487,500 | 715,249.5 | 0.95 |

| 0.2 | 104,600,800 | 730,693 | 0.64 | 107,906,800 | 711,726 | 0.97 |

| 0.1 | 107,487,500 | 715,249.5 | 0.95 | 107,906,800 | 711,726 | 0.97 |

| 0 | 107,906,800 | 711,726 | 0.97 | 107,906,800 | 711,726 | 0.97 |

| average | / | / | 0.41 | / | / | 0.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Li, X.; Gao, Q.; Li, S. Optimizing Reverse Logistics Network for Waste Electric Vehicle Batteries: The Impact Analysis of Chinese Government Subsidies and Penalties. Sustainability 2025, 17, 3885. https://doi.org/10.3390/su17093885

Fan Z, Li X, Gao Q, Li S. Optimizing Reverse Logistics Network for Waste Electric Vehicle Batteries: The Impact Analysis of Chinese Government Subsidies and Penalties. Sustainability. 2025; 17(9):3885. https://doi.org/10.3390/su17093885

Chicago/Turabian StyleFan, Zhiqiang, Xiaoxiao Li, Qing Gao, and Shanshan Li. 2025. "Optimizing Reverse Logistics Network for Waste Electric Vehicle Batteries: The Impact Analysis of Chinese Government Subsidies and Penalties" Sustainability 17, no. 9: 3885. https://doi.org/10.3390/su17093885

APA StyleFan, Z., Li, X., Gao, Q., & Li, S. (2025). Optimizing Reverse Logistics Network for Waste Electric Vehicle Batteries: The Impact Analysis of Chinese Government Subsidies and Penalties. Sustainability, 17(9), 3885. https://doi.org/10.3390/su17093885