Comparative Life Cycle Assessment (LCA) of Packaging Materials for Tomato-Based Products to Pave the Way for Increasing Tomato Processing Industry Sustainability

Abstract

1. Introduction

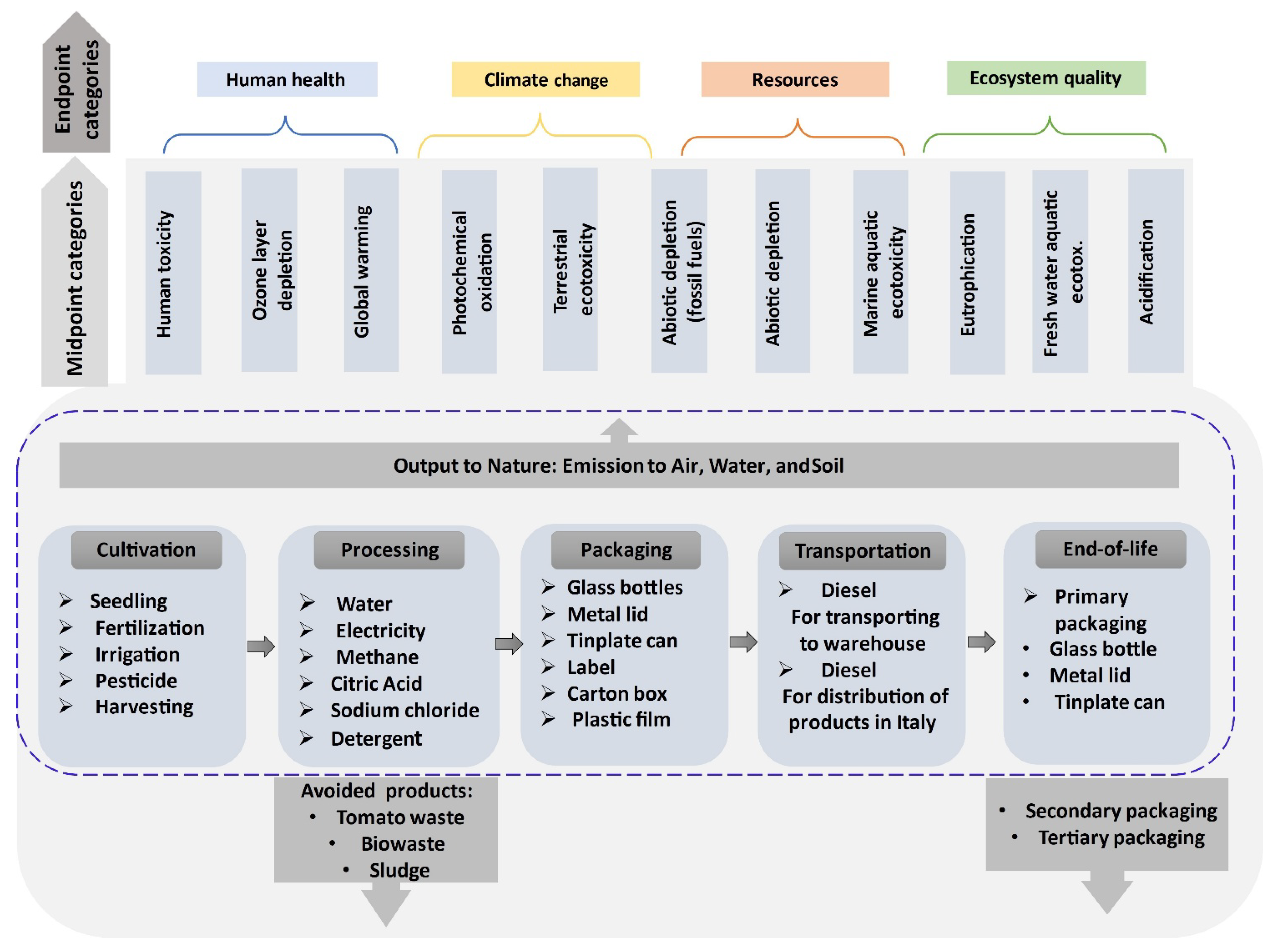

2. Materials and Methods

2.1. Description of Tomato Puree and Peeled Tomato Production Processes

2.1.1. Tomato Puree Production

Preliminary Stage (Receiving, Washing, and Sorting)

Processing Stage (Chopping, Hot Break, Juice Extraction, Evaporation, and Pasteurization)

Packaging Stage (Primary, Secondary, and Tertiary Packaging)

2.1.2. Peeled Tomato Production Line

2.2. Life Cycle Assessment Methodology

2.2.1. Definition of the Goal and Scope of the Study

Functional Unit

System Boundaries and Key Assumptions

2.2.2. Data Collection and Life Cycle Inventory

2.2.3. Impact Assessment

3. Results and Discussion

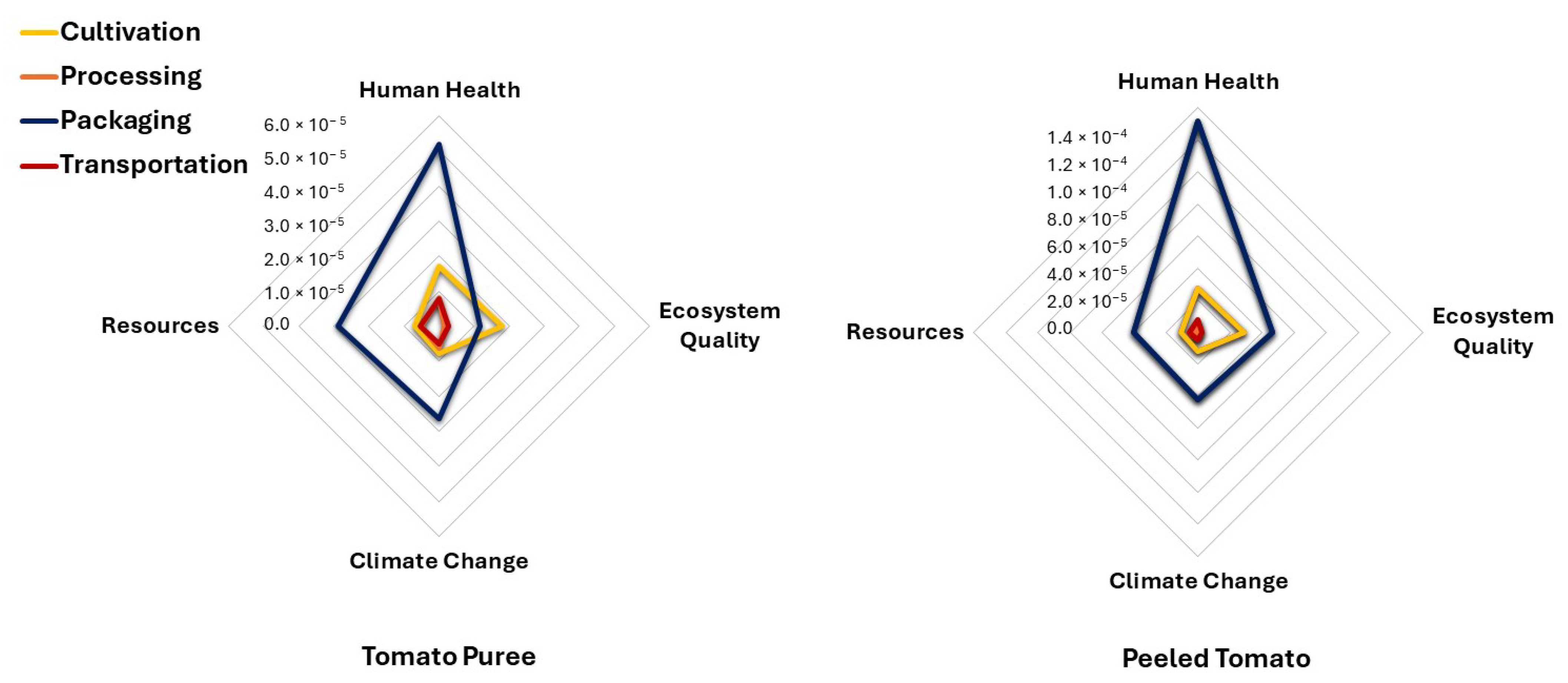

3.1. Contribution at the Midpoint Level: From Cultivation to Transportation

3.2. Endpoint Level Contribution with Value Normalization

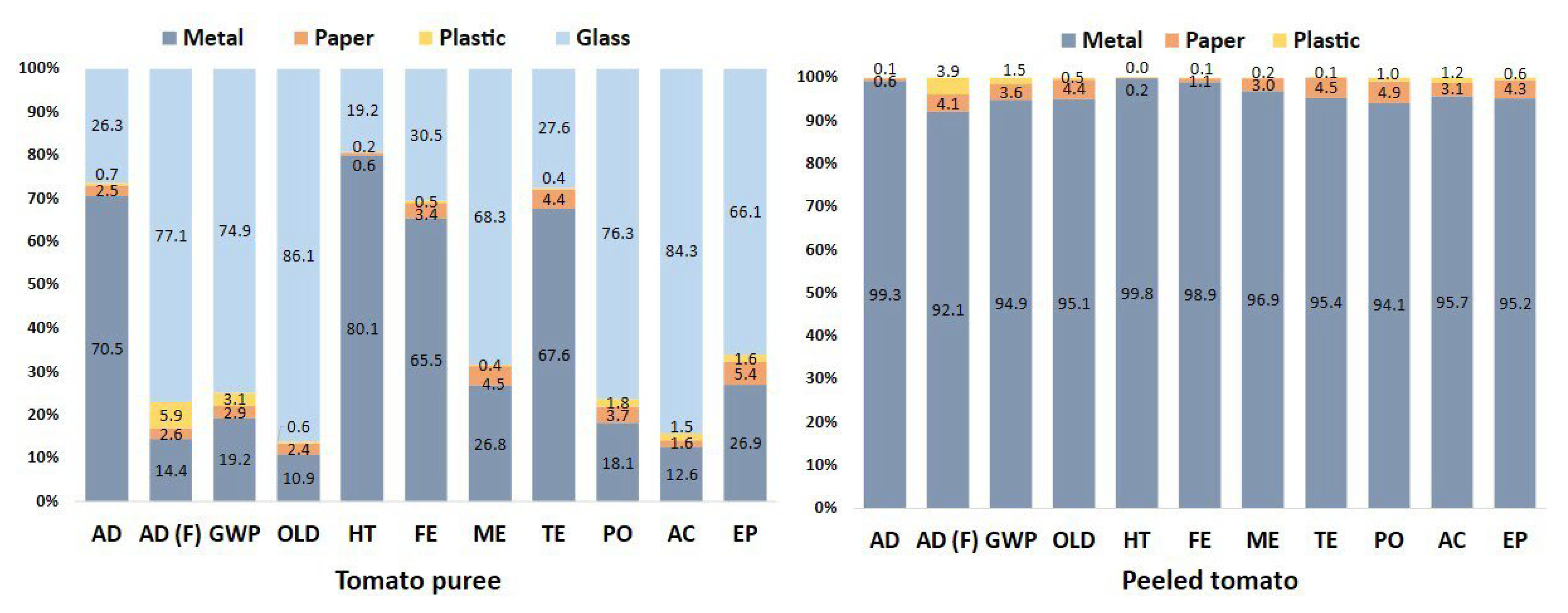

3.3. Contribution of the Packaging Phase to Environmental Impact at the Midpoint Level

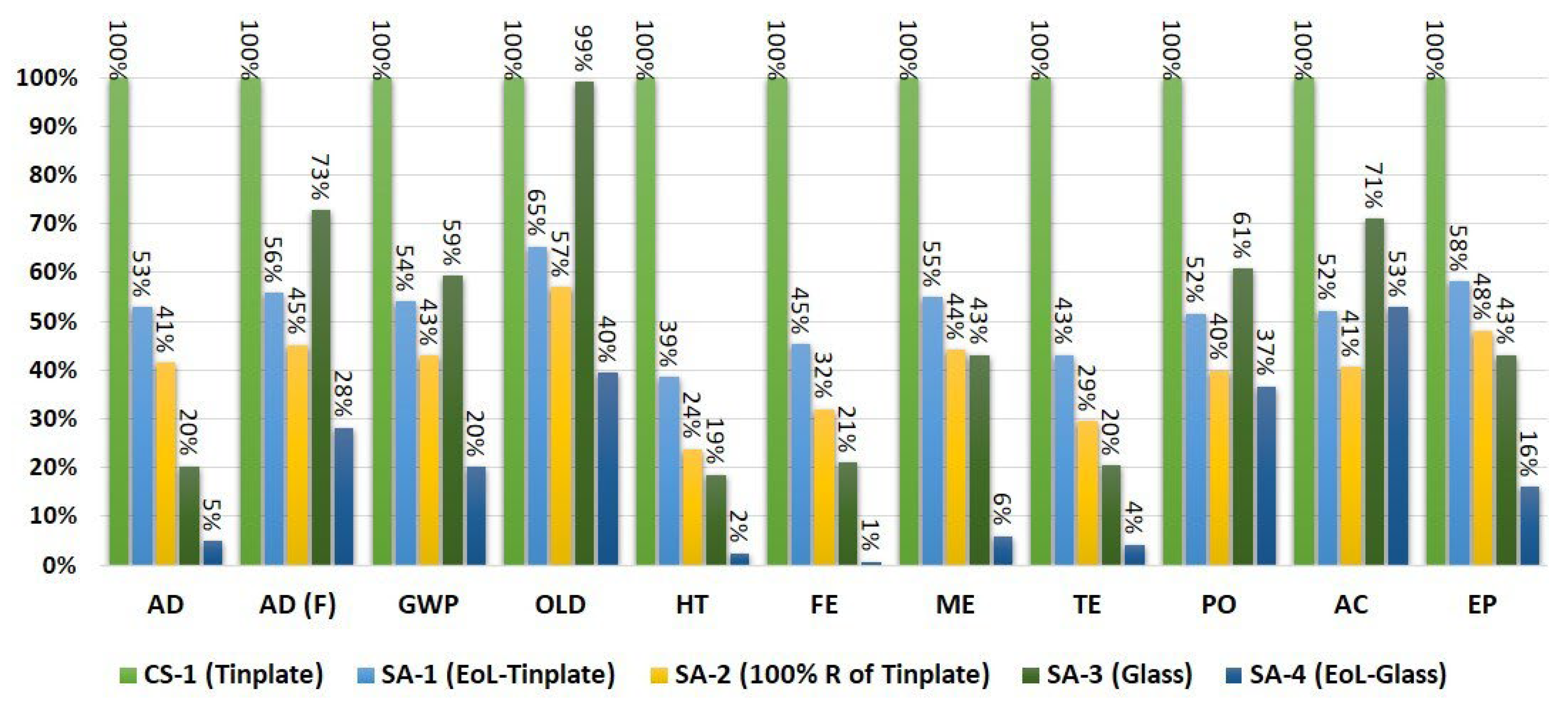

3.4. Development Scenarios and Sensitivity Analysis to Mitigate the Environmental Impact of the Packaging Phase in Tomato Processing

- CS-1: Baseline scenario reflecting the current state of the primary packaging stage for peeled tomatoes with tinplate cans.

- SA-1: EoL scenario of tinplate packaging (current situation in Italy).

- SA-2: EoL scenario of tinplate packaging (100% recycling).

- SA-3: Replacement of tinplate packaging with glass packaging.

- SA-4: EoL scenario of glass packaging (current situation in Italy).

- CS-2: Baseline scenario reflecting the current state of the primary packaging stage for tomato puree with glass bottles.

- SA-5: EoL scenario of glass packaging (current situation in Italy).

- SA-6: EoL scenario of glass packaging (100% recycling).

- SA-7: Replacement of glass bottles with flexible pouch packaging.

- SA-8: Replacement of glass bottles with cardboard containers.

- SA-9: EoL scenario of glass packaging in Switzerland, which is the country with the lowest environmental impact in glass production.

Sensitivity Analysis to Identify Potentials for Improvement

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sala, S.; Anton, A.; McLaren, S.J.; Notarnicola, B.; Saouter, E.; Sonesson, U. In quest of reducing the environmental impacts of food production and consumption. J. Clean. Prod. 2017, 140, 387–398. [Google Scholar] [CrossRef]

- United Nations. The Sustainable Development Agenda—United Nations Sustainable Development. 2015. Available online: https://www.un.org/sustainabledevelopment/development-agenda/ (accessed on 12 July 2023).

- Kucukvar, M.; Onat, N.C.; Abdella, G.M.; Tatari, O. Assessing regional and global environmental footprints and value added of the largest food producers in the world. Resour. Conserv. Recycl. 2019, 144, 187–197. [Google Scholar] [CrossRef]

- Filho, W.L.; Setti, A.F.F.; Azeiteiro, U.M.; Lokupitiya, E.; Donkor, F.K.; Etim, N.A.N.A.; Matandirotya, N.; Olooto, F.M.; Sharifi, A.; Nagy, G.J.; et al. An overview of the interactions between food production and climate change. Sci. Total Environ. 2022, 838, 156. [Google Scholar] [CrossRef] [PubMed]

- Waheed, A.; Zhang, Q.; Rashid, Y.; Tahir, M.S.; Zafar, M.W. Impact of green manufacturing on consumer ecological behavior: Stakeholder engagement through green production and innovation. Sustain. Dev. 2020, 28, 1395–1403. [Google Scholar] [CrossRef]

- Ghnimi, S.; Nikkhah, A.; Dewulf, J.; Van Haute, S. Life cycle assessment and energy comparison of aseptic ohmic heating and appertization of chopped tomatoes with juice. Nat. Publ. Group UK 2021, 11, 13041. [Google Scholar] [CrossRef]

- Del Borghi, A.; Moreschi, L.; Gallo, M. Life cycle assessment in the food industry. In The Interaction of Food Industry and Environment; Galanakis, C., Ed.; Elsevier: London, UK, 2022; pp. 63–118. [Google Scholar] [CrossRef]

- Amienyo, D.; Gujba, H.; Stichnothe, H.; Azapagic, A. Life cycle environmental impacts of carbonated soft drinks. Int. J. Life Cycle Assess. 2013, 18, 77–92. [Google Scholar] [CrossRef]

- Del Borghi, A.; Gallo, M.; Strazza, C.; Del Borghi, M. An evaluation of environmental sustainability in the food industry through Life Cycle Assessment: The case study of tomato products supply chain. J. Clean. Prod. 2014, 78, 121–130. [Google Scholar] [CrossRef]

- Del Borghi, A.; Strazza, C.; Magrassi, F.; Taramasso, A.C.; Gallo, M. Life Cycle Assessment for eco-design of product–package systems in the food industry—The case of legumes. Sustain. Prod. Consum. 2018, 13, 24–36. [Google Scholar] [CrossRef]

- Amienyo, D.; Azapagic, A. Life cycle environmental impacts and costs of beer production and consumption in the UK. Int. J. Life Cycle Assess. 2016, 21, 492–509. [Google Scholar] [CrossRef]

- The Tomato News Conference. Lighter and More Long-Lasting: The Challenges of Packaging. 2024. Available online: https://www.tomatonews.com/en/lighter-and-more-long-lasting-the-challenges-of-packaging_2_206.html (accessed on 26 March 2025).

- Marsh, K.; Bugusu, B. Food Packaging—Roles, Materials, and Environmental Issues. J. Food Sci. 2007, 72, 39–55. [Google Scholar] [CrossRef]

- Dauthy, M.E. Packaging Materials; Chapter 7 in Fruit and Vegetable Processing; Food and Agriculture Organization of the United Nations: Rome, Italy, 1995; ISBN 92-5-103657-8. [Google Scholar]

- Manfredi, M.; Vignali, G. Life cycle assessment of a packaged tomato puree: A comparison of environmental impacts produced by different life cycle phases. J. Clean. Prod. 2014, 73, 275–284. [Google Scholar] [CrossRef]

- Brodt, S.; Kramer, K.J.; Kendall, A.; Feenstra, G. Comparing environmental impacts of regional and national-scale food supply chains: A case study of processed tomatoes. Food Policy 2013, 42, 106–114. [Google Scholar] [CrossRef]

- Winans, K.; Brodt, S.; Kendall, A. Life cycle assessment of California processing tomato: An evaluation of the effects of evolving practices and technologies over a 10-year (2005–2015) timeframe. Int. J. Life Cycle Assess. 2020, 25, 538–547. [Google Scholar] [CrossRef]

- Parajuli, R.; Matlock, M.D.; Thoma, G. Cradle to grave environmental impact evaluation of the consumption of potato and tomato products. Sci. Total Environ. 2021, 758, 143662. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Li, Y.; Liu, J.; Qi, G.; Liu, O.; Dong, L. Life cycle assessment of environmental impacts of cold and hot break tomato paste packaged in steel drums and exported from Xinjiang, China. Environ. Impact Assess. Rev. 2023, 98, 106939. [Google Scholar] [CrossRef]

- Wohner, B.; Helene, V.; Krenn, B.; Krauter, V.; Tacker, M. Science of the Total Environment Environmental and economic assessment of food-packaging systems with a focus on food waste. Case study on tomato ketchup. Sci. Total Environ. 2020, 738, 139846. [Google Scholar] [CrossRef]

- Vignali, G. Life-Cycle Assessment of Food-Packaging Systems. In Environmental Footprints and Eco-Design of Products and Processes; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–22. [Google Scholar] [CrossRef]

- FoodPrint. The Environmental Impact of Food Packaging. 2025. Available online: https://foodprint.org/issues/the-environmental-impact-of-food-packaging/ (accessed on 19 July 2023).

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The Next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef]

- Jiménez-González, C.; Kim, S.; Overcash, M.R. Methodology for Developing Gate-to-Gate Life Cycle Inventory Information. Int. J. Life Cycle Assess. 2000, 5, 153–159. [Google Scholar] [CrossRef]

- Shahvarooghi Farahani, S.; Soheilifard, F.; Ghasemi Nejad Raini, M.; Kokei, D. Comparison of different tomato puree production phases from an environmental point of view. Int. J. Life Cycle Assess. 2019, 24, 1817–1827. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management-Life Cycle Assessment-Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- European Court of Auditors. Special Report 12/2021: The Polluter Pays Principle: Inconsistent Application Across EU Environmental Policies and Actions. 2021. Available online: https://www.eca.europa.eu/en/publications?did=58811 (accessed on 15 November 2024).

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment: Theory and Practice; Spinger: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Eastern Research Group. Emission Factor Documentation for Ap-42 Section 1.4 Natural Gas Combustion; United States Environmental Protection Agency (EPA): Morrisville, NC, USA, 1998.

- Center of Environmental Science (CML). CML-IA Characterisation Factors. Leiden Univ. 2016. Available online: http://cml.leiden.edu/software/data-cmlia.html (accessed on 7 November 2024).

- Arnal, Á.J.; Royo, P.; Pataro, G.; Ferrari, G.; Ferreira, V.J.; López-Sabirón, A.M.; Ferreira, G.A. Implementation of PEF treatment at real-scale tomatoes processing considering LCA methodology as an innovation strategy in the agri-food sector. Sustainability 2018, 10, 979. [Google Scholar] [CrossRef]

- Bacenetti, J.; Negri, M.; Duca, D.; Fiala, M. Environmental impact of tomato purée: Anaerobic digestion of by-products as mitigation strategy. Procedia Environ. Sci. Eng. Manag. 2015, 2, 169–175. [Google Scholar]

- De Marco, I.; Riemma, S.; Iannone, R. Environmental analysis of a mashed tomato production: An Italian case study. Chem. Eng. Trans. 2017, 57, 1825–1830. [Google Scholar] [CrossRef]

- Aganovic, K.; Smetana, S.; Grauwet, T.; Toepfl, S.; Mathys, A.; Van Loey, A.; Heinz, V. Pilot scale thermal and alternative pasteurization of tomato and watermelon juice: An energy comparison and life cycle assessment. J. Clean. Prod. 2017, 141, 514–525. [Google Scholar] [CrossRef]

- Garofalo, P.; DAndrea, L.; Tomaiuolo, M.; Venezia, A.; Castrignan, A. Environmental sustainability of agri-food supply chains in Italy: The case of the whole-peeled tomato production under life cycle assessment methodology. J. Food. Eng. 2017, 200, 1–12. [Google Scholar] [CrossRef]

- De Marco IDe Riemma, S.; Iannone, R. Uncertainty of input parameters and sensitivity analysis in life cycle assessment: An Italian processed tomato product. J. Clean. Prod. 2018, 177, 315–325. [Google Scholar] [CrossRef]

- Ecoreactor. Packaging from Plastic, Aluminum or Glass—Which is Better? 2022. Available online: https://ecoreactor.org/en/packaging-from-plastic-aluminum-or-glass/ (accessed on 19 July 2023).

- Almeida, C.; Loubet, P.; da Costa, T.P.; Quinteiro, P.; Laso, J.; Baptista de Sousa, D.; Cooney, R.; Mellett, S.; Sonnemann, G.; Rodríguez, C.J.; et al. Packaging environmental impact on seafood supply chains: A review of life cycle assessment studies. J. Ind. Ecol. 2022, 26, 1961–1978. [Google Scholar] [CrossRef]

- Goel, V.; Sharma, A.; Nautiyal, H. Environmental Impacts of Packaging Materials. In Environmental Footprints of Packaging. Environmental Footprints and Eco-Design of Products and Processes; Muthu, S., Ed.; Springer: Singapore, 2016; pp. 115–137. [Google Scholar] [CrossRef]

- Lam, W.Y.; van Zelm, R.; Benítez-Loópez, A.; Kulak, M.; Sim, S.; King, J.H.; Huijbregts, M.A. Variability of Greenhouse Gas Footprints of Field Tomatoes Grown for Processing: Interyear and Intercountry Assessment. Environ. Sci. Technol. 2018, 52, 135–144. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Panjagari, N.R. Review on metal packaging: Materials, forms, food applications, safety and recyclability. J. Food Sci. Technol. 2020, 57, 2377–2392. [Google Scholar] [CrossRef]

- International Tin Association. Tinplate: Most Recycled Packaging in Germany. 2021. Available online: https://www.internationaltin.org/tinplate-most-recycled-packaging-in-germany/ (accessed on 14 July 2023).

- Glass Packaging Institute. Glass Container Recycling Loop. 2023. Available online: https://www.gpi.org/glass-recycling-facts (accessed on 14 July 2023).

- Ferrara, C.; De Feo, G. Comparative life cycle assessment of alternative systems for wine packaging in Italy. J. Clean. Prod. 2020, 259, 120888. [Google Scholar] [CrossRef]

- Walker, T.W.; Frelka, N.; Shen, Z.; Chew, A.K.; Banick, J.; Grey, S.; Kim, M.S.; Dumesic, J.A.; Van Lehn, R.C.; Huber, G.W. Recycling of multilayer plastic packaging materials by solvent-targeted recovery and precipitation. Sci. Adv. 2020, 6, eaba7599. [Google Scholar] [CrossRef] [PubMed]

- Barlow, C.Y.; Morgan, D.C. Polymer film packaging for food: An environmental assessment. Resour. Conserv. Recycl. 2013, 78, 74–80. [Google Scholar] [CrossRef]

- Hou, P.; Xu, Y.; Taiebat, M.; Lastoskie, C.; Miller, S.A.; Xu, M. Life cycle assessment of end-of-life treatments for plastic film waste. J. Clean. Prod. 2018, 201, 1052–1060. [Google Scholar] [CrossRef]

- Statista. EU-27: Packaging Recycling Rate Targets, 2030. 2025. Available online: https://www.statista.com/statistics/1316423/recycling-rate-targets-for-packaging-types-in-european-union/ (accessed on 14 July 2023).

- RicreaConsorzio. Raccolta e Riciclo Imballaggi Acciaio. 2022. Available online: https://www.consorzioricrea.org (accessed on 15 July 2023).

- Coreve. Tasso di Riciclo del Vetro Oltre l’80%, +4,2% Rispetto All’anno Scorso. 2023. Available online: https://coreve.it/tasso-di-riciclo-del-vetro-oltre-l80-42-rispetto-allanno-scorso/ (accessed on 15 July 2023).

- Etichetta-Conai. Polylaminate Archivi—Environmental Labelling for Packaging. 2021. Available online: https://www.etichetta-conai.com/en/faqs/categories/polylaminate/ (accessed on 30 July 2023).

- Flexible Packaging Europe (FPE). Comparative Life Cycle Assessment of Different Pouches and Alternative Packaging Systems for Food (Pasta Sauce and Olives) on the European Market. 2021. Available online: https://www.flexpack-europe.org/files/images_flexpack-europe/Inhaltsbilder/Sustainability/Food_Lifecycle_Studies/ifeu-study-2021-LCA-Pouches-Executive-summary-report.pdf (accessed on 23 July 2024).

- EURIC. Metal Recycling Factsheet—European Circular Economy Stakeholder Platform. 2019. Available online: https://circulareconomy.europa.eu/platform/en/knowledge/metal-recycling-factsheet-euric (accessed on 10 September 2024).

- Federation of European Manufacturers of Glass Containers (FEVE). Recycling: Why Glass Always Has a Happy CO2 Ending. 2010. Available online: https://feve.org/wp-content/uploads/2016/04/FEVE-brochure-Recycling-Why-glass-always-has-a-happy-CO2-ending-.pdf (accessed on 14 July 2024).

- Foodtimes. 8 out of 10 Consumers Choose Glass Packaging. Search InSites. 2022. Available online: https://www.foodtimes.eu/food-system-en/8-out-of-10-consumers-choose-glass-packaging-search-insites/ (accessed on 7 February 2025).

- Federation of European Manufacturers of Glass Containers (FEVE). Consumers Recognise Glass Packaging as Safe, Sustainable and Fit for the Future. 2022. Available online: https://feve.org/wp-content/uploads/2022/11/FEVE-InSites-Press-Release-2022-FINAL.pdf (accessed on 15 September 2024).

- SWI Swissinfo.ch. How Much Trash Is Tossed—And Recycled—In Switzerland? 2020. Available online: https://www.swissinfo.ch/eng/society/switzerland-recycling-statistics/45802874 (accessed on 13 September 2023).

| Product | Impact Category | Unit | Total | Cultivation | Processing | Packaging | Transportation |

|---|---|---|---|---|---|---|---|

| PT | AD | kg Sb eq | 1.26 × 10−5 | 1.441 × 10−6 | 7.82 × 10−8 | 1.10 × 10−5 | 1.387 × 10−7 |

| TP | 3.04 × 10−6 | 9.17 × 10−7 | 1.16 × 10−7 | 1.82 × 10−6 | 1.39 × 10−7 | ||

| PT | AD (FF) | MJ | 6.90 × 100 | 1.222 × 100 | 2.84 × 10−1 | 4.63 × 100 | 7.639 × 10−1 |

| TP | 5.66 × 100 | 7.77 × 10−1 | 5.54 × 10−1 | 3.51 × 100 | 7.64 × 10−1 | ||

| PT | GWP100a | kg CO2 eq | 6.66 × 10−1 | 1.311 × 10−1 | 4.54 × 10−2 | 4.40 × 10−1 | 4.976 × 10−2 |

| TP | 4.79 × 10−1 | 8.34 × 10−2 | 7.42 × 10−2 | 2.57 × 10−1 | 4.98 × 10−2 | ||

| PT | OLD | kg CFC-11 eq | 5.64 × 10−8 | 1.586 × 10−8 | 2.44 × 10−9 | 2.87 × 10−8 | 9.362 × 10−9 |

| TP | 5.48 × 10−8 | 1.01 × 10−8 | 5.11 × 10−9 | 2.99 × 10−8 | 9.36 × 10−9 | ||

| PT | HT | kg 1,4-DB eq | 5.20 × 100 | 6.348 × 10−2 | 1.12 × 10−2 | 5.11 × 100 | 1.651 × 10−2 |

| TP | 8.32 × 10−1 | 4.04 × 10−2 | 1.99 × 10−2 | 7.50 × 10−1 | 1.65 × 10−2 | ||

| PT | FE | kg 1,4-DB eq | 1.14 × 100 | 3.778 × 10−2 | 1.86 × 10−2 | 1.08 × 100 | 4.524 × 10−3 |

| TP | 2.76 × 10−1 | 2.40 × 10−2 | 3.37 × 10−2 | 1.92 × 10−1 | 4.52 × 10−3 | ||

| PT | ME | kg 1,4-DB eq | 1.67 × 103 | 1.148 × 102 | 4.67 × 101 | 1.49 × 103 | 1.329 × 101 |

| TP | 8.41 × 102 | 7.30 × 101 | 1.04 × 102 | 6.42 × 102 | 1.33 × 101 | ||

| PT | TE | kg 1,4-DB eq | 7.78 × 10−3 | 5.544 × 10−4 | 1.96 × 10−4 | 6.96 × 10−3 | 7.115 × 10−5 |

| TP | 1.87 × 10−3 | 3.53 × 10−4 | 2.78 × 10−4 | 1.16 × 10−3 | 7.11 × 10−5 | ||

| PT | PO | kg C2H4 eq | 1.86 × 10−4 | 3.304 × 10−5 | 8.23 × 10−6 | 1.36 × 10−4 | 9.111 × 10−6 |

| TP | 1.29 × 10−4 | 2.10 × 10−5 | 1.38 × 10−5 | 8.34 × 10−5 | 9.11 × 10−6 | ||

| PT | AC | kg SO2 eq | 3.72 × 10−3 | 8.579 × 10−4 | 3.83 × 10−4 | 2.23 × 10−3 | 2.521 × 10−4 |

| TP | 3.42 × 10−3 | 5.46 × 10−4 | 5.80 × 10−4 | 2.00 × 10−3 | 2.52 × 10−4 | ||

| PT | EP | kg PO4 eq | 1.79 × 10−3 | 6.711 × 10−4 | 1.96 × 10−4 | 8.59 × 10−4 | 6.055 × 10−5 |

| TP | 1.12 × 10−3 | 4.27 × 10−4 | 2.59 × 10−4 | 3.60 × 10−4 | 6.06 × 10−5 |

| Functional Unit | Country | Considering Phase | Methodology | Environmental Hotspots | CO2eq (kg) | R-Year |

|---|---|---|---|---|---|---|

| 1 kg of tomato paste and diced tomato in tinplate cans | USA | Cultivation Processing Packaging Transportation | Not available | Packaging processing | 1.46–1.65 Tomato paste 0.711–0.999 Tomato puree | [16] |

| 1 kg of chopped tomato, peeled tomato, and tomato purée in glass, carton-based and can packaging | Italy | Cultivation Processing Packaging | CML 2001 | Packaging agricultural | 0.97–1.55 | [9] |

| Tomato puree in glass jars (700 g) | Northern Italy | Cultivation Processing Packaging Transportation | CML 2001 and ReCiPe | Packaging agricultural | 0.674 | [15] |

| 1 kg of tomato puree Without packaging | Northern Italy | Processing Waste management | Recipe | Processing | 0.116 | [34] |

| Tomato puree in carton (500 g) | Italy | Processing Packaging Transportation | IMPACT 2002+ | Processing | 0.172 | [35] |

| 1 kg of tomato juice in plastic bottle | Germany | Cultivation Processing Packaging | IMPACT 2002+ | Packaging | 1.83 | [36] |

| Peeled tomato in tinplate (400 g) | Italy | Cultivation Processing Packaging Transportation End of life | ILCD 2011 | Waste treatment | 0.447 | [37] |

| Tomato puree in carton (500 g) | Italy | Cultivation Processing Packaging Transportation End of life | ReCiPe 2016 | Cultivation | 0.774 | [38] |

| 1 kg peeled tomato in tinplate can (without juice) | Italy | Processing | ReCiPe | Packaging | 1.50 | [33] |

| Tomato puree In tinplate with plastic cap (500 g) | Iran | Cultivation Processing Packaging Transportation | CML-IA baseline | Packaging | 0.338 | [25] |

| 1 kg tomato pasta sauce in glass and tin lid | USA | Cultivation Processing Packaging Transportation End of life | ReCiPe 2016 | Processing agriculture | 1.50 | [18] |

| 1 kg Diced tomato and tomato paste during (2005–2015) | USA | Cultivation Processing Transportation | CLM | Cultivation Processing | 0.213–0.157 Diced tomato 0.945–0.827 Tomato paste | [17] |

| 1 kg chopped tomatoes with juice in multi-layer plastic pouches, and tinplate can | Italy | Cultivation Processing Packaging | CML-IA baseline | Processing Appertization Ohmic heating | 2.52–4.38 | [6] |

| Tomato paste packaged in 220-L steel drums | China | Cultivation Processing Packaging Transport | CML 2002 and EI99 | Cultivation Processing | 490 for cold break, 516 for hot break | [19] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eslami, E.; Carpentieri, S.; Pataro, G.; Ferrari, G. Comparative Life Cycle Assessment (LCA) of Packaging Materials for Tomato-Based Products to Pave the Way for Increasing Tomato Processing Industry Sustainability. Sustainability 2025, 17, 3648. https://doi.org/10.3390/su17083648

Eslami E, Carpentieri S, Pataro G, Ferrari G. Comparative Life Cycle Assessment (LCA) of Packaging Materials for Tomato-Based Products to Pave the Way for Increasing Tomato Processing Industry Sustainability. Sustainability. 2025; 17(8):3648. https://doi.org/10.3390/su17083648

Chicago/Turabian StyleEslami, Elham, Serena Carpentieri, Gianpiero Pataro, and Giovanna Ferrari. 2025. "Comparative Life Cycle Assessment (LCA) of Packaging Materials for Tomato-Based Products to Pave the Way for Increasing Tomato Processing Industry Sustainability" Sustainability 17, no. 8: 3648. https://doi.org/10.3390/su17083648

APA StyleEslami, E., Carpentieri, S., Pataro, G., & Ferrari, G. (2025). Comparative Life Cycle Assessment (LCA) of Packaging Materials for Tomato-Based Products to Pave the Way for Increasing Tomato Processing Industry Sustainability. Sustainability, 17(8), 3648. https://doi.org/10.3390/su17083648