Sustainable Self-Compacting Concrete with Recycled Aggregates, Ground Granulated Blast Slag, and Limestone Filler: A Technical and Environmental Assessment

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

2.1.1. Cement

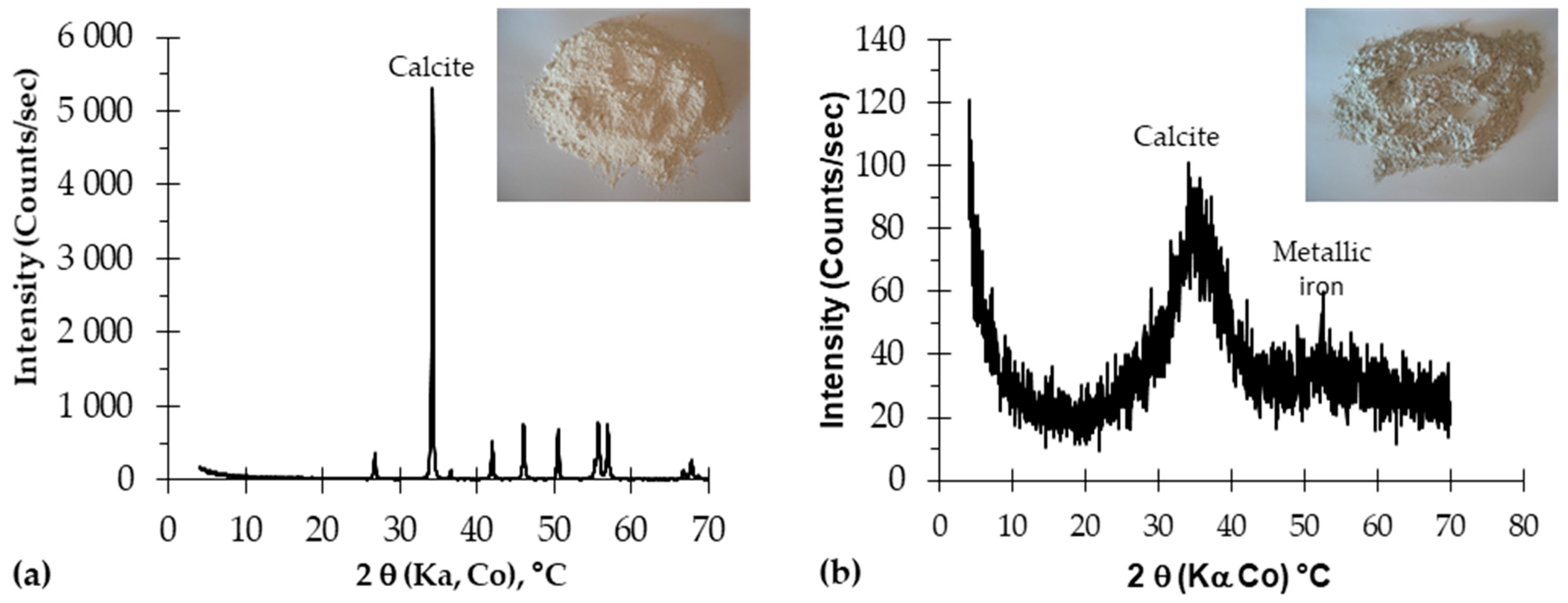

2.1.2. Mineral Admixtures

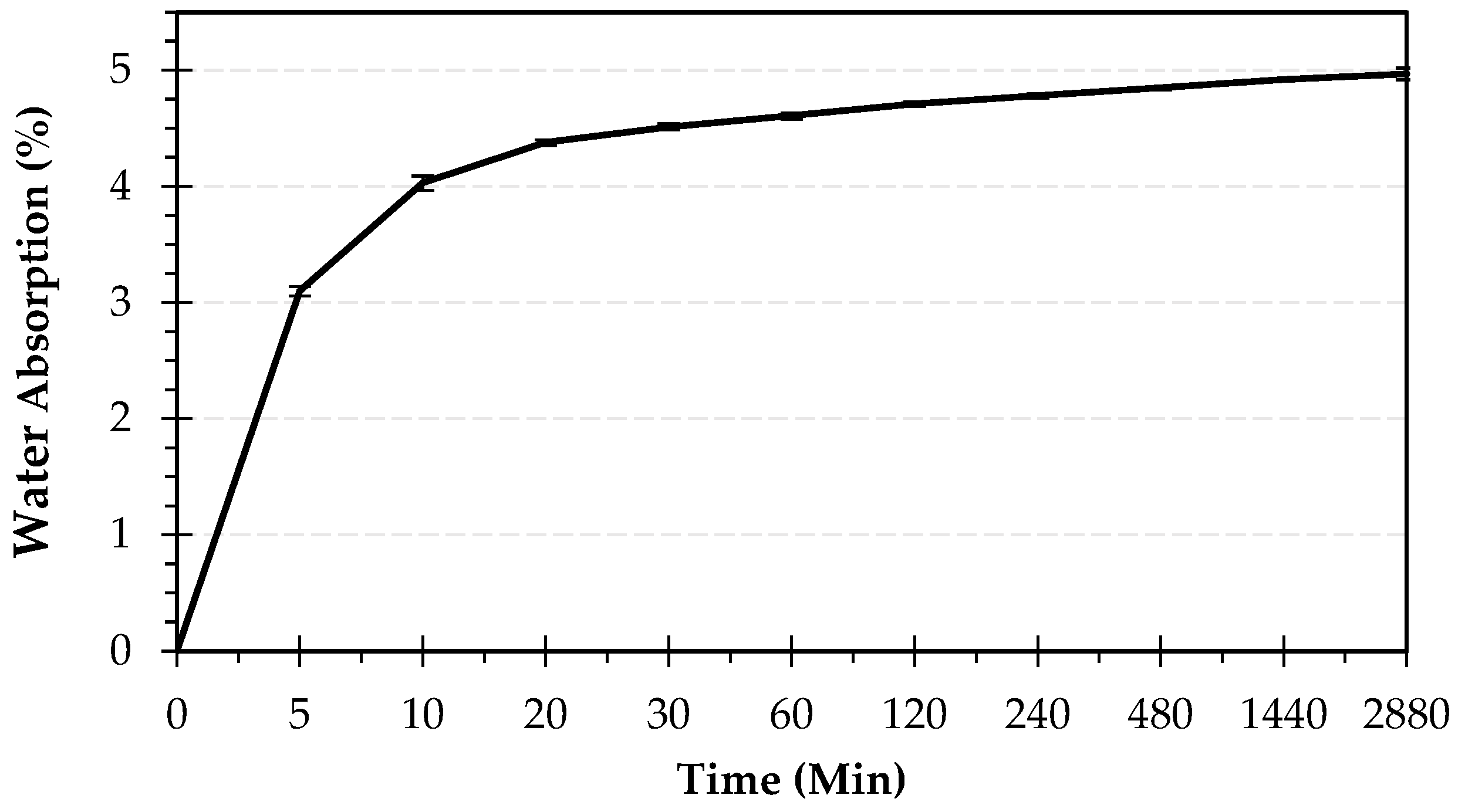

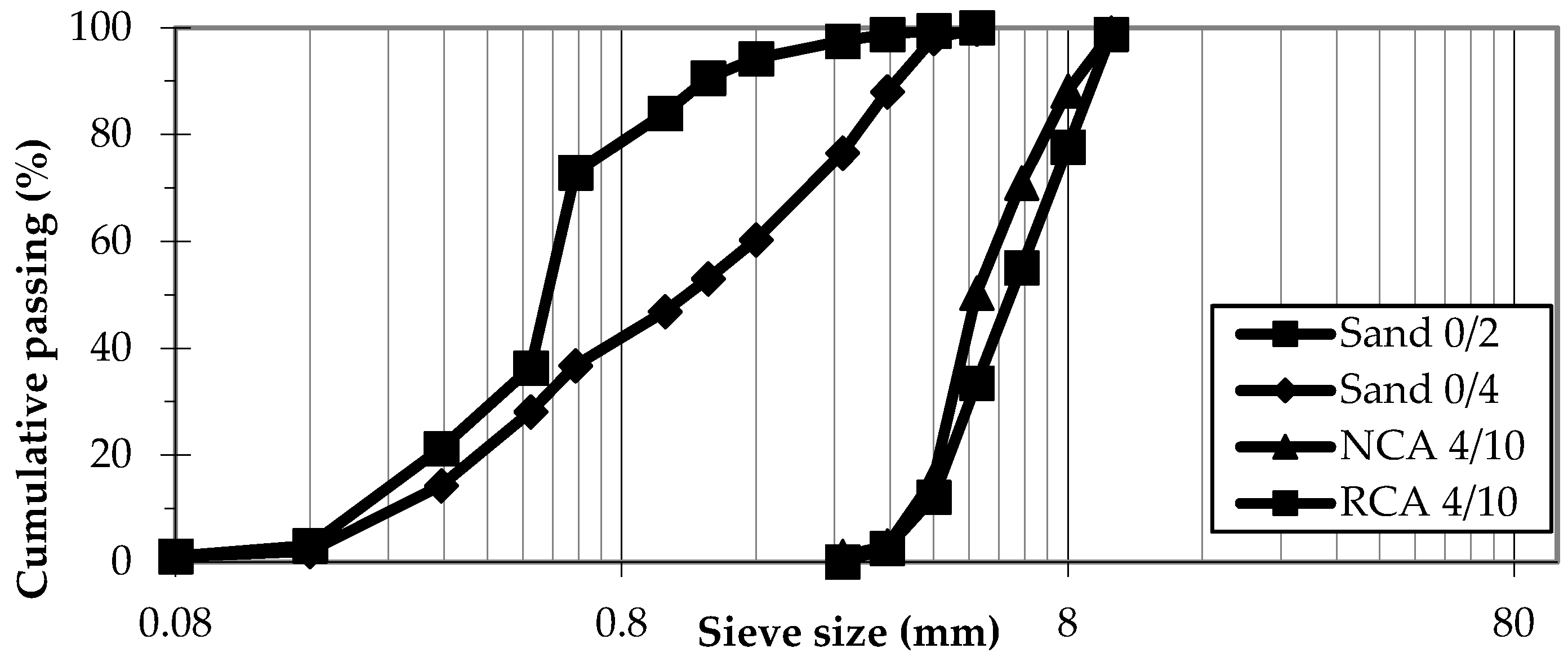

2.1.3. Aggregates

2.1.4. Chemical Admixture

2.2. Mixture Design

2.3. Test Methods

2.3.1. SCC Fresh-State Properties

2.3.2. Hardened-State Properties of SCC

3. Results

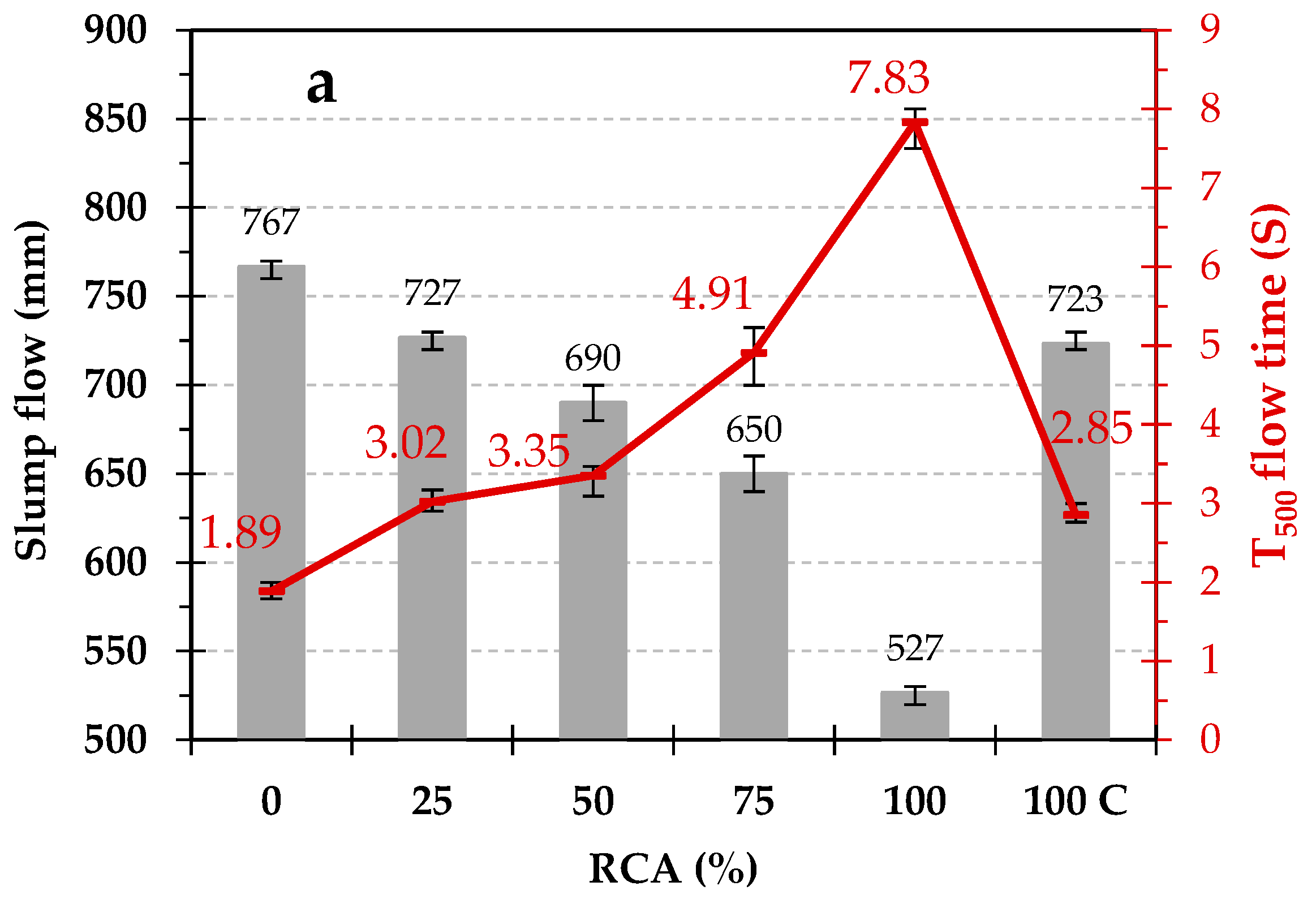

3.1. Fresh Properties of SCC

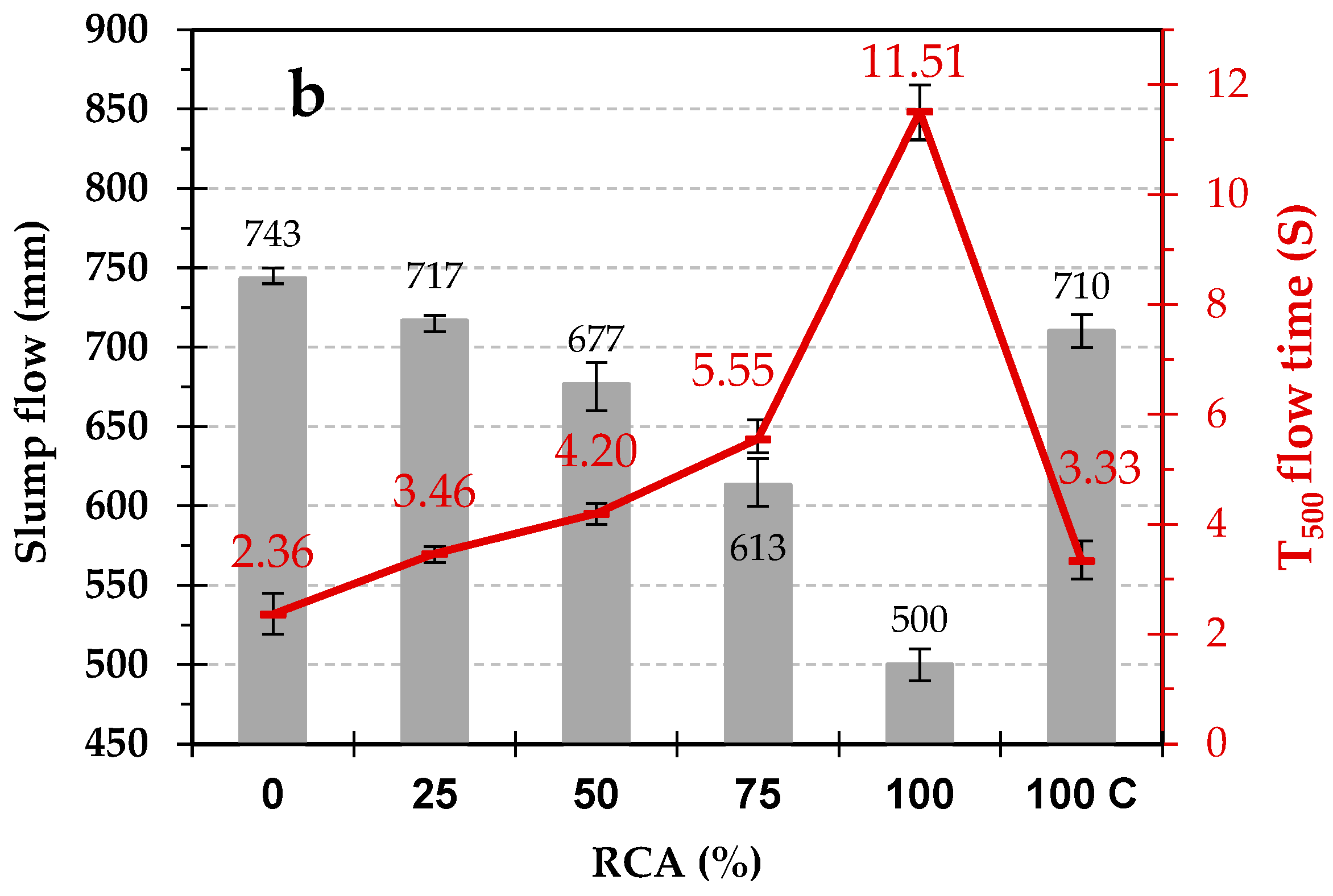

3.1.1. Slump Flow Test and Slump Flow Time

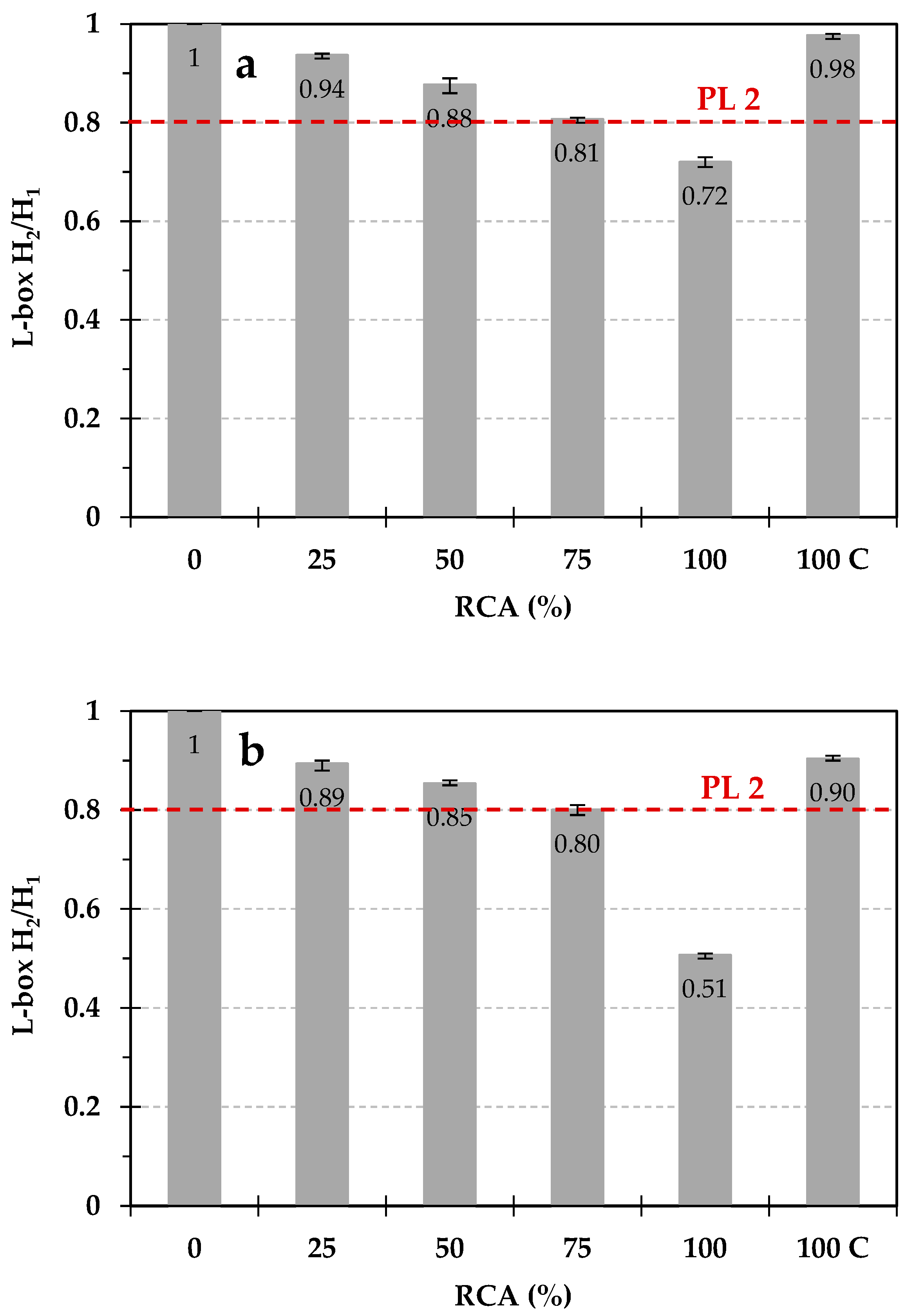

3.1.2. L-Box Test

3.1.3. Sieve Segregation Test

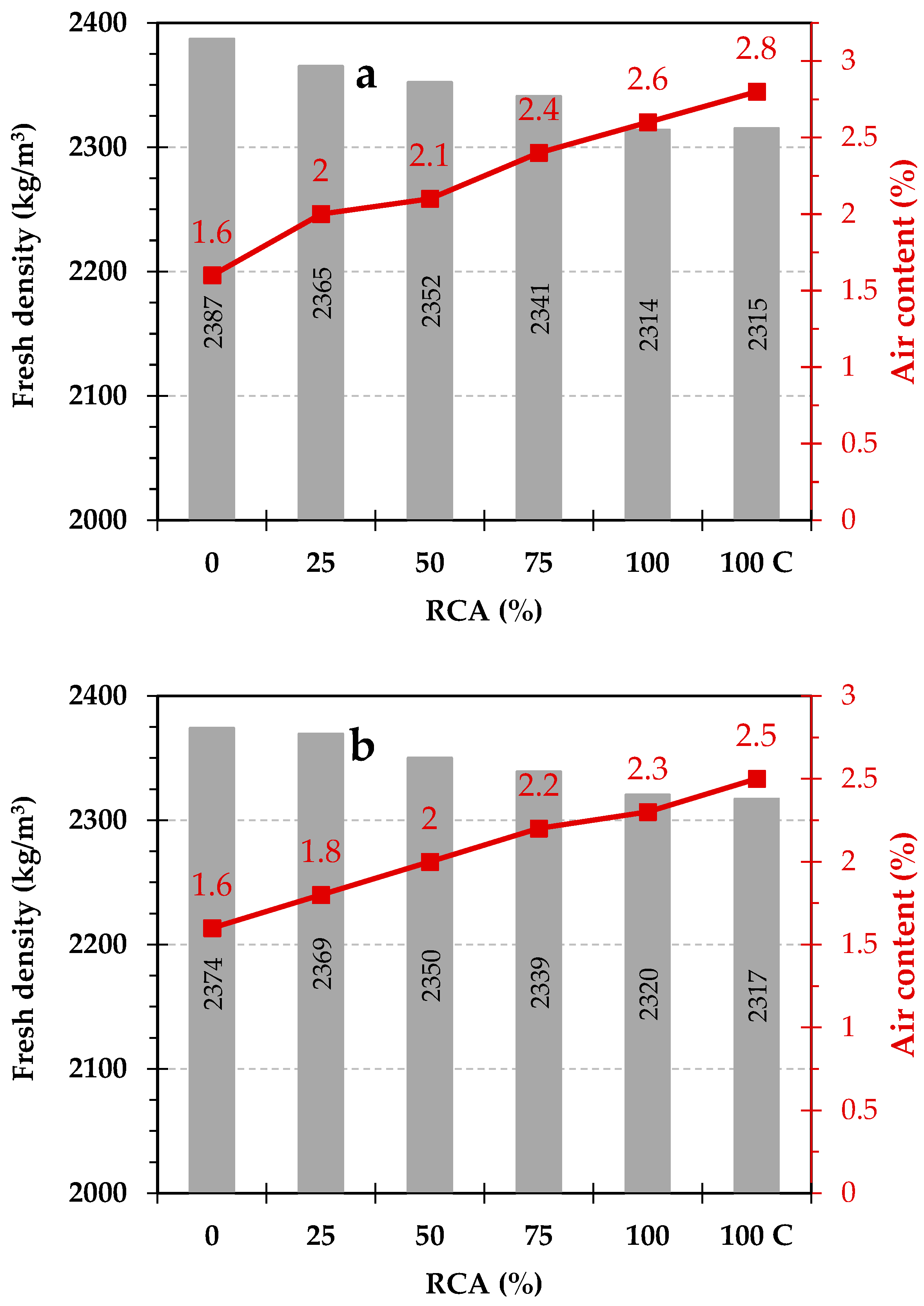

3.1.4. Fresh Density and Air Content

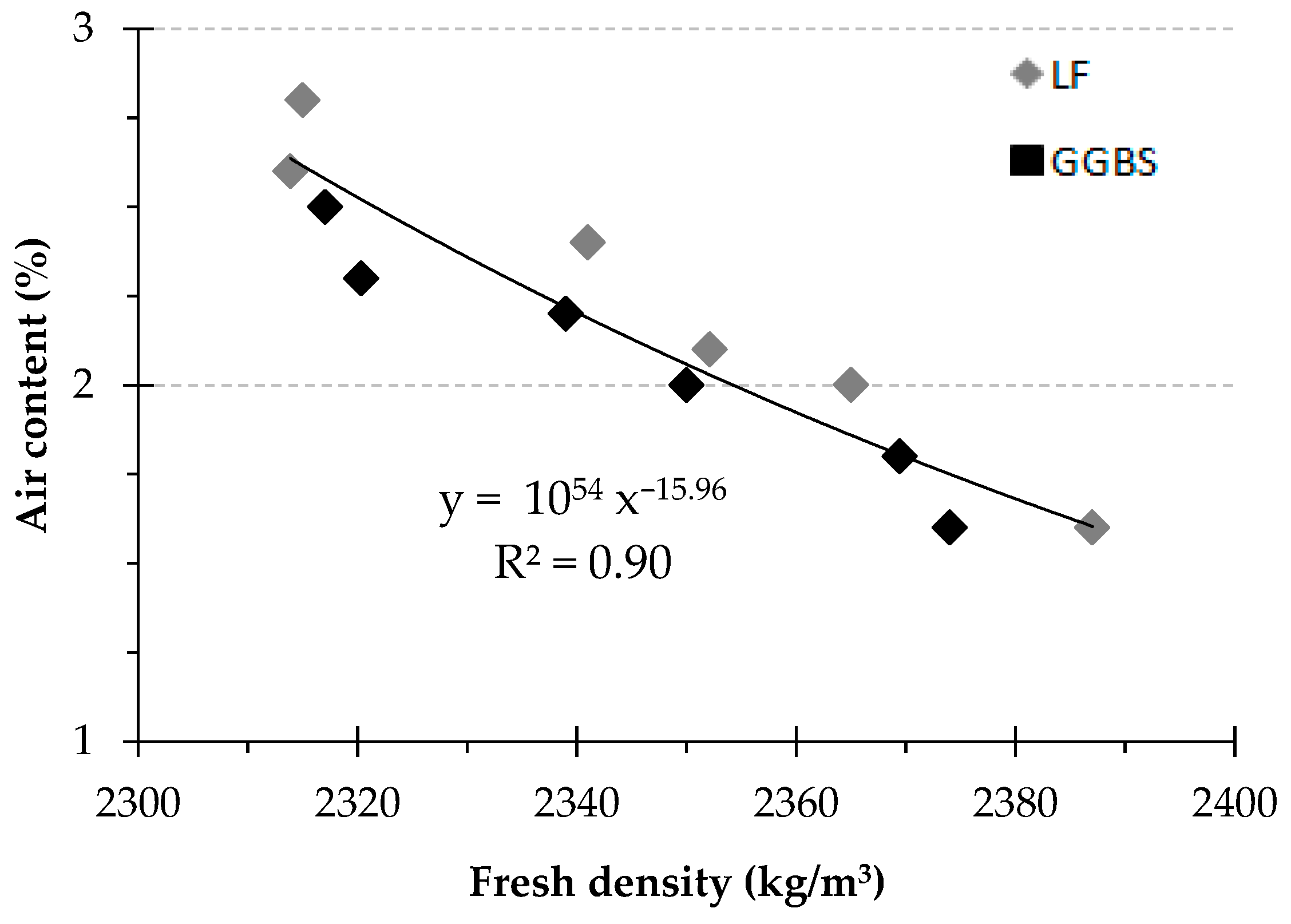

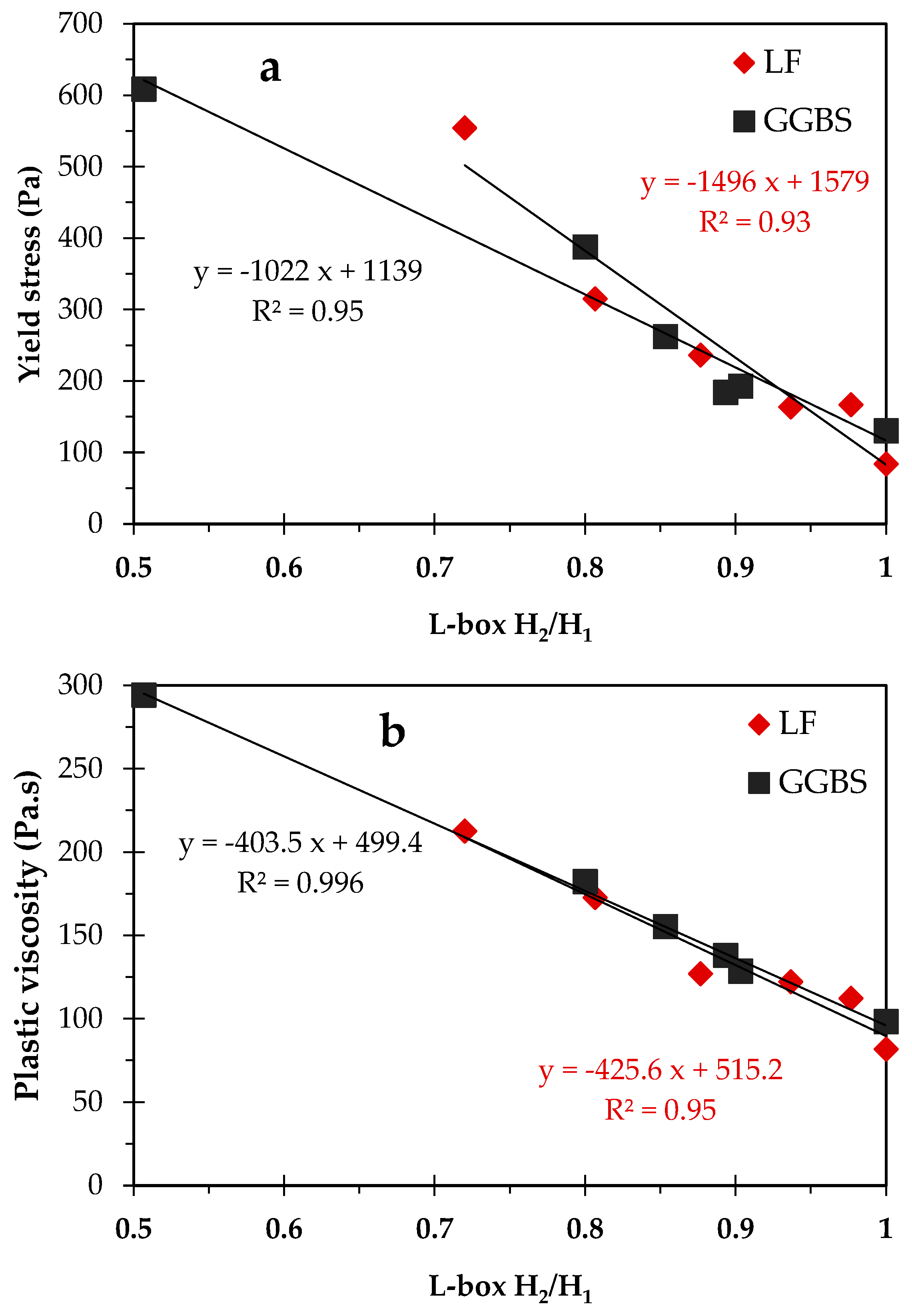

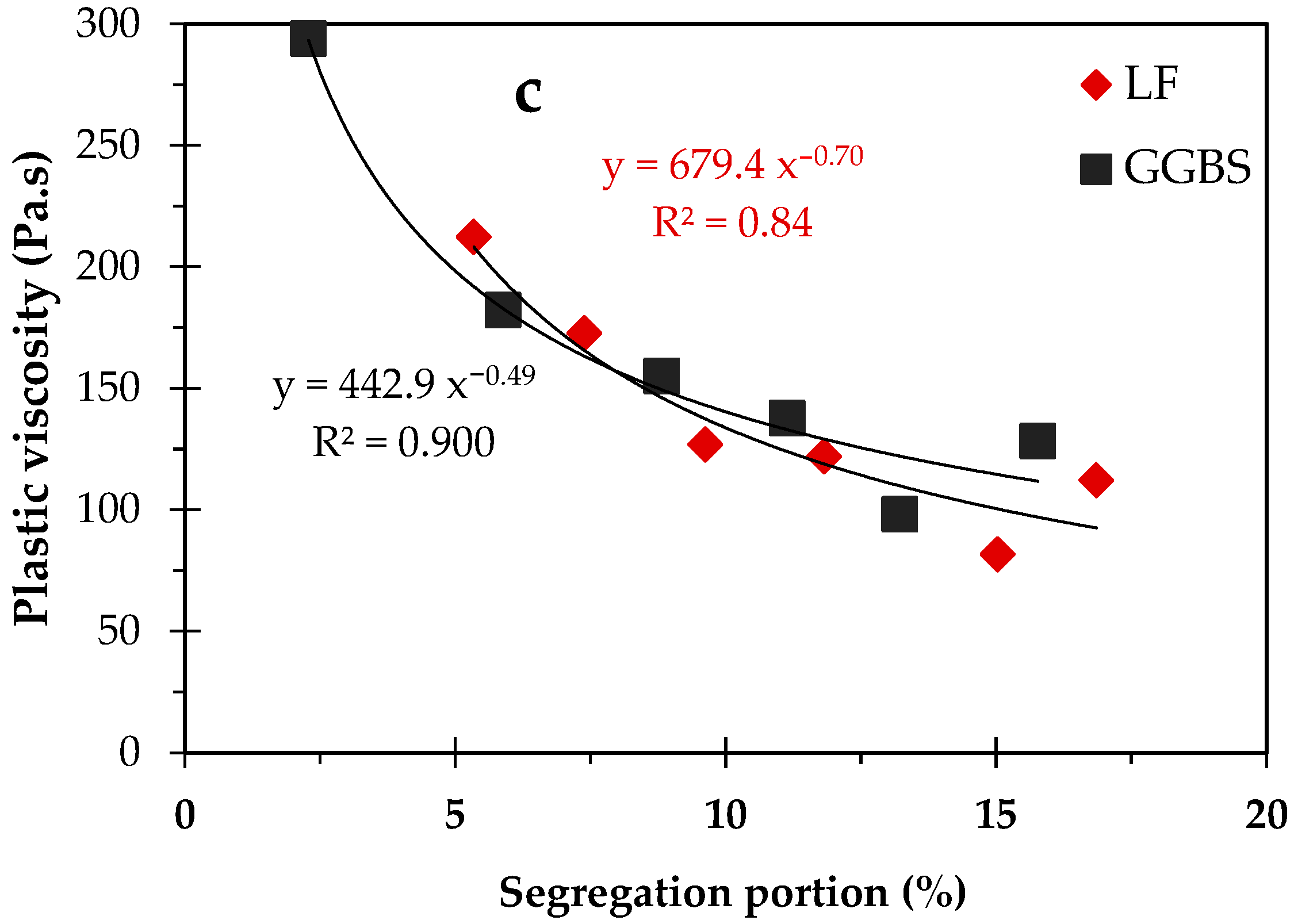

3.1.5. Rheological Correlations

3.2. Hardned Properties of SCC

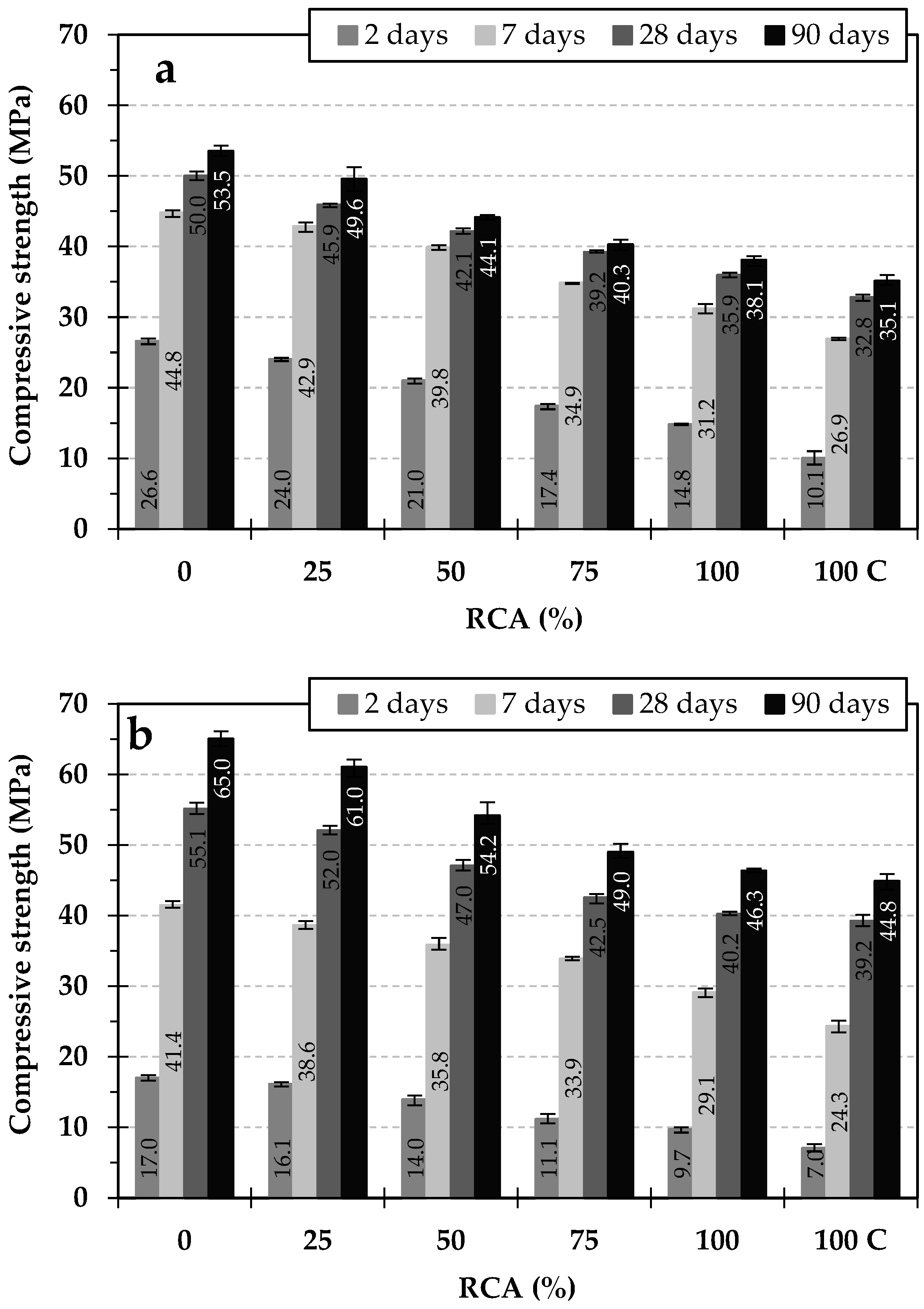

3.2.1. Compressive Strength

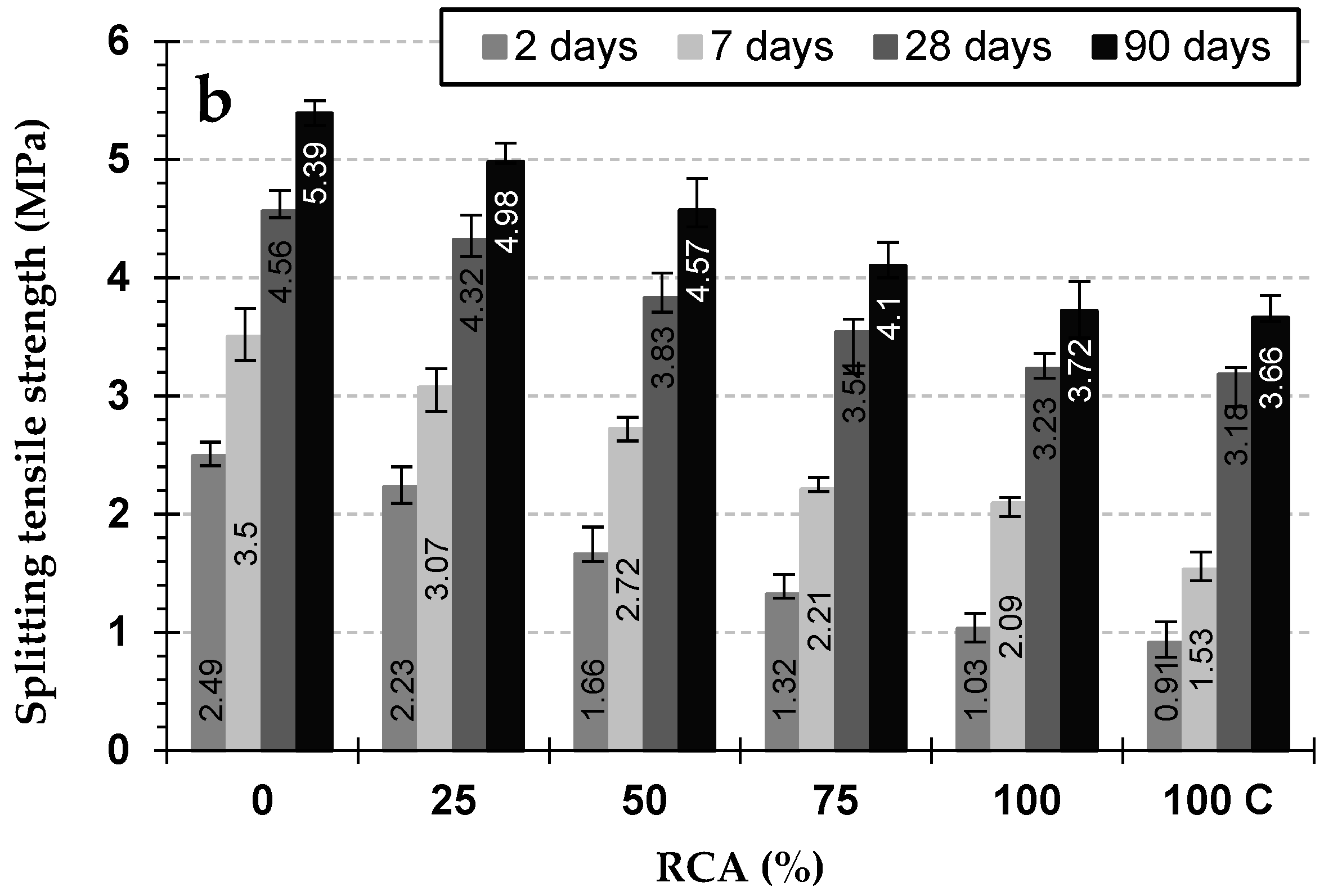

3.2.2. Tensile Strength

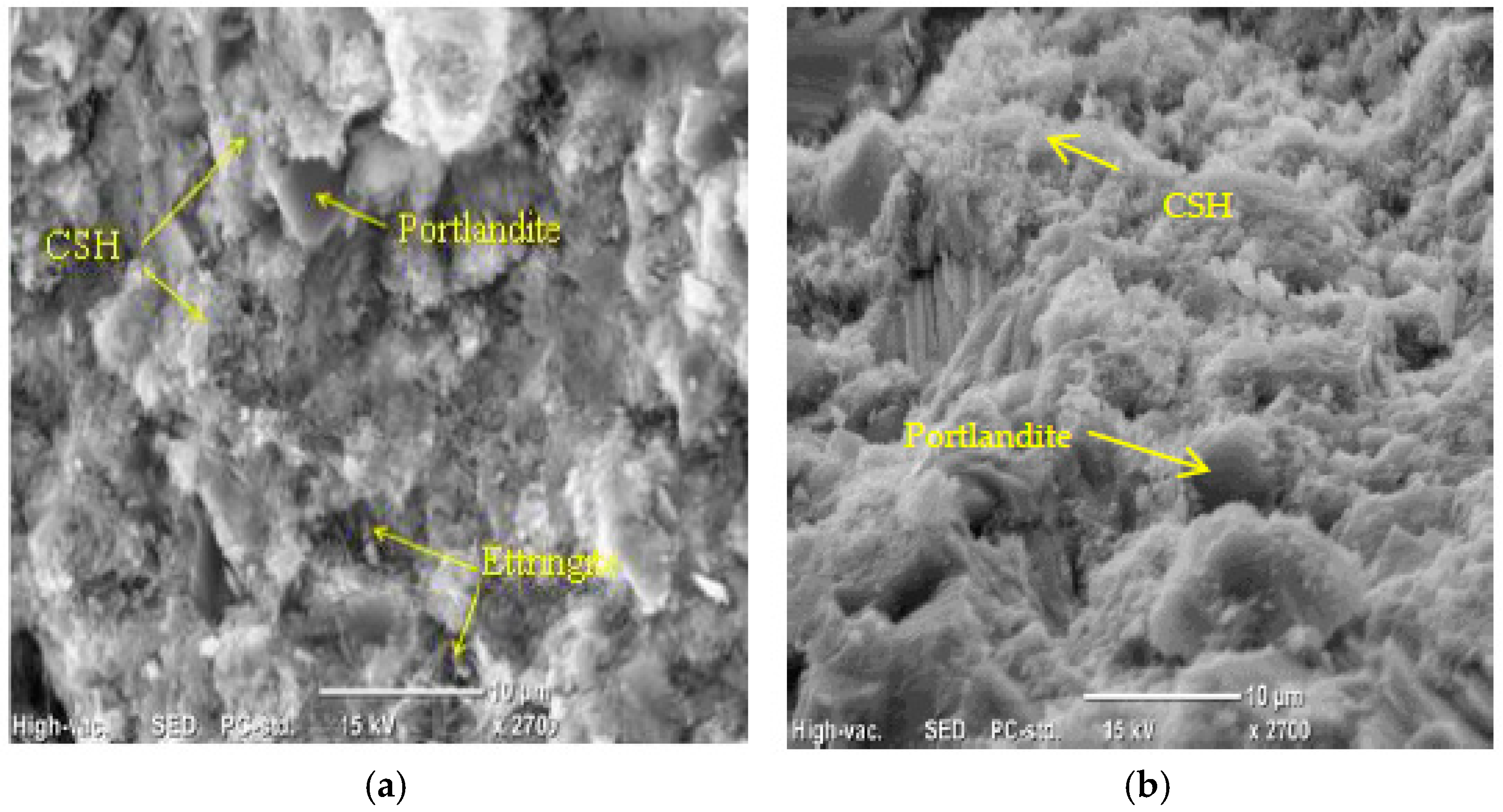

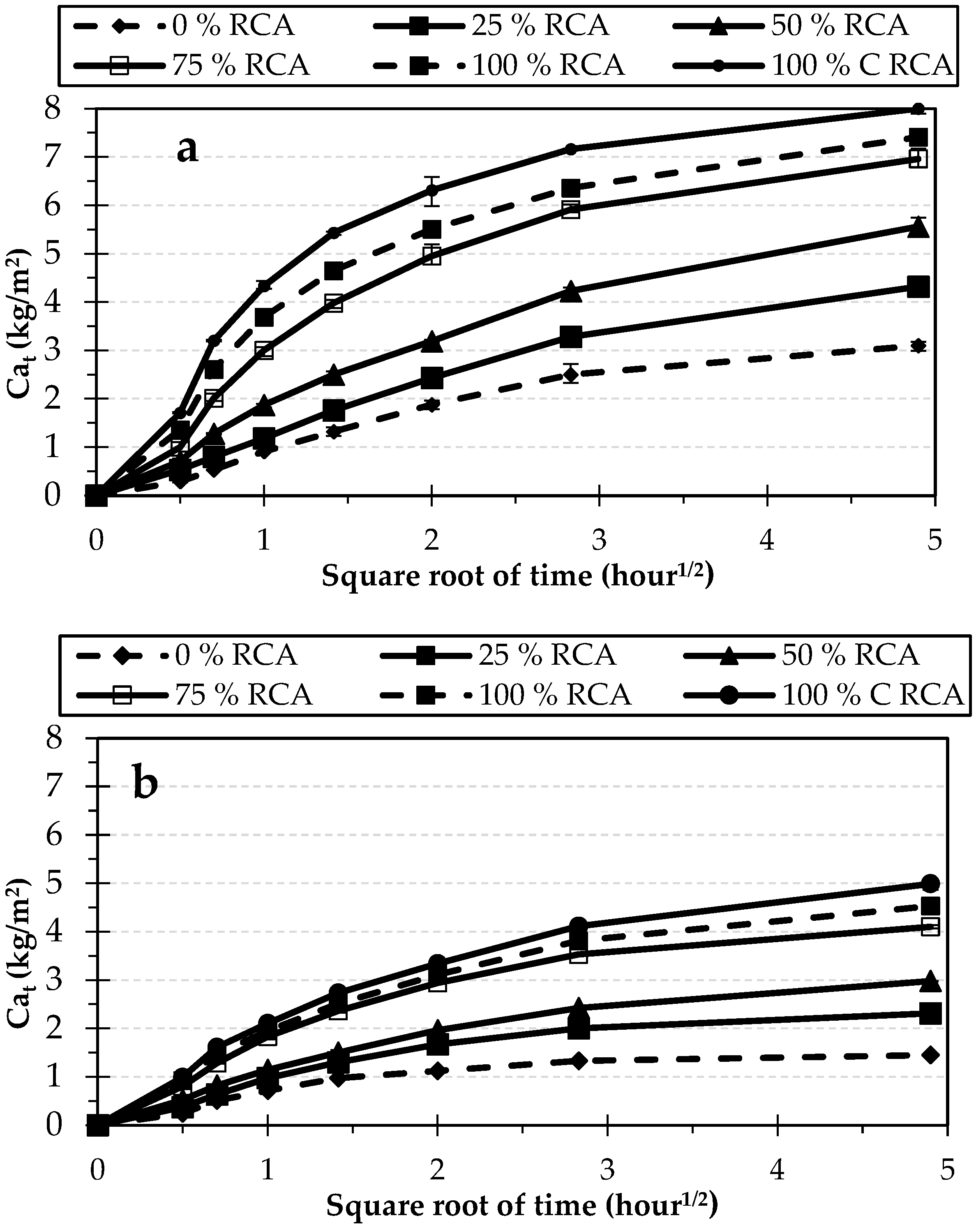

3.2.3. Capillary Water Absorption

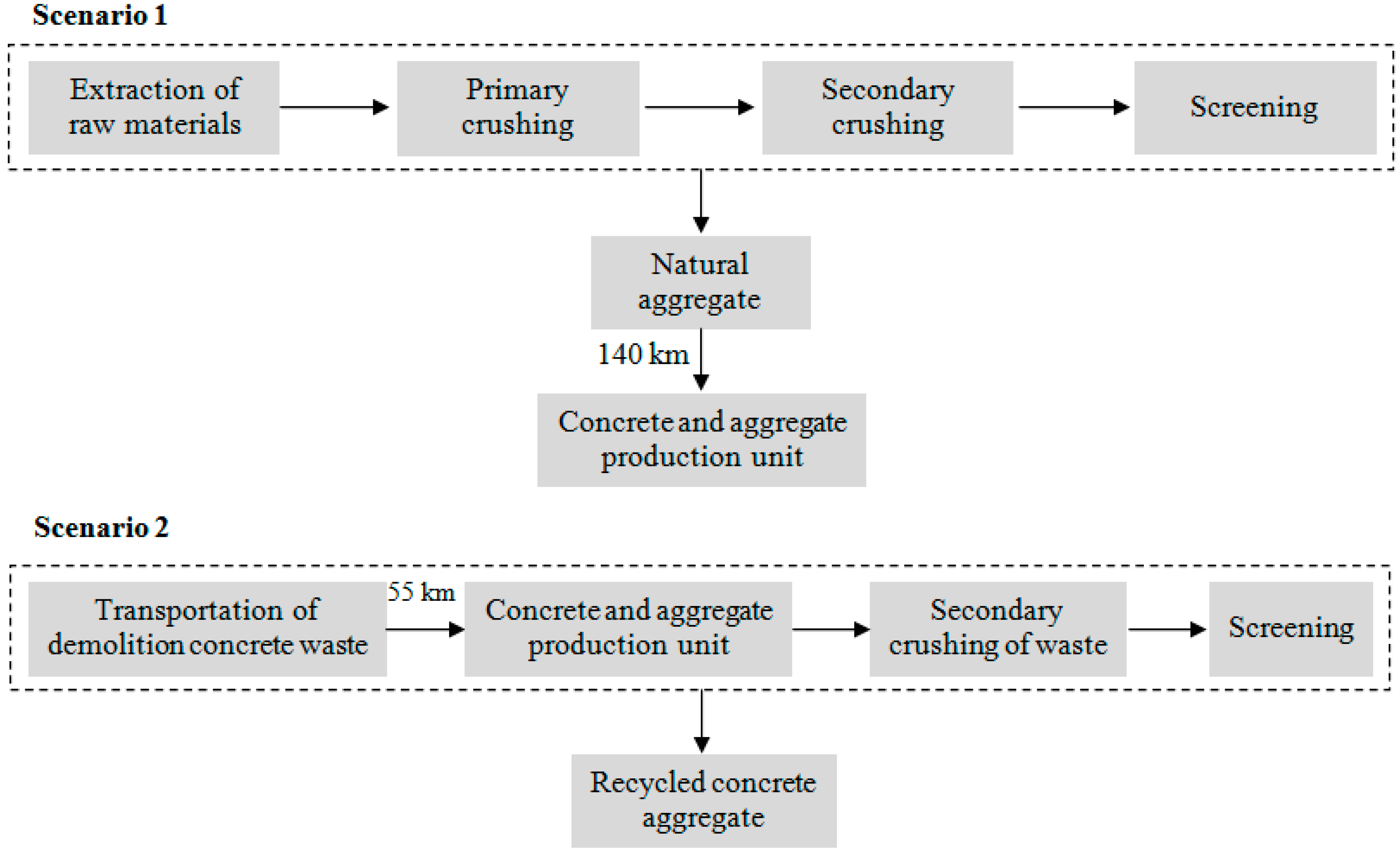

3.3. Environmental Assessments

4. Conclusions

- Fresh-State Properties: Increasing the RCA content reduced the free flow of SCC (as observed in the slump flow test) and horizontal flow (L-box test), while increasing the flow time (T500 test) and resistance to static segregation (sieve stability test). For mixtures containing 100% RCA, specific adjustments to the water-to-cement (W/C) ratio were made to compensate for the water absorption of recycled aggregate, which is particularly pronounced within the first 20 min. These adjustments successfully improved the SCC’s properties, maintaining its flowability and stability, despite the challenges posed by RCA’s characteristics. The addition of GGBS, compared to LF, exhibited a declining trend in fresh-state properties.

- Rheological Parameters: Higher RCA content increased both the static yield stress and plastic viscosity, effects that were further amplified with the use of GGBS. Rheological parameters, derived using the model proposed by Sedran and de Larrard (1999), correlated well with the L-box and stability test results.

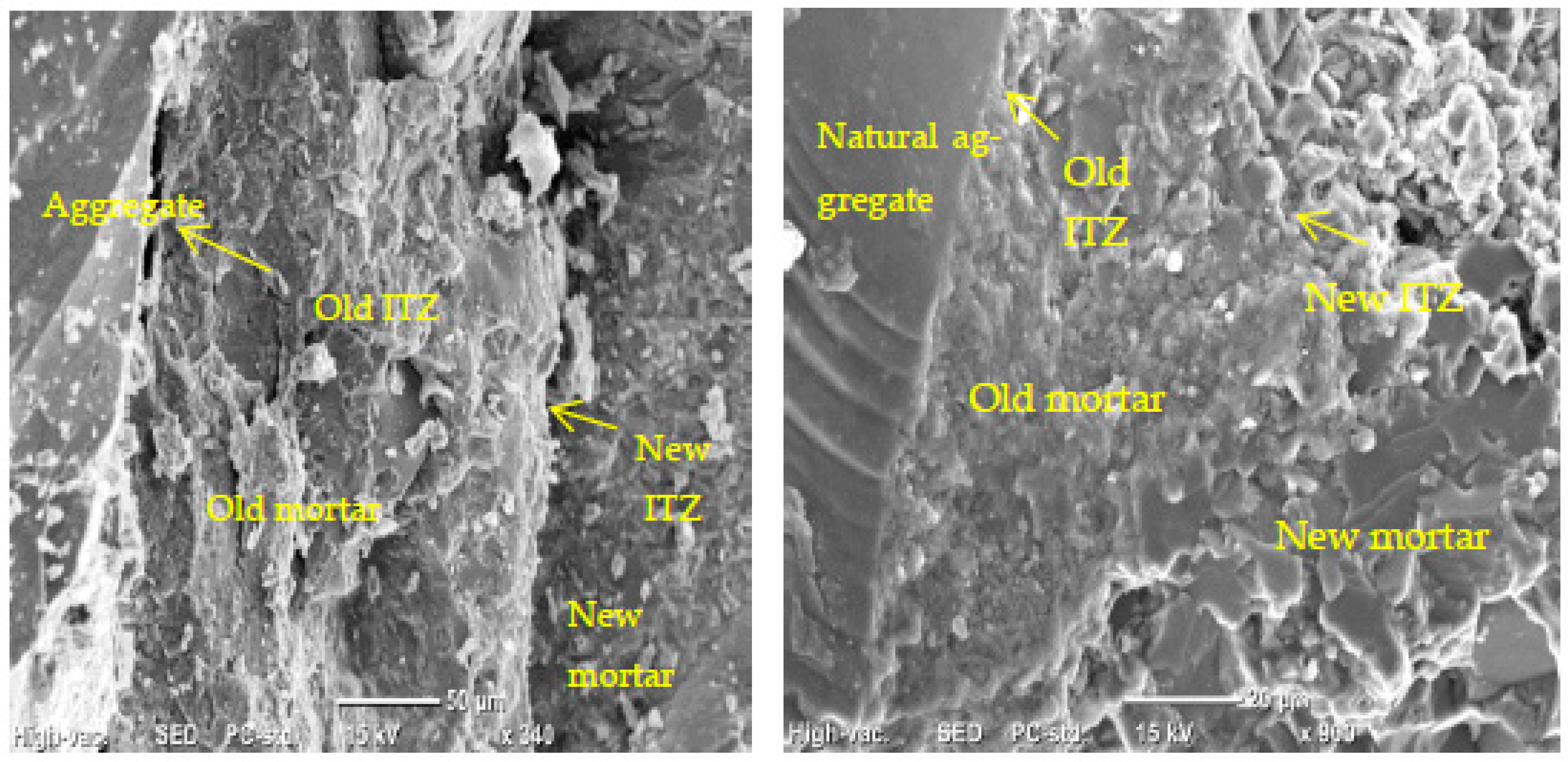

- Mechanical Strength: The significant porosity within RCA, primarily in the old mortar, led to a proportional reduction in mechanical strength as the RCA content increased. This reduction, estimated at 28 days, was 8.2%, 15.8%, 21.6%, and 28.2% for mixtures containing LF, and 5.6%, 14.7%, 22.9%, and 27% for those incorporating GGBS, depending on the progressive replacement of NA with RCA from 0 to 100%. However, the inclusion of GGBS had a positive impact on long-term strength, partially offsetting the reduction observed in the recycled SCC mixtures. Notably, at 90 days, the mixtures containing 100% RCA with an adjusted water dosage and incorporating GGBS exhibited 27.7% higher strength compared to SCC mixtures containing LF.A similar trend was observed for splitting tensile strength. SCC formulated with 100% NA showed the best performance, while the gradual replacement of NA with recycled aggregate resulted in a marked reduction. At 28 days, this reduction reached around 30.2% for BAPs containing LF, and 29.2% for those incorporating GGBS.

- Capillary Water Absorption: An increase in capillary water absorption was observed with higher RCA content, due to the material’s high porosity, especially in the interfacial transition zone (ITZ). However, replacing LF with GGBS resulted in lower capillary absorption coefficients.

- Environmental Impact: For the Annaba region in eastern Algeria, the annual application of a 50% RCA replacement rate in concrete production could potentially reduce fossil fuel consumption by up to 35% and greenhouse gas emissions by as much as 32%. These results demonstrate that using recycled aggregates significantly limits the environmental impact of concrete production, while reducing dependence on the extraction of natural aggregates. By integrating RCA into the production of SCC, this study highlights the role of recycled aggregates in reducing the carbon footprint of the concrete industry by valorizing construction wastes. This finding emphasizes the importance of developing practical solutions to promote the use of recycled materials in construction practices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Yu, J.; Wu, H.L.; Mishra, D.K.; Li, G.; Leung, C.K. Compressive Strength and Environmental Impact of Sustainable Blended Cement with High-Dosage Limestone and Calcined Clay (LC2). J. Clean. Prod. 2021, 278, 123616. [Google Scholar] [CrossRef]

- Hameed, R.; Seo, J.; Park, S.; Amr, I.T.; Lee, H.K. CO2 Uptake and Physicochemical Properties of Carbonation-Cured Ternary Blend Portland Cement–Metakaolin–Limestone Pastes. Materials 2020, 13, 4656. [Google Scholar] [CrossRef] [PubMed]

- Abriak, Y.; Maherzi, W.; Benzerzour, M.; Senouci, A.; Rivard, P. Valorization of dredged sediments and recycled concrete aggregates in road subgrade construction. Buildings 2023, 13, 646. [Google Scholar] [CrossRef]

- Bellara, S.; Maherzi, W.; Mezazigh, S.; Senouci, A. Mineral waste valorization in road subgrade construction: Algerian case study based on technical and environmental features. Case Stud. Constr. Mater. 2024, 20, e02764. [Google Scholar] [CrossRef]

- Muduli, R.; Mukharjee, B.B. Performance assessment of concrete incorporating recycled coarse aggregates and metakaolin: A systematic approach. Constr. Build. Mater. 2020, 233, 117223. [Google Scholar] [CrossRef]

- Fraj, A.B.; Idir, R. Concrete based on recycled aggregates–Recycling and environmental analysis: A case study of paris’ region. Constr. Build. Mater. 2017, 157, 952–964. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Wan, D.L.Y.; Muselin, G. Development of high-performance self-compacting concrete using waste recycled concrete aggregates and rubber granules. J. Clean. Prod. 2018, 182, 553–566. [Google Scholar] [CrossRef]

- Aditto, F.S.; Sobuz, M.H.R.; Saha, A.; Jabin, J.A.; Kabbo, M.K.I.; Hasan, N.M.S.; Islam, S. Fresh, mechanical and microstructural behaviour of high-strength self-compacting concrete using supplementary cementitious materials. Case Stud. Constr. Mater. 2023, 19, e02395. [Google Scholar] [CrossRef]

- Kennedy, C.T. The design of concrete mixes. J. Proc. 1940, 36, 373–400. [Google Scholar]

- Kou, S.C.; Poon, C.S. Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- Kapoor, K.; Singh, S.P.; Singh, B.; Singh, P. Effect of recycled aggregates on fresh and hardened properties of self compacting concrete. Mater. Today Proc. 2020, 32, 600–607. [Google Scholar] [CrossRef]

- Kebaïli, O.; Mouret, M.; Arabi, N.; Cassagnabere, F. Adverse effect of the mass substitution of natural aggregates by air-dried recycled concrete aggregates on the self-compacting ability of concrete: Evidence and analysis through an example. J. Clean. Prod. 2015, 87, 752–761. [Google Scholar] [CrossRef]

- Safiuddin, M.D.; Salam, M.A.; Jumaat, M.Z. Effects of recycled concrete aggregate on the fresh properties of self-consolidating concrete. Arch. Civ. Mech. Eng. 2011, 11, 1023–1041. [Google Scholar] [CrossRef]

- Djelloul, O.K.; Menadi, B.; Wardeh, G.; Kenai, S. Performance of self-compacting concrete made with coarse and fine recycled concrete aggregates and ground granulated blast-furnace slag. Adv. Concr. Constr. 2018, 6, 103. [Google Scholar] [CrossRef]

- Panda, K.C.; Bal, P.K. Properties of self compacting concrete using recycled coarse aggregate. Procedia Eng. 2013, 51, 159–164. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr. Compos. 2017, 84, 214–221. [Google Scholar] [CrossRef]

- Nili, M.; Sasanipour, H.; Aslani, F. The effect of fine and coarse recycled aggregates on fresh and mechanical properties of self-compacting concrete. Materials 2019, 12, 1120. [Google Scholar] [CrossRef]

- Fakitsas, C.G.; Papakonstantinou, P.E.A.; Kiousis, P.D.; Savva, A. Effects of recycled concrete aggregates on the compressive and shear strength of high-strength self-consolidating concrete. J. Mater. Civ. Eng. 2012, 24, 356–361. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, J.; Jiang, T.; Jiang, T.; Chen, C.; Bo, R.; Sun, Y. Development of sustainable self-compacting concrete using recycled concrete aggregate and fly ash, slag, silica fume. Eur. J. Environ. Civ. Eng. 2022, 26, 1453–1474. [Google Scholar] [CrossRef]

- Khodair, Y. Self-compacting concrete using recycled asphalt pavement and recycled concrete aggregate. J. Build. Eng. 2017, 12, 282–287. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Assessment of mechanical properties of concrete incorporating carbonated recycled concrete aggregates. Cem. Concr. Compos. 2016, 65, 67–74. [Google Scholar] [CrossRef]

- Sun, C.; Chen, Q.; Xiao, J.; Liu, W. Utilization of waste concrete recycling materials in self-compacting concrete. Resour. Conserv. Recycl. 2020, 161, 104930. [Google Scholar] [CrossRef]

- Fiol, F.; Revilla-Cuesta, V.; Thomas, C.; Manso, J.M. Self-compacting concrete containing coarse recycled precast-concrete aggregate and its durability in marine-environment-related tests. Constr. Build. Mater. 2023, 377, 131084. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Xiao, J.; Lei, B.; Zhang, C. On carbonation behavior of recycled aggregate concrete. Sci. China Technol. Sci. 2012, 55, 2609–2616. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mater. 2020, 236, 117540. [Google Scholar] [CrossRef]

- Jin, R.; Chen, Q.; Soboyejo, A. Survey of the current status of sustainable concrete production in the US. Resour. Conserv. Recycl. 2015, 105, 148–159. [Google Scholar] [CrossRef]

- Reddy, A.S.; Kumar, P.R.; Raj, P.A. Development of sustainable performance index (SPI) for self-compacting concretes. J. Build. Eng. 2020, 27, 100974. [Google Scholar] [CrossRef]

- NF EN 197-1; Cement-Composition, Specifications and Compliance Criteria for Common Cements. Afnor Editions: St. Denis, France, 2013.

- Ali-Boucetta, T.; Behim, M.; Cassagnabere, F.; Mouret, M.; Ayat, A.; Laifa, W. Durability of self-compacting concrete containing waste bottle glass and granulated slag. Constr. Build. Mater. 2021, 270, 121133. [Google Scholar] [CrossRef]

- Quattrone, M.; Cazacliu, B.; Angulo, S.C.; Hamard, E.; Cothenet, A. Measuring the water absorption of recycled aggregates, what is the best practice for concrete production? Constr. Build. Mater. 2016, 123, 690–703. [Google Scholar] [CrossRef]

- Ferreira, L.; De Brito, J.; Barra, M. Influence of the pre-saturation of recycled coarse concrete aggregates on concrete properties. Mag. Concr. Res. 2011, 63, 617–627. [Google Scholar] [CrossRef]

- NF EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. Afnor Editions: St. Denis, France, 2022.

- Liang, K.; Hou, Y.; Sun, J.; Li, X.; Bai, J.; Tian, W.; Liu, Y. Theoretical analysis of water absorption kinetics of recycled aggregates immersed in water. Constr. Build. Mater. 2021, 302, 124156. [Google Scholar] [CrossRef]

- Duan, Z.; Zhao, W.; Ye, T.; Zhang, Y.; Zhang, C. Measurement of Water Absorption of Recycled Aggregate. Materials 2022, 15, 5141. [Google Scholar] [CrossRef] [PubMed]

- Evangelista, L.; Guedes, M.; De Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Sosa, M.E.; Zaccardi, Y.A.V.; Zega, C.J. A critical review of the resulting effective water-to-cement ratio of fine recycled aggregate concrete. Constr. Build. Mater. 2021, 313, 125536. [Google Scholar] [CrossRef]

- AFGC. Provisional Recommandations for the Use of SCC, 2nd ed.; AFGC: Paris, France, 2008. [Google Scholar]

- NF EN 206-9; Concrete—Part 9: Additional Rules for Self-Compacting Concrete (SCC). Afnor Editions: St. Denis, France, 2010.

- NF EN 206+A2; Concrete—Specification, Performance, Production and Conformity. Afnor Editions: St. Denis, France, 2021.

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- NF EN 12350-8; Testing Fresh Concrete—Part 8: Self-Compacting Concrete—Slump-Flow Test. Afnor Editions: St. Denis, France, 2019.

- Sedran, T.; de Larrard, F. Optimization of self-compacting concrete thanks to packing model. In Proceedings of the 1st SCC Symposium, RILEM PRO7, Stockholm, Sweden, 13–14 September 1999; pp. 321–332. Available online: https://www.researchgate.net/publication/287102598 (accessed on 25 September 2024).

- NF EN 12350-10; Testing Fresh Concrete—Part 10: Self-Compacting Concrete—L Box Test. Afnor Editions: St. Denis, France, 2010.

- NF EN 12350-11; Testing Fresh Concrete—Part 11: Self-Compacting Concrete—Sieve Segregation Test. Afnor Editions: St. Denis, France, 2010.

- NF EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Afnor Editions: St. Denis, France, 2019.

- NF P-18-408; Norme d’essai mécanique sur les bétons. Essai de fendage. Afnor Editions: St. Denis, France, 1981.

- AFREM-AFPC. Report of the AFPC-AFREM Technical Days. Concrete Durability Working Group, Recommended Methods for Measuring Quantities Associated with Durability; INSA: Toulouse, France, 1997. [Google Scholar]

- De Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, X.; Liu, W.; Zhao, B.; Wang, Q. Influence of the moisture states of aggregate recycled from waste concrete on the performance of the prepared recycled aggregate concrete (RAC)–A review. Constr. Build. Mater. 2022, 326, 126891. [Google Scholar] [CrossRef]

- Neeraja, V.S.; Sharma, V. An overview of fresh and mechanical properties of recycled coarse aggregate self-compacting concrete. Mater. Today Proc. 2023, 93, 211–216. [Google Scholar] [CrossRef]

- Michel, F.; Piérard, J.; Courard, L.; Pollet, V. Influence of physico-chemical characteristics of limestone fillers on fresch and hardened mortar performances. In Proceedings of the 5th International RILEM Symposium on Self-Compacting Concrete, Proceedings PRO 54, Ghent, Belgium, 3–5 September 2007; RILEM Publications SARL: Bagneux, France, 2007. [Google Scholar]

- Bigas, J.P.; Gallias, J.L. Effect of fine mineral additions on granular packing of cement mixtures. Mag. Concr. Res. 2002, 54, 155–164. [Google Scholar] [CrossRef]

- Younsi, A.; Mahi, M.A.; Hamami, A.E.A.; Belarbi, R.; Bastidas-Arteaga, E. High-volume recycled waste glass powder cement-based materials: Role of glass powder granularity. Buildings 2023, 13, 1783. [Google Scholar] [CrossRef]

- Martínez-García, R.; Jagadesh, P.; Fraile-Fernández, F.J.; Morán-del Pozo, J.M.; Juan-Valdés, A. Influence of design parameters on fresh properties of self-compacting concrete with recycled aggregate—A review. Materials 2020, 13, 5749. [Google Scholar] [CrossRef]

- Benjeddou, O.; Alwetaishi, M.; Tounsi, M.; Alyousef, R.; Alabduljabbar, H. Effects of limestone filler fineness on the rheological behavior of cement–Limestone filler grouts. Ain Shams Eng. J. 2021, 12, 3569–3578. [Google Scholar] [CrossRef]

- Barroqueiro, T.; da Silva, P.R.; De Brito, J. Fresh-state and mechanical properties of high-performance self-compacting concrete with recycled aggregates from the precast industry. Materials 2019, 12, 3565. [Google Scholar] [CrossRef]

- Santos, S.; Da Silva, P.R.; De Brito, J. Self-compacting concrete with recycled aggregates–a literature review. J. Build. Eng. 2019, 22, 349–371. [Google Scholar] [CrossRef]

- Han, F.; Li, Y.; Jiao, D. Understanding the rheology and hydration behavior of cement paste with nickel slag. J. Build. Eng. 2023, 73, 106724. [Google Scholar] [CrossRef]

- Rizwan, S.A.; Irfan-ul-Hassan, M.; Rahim, A.; Ali, S.; Sultan, A.; Syamsunur, D.; Md Yusoff, N.I. Recycled Coarse Aggregate for Sustainable Self-Compacting Concrete and Mortar. Adv. Mater. Sci. Eng. 2022, 12. [Google Scholar] [CrossRef]

- Järvenpää, H. Quality Characteristics of Fine Aggregates and Controlling Their Effects on Concrete. Ph.D. Thesis, Helsinki University of Technology, Espoo, Finland, 2001. [Google Scholar]

- Lavado, J.; Bogas, J.; De Brito, J.; Hawreen, A. Fresh properties of recycled aggregate concrete. Constr. Build. Mater. 2020, 233, 117322. [Google Scholar] [CrossRef]

- Mandal, R.; Panda, S.K.; Nayak, S. Evaluation of rheological properties of sustainable self-compacting recycled aggregate concrete produced by two-stage mixing approach. J. Build. Eng. 2024, 87, 109126. [Google Scholar] [CrossRef]

- Mandal, R.; Panda, S.K.; Nayak, S. Rheology of Concrete: Critical Review, recent Advancements, and future prospectives. Constr. Build. Mater. 2023, 392, 132007. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete-A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- González-Taboada, I.; González-Fonteboa, B.; Martínez-Abella, F.; Carro-López, D. Self-compacting recycled concrete: Relationships between empirical and rheological parameters and proposal of a workability box. Constr. Build. Mater. 2017, 143, 537–546. [Google Scholar] [CrossRef]

- Rashid, K.; Rehman, M.U.; de Brito, J.; Ghafoor, H. Multi-criteria optimization of recycled aggregate concrete mixes. J. Clean. Prod. 2020, 276, 124316. [Google Scholar] [CrossRef]

- Piccinali, A.; Diotti, A.; Plizzari, G.; Sorlini, S. Impact of recycled aggregate on the mechanical and environmental properties of concrete: A review. Materials 2022, 15, 1818. [Google Scholar] [CrossRef]

- Ye, G.; Liu, X.; De Schutter, G.; Poppe, A.M.; Taerwe, L. Influence of limestone powder used as filler in SCC on hydration and microstructure of cement pastes. Cem. Concr. Compos. 2007, 29, 94–102. [Google Scholar] [CrossRef]

- Kadri, E.H.; Aggoun, S.; De Schutter, G.; Ezziane, K. Combined effect of chemical nature and fineness of mineral powders on Portland cement hydration. Mater. Struct. 2010, 43, 665–673. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Butler, L.; West, J.S.; Tighe, S.L. The effect of recycled concrete aggregate properties on the bond strength between RCA concrete and steel reinforcement. Cem. Concr. Res. 2011, 41, 1037–1049. [Google Scholar] [CrossRef]

- Mindess, S. Sustainability of concrete. In Developments in the Formulation and Reinforcement of Concrete, 2nd ed.; Woodhead Publish: Cambridge, UK, 2019; pp. 3–17. [Google Scholar] [CrossRef]

- Badreddine-Bessa, A. Etude de la Contribution des Additions Minérales aux Propriétés Physiques, Mécaniques et de Durabilité des Mortiers. Ph.D. Thesis, Cergy-Pontoise University, Cergy, France, 2004. [Google Scholar]

- Hadj-sadok, A.; Kenai, S.; Courard, L.; Darimont, A. Microstructure and durability of mortars modified with medium active blast furnace slag. Constr. Build. Mater. 2011, 25, 1018–1025. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Life cycle assessment and life cycle costing toward eco-efficiency concrete waste management in Malaysia. J. Clean. Prod. 2018, 172, 3415–3427. [Google Scholar] [CrossRef]

| Physical Properties | |||||||

| Bulk Density | True Density | Blaine Specific Surface | Initial Setting Time | Final Setting Time | Normal Consistency | Residue on 40 μm Sieve | |

| (kg/m3) | (kg/m3) | (cm2/g) | (min) | (min) | (%) | (%) | |

| OPC | 980 | 3100 | 3728 | 220 | 280 | 26 | 12 |

| Oxide Composition Estimation via Bogue Equations | |||||||

| Oxides | C3S | C2S | C3A | C4AF | Gypsum | ||

| (%) | 68.8 | 8.6 | 5.6 | 11.0 | 5 | ||

| Physical Characteristics | |||||||||

| Bulk Density | True Density | Blaine Specific Surface | 40 μm Sieve Residue | 80 μm Sieve Residue | D50 | Water Demand | |||

| (kg/m3) | (kg/m3) | (cm2/g) | (%) | (%) | (µm) | (%) | |||

| LF | 1090 | 2680 | 5108 | 12.9 | 2.5 | 6.9 | 31 | ||

| GGBS | 940 | 2900 | 5797 | 12.2 | 2.3 | 3.4 | 33 | ||

| Chemical compositions | |||||||||

| Oxides (%) | CaO | Al2O3 | Fe2O3 | SiO2 | MgO | Na2O | SO3 | K2O | LOI |

| LF | 53.49 | 0.02 | 0.27 | 0.05 | 0.22 | 0.07 | 0.00 | 0.01 | 43.29 |

| GGBS | 44.73 | 6.80 | 1.60 | 36.37 | 3.21 | 0.24 | 0.35 | 0.68 | - |

| OPC | 64.67 | 4.41 | 3.62 | 21.0 | 2.37 | - | 2.70 | 0.67 | 2.92 |

| Characteristics | Unit | S1 | S2 | NCA | RCA |

|---|---|---|---|---|---|

| Apparent density | kg/m3 | 1480 | 1500 | 1490 | 1180 |

| Absolute density | kg/m3 | 2620 | 2620 | 2670 | 2420 |

| d/D | - | 0/2 | 0/4 | 4/10 | 4/10 |

| Fineness modulus | - | 2.10 | 3.20 | - | - |

| Sand equivalent | % | 79 | 77.2 | - | - |

| Methylene blue | % | 0.75 | 0.75 | - | - |

| Absorption coefficients at 24 h | % | 1.72 | 2.15 | 1.5 | 5 |

| Flattening coefficient | % | - | - | 14.7 | 10.8 |

| Los Angeles testing * | % | - | - | 24 | 40 |

| Micro Deval testing * | % | - | - | 19 | 38.6 |

| Absolute Density | pH | Solid Content | Cl Ion Content | Na2O eq Content | Use Range | |

|---|---|---|---|---|---|---|

| LSR 8800 | 1.07 ± 0.02 | 5.0 to 5.5 | 29% | ≤0.1% | ≤1.0% | 0.3 à 3.0% |

| Group | Mix | OPC kg/m3 | SCM kg/m3 | Water kg/m3 | SP kg/m3 | S1 kg/m3 | S2 kg/m3 | NCA kg/m3 | RCA kg/m3 | Weff/B |

|---|---|---|---|---|---|---|---|---|---|---|

| LF | SCC0 | 350 | 180 | 189 | 5.83 | 525.5 | 310 | 784.4 | - | 0.36 |

| SCC25 | 350 | 180 | 189 | 5.83 | 525.5 | 310 | 588.3 | 177.8 | 0.36 | |

| SCC50 | 350 | 180 | 189 | 5.83 | 525.5 | 310 | 392.2 | 355.8 | 0.36 | |

| SCC75 | 350 | 180 | 189 | 5.83 | 525.5 | 310 | 196.1 | 533.7 | 0.36 | |

| SCC100 | 350 | 180 | 189 | 5.83 | 525.5 | 310 | - | 711.6 | 0.36 | |

| SCC100C * | 350 | 180 | 196 | 5.83 | 525.5 | 310 | - | 711.6 | 0.37 | |

| GGBS | SCC0 | 350 | 150 | 189 | 5.50 | 525.5 | 310 | 784.4 | - | 0.38 |

| SCC25 | 350 | 150 | 189 | 5.50 | 525.5 | 310 | 588.3 | 177.8 | 0.38 | |

| SCC50 | 350 | 150 | 189 | 5.50 | 525.5 | 310 | 392.2 | 355.8 | 0.38 | |

| SCC75 | 350 | 150 | 189 | 5.50 | 525.5 | 310 | 196.1 | 533.7 | 0.38 | |

| SCC100 | 350 | 150 | 189 | 5.50 | 525.5 | 310 | - | 711.6 | 0.38 | |

| SCC100C * | 350 | 150 | 196 | 5.50 | 525.5 | 310 | - | 711.6 | 0.39 |

| Energy, Fossil Fuels (MJ/t) | GWP (kg eq. CO2/t) | References | |

|---|---|---|---|

| Natural gravel production | 30 | 7.9 | Calculated |

| Coarse recycled concrete aggregate | 4 | 2.5 | [77,78] |

| Transportation (truck transport 40 tons) | 0.39 | 0.07 | Calculated |

| Production Process Activities | Gravel Quantity | Energy Consumption | |

|---|---|---|---|

| Natural Gravel Production | Recycled Gravel | ||

| Extraction, Primary Crushing, Secondary Crushing, Screening | Primary Crushing, Separation, Secondary Crushing, Screening | ||

| Production (MJ) | 1 ton | 30 | 4 |

| 42,000 tons | 1260 | 168 | |

| Transportation (MJ) | 1 ton | 54.6 (140 Km) | 21.6 (55 km) |

| 42,000 | 2293.2 | 907.2 | |

| Total energy consumed (MJ) | 1 ton | 84.6 | 25.6 |

| 42,000 tons | 3553.2 | 1075.2 | |

| Total energy consumption prevented (MJ) | 42,000 tons | 2478 | |

| Production Process Activities | Gravel Quantity Production | Greenhouse Gas Emissions | |

|---|---|---|---|

| Natural Gravel Production | Recycled Gravel | ||

| Extraction, Primary Crushing, Secondary Crushing, Screening | Primary Crushing, Separation, Secondary Crushing, Screening | ||

| Production (kg eq. CO2) | 1 ton | 7.9 | 2.5 |

| 42,000 tons | 331.8 | 105 | |

| Transportation (kg eq. CO2) | 1 ton | 10 (140 Km) | 3.9 (55 km) |

| 42,000 | 420 | 163.8 | |

| Total energy consumed (kg eq. CO2) | 1 ton | 17.9 | 6.4 |

| 42,000 tons | 751.8 | 268.8 | |

| Total energy consumption prevented (kg eq. CO2) | 42,000 tons | 483 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamza, F.; AliBoucetta, T.; Behim, M.; Bellara, S.; Senouci, A.; Maherzi, W. Sustainable Self-Compacting Concrete with Recycled Aggregates, Ground Granulated Blast Slag, and Limestone Filler: A Technical and Environmental Assessment. Sustainability 2025, 17, 3395. https://doi.org/10.3390/su17083395

Hamza F, AliBoucetta T, Behim M, Bellara S, Senouci A, Maherzi W. Sustainable Self-Compacting Concrete with Recycled Aggregates, Ground Granulated Blast Slag, and Limestone Filler: A Technical and Environmental Assessment. Sustainability. 2025; 17(8):3395. https://doi.org/10.3390/su17083395

Chicago/Turabian StyleHamza, Fadhila, Tahar AliBoucetta, Mourad Behim, Selma Bellara, Ahmed Senouci, and Walid Maherzi. 2025. "Sustainable Self-Compacting Concrete with Recycled Aggregates, Ground Granulated Blast Slag, and Limestone Filler: A Technical and Environmental Assessment" Sustainability 17, no. 8: 3395. https://doi.org/10.3390/su17083395

APA StyleHamza, F., AliBoucetta, T., Behim, M., Bellara, S., Senouci, A., & Maherzi, W. (2025). Sustainable Self-Compacting Concrete with Recycled Aggregates, Ground Granulated Blast Slag, and Limestone Filler: A Technical and Environmental Assessment. Sustainability, 17(8), 3395. https://doi.org/10.3390/su17083395