Molecular Dynamics Simulation of CNT Reinforced Cement: A Step Toward Sustainable Construction

Abstract

1. Introduction

2. Materials and Methods

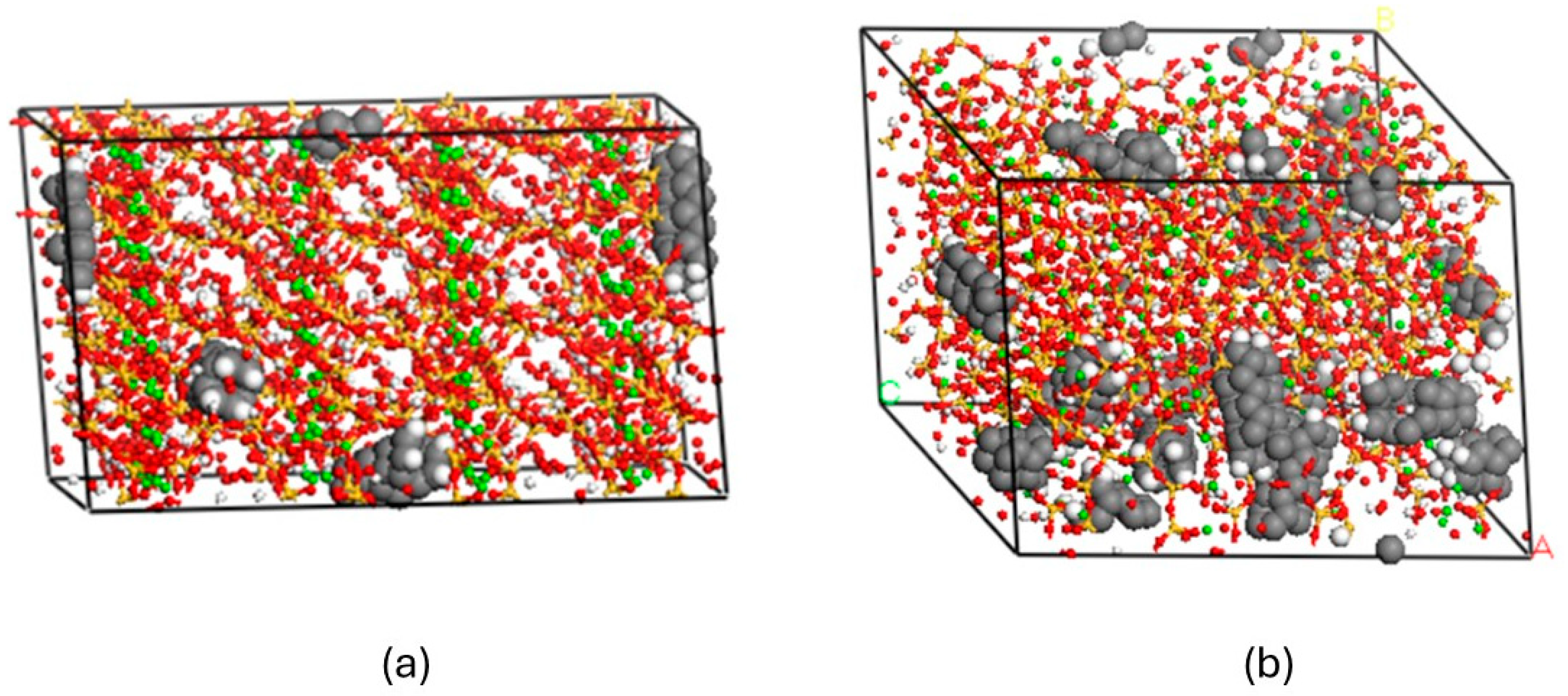

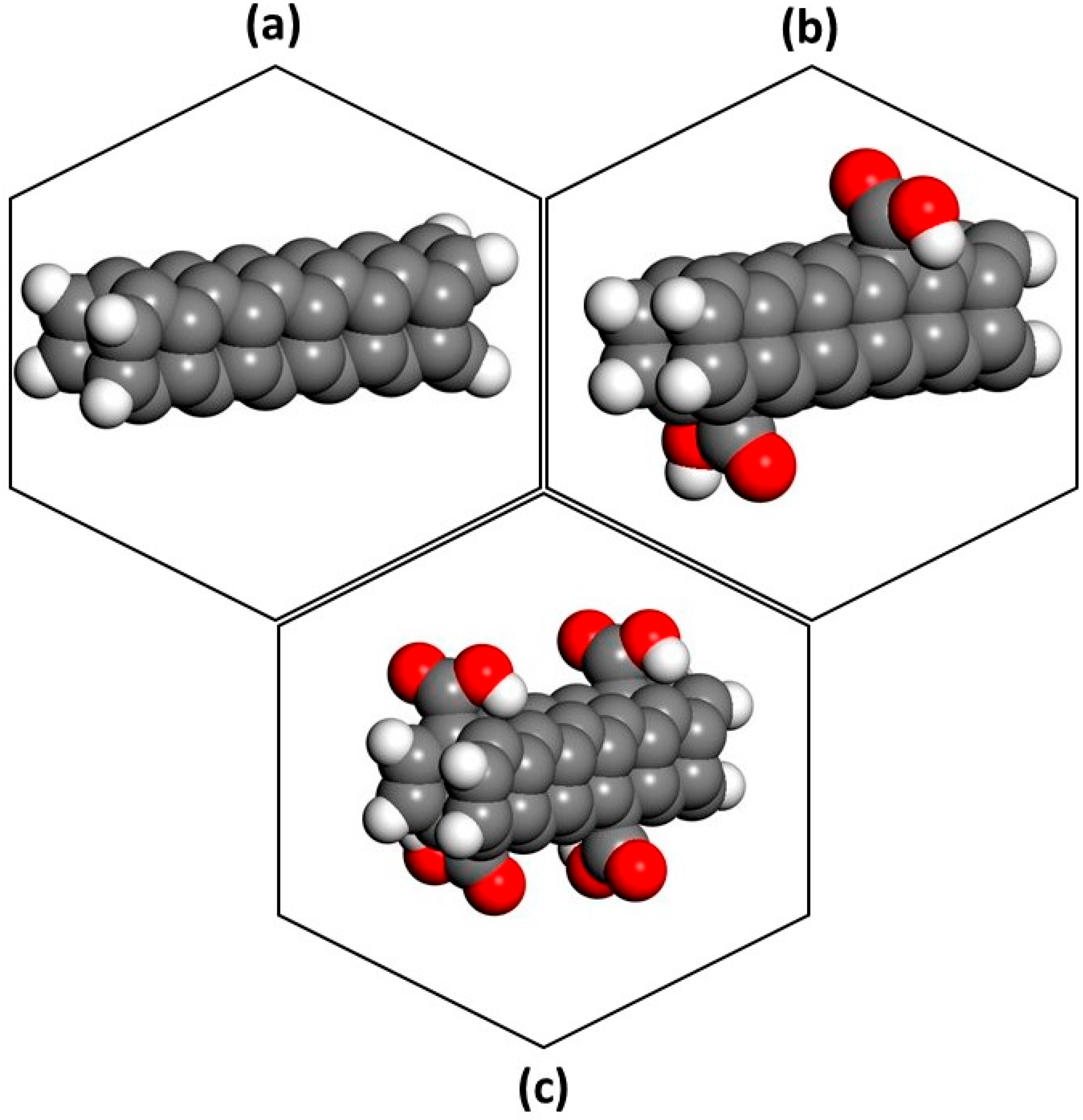

2.1. Models

2.2. Calculations

3. Results and Discussion

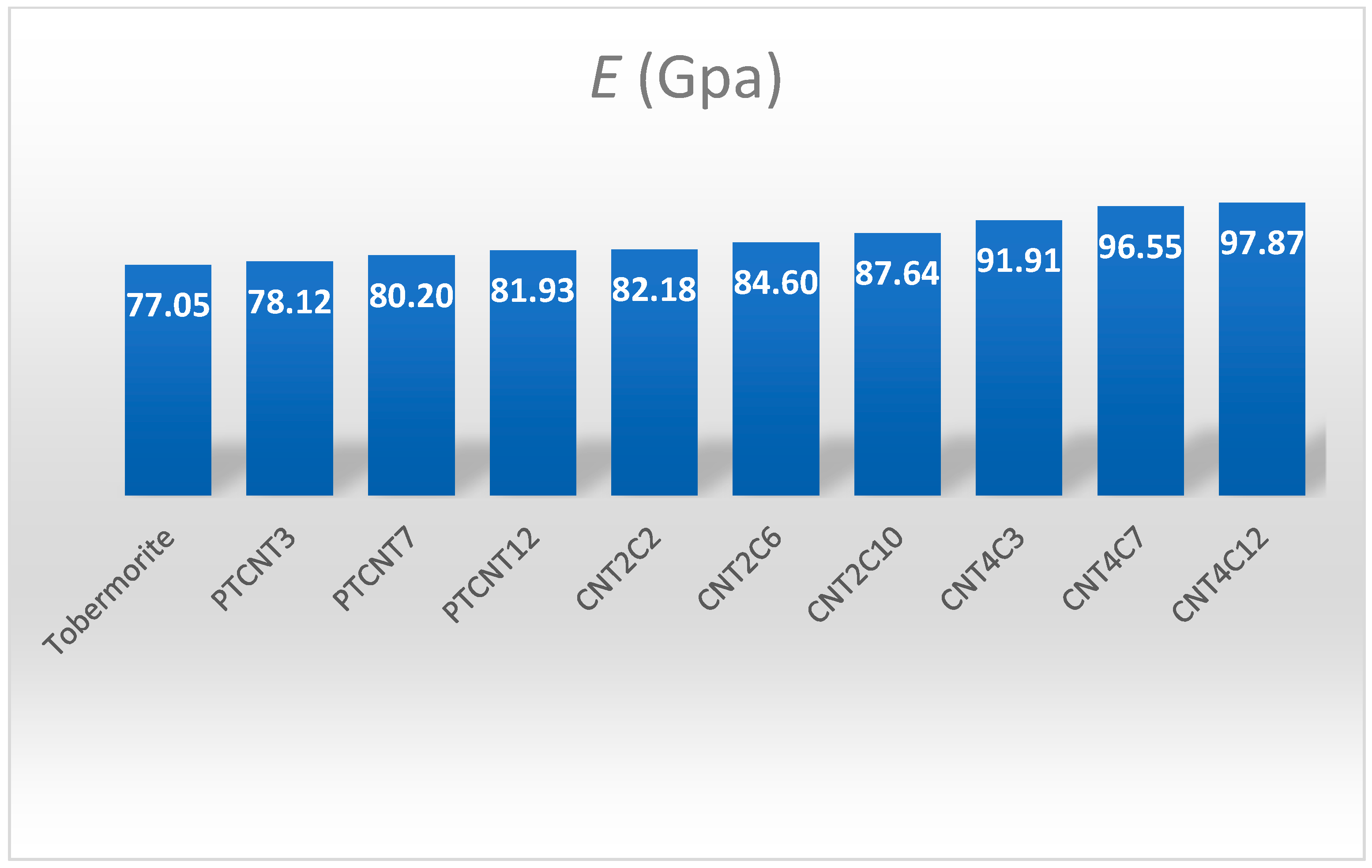

3.1. Mechanical Properties

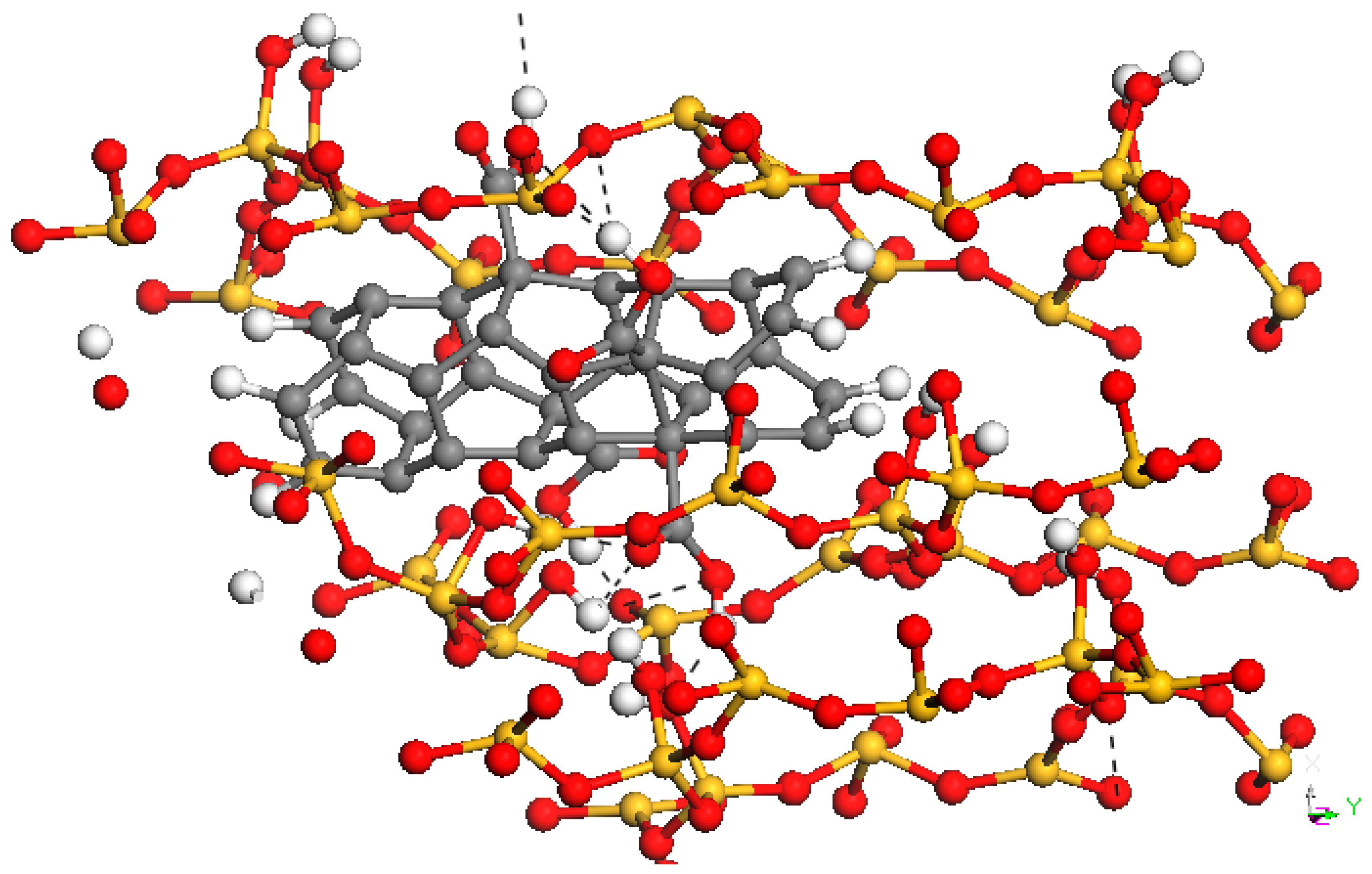

3.2. Hydrogen Bond Analysis

4. Conclusions

- The incorporation of CNTs into the tobermorite structure significantly enhances the elastic modulus of the composite. Functionalized CNTs exhibit a stronger effect due to hydrogen bond formation between carboxyl groups and the matrix, reinforcing interfacial interactions.

- A direct correlation is observed between the density of functional groups and mechanical reinforcement. Increasing the degree of CNT functionalization enhances mechanical performance without requiring higher CNT concentrations, enabling the design of optimized reinforcement strategies with reduced material costs and aggregation issues.

- Structural parameters such as CNT length, diameter, and alternative functional groups (e.g., amino or epoxy) should be investigated to further improve CNT dispersion and reinforcement efficiency in cementitious matrices. Additionally, combining CNTs with other nanomaterials, such as nanoparticles or fibers, could lead to hybrid reinforcement systems with superior mechanical and durability properties.

- From a computational perspective, coarse-grained MDs simulations could address the limitations of all-atom MDs models (small systems, short calculation times, presence of defects, porosity, etc.), allowing the study of larger system sizes and longer time scales while preserving essential insights into the mechanical behavior of cement–CNT composites.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [PubMed]

- Nikolakopoulos, A.; Steriotis, T.; Charalambopoulou, G.; Karagiannakis, G.; Dimitrakis, D.; Michalis, V.; Katsiotis, M. Reducing carbon emissions in cement production through solarization of the calcination process and thermochemical energy storage. Comput. Chem. Eng. 2024, 180, 108506. [Google Scholar]

- Wang, W.; Chu, H.; Jiang, J.; Zhu, B. Enhancing mechanical performance and durability of high strength mortar with incineration bottom ash via Al2O3 micro-powder: An experimental study. J. Build. Eng. 2024, 89, 109268. [Google Scholar]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2018, 122, 257–273. [Google Scholar]

- Bergonzoni, M.; Melloni, R.; Botti, L. Analysis of sustainable concrete obtained from the by-products of an industrial process and recycled aggregates from construction and demolition waste. Procedia Comput. Sci. 2023, 217, 41–51. [Google Scholar]

- Navaratnam, S.; Tushar, Q.; Jahan, I.; Zhang, G. Environmental Sustainability of Industrial Waste-Based Cementitious Materials: A Review, Experimental Investigation and Life-Cycle Assessment. Sustainability 2023, 15, 1873. [Google Scholar] [CrossRef]

- Huseien, G.F. A Review on Concrete Composites Modified with Nanoparticles. J. Compos. Sci. 2023, 7, 67. [Google Scholar] [CrossRef]

- Reaches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 175, 483–495. [Google Scholar]

- Selima, F.A.; Amina, M.S.; Ramadana, M.; Hazem, M.M. Effect of elevated temperature and cooling regimes on the compressive strength, microstructure and radiation attenuation of fly ash–cement composites modified with miscellaneous nanoparticles. Constr. Build. Mater. 2020, 258, 119648. [Google Scholar]

- El-Gamal, S.M.A.; El-Hosiny, F.I.; Amin, M.S.; Sayed, D.G. Ceramic waste as an efficient material for enhancing the fire resistance and mechanical properties of hardened Portland cement pastes. Constr. Build. Mater. 2015, 154, 1062. [Google Scholar]

- Ahmad, J.; Zhou, Z. Properties of concrete with addition carbon nanotubes: A review. Constr. Build. Mater. 2023, 393, 132066. [Google Scholar]

- Jayakumari, Y.; Swaminathan, E.N.; Partheeban, P. A review on characteristics studies on carbon nanotubes-based cement concrete. Constr. Build. Mater. 2023, 367, 130344. [Google Scholar]

- Makul, N. Advanced smart concrete—A review of current progress, benefits and Challenges. J. Clean. Prod. 2020, 274, 122899. [Google Scholar]

- Bhatrola, K.; Maurya, S.K.; Kothiyal, N.C. An updated review on scientometric analysis and physico-mechanical performance of nanomaterials in cementitious composites. Structures 2023, 58, 105421. [Google Scholar]

- Mohsen, O.; Al Ansari, M.S.; Taha, R.; Al Nuaimi, N.; Taqa, A.A. Carbon Nanotube Effect on the Ductility, Flexural Strength, and Permeability of Concrete. J. Nanomater. 2019, 2019, 6490984. [Google Scholar]

- Ghogare, R.B.; Londhe, S.K.; Hande, S.A.; Bhosale, C.G.; Mane, A.V. To Improve the Strength of Concrete by Using Carbon Nanotubes (CNTs). Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 6344. [Google Scholar]

- Güler, Ö.; Cacim, N.N.; Evin, E.; Yahia, I.S. The synergistic effect of CNTs-polymeric surfactant on the properties of concrete nanocomposites: Comparative study. J. Compos. Mater. 2020, 55, 1371–1384. [Google Scholar]

- Onaizi, A.M.; Huseien, G.F.; Lim, N.H.; Amran, M.; Samadi, F. Effect of nanomaterials inclusion on sustainability of cement-based concretes: A comprehensive review. Constr. Build. Mater. 2021, 306, 124850. [Google Scholar]

- Abdel-Mohti, A.; Soliman, E.; Shen, H. Effect of Adding Carbon Nanotubes on the Freeze-Thaw and Thermal Fatigue Resistance of Latex Modified Mortar. Fibers 2018, 6, 19. [Google Scholar] [CrossRef]

- Rodriguez, B.; Correa, E.; Arias, Y.P.; Quintero, J.H.; Calderon, J.A.; Mendoza, O.A. Carbonation study in a cement matrix with carbon nanotubes. J. Phys. 2019, 1247, 12024. [Google Scholar]

- Panagiotakopoulou, C.; Papandreopoulos, P.; Batis, G. Investigation of Corrosion Protection Through CNTs/CNFs Modified Cement Mortars. Curr. Nanomat. 2024, 9, 266. [Google Scholar]

- Sldozian, R.; Burakova, I.; Burakov, A.; Aljaboobi, Z.; Hamad, A.; Tkachev, A. The effect of multi-walled carbon nanotubes on mechanical properties and water adsorption of lightweight foamed concrete. Res. Eng. Struct. Mater. 2024, 10, 1139. [Google Scholar]

- Singh, N.B.; Rai, S. Properties of cementitious materials in presence of nano carbon. Mater. Today Proc. 2020, 29, 999–1005. [Google Scholar]

- Wang, J.; Dong, S.; Pang, S.D.; Zhou, C.; Han, B. Pore structure characteristics of concrete composites with surface-modified carbon nanotubes. Cem. Concr. Compos. 2022, 128, 104453. [Google Scholar]

- Lan, Y.; Zheng, B.; Shi, T.; Ma, C.; Liu, Y.; Zhao, Z. Crack resistance properties of carbon nanotube-modified concrete. Mag. Concr. Res. 2022, 74, 1165–1175. [Google Scholar]

- Bogas, J.A.; Ahmed, H.H.; Diniz, T. Influence of Cracking on the Durability of Reinforced Concrete with Carbon Nanotubes. Appl. Sci. 2021, 11, 1672. [Google Scholar] [CrossRef]

- Hassan, A.; Elkady, H.; Shaaban, I.G. Effect of Adding Carbon Nanotubes on Corrosion Rates and Steel-Concrete Bond. Sci. Rep. 2019, 9, 6285. [Google Scholar]

- Joshi, M.; Bavache, P.; Jamdar, M.; Bhanase, S.; Bhonge, S.; Chougule, S. Concrete Structure by Using Carbon Nanotube and Its Use to Monitor Its Structural Health. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 1995. [Google Scholar]

- Liu, Y.; Zhong, X.; Mohammadian, H.R. Role carbon nanomaterials in reinforcement of concrete and cement; A new perspective in civil nengineering. Alex. Eng. J. 2023, 72, 649–656. [Google Scholar]

- Pisello, A.L.; D’Alessandro, A.; Sambuco, S.; Rallini, M.; Ubertini, F.; Asdrubali, F.; Materazzi, A.L.; Cotana, F. Multipurpose experimental characterization of smart nanocomposite cement-based materials for thermal-energy efficiency and strain-sensing capability. Sol. Energy Mater. Sol. Cells 2017, 161, 77–88. [Google Scholar]

- Dinesh, A.; Ashwathi, R.; Kamal, B.; Akash, S.; Sujith, S. Influence of carbon nanotube on the mechanical and electrical characteristics of concrete—A review. Mater. Today Proc. 2023, 29, 999–1005. [Google Scholar] [CrossRef]

- Al-Rub, R.K.A.; Asce, M.; Tyson, B.M.; Asce, S.M.; Yazdanbakhsh, A.; Grasley, Z. Mechanical Properties of Nanocomposite Cement Incorporating Surface-Treated and Untreated Carbon Nanotubes and Carbon Nanofibers. J. Nanomechanics Micromech. 2011, 2, 1–6. [Google Scholar] [CrossRef]

- Yan, X.; Cui, H.; Qin, Q.; Tang, W.; Zhou, X. Study on Utilization of Carboxyl Group Decorated Carbon Nanotubes and Carbonation Reaction for Improving Strengths and Microstructures of Cement Paste. Nanomaterials 2016, 6, 153. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhang, Y.; Cheng, C.; Wei, H.; Du, S.; Yan, J. Surface-treated carbon nanotubes in cement composites: Dispersion, mechanical properties and microstructure. Constr. Build. Mater. 2021, 310, 125262. [Google Scholar] [CrossRef]

- Cui, K.; Liang, K.; Jiang, T.; Zhang, J.; Lau, D.; Chang, J. Understanding the role of carbon nanotubes in low-carbon concrete: From experiment to molecular dynamics. Cem. Concr. Compos. 2023, 142, 105189. [Google Scholar] [CrossRef]

- Zhao, L.; Nasution, M.K.N.; Hekmatifar, M.; Sabetvand, R.; Kamenskov, P.; Toghraie, D. The improvement of mechanical properties of conventional concretes using carbon nanoparticles using molecular dynamics simulation. Sci. Rep. 2021, 11, 20265. [Google Scholar] [CrossRef]

- Roopa, A.K.; Hunashyal, A.M.; Patil, A.Y.; Patil, A.; Soudagar, M.; Shahapurkar, K.; Khan, Y.; Kalam, M.A. Study on Interfacial Interaction of Cement-Based Nanocomposite by Molecular Dynamic Analysis and an RVE Approach. Adv. Civ. Eng. 2023, 2023, 8404335. [Google Scholar] [CrossRef]

- Qin, R.; Zhou, A.; Yu, Z.; Wang, Q.; Lau, D. Role of carbon nanotube in reinforcing cementitious materials: An experimental and coarse-grained molecular dynamics study. Cem. Concr. Res. 2021, 147, 106517. [Google Scholar] [CrossRef]

- Sindu, B.S.; Sasmal, S. Molecular dynamics simulations for evaluation of surfactant compatibility and mechanical characteristics of carbon nanotubes incorporated cementitious composite. Constr. Build. Mater. 2020, 253, 119190. [Google Scholar]

- Yu, Z.; La, D. Evaluation on mechanical enhancement and fire resistance of carbon nanotube (CNT) reinforced concrete. Coupled Syst. Mec. 2017, 6, 335. [Google Scholar]

- Merodio-Perea, R.G.; Páez-Pavón, A.; Lado-Touriño, I. Reinforcing cement with pristine and functionalized carbon nanotubes: Experimental and simulation studies. Int. J. Smart Nano Mater. 2020, 11, 370–386. [Google Scholar] [CrossRef]

- Biovia Materials Studio, an Integrated, Multi-Scale Modelling Environment. Available online: https://www.3ds.com/productsservices/biovia/products/molecular-modeling-simulation/biovia-materials-studio (accessed on 14 January 2025).

- Hoover, W.G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 1985, 31, 1695–1697. [Google Scholar] [CrossRef] [PubMed]

- Nosé, S. A molecular dynamics method for simulations in the canonical ensemble. Mol. Phys. 1984, 52, 255–268. [Google Scholar] [CrossRef]

- Sun, H.; Ren, P.; Fried, J.R. The COMPASS force field: Parameterization and validation for phosphazenes. Comput. Theor. Polym. Sci. 1998, 8, 229–246. [Google Scholar] [CrossRef]

- Bhuvaneshwari, B.; Palani, G.S.; Karunya, R.; Iyer, N.R. Nano mechanical properties on the mineralogical array of calcium silicate hydrates and calcium hydroxide through molecular dynamics. Curr. Sci. 2015, 108, 1058–1065. [Google Scholar]

- Li, K.; Shui, Z.H.; Dai, W. Molecular dynamic simulation of structural and mechanical properties of cement hydrates: From natural minerals to amorphous phases. Mater. Res. Innov. 2011, 16, 338–344. [Google Scholar] [CrossRef]

- Hajilar, S.; Shafei, B. Nano-scale investigation of elastic properties of hydrated cement paste constituents using molecular dynamics simulations. Comput. Mater. Sci. 2015, 101, 216–226. [Google Scholar] [CrossRef]

- Afsharhashemkhani, S.; Jamal-Omidi, M.; Tavakolian, M. A molecular dynamics study on the mechanical properties of defective CNT/epoxy nanocomposites using static and dynamic deformation approaches. Int. Polym. Process. 2022, 37, 176–190. [Google Scholar] [CrossRef]

- Arar, A. Elastic Properties of Cement Phases Using Molecular Dynamic Simulation. Ph.D. Thesis, Toronto Metropolitan University, Toronto, Canada, 2016. [Google Scholar]

- Hajilar, S.; Shafei, B. Molecular Dynamics Simulation of Elastic Properties of Ordered CSH Gel: Case Study of Tobermorite and Jennite. In Proceedings of the 5th International Symposium of Nanotechnology in Construction (NICOM-5), Chicago, IL, USA, 24–26 May 2015. [Google Scholar]

- Hajilar, S.; Shafei, B. Molecular dynamics simulation of elastic properties of tobermorite family. In Proceedings of the 4th RILEM International Symposium on Concrete Modeling (CONMOD 2014), Beijing, China, 12–14 October 2014. [Google Scholar]

- Cho, B.H.; Chung, W.; Nam, B.H. Molecular Dynamics Simulation of Calcium-Silicate-Hydrate for Nano-Engineered Cement Composites—A Review. Nanomaterials 2020, 10, 2158. [Google Scholar] [CrossRef]

- Chung, D.H.; Buessem, W.R. The Voigt-Reuss-Hill Approximation and Elastic Moduli of Polycrystalline MgO, CaF2, ZnS, ZnSe, and CdTe. J. Appl. Phys. 2004, 38, 2535. [Google Scholar]

- Eftekhari, M.; Mohammadi, S. Molecular Dynamics Simulation of the Nonlinear Behavior of the CNT-Reinforced Calcium Silicate Hydrate (C-S-H) Composite. Compos. A Appl. Sci. Manuf. 2016, 82, 78–87. [Google Scholar]

- Musso, S.; Tulliani, J.M.; Ferro, G.; Tagliaferro, A. Influence of carbon nanotubes structure on the mechanical behavior of cement composites. Compos. Sci. Technol. 2009, 69, 1985–1990. [Google Scholar]

- Wang, J.F.; Zhang, L.W.; Liew, K.M. Multiscale simulation of mechanical properties and microstructure of CNT-reinforced cement-based composites. Comput. Methods Appl. Mech. Eng. 2017, 319, 393–413. [Google Scholar]

- Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr. Build. Mater. 2022, 315, 125100. [Google Scholar]

- Velez, K.; Maximilien, S.; Damidot, D.; Fantozzi, G.; Sorrentino, F. Determination by nanoindentation of elastic modulus and hardness of pure constituents of Portland cement clinker. Cem. Concr. Res. 2001, 31, 555–561. [Google Scholar]

- Jennings, H.M. A model for the microstructure of calcium silicate hydrate in cement paste. Cem. Concr. Res. 2000, 30, 110–116. [Google Scholar]

- Yoshimura, H.N.; Molisani, A.L.; Narita, N.E.; Cesar, P.F.; Goldenstein, H. Porosity dependence of elastic constants in aluminum nitride ceramics. Mater. Res. 2007, 10, 127–133. [Google Scholar]

- Fu, J.; Bernard, S.; Kamali-Bernard, S. Assessment of the elastic properties of amorphous calcium silicates hydrates (I) and (II) structures by molecular dynamics simulation. Mol. Simul. 2018, 44, 285–299. [Google Scholar]

- González-Teresa, R.; Morales-Florez, V.; Manzano, H.; Dolado, J.S. Modelos estructurales del empaquetamiento aleatorio de partículas esféricas de Tobermorita: Una aproximación computacional sencilla. Mater. Constr. 2010, 60, 7–15. [Google Scholar]

- Constantinides, G.; Ulm, F.J. The effect of two types of C-S-H on the elasticity of cement-based materials: Results from nanoindentation and micromechanical modeling. Cem. Concr. Res. 2004, 34, 67–80. [Google Scholar]

- Keinde, D. Etude du Béton à l’échelle Mesoscopique: Simulation Numérique et Tests de Micro-Indentation. Ph.D. Thesis, Institut National des Sciences Appliquées de Rennes, Rennes, France, 2014. [Google Scholar]

- Sánchez, F.; Zhang, L. Molecular dynamics modeling of the interface between surface functionalized graphitic structures and calcium–silicate–hydrate: Interaction energies, structure, and dynamics. J. Colloid. Interface Sci. 2008, 323, 349–358. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz, Y.I. Analyzing Single Fiber Fragmentation Test Data by Using Stress Transfer Model. J. Compos. Mater. 2002, 36, 537–551. [Google Scholar]

- Al-Muhit, B.; Sanchez, F. Nano-engineering of the mechanical properties of tobermorite 14 Å with graphene via molecular dynamics simulations. Constr. Build. Mater. 2020, 233, 117237. [Google Scholar] [CrossRef]

| Structure | No. of CNTs |

|---|---|

| Tobermorite + CNT (PTCNT3) | 3 (2.5) |

| Tobermorite + CNT (PTCNT7) | 7 (2.6) |

| Tobermorite + CNT (PTCNT12) | 12 (2.7) |

| Tobermorite + CNT + 2COOH (CNT2C2) | 2 (2.5) |

| Tobermorite + CNT + 2COOH (CNT2C6) | 6 (2.6) |

| Tobermorite + CNT + 2COOH (CNT2C10) | 10 (2.7) |

| Tobermorite + CNT + 4COOH (CNT4C3) | 3 (2.5) |

| Tobermorite + CNT + 4COOH (CNT4C7) | 7 (2.6) |

| Tobermorite + CNT + 4COOH (CNT4C12) | 12 (2.7) |

| Structure | K (GPa) | G (GPa) | E (GPa) | ν |

|---|---|---|---|---|

| Tobermorite | 43.99 | 31.98 | 77.05 | 0.21 |

| PTCNT3 | 45.43 | 32.46 | 78.12 | 0.21 |

| PTCNT7 | 46.93 | 33.17 | 80.20 | 0.21 |

| PTCNT12 | 65.56 | 32.53 | 81.93 | 0.27 |

| CNT2C2 | 89.94 | 32.41 | 82.18 | 0.27 |

| CNT2C6 | 52.05 | 34.54 | 84.60 | 0.22 |

| CNT2C10 | 68.69 | 34.23 | 87.64 | 0.28 |

| CNT4C3 | 54.22 | 33.48 | 91.91 | 0.24 |

| CNT4C7 | 80.06 | 37.35 | 96.55 | 0.29 |

| CNT4C12 | 57.50 | 40.90 | 97.87 | 0.20 |

| Structure | Eo (GPa) | E (Gpa) p = 0.26 | E (Gpa) p = 0.36 |

|---|---|---|---|

| Tobermorite | 77.05 | 31.83 | 22.66 |

| PTCNT3 | 78.12 | 32.27 | 22.97 |

| PTCNT7 | 80.20 | 33.13 | 23.58 |

| PTCNT12 | 81.93 | 33.85 | 24.09 |

| CNT2C2 | 82.18 | 33.95 | 24.16 |

| CNT2C6 | 84.60 | 34.95 | 24.88 |

| CNT2C10 | 87.64 | 36.20 | 25.77 |

| CNT4C3 | 91.91 | 37.97 | 27.03 |

| CNT4C7 | 96.55 | 39.89 | 28.39 |

| CNT4C12 | 97.87 | 40.43 | 28.78 |

| Structure | NHB | dHB (Å) |

|---|---|---|

| CNT2C2 | 10.00 | 1.85 |

| CNT2C6 | 37.00 | 1.92 |

| CNT2C10 | 49.00 | 1.95 |

| CNT4C3 | 25.00 | 1.89 |

| CNT4C7 | 52.67 | 1.97 |

| CNT4C12 | 86.00 | 1.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merodio-Perea, R.G.; Terrón-López, M.-J.; Lado-Touriño, I. Molecular Dynamics Simulation of CNT Reinforced Cement: A Step Toward Sustainable Construction. Sustainability 2025, 17, 3185. https://doi.org/10.3390/su17073185

Merodio-Perea RG, Terrón-López M-J, Lado-Touriño I. Molecular Dynamics Simulation of CNT Reinforced Cement: A Step Toward Sustainable Construction. Sustainability. 2025; 17(7):3185. https://doi.org/10.3390/su17073185

Chicago/Turabian StyleMerodio-Perea, Rosario G., María-José Terrón-López, and Isabel Lado-Touriño. 2025. "Molecular Dynamics Simulation of CNT Reinforced Cement: A Step Toward Sustainable Construction" Sustainability 17, no. 7: 3185. https://doi.org/10.3390/su17073185

APA StyleMerodio-Perea, R. G., Terrón-López, M.-J., & Lado-Touriño, I. (2025). Molecular Dynamics Simulation of CNT Reinforced Cement: A Step Toward Sustainable Construction. Sustainability, 17(7), 3185. https://doi.org/10.3390/su17073185