Solutions for Energy and Raw Material Recovery from Sewage Sludge Within the Concept of Circular Economy

Abstract

1. Introduction

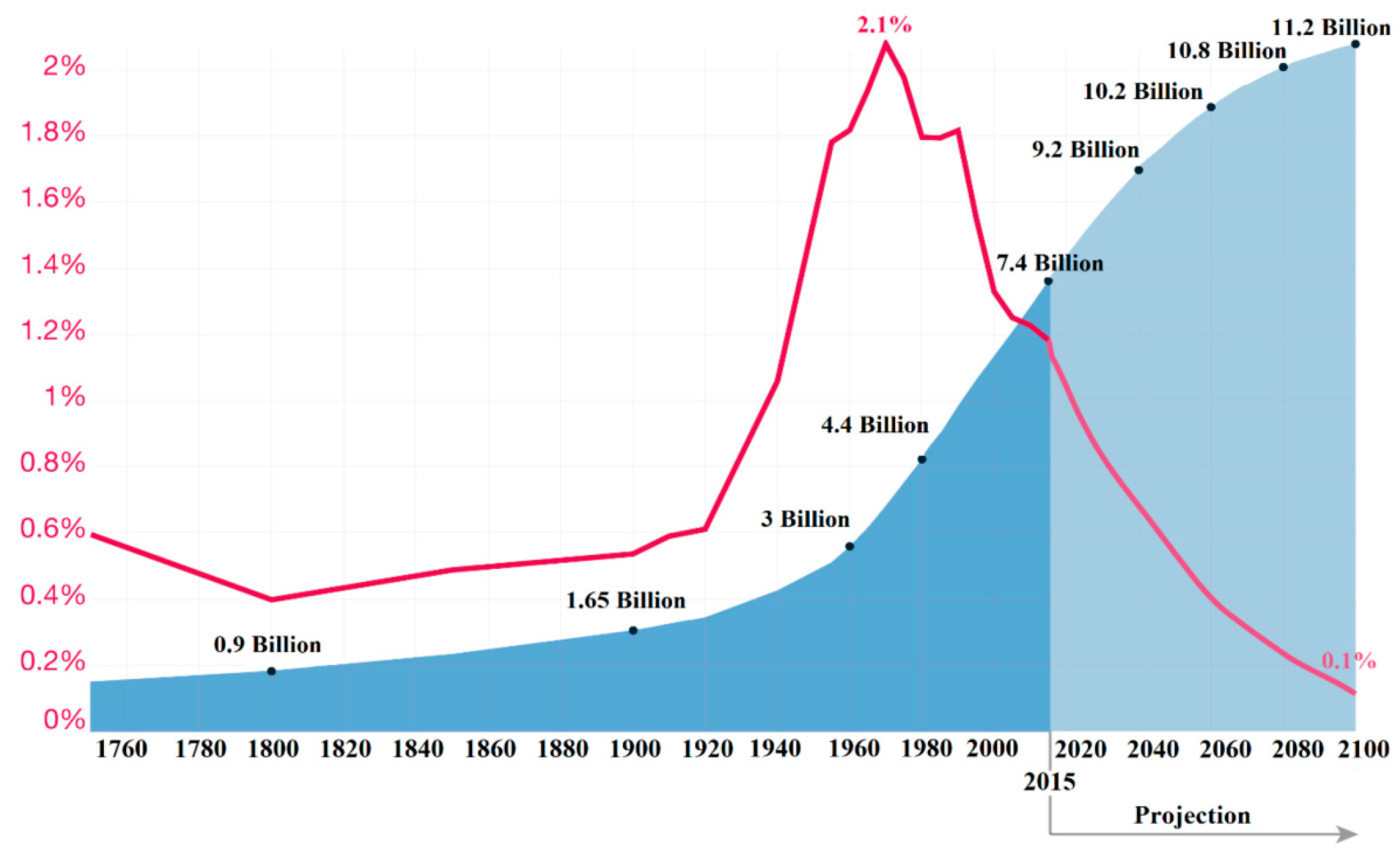

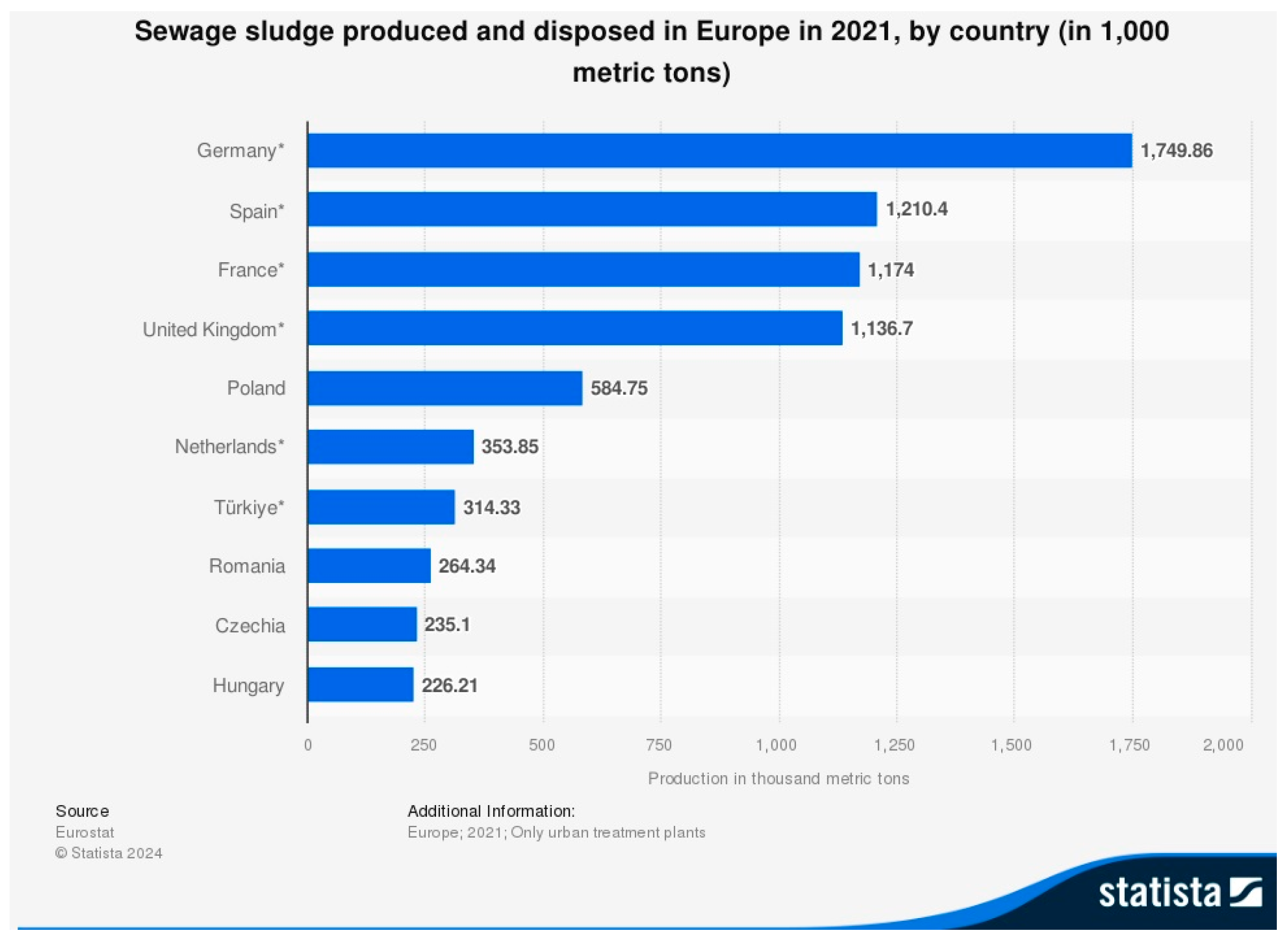

1.1. Motivation and Purpose

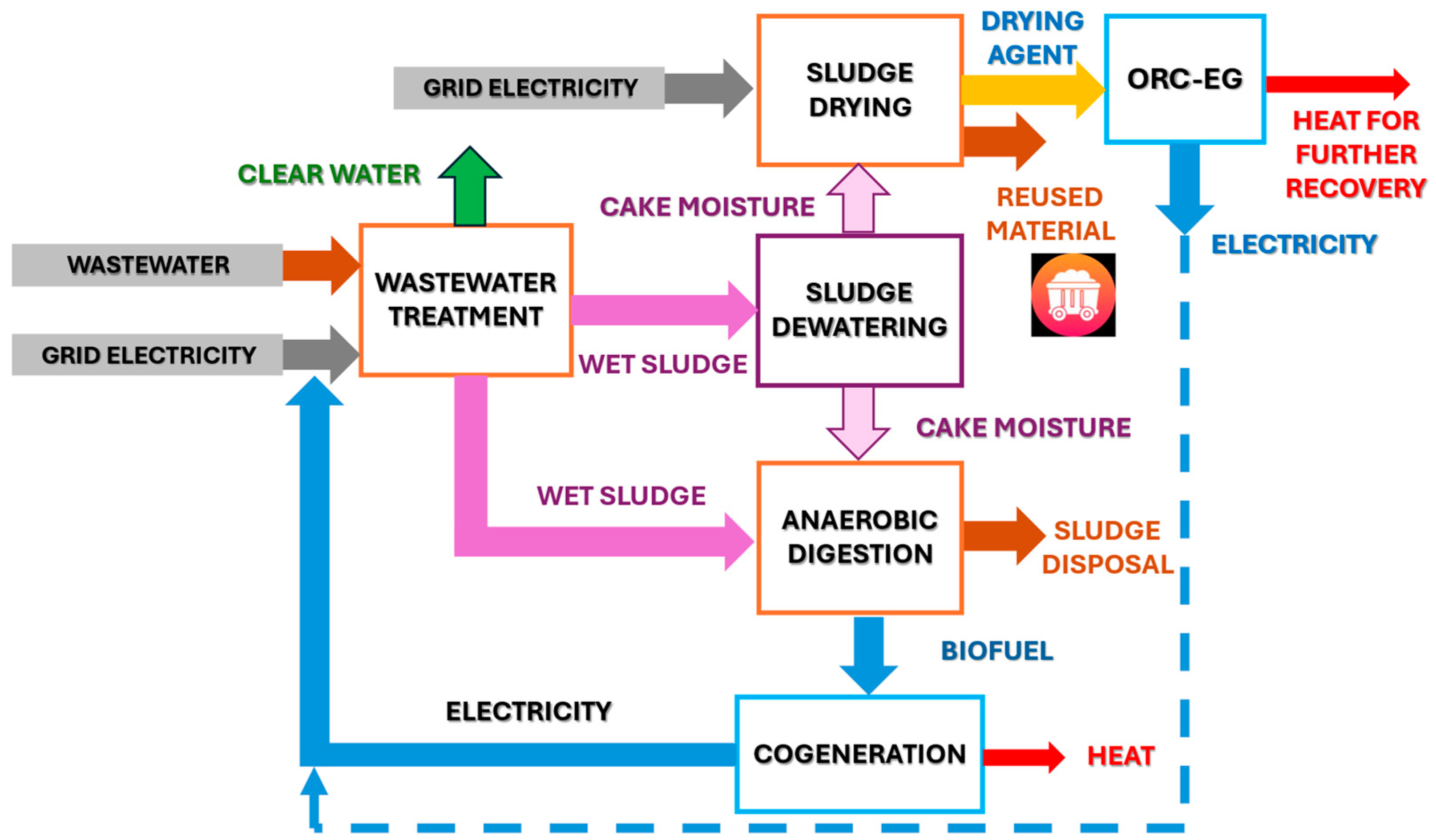

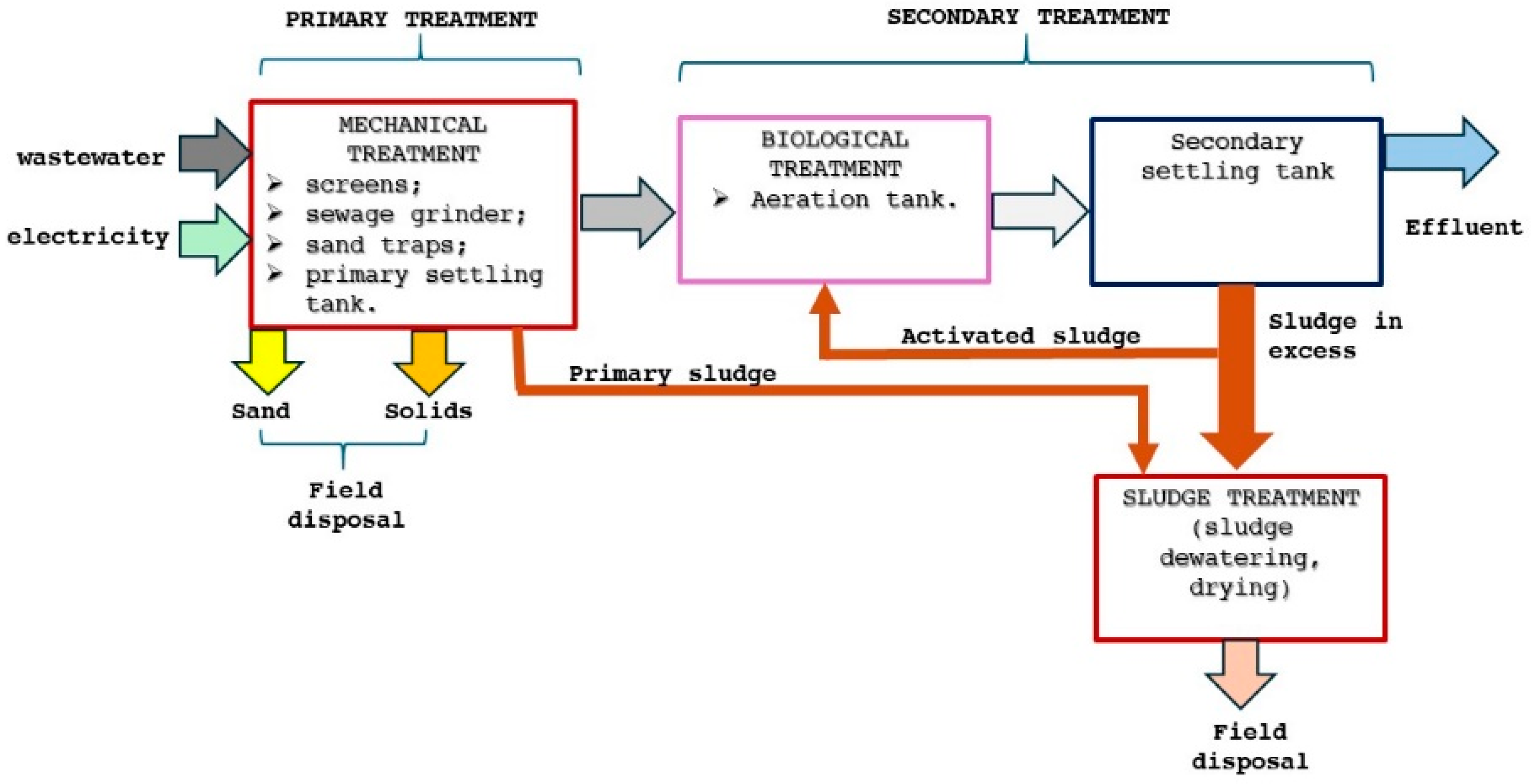

1.2. Sewage Sludge Treatment Methods and Management

1.3. Constanta North Wastewater Treatment Plant

2. Materials and Methods

2.1. Sample Analysis Methods

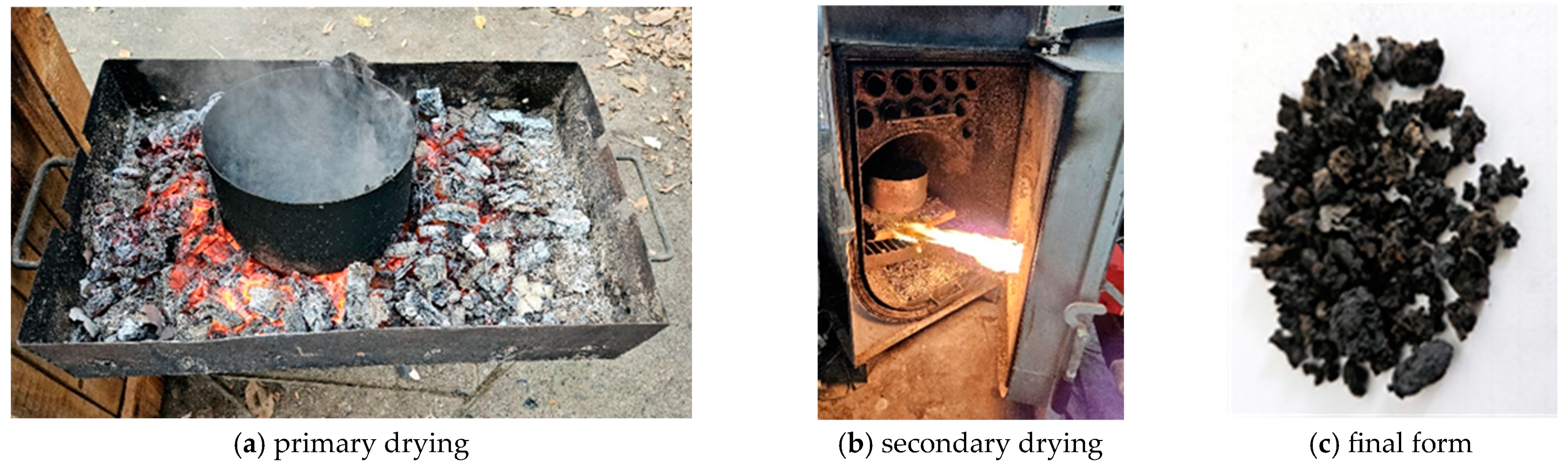

2.2. Drying Installation Description and Related Technology

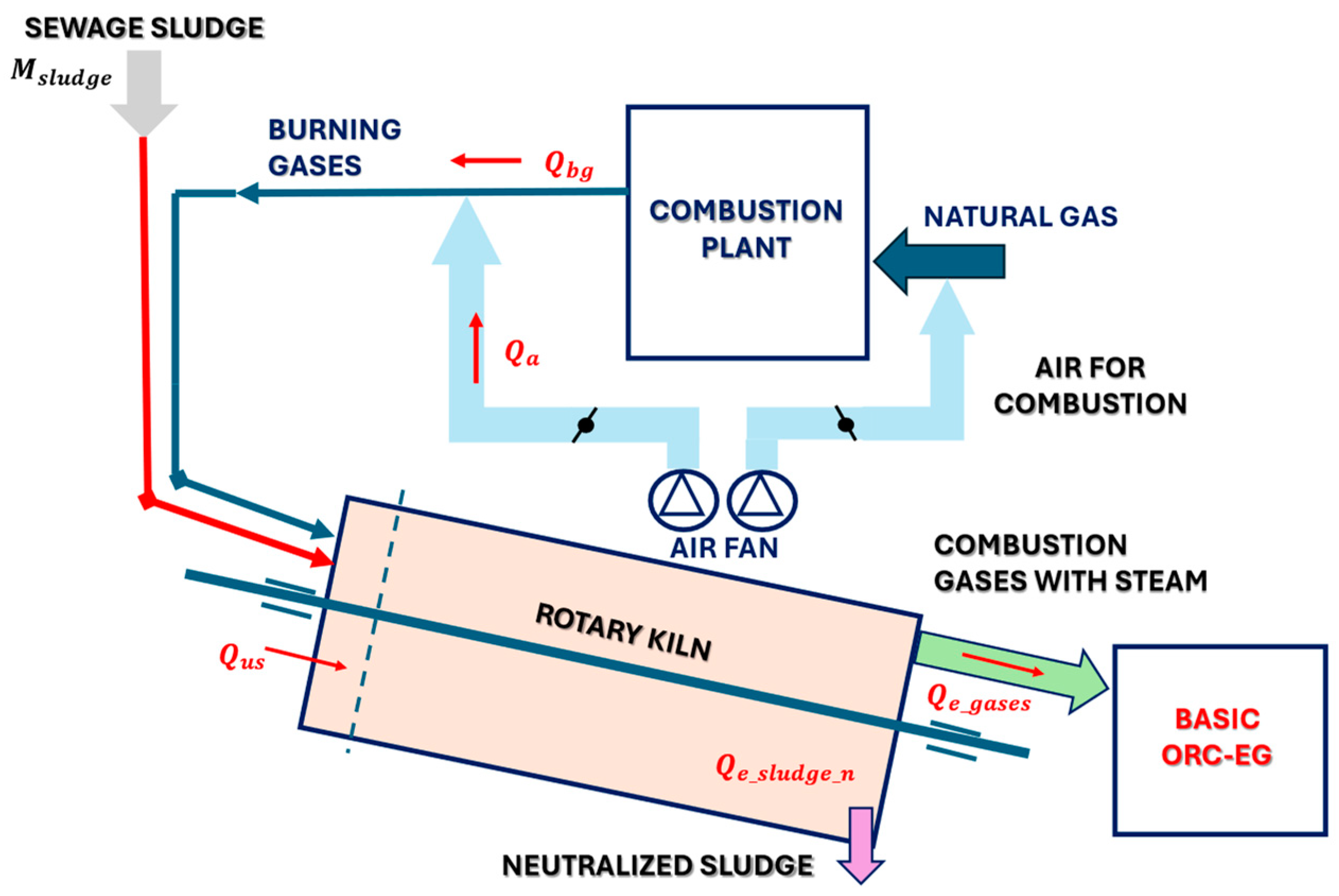

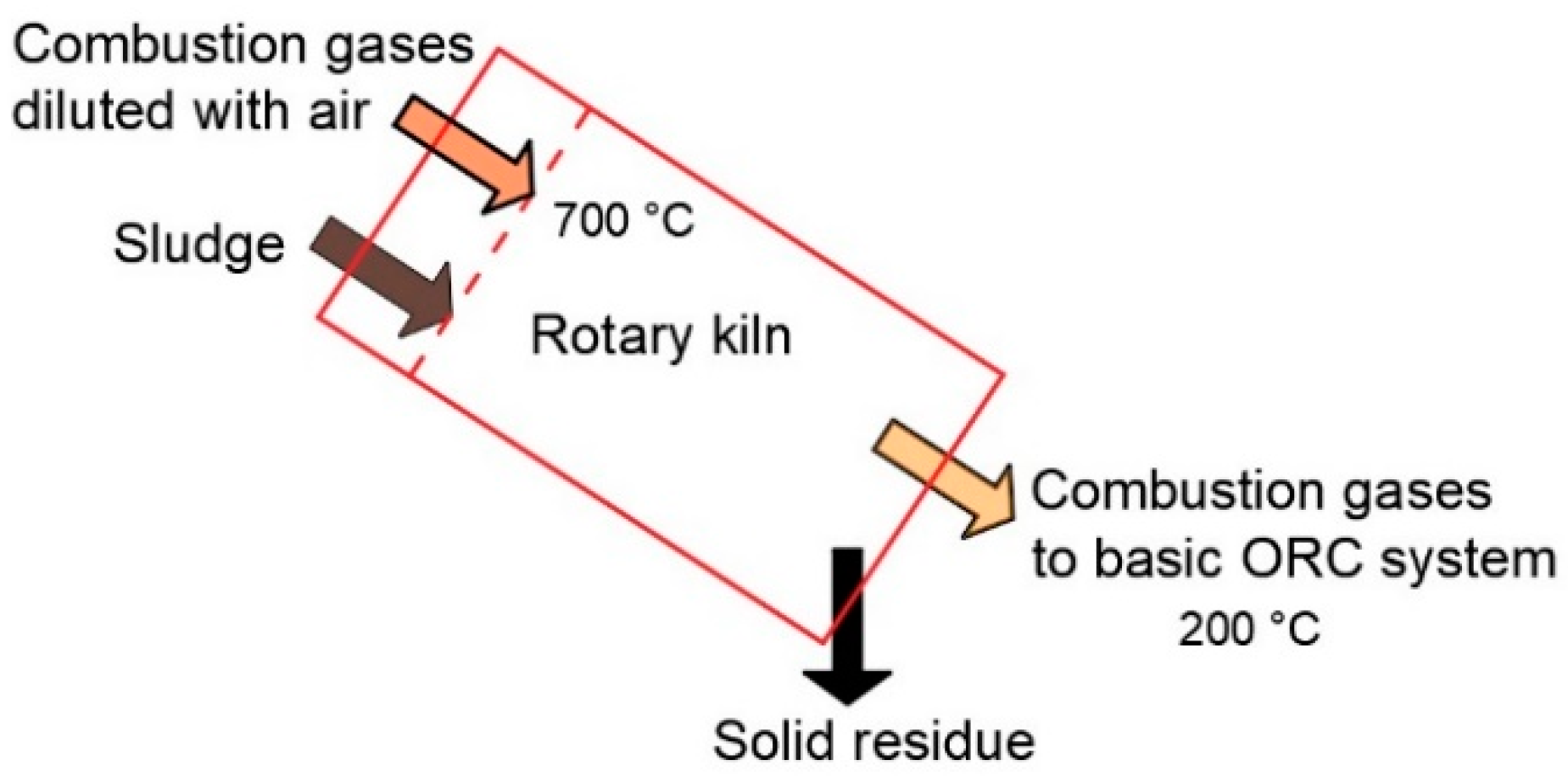

2.3. Energy Balance of the Plant

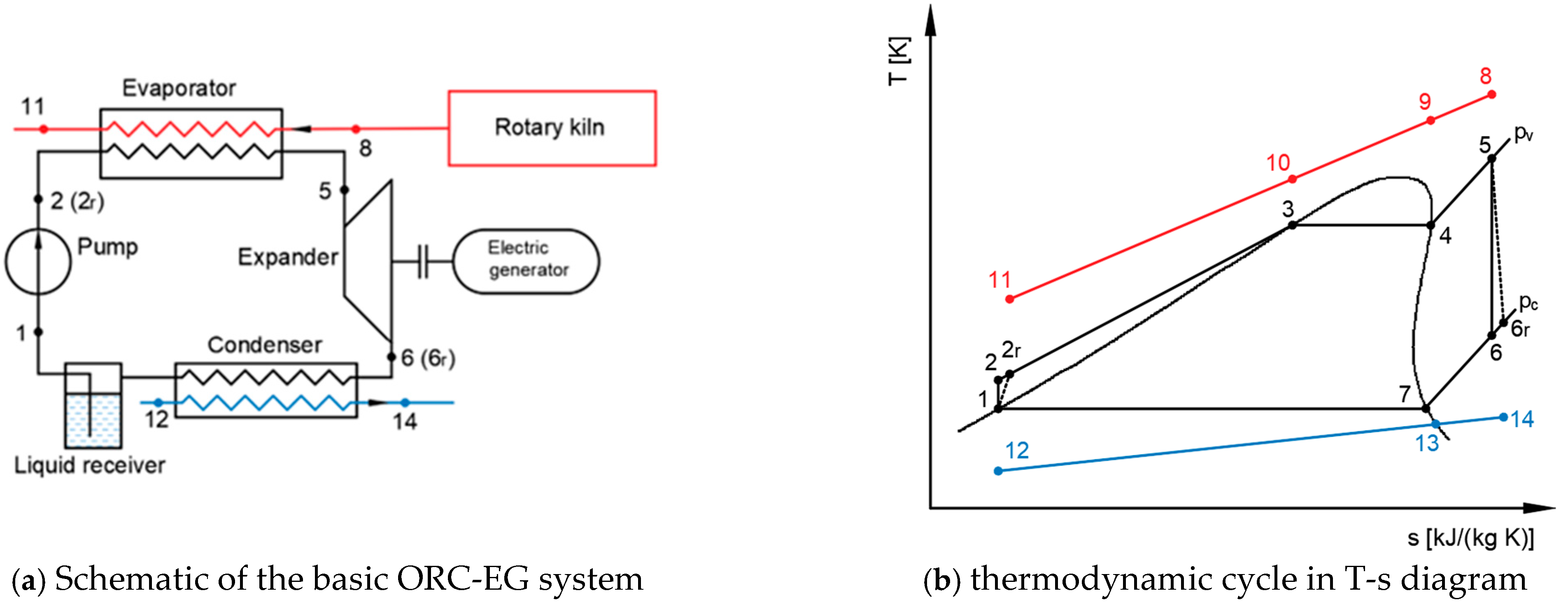

2.4. Energy Recovery by an ORC System

3. Results and Discussion

3.1. Analysis of Sewage Sludge

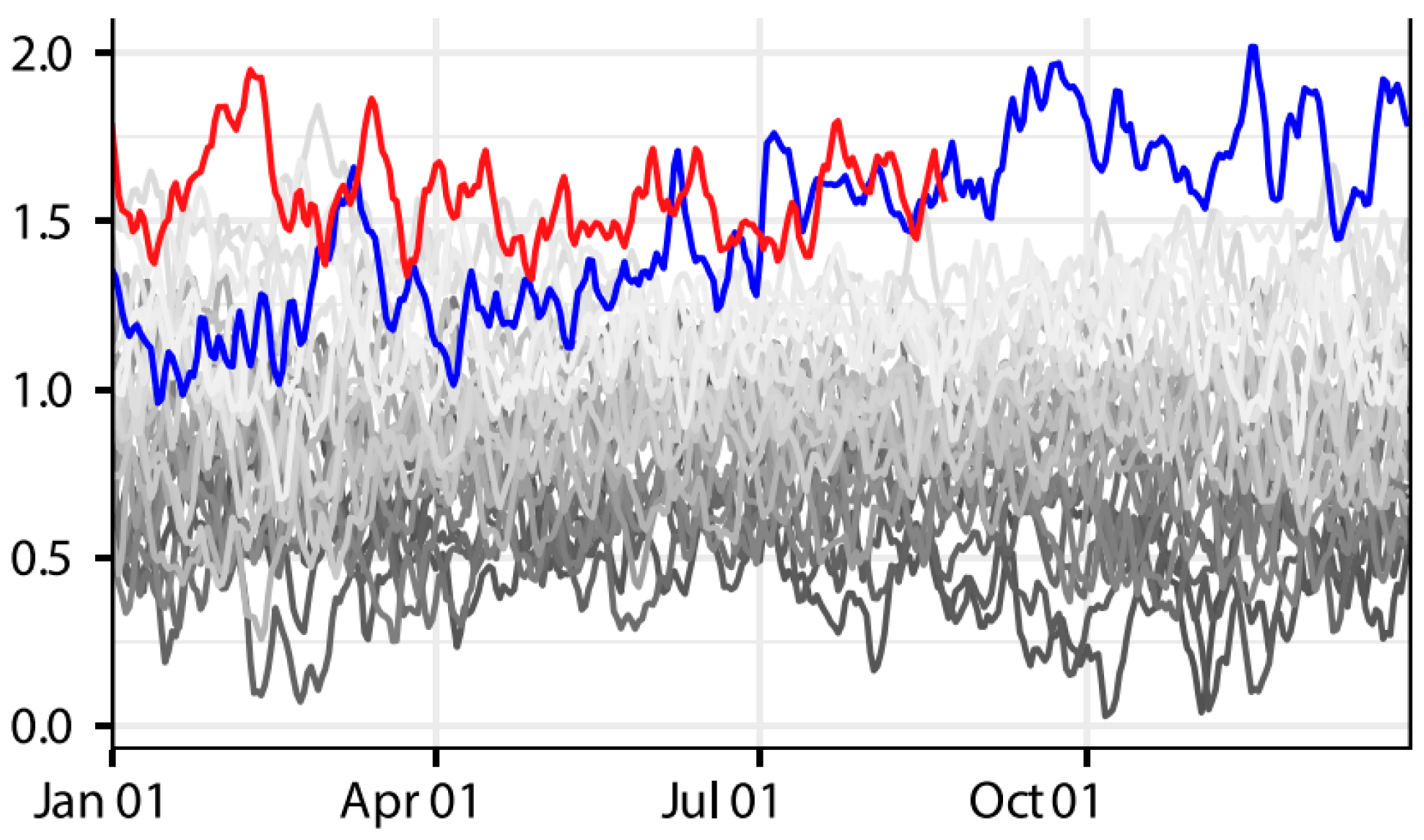

3.2. Gas Flow Rate and Power Calculated for Different Sludge Flow Rates

3.3. Results Regarding Energy Recovery by the ORC-EG System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WWTP | Wastewater Treatment Plant |

| AnMBR | Anaerobic Membrane Bioreactors |

| CAD | Conventional Anaerobic Digestion |

| PE | People Equivalent |

| HTC | Hydrothermal Carbonization |

| HTL | Hydrothermal Liquefaction |

| ORC | Organic Rankine Cycle |

| EES | Engineering Equation Solver |

| SDGs | Sustainable Development Goals |

| Wt | Total Water Content |

| V | Volatile Matter |

| A | Ash Content |

| Cf | Carbon Fixed Content |

References

- Ripple, W.J.; Wolf, C.; Gregg, J.W.; Rockström, J.; Mann, M.E.; Oreskes, N.; Lenton, T.M.; Rahmstorf, S.; Newsome, T.M.; Xu, C.; et al. The 2024 state of the climate report: Perilous times on planet Earth. BioScience 2024, 74, 812–824. [Google Scholar] [CrossRef]

- Rutgersson, A.; Kjellström, E.; Haapala, J.; Stendel, M.; Danilovich, I.; Drews, M.; Jylhä, K.; Kujala, P.; Larsén, X.G.; Halsnæs, K.; et al. Natural hazards and extreme events in the Baltic Sea region. Earth Syst. Dynam. 2022, 13, 251–301. [Google Scholar] [CrossRef]

- Roser, M.; Ritchie, H. How Has World Population Growth Changed Over Time? Available online: https://ourworldindata.org/population-growth-over-time (accessed on 17 January 2024).

- Mesterházy, Á.; Oláh, J.; Popp, J. Losses in the Grain Supply Chain: Causes and Solutions. Sustainability 2020, 12, 2342. [Google Scholar] [CrossRef]

- Benidickson, J. The Culture of Flushing: A Social and Legal History of Sewage; UBC Press: Vancouver, BC, Canada, 2011; pp. 98–120. [Google Scholar]

- Spellman, F.R. Handbook of Water and Wastewater Treatment Plant; CRC Press LLC: Boca Raton, FL, USA, 2003; pp. 46–48. [Google Scholar]

- Hernández-Chover, V.; Castellet-Viciano, L.; Fuentes, R.; Hernández-Sancho, F. Circular economy and efficiency to ensure the sustainability in the wastewater treatment plants. J. Clean. Prod. 2023, 384, 13563. [Google Scholar] [CrossRef]

- Available online: https://www.statista.com/statistics/1393771/sewage-sludge-generation-europe/ (accessed on 24 January 2025).

- Cîrstea, Ș.D.; Moldovan-Teselinos, C.; Cîrstea, A.; Turcu, A.C.; Darab, C.P. Evaluating renewable energy sustainability by composite index. Sustainability 2018, 10, 811. [Google Scholar] [CrossRef]

- Gonçales, R.F.; Luduvice, M.; von Sperling, M. Sludge thickering and dewatering. In Sludge Treatment and Disposal, 1st ed.; Andreoli, C.V., von Sperling, M., Fernandes, F., Eds.; IWA Publishing: London, UK, 2007; Volume 6, pp. 82–119. [Google Scholar]

- Kiselev, A.; Glushankova, I.; Rudakova, L.; Baynkin, A.; Magarili, E.; Rada, E. Energy and material assessment of municipal sewage sludge applications under circular economy. Int. J. Energy Prod. Manag. 2020, 5, 234–244. [Google Scholar]

- Kadibu, T.N. Circular Economy in the Water and Wastewater Sector: Possibilities for the Local Production and Sale of Biogas and Biochar to Finance Municipal Treatment Plant’s Operation and Maintenance Costs and Enhance Sustainability. Master’s Thesis, Norwegian University of Life Sciences, Ås, Norway, 2023. Available online: https://core.ac.uk/download/591078584.pdf (accessed on 24 January 2025).

- Kehrein, P.; van Loosdrecht, M.; Osseweijer, P.; Garfí, M.; Dewulf, J.; Posada, J. A critical review of resource recovery from municipal wastewater treatment plants: Market supply potentials, technologies and bottlenecks. Environ. Sci. Water Res. Technol. 2020, 6, 877–910. Available online: https://core.ac.uk/download/287941394.pdf (accessed on 24 January 2025).

- Cheng, W.; Lin, X.; Liu, W.; Cao, H.; Xu, J. Evaluation of the Feasibility and Utilizability of Pretreated Sewage Sludge in Cement Kiln Co-Processing. Sustainability 2024, 16, 9025. [Google Scholar] [CrossRef]

- Mislej, V.; Novosel, B. Specification and Classification of Pelletised Dried Sewage Sludge: Identifying Its Key Properties as a Renewable Material for Enabling Environmentally Non-Harmful Energy Utilisation. Sustainability 2022, 14, 14836. [Google Scholar] [CrossRef]

- Berroug, F.; Bellaziz, Y.; Tagnamas, Z.; Bahammou, Y.; Faraji, H.; Bougayr, E.H.; Ouazzani, N. Drying Performance of a Combined Solar Greenhouse Dryer of Sewage Sludge. Sustainability 2024, 16, 9925. [Google Scholar] [CrossRef]

- Đurđević, D.; Blecich, P.; Jurić, Ž. Energy Recovery from Sewage Sludge: The Case Study of Croatia. Energies 2019, 12, 1927. [Google Scholar] [CrossRef]

- Pratap, V.; Kumar, S.; Yadav, B.R. Yadav, Sewage sludge management and enhanced energy recovery using anaerobic digestion: An insight. Water Sci. Technol. 2024, 90, 696. [Google Scholar] [CrossRef]

- Xu, C.C.; Lancaster, J. Treatment of Secondary Sludge for Energy Recovery; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2009. [Google Scholar]

- Bień, J.; Bień, B. Energy Recovery from Municipal Sewage Sludge: Combustion Kinetics in a Varied Oxygen–Carbon Dioxide Atmosphere. Energies 2024, 17, 5382. [Google Scholar] [CrossRef]

- Vatachi, N. Wastewater sludge to energy production. A review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 595, 012053. [Google Scholar] [CrossRef]

- Tran, T.; Lan, P.N.K.; Thi, V.D.; Van Giang, L.; Van Tan, L. Energy recovery of sewage sludge treatment by anaerobic co-digestion. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1126, 012031. [Google Scholar] [CrossRef]

- Cengiz, A.I.; Guven, H.; Ozgun, H.; Ersahin, M.E. Enhanced energy recovery in municipal wastewater treatment plants through co-digestion by anaerobic membrane bioreactors: Current status and future perspectives. Rev. Environ. Sci. Biotechnol. 2024, 23, 385–410. [Google Scholar] [CrossRef]

- Saud, A.; Havukainen, J.; Peltola, P.; Horttanainen, M. Integrating Pyrolysis or Combustion with Scrubbing to Maximize the Nutrient and Energy Recovery from Municipal Sewage Sludge. Recycling 2021, 6, 52. [Google Scholar] [CrossRef]

- Li, C.; Li, J.; Xie, S.; Zhu, X.; Wang, X.; Wang, Y.; Angelidaki, I. Enhancement of energy recovery from synergetic treatment of sewage sludge and food waste. In Proceedings of the Applied Energy Symposium 2020: Low Carbon Cities and Urban Energy Systems, Tokyo, Japan, 10–17 October 2020; Paper ID: CUE2020-D-093. 2020. [Google Scholar]

- Bezirgiannidis, A.; Chatzopoulos, P.; Tsakali, A.; Ntougias, S.; Melidis, P. Renewable energy recovery from sewage sludge derived from chemically enhanced precipitation. Renew. Energy 2020, 162, 1811–1818. [Google Scholar]

- Wang, R.; Wang, C.; Zhao, Z.; Jia, J.; Jin, Q. Energy recovery from high-ash municipal sewage sludge by hydrothermal carbonization: Fuel characteristics of biosolid products. Energy 2019, 186, 115848. [Google Scholar]

- Capodaglio, A.G.; Callegari, A. Energy and resources recovery from excess sewage sludge: A holistic analysis of opportunities and strategies. Resour. Conserv. Recycl. Adv. 2023, 19, 200184. [Google Scholar]

- Das, P.; Khan, S.; AbdulQuadir, M.; Thaher, M.; Waqas, M.; Easa, A.; Attia, E.S.M.; Al-Jabri, H. Energy recovery and nutrients recycling from municipal sewage sludge. Sci. Total Environ. 2020, 715, 136775. [Google Scholar]

- Ion, N.; Mihăescu, L.; Ionescu, G.; Pop, E.; Negreanu, G.P.; Safta, C.A. Analysis of energy consumption for neutralization of the wastewater treatment plants sludge. E3S Web Conf. 2025, 608, 05017. [Google Scholar] [CrossRef]

- Ion, N. Optimizarea Consumului de Energie Electrică în Stațiile de Epurare a Apelor Uzate Folosind Surse Regenerabile de Energie, în Contextul Conceptului de Economie Circulară (Optimizing Electricity Consumption in Wastewater Treatment Plants Using Renewable Energy Sources, in the Context of the Circular Economy Concept). Ph.D. Thesis, Politehnica Bucharest, Bucharest, Romania, 2024. [Google Scholar]

- Ion, N.; Safta, C.A. Circular economy indicators applied to wastewater treatment process. U.P.B. Sci. Bull. Ser. C 2025, 87, 401–416. [Google Scholar]

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering: Treatment and Reuse; McGraw Hill: New York, NY, USA, 2014. [Google Scholar]

- Thermo Scientific UniQuant Software, Program for Quantitative XRF Analysis Using Thermo Scientific ARL WDXRF Spectrometers. Product Specifications PS41207. Available online: https://assets.thermofisher.com/TFS-Assets/MSD/Specification-Sheets/XR-PS41207-UniQuant.pdf (accessed on 24 January 2025).

- Pănoiu, M.; Mihăescu, L.; Cazacu Popescu, C.L.; Bidleșeanu, D.; Bălan, P. The Combustion Installations Modernization for Industrial Boilers; Ed. Tehnică: Bucharest, Romanian, 1993. (In Romanian) [Google Scholar]

- Bădescu, V.; Aboaltabooq, M.H.K.; Pop, H.; Apostol, V.; Prisecaru, M.; Prisecaru, T. Design and operational procedures for ORC-based systems coupled with internal combustion engines driving electrical generators at full and partial load. Energy Convers. Manag. 2017, 139, 206–221. [Google Scholar] [CrossRef]

- Bădescu, V.; Aboaltabooq, M.H.K.; Pop, H.; Apostol, V.; Prisecaru, M.; Prisecaru, T. Avoiding malfunction of ORC-based systems for heat recovery from internal combustion engines under multiple operation conditions. Appl. Therm. Eng. 2019, 150, 977–986. [Google Scholar] [CrossRef]

- Engineering Equation Solver Academic Professional; V.10.664-3D #4487; Faculty of Mechanical Engineering, University Politehnica of Bucharest: Bucharest, Romania, 2019.

- Smith, S.R. Organic contaminants in sewage sludge (biosolids) and their significance for agricultural recycling. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 4005–4041. [Google Scholar]

- Rashid, A.; Schutte, B.J.; Ulery, A.; Deyholos, M.K.; Sanogo, S.; Lehnhoff, E.A.; Beck, L. Heavy Metal Contamination in Agricultural Soil: Environmental Pollutants Affecting Crop Health. Agronomy 2023, 13, 1521. [Google Scholar] [CrossRef]

- Zabielska-Adamska, K. Sewage sludge bottom ash characteristics and potential application in road embankment. Sustainability 2019, 12, 39. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S.; West, R.P. Sewage sludge ash characteristics and potential for use in concrete. Constr. Build. Mater. 2015, 98, 767–779. [Google Scholar]

- Cement Rotary Kiln. Available online: https://cementplantequipment.com/products/rotary-kiln/ (accessed on 20 January 2025).

- Regulation (EU) 2024/573 of the European Parliament and of the Council of 7 February 2024 on Fluorinated Greenhouse Gases, Amending Directive (EU) 2019/1937 and Repealing Regulation (EU) No 517/2014. Available online: https://eur-lex.europa.eu/eli/reg/2024/573/oj/eng (accessed on 24 January 2025).

- Matuszewska, D. Economic Analysis of Gas Turbine Using to Increase Efficiency of the Organic Rankine Cycle. Sustainability 2024, 16, 75. [Google Scholar] [CrossRef]

- Javanshir, A.; Sarunac, N.; Razzaghpanah, Z. Thermodynamic analysis of a regenerative organic Rankine cycle using dry fluids. Appl. Therm. Eng. 2017, 123, 852–864. [Google Scholar] [CrossRef]

| No. crt | Quantity | Symbol | Value | Unit |

|---|---|---|---|---|

| 1. | Temperature of the combustion gases at the evaporator inlet | t8 | 200 | °C |

| 2. | Pressure of the combustion gases | p8 | 1.1 | bar |

| 3. | Volume fraction of CO2 from combustion gases | rCO2 | 0.09 | - |

| 4. | Volume fraction of N2 from combustion gases | rN2 | 0.67 | - |

| 5. | Volume fraction of H2O from combustion gases | rH2O | 0.24 | - |

| 6. | Critical temperature | tcr | Depending on the working fluid | °C |

| 7. | Temperature difference between the critical temperature and the evaporating temperature | Δtv | 20 | °C |

| 8. | Isentropic efficiency of the pump | ηP | 0.8 | - |

| 9. | Isentropic efficiency of the expander | ηD | 0.7 | - |

| 10. | Pressure of condenser cooling water | pw | 1.1 | bar |

| 11. | Temperature of the water at the condenser inlet | t12 | 25 | °C |

| 12. | Temperature difference between t13 and t12 | Δtw | 5 | °C |

| 13. | Temperature difference between t7 and t13 | Δtw,con | 5 | °C |

| Sample | Wt (%) | A (%) | V (%) | Cf (%) |

|---|---|---|---|---|

| Sewage sludge before thermal-drying process | 73.92 | 11.40 | 14.05 | 0.63 |

| Solid residue after thermal-drying process | 2.85 | 56.78 | 30.14 | 10.23 |

| Element | Weight [%] |

|---|---|

| Fe | 31.56 |

| Ca | 21.14 |

| Si | 18.18 |

| Px | 8.75 |

| K | 7.43 |

| Al | 4.19 |

| Sx | 1.66 |

| Ti | 1.66 |

| Mg | 0.797 |

| Zn | 0.599 |

| Sr | 0.439 |

| Cl | 0.315 |

| Ba | 0.298 |

| Mn | 0.267 |

| Br | 0.243 |

| Cu | 0.233 |

| Zr | 0.227 |

| Mo | 0.0723 |

| Pb | 0.0595 |

| Cr | 0.0528 |

| Ni | 0.0367 |

| V | 0.0354 |

| Cd | 0.0237 |

[kg/h] | [kg/kg] | [Nm3/kg] | [kW] | [Nm3/h] |

|---|---|---|---|---|

| 5000 | 0.6 | 3.380 | 3331 | 373.22 |

| 0.65 | 3.630 | 3577 | 400.82 | |

| 0.7 | 3.880 | 3824 | 428.42 | |

| 10,000 | 0.6 | 3.380 | 6662 | 746.44 |

| 0.65 | 3.630 | 7155 | 801.64 | |

| 0.7 | 3.880 | 7647 | 856.84 | |

| 20,000 | 0.6 | 3.380 | 13,324 | 1492.88 |

| 0.65 | 3.630 | 14,309 | 1603.28 | |

| 0.7 | 3.880 | 15,295 | 1713.68 |

[kg/h] | [kg/kg] | [Nm3/kg] | [kW] | [Nm3/h] |

|---|---|---|---|---|

| 5000 | 0.6 | 2.433 | 2398 | 268.65 |

| 0.65 | 2.802 | 2761 | 309.32 | |

| 0.7 | 3.170 | 3124 | 349.99 | |

| 10,000 | 0.6 | 2.433 | 4795 | 537.29 |

| 0.65 | 2.802 | 5521 | 618.64 | |

| 0.7 | 3.170 | 6247 | 699.98 | |

| 20,000 | 0.6 | 2.433 | 9591 | 1074.58 |

| 0.65 | 2.802 | 11,043 | 1237.27 | |

| 0.7 | 3.170 | 12,495 | 1399.96 |

| Capacity [kg/h] | ||

|---|---|---|

| 5000–10,000 | >20,000 | |

| Specification [m] | Φ2.8/2.5 × 44 | Φ3 × 48 |

| Thrust roller type | mechanical | mechanical or hydraulic |

| Kiln rotation speed [rpm] | 0.445–2.22 | 0.676–3.38 |

| Motor | ||

| Model | ZSN4-225-21 | Z2-101 |

| Rated power [kW] | 55 | 100 |

| Speed regulation range [rpm] | ~1000 | ~1500 |

| Reducer | ||

| Model | ZS145-1-1 | ZS145-1-1 |

| Overall speed ratio | 49–63 | 50 |

| No. crt. | Quantity | Symbol | Value | Unit |

|---|---|---|---|---|

| 1. | Volume of combustion gases for 1 kg of sludge dried in the rotary kiln | V | 3 | m3 |

| 2. | Partial pressure of CO2 from combustion gases | pCO2 | 0.099 | bar |

| 3. | Partial pressure of N2 from combustion gases | pN2 | 0.737 | bar |

| 4. | Partial pressure of H2O from combustion gases | pH2O | 0.264 | bar |

| 5. | Mass fraction of CO2 from combustion gases | gCO2 | 0.147 | - |

| 6. | Mass fraction of N2 from combustion gases | gN2 | 0.694 | - |

| 7. | Mass fraction of H2O from combustion gases | gH2O | 0.159 | - |

| 8. | Mass-specific heat at constant pressure for CO2 | cp,CO2 | 0.958 | kJ/(kg·K) |

| 9. | Mass-specific heat at constant pressure for N2 | cp,N2 | 1.047 | kJ/(kg·K) |

| 10. | Mass-specific heat at constant pressure for H2O | cp,H2O | 1.931 | kJ/(kg·K) |

| 11. | Mass-specific heat at constant pressure for the combustion gases | cp,g | 1.175 | kJ/(kg·K) |

| 12. | Mass of combustion gases for 1 kg of sludge dried in the rotary kiln | mg | 2.268 | kg |

| 13. | Density of combustion gases | ρg | 0.756 | kg/m3 |

| 14. | Heat recovered from combustion gases for 1 kg of sludge dried in the rotary kiln | Qrec | 266.5 | kJ/kg of sludge |

| Working Fluid | Sludge Mass Flow Rate [kg/h] | [kW] | ΔTsh [°C] | [kg/s] | Pnet [kW] | ηt [-] | [kg/s] | Ep [kWh/day] |

|---|---|---|---|---|---|---|---|---|

| R600a | 5000 | 370.2 | 23 | 0.788 | 38.84 | 0.1049 | 3.601 | 913.4 |

| 10,000 | 740.4 | 1.577 | 77.68 | 7.201 | 1826.8 | |||

| 20,000 | 1480.7 | 3.154 | 155.36 | 14.402 | 3653.3 | |||

| R1336mzz(Z) | 5000 | 370.2 | 1 | 1.483 | 46.86 | 0.1266 | 3.531 | 1102.3 |

| 10,000 | 740.3 | 2.966 | 93.73 | 7.063 | 2204.3 | |||

| 20,000 | 1480.7 | 5.932 | 187.46 | 14.127 | 4409.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pop, E.; Mihăescu, L.; Safta, C.A.; Pop, H.L.; Negreanu, G.P.; Pîșă, I. Solutions for Energy and Raw Material Recovery from Sewage Sludge Within the Concept of Circular Economy. Sustainability 2025, 17, 3181. https://doi.org/10.3390/su17073181

Pop E, Mihăescu L, Safta CA, Pop HL, Negreanu GP, Pîșă I. Solutions for Energy and Raw Material Recovery from Sewage Sludge Within the Concept of Circular Economy. Sustainability. 2025; 17(7):3181. https://doi.org/10.3390/su17073181

Chicago/Turabian StylePop, Elena, Lucian Mihăescu, Carmen Anca Safta, Horațiu Lucian Pop, Gabriel Paul Negreanu, and Ionel Pîșă. 2025. "Solutions for Energy and Raw Material Recovery from Sewage Sludge Within the Concept of Circular Economy" Sustainability 17, no. 7: 3181. https://doi.org/10.3390/su17073181

APA StylePop, E., Mihăescu, L., Safta, C. A., Pop, H. L., Negreanu, G. P., & Pîșă, I. (2025). Solutions for Energy and Raw Material Recovery from Sewage Sludge Within the Concept of Circular Economy. Sustainability, 17(7), 3181. https://doi.org/10.3390/su17073181