1. Introduction

Climate change due to greenhouse gas (GHG) emissions is one of the environmental challenges that cannot be neglected anymore, considering its dramatic consequences on human life and global ecosystem equilibrium [

1,

2]. Among different proposed strategies to face the problem, the use of sustainable sources for energy production, such as plant biomass (PB), plays a central role [

3]. PB represents a renewable energy source that can be considered carbon-neutral under specific conditions, particularly when its production and management follow sustainable practices; this neutrality arises from the fact that the carbon released during combustion corresponds to the amount absorbed by the PB throughout its growth cycle. It is characterized by significant advantages compared to other renewable sources, related to its wide availability and potential high yield [

4]. In addition, the use of PB for energy production is not dependent on environmental conditions [

4] and does not require the recourse to critical raw materials [

5,

6], as in the case of wind power or photovoltaic energy. PB can be adopted in small-to-medium-scale plants and can produce electricity through cogeneration, although, more conveniently, it can be used to provide domestic heat [

7].

In the last 20 years, many efforts have been focused on the possibility of transforming PB into a more efficient fuel, such as syngas [

8], biodiesel [

9], bio-hydrogen [

10], or bio-char [

11]. Unfortunately, the available technologies that allow for these transformations are still limited by economical and management constraints [

12] and are therefore not widely applied. On the contrary, the possibility of using PB in the form of wood pellets (WPEs) or wood chips (WCHs) relies on well-established processes and inexpensive technologies, such as drying, shredding, and pressing, and represents, therefore, a more viable alternative [

13].

From a waste management perspective, biomass utilization enables a significant reduction in waste generation, as it allows for the recovery and valorization of organic material derived from agricultural, forestry, and industrial processes [

14]. This approach optimizes resource flows, minimizing disposal requirements and enhancing the overall efficiency of the production system.

Another critical aspect concerns energy security, as the integration of biomass into national energy mixtures contributes to greater energy independence, reducing the reliance on fossil fuels imports. This is particularly relevant for countries that have abundant agroforestry resources and biomass residues but are dependent on fuel imports for energy production.

Nonetheless, according to the planetary boundary theory [

1], climate change is only one of the consequences of anthropogenic activities, and therefore each solution aimed at mitigating it must be considered in a more holistic vision, verifying the effect of the proposed strategy on other planetary systems [

1]. Therefore, although the use of PB as an energy source may certainly contribute to reaching carbon neutrality and fighting against climate change [

7], it is imperative to verify, through a broader analysis, its consequences on other environmental compartments, to mitigate possible negative effects.

A fundamental aspect is related to the sustainable management of forests, which is essential to ensure ecosystem conservation, to protect biodiversity, and to prevent wildfire [

15]. Indeed, the use of biomass derived from processing residues and controlled silvicultural practices supports the ecosystem equilibrium by preventing the excessive exploitation of forest resources.

However, for biomass to be considered a truly sustainable energy source, it is essential to implement responsible resource management strategies, avoiding uncontrolled deforestation and prioritizing the refuse of waste and residues rather than large-scale dedicated crop cultivations. Adopting an integrated approach based on environmental, economic, and social sustainability criteria, it is possible to maximize the benefits of biomass utilization while minimizing its potential negative impacts [

15].

Starting from these premises, the present paper proposes the use of life cycle assessment (LCA) as an effective way to understand the impact generated by adopting WPEs and WCHs to replace natural gas (NG), assumed as a reference fuel. No other existing study on biomass use for energy production has ever proposed a similar approach. The effects on individual environmental categories generated by this replacement are analyzed in detail, highlighting the critical issues related to human health and ecosystems. LCA enables the comparison of different potential scenarios for heat production, demonstrating that the replacement of an outdated technology with a more modern one leads to environmental benefits.

This study also aims to identify the processes associated with the use of WPEs and WCHs that require improvement, suggesting the best practices to mitigate negative effects. This approach paves the way for new solutions to enhance existing technologies, making them more efficient in preserving the environmental quality.

2. Materials and Methods

To carry out, in a more holistic view, a rigorous study aimed at verifying the real convenience of using WPEs and WCHs to replace NG, it is necessary to have an assessment tool that can guarantee reliable and reproducible results. In the present paper, the LCA approach was adopted, applied following the procedure established by the International Reference Life Cycle Data System (ILCD) [

16]. This evaluation is articulated in the following steps: goal, scope, and boundary definition; inventory analysis; impact assessment; and interpretation. This approach ensures a comprehensive and standardized evaluation of the environmental impacts associated with the product or process under study. SimaPro 9.5.0.2 PhD software and the ReCiPe 2016 Endpoint (H) V1.08/World (2010) Hierarchy/Average analysis method were used to carry out the analysis. The database that was consulted for the analysis of background processes was Ecoinvent 3.9.1—allocation, cut-off by classification, and unit.

2.1. Goal, Scope, and Target

The goal of this study was to evaluate and compare the environmental impacts generated by different fuels used for heat production. As our model situation, we considered the heating system of the Superior School of Education in Viseu (SSEV), Portugal (PT), which had replaced its NG heat generation plant with a PB one, able to be powered either by WPEs or by WCHs.

The scope of this study extended to the identification of the phases of the system requiring improvement in terms of environmental efficiency.

The target audience was individuated from the scientific community and from stakeholders working as public managers or in the energy and wood industries. These latter, indeed, represent decision-makers having the precise responsibility of directing, in an innovative way, the choices that affect the economic, social, and environmental future of a community.

2.2. Boundaries and Functional Unity

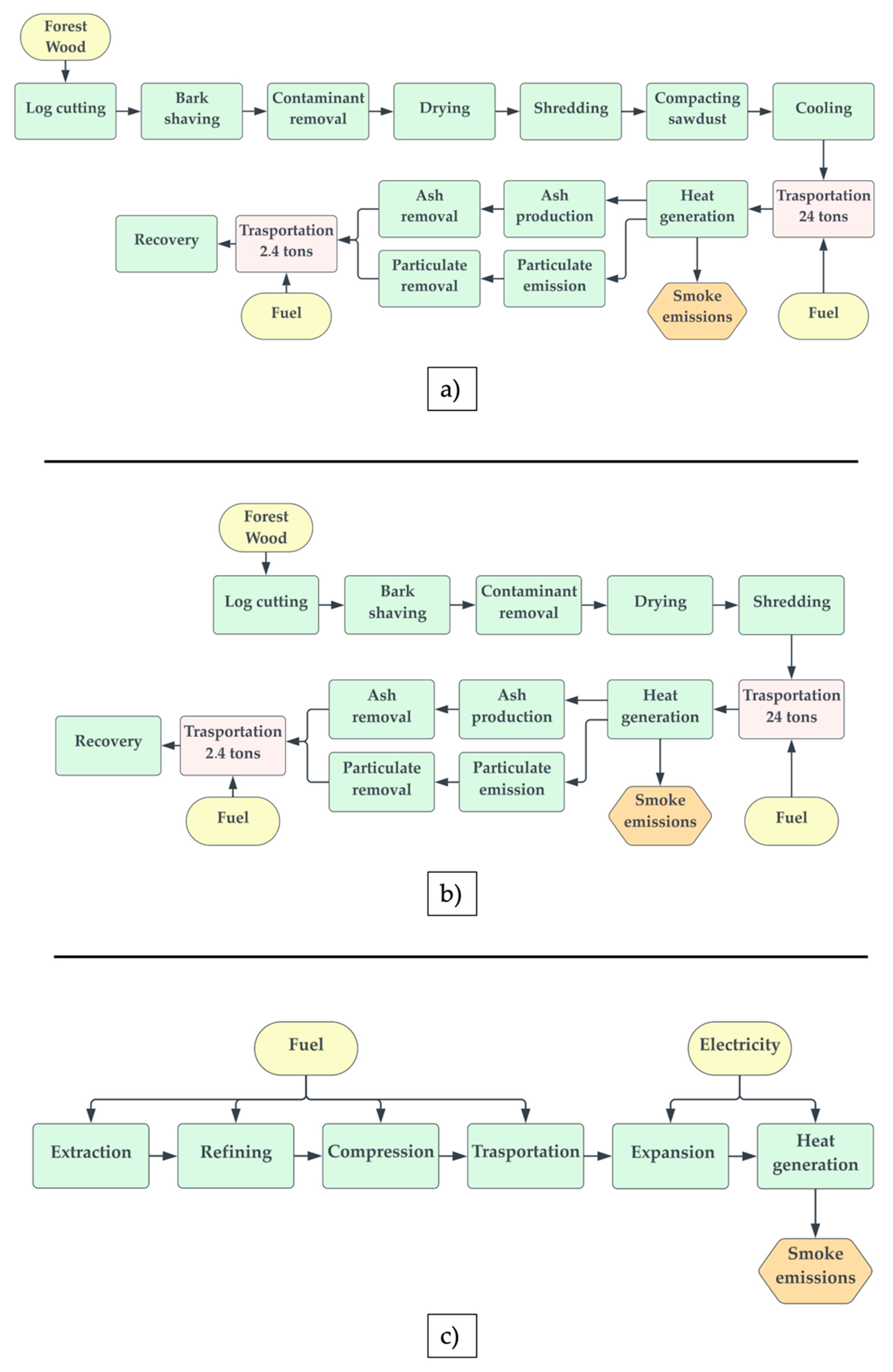

To reach the established objectives, the LCA investigation was conducted from cradle to gate, referring to the following scenarios: In the first scenario (SC1), illustrated in

Figure 1a, the heat supply for the school is provided by the existing PB heating system, which operates using WPEs as its energy source. In the second scenario (SC2), shown in

Figure 1b, the same PB heating system remains in use; however, it is powered by WCHs. Results were compared with those obtained for a background scenario (SCBK) shown in

Figure 1c, referred to as the old heating system of the school, powered by NG. The boundaries of the system were individuated as indicated in

Figure 1.

To make this study broad enough to highlight the overall effects of the considered systems on different environmental compartments, an attempt was made to include all processes responsible for potential impacts. The assessment, therefore, included the stages of raw material extraction and processing, fuel production and utilization, and residue disposal/recovery.

Processes and impact categories that could have deviated from research results were, of course, excluded.

Considering the existence of an NG network in the town, the impacts due to infrastructures were subtracted in the analysis of SCBK [

17]. At the same time, the non-use of the NG heating system was considered an avoided product [

18] in the analysis of SC1 and SC2. The functional unit was fixed at 1 MJ of energy production. The same energy demand was assumed in all cases for the sake of comparison.

2.3. Inventory Analysis

The inventory analysis included the collection of data and the quantification of system-relevant information for the impact assessment. Used data were obtained from the field and, when not available, data were obtained either from the Ecoinvent 3.9.1 database—allocation, cut-off by classification, and from the literature, adapted to the case study.

To strengthen the robustness of this study, a sensitivity analysis was conducted as the final step to verify that the used data and the formulated assumptions led to consistent results. In more detail, a univariate analysis was performed, altering one parameter at a time while keeping the others constant, checking how variations in input data influenced the final outcomes. The selection of input parameters to be varied was effectuated focusing on those parameters having the highest initial uncertainty, i.e., the parameters with the least available data. These included a comparison with a background scenario using more modern and efficient NG boilers, the operational efficiency of the cyclone for removing fine dust particles from flue gases, the concentration of K2O and P2O5 molecules in the combustion ashes, the distance traveled (in kilometers), and the EURO classification of the transport vehicles.

To further corroborate the results obtained using the ReCiPe 2016 methodology, the input data were also analyzed using an alternative impact assessment approach, namely CML-IA baseline V3.09/World 2000. This method was chosen because of its capacity to evaluate the impacts at different midpoint levels while referring to the same endpoints as the ReCiPe 2016 methodology employed in this study.

The outcome data of the sensitivity analysis are properly presented in the

Section 3.

Process Modeling

As indicated in

Figure 1c, the main processes considered in the background scenario (SCBK) included (i) extraction; (ii) refining; (iii) transportation; (iv) compression/decompression; and (v) heat generation. The first four processes were modeled using the Ecoinvent database. At this point, the European gas supply mix was considered, and therefore different locations of NG deposits, assuming both extraction conditions from onshore (i.e., on the land) deposits and offshore (i.e., in the marine subsoil) ones.

Heat production, instead, was modeled using field data, i.e., considering the existing system, consisting of five boilers of 105 kWh each, operating in series, lacking condenser and NOx emission reduction system, with an efficiency of 85%. Although this assumption could have affected the results as the considered system was not based on modern energy efficiency and impact reduction technologies, the overmentioned sensitivity analysis allowed for verification of the differences on the obtained results in cases of the use of more modern and efficient boilers for heat production.

Processes considered in SC1 (

Figure 1a) included, instead, (i) log cutting; (ii) bark shaving; (iii) removal of mineral contaminants; (iv) drying; (v) shredding; (vi) compacting sawdust; (vii) cooling; (viii) transportation of WPEs to the boiler; (ix) heat generation; (x) smoke emission; (xi) ash production; (xii) particulate emission; (xiii) ash removal; (xiv) particulate removal; (xv) transportation of ash and particulate to recovery; and (xvi) recovery. The same processes were also considered in SC2, except compacting sawdust and cooling (

Figure 1b).

For both SC1 and SC2, the heat production system consisted of a 220 kWh SCIVENÒ boiler (

Figures S1 and S2) with an efficiency of 95%. This boiler is equipped with a combustion chamber and a post-combustion chamber, both fed by an auger that supplies fuel only when needed. Two fans ensure air supply to facilitate oxygen entry. It also includes an ash removal system for the accumulation of heavy ash at the bottom of the combustion chamber and between the heat exchanger tubes, and a cyclone operating at 1500 rpm, to remove fly ashes from flue gases. The operation of these auxiliary systems relies on electricity drawn from the public grid. To evaluate produced ashes, class A1 WPEs and WCHs, as per the European ENplus standard [

19], were tested, obtaining, respectively, a value of 0.07% (

w/

w) for WPEs and 0.1% (

w/

w) for WCHs.

Although the considered boiler operates similarly with WPEs and WCHs, different service lives were considered for the two supply systems to appropriately model the differences. Indeed, generally, the boiler has a longer lifespan when using WPEs due to lower wear and tear associated with reduced ash production. As WCHs generate 45% more ashes than WPEs, the boiler’s service life was assumed to be 45% shorter for scenario SC2 than for scenario SC1, following a conservative approach and according to the indications of the manufacturer.

In the absence of precise data on particulate emissions into the atmosphere, a conservative estimate was employed. This includes the known particulate mass per unit gas volume at the outlet, assuming a cyclone efficiency of 70%, and considering that particles passing through the vortex are smaller than 10 µm, corresponding to those most harmful to human health [

20]. The flows of the main gaseous pollutants were reported using both field data and literature sources. The field data were provided by the boiler manufacturer, who conducted emission gas analyses using an unspecified type of biomass pellets. Conversely, the literature was consulted to investigate the average chemical composition of the gases generated during the combustion of the PB used in this study [

21]. The weighted combination of these two data sets allowed for the quantification of the following gaseous pollutants: CO, CO

2, NOx, unburned hydrocarbons, and particulate matter < 10 µm.

All ashes collected during the different phases were supposed to be sent to an agrifood company to be used as soil fertilizers. This stage was modeled as a process that generates an avoided impact, corresponding to the displacement of conventional fertilizer production. To estimate the amount of avoided fertilizer production, two specific compounds with fertilizing properties found in PB ash were considered: potassium oxide (K

2O) and phosphoric anhydride (P

2O

5). The quantities of these compounds in the ash were estimated based on literature data [

22]. Conversely, the nitrogen present in PB, which could also act as a fertilizer, is entirely converted into a gaseous product and was therefore excluded from consideration for this phase.

For the transportation phase, two distinct systems were assumed: one for the delivery of the wood fuel (WPEs or WCHs) to the boiler and another for the transportation of the ashes to the collection centers. Both transportation systems (delivery of the wood fuel to the boiler and delivery of the ashes to the agrobusiness) were supposed to make use of fully loaded EURO 4 trucks, differing only in their nominal capacity—24 tons for the fuel transportation and 2.4 tons for the ashes transportation. A 150 km journey was considered in both cases. The distance corresponds to the real distance between the pellet production site and the school, and the distance that separates the school from an agricultural area located outside the city is the same. The different densities of the two fuels (650 kg/m3 for WPE and 250 kg/m3 for WCH) were considered, while modeling the transportation phases. To avoid underestimating environmental impacts, trucks were assumed to return empty to their origin without carrying additional goods.

Table 1 summarizes the main input and output data used for SC1 and SC2, derived from the available literature or obtained by the manufacturer of the operating apparatus. Data used for the background scenario are not reported, as they were entirely obtained from the Ecoinvent database.

2.4. Impact Assessment

The impact assessment phase of the LCA aims to assess the significance of potential environmental impacts using the results of the inventory analysis [

23]. In general, this process involves associating inventory data with specific environmental impact categories and category indicators, thereby seeking to understand these impacts [

24].

Impacts assessed with LCA are potential, not actual, as they describe the life-cycle impact of a reference flow used to describe a functional unit. Impacts associated with secondary streams produced by the same process are not considered. Furthermore, they are based on inventory data integrated in space and time; in fact, they often occur at different locations and time horizons.

The chosen method, ReCiPe 2016, is a comprehensive method with an endpoint approach characterized by the following factors [

25]:

Human health (HH), expressed as the number of years of life lost or lived with disability. The units of measurement is DALY.

Ecosystems, expressed as loss of species in a certain area over a certain period. The unit of measurement is species.yr.

Resource scarcity, expressed as the excess cost of future resource production over an infinite period of time (assuming constant annual production). The unit of measurement is USD13.

At the midpoint level, 22 impact categories are treated; these are multiplied by the damage factors and aggregated into three endpoint categories, i.e., the endpoints [

25], and the results can then be normalized. The categories analyzed within this study are global warming human health (GW-HH); global warming terrestrial ecosystems (GW-TEs); global warming freshwater ecosystems (GW-FWEs); stratospheric ozone depletion (OD); ionizing radiation (IR); ozone formation human health (OF-HH); fine particulate matter formation (FP); ozone formation terrestrial ecosystems (OF-TEs); terrestrial acidification (TA); freshwater eutrophication (FE); marine eutrophication (ME); terrestrial ecotoxicity (T-ET); freshwater ecotoxicity (FW-ET); marine ecotoxicity (M-ET); human carcinogenic toxicity (H-CT); human non carcinogenic toxicity (H-NCT); land use (LU); mineral resource scarcity (MRS); fossil resource scarcity (FRS); water consumption human health (WC-HH); water consumption terrestrial ecosystem (WC-TE); water consumption aquatic ecosystems (WC-AEs).

3. Results

The SCBK scenario simulates the impacts associated with the NG heating system and was used as a reference to characterize the impacts in scenarios SC1 and SC2, thereby highlighting the differences among the various alternatives. Indeed, the results presented in the following sections include not only the impacts associated with the use of WPEs and WCHs but also the avoided impacts due to the discontinuation of the NG-powered boiler.

With the functional unit set at 1 MJ of energy produced and the boiler’s power known, data from the Ecoinvent database were used as inputs. This approach was chosen both due to a lack of field data and to rely on a standardized reference system. A concise summary of NG impacts on the analyzed categories is presented in

Figure 2.

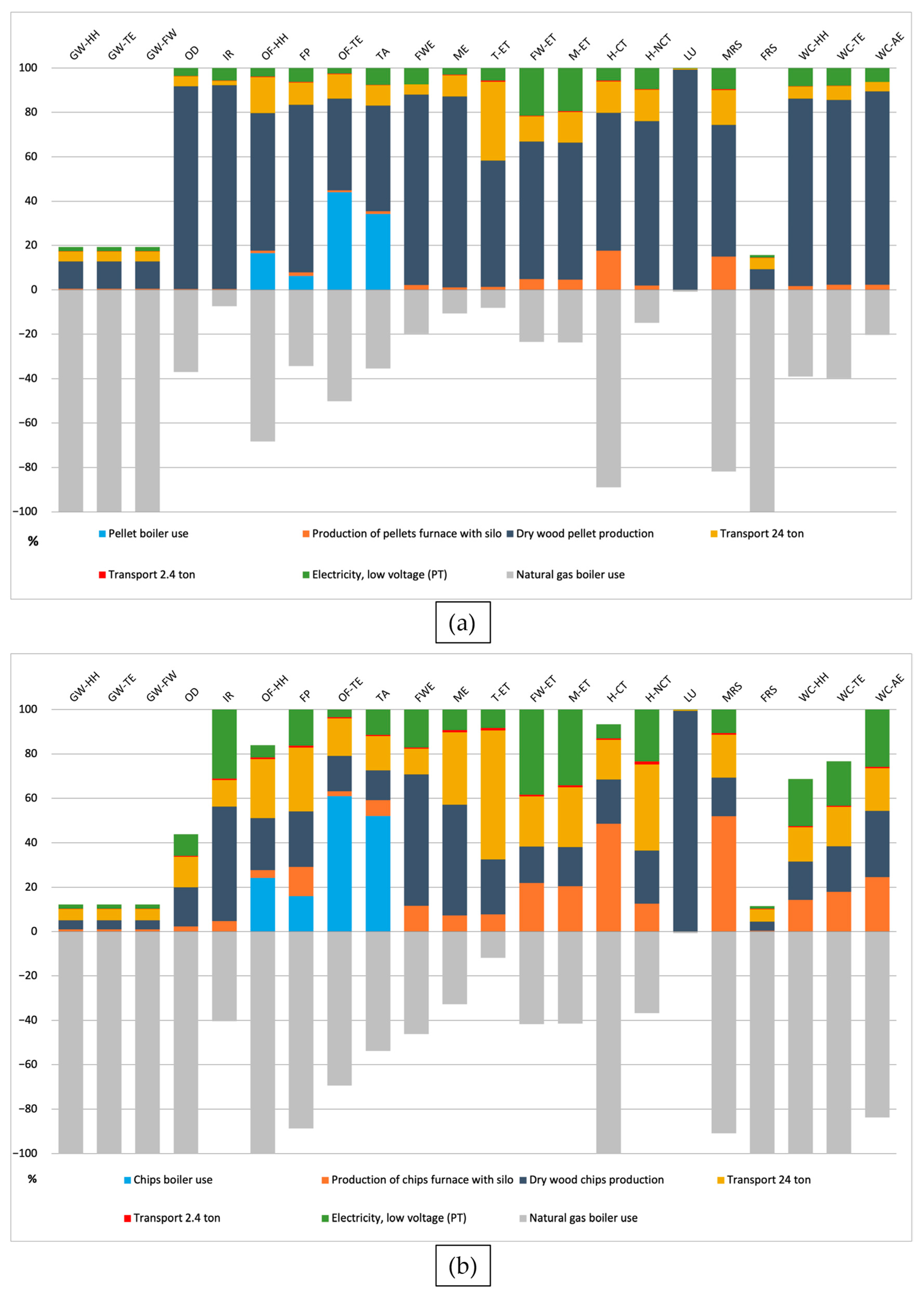

Figure 3 illustrates the reduction in the impacts of SC1 (

Figure 3a) and SC2 (

Figure 3b) on the intermediate categories, mainly due to the avoided use of natural gas (NG). The following section presents a detailed identification of the processes that exert the most significant environmental effects, along with the corresponding impact categories and the main contributing causes. For a more complete analysis, detailed numerical data and further breakdowns are provided in the

Supplementary Materials: Tables S1–S3 for WPEs and

Tables S4–S6 for WCHs.

The impacts of the processes analyzed in scenarios SC1 and SC2 are primarily attributable to the fuel production phases from PB, occurring before its utilization as a fuel. Additionally, emissions are further exacerbated by its combustion in boilers for heat generation and, lastly, transportation also plays a significant role in the overall impact balance, representing a considerable share of the total environmental burden.

Focusing on

Figure 3a, the “pellet boiler use” predominantly affects the OF-HH, OF-TE, and TA categories, primarily due to the release of nitrogen oxides into the atmosphere, which contribute to air pollution and related environmental issues.

The “dry wood pellet production” has a substantial impact on nearly all categories. This is attributed to the extensive use of water resources, land occupation, and both intensive and extensive forest transformation. Additionally, the emissions of nitrogen oxides, carbon dioxide, fine particulate matter (<2.5 µm), and sulfur dioxide, along with the extraction of fossil fuels (crude oil, natural gas, and hard coal) and iron, further exacerbate its environmental footprint.

“Transport 24 tons” contributes significantly to nearly all impact categories, with a particularly pronounced effect on T-ET. This is mainly due to the extraction of fossil fuels and iron, coupled with the emission of pollutants such as carbon dioxide, nitrogen oxides, fine particulate matter, sulfur dioxide, and methane. Furthermore, the release of chromium into water systems adds to the environmental burden.

“Production of pellet furnace with silo” primarily affects the H-CT category due to emissions of carbon dioxide, fine particulate matter, and sulfur dioxide, as well as significant water consumption and chromium release into aquatic environments. Additionally, its environmental footprint extends to the MRS category due to the extraction of fossil fuels and iron.

Finally, “electricity, low voltage (PT)” exerts major impacts on FW-ET and M-ET, largely as a result of high water consumption, emissions of carbon dioxide, sulfur dioxide, and nitrogen oxides, and the extensive use of fossil fuels and metals such as copper. The environmental impacts associated with the use of PB boilers, production, transportation, and related processes are distributed across multiple impact categories, driven by emissions, resource extraction, and land use changes.

Figure 3b shows the results for SC2, where it can be seen that the “

chips boiler use” contributes significantly to the OF-HH, OF-TE, and TA categories, largely as a result of nitrogen oxide emissions, which have detrimental effects on air quality and human health. These pollutants are known to contribute to respiratory issues and atmospheric reactions that lead to further environmental degradation.

The “production of chips furnace with silo” generates a notable environmental burden, particularly affecting F-ET, M-ET, H-CT, and WC-AE. This is primarily due to the release of chromium into water bodies, emissions of carbon dioxide, sulfur dioxide, and fine particulate matter (<2.5 µm) into the atmosphere, as well as extensive water consumption and land occupation. Furthermore, the extraction of fossil fuels, including crude oil, natural gas, and hard coal, along with iron mining, contributes significantly to the MRS category.

The “dry wood chips production” has a profound impact on IR, FWE, ME, and LU, primarily due to its high demand for water resources and its role in both intensive and extensive forest occupation and transformation. These processes lead to substantial emissions of carbon dioxide, nitrogen oxides, fine particulate matter, and sulfur dioxide, further amplifying their environmental consequences. Additionally, the extraction of fossil fuels (crude oil, natural gas, and hard coal) and iron for energy and material requirements plays a critical role in increasing the overall environmental footprint of this stage.

“Transport 24 tons” emerges as another major contributor to environmental impacts, influencing nearly all categories, with particularly significant effects on ME, T-ET, and H-NCT. The transportation phase is heavily dependent on fossil fuel extraction and combustion, leading to substantial emissions of carbon dioxide, nitrogen oxides, fine particulate matter, sulfur dioxide, and methane. Moreover, the release of chromium into water sources further compounds its negative environmental effects.

Lastly, “electricity, low voltage (PT)” predominantly affects IR, FW-ET, and M-ET, primarily as a result of water-intensive processes, emissions of key atmospheric pollutants such as carbon dioxide, sulfur dioxide, and nitrogen oxides, and the reliance on non-renewable resources, including crude oil, natural gas, hard coal, and copper.

The most interesting result can be seen by emphasizing the avoided products visible in the negative values of the graph (

Figure 3). The “natural gas avoided” scenario, which represents the environmental benefit of eliminating the use of natural gas (NG), has a positive influence across nearly all impact categories. This finding underscores the significant advantage of substituting NG with an alternative energy source, as it mitigates the environmental burden associated with fossil fuel consumption. Although the utilization of plant biomass (PB) is not without environmental impacts, its overall contribution remains beneficial when considering the avoided emissions and resource depletion associated with NG usage.

The data suggest that the net effect of this substitution leads to a favorable environmental balance, highlighting the potential of PB as a viable alternative for reducing reliance on conventional fossil fuels and minimizing associated environmental pressures.

Among the impacts avoided are also the recovery of organic compounds from ashes as K2O and P2O5 used as fertilizers. Unfortunately, the reduction in impact is negligible, due to the low amount of fertilizing molecules recovered from the ash. However, this denotes the high efficiency of combustion, given both by the good qualities of the fuel input and the excellent efficiencies of today’s PB-fueled boilers.

These findings highlight the multifaceted nature of environmental impacts across different life cycle stages.

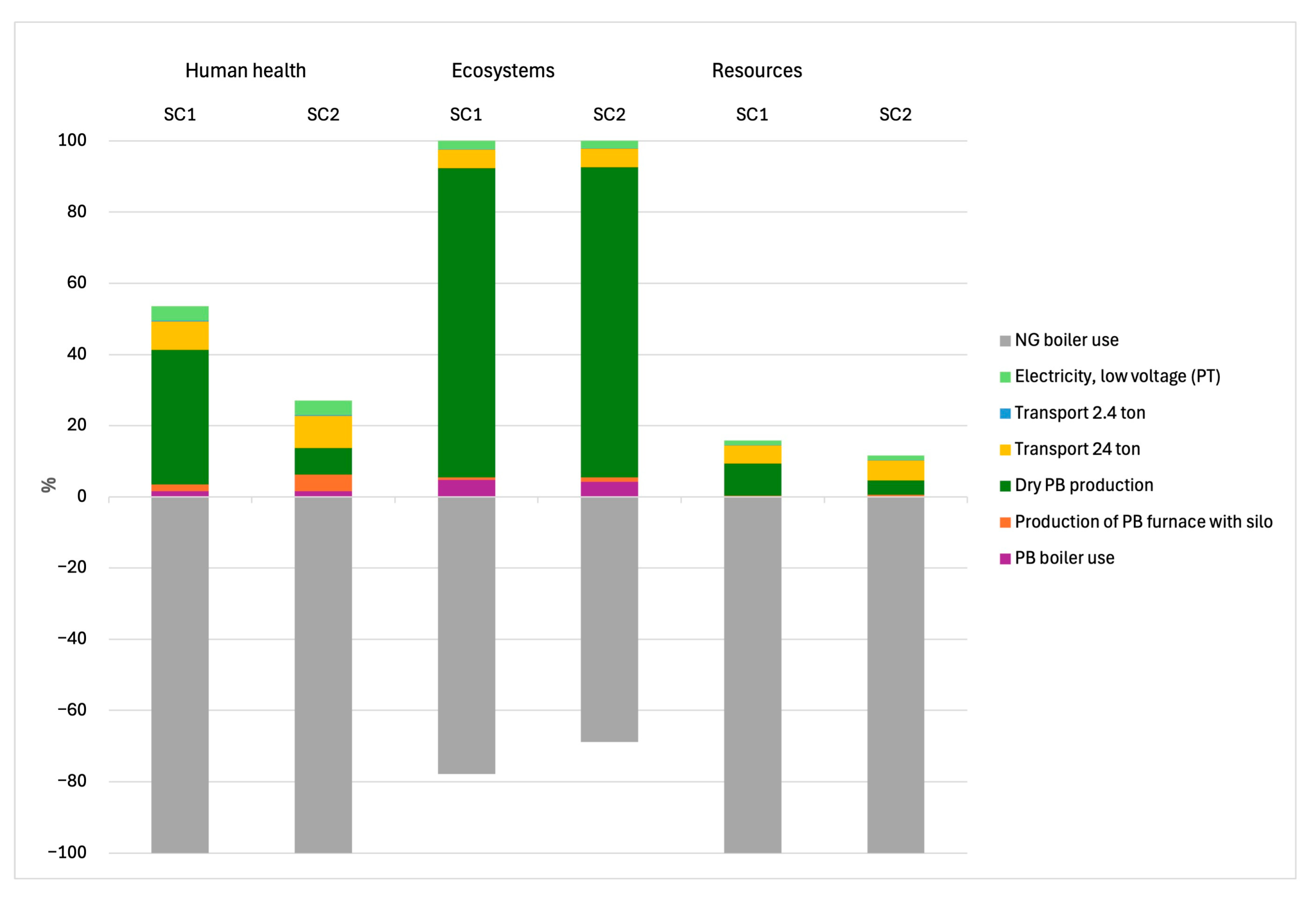

Figure 4 presents the environmental impacts at the end-point level, providing a comprehensive assessment of the overall burden associated with the analyzed scenarios. The graph compares the impacts of the two scenarios for each category—human health, ecosystem wellness, and resource scarcity.

This additional analysis, which directly compares the two scenarios, provides a clear visualization of their relative environmental performance. The results demonstrate that SC2 consistently exhibits a lower impact than SC1 across all assessed categories, indicating a more favorable environmental profile. It also allows us, once again, to emphasize how the adoption of PBs as a substitute fuel to NG brings noticeable benefits, shown in the negative values in the graph.

Sensitivity Analysis

In the sensitivity analysis, the impact associated with an alternative reference scenario was evaluated, specifically a background scenario considering the use of more modern and efficient NG boilers compared to the one currently in use. However, the results demonstrated an overall impact analogous to that of the reference scenario employed in this study, indicating a limited influence of this technological variation on the overall environmental balance.

The efficiency of the cyclone in the removal of fine particulate matter was conservatively set at 70%. Taking it up to 95 per cent shows a negligible difference in impact, less than 1.0 × 10−8%, on the endpoint categories human health and ecotoxicity, for both the WPE and WCH processes.

The concentrations of the molecules K2O and P2O5 within the ash used in agriculture were considered as avoided products, given their use in agriculture. By increasing their production by an order of magnitude, the impact on the endpoint ecosystem category is reduced by 0.01% due to the reduction in water turbine use, crude oil, chrome, and zinc.

Within this study, actual values of kilometers traveled by goods arriving at and leaving the plant were considered. Two alternative scenarios were evaluated, in which distances were reduced (

Table S7), and impact reductions were analyzed. Graphical results can be found in the

Supplementary Materials (Figure S3).

Scenario variation (SV1): 50% reduction in inbound and outbound km. There is a significant reduction in impact on all endpoint categories analyzed.

Scenario variation (SV2): No reduction in inbound km and 90% reduction in outbound km. No significant impact reductions are observed, which underscores that the effects are mainly due to inbound transport on heavy vehicles.

Similar results were obtained using EURO 6 vehicles instead of EURO 4.

Finally, a comparison of the results with those obtained using an alternative impact assessment method, namely ML-IA baseline V3.09/World 2000, revealed substantial agreement. Specifically, similarities were observed in the ranking of the most impactful processes and the primary sources of emissions. In addition to the analyzed parameters, further analyses could be performed on different PB fuel production technologies or on different scales of operation.

4. Discussion and Conclusions

The presence of important trans-national pipelines has led to the spread of a capillary NG distribution network, especially in large urban agglomerations. The presence of a consolidated infrastructure that facilitates access to this energy source and the macroeconomic mechanisms that this has triggered have determined its strong practicality for use and economic convenience.

The direction that international energy policy has taken so far has meant that the heat used for domestic and medium-scale use comes mainly from the use of NG-fueled boilers. On the other hand, PB-fueled systems have had a more recent development, and, to date, it is difficult to imagine a logistical network so efficient as to bring the fuel directly to the boiler, as is the case with liquid and gaseous fuels. They have a clear economic advantage [

26] but also several critical issues and limitations. They require volume for fuel storage, that the fuel be refilled periodically, and that it not be exposed to external agents; in addition, PB-fueled boilers have start-up times that are several minutes longer. Thus, while this may not be easy for the individual end user, it is a different matter for centralized heat systems, used for small businesses, public buildings, or medium-to-large residential buildings, where all the problems illustrated are drastically reduced.

When comparing different alternatives with the aim of identifying the one with the lowest impact, it is necessary to refer to the overall impacts, considered as the sum of the impacts on all the categories analyzed.

The proposed results support the theory that the use of PB for heat production has a lower impact than the use of NG.

The objective of this study goes beyond finding a more sustainable solution than a conventional one; it seeks to highlight the problems of producing heat from PB and proposes actions to be taken to reduce the ecological footprint, so as to not exacerbate impact categories that may have been poorly affected by conventional technologies.

Analyzing the results from an individual impact point of view, the effects of using WPEs and WCHs on human health and ecosystems are significant; moreover, these two categories are closely linked, and impacts on one can aggravate the effects on the other. An in-depth examination is therefore called for, in which the critical areas of these technologies are highlighted and the foundations are laid for experimenting with solutions that make them more sustainable. These technologies, in fact, determine a significant use of the soil, where the impoverishment of this environmental resource is due to the occupation of originally natural or agricultural areas, converted to make room for buildings, infrastructures, and energy-efficient monocultures. This, in cascade, leads to an impoverishment of the chemical and biological characteristics of the soil, a reduction in biodiversity, and an overuse of fertilizers or pesticides that can compromise groundwater and air [

27].

The pressure on these categories must be given high consideration, and current environmental trade-offs may facilitate the development of subsequent innovations. It is well known that all activities requiring the use of woody PB demand sustainable management of the forests from which the raw material is sourced. In the scenarios proposed in this study, the raw material usable for WPE and WCH production could come from sectors that generate waste or by-products. Therefore, the responsible management of forest resources, which includes careful timber harvesting and proper waste management, sees an additional pathway for the valorization of residues and further support for sustainable management strategies in the production of WPEs and WCHs for heat generation.

It should also be reported that the construction and use of machinery for the production, logistics, and transport of WPEs and WCHs result in the use of resources, the release of atmospheric particulate matter, and greenhouse gases that burden both human health and ecosystems, with significant long-term consequences.

The results of this study also show how PB differs in terms of its impact. In fact, those that are less processed such as WCHs, which need fewer production steps and less stringent treatment, can lighten the environmental load and represent a more sustainable alternative to WPEs.

It should also be emphasized that the reduced mass of fertilizer recovered from combustion ashes does not guarantee a significant reduction in impact on any category. Therefore, there is no justification for recovering these substances in agriculture, unless the distances traveled are considerably reduced or the ash is transported together with other goods. It is worth mentioning that impact due to transportation significantly affects overall PB impact assessment.

PB is a sustainable alternative to the use of NG for heating; modern technologies have made them extremely efficient, and the waste produced can be reused in a circular economy. They are considered a carbon-neutral energy source, but this is not enough to call them impact-free. While it is true that the CO2 emitted is offset by that absorbed, the same cannot be said of the CO2 produced by logging, transport, processing, and all those steps required to produce marketable WPEs and WCHs. This opens several possible scenarios to mitigate the negative effects these technologies have on human health, ecosystem well-being, and resource consumption, offering space to provide recommendations for improving the environmental performance of the systems analyzed.

Firstly, the construction of infrastructure can be optimized by repurposing existing structures, thereby reducing initial impacts and distributing residual ones over time, which are offset by ecological benefits.

Additionally, integrating a circular economy using recycled and recyclable materials, extending the lifespan of equipment via maintenance, and utilizing renewable energy sources are key strategies.

Finally, continuous technological advancements are crucial for improving system efficiency, minimizing environmental impacts, and adapting to emerging needs, ensuring greater sustainability in the long term.

When studying a plant source for heat production, one is faced with a vast array of options; these include different varieties, but also different origins. The evidence from the results of this study showed that land occupation is the category most affected by the effects of WPE and WCH production; this aspect can be improved if the raw material, instead of being derived from species cultivated exclusively for energy purposes, is derived from the recovery of plant residues from other productions, representing possible new research directions. In fact, plant species with different characteristics [

13] can be used for this purpose, but for energy valorization to be worthwhile, it is necessary to transform them into WPEs or WCHs to increase their calorific value.

The potential of PB as compost or mulch is recognized [

28], but there are several sectors that produce vegetable PB that would have to be disposed of and that often end up in landfills, so some industrial waste [

29], agricultural residue, some urban waste, and waste from the maintenance of forests or public green spaces can represent a raw material to be valorized as an energy source. Therefore, the spread of PB plants with a low environmental impact and the use of these secondary raw materials could lead to several positive consequences. Considering that heat must be generated in some way, some decision-making bodies, such as public bodies, could incentivize the use of PB plants by first using them in their own buildings. This would consequently increase the demand for raw material, which could come precisely from WPEs and WCHs made from public and private plant residues.

One could imagine the transformation of public collection and transfer centers into real WPE and WCH packaging companies, with machinery for drying, shredding, and pelletizing. In this scenario, transport impacts could also be lowered by bringing the place of collection of the raw material closer to the place of processing and use.

The production of WPEs and WCHs does not require complex machinery, and there is equipment of reduced size and cost that can be used for modest production runs.

Although the product may not meet the highest standards, it could complement the use of better-quality WPEs and WCHs and be used in plants operated by public authorities, which should be the first supporters of this initiative.

This system would lead to a reduction in energy expenditure, benefits on waste management charges, and a reduction in environmental impact. It is therefore the responsibility of those in charge of the energy and waste sector of a public or private entity to implement initiatives to incentivize the use of PB systems, valorize waste raw materials, and make collection and delivery more efficient. All this should be achieved in synergy with the social and industrial fabric and could trigger economic compensation mechanisms that would bring concrete benefits to the population and businesses, which, in doing so, would become active players in the challenge of reducing the community’s ecological footprint.