The Integration of a Multidomain Monitoring Platform with Structural Data: A Building Case Study

Abstract

1. Introduction

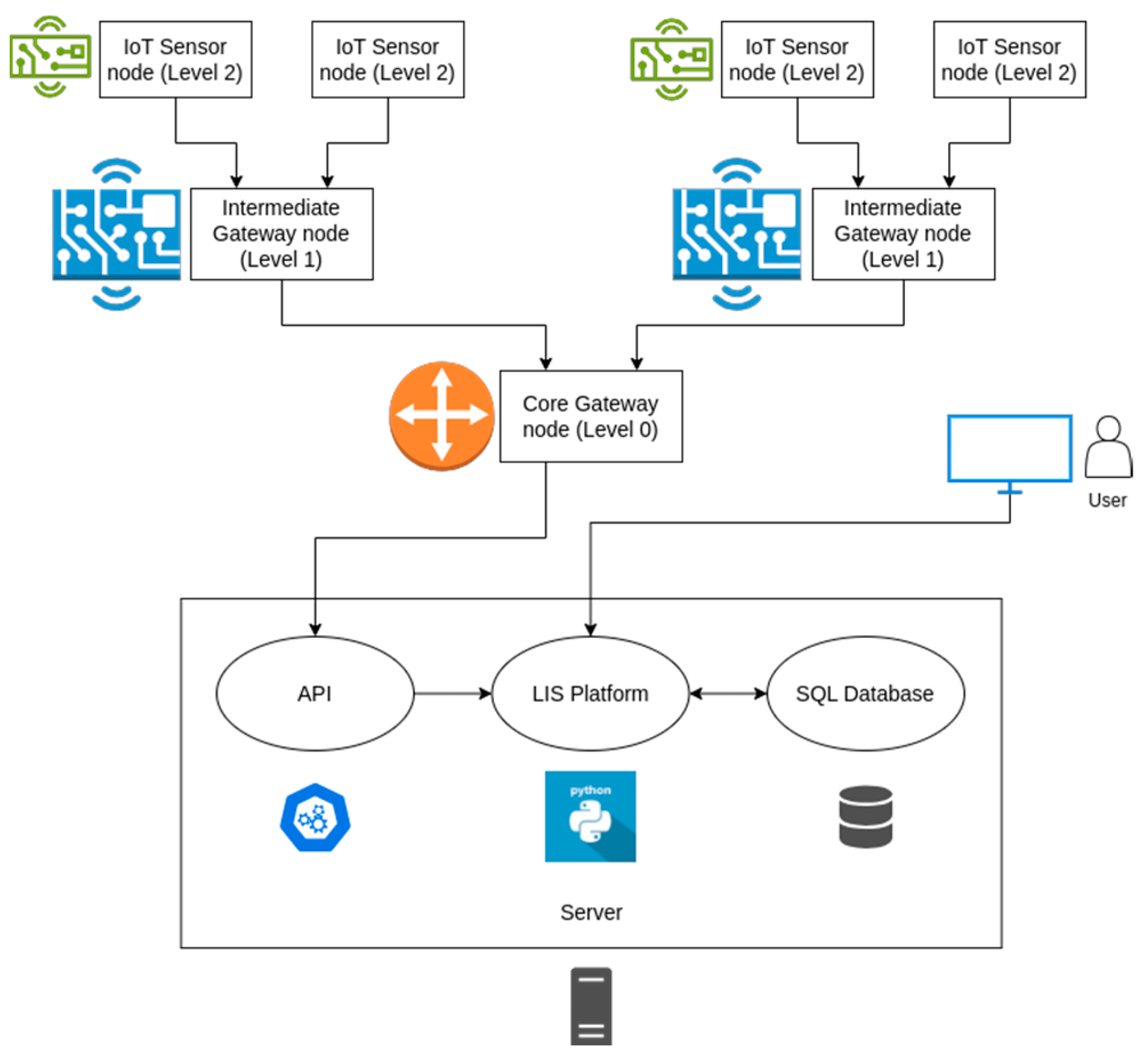

2. LIS Platform Design and Development

2.1. Gateways

2.2. Sensor Nodes

2.3. API/Integration

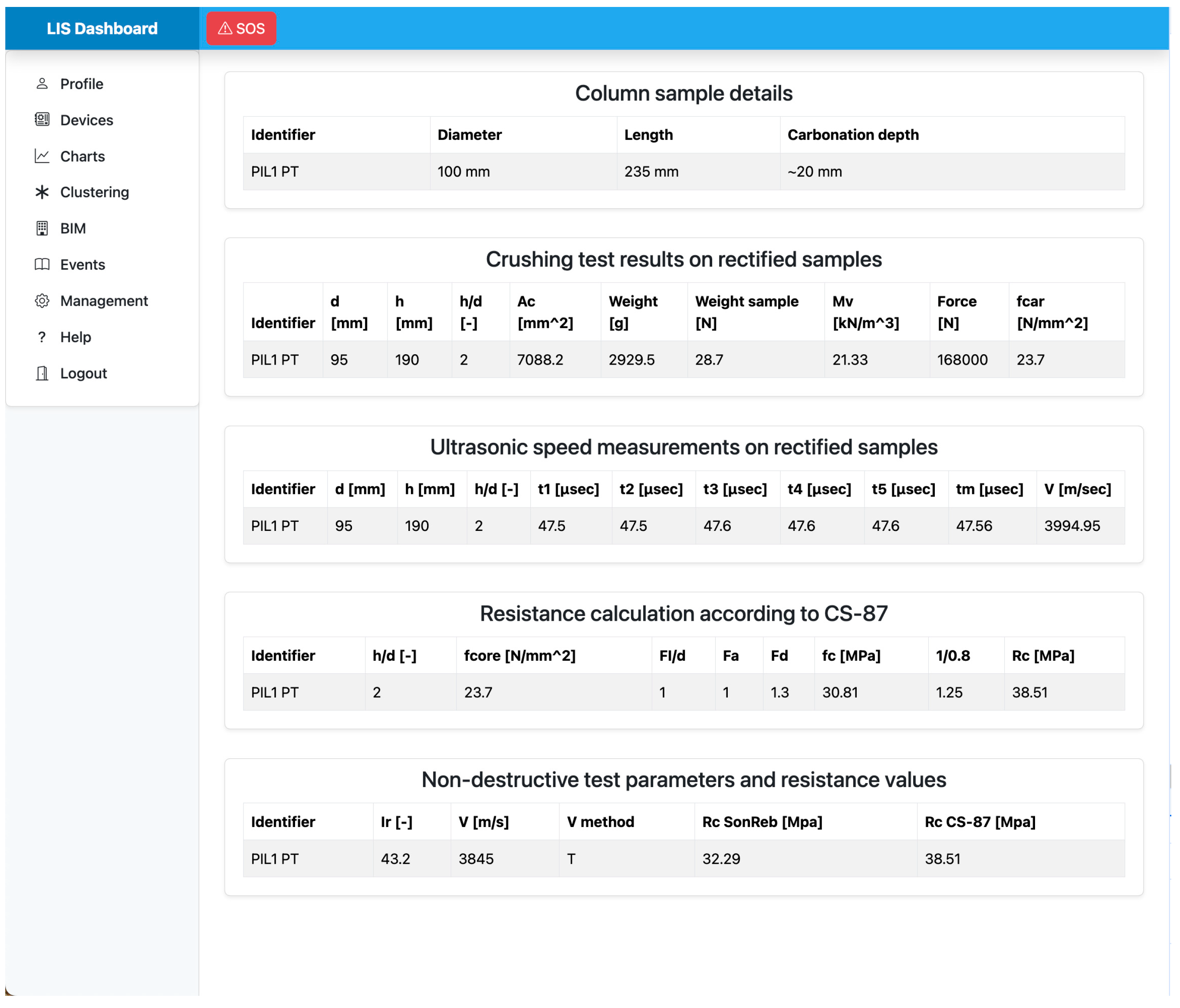

2.4. Web Application

2.5. Data Management

2.6. Mobile App

3. In Situ ND Tests: Typologies and Outputs

- -

- Pachometric test

- -

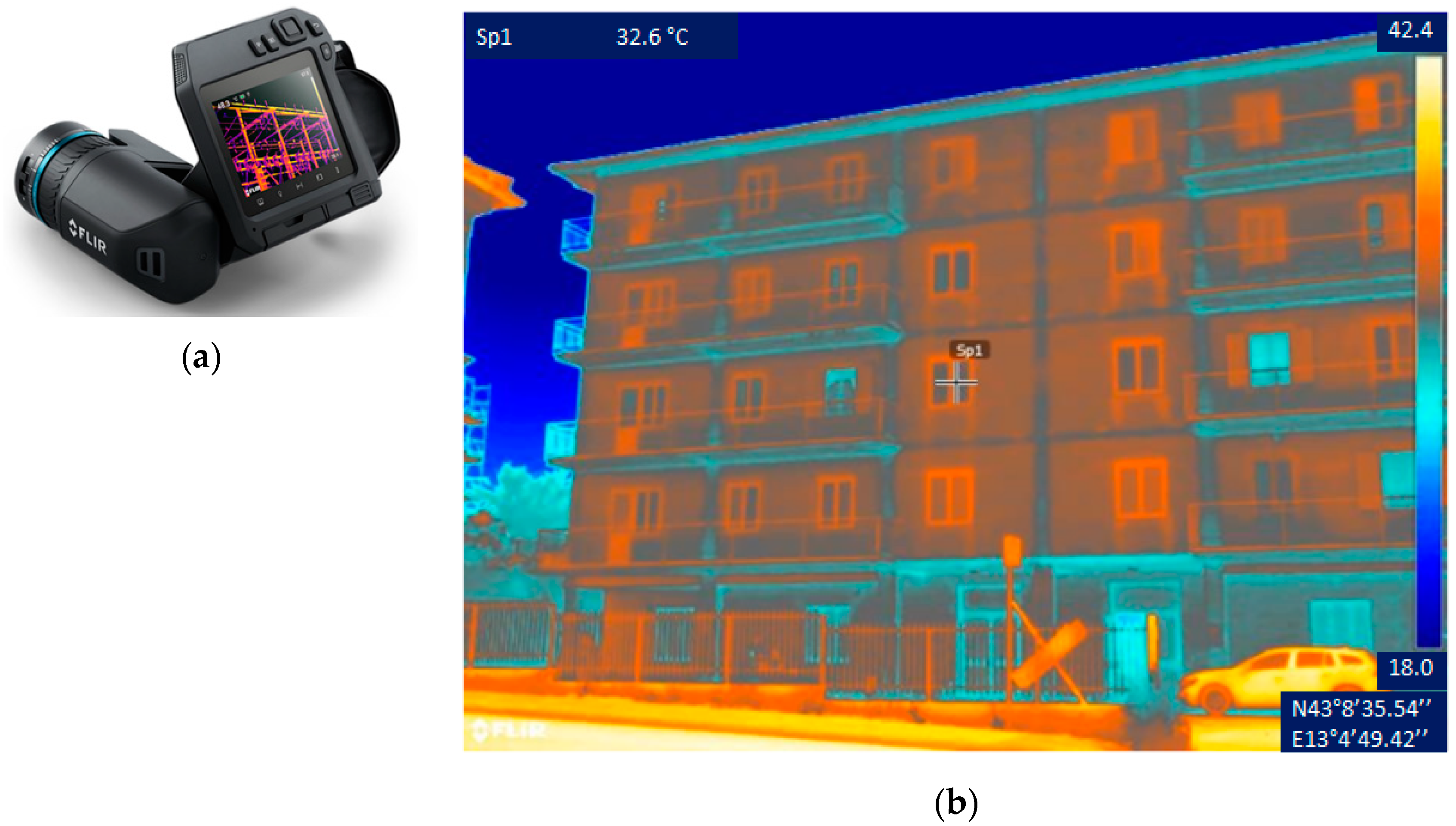

- Thermographic test

- -

- Rebound hammer (RH)

- -

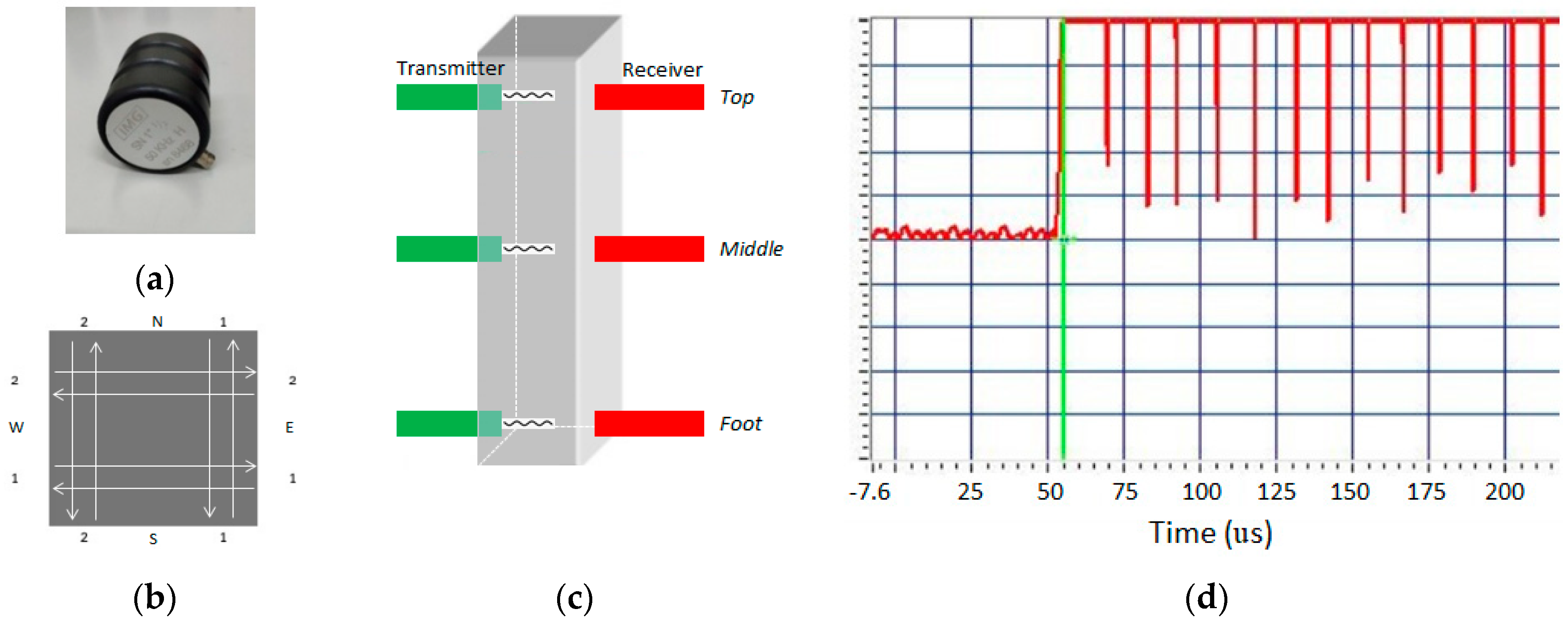

- Ultrasonic pulse velocity (UPV)

- -

- Sonic test

- -

- To identify structural elements with the same characteristics of the concrete, about velocity values, to plan other tests, and to limit destructive tests [18];

- -

- When surveying an existing structure in cases where no design documents exist but important changes must be made to the structure (removal of load carrying elements, changes to structural system) [15];

- -

- For the localization of defects in new structures due to poor construction quality and to elaborate means of compensation;

- -

- When monitoring of a structure during its lifetime;

- -

- Knowing the characteristics of the concrete over time allows for a comparison after an extreme event (e.g., an earthquake, fire, or flood).

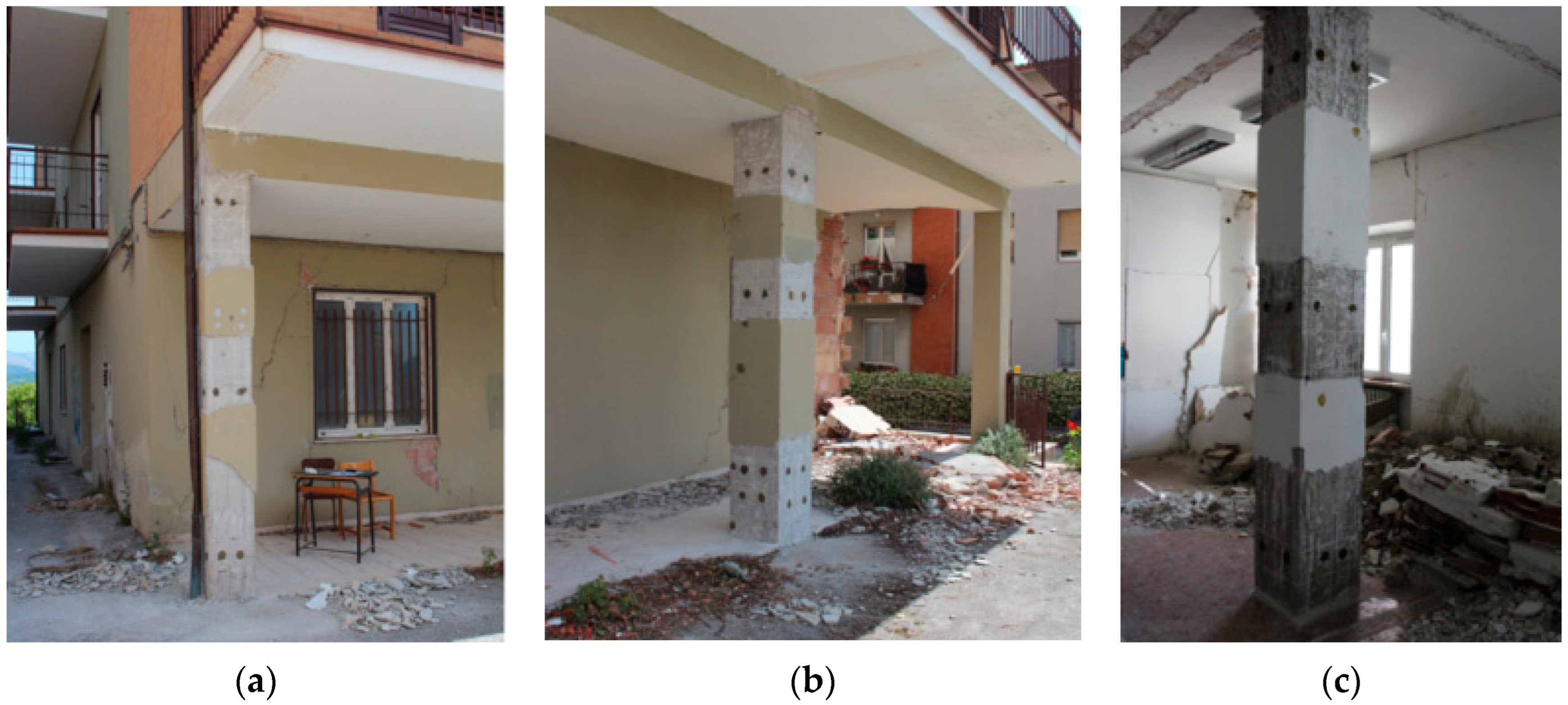

4. The Study Case: Palazzo Fazzini

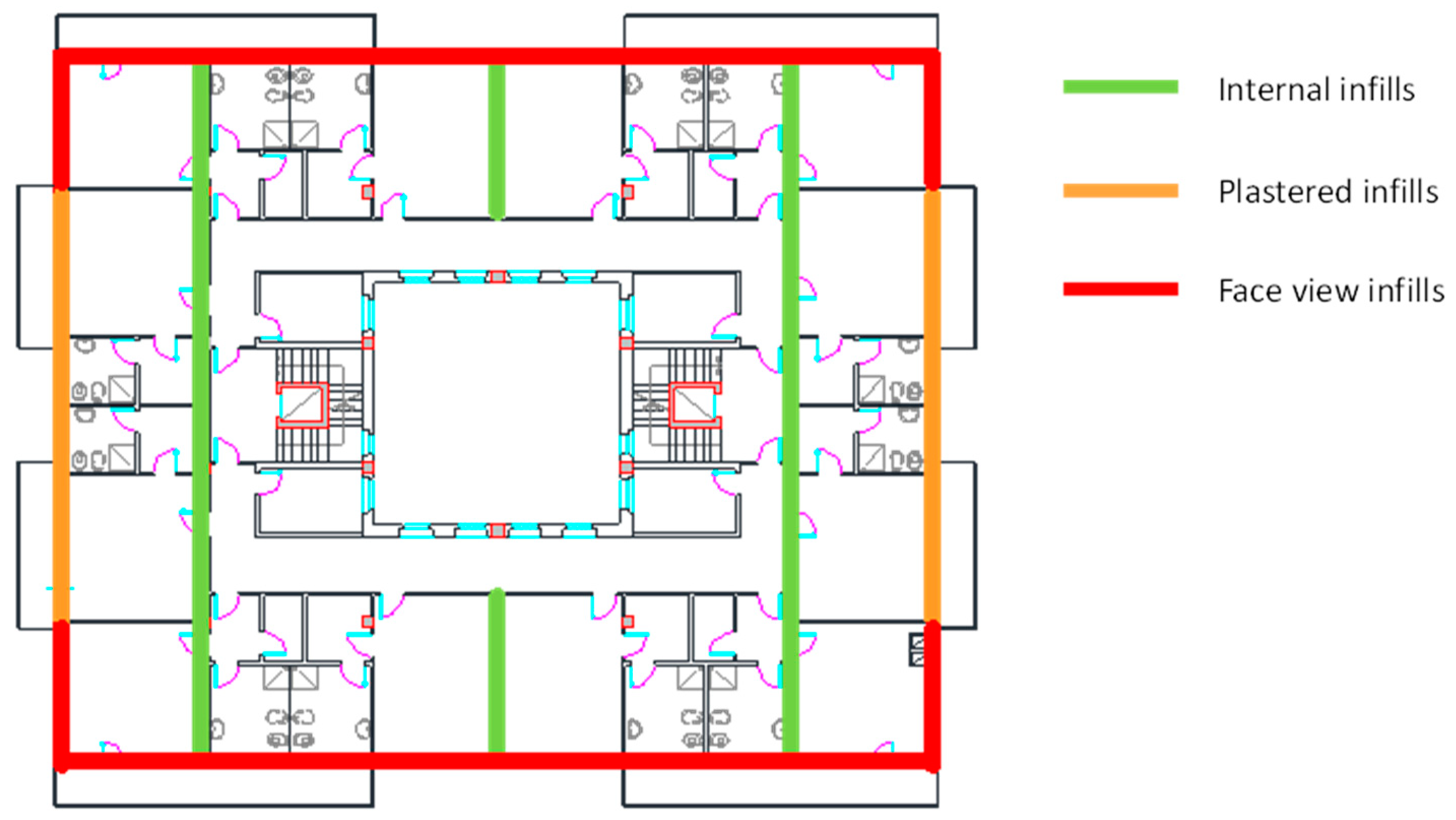

4.1. Building Description

4.2. ND Tests: Experimental Setup and Results

4.2.1. Test Plan

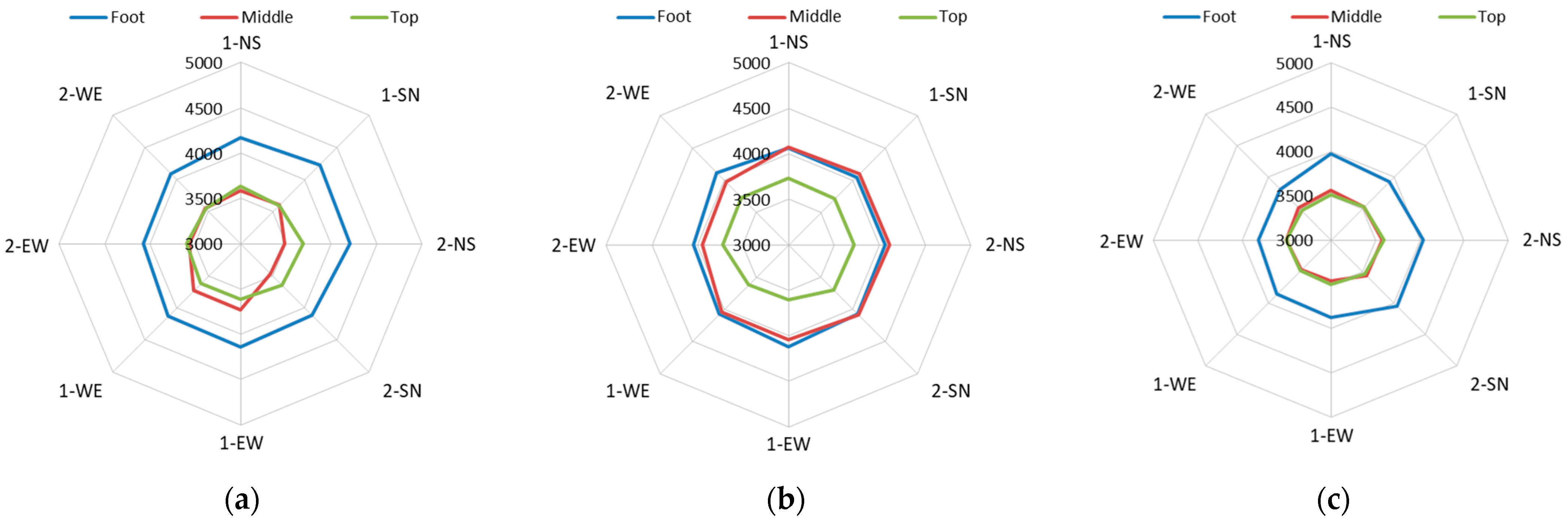

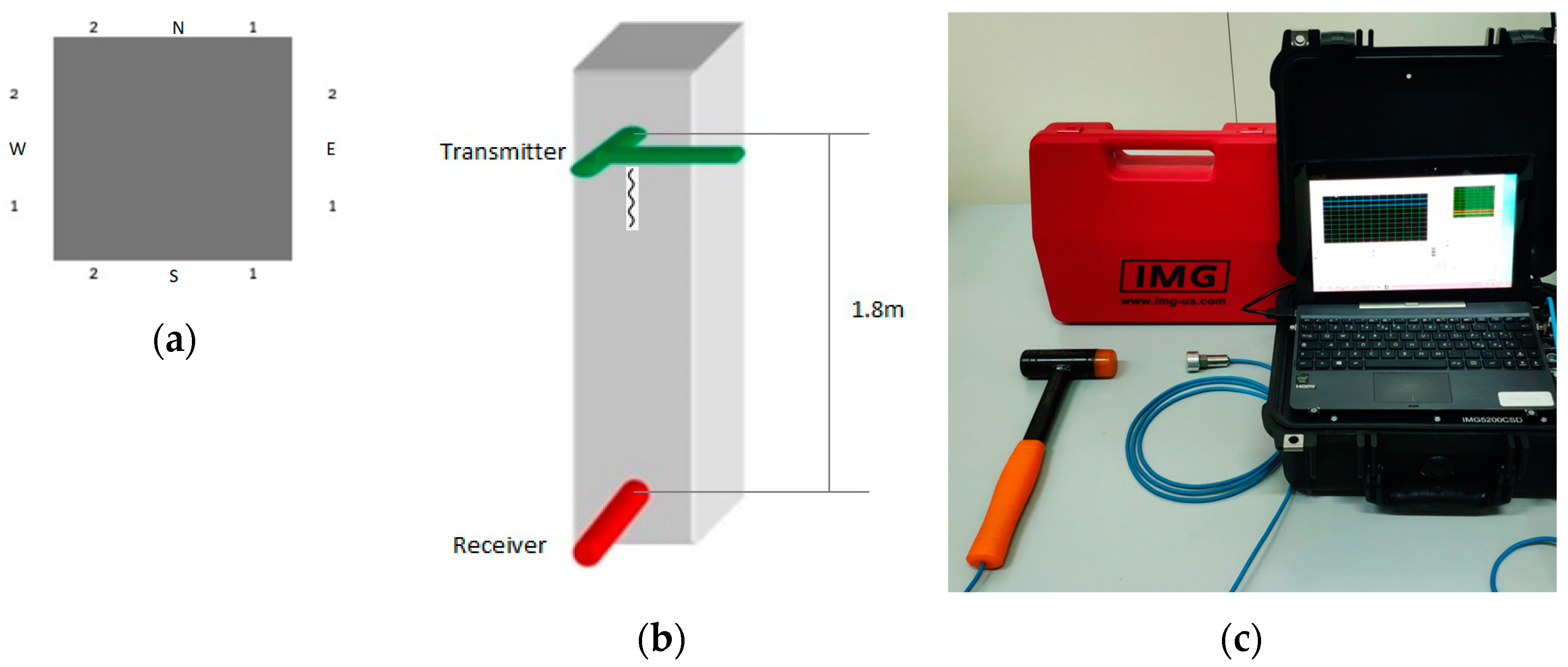

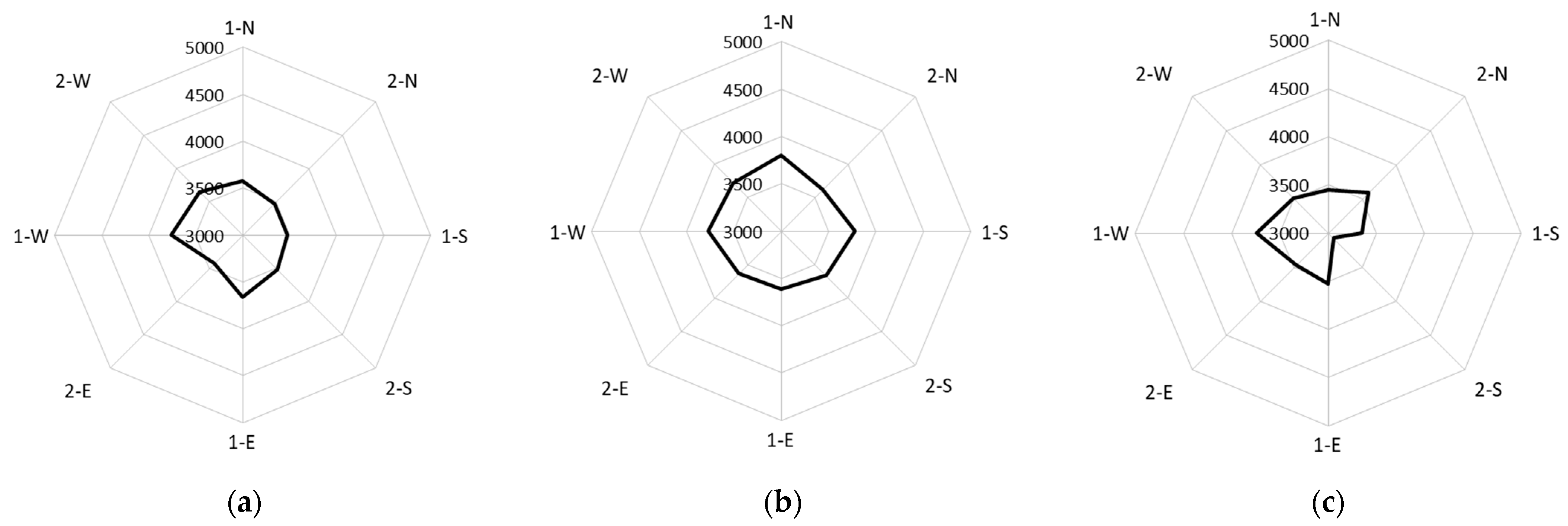

4.2.2. Ultrasonic Tests

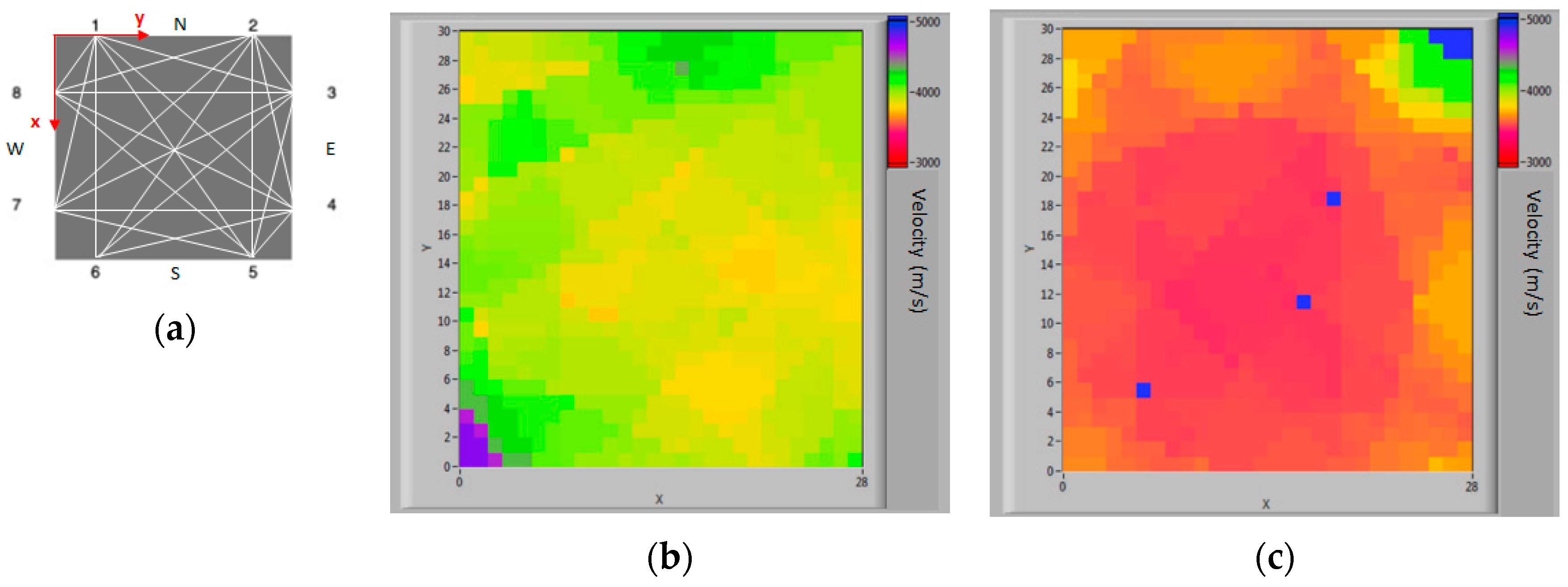

4.2.3. Sonic Tests

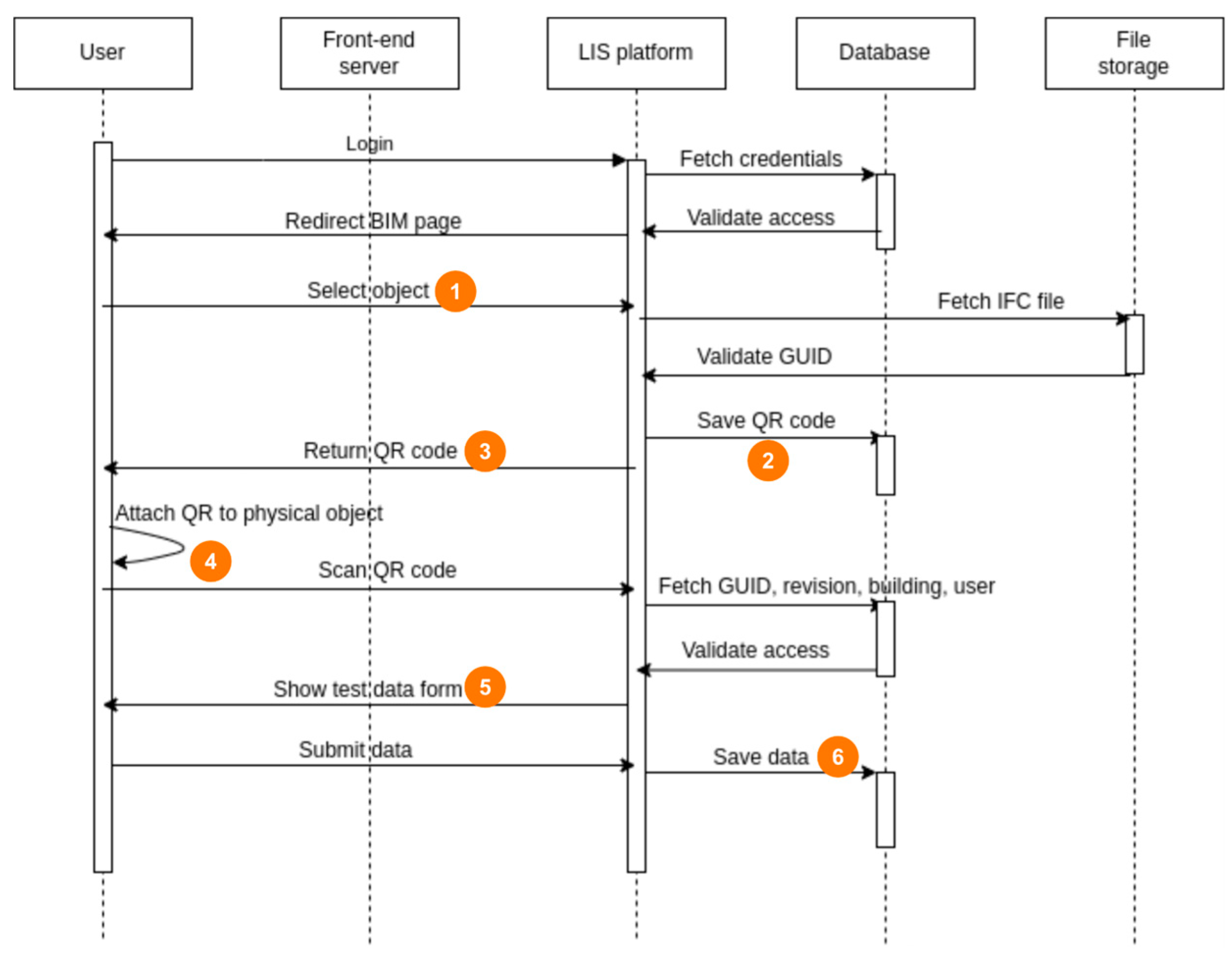

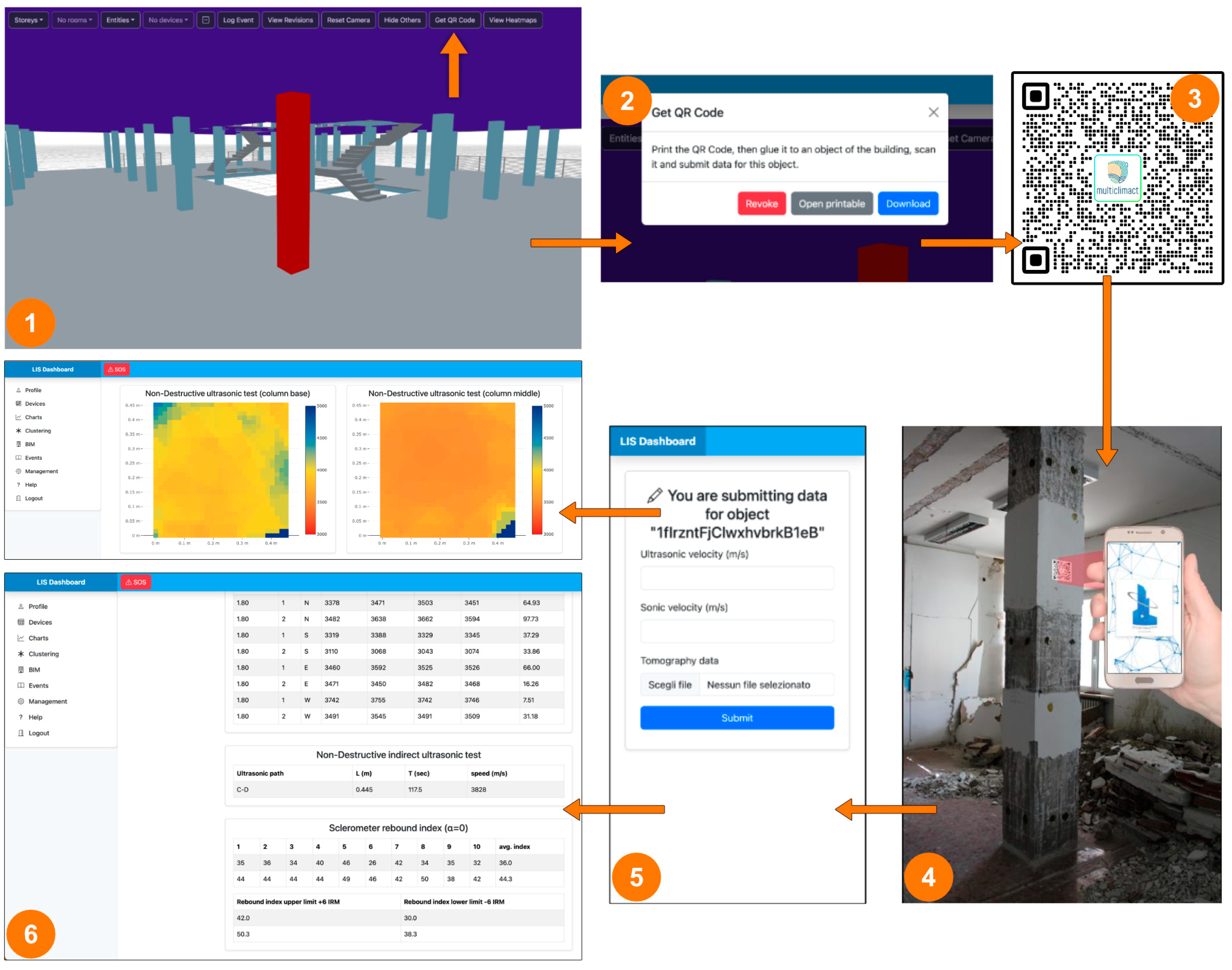

4.3. Implementation of the LIS Platform

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ibrahim, E.A.; Goff, D.; Keyvanfar, A.; Jonaidi, M. Assessing Post-Fire Damage in Concrete Structures: A Comprehensive Review. Buildings 2025, 15, 485. [Google Scholar] [CrossRef]

- D’Amico, F.; Bertolini, L.; Napolitano, A.; Ciampoli, L.B.; Manalo, J.; Gagliardi, V.; Calvi, A. A possible implementation of non-destructive data surveys in the definition of BIM models for the analysis of road assets. Transp. Res. Procedia 2023, 69, 187–194. [Google Scholar] [CrossRef]

- MIMS. Ministero delle Infrastrutture e della Mobilità Sostenibile; DM 312/2021: Modifiche al DM 560/2017; Ministero delle Infrastrutture e della Mobilità Sostenibile: Rome, Italy, 2021.

- MIT. Modalità e i Tempi Di Progressiva Introduzione dei Metodi e Degli Strumenti Elettronici di Modellazione per l’edilizia e le Infrastrutture; DM 560/2017; Ministero delle Infrastrutture e dei Trasporti: Rome, Italy, 2017. [Google Scholar]

- MIT. Legge 109/2018: Disposizioni Urgenti per la Città di Genova, la Sicurezza Della Rete Nazionale Delle Infrastrutture e Dei Trasporti, Gli Eventi Sismici del 2016 e 2017, il Lavoro e le Altre Emergenze; Ministero delle Infrastrutture e dei Trasporti: Rome, Italy, 2018.

- Bertolini, L.; D’amico, F.; Napolitano, A.; Ciampoli, L.B.; Gagliardi, V.; Manalo, J.R.D. A BIM-Based Approach for Pavement Monitoring Integrating Data from Non-Destructive Testing Methods (NDTs). Infrastructures 2023, 8, 81. [Google Scholar] [CrossRef]

- Zhu, H.; Huang, M.; Zhang, Q.-B. TunGPR: Enhancing data-driven maintenance for tunnel linings through synthetic datasets, deep learning and BIM. Tunn. Undergr. Space Technol. 2024, 145, 105568. [Google Scholar] [CrossRef]

- Solla, M.; Gonçalves, L.M.S.; Gonçalves, G.; Francisco, C.; Puente, I.; Providência, P.; Gaspar, F.; Rodrigues, H. A Building Information Modeling Approach to Integrate Geomatic Data for the Documentation and Preservation of Cultural Heritage. Remote. Sens. 2020, 12, 4028. [Google Scholar] [CrossRef]

- Artopoulos, G.; Fokaides, P.; Lysandrou, V.; Deligiorgi, M.; Sabatakos, P.; Agapiou, A. Data-Driven Multi-Scale Study of Historic Urban Environments by Accessing Earth Observation and Non-Destructive Testing Information via an HBIM-Supported Platform. Int. J. Arch. Heritage 2023, 18, 920–939. [Google Scholar] [CrossRef]

- Polimeno, M.R.; Roselli, I.; Luprano, V.A.; Mongelli, M.; Tatì, A.; De Canio, G. A non-destructive testing methodology for damage assessment of reinforced concrete buildings after seismic events. Eng. Struct. 2018, 163, 122–136. [Google Scholar] [CrossRef]

- Cassandras, C.G.; Lafortune, S. Introduction to Discrete Event Systems, 2nd ed.; Springer: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital Twin-Driven Product Design Framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Santarsiero, G.; Misceo, M.; Aversa, P.; Candigliota, E.; Di Micco, A.; Hugony, F.; Manfredi, V.; Marghella, G.; Marzo, A.; Masi, A.; et al. Holistic Assessment for Social Housing Retrofitting: Integrating Seismic, Energy, and Social Aspects in the REHOUSE Project. Buildings 2024, 14, 3659. [Google Scholar] [CrossRef]

- Caballero, A.A.; Yen, K.K. The Use of Micro-Electro-Mechanical Systems (MEMS) in the Construction Industry. In Proceedings of the 20th International Symposium on Automation and Robotics in Construction (ISARC 2003), Eindhoven, The Netherlands, 21–24 September 2003; pp. 73–78. [Google Scholar] [CrossRef]

- Lang, C.; Willmes, M. Non-Destructive Testing of Reinforced Concrete Structures. In Proceedings of the International Symposium on Structural Health Monitoring and Nondestructive Testing, Saarbruecken, Germany, 4–5 October 2018. [Google Scholar]

- NTC. Aggiornamento Delle “Norme Tecniche per le Costruzioni”; Decreto 17 Gennaio 2018; Ministero delle Infrastrutture e Trasporti: Rome, Italy, 2018.

- Aydin, F. Schmidt hammer using on concrete of existing building, II. In Proceedings of the International Workshop on Earthquake and Sustainable Materials (IWesM), Ankara, Turkey, 23 January 2013. [Google Scholar]

- RILEM TC 249-ISC. Non destructive In Situ Strength Assessment of Concrete. Available online: https://www.rilem.net/groupe/249-isc-non-destructive-in-situ-strength-assessment-of-concrete-295 (accessed on 4 November 2024).

- Siorikis, V.G.; Antonopoulos, C.P.; Pelekis, P.; Christovasili, K.; Hatzigeorgiou, G.D. Numerical and experimental evaluation of sonic resonance against ultrasonic pulse velocity and compression tests on concrete core samples. Vibroengineering PROCEDIA 2020, 30, 168–173. [Google Scholar] [CrossRef][Green Version]

- Gioiella, L.; Tubaldi, E.; Gara, F.; Dezi, L.; Dall’Asta, A. Modal properties and seismic behaviour of buildings equipped with external dissipative pinned rocking braced frames. Eng. Struct. 2018, 172, 807–819. [Google Scholar] [CrossRef]

- Gioiella, L.; Tubaldi, E.; Gara, F.; Dezi, L.; Dall’Asta, A. Stochastic seismic analysis and comparison of alternative external dissipative systems. Shock. Vib. 2018, 2018, 5403737. [Google Scholar] [CrossRef]

- Karatosun, S.; Yazar, M.; Gunes, O.; Taskin, B. Critical evaluation of NDT for rapid condition assessment of existing RC buildings: A case study. MATEC Web Conf. 2022, 361, 07001. [Google Scholar] [CrossRef]

| Floor | Tests Performed |

|---|---|

| Basement floor | n. 1 horizontal endoscopy n. 7 magnetic investigations to identify reinforcements n. 7 non-destructive concrete tests using the SonReb method n. 1 survey on the perimeter wall n. 3 foundation surveys n. 2 core samplings |

| Ground floor | n. 2 horizontal endoscopies n. 1 vertical endoscopy for stratification of the lower slab n. 16 magnetic investigations to identify reinforcements n. 16 non-destructive concrete tests using the SonReb method n. 1 survey on the wall n. 1 survey on the beam to verify construction details n. 1 survey on the intrados of the upper slab n. 4 core samplings |

| 1st floor | n. 4 horizontal endoscopies n. 2 vertical endoscopies for stratification of the lower slab n. 7 magnetic investigations to identify reinforcements n. 7 non-destructive concrete tests using the SonReb method n. 1 survey on the wall n. 3 surveys on beams to verify construction details n. 1 survey on the slab to verify construction details n. 2 core samplings n. 3 load tests on slabs n. 2 load tests on beams |

| 2nd floor | n. 7 magnetic investigations for reinforcement detection n. 7 non-destructive concrete tests using the SonReb method n. 2 core drillings |

| 3rd floor | n. 6 magnetic investigations for reinforcement detection n. 6 non-destructive concrete tests using the SonReb method n. 2 core drillings n. 1 reinforcement bar sampling |

| 4th floor | n. 6 magnetic investigations for reinforcement detection n. 6 non-destructive concrete tests using the SonReb method n. 2 core drillings n. 1 survey on slab to verify construction details |

| Attic floor | n. 1 vertical endoscopy for lower slab stratification n. 1 magnetic investigations for reinforcement detection n. 1 non-destructive concrete tests using the SonReb method n. 1 reinforcement sample extraction n. 1 survey on beam to verify construction details n. 1 survey on slab to verify construction details |

| Location: Foot; Side: 0.452 m; Height from Base: 0.33 m | |||||

|---|---|---|---|---|---|

| Point | Direction | Speed 1 (m/s) | Speed 2 (m/s) | Speed 3 (m/s) | Mean Speed (m/s) |

| 1 | NS | 3984 | 3961 | 3967 | 3971 |

| SN | 3941 | 3931 | 3929 | 3934 | |

| 2 | NS | 4035 | 4023 | 4044 | 4034 |

| SN | 4039 | 4042 | 4062 | 4048 | |

| 1 | EW | 3867 | 3873 | 3867 | 3869 |

| WE | 3862 | 3862 | 3869 | 3864 | |

| 2 | EW | 3808 | 3806 | 3821 | 3812 |

| WE | 3807 | 3802 | 3806 | 3805 | |

| Location: Middle; Side: 0.452 m; Height from Base: 1.72 m | |||||

| Point | Direction | Speed 1 (m/s) | Speed 2 (m/s) | Speed 3 (m/s) | Mean Speed (m/s) |

| 1 | NS | 3566 | 3543 | 3560 | 3556 |

| SN | 3527 | 3542 | 3516 | 3528 | |

| 2 | NS | 3575 | 3578 | 3579 | 3577 |

| SN | 3581 | 3562 | 3560 | 3568 | |

| 1 | EW | 3469 | 3469 | 3458 | 3465 |

| WE | 3476 | 3465 | 3473 | 3471 | |

| 2 | EW | 3507 | 3502 | 3499 | 3503 |

| WE | 3511 | 3515 | 3504 | 3510 | |

| Location: Top; Side: 0.452 m; Height from Base: 3.11 m | |||||

| Point | Direction | Speed 1 (m/s) | Speed 2 (m/s) | Speed 3 (m/s) | Mean Speed (m/s) |

| 1 | NS | 3517 | 3519 | 3500 | 3512 |

| SN | 3530 | 3525 | 3539 | 3531 | |

| 2 | NS | 3588 | 3606 | 3589 | 3594 |

| SN | 3515 | 3549 | 3551 | 3538 | |

| 1 | EW | 3495 | 3500 | 3516 | 3504 |

| WE | 3496 | 3480 | 3488 | 3488 | |

| 2 | EW | 3495 | 3503 | 3509 | 3502 |

| WE | 3464 | 3462 | 3472 | 3466 | |

| Location: Foot; Side: 0.452 m; Height of Impact Point from Base: 2.13 m | |||||

|---|---|---|---|---|---|

| Side | Point | Speed 1 (m/s) | Speed 2 (m/s) | Speed 3 (m/s) | Mean Speed (m/s) |

| N | 1 | 3378 | 3471 | 3503 | 3451 |

| 2 | 3482 | 3638 | 3662 | 3594 | |

| S | 1 | 3319 | 3388 | 3329 | 3345 |

| 2 | 3110 | 3068 | 3043 | 3074 | |

| E | 1 | 3460 | 3592 | 3525 | 3526 |

| 2 | 3471 | 3450 | 3482 | 3468 | |

| W | 1 | 3742 | 3755 | 3742 | 3746 |

| 2 | 3491 | 3545 | 3491 | 3509 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Candigliota, E.; Colaneri, O.; Gioiella, L.; Leggieri, V.; Marghella, G.; Marzo, A.; Mazzarelli, S.; Morici, M.; Murazzo, S.; Seferi, R.; et al. The Integration of a Multidomain Monitoring Platform with Structural Data: A Building Case Study. Sustainability 2025, 17, 3076. https://doi.org/10.3390/su17073076

Candigliota E, Colaneri O, Gioiella L, Leggieri V, Marghella G, Marzo A, Mazzarelli S, Morici M, Murazzo S, Seferi R, et al. The Integration of a Multidomain Monitoring Platform with Structural Data: A Building Case Study. Sustainability. 2025; 17(7):3076. https://doi.org/10.3390/su17073076

Chicago/Turabian StyleCandigliota, Elena, Orazio Colaneri, Laura Gioiella, Valeria Leggieri, Giuseppe Marghella, Anna Marzo, Saverio Mazzarelli, Michele Morici, Simone Murazzo, Rifat Seferi, and et al. 2025. "The Integration of a Multidomain Monitoring Platform with Structural Data: A Building Case Study" Sustainability 17, no. 7: 3076. https://doi.org/10.3390/su17073076

APA StyleCandigliota, E., Colaneri, O., Gioiella, L., Leggieri, V., Marghella, G., Marzo, A., Mazzarelli, S., Morici, M., Murazzo, S., Seferi, R., Tatì, A., Tripepi, C., & Luprano, V. A. M. (2025). The Integration of a Multidomain Monitoring Platform with Structural Data: A Building Case Study. Sustainability, 17(7), 3076. https://doi.org/10.3390/su17073076