Trade-Offs and Synergies of Key Biobased Value Chains and Sustainable Development Goals (SDGs)

Abstract

1. Introduction

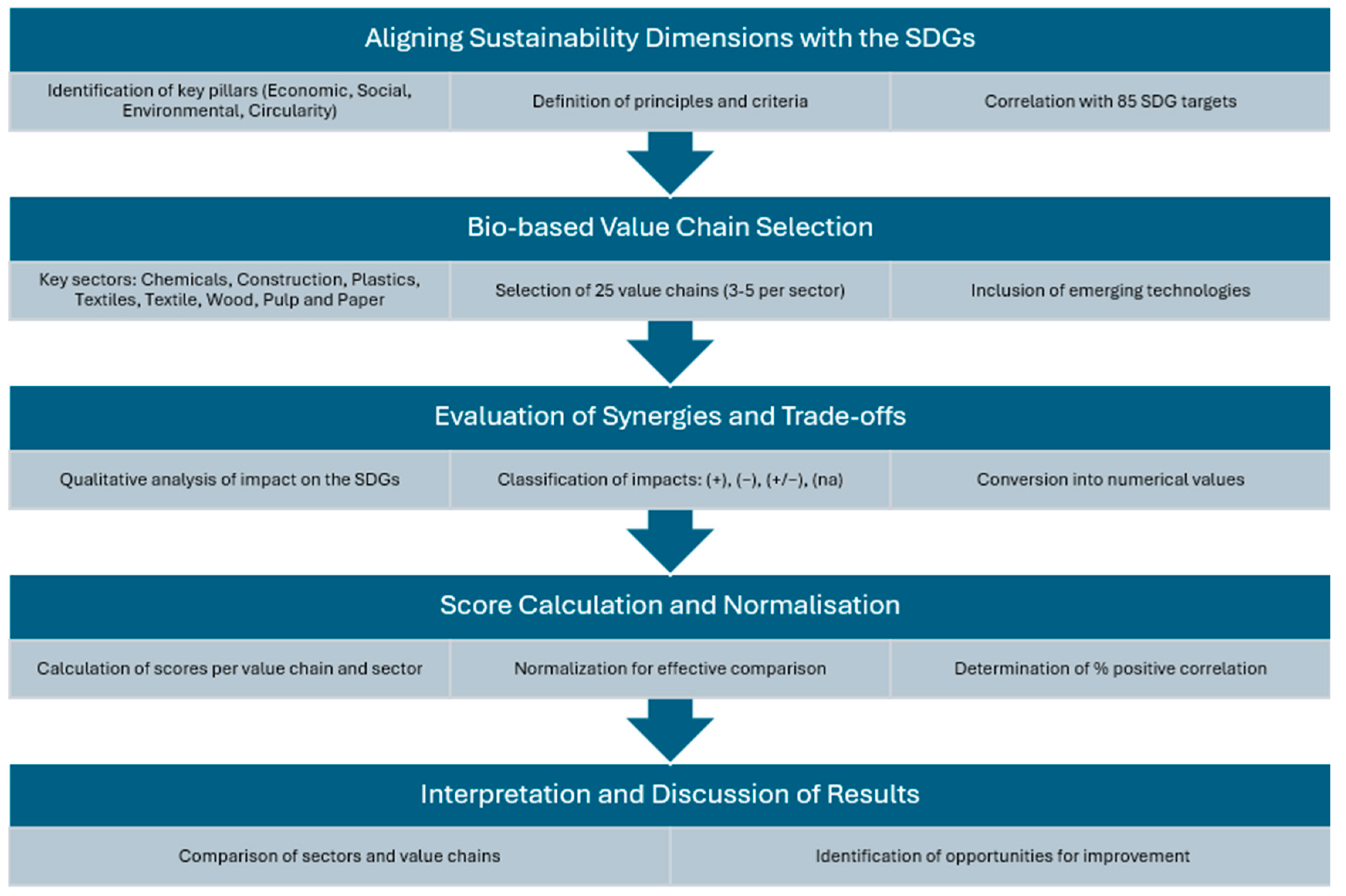

2. Materials and Methods

2.1. Linking Sustainability Dimensions with SDG Targets

2.2. Selection of Representative Biobased Value Chains as Example for Each Sector

2.3. Synergies and Trade-Offs Assessment

3. Results

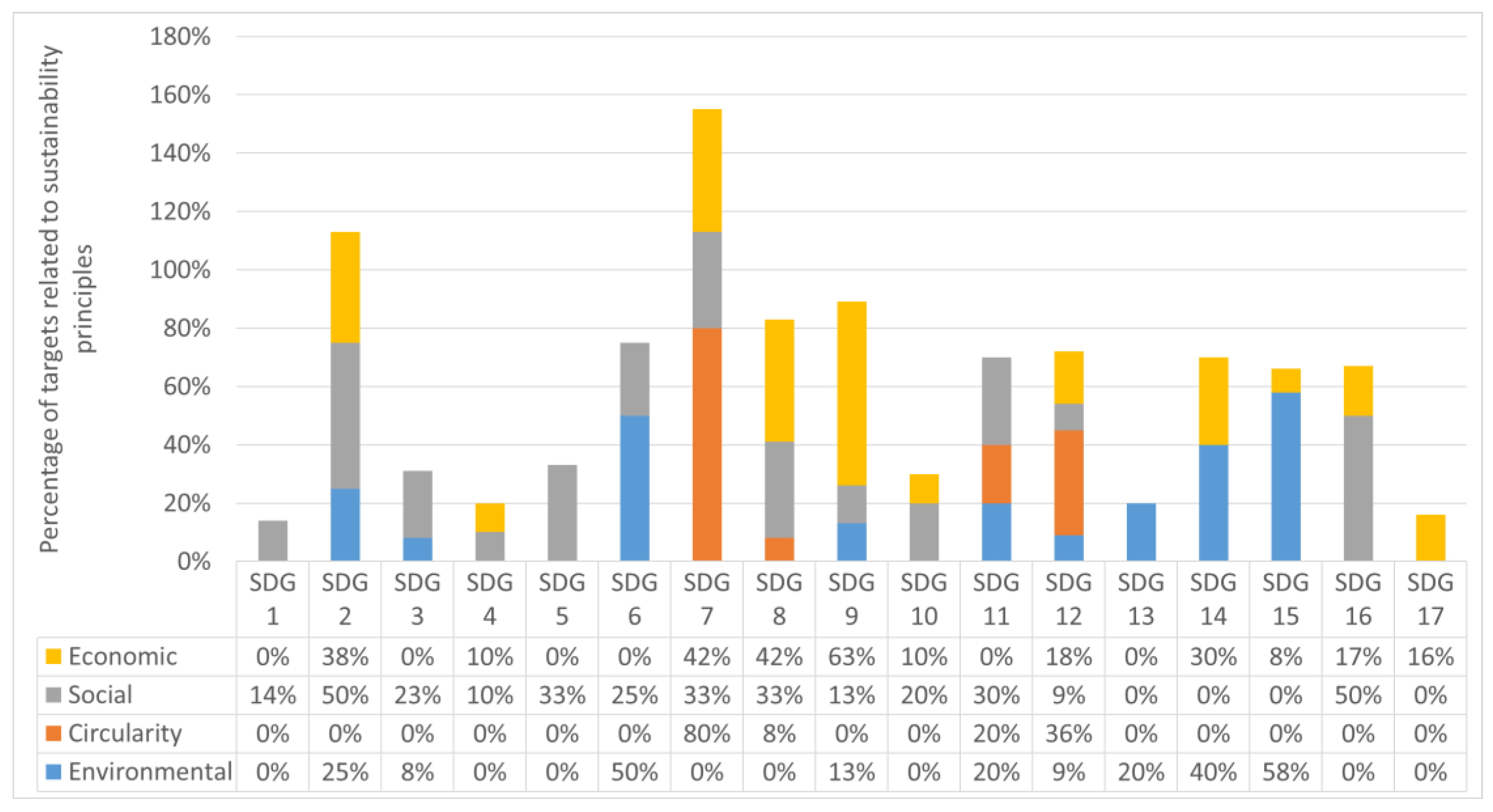

3.1. SDGs Against Sustainability Dimensions

3.1.1. Environmental Dimension

3.1.2. Circularity Dimension

3.1.3. Social Dimension

3.1.4. Economic Dimension

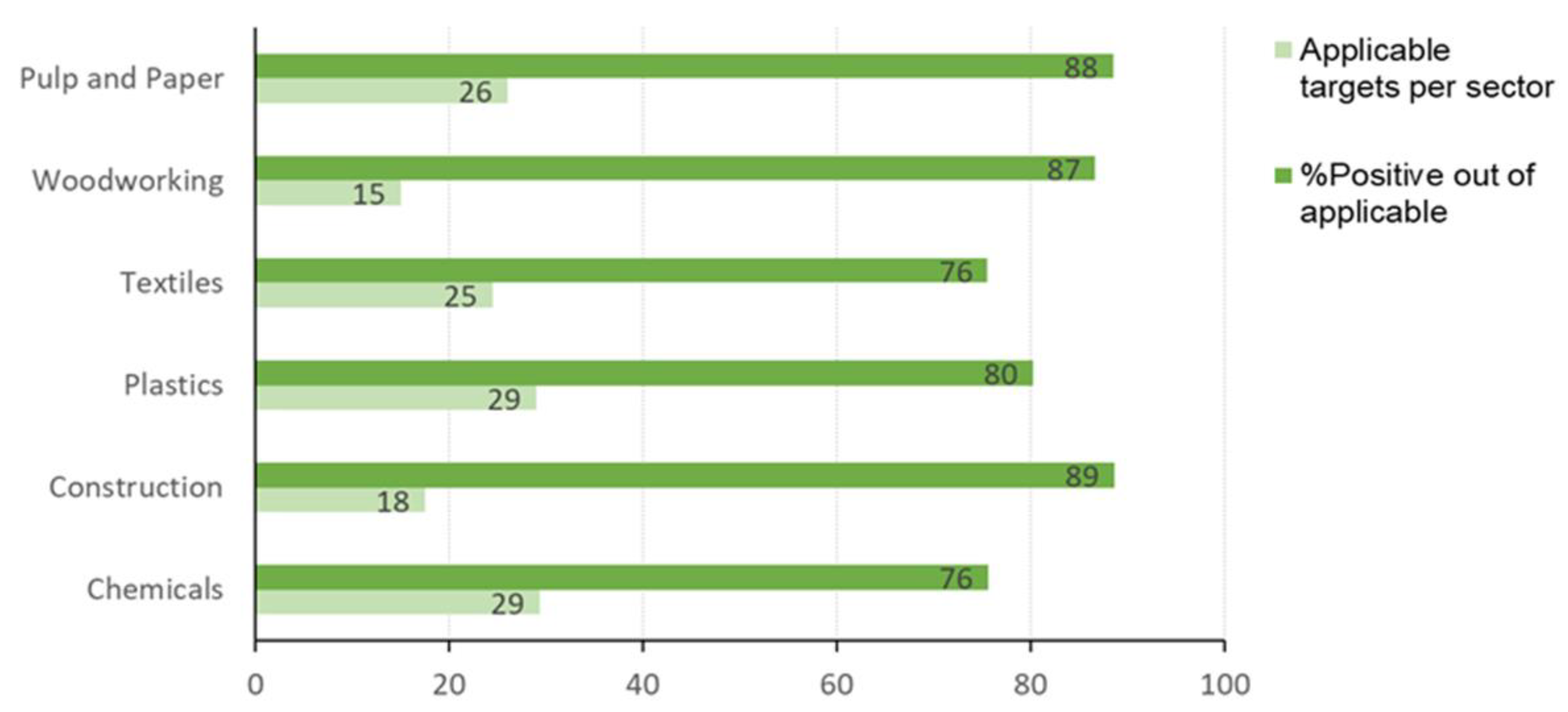

3.2. Analysis of Representative Biobased Value Chains with Respect to SDG Targets

3.2.1. Chemicals Sector

3.2.2. Construction Sector

3.2.3. Plastics Sector

3.2.4. Textile Sector

3.2.5. Woodworking Sector

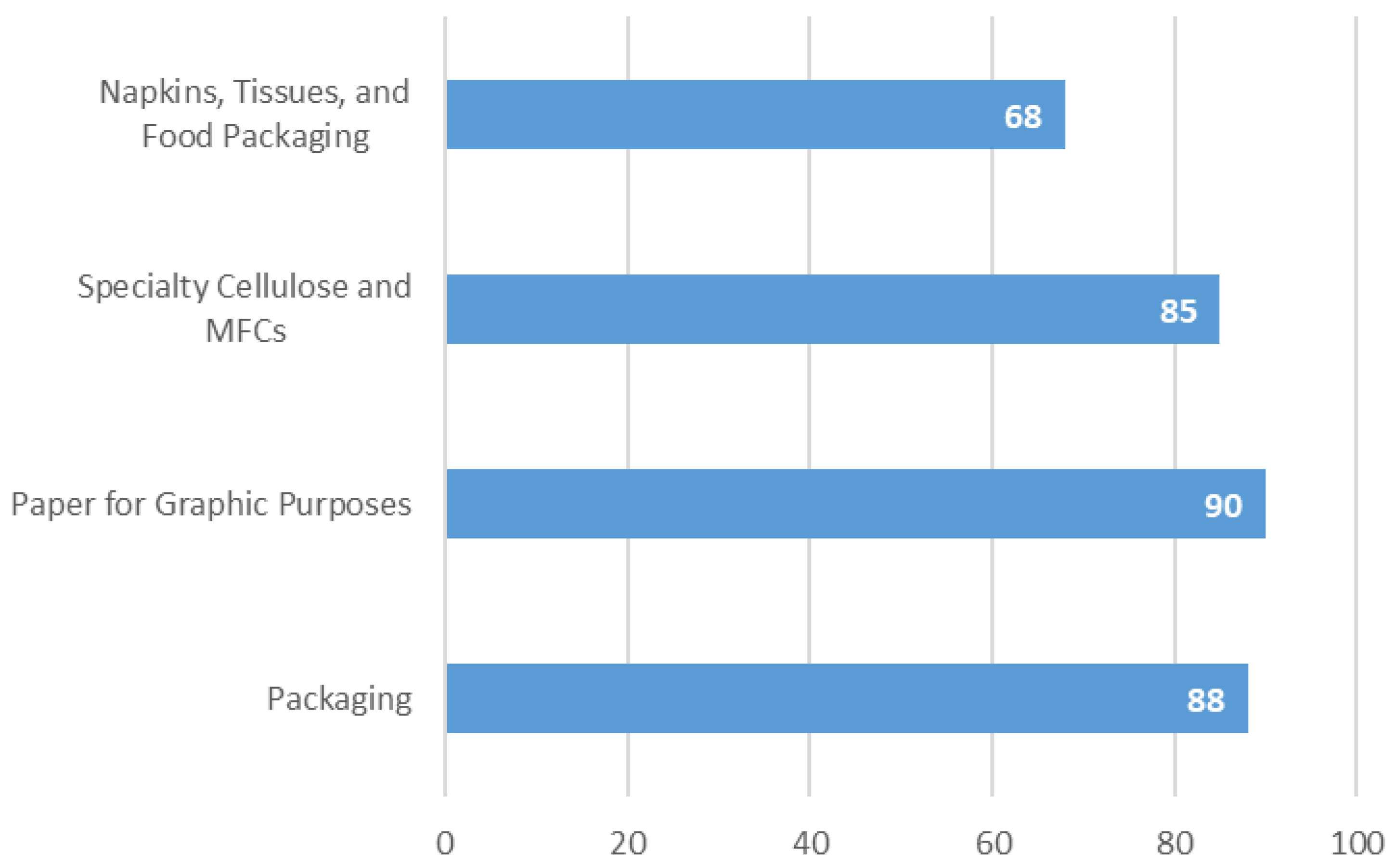

3.2.6. Pulp and Paper Sector

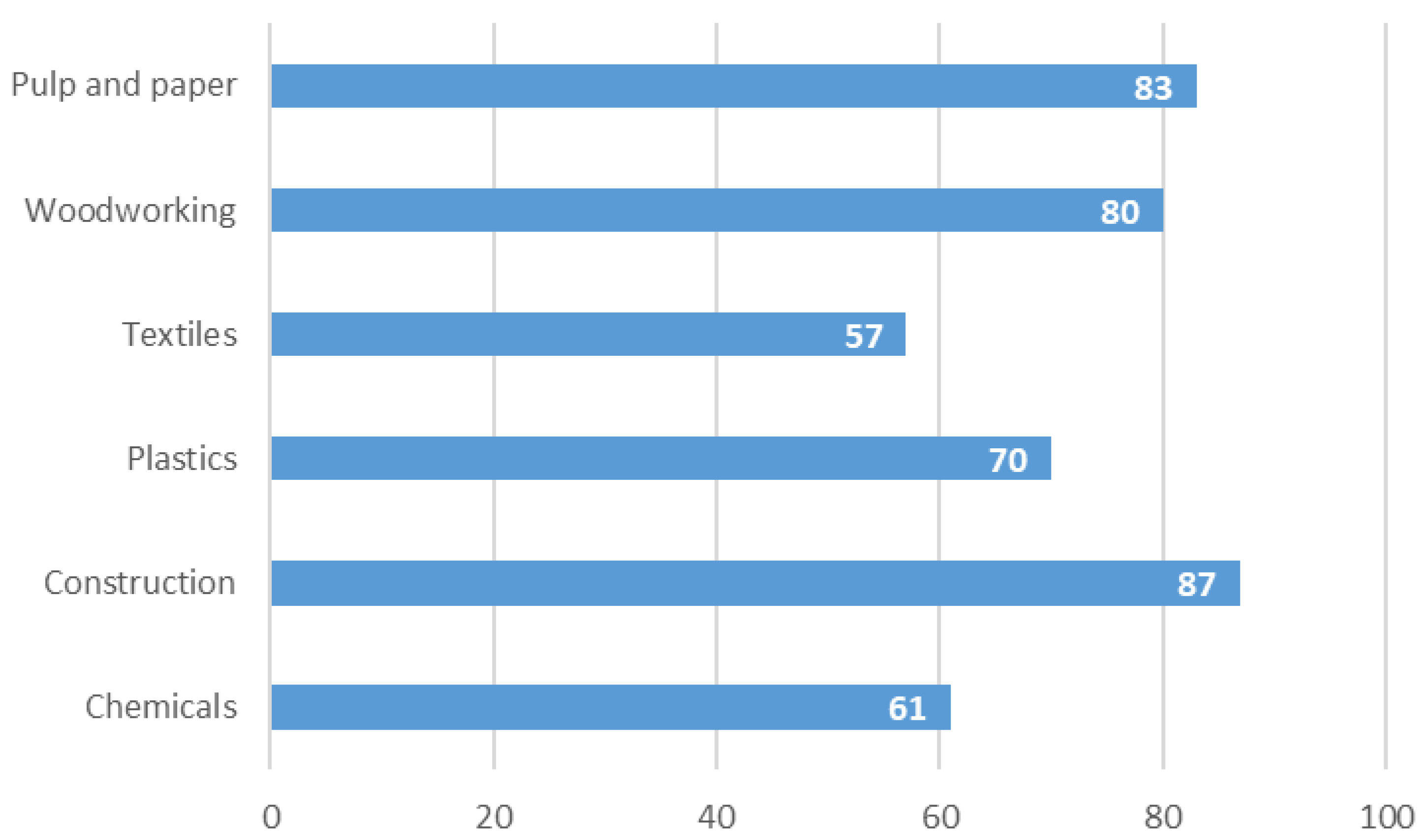

3.2.7. Sectors Overview

- Social and environmental issues: Some supply chains, particularly those linked to sugar, cotton, and textiles manufacturing, are notorious for social and environmental challenges. The EU’s dependence on imports from these sectors often exacerbates these issues, impacts traceability, and causes competition with food production.

- Polluting chemicals: many biobased value chains continue to depend on polluting chemicals and resource-intensive processes, further limiting their sustainability.

- Non-biodegradability: a significant concern is the non-biodegradability and/or difficulty in recycling certain biobased products, limiting their overall environmental benefits.

- Manufacturing challenges: producing fully biobased products that meet industry standards remains challenging, often resulting in only partial substitutions for conventional materials.

4. Conclusions

- Adapting the bioeconomy concept: tailoring the bioeconomy framework to fit each local context, taking regional strengths and weaknesses into account;

- Intensifying cooperation: collaborating with the waste management sector to ensure that biobased products can be effectively integrated into collection, separation, recycling, and composting initiatives;

- Standardizing sustainability information: standardizing sustainability information will streamline regulation and oversight while fostering the adoption of innovative value chains among governments, industry actors, and society.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stegmann, P.; Londo, M.; Junginger, M. The Circular Bioeconomy: Its Elements and Role in European Bioeconomy Clusters. Resour. Conserv. Recycl. X 2020, 6, 100029. [Google Scholar] [CrossRef]

- Pfau, S.F.; Hagens, J.E.; Dankbaar, B.; Smits, A.J.M. Visions of Sustainability in Bioeconomy Research. Sustainability 2014, 6, 1222–1249. [Google Scholar] [CrossRef]

- Tan, E.C.D.; Lamers, P. Circular Bioeconomy Concepts—A Perspective. Front. Sustain. 2021, 2, 701509. [Google Scholar] [CrossRef]

- Ronzon, T.; Sanjuán, A.I. Friends or Foes? A Compatibility Assessment of Bioeconomy-Related Sustainable Development Goals for European Policy Coherence. J. Clean. Prod. 2020, 254, 119832. [Google Scholar] [CrossRef]

- Vera, I.; Wicke, B.; Lamers, P.; Cowie, A.; Repo, A.; Heukels, B.; Zumpf, C.; Styles, D.; Parish, E.; Cherubini, F.; et al. Land Use for Bioenergy: Synergies and Trade-Offs between Sustainable Development Goals. Renew. Sustain. Energy Rev. 2022, 161, 112409. [Google Scholar] [CrossRef]

- Vargas-Carpintero, R. Development of an Integrated Multi-Criteria Framework to Assess the Implementation Potential of Biobased Value Chains and Webs with a Territorial Approach. Ind. Crops. Prod. 2025, 223, 120104. [Google Scholar] [CrossRef]

- Hetemäki, L.; D’Amato, D.; Giurca, A.; Hurmekoski, E. Synergies and Trade-Offs in the European Forest Bioeconomy Research: State of the Art and the Way Forward. For. Policy Econ. 2024, 163, 103204. [Google Scholar] [CrossRef]

- Calixto, P.S.; Prados, M.Á.H. La evolución del concepto de sostenibilidady suincidencia en la educación ambiental. Teoría De La Educación Rev. Interuniv. 2008, 20, 179–204. [Google Scholar] [CrossRef]

- Berlin, E.; Hamilton, M. Minimal Footprint, Maximum Circularity—The New Kind of Smart. In Smart Clothes and Wearable Technology, 2nd ed.; McCann, J., Bryson, D., Eds.; The Textile Institute Book Series; Woodhead Publishing: Sawston, UK, 2023; pp. 83–96. ISBN 978-0-12-819526-0. [Google Scholar]

- European Commission Renewcell Dissolves Natural Fibres into Biodegradable Pulp. Available online: https://circulareconomy.europa.eu/platform/en/good-practices/renewcell-dissolves-natural-fibres-biodegradable-pulp (accessed on 21 November 2024).

- Marquis, C. UBQ Materials’ Waste-Based Thermoplastic Is Preventing Methane and Enabling Circular Manufacturing. Available online: https://www.forbes.com/sites/christophermarquis/2022/11/08/ubq-materials-waste-based-thermoplastic-is-preventing-methane-and-enabling-circular-manufacturing/ (accessed on 21 November 2024).

- Spekreijse, J.; Lammens, T.; Parisi, C.; Ronzon, T.; Vis, M. Insights into the European Market for Bio-Based Chemicals; JRC Publications Repository: Belgium, Brussels, 2019. [Google Scholar]

- Aeschelmann, F.; Carus, M. Biobased Building Blocks and Polymers in the World: Capacities, Production, and Applications–Status Quo and Trends Towards 2020. Ind. Biotechnol. 2015, 11, 154–159. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V.A. Polyhydroxyalkanoate (PHA): Review of Synthesis, Characteristics, Processing and Potential Applications in Packaging. Express Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An Overview of the Recent Developments in Polylactide (PLA) Research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef] [PubMed]

- textile magazine, T. Spinnova to Commence Commercial Production of the World’s Most Sustainable Textile Fibre. Available online: https://www.indiantextilemagazine.in/spinnova-to-commence-commercial-production-of-the-worlds-most-sustainable-textile-fibre/ (accessed on 21 November 2024).

- Project STAR-ProBio STAR-ProBio Deliverable D8.2: Blueprint of Sustainability Certification Schemes for Bio-Based Products. Available online: http://www.star-probio.eu/wp-content/uploads/2017/04/D8.2_SAT-ProBio-blueprint_final-report_3-scalone.pdf (accessed on 6 March 2025).

- Heimann, T. Bioeconomy and SDGs: Does the Bioeconomy Support the Achievement of the SDGs? Earths Future 2019, 7, 43–57. [Google Scholar] [CrossRef]

- Pörtner, H.-O.; Roberts, D.C.; Tignor, M.M.B.; Poloczanska, E.; Mintenbeck, K.; Alegría, A.; Craig, M.; Langsdorf, S.; Löschke, S.; Möller, V.; et al. IPPC 2022: Climate Change 2022: Impacts, Adaptation and Vulnerability: Working Group II Contribution to the Sith Assessment Report of the Intergovernmental Panel on Climate Change. Available online: https://oceanrep.geomar.de/id/eprint/57717/ (accessed on 21 November 2024).

- Deeley, R. Human Rights Violations Are Increasing in Fashion’s Manufacturing Hubs. Available online: https://www.businessoffashion.com/news/sustainability/human-rights-violations-are-increasing-in-fashions-manufacturing-hubs/ (accessed on 21 November 2024).

- European Commission Forestry in the EU and the World. Available online: https://ec.europa.eu/eurostat/web/products-statistical-books/-/KS-31-11-137 (accessed on 21 November 2024).

- Kardung, M.; Cingiz, K.; Costenoble, O.; Delahaye, R.; Heijman, W.; Lovrić, M.; van Leeuwen, M.; M’Barek, R.; van Meijl, H.; Piotrowski, S.; et al. Development of the Circular Bioeconomy: Drivers and Indicators. Sustainability 2021, 13, 413. [Google Scholar] [CrossRef]

- Orjuela, A.; Clark, J. Green Chemicals from Used Cooking Oils: Trends, Challenges, and Opportunities. Curr. Opin. Green Sustain. Chem. 2020, 26, 100369. [Google Scholar] [CrossRef]

- Foo, W.H.; Koay, S.S.N.; Chia, S.R.; Chia, W.Y.; Tang, D.Y.Y.; Nomanbhay, S.; Chew, K.W. Recent Advances in the Conversion of Waste Cooking Oil into Value-Added Products: A Review. Fuel 2022, 324, 124539. [Google Scholar] [CrossRef]

- Zhou, X.; Du, G.; Zhou, X.; Du, G. Applications of Tannin Resin Adhesives in the Wood Industry. Available online: https://www.intechopen.com/chapters/67149 (accessed on 21 November 2024).

- Dhawale, P.V.; Vineeth, S.K.; Gadhave, R.V.; Fatima, M.J.J.; Supekar, M.V.; Thakur, V.K.; Raghavan, P. Tannin as a Renewable Raw Material for Adhesive Applications: A Review. Mater. Adv. 2022, 3, 3365–3388. [Google Scholar] [CrossRef]

- Material Transition-ARC CBBC. Available online: https://arc-cbbc.nl/research/material-transition (accessed on 21 November 2024).

- European Commission Lignicoat Project. Available online: https://www.lignicoat.eu/objectives/ (accessed on 21 November 2024).

- Liu, Y.; Yu, Z.; Wang, B.; Li, P.; Zhu, J.; Ma, S. Closed-Loop Chemical Recycling of Thermosetting Polymers and Their Applications: A Review. Green Chem. 2022, 24, 5691–5708. [Google Scholar] [CrossRef]

- Rhovanil®. Available online: https://www.solvay.com/en/brands/rhovanil (accessed on 21 November 2024).

- Kumar, N.; Pruthi, V. Potential Applications of Ferulic Acid from Natural Sources. Biotechnol. Rep. 2014, 4, 86–93. [Google Scholar] [CrossRef]

- Saur Modahl, I.; Brekke, A.; Lerche Raadal, H. Life Cycle Assessment of Cellulose, Ethanol, Lignin and Vanillin from Borregaard, Sarpsborg. Available online: https://norsus.no/en/publikasjon/life-cycle-assessment-of-cellulose-ethanol-lignin-and-vanillin-from-borregaard-sarpsborg/ (accessed on 21 November 2024).

- Ciriminna, R.; Fidalgo, A.; Meneguzzo, F.; Parrino, F.; Ilharco, L.M.; Pagliaro, M. Vanillin: The Case for Greener Production Driven by Sustainability Megatrend. ChemistryOpen 2019, 8, 660–667. [Google Scholar] [CrossRef]

- Ögmundarson, Ó.; Herrgård, M.J.; Forster, J.; Hauschild, M.Z.; Fantke, P. Addressing Environmental Sustainability of Biochemicals. Nat. Sustain. 2020, 3, 167–174. [Google Scholar] [CrossRef]

- Suen, Z. Do You Know Where Your Fragrance Comes From? Available online: https://atmos.earth/perfume-fragrance-climate-change-sustainable-environment/ (accessed on 21 November 2024).

- Victoria Why Frankincense Is On The Verge of Disappearing. Available online: https://boisdejasmin.com/2021/07/why-frankincense-is-on-the-verge-of-disappearing.html (accessed on 21 November 2024).

- Responsible Sourcing Givaudan. Available online: https://www.givaudan.com/sustainability/sustainable-business/position-statements-policies-reports/responsible-sourcing-policy (accessed on 21 November 2024).

- Manker, L.P.; Dick, G.R.; Demongeot, A.; Hedou, M.A.; Rayroud, C.; Rambert, T.; Jones, M.J.; Sulaeva, I.; Vieli, M.; Leterrier, Y.; et al. Sustainable Polyesters via Direct Functionalization of Lignocellulosic Sugars. Nat. Chem. 2022, 14, 976–984. [Google Scholar] [CrossRef] [PubMed]

- Child Labour in the Primary Production of Sugarcane. Available online: https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@ed_norm/@ipec/documents/publication/wcms_ipec_pub_29635.pdf (accessed on 21 November 2024).

- Sherfinski David, F.T. Ethanol: Brazil’s Sugar-Based Biofuel Built on Labor Abuse Context. Available online: https://www.context.news/money-power-people/long-read/ethanol-brazils-sugar-based-biofuel-built-on-labor-abuse (accessed on 21 November 2024).

- Heritage, U.W. The Industrial Heritage of Barbados: The Story of Sugar and Rum. Available online: https://whc.unesco.org/en/tentativelists/5942/ (accessed on 21 November 2024).

- Pang, Z.; Tayyab, M.; Kong, C.; Liu, Q.; Liu, Y.; Hu, C.; Huang, J.; Weng, P.; Islam, W.; Lin, W.; et al. Continuous Sugarcane Planting Negatively Impacts Soil Microbial Community Structure, Soil Fertility, and Sugarcane Agronomic Parameters. Microorganisms 2021, 9, 2008. [Google Scholar] [CrossRef] [PubMed]

- UNEP, S.E. Impacts of Unsustainable Oil Palm Plantation. Available online: https://tunza.eco-generation.org/ambassadorReportView.jsp?viewID=13704 (accessed on 21 November 2024).

- van Sloten, R. Competitive Distortions in the Access to Raw Materials for the European Chemical Industry. Available online: https://www.wto.org/english/res_e/publications_e/wtr10_forum_e/wtr10_25june10_e.htm (accessed on 21 November 2024).

- Life Cycle Analysis (LCA) of Avantium Products. Available online: https://www.avantium.com/lca/ (accessed on 21 November 2024).

- Ramsden, K. Cement and Concrete: The Environmental Impact. Available online: https://psci.princeton.edu/tips/2020/11/3/cement-and-concrete-the-environmental-impact (accessed on 21 November 2024).

- Arehart, J.H.; Nelson, W.S.; Srubar, W.V. On the Theoretical Carbon Storage and Carbon Sequestration Potential of Hempcrete. J. Clean. Prod. 2020, 266, 121846. [Google Scholar] [CrossRef]

- Arrigoni, A.; Pelosato, R.; Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life Cycle Assessment of Natural Building Materials: The Role of Carbonation, Mixture Components and Transport in the Environmental Impacts of Hempcrete Blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Karoly, W.J.; Flatley, J.J.; Stevenson, R.D.; Bowers, J.D. Airborne Concentrations of Methylene Diphenyl Diisocyanate (MDI) in North American Wood Mills during the Manufacturing of Oriented Strand Board (OSB). J. Occup. Environ. Hyg. 2004, 1, 789–798. [Google Scholar] [CrossRef]

- Hiziroglu, S. Basics of Formaldehyde Emission from Wood Composite Panels. Available online: https://extension.okstate.edu/fact-sheets/basics-of-formaldehyde-emission-from-wood-composite-panels.html (accessed on 21 November 2024).

- Luo, S.; Gao, L.; Guo, W. Effect of Incorporation of Lignin as Bio-Polyol on the Performance of Rigid Lightweight Wood–Polyurethane Composite Foams. J. Wood Sci. 2020, 66, 23. [Google Scholar] [CrossRef]

- Ma, X.; Chen, J.; Zhu, J.; Yan, N. Lignin-Based Polyurethane: Recent Advances and Future Perspectives. Macromol. Rapid Commun. 2021, 42, 2000492. [Google Scholar] [CrossRef]

- Li, H.; Liang, Y.; Li, P.; He, C. Conversion of Biomass Lignin to High-Value Polyurethane: A Review. J. Bioresour. Bioprod. 2020, 5, 163–179. [Google Scholar] [CrossRef]

- LignoValue Pilot. Available online: https://biconsortium.eu/lignovalue-pilot (accessed on 21 November 2024).

- Green, T.S. PHA: Is it the Future of Bioplastics? Available online: https://www.sourcegreen.co/plastics/pha-biobased-polymer-packaging/ (accessed on 21 November 2024).

- Wang, G.-X.; Huang, D.; Ji, J.-H.; Völker, C.; Wurm, F.R. Seawater-Degradable Polymers—Fighting the Marine Plastic Pollution. Adv. Sci. 2021, 8, 2001121. [Google Scholar] [CrossRef]

- Certified B CorpTM-UBQ Materials. Available online: https://www.ubqmaterials.com/b-corp/ (accessed on 21 November 2024).

- Haines-Gadd, M.; Charnley, F.; Encinas-Oropesa, A. Self-Healing Materials: A Pathway to Immortal Products or a Risk to Circular Economy Systems? J. Clean. Prod. 2021, 315, 128193. [Google Scholar] [CrossRef]

- Orbach, M. UBQ Materials Raises $170 Million to Convert Landfill Waste into Recyclable Plastic Substitute. Available online: https://www.calcalistech.com/ctech/articles/0,7340,L-3925097,00.html (accessed on 21 November 2024).

- Moretti, C.; Junginger, M.; Shen, L. Environmental Life Cycle Assessment of Polypropylene Made from Used Cooking Oil. Resour. Conserv. Recycl. 2020, 157, 104750. [Google Scholar] [CrossRef]

- Braskem I’m Green—Biobased PE. Available online: https://www.braskem.com.br/imgreen/ (accessed on 21 November 2024).

- Polylactic Acid Market Size & Share Analysis-Growth Trends & Forecasts (2024–2029); Mordor Intelligence: Telangana, India, 2024.

- Technology Spinnova. Available online: https://spinnova.com/technology/ (accessed on 21 November 2024).

- CIRCULOSE®. Available online: https://www.renewcell.com/en/circulose (accessed on 21 November 2024).

- Linen: A Precious, Zero-Waste and Sustainable Vegetal Fiber; Manteco: Manteco, Italy, 2022.

- Estimating the Carbon Footprint of a Fabric. Available online: https://oecotextiles.blog/2011/01/19/estimating-the-carbon-footprint-of-a-fabric/ (accessed on 22 November 2024).

- European Commission The Impact of Textile Production and Waste on the Environment. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20201208STO93327/the-impact-of-textile-production-and-waste-on-the-environment-infographic (accessed on 21 November 2024).

- Boustany, N. The Dark Side of the Cotton Industry. Available online: https://www.traceplanet.org/regeneration-journal/the-dark-side-of-the-cotton-industry (accessed on 31 January 2025).

- Nguyen, Q. How Sustainable Are Viscose Fabrics? A Life-Cycle Analysis. Available online: https://impactful.ninja/how-sustainable-are-viscose-fabrics/ (accessed on 21 November 2024).

- Ritchie, H.; Roser, M. Forests and Deforestation. Available online: https://ourworldindata.org/deforestation (accessed on 21 November 2024).

- European Commission Short Term Outlook—Agriculture and Rural Development. Available online: https://agriculture.ec.europa.eu/data-and-analysis/markets/outlook/short-term_en (accessed on 21 November 2024).

- Coelho, P.M.; Corona, B.; ten Klooster, R.; Worrell, E. Sustainability of Reusable Packaging–Current Situation and Trends. Resour. Conserv. Recycl. X 2020, 6, 100037. [Google Scholar] [CrossRef]

- Toczyłowska-Mamińska, R. Limits and Perspectives of Pulp and Paper Industry Wastewater Treatment—A Review. Renew. Sustain. Energy Rev. 2017, 78, 764–772. [Google Scholar] [CrossRef]

- Jung, Y.H.; Chang, T.-H.; Zhang, H.; Yao, C.; Zheng, Q.; Yang, V.W.; Mi, H.; Kim, M.; Cho, S.J.; Park, D.-W.; et al. High-Performance Green Flexible Electronics Based on Biodegradable Cellulose Nanofibril Paper. Nat. Commun. 2015, 6, 7170. [Google Scholar] [CrossRef]

- Arca, H.C.; Mosquera-Giraldo, L.I.; Bi, V.; Xu, D.; Taylor, L.S.; Edgar, K.J. Pharmaceutical Applications of Cellulose Ethers and Cellulose Ether Esters. Biomacromolecules 2018, 19, 2351–2376. [Google Scholar] [CrossRef]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A Review of Cellulose and Its Derivatives in Biopolymer-Based for Food Packaging Application. Trends Food Sci. Technol. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- Shaghaleh, H.; Xu, X.; Wang, S. Current Progress in Production of Biopolymeric Materials Based on Cellulose, Cellulose Nanofibers, and Cellulose Derivatives. RSC Adv. 2018, 8, 825–842. [Google Scholar] [CrossRef]

- Ullah, H.; Santos, H.A.; Khan, T. Applications of Bacterial Cellulose in Food, Cosmetics and Drug Delivery. Cellulose 2016, 23, 2291–2314. [Google Scholar] [CrossRef]

- Scholten, P.B.V.; Figueirêdo, M.B. Back to the Future with Biorefineries: Bottom-Up and Top-Down Approaches toward Polymers and Monomers. Macromol. Chem. Phys. 2022, 223, 2200017. [Google Scholar] [CrossRef]

- Lipiäinen, S.; Kuparinen, K.; Sermyagina, E.; Vakkilainen, E. Pulp and Paper Industry in Energy Transition: Towards Energy-Efficient and Low Carbon Operation in Finland and Sweden. Sustain. Prod. Consum. 2022, 29, 421–431. [Google Scholar] [CrossRef]

- Bhardwaj, N.K.; Kaur, D.; Chaudhry, S.; Sharma, M.; Arya, S. Approaches for Converting Sugarcane Trash, a Promising Agro Residue, into Pulp and Paper Using Soda Pulping and Elemental Chlorine-Free Bleaching. J. Clean. Prod. 2019, 217, 225–233. [Google Scholar] [CrossRef]

- Tsakalova, M.; Onorato, C.; Karathanasis, A.Z.; Deligkiozi, I. A Circular Economy Framework for the Assessment of Bio-Based Value Chains. Sustain. Chem. Environ. 2024, 6, 100099. [Google Scholar] [CrossRef]

- OECD Realising the Circular Bioeconomy. Available online: https://www.oecd.org/content/dam/oecd/en/publications/reports/2018/11/realising-the-circular-bioeconomy_0c839f0a/31bb2345-en.pdf (accessed on 19 March 2025).

- Vural Gursel, I.; Elbersen, B.; Meesters, K.P.H.; van Leeuwen, M. Defining Circular Economy Principles for Biobased Products. Sustainability 2022, 14, 12780. [Google Scholar] [CrossRef]

- Rossi, C.; Shen, L.; Junginger, M.; Wicke, B. Sustainability Certification of Bio-Based Products: Systematic Literature Review of Socio-Economic Impacts along the Supply Chain. J. Clean. Prod. 2024, 468, 143079. [Google Scholar] [CrossRef]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a Circular Economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef]

- Sustainability Directory Sustainability Standards Harmonization. Available online: https://sustainability-directory.com/term/sustainability-standards-harmonization/ (accessed on 19 March 2025).

- Anguiano-Santos, C.; Salazar-Ordóñez, M.; Tornel-Vázquez, R.; Rodríguez-Entrena, M. Sustainability Reporting Harmonisation? A Utopian Endeavour for European Agri-Food Companies. J. Policy Model. 2024, 46, 354–368. [Google Scholar] [CrossRef]

- iRIS CARBON Sustainability Reporting Challenges: Where Companies Often Miss the Mark. Available online: https://www.iriscarbon.com/sustainability-reporting-challenges-where-companies-often-miss-the-mark/#5Standardization_and_Harmonization (accessed on 19 March 2025).

| Dimension | Principles | Criteria |

|---|---|---|

| Environmental | Reduce GHG emissions | Lifecycle GHG emissions |

| Conserve land with high carbon stock and peatland | Protection of land with high carbon stock | |

| Protection of peatland | ||

| Promote sustainable forest management | Maintaining forest productivity | |

| Promote the positive and reduce the negative impacts on ecosystems and biodiversity | Protection of land with a high biodiversity value | |

| Restoration, preservation, and strengthening of biodiversity | ||

| Conserve and protect water resources | Sustainable use of water | |

| Maintaining and enhancing water quality | ||

| Protect soil quality and productivity | Maintaining and enhancing soil quality | |

| Use of residual flows | ||

| Implement best practices for the use of (agro)chemicals | Prohibition on the use of hazardous/toxic chemicals | |

| Use, storage, handling, and disposal of (agro)chemicals | ||

| Restrict air pollution and promote good air quality | Air quality | |

| Restriction on open-air burning | ||

| Limit the risk of indirect land use change | ILUC low risk | |

| Circularity | Promote responsible waste management | Waste management |

| Valorization of residual flows | ||

| Promote efficient use of energy and material resources | Raw material efficiency | |

| Efficient use of energy | ||

| Use of renewable and non-renewable sources | ||

| Promote material circularity | Material circularity | |

| Social | Labor rights | Child labor |

| Forced and compulsory labor | ||

| Fair salary and remuneration | ||

| Association and collective bargaining rights | ||

| Equal opportunities/discrimination | ||

| Grievance mechanism | ||

| Working conditions | Contract | |

| Training | ||

| Occupational health and safety | ||

| Harassment and violence | ||

| Hours of work and overtime | ||

| Property and usage rights | Land use rights (including land tenure) | |

| Water use rights | ||

| Well-being of the local population | Health and safety of local community | |

| Local services (health, education, infrastructure, …)/prosperity | ||

| Local values | ||

| Community involvement | ||

| Food security | ||

| Economic | Financial and economic viability (economic sustainability and continual improvement) | |

| Fair business practices and integrity (fraudulent, deceptive, or dishonest) | ||

| Inclusive economic growth | Local employment and procurement | |

| Community investment | ||

| Use of knowledge and technology | Compensate Indigenous knowledge | |

| Use of technology | ||

| Fair trade and market practices | ||

| Risk assessment and management |

| Dimension | Principle | Criteria | Correspondence to SDGs and Targets |

|---|---|---|---|

| Environmental | Reduce GHG emissions | Lifecycle GHG emissions | Target 9.4 Target 11.B Target 13.2 |

| Conserve land with high carbon stock and peatland | Protection of land with high carbon stock | Target 15.1 Target 15.2 | |

| Protection of peatland | Target 6.6 Target 15.1 Target 15.5 | ||

| Promote sustainable forest management | Maintaining forest productivity | Target 15.2 Target 15.B | |

| Promote the positive and reduce the negative impacts on ecosystems and biodiversity | Protection of land with a high biodiversity value | Target 14.5 Target 15.1 Target 15. | |

| Restoration, preservation, and strengthening of biodiversity | Target 2.5 Target 14.2 Target 15.1 Target 15.5 Target 15.8 Target 15.A | ||

| Conserve and protect water resources | Sustainable use of water | Target 6.4 Target 6.5 | |

| Maintaining and enhancing water quality | Target 6.3 Target 14.1 Target 14.3 | ||

| Protect soil quality and productivity | Maintaining and enhancing soil quality | Target 2.4 Target 15.3 | |

| Use of residual flows | Target 12.5 | ||

| Implement best practices for the use of (agro)chemicals | Prohibition on the use of hazardous/toxic chemicals | Target 3.9 | |

| Use, storage, handling, and disposal of (agro)chemicals | Target 12.4 | ||

| Restrict air pollution and promote good air quality | Air quality | Target 11.6 | |

| Restriction on open-air burning | |||

| Limit the risk of indirect land use change | ILUC low risk | Target 15.2 | |

| Circularity | Promote responsible waste management | Waste management | Target 11.6 Target 12.4 Target 12.5 |

| Valorization of residual flows | Target 8.4 Target 12.3. Target 12.5 | ||

| Promote efficient use of energy and material resources | Raw material efficiency | Target 8.4 Target 11.B Target 12.2 | |

| Efficient use of energy | Target 7.3 Target 7.4 | ||

| Use of renewable and non-renewable sources | Target 7.2 Target 7.5 | ||

| Promote material circularity | Material circularity | Target 12.5 | |

| Social | Labor rights | Child labor | Target 4.1 Target 8.7 Target 16.2 |

| Forced and compulsory labor | Target 8.7 Target 8.8 | ||

| Fair salary and remuneration | Target 8.5 | ||

| Association and collective bargaining rights | Target 8.8 Target 16.C | ||

| Equal opportunities/discrimination | Target 5.1 Target 8.5 Target 10.3. Target 10.4 | ||

| Grievance mechanism | Target 8.8 Target 16.3. | ||

| Working conditions | Contract | Target 8.5 | |

| Training | Target 8.6 | ||

| Occupational health and safety | Target 8.8 | ||

| Harassment and violence | Target 5.2 Target 10.3 Target 16.1. Target 16.B | ||

| Hours of work and overtime | |||

| Property and usage rights | Land use rights (including land tenure) | Target 1.4 Target 2.3 Target 5.7 | |

| Water use rights | Target 1.4 | ||

| Well-being of the local population | Health and safety of local community | Target 2.2 Target 3.9 Target 12.4 | |

| Local services (health, education, infrastructure, …)/prosperity | Target 1.4 Target 3.8 Target 3.B Target 4.1 Target 6.2 Target 7.1 Target 9.1 Target 11.1 Target 11.2 | ||

| Local values | Target 11.4 | ||

| Community involvement | Target 6.8 Target 16.7 | ||

| Food security | Target 2.1 Target 2.C. | ||

| Financial and economic viability (economic sustainability and continual improvement) | Target 8.1 Target 8.2 Target 12.6 Target 14.7 | ||

| Fair business practices and integrity (fraudulent, deceptive, or dishonest) | Target 15.6 Target 16.5 Target 16.6 | ||

| Inclusive economic growth | Local employment and procurement | Target 2.3 Target 8.3 Target 9.1 | |

| Community investment | Target 4.4 Target 8.6 Target 9.8 | ||

| Use of knowledge and technology | Compensate Indigenous knowledge | ||

| Use of technology | Target 2.A Target 9.5 Target 9.7 Target 14.A Target 17.7 | ||

| Fair trade and market practices | Target 2.B Target 8.B Target 9.3 Target 10.5 Target 12.C Target 14.B Target 17.A Target 17.C | ||

| Risk assessment and management |

| Sector | Value Chain | Feedstock | Feedstock Classification | General Comments |

|---|---|---|---|---|

| CHEMICALS | Novel and drop-in chemical building blocks (e.g., ethylene, succinic acid, and lactic acid) | Sugar and starch crops | Primary dedicated | Used as building blocks to produce a range of chemicals and materials, Replacement of fossil-based chemicals |

| Novel and drop-in chemical building blocks (e.g., dicarboxylic acids, glycols, and diols) | Sugars from lignocellulosic residues, e.g., wheat straw | Primary and secondary plant residues from agriculture and forestry | ||

| Novel resins from forest residues | Tall oil, lignin, and tannins | Primary and secondary residues and residues from forest industry | Replacement of fossil-based chemicals in adhesives, coatings, and paints for various applications | |

| Oleochemicals (e.g., fatty acids, fatty acids esters, fatty alcohols, and glycerine) | Animal fat waste, used cooking oil, and waste from vegetable oils processing | Secondary residues from agri-food industry and meat processing industry and tertiary residues and wastes | Replacement of fossil-based chemicals used in lubricants and surfactants, use as chemical building blocks and in cosmetic formulations | |

| Oleochemicals (e.g., fatty acids, fatty acids esters, fatty alcohols, and glycerine) | Oil crops, e.g., palm, soy, and rapeseed | Primary dedicated | ||

| Fine chemicals (e.g., vanillin, geraniol, cinnamic acid, geranyl acetate, and linalool) | Biobased sources, e.g., flowers, leaves, and vanillin from lignin | Primary dedicated and primary residues | Replacement of petro-based chemicals used in high-value industries such as fragrance and flavor and cosmetics | |

| CONSTRUCTION | Rigid polyurethane foams (rPUs) | Lignin, tall oil, and hemicelluloses | Secondary residues and residues from forest industry | Replacement of petro-based polyols in rPUs, which are used for insulation in roofing and flooring |

| Fiberboards and concrete | Hemp | Primary dedicated | Replacement of energy intensive, inorganic materials (aluminum, steel, and concrete) with natural materials, upcycling side streams | |

| Oriented strand board | Lignocellulosic residues, e.g., wheat straw | Primary and secondary plant residues from agriculture and forestry | ||

| Wood-based particleboards for interior construction | Wood residues | Primary residues from forestry | ||

| PLASTICS | Polypropylene (PP) | Used cooking oil | Tertiary residues and wastes | Replacement of PP made of petro-based propylene |

| Polyethylene (PE) and ethylene vinyl acetate (EVA) using green ethylene and polylactic acid (PLA) | Sugar crops | Primary dedicated and primary plant residues | Replacement of PE and EVA made from petro-based ethylene, PLA as a more environmentally friendly packaging solution | |

| Novel composites and thermoplastic materials from waste | Forestry waste and municipal waste | Secondary and tertiary residues and wastes | Replacement of both single-use and durable plastics, adhesives or thin coatings used in paper and cardboard | |

| Bioplastics using biological metabolism (such as PHA) | Organic waste and wastewater | Tertiary residues and wastes | Replacement of plastics from petrol to PHA produced by bacteria | |

| TEXTILE | Cotton textile value chain | Cotton | Primary dedicated | Traditional industry |

| Recycling cotton and other cellulose-rich textiles and novel efficient spinning technologies | New and used textile fibers | Primary dedicated and tertiary residues and wastes | Water-based chemical processes (no harmful chemicals) able to recycle cellulose-rich textiles into new yarns of high quality and new spinning technologies that save water | |

| Textiles from other natural fibers | Flax and hemp | Primary dedicated | Textile fibers from other natural (agricultural) sources | |

| Cellulosic fibers (e.g., Lyocell and Viscose) | Wood | Primary dedicated | Traditional industry that can replace fossil-based fibers, such as polyesters and nylon | |

| WOODWORKING | Use of lignocellulosic residues for interiors and decoration | Lignocellulosic resources, e.g., wheat straw and hemp | Primary dedicated and (mostly) primary residues from agriculture and forestry | Replacing plastics and primary dedicated wood |

| Particleboards for interior construction and carpentry pieces (cases, boxes, crates, drums, etc.) | Wood residues | Primary residues from forestry | Wood residues (particularly coniferous) as a replacement to durable plastics | |

| Use of sawdust and other subproducts in woodworking industry | Sawdust | Secondary residue from forestry | Substitute of primary dedicated wood by subproducts of wood industry | |

| PULP&PAPER | Resistant packaging (cartons, boxes, and cases of corrugated paper) from mechanical or semi-chemical pulp | Wood | Primary dedicated | Traditional industry, uses wood (particularly coniferous), and can replace plastics |

| Paper for graphic purposes | Recycled paper | Tertiary residues or waste | Use (recycling) of paper waste into new paper with artistic value | |

| Specialty cellulose, cellulosic microfibrils (MFCs), and micro-nano crystalline cellulose (MCCs and CNCs) | Wood | Primary dedicated mostly, but possible primary residues from agriculture and forestry | Specialty cellulose: traditional product with use in textiles, pharma, food, and cosmetic industries (e.g., viscose, cellulose ethers, acetate, and nitrocellulose). MFCs and MCCs as emerging cellulosic materials with potential ranging from cosmetics to batteries and coatings, replacing inorganic and petro-based materials. | |

| Napkins, tissues, and food packaging | Fibers from lignocellulosic sources, e.g., sugarcane bagasse | Secondary plant residues from the agri-food industry | Secondary residues to replace virgin wood and single-use plastics |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández Ocamica, V.; Palacino, B.; Bartolomé, C.; Bernardes Figueirêdo, M.; Lázaro García, C. Trade-Offs and Synergies of Key Biobased Value Chains and Sustainable Development Goals (SDGs). Sustainability 2025, 17, 3040. https://doi.org/10.3390/su17073040

Fernández Ocamica V, Palacino B, Bartolomé C, Bernardes Figueirêdo M, Lázaro García C. Trade-Offs and Synergies of Key Biobased Value Chains and Sustainable Development Goals (SDGs). Sustainability. 2025; 17(7):3040. https://doi.org/10.3390/su17073040

Chicago/Turabian StyleFernández Ocamica, Víctor, Bárbara Palacino, Carmen Bartolomé, Monique Bernardes Figueirêdo, and Cristina Lázaro García. 2025. "Trade-Offs and Synergies of Key Biobased Value Chains and Sustainable Development Goals (SDGs)" Sustainability 17, no. 7: 3040. https://doi.org/10.3390/su17073040

APA StyleFernández Ocamica, V., Palacino, B., Bartolomé, C., Bernardes Figueirêdo, M., & Lázaro García, C. (2025). Trade-Offs and Synergies of Key Biobased Value Chains and Sustainable Development Goals (SDGs). Sustainability, 17(7), 3040. https://doi.org/10.3390/su17073040