Abstract

The circular economy, in which recycling plays a significant role, is increasingly becoming a primary requirement for packaging. Our research focused on the recycling of intelligent cardboard packaging. The focus of the study was to manufacture and recycle cardboard embedded with a printed RFID antenna and a thermochromic indicator and to evaluate their recyclability. The Confederation of European Paper Industries (CEPI) method was employed to assess the recyclability of cardboard printed using digital printing techniques with integrated intelligent elements. The coarse reject and concentration following coarse screening were determined, and laboratory hand sheets were made for the adhesiveness test and visual evaluation. The fine screening procedure was performed. The acquired samples were evaluated for basic, mechanical, and optical properties. The analysis indicated that the recyclability of all examined materials was exceptionally good, confirming their suitability for normal recycling processes. Furthermore, the recycling efficiency exceeds 99% for all samples. Despite the variances in the samples, including metallic functional and thermochromic ink, they did not significantly impact the final outcome. Moreover, little variations in recyclability were seen between intelligent elements printed directly on cardboard and those printed on self-adhesive labels applied to the cardboard. The research has confirmed that the printed RFID antenna and thermochromic indicator have a negligible impact on the recyclability process and final score.

1. Introduction

Environmental considerations have recently become integral to every product and manufacturing process, especially for items with short lifespans, such as packaging. At product design efficient use of materials, sourcing from renewable resources, and a design for reuse and recycling are particularly important [1]. Sustainable product design also incorporates the use of recycled materials and aims to ensure the recyclability of all components [2]. In Europe, paper for recycling, i.e., all collected paper and cardboard intended for recycling, is the most recycled material, exemplifying a circular economy [3]. However, mega trends suggest a slight decline in both recycling rates and the quality of recycled paper, a trend observed in last decade [4]. One emerging factor potentially affecting paper recyclability is the increasing use of smart packaging in paper and cardboard products [5]. Smart packaging is gaining popularity for its role in preserving product quality, facilitating product tracking, and enhancing communication between producers and consumers [6]. Intelligent packaging extends packaging’s communication function, engaging with consumers and monitoring conditions within or around the packaging. It detects, records, and communicates various environmental or product status indicators [7,8]. Intelligent packaging elements are divided by function: indicators provide a visual indication of product status; sensors measure specific conditions within the package; and interactive packaging supports data transfer via technologies such as 2D barcodes, RFID, and NFC [9]. RFID tags, for instance, improve traceability, safeguard against theft, and enable interactivity [10]. Printing intelligent components directly onto packaging materials offers a cost-effective production approach, as the packaging industry has developed efficient printing techniques for both large- and small-scale production [11]. Intelligent elements are printed with special inks, thermochromic ink for temperature indicators, and functional conductive ink for RFID tags. However, the question of recyclability arises, as intelligent elements may affect the material’s ability to be recycled.

The recyclability of paper tells us how well the material can be recycled or whether it is even suitable for the entire recycling process. Based on the obtained laboratory sheets of recycled paper, recyclability points are calculated. The final assessment considers three components: yield, which evaluates the amount of fibrous material; visual value, which indicates the optical quality of the obtained material; and sheet adhesion, which assesses the formation of sticky contaminants that can be harmful in the paper production process [12]. Research conducted on the recyclability of paper and cardboard was mainly focused on the determination of the deinkability of products printed with different printing techniques [13,14,15]. Only a few studies have reported about the recyclability of intelligent cardboard packaging. In the process of paper and cardboard recycling, intelligent elements, such as RFID tags or thermochromic indicators, attached to packaging enter the recycling process without having been separated in advance. The components of these elements are separated during recycling in the disintegration and mechanical separation processes. Atkinson investigated the behavior of different metallic conductive inks during the recycling process and found that nickel and silver particles remain in suspension along with the fibers, while nano-silver particles end up in the wastewater [16]. In the study of Aliaga et al., the effects of printed electronics on the recyclability of envelopes used for postal and courier servers was evaluated [5]. The results showed that printed electronic components were mainly retained on screens during the pulping process. However, they noted that the inks from the conductive labels partially dissolved in water, causing minor changes in the optical properties of the recycled paper. Nevertheless, they concluded that the deviations were not significant enough to cause issues in the paper recycling processes [5]. A comparison between the recyclability and deinkability of the offset and digital prints and two conductive functional inks was made by Pogačar et al. [17]. For the printed RFID antennas on both the offset and electrographic prints, good deinkability was determined, with only a small deterioration in optical properties, especially when nano-silver conductive ink was used. The study of Kavčič et al. revealed that paper with printed electronics can indeed be decolorized, but the effectiveness of the process depends on the printing ink and the type of substrate [18]. Since not all paper products are equally suitable for recycling, the potential accumulation of heavy metal or silver particles must also be considered during decolorization. These particles can accumulate during the removal of the printing ink and remain in the water residues, negatively impacting the environment [18]. The need for designing paper-based printed electronics for recycling was investigated by Sudeshwar et al. [19]. They compared traditional printed circuit boards with printed electronics on paper and assessed the significance of recycling electronic waste. A comparative life cycle assessment of both options was conducted, and the impact on global warming was calculated. The results showed that printed electronics offer greater sustainability compared to traditional printed circuit boards by allowing for the recycling of silver at the end of its life cycle. They found that printed electronics have many advantages over conventional printed circuit boards [19].

With sustainability and circular economy principles gaining importance, it is essential to ensure that intelligent packaging solutions, which incorporate elements like RFID and thermochromic indicators, do not hinder recyclability, which was the main motivation for our study. In our research, the focus was on the assessment of the recyclability of printed cardboard equipped with a printed thermochromic indicator and RFID antenna. The increasing adoption of intelligent packaging raises concerns about its impact on recyclability, yet there is limited research on the recycling performance of printed RFID antennas and thermochromic indicators in fiber-based packaging. Existing studies primarily focus on the recyclability of standard printed or coated paperboard and plastic-based smart packaging, leaving a gap in understanding how printed electronic components and thermochromic inks affect fiber recovery, adhesion, and optical properties in paper recycling processes.

The main research question in our study was: How does the integration of printed intelligent elements affect the recyclability of cardboard packaging? The specific goal of our research was to develop cardboard packaging incorporating printed electronics, subject it to the recycling process, and evaluate its recyclability using the Confederation of European Paper Industries (CEPI) method. The analysis included assessing the impact of digital printing, as well as the presence of metallic functional conductive and thermochromic inks, on fiber recovery, adhesion, and optical properties. One of the important goals was also to compare the recyclability between directly printed intelligent elements and those applied via self-adhesive labels.

2. Materials and Methods

2.1. Materials

The packaging material used was a commercial coated cardboard Xerox Colotech+ with a base weight of 350 g/m2. Xerox Colotech+ is a commonly used coated cardboard in commercial printing and packaging applications, making it a relevant material for evaluating the recyclability of printed intelligent elements. By using a commercially available material, the study ensures that the results are applicable to real-world packaging and recycling scenarios.

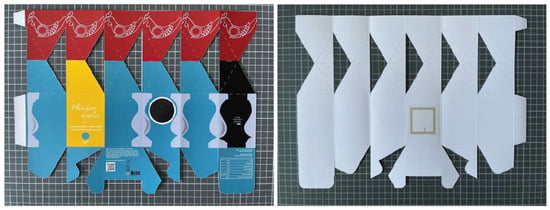

CMYK (cyan, magenta, yellow, and black) color patches with 100% coverage were printed using electrophotography. The cardboard was printed on the top side. The RFID antenna and a thermochromic indicator were printed on the cardboard using a screen-printing technique. The RokuPrint SD 05 (RokuPrint, Oberdischingen, Germany) semi-automatic screen-printing machine was used. For the RFID antenna, the metallic functional conductive ink CRSN2442 SunTronic Silver 280 (Thermal Drying Silver Conductive Ink) was used, which is designed for printing on flexible surfaces. The ink was dried at 110 °C for 10 min after application. A thermochromic ink (Chromatic Technologies (CTI) UV Screen Ink), which changes color at 30 °C, was used to apply the thermochromic indicator. The thermochromic indicator was included on the outside of the packaging, as it is meant to be visible to the user, while the RFID tag was placed on the inside of the packaging to keep it hidden from the user. As well as including intelligent elements directly printed onto the cardboard, in one case, they were printed onto the self-adhesive label and afterward attached to the cardboard. In Figure 1, sample V6 is presented, where both intelligent elements were printed on the self-adhesive label. Table 1 shows the differences between six samples: base cardboard (V1); base cardboard with RFID antenna and thermochromic indicator (V2); digitally printed cardboard (V3); digitally printed cardboard with RFID antenna and thermochromic indicator (V4); digitally printed cardboard with self-adhesive label (V5); and digitally printed cardboard with RFID antenna, thermochromic indicator and self-adhesive label (V6). All samples contain starch adhesive, as it is mostly present when assembling the packaging.

Figure 1.

The image shows an example of a sample from the front and back. The displayed pattern includes digital printing, an RFID tag, a thermochromic indicator, and a self-adhesive label.

Table 1.

Description of the cardboard samples, with different features included.

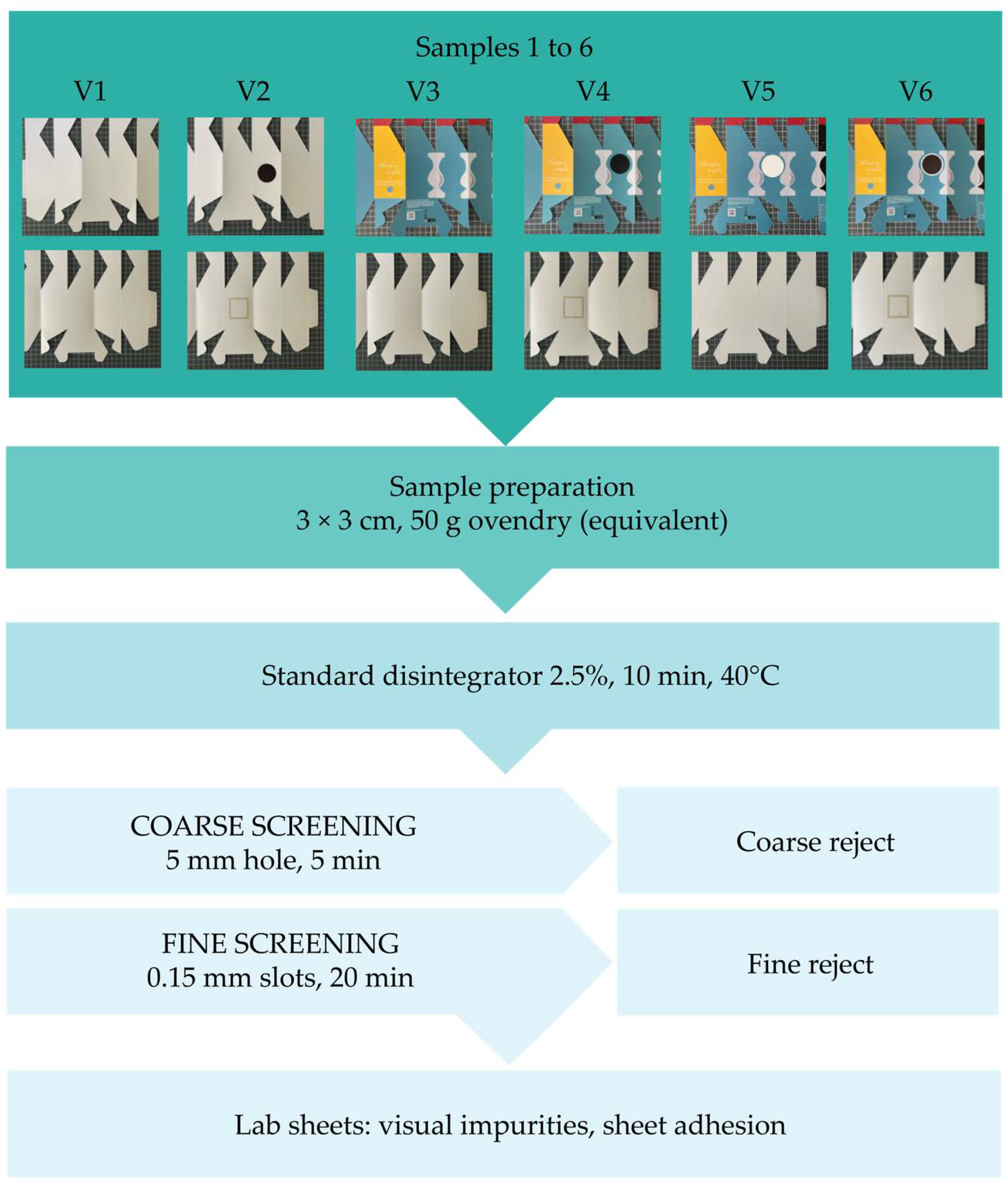

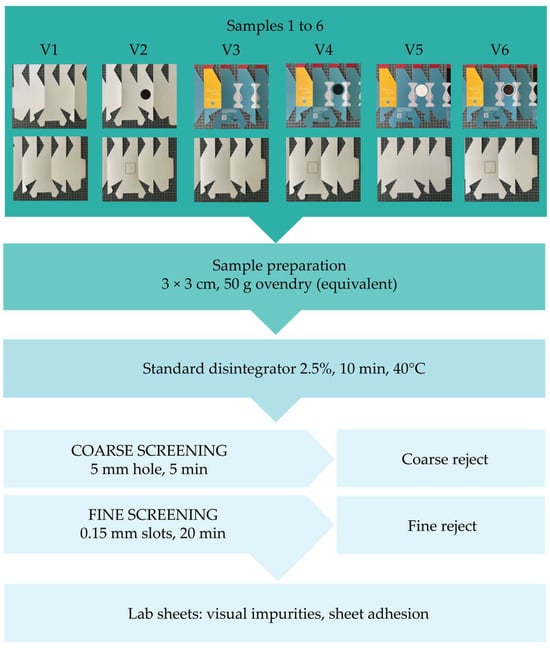

2.2. Methods

The CEPI Recyclability Laboratory Test Method, Version 2 [20], was used for testing the recyclability of all cardboard samples (V1 to V6). The method defines a laboratory procedure with the most relevant process stages: pulping, coarse and fine screening, and sheet formation, and provides results relevant to the process efficiency (yield, coarse and fine reject amount) as well as to the recycled paper quality (visual impurities and sheet adhesion). In Figure 2, a comprehensive flowchart diagram showing the steps for recyclability testing is presented.

Figure 2.

Comprehensive flowchart diagram showing samples and methodology used for testing recyclability.

The samples’ dimensions were 360 mm × 272 mm. To carry out the recycling of the samples, 50 g of oven-dry material was used, cut into 3 cm × 3 cm large pieces. Each sample was disintegrated using the disintegrator compliant with ISO 5263-1:2005 [21]; for 10 min at a speed of 3000 revolutions per minute, at a concentration of 2.5%. Slightly alkaline (pH 7–8) and warm (40 ± 1 °C) tap water was used for the disintegration step. For the coarse screening, the total amount of the sample suspension was used, i.e., 50 g of oven-dry material. The coarse screening was performed using a Somerville screen (Somerville Universal Engineering Corporation, Uttar Pradesh, India) equipped with a perforated plate with 5 mm holes and a water flow rate of 8.6 L/min for 5 min. The determination of the coarse reject was done according to the TAPPI/ANSI T275 [22]. The material remaining on the perforated plate represented the coarse reject, which was transferred to a clean bucket. A pre-weighed filter paper with grade 388 was placed in a Büchner funnel, through which the contents of the bucket with the coarse reject were filtered. The filter paper was first dried in the Rapid Köthen dryer at 93 °C for 10 min and then in the oven at 105 °C until it reached a constant mass. The consistency of the screened suspension was determined according to ISO 4119 [23], which served as a basis for the production of hand sheets with a grammage of 60 ± 2 g/m2. Sheets were produced on a laboratory Rapid Köthen sheet former machine to evaluate sheet adhesion after coarse screening.

Sheet adhesion is an evaluation of the tackiness of a hand sheet. After forming, the hand sheet is covered on one side with a carrier board and on the other side with a cover sheet from the other side. After drying in the Rapid Köthen dryer, the obtained hand sheet, together with carrier board and cover sheet, was placed between two preheated metal plates in the oven and dried at 130 °C for 2 min at a pressure of 1.18 kPa. After cooling in the desiccator for 10 min, the cover sheet and carrier board were separated from the hand sheet. The sheet adhesion test was performed by assessing any damage or breakages [12]. If the hand sheet can be separated completely from the carrier board without damage, the tackiness is absent and is characterized as Level 1. In cases where fiber tears and particles are present on both the carrier board and the hand sheet itself, the tackiness is partly present (Level 2). However, if the hand sheet breaks or holes occur, Level 3 is reached. The hand sheet obtained was also used to determine the visual impurities with direct and transmitted light. The amount of visual impurities per hand sheet was assessed as “few”, if they were fewer than 10, as “some” if they ranged between 10 and 100, and as “a lot” if they exceeded 100 [12].

For the determination of the fine reject, 20 g of oven-dry material was used and screened in a Somerville screen equipped with a perforated plate with 0.15 mm slots at a water flow rate of 8.6 L/min for 20 min. The material remaining on the perforated plate represented the fine reject, which was transferred to a clean bucket. The rest of the procedure is the same as for coarse screening: producing hand sheets, testing of sheet adhesion, and observing visual impurities.

After coarse and fine screening, the yield (Y) was calculated (Equation (1)) from the total reject (TR), which measures how much material was screened. The coarse reject (CR) is defined as the mass weight percent of material retained on a coarse screen after repulping, whereas the fine reject (FR) is given as the mass weight percent of material retained on a fine screen after repulping and coarse screening.

Y = 100% − TR; where TR = CR (%) + FR (%) × 0.9

The recyclability score was calculated from the coarse reject, fine reject, visual impurities, and sheet adhesion from the accepted material after fine screening. The total score is given as the sum of yield score, sheet adhesion score, and visual impurity score [12]. Various parameters have different impacts on the total score, as seen in Table 2.

Table 2.

Parameters used for recyclability score calculation: yield and conversion to yield score, sheet adhesion level and score, visual impurity level, and score.

Additionally, several properties of hand sheets were measured according to standards methods: grammage (SIST EN ISO 536:2020) [24], thickness (EN ISO 534:2012) [25], tear index (SIST EN ISO 1974:2012) [26], burst index (SIST EN ISO 2758:2014) [27], tensile index and elongation (SIST EN ISO 1924–2:2009) [28], ISO brightness (SIST ISO 2470–1:2017) [29] and opacity (SIST ISO 2471:2011) [30]. Also, the color, which is characterized by three coordinates, L*, a*, and b*, was measured, where L* indicates the brightness of the color and is given on a scale from 0 to 100, a* represents the position of the color on the red-green axis, and b* indicates the position of the color on the yellow-blue axis. All optical properties were measured using the Elrepho 450X, Data-Color apparatus, Datacolor GmbH, Marl, Germany.

To analyze the measured values, descriptive statistics were used. With the mean value, a central density of the data set was described, and the variability was assessed with the standard variation, which gives the dispersion of the data set.

3. Results

The recyclability of intelligent cardboard packaging was determined using a laboratory procedure that emulates the most relevant industrial phases in a conventional paper recycling mill. The evaluated parameters indicate the ease with which fibers can be separated, the level of coarse and fine reject, the presence of adhesives and impurities, and the potential to form sheets from the recycled fibers, along with their visual appearance. In Table 3, results obtained for coarse reject, fine reject, yield, visual impurities, and sheet adhesion test after fine screening, as well as the recyclability score, are presented.

Table 3.

Results for coarse reject, fine reject, yield, visual impurities after fine screening, sheet adhesion after fine screening, and recyclability score for cardboard samples.

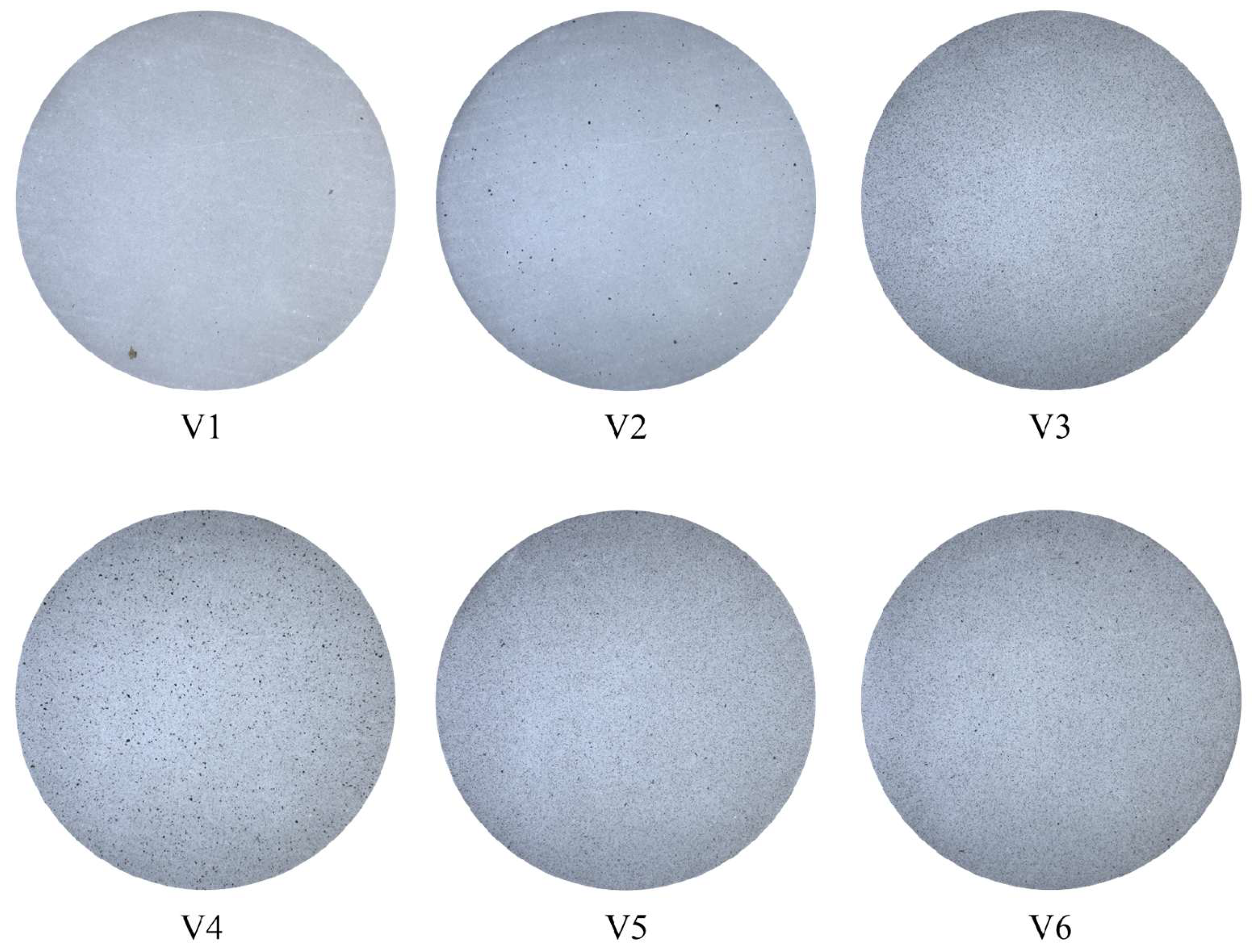

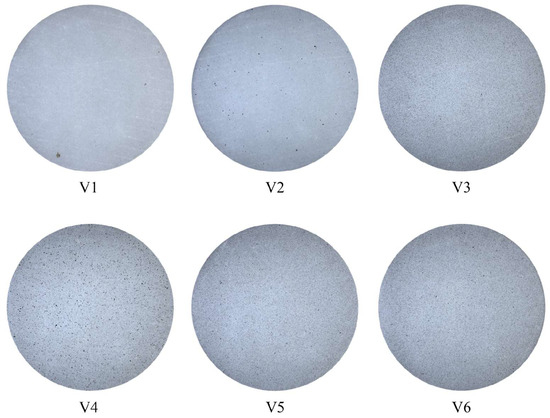

The recycling tests of six cardboard samples tested indicated both similarities and differences. The first sample achieved a recyclability score of 100/100, meaning that it is suitable for standard recycling, with no stickiness or visual impurities. The second sample scored 85/100, and it is also suitable for standard recycling, with no stickiness issues but visible color particles. The third sample scored 95/100, which is suitable for standard recycling, with some small color particles and no stickiness issues. The fourth sample scored 85/100, which is suitable for standard recycling, but more color particles were present, placing it in the third level according to visual appearance. The fifth sample scored 84/100, which is suitable for standard recycling, with visible impurities and more small printing color particles. The sixth sample scored 84/100, which is suitable for standard recycling, with visible impurities, printing color particles, and RFID antenna residues but no stickiness issues. All samples are according to a recyclability score suitable for standard recycling, but the level of visual impurities varied, affecting the overall quality. In Figure 3, the image of hand sheets created after fine screening is shown. The presence of impurities is clearly seen in recycled samples that were printed, either with conventional printing ink or with functional conductive and thermochromic ink. The amount of visual impurities per hand sheet exceeded 100 and was the highest in the sample printed with all three inks.

Figure 3.

The image of hand sheets after fine screening of samples, photographed using transmitted light. V1 is unprinted cardboard sample, V2 is unprinted cardboard sample with RFID Antenna and Thermochromic Indicator, V3 is Digital Printed Cardboard sample, V4 is Digital Printed Cardboard sample with RFID Antenna and Thermochromic Indicator, V5 is Digital Printed Cardboard sample with Self-Adhesive Label and V6 is Digital Printed Cardboard sample with RFID Antenna, Thermochromic Indicator and Self-Adhesive Label.

The data in Table 4 present various material properties for all samples (V1 to V6). The grammage values range from 77.9 to 79.6 g/m2, with thicknesses around 137 to 145 µm. Tear Index values vary between 5.60 and 6.42 mNm2/g, while burst index values are relatively consistent, ranging from 1.34 to 1.80 kPa m2/g. Tensile Index and Elongation values also vary slightly, with tensile index values ranging from 26.0 to 32.9 Nm/g and Elongation percentages varying between 1.46% and 1.75%. These measurements reflect small variations in mechanical properties across the different samples.

Table 4.

Mechanical properties of hand sheets produced after fine screening, given as the average value and standard deviation.

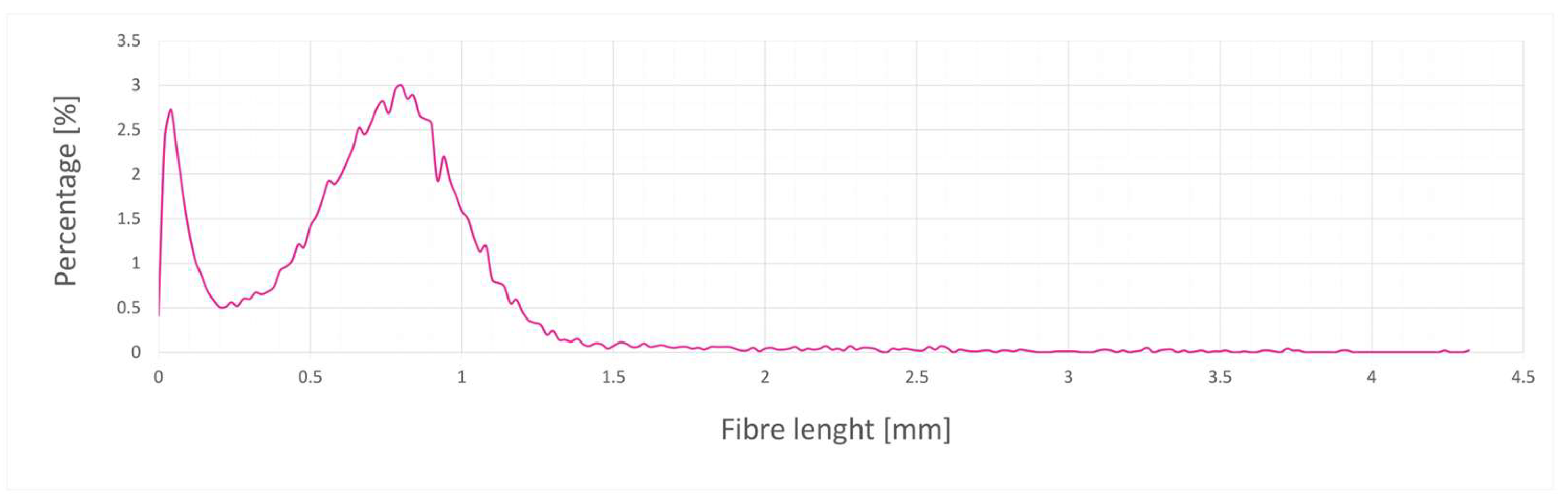

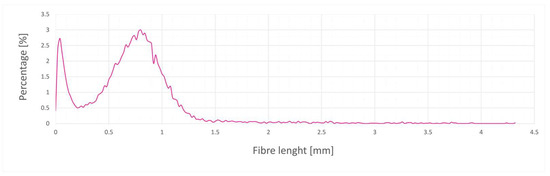

The quantity and length of the fibers also have a significant impact on the mechanical properties of the paper. The morphological properties of the fibers from the selected cardboard sample V1 (Figure 4) were determined. The graph shows that most of the fibers are up to 1.5 mm long. The majority of fibers are between 0.1 and 0.2 mm and between 0.6 and 0.9 mm.

Figure 4.

The distribution of fiber length obtained from the hand sheet produced after fine screening process of sample V1.

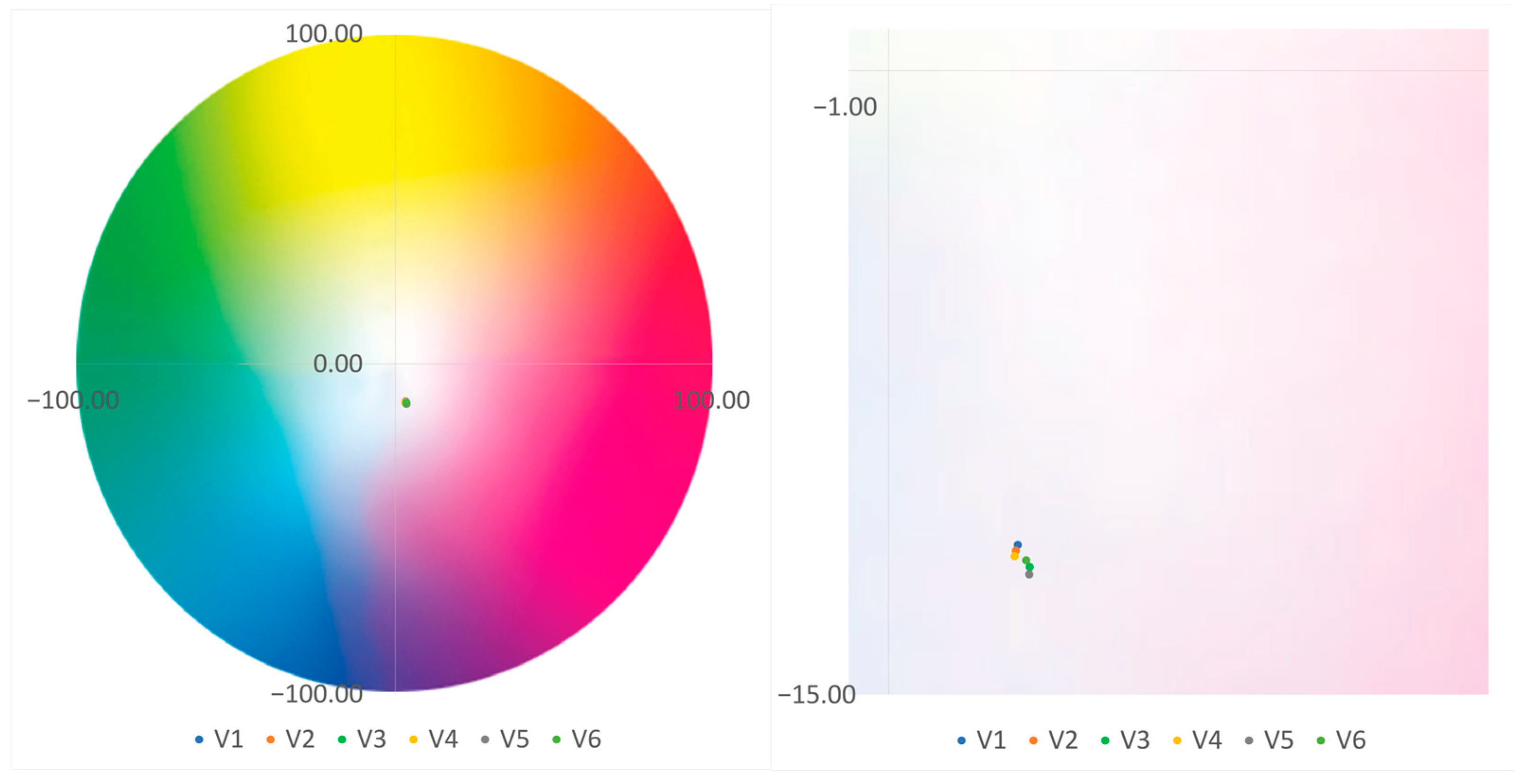

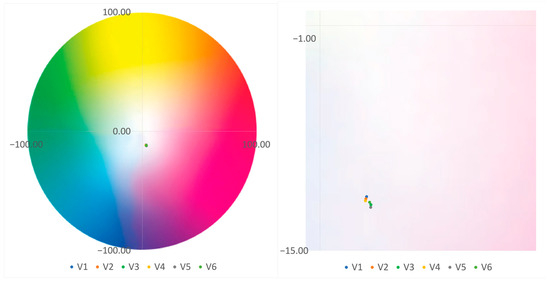

In the analysis of the color values L*, a*, b*, ISO Brightness, and opacity of the samples, the following results were observed (Figure 5). Sample V2 has the highest average brightness, followed by V1, meaning these two samples are the brightest. The lowest brightness is found in V4. The a* values indicate that V3 is the most red, V1 is the most yellow, while V5 is closest to a neutral tone. The opacity is highest in V4, and lowest in V1 and V2. Overall, the recycled unprinted cardboard samples (V1 and V2) exhibit the highest brightness and opacity, while the recycled printed cardboard with integrated printed electronics (V4) has lower values. V6, which contains printed smart elements on a self-adhesive label, has slightly higher values than V4.

Figure 5.

The graph of CIE L*a*b* values of all six hand sheets produced after fine screening.

4. Discussion

To maintain and further increase the sustainability and circularity of the cardboard packaging value chain, it is crucial to ensure that cardboard packaging equipped with intelligent elements is recyclable by the paper industry. Our research differs from similar studies primarily by incorporating two smart indicators at the same time—both an RFID antenna and a thermochromic indicator. Most previous studies focus on only one of these elements, which limits their applicability. By combining both technologies, our research enables more comprehensive monitoring of recyclability. To confirm the recyclability of intelligent cardboard packaging, it is important to test the recyclability using a test method that emulates the most common procedures in the paper mill. With the CEPI method, both process parameters (coarse reject, fine reject) and quality parameters (sheet formation, presence of adhesiveness, and visual impurities) are assessed, resulting in greater reliability of results.

The total reject obtained after the coarse and fine screening measures how much material is screened out and how much from the packaging will not be recycled. Results show that after coarse screening, nearly no rejects remained on the perforated plate in all samples, aligning with our expectations. The amount of coarse reject ranged from 0.03% to 0.11%, consisting primarily of a few fiber flakes and remnants of printing ink trapped in the spaces between the 5 mm holes after the dewatering process in Somerville. After fine screening, a higher percentage of rejects was expected due to the smaller openings in the screen plate through which the good material is screened. The amount of fine rejects varied between 0.08% and 0.55%. Sample V1, i.e., unprinted cardboard glued with the starch adhesive, as well as sample V3, i.e., printed cardboard glued with the starch adhesive, left almost no reject on the plate. Only a few small fiber flakes were visible. In the samples containing the thermochromic indicator (V2, V4, and V6), many small particles of the thermochromic ink remained on the plate. Traces of the functional conductive ink of the RFID antenna could not be seen on the plate with the naked eye, but we could see small silver dots in the screening material. This means that the printed antenna was broken down into such small particles during the screening process, allowing them to pass through the perforated screen. A similar conclusion was obtained in the study of Aliaga et al. [5]. At samples V5 and V6, we expected the highest percentage of rejects, as the self-adhesive label can bond the single fibers, fiber flakes, and inks together to form larger agglomerates that remain on the screen plate. This expectation proved correct, suggesting that the self-adhesive label influenced the screening process, causing some single fibers and fiber flakes to remain on the plate rather than being recycled into new fiber-based products. It can be concluded that the produced hand sheets likely contained a minimal amount of adhesive, resulting in no noticeable tackiness, so the level of sheet adhesion in all samples was scored as 1, meaning no adhesion issues were observed when processing the recovered material.

On the hand sheets produced after a fine screening process (Figure 3), some traces of ink in the form of tiny dots of different colors were seen. These residues have tinted the sheets slightly purple, which was not observed in the first unprinted sample. The color of the hand sheets was also influenced by the presence of thermochromic ink, as the larger black dots contributed to the visual impurities of the recycled paper. In samples V2 and V6, some silver dots were seen on the sheet, which was due to the presence of the functional conductive ink. These small impurities were only observed on close inspection of the hand sheet so they did not have a significant effect on the optical properties. Like Aliaga et al. [5], we came to the same conclusion, namely that the variations in visual properties were not so large as to cause problems in the sample recycling procedures. The consistency of the results after fine screening was least affected by the combination of electrophotographic printing and adhesive labels.

The influence of printing and the inclusion of intelligent elements on the mechanical properties of the recycled samples is presented in Table 4. The recycled printed samples exhibited higher tear resistance, tensile strength, modulus of elasticity, and tensile breaking energy than the recycled unprinted cardboard. The mechanical properties were most affected by the self-adhesive label in combination with electrophotographic printing. This is immediately followed by the combination of electrophotographic printing and directly printed thermochromic ink and RFID antenna.

As expected, samples V1 and V2 showed the highest value of ISO brightness and lightness, as both samples were recycled from unprinted cardboard (Table 5). For samples V3 and V5, the color and brightness of the hand sheets were influenced by the remains of electrophotographic printing, while the self-adhesive label had no influence. The color of the thermochromic indicator had a greater effect on the brightness of the sheet than the functional conductive ink. In combination with electrophotographic printing, the greatest difference in coloration for samples V4 and V6 was observed. The differences in color components a* and b* between all six samples are negligible, as seen in Table 5. Regarding optical properties, we are talking about minimal differences, as seen in Figure 5, where all samples are shown on the color spectrum.

Table 5.

Optical properties of hand sheets produced after fine screening, given as the average value and standard deviation.

5. Conclusions

The topic of this research is crucial for sustainable development and the circular economy, as it emphasizes reuse and highlights the challenges posed by technological advancements, aligning with the directives of the EU and Slovenia. Intelligent packaging, including RFID-printed antennas and thermochromic indicators, can be sustainable if designed with recyclability, material efficiency, and environmental impact in mind. Printing RFID antennas directly onto the packaging instead of using separate electronic components reduces material use and waste. Similarly, thermochromic indicators eliminate the need for additional sensors or batteries, making the packaging more resource efficient. If designed correctly, intelligent packaging can be reused, repulped, or integrated into existing recycling streams, supporting the principles of a circular economy without compromising sustainability.

Our research revealed that while electrographic printing, thermochromic ink, and functional conductive ink have influenced the recyclability of cardboard packaging to some degree, the impact is minimal. All samples proved to be suitable for the standard recycling process and are considered best in the class, with recycling efficiencies above 99% and recyclability scores from 84 to 100%. The inclusion of a self-adhesive label did not negatively affect the results of recyclability and did not introduce issues with stickiness.

The research confirmed that the packaging, including printed RFID antennas and thermochromic indicators, would maintain high recyclability, with negligible impact on recycling processes. No significant difference in recyclability between intelligent elements printed directly on cardboard and those on self-adhesive labels was obtained, although self-adhesive labels contributed a minor improvement in mechanical properties.

Research also supports sustainable intelligent packaging development by ensuring compatibility with existing recycling processes.

The study focused on a specific type of commercial cardboard, specific inks, and electrophotographic printing techniques. Other materials and printing techniques may yield different recyclability outcomes. Testing a wider range of intelligent packaging elements and alternative substrates could provide more insight into recyclability and expand the applicability of sustainable intelligent packaging. Industrial recycling trials would provide insight into the behavior of intelligent cardboard packaging in real-world conditions and support the integration of these kinds of solutions into sustainable packaging approaches by enabling circularity, improving waste management and reducing resource consumption.

Author Contributions

Conceptualization, P.P., T.K. and D.G.-S.; methodology, P.P.; validation, P.P., T.K. and D.G.-S.; formal analysis, P.P.; investigation, P.P.; writing—original draft preparation, P.P.; writing—review and editing, P.P. and D.G.-S.; visualization, P.P.; supervision, D.G.-S.; funding acquisition, D.G.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Slovenian Research and Innovation Agency [Program P2-0213].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original data presented in this study are openly available in the RUL at https://repozitorij.uni-lj.si/izpisGradiva.php?id=155028&lang=slv (accessed on 17 February 2025).

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CEPI | Confederation of European Paper Industries |

| RFID | radio-frequency identification |

| CMYK | Cyan, Magenta, Yellow, Black |

| CTI | Chromatic Technologies |

References

- Birkeland, J. Design for Sustainability: A Sourcebook of Integrated Ecological Solutions, 1st ed.; Routledge: London, UK, 2012. [Google Scholar]

- Nordin, N.; Selke, S. Social aspect of sustainable packaging. Packag. Technol. Sci. 2010, 23, 317–326. [Google Scholar]

- CEPI. Cepi Preliminary Statistics 2022 Million Tonnes. Available online: https://www.cepi.org/statistics/ (accessed on 21 February 2025).

- Bajpai, P. Recycling and Deinking of Recovered Paper. In Recycling and Deinking of Recovered Paper, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2024. [Google Scholar]

- Aliaga, C.; Zhang, H.; Dobon, A.; Hortal, M.; Beneventi, D. The influence of printed electronics on the recyclability of paper: A case study for smart envelopes in courier and postal services. Waste Manag. 2015, 38, 41–48. [Google Scholar] [CrossRef] [PubMed]

- Vanderroost, M.; Ragaert, P.; Devlieghere, F.; De Meulenaer, B. Intelligent food packaging: The next generation. Trends Food Sci. Technol. 2014, 39, 47–62. [Google Scholar] [CrossRef]

- Restuccia, D.; Spizzirri, U.G.; Parisi, O.I.; Cirillo, G.; Curcio, M.; Iemma, F.; Puoci, F.; Vinci, G.; Picci, N. New EU regulation aspects and global market of active and intelligent packaging for food industry applications. Food Control 2010, 21, 1425–1435. [Google Scholar]

- Realini, C.E.; Marcos, B. Active and intelligent packaging systems for a modern society. Meat Sci. 2014, 98, 404–419. [Google Scholar] [PubMed]

- AIPIA. Available online: https://www.aipia.info/why-aipia.php (accessed on 21 February 2025).

- Gregor-Svetec, D. Intelligent Packaging. In Nanomaterials for Food Packaging; Elsevier: Amsterdam, The Netherlands, 2018; pp. 203–247. [Google Scholar]

- Nilsson, H.-E.; Unander, T.; Siden, J.; Andersson, H.; Manuilskiy, A.; Hummelgard, M.; Gulliksson, M. System Integration of Electronic Functions in Smart Packaging Applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 2, 1723–1734. [Google Scholar]

- 4evergreen. Fibre-Based Packaging Recyclability Evaluation Protocol; CEPI: Brussels, Belgium, 2022. [Google Scholar]

- EcoPaperLoop. Enhancing the Quality of Paper for Recycling in Europe: Optimising Paper Products, Packaging and Collection Systems: Outcome—Guidelines and Recommendations; European Union: Brussels, Belgium; European Fund for Regional Development: Brussels, Belgium, 2014. [Google Scholar]

- Vukoje, M.; Bolanca Mirkovic, I.; Bolanca, Z. Influence of Printing Technique and Printing Conditions on Prints Recycling Efficiency and Effluents Quality. Sustainability 2021, 14, 335. [Google Scholar] [CrossRef]

- Obradovic, D.; Mishra, L. Mechanical Properties of Recycled Paper and Cardboard. J. Eng. Exact Sci. 2020, 6, 429–434. [Google Scholar] [CrossRef]

- Atkinson, J.E. Fate of Conductive Ink Pigments During Recycling and Landfill Fate of Conductive Ink Pigments During Recycling and Landfill Deposition of Paper-Based Printed Electronics. Ph.D. Thesis, Western Michigan University, Kalamazoo, MI, USA, 2017. Available online: https://scholarworks.wmich.edu/dissertations (accessed on 26 December 2024).

- Pogačar, A.; Bolanča-Mirković, I.; Gregor-Svetec, D. Print Durability and Recyclability of Label Paper Equipped with Printed RFID Antenna. Sustainability 2023, 16, 129. [Google Scholar] [CrossRef]

- Kavcic, U.; Karlovits, I.; Zule, J. Deinking of Screen-Printed Electrodes Printed on Invasive Plant-Based Paper. Sustainability 2020, 12, 41350. [Google Scholar] [CrossRef]

- Sudheshwar, A.; Malinverno, N.; Hischier, R.; Nowack, B.; Som, C. The need for design-for-recycling of paper-based printed electronics—A prospective comparison with printed circuit boards. Resour. Conserv. Recycl. 2023, 189, 106757. [Google Scholar] [CrossRef]

- Harmonised European Laboratory Test Method to Generate Parameters Enabling the Assessment of the Recyclability of Paper and Board Products in Standard Paper and Board Recycling Mills. Available online: www.paperforrecycling.eu (accessed on 21 February 2025).

- ISO 5263-1:2005; Pulps—Laboratory Wet Disintegration—Part 1: Disintegration of Chemical Pulps. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2005.

- TAPPI/ANSI T275; Technical Association of the Pulp and Paper Industry. Available online: https://industrialphysics.com/standards/tappi-t-275/ (accessed on 25 February 2025).

- ISO 4119:2000; Pulps-Determination of Stock Concentration. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2000.

- SIST EN ISO 536:2020; Paper and Board—Determination of Grammage. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2020.

- SIST EN ISO 534:2012; Paper and Board—Determination of Thickness, Density and Specific Volume. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2012.

- SIST EN ISO 1974:2012; Paper—Determination of Tearing Resistance (Elmendorf Method). Slovenian Institute for Standardization: Ljubljana, Slovenia, 2012.

- SIST EN ISO 2759:2014; Board—Determination of Bursting Strength. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2014.

- SIST EN ISO 1924-2:2008; Paper and Board—Determination of Tensile Properties—Part 2: Constant Rate of Elongation Method. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2008.

- SIST ISO 2470-1:2017; Paper, Board and Pulps—Measurement of Diffuse Blue Reflectance Factor—Part 1: Indoor Daylight Conditions (ISO Brightness). Slovenian Institute for Standardization: Ljubljana, Slovenia, 2017.

- SIST ISO 2471:2011; Paper and Board—Determination of Opacity (Paper Backing)—Diffuse Reflectance Method. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2011.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).