Abstract

Electric vehicles are regarded as key players in reducing CO2 emissions. However, managing the end-of-life (EoL) of lithium-ion batteries (LIBs) poses significant environmental and technical challenges. This presents a daunting task for governments, companies, and academics when discussing and developing initiatives for the EoL of LIBs. As more LIBs reach the end of their vehicular use, it becomes essential to identify key challenges. This research aims to analyze possible pathways, identify LIBs’ challenges in reaching the appropriate destinations, and propose actions to overcome these obstacles. Additionally, this study addresses those responsible for each challenge. A narrative review was employed as a methodological approach to achieve the proposed objectives, utilizing available literature on EoL LIB management. The research findings highlight various challenges, including safety, commercialization, and disassembly. To address these issues, this work recommends strategies such as extended producer responsibility, automation, and regulation. The study also emphasizes the necessity for a collaborative effort, particularly highlighting the key roles of government and industry in developing regulations, implementing effective waste management strategies, and driving market expansion, while academia contributes through research and technological advancements. The research contributes to a better understanding of sustainable LIB management, advocating for responsible disposal and reducing environmental and economic impacts.

1. Introduction

The use of fossil fuels has proven essential for developing economic activities; however, burning these fuels releases greenhouse gas emissions (GHG) responsible for the planet’s warming [1]. The transportation sector is the third most polluting, behind the energy and construction industries [2]. Over the past few decades, the increasing GHG emissions from this sector have raised concerns; consequently, it is imperative to develop initiatives to minimize these impacts on the environment and society [3]. For instance, a significant alternative to reduce GHG emissions in the transport sector is the widespread introduction of electric vehicles (EVs), as these vehicles produce zero CO2 emissions during use [4].

Lithium-ion batteries (LIBs) are a well-known technology commonly used as energy storage for EVs due to their high specific energy, high power, high safety level, and long lifespan [5,6]. However, despite being considered green and clean energy [7], the production of LIBs presents a heavy carbon footprint because it emits around 40 to 60% of the total emissions released in the production of EVs and trucks [8]. It can be justified due to the components present in the battery, such as cobalt, nickel, manganese, lithium, and graphite [9], the large amounts of GHG emissions released during the mining and refining processes, and the complexity and the presence of hazardous materials; batteries cannot just be disposed of in the environment [10].

The large volume of LIBs approaching the end of their life is a significant concern related to what will be done with them in terms of waste management. For instance, the research developed by [11] pointed out three main concerns about end-of-life (EoL) EV batteries, namely, (i) retired EV batteries must be properly disposed of to avoid toxic electrolytes and plastic present in their structure; (ii) it is mandatory to reduce raw material through recycling due to the faster depletion of lithium and cobalt caused by the growth in the number of EV batteries; (iii) retired EV batteries are a competitive option in applications requiring less energy because of their residual capacity.

The research developed by [12] also argues that access to the components and materials found in EV batteries is limited in many countries, highlighting the importance of securing a stable supply chain through resource availability. Ref. [13] further asserts that the cost of developing new batteries for production is crucial in evaluating and comparing the benefits of the retirement options (recycling, reuse, and remanufacturing). To assess potential financial benefits compared to buying new batteries, it is crucial to consider various options for reusing these batteries. Ref. [14] states that while EoL batteries no longer meet the power and energy requirements for most automotive applications, they can still be useful for grid-storage purposes, such as powering electric golf vehicles. In this context, from a sustainability perspective, the authors of [15] emphasize that the EoL phase is particularly intriguing because a well-designed EoL strategy can reduce direct emissions and mitigate the environmental impact associated with mining and waste disposal.

Considering the importance of developing sustainable EoL strategies for LIBs, as well as the need to understand the environmental, economic, and technical challenges associated with their management, this research aims to contribute to this context by achieving the following objectives:

- To analyze the latest pathways for EoL management of LIBs available in the current literature;

- To identify the main challenges faced by EoL LIBs in reaching the appropriate destination;

- To explore possible actions to overcome the barriers faced by LIBs to achieve effective waste management;

- To assign responsibilities for retired LIBs scenarios.

2. Materials and Methods

Due to the increasing number of EVs, EoL LIBs pose a significant challenge. This research proposes an approach to identifying these challenges, recommending measures to overcome them, and addressing responsibilities. The methodology is grounded in a narrative review of the existing literature concerning LIB waste management.

The narrative review consists of an unsystematic literature review that discusses relationships among studies regarding their contributions [16]. It requires identifying and analyzing relevant studies but does not necessitate clearly defined criteria for selecting publications. It is less formal than a systematic review, and the reviewed papers may not be fully comprehensive [17]. In contrast, the narrative review focuses on identifying and analyzing relevant studies, offering a broad overview instead of an exhaustive literature synthesis.

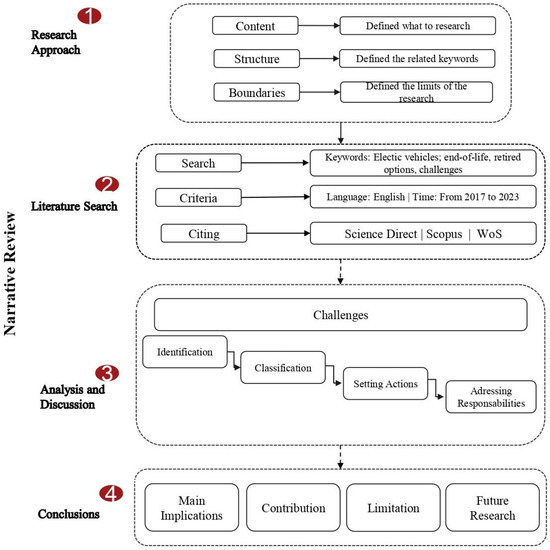

Although the narrative does not require a defined criterion for selecting articles, this research has chosen to establish the parameters for the selection of the articles base, which will be explained in detail later. The narrative review can be very useful for generating debate, identifying existing knowledge gaps on certain topics, and paving the way for future research. Therefore, the narrative review approach was chosen as a starting point for a thorough analysis of EoL LIB options. In this context, the methodological approach guiding this research is inspired by the work presented in [18], and the path for the narrative review outlined in this research is summarized in Figure 1.

Figure 1.

Methodological approach.

As shown in Figure 1, the methodology proposed in this research consisted of four main phases, ensuring a cohesive approach to analyzing the challenges faced by LIBs at the end of their useful life. First, the purpose of the research was established, identifying key terms and defining the boundaries of the study to maintain focus in the literature review [17]. The clear formulation of the objectives not only highlights the necessity of the investigation but also enhances the process’s efficiency by limiting the analysis to relevant studies [19].

The narrative review was conducted using strategically selected keywords to address the challenges associated with EoL in EVs. Reliable sources were extracted from renowned academic databases, such as Science Direct, Scopus, and Web of Science, prioritizing articles published between 2017 and 2023. The discussion developed from identifying the main pathways for the disposal of these batteries, using a Causal Loop Diagram to relate challenges and suggested actions to overcome them. This process involved identifying the main obstacles to the correct disposal of batteries, categorizing these challenges, recommending measures present in the literature, and assigning responsibilities within this scenario. Finally, the research summarizes the main findings, highlighting trends, gaps, and their relevance to the area and suggesting directions for future research.

3. Results

This section presents the main findings from the narrative review, focusing on the possible pathways for EoL LIBs to meet the first objective of this research, which is to present the latest and most effective solutions for the EoL management of LIBs.

Additionally, based on the main findings of the narrative, this section highlights the challenges encountered in their management (Objective 2). It aims later to promote the development of a Causal Loop Diagram and encourage discussion on the suggested actions to address these challenges (Objective 3). This section follows phase 3, as previously illustrated in Figure 1.

3.1. Possible Pathways for EoL LIBs

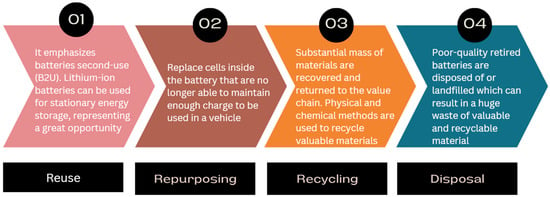

Based on the research conducted, the current literature identifies four main pathways for handling retired LIBs, which are summarized in Figure 2. This research proposed a ranking for the identified pathways based on the Waste Management Hierarchy cited by [12]. As shown in Figure 2, the ranking ranges from 01 to 04, indicating the most desirable to the least desirable options based on environmental impact and economic benefits, which will be discussed further in this section.

Figure 2.

Possible Pathways for EoL LIBs.

After presenting the possible pathways for EoL LIBs in decreasing order of economic and environmental benefits, each path was analyzed and discussed separately.

3.1.1. Reuse

The current literature on waste management presents the possibility of reuse as one of the most attractive options for retired LIBs. Reusing batteries offers a chance to extend their lifespan until the end of their operational lifetime and has numerous applications, including grid management, industry, and residential buildings. Depending on the particulars of each scenario, there are even an infinite number of configuration options for each application [13], for example, the domestic use to store solar or wind energy. According to [20], 80% of the energy in traction batteries and a sizable portion of the energy left in used batteries from other sources will be wasted if batteries are not reused.

In line with the research developed by [12,13], reuse is often preferred over recycling because it allows maximum economic value extraction while minimizing environmental impacts according to the waste management hierarchy. They emphasize that profitable secondary applications provide a promising revenue stream that can offset the eventual costs of recycling. Ref. [21] also argues that second-use LIBs present the potential for renewable energy grid storage, enhancing self-sufficiency in daily operations and serving as backup power supplies during or after disasters.

According to [14], battery reuse has emerged as a global priority due to environmental concerns and the need to maximize the valuable materials used in battery manufacturing. In this context, the results highlight the significant benefits of reusing retired LIBs. Reuse extends the operational lifespan of batteries and provides various applications, such as grid management and renewable energy storage, which aid in mitigating energy waste and environmental impact. In this scenario, the reuse of LIBs is becoming increasingly essential, ensuring the optimal use of valuable materials and promoting sustainability.

3.1.2. Repurposing

Regarding repurposing, the results from the narrative review indicate a discrepancy in the correct definition of the pathway between reuse and recycling. For this research, the term “repurposing” is presented as an alternative to reuse. In this context, repurposing, remanufacturing, or restoring are options that lie between recycling and reuse, where a battery with less than 80% of its original nominal capacity can be utilized in suitable applications with the same or lower power requirements after it has been disassembled and its components restored or replaced [22]. Furthermore, analyzing the literature regarding the results reveals that the research developed calls attention to the fact that accommodating non-vehicle applications requires repurposing not only to involve replacing damaged cells or modules but also reconfiguring the modules or packs, along with establishing new battery management systems [23].

Due to the limited life span of LIBs in automotive use, the results from the work developed by [24] affirm that employing EV batteries in less intensive applications could extend their lifespan. They also added that the overall emissions generated during the battery repurposing process must be lower than those produced during the production of a new battery to become environmentally beneficial.

Considering the literature review, it is possible to spread the word among academia, industries, governments, and practitioners that repurposing takes priority over recycling to maximize resource utilization, optimize economic benefits, and minimize environmental impacts. For instance, retired LIBs can be repurposed for stationary energy storage in renewable energy systems or as backup power sources for commercial and residential applications, extending their lifespan and delaying the need for material recovery. However, despite the advantages of repurposing, retired LIBs will eventually necessitate recycling at their EoL, as discussed by [25,26].

The results also draw attention to the relationship between reuse and recycling, highlighting a lack of consensus regarding terminology. The advantages of this alternative to reuse are clear, encompassing remanufacturing and restoration, which provide viable options for batteries with reduced capacity to serve applications with lower power needs. Studies such as [23,24] emphasize the necessity of replacing damaged cells and reconfiguring battery modules for non-vehicle applications, as well as the environmental benefits of repurposing compared to manufacturing new batteries. Finally, raising awareness among academia, industries, governments, and practitioners about the significance of prioritizing repurposing over recycling can enhance resource utilization, optimize economic gains, and lessen environmental impacts, although eventual recycling of retired LIBs will still be necessary.

3.1.3. Recycling

Recycling is a well-known option for various products, including LIBs from EVs. The available literature highlights numerous benefits, which are further discussed. As argued by [8], the growing number of EVs underscores the need for effective recycling before many of these vehicles end their useful lives. The literature outlines several strategies for recycling EoL LIBs; however, a standardized process chain has not yet been established [27].

Recycling goes beyond the environmental issues. It is essential for many reasons, namely economic, environmentally friendly, resource conservation, waste reduction, circular economy, and social impact. From the literature consulted, a set of research was used to illustrate these reasons; for instance, the research developed by [12] highlights the main reasons: significant environmental effects may arise from processing large quantities of raw materials. However, if more materials can be recovered from EoL LIBs, the overall impact of LIB production can be significantly decreased. In certain regions, the growth of the recycling industry may be inhibited by the benefits recycling offers in terms of the environment and the economy. Additionally, Ref. [12] points out the need to pay attention to the components and materials used in batteries, which are unavailable in many countries, and a stable supply chain depends on having access to resources. In this scenario, EoL LIB recycling has the potential to yield significant economic gains by reducing the need for new mineral extraction and bolstering the LIB supply chain’s resilience against weak points and supply risks. It can also promote a circular economy by integrating recycled materials into the supply chain, reducing the need for virgin resources and minimizing environmental impact.

The research results also highlight the need for further discussion regarding the future viability of the automotive sector, which undoubtedly relies on the efficient management of resources for recycling EV batteries to ensure sustainability and material availability. For instance, Ref. [27] argues that there is a need to disseminate the idea that recycling contributes to reducing unnecessary mining of additional raw materials by efficiently utilizing materials already in circulation. In the same way, Ref. [14] used their work to discuss the benefits of recycling LIBs for recovering valuable materials, which decreases the demand for new raw materials and mitigates the environmental impact of extraction. The results showed that, when implemented, recycling reduces the risk of fire hazards associated with degraded batteries. Although batteries can be reused in second-life applications, eventually, recycling becomes necessary.

Regarding the benefits discussed above, waste from retired batteries can be considered a valuable resource, offering opportunities for material recovery and preservation of structural value and quality by preventing contamination through recycling [12]. Additionally, aspects such as extracting materials for LIBs raise significant social and ethical concerns, including child labor in artisanal mines, which disproportionately affects vulnerable populations.

Regarding the benefits of recycling, specifically waste reduction and environmental friendliness, the authors of Ref. [14] disagree. They argue that since these recycling processes use energy and generate emissions and waste, their environmental impact can sometimes outweigh the advantages. Likewise, Ref. [28] confirms that it is not possible to produce or recycle LIBs without affecting the environment.

Based on the results from the narrative, this research indicated three conventional recycling methods: hydrometallurgical, pyrometallurgical, and direct recycling processes [14,23,27,29]. These methods are detailed as follows:

- Pyrometallurgical Recovery: Pyrometallurgical methods are commonly used for their versatility and ease of application in the industry, such as metallurgy and steel, battery recycling, mining, and electronics. However, these methods are labor-intensive and can only extract a few metals (nickel, aluminum, cobalt, and copper) through high-temperature chemical reactions. Some LIB’s cathode chemistries, like lithium iron phosphate (LFP), release significant amounts of CO2 and may contribute to a net increase in carbon emissions.

- Hydrometallurgical: This process uses a series of solvent-based chemical processes and operates at much lower temperatures than pyrometallurgy, reducing energy consumption. However, it requires critical preparatory stages such as disassembly, separation, and grinding. This method can extract a broader range of materials, including cathode metals, lithium, and graphite, and it can be combined with pyrometallurgical methods for enhanced efficiency.

- Direct Recycling Process: LIBs can recover their active materials while retaining the original compound structure through direct recycling; however, ensuring material purity is challenging. Unlike hydrometallurgy and pyrometallurgy, this method produces less pollution and emissions because it avoids energy-intensive processes and acid leaching, resulting in minimal environmental impact.

3.1.4. Disposal

Of the three options discussed, disposal is the one with more concerns in terms of environmental impact. The works consulted showed that it is the least desirable pathway for treating EoL LIBs in terms of environmental impact [30]. According to [31], disposal should be avoided due to the actual risks of environmental pollution and health problems associated with toxicity; both of these problems arise from the negligent disposal of LIBs. Ref. [14] agrees with the explanation that direct disposal of LIBs can lead to environmental and health risks because they contain toxic materials like cobalt, lithium, and nickel. These substances can leach into soil and water or be released into the air, causing long-term harm to both human health and ecosystems.

The work developed by [32] showed that many different kinds of batteries end up in landfills or are burned, mostly because regulations are inadequate and there is a lack of any practical or comprehensive national programs for collecting and recycling batteries. The main concern is the generation of leachate. The fact that all batteries—from first to second life—end up being recycled makes this option crucial [13], not only for ecological reasons but also from an economic perspective due to recovering valuable materials when the battery reaches the end of its useful life.

3.2. Challenges Faced by LIBs for EoL Management

This section discusses possible challenges LIBs face in reaching the proper destination after their vehicular useful life. However, because initiatives to mitigate these challenges are needed, this work not only identified them but also analyzed them to propose possible actions for retired batteries. These challenges relate to aspects such as battery layout, safety and environmental issues, logistics, industrialization, commercialization, and regulation.

3.2.1. Battery Design

In the past decade, LIBs have evolved significantly, contributing to the popularity of EVs. However, these advancements involve a variety of sizes and shapes, making the disassembly and separation of components much more challenging [33]. According to [13], the heterogeneity in battery types, shapes, controls, chemistry, and electrical properties, among other factors, is generally undesirable. Additionally, Ref. [34] states that this heterogeneity complicates and increases the cost of the state of health (SoH) evaluation process, as each type of battery necessitates specific handling techniques, resulting in more complex and expensive recycling operations. The study conducted by [35] highlights that, apart from the diversity in battery designs, the construction of batteries themselves complicates recycling further due to their complexity; battery packs can contain thousands of cells consisting of a cathode, an anode, a separator, and an electrolyte organized into modules, along with sensors, safety devices, and circuits that manage the battery’s operation.

The design of the battery affects not only the disassembly process or recycling but also its second use. This is because different trends are emerging in the design of automotive batteries, and batteries not designed for second-life applications have been given the second-use model designation [36]. However, their designs lack features that mitigate risks (such as thermal runaways, fires, or explosions caused by the high specific energy of these batteries) during EoL handling [37].

Overall, the primary challenges related to battery design involve the variety of sizes, shapes, and configurations, which pose significant difficulties for disassembly and component separation. This battery heterogeneity further complicates the SoH evaluation and recycling processes, making them complex and costly. Therefore, focusing on designing batteries for second-life use while incorporating safety features is crucial.

3.2.2. Disassembly

Disassembly focuses on how LIBs are sent to a collection point after being used in vehicles, where their actual condition will be evaluated. As noted by [36], a brief assessment of the SoH is necessary to determine the appropriate onward destination. As a battery ages, its performance diverges from its original condition. Thus, the SoH indicates how well a battery meets its initial design specifications. Accurately assessing the SoH is essential to decide whether batteries are suitable for reuse, including identifying appropriate applications or if they should be remanufactured or recycled [12]. Therefore, evaluating the battery is crucial to determining the pathways it should follow.

The disassembly process is not simple. It involves opening the battery system by removing the cover, cutting the electrical connections between battery modules and electronic components, detaching mechanical connections, removing electronic components and battery modules, and finally, disassembling the modules to extract the battery cells [38]. Therefore, disassembling automotive battery packs necessitates specialized training in high-voltage safety protocols and insulated tools to prevent operator electrocution or short-circuiting the pack [12].

Additionally, the research developed by [22] identifies three main challenges related to the process of LIBs at their EoL. The first problem is that removing the traction battery from an EV requires training and time. The second is that the battery might not have a positive value, and recycling it could be expensive. Lastly, the security of the person taking the battery out and those handling it after removal is also a concern.

Assessing the battery’s SoH provides insight into its actual condition, allowing it to be placed on the appropriate path after vehicle use. This context highlights the disassembly process. The findings demonstrate the complexity of this procedure, requiring a specialized workforce and strict security protocols. Furthermore, a dismantler will not purchase a vehicle that has a negative value, shifting the costs of training, labor, and appropriate handling onto the vehicle owner. This situation can prompt undesirable actions such as abandonment, stockpiling, and improper treatment [22].

3.2.3. Environmental Concerns

Environmental concerns related to LIBs arise in the production and at the end of their life cycle. The production phase involves mining and processing raw materials such as lithium and cobalt, activities that significantly impact the environment. These activities contribute to habitat destruction, water contamination, and high carbon emissions. However, this research addresses the pollution caused by improper disposal of LIBs and incorrect waste management. LIBs contain hazardous substances, including heavy metals like nickel and cobalt.

From this perspective, the results indicate that a significant increase in waste batteries from EVs is expected 10–15 years after production, making it one of the fastest-growing waste streams and increasing the demand for landfill sites globally, posing a serious risk of releasing harmful chemicals into the environment [28].

LIBs are pivotal for reducing GHC emissions and promoting sustainable transportation. However, managing their EoL presents a significant environmental challenge. Due to their chemical composition and reactive elements, LIBs represent a risk to the environment and health from improper treatment of EoL batteries, illegal disposal, and traffic accidents. The heavy metal released from the EoL can lead to soil pollution (food chain) and water and air pollution, harming human health [39].

Due to the many stages involved in metal recovery, the production and recycling of LIBs have a significant environmental impact [28]. In particular, the recycling process can generate various types of pollution, including air pollution from emissions, wastewater from chemical treatments, and solid waste from residual materials.

From an environmental perspective, despite the benefits discussed in this research, LIBs pose a significant threat to the environment at the end of their lives if not managed responsibly. Therefore, environmental considerations present a challenge to inadequate waste management due to the rapid growth in vehicles and, consequently, a massive increase in waste.

3.2.4. Reliable Recycled Components

Another challenge identified in this research concerns the reliable recycled components, and according to the literature consulted, contrasted with the original, persuading the production lines to accept recycled materials is more complex [40]. The adoption of recycled materials by industrial manufacturers requires reliable testing at larger scales than coin cells, and single-layer pouch cells are needed [41]. Consumer perception and acceptance play a key role in enabling the seamless integration of EoL batteries into secondary applications, and this acceptance impacts the capacity needed for repurposing facilities and retired battery hubs [42]. By aligning battery manufacturers’ perceptions with the practical benefits and environmental advantages associated with repurposing EoL batteries, stakeholders can pave the way for sustainable and efficient resource utilization, contributing to the overarching goals of circular economy principles and environmental stewardship.

The results emphasize how challenging it is to convince production lines to use recycled materials due to concerns about their reliability compared to original components. To ensure manufacturers adopt these materials, rigorous tests at practical scales are necessary. The outcomes also highlight the role of consumer perception and acceptance in integrating EoL LIBs.

3.2.5. Transportation

One of the challenges faced by LIBs in reaching their proper destinations is transportation. According to the consulted literature, this refers to safely transporting these batteries to retirement facilities. LIBs have a high energy density and contain hazardous, flammable substances that pose serious safety threats during handling and transport [43]. As reported by [40], due to their high energy density and flammable organic electrolytes, LIBs carry the risk of “thermal runaway”, which involves the rapid heating and self-ignition from exothermic chemical reactions.

The current literature discusses the risks that LIBs present due to their internal components but does not adequately address transportation, with only a few papers focusing on the collection and transportation phase [44]. However, because of the challenges of safely transporting batteries in compliance with regulations and the economic advantages of bulk shipping, developing facilities that collect and store batteries will become a crucial aspect of the EoL ecosystem. Similarly, the collection phase has been recognized as a potential bottleneck, and the complexity of these considerations makes optimizing collection and transportation logistics a multifaceted challenge that requires thorough planning and coordination. With safe transportation in mind, it is vital to optimize logistics to ensure economic and safety efficiencies in the EoL ecosystem [26].

3.2.6. Safety

Safety concerns can significantly affect the stability of LIBs and create serious barriers to adopting EoL and circular economy practices. Thus, identifying sources of safety hazards and their impacts on various EoL management activities is a crucial initial step. According to [30], one of the most essential conditions for reusing retired batteries is addressing safety concerns, as the characteristics of the battery can change dramatically after hundreds or thousands of cycles in extreme conditions.

Safety concerns are present at all stages of the LIB supply chain (movement, transportation, storage, inventory, and operation), and LIB stability can be influenced by temperature and humidity [45]. Additionally, harsh environments and extreme operating conditions can change the battery’s internal structure, leading to excessive heat generation and potentially causing thermal runaway [46]. Furthermore, design flaws and uneven material distribution during manufacturing can further elevate the risk of thermal runaway.

Additionally, the batteries pose safety hazards, including the risks of fire and workplace exposure to metals and fluorides during battery disassembly, shredding, and smelting [22]. Moreover, gas cleanup might be necessary for recycling facilities. Furthermore, if the cells are damaged, lithium metal could accumulate on the anode, leading to a violent reaction when exposed to moisture. Specific procedures, such as handling in glove boxes or using inert gas chambers, may require an inert or controlled environment.

3.2.7. Commercialization

The results identified commercialization as one challenge faced by LIBs at the EoL, based on scaling up. Most tests conducted today are still bench-scale [47], which has led to significant technological advances in recycling LIBs. However, one of the challenges concerns increasing performance beyond pilot-scale installations. Ref. [47] strongly recommends conducting more pilot-scale investigations and translating these technologies into commercialization. There is an information gap between academia and industry that could limit the development of recycling technology [33]. For [48], several bottlenecks make larger-scale industrialization of second-life battery applications difficult, and therefore, it requires extensive analysis of economic and technical aspects. The real-world issues are more complex due to social and environmental concerns [48].

Therefore, while bench-scale testing has driven progress, overcoming the scaling-up and addressing real-world complexities are essential for realizing the full potential of LIB industrial applications.

3.2.8. Economic Viability

In this research, the consulted literature indicates that economic viability is another challenge LIBs face at the end of their lives, which, according to [30], is a primary concern. Additionally, the research developed by [48] showed that evaluating economic viability requires an understanding of the effects of some key parameters, such as (1) competition with new LIBs—the growth of the EV market will drive the development of new low-cost technologies, and therefore, the refurbishment cost of LIBs must consistently be lower than the price of new batteries, which is a moving target; (2) competition with other types of batteries—new technologies are continuously being developed that could offer sufficient cost or performance advantages over retired LIBs, diminishing the need for second-life LIBs; (3) recycling value of recycling EoL batteries—the value of materials recovered after recycling decreases as the cell manufacturing industry seeks to cut costs by using less expensive raw materials or fewer of them; (4) availability of second-life batteries; (5) refurbishment costs, which depend on the logistics of collection, testing for remaining useful life, and the physical break-up and repackaging of cells, modules, and packs; (6) performance, meaning the number of years the batteries last in their second application.

Regarding the first key parameter mentioned, competition with new LIBs, the cost of second-life batteries is not expected to rise above the cost of new batteries for now [20]. However, it may still become more prominent if significant advances in battery technology occur. Therefore, aspects such as new batteries, different battery types, recycling and repurposing costs, second-life use, and performance were considered key elements to the comprehension of economic viability and can contribute to creating a complex and dynamic economic landscape to achieve a sustainable, viable future for EoL LIBs.

3.2.9. Market Regulations

After reviewing the literature, it became clear that market regulations pose a challenge due to the lack of global rules governing practices related to the EoL management of batteries. In agreement, Ref. [40] identifies the lack of government regulations and legislative management as a challenge to supporting LIB recycling. It is important to specify the roles and responsibilities of the various organizations involved in the spent LIB recycling sector to manage solid and hazardous waste. However, while most nations currently lack government-affiliated LIB recycling centers, such centers are expected to be developed following national realities in the future [40]. Additionally, government regulations and legislative management supporting LIBs EoL must also be established worldwide.

According to [14], there are currently no standards or regulations for managing LIBs at the end of their useful lives. Nations vary significantly in their approaches to balancing economic and environmental objectives and technological and recycling infrastructure availability. However, Ref. [49] affirms that the market for second-life batteries resembles the used automotive parts market, characterized by complex relationships among various entities. The authors present three business models to illustrate how different stakeholders interact and collaborate: closed, intermediary-based, and open markets. In the first business model, relationships primarily exist between customers and companies, emphasizing the importance of data confidentiality.

Additionally, Original Equipment Manufacturers (OEMs) lease batteries, reclaim and repurpose them for secondary applications, and take responsibility for recycling. In the intermediary-based market, OEMs partner with other industry stakeholders (e.g., automakers, battery manufacturers, logistics, recycling, and refurbishment firms) to create circular channels for battery repurposing. An intermediary manages the connection between OEMs and customers, potentially sharing knowledge and data about second-life batteries.

In the open market model, a marketplace operator manages an online platform that connects customers and sellers based on the supply and demand for second-life batteries. At this stage, challenges related to opportunistic behavior, transparency regarding battery history, and pricing complexities resulting from varying aging patterns exist. Consequently, this model introduces uncertainty about battery performance, longevity, reliability, and safety, making it difficult for EV owners to trade these batteries with each other.

However, the models reported by [49] are only proposals, and no model is currently in operation, as shown in the literature consulted. Overall, the creation of specific legislation for LIBs, as well as the allocation of responsibilities, will make it possible to overcome this problem.

A specific case illustrating the regulatory challenges mentioned is the European Union, which adopted Regulation (EU) 2023/1542. This regulation establishes rules to reduce the carbon footprint of batteries, minimize hazardous substances, and increase the recycling rate [50]. It imposes ambitious targets, such as recovering 50% of lithium by 2027 and 80% by 2031 while requiring a minimum recycled material content in new batteries. This approach aims to standardize battery management across member countries, decreasing reliance on virgin raw materials.

China is an example of this with its advanced regulations for managing EoL batteries. As a leading producer of lithium batteries, the country has put stringent rules in place to ensure their proper disposal and to encourage recycling efforts. Since 2021, the government has mandated that by 2025, 20% of lithium material demand must be fulfilled through recycled sources. Furthermore, Chinese research institutions have developed technologies that can recover over 90% of lithium from retired batteries, significantly enhancing the circular economy in this sector.

4. Discussion

This section addresses Objective 3 (exploring strategies to overcome these barriers and improve waste management) and Objective 4 (assigning responsibilities) proposed by this research. Thus, it encourages discussion about the main findings presented in the literature review, specifically regarding pathways and challenges (Section 3). From there, a cross-analysis was conducted, and a causal loop was proposed to enhance the results and foster a more mature discussion about them.

4.1. Pathways Cross-Analysis

Based on the literature review, a cross-analysis was conducted to compare the pathways across various scenarios critically. The main objective of this step was to discuss each pathway’s advantages and disadvantages, economic viability, and environmental impact, which can vary in different contexts. The results of the cross-analysis can be seen in Table 1.

Table 1.

The cross-analysis outcomes.

The cross-analysis shows that, regarding environmental impact and economic viability, reuse and repurposing are the most advantageous scenarios where batteries can be adapted for new uses. However, recycling is the only viable solution when batteries end their useful life, although the environmental impact and associated costs can be high. Disposal should be avoided at all costs due to the high environmental impacts and loss of valuable materials. Developing recycling and repurposing technologies with lower environmental impact and greater efficiency will be crucial to optimizing the treatment of LIBs in the future.

Additionally, it can be inferred that recycling methods (pyrometallurgy, hydrometallurgy, and direct recycling) are unique and have positive and negative aspects. The pyrometallurgical method is popular for its straightforward industrial application and ability to handle large quantities of materials. Nonetheless, its significant energy usage and restricted material recovery hinder its sustainability and emit minor CO2 levels, which vary based on the cathode composition. Despite this, its economic advantage lies in effectively separating valuable metals like nickel, cobalt, and copper, which diminishes the reliance on primary mining.

In contrast, the hydrometallurgical method uses chemical solvents to selectively dissolve battery components, facilitating the recovery of a broader range of materials while consuming less energy and generating lower CO2 emissions. However, this approach necessitates critical preliminary steps and chemical reagents, which can lead to complex liquid waste that requires additional treatments to mitigate environmental effects. Conversely, direct recycling aims to maintain the original structure of active materials, reducing the need for chemical and energy reprocessing and resulting in lower emissions and waste. Nevertheless, challenges arise in its implementation, as the purity of the recovered materials may be compromised, limiting their potential for direct reuse. Therefore, the choice of recycling method must balance material recovery efficiency, operational costs, and environmental impact; hybrid processes may offer a promising opportunity to optimize the environmental and economic benefits of LIB recycling.

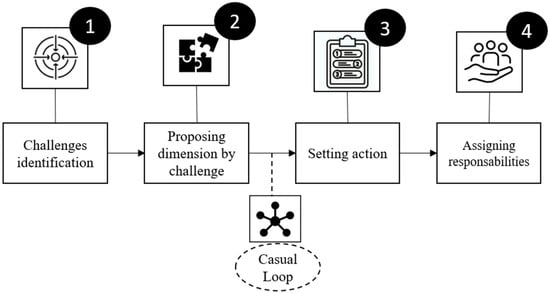

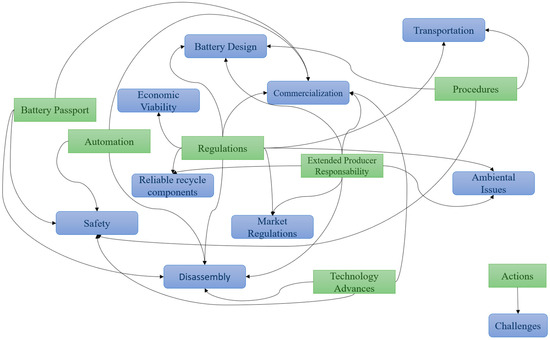

4.2. Designing a Causal Loop Diagram

A Causal Loop Diagram was proposed to support the discussion between challenges and the actions suggested to overcome them. It was developed based on the findings of the narrative review to outline actions and allocate responsibilities for each previously identified challenge. The steps for its construction are presented in Figure 3.

Figure 3.

Causal Loop Development Process.

Based on the narrative review, the challenges presented in step 1 of Figure 3 could first be identified as battery design, disassembly, environmental aspects, reliable recycle components, transportation, safety, commercialization, economic viability, and market regulation. The challenges identified have already been discussed separately in Section 3.2.

Once the barriers were analyzed, similarities and differences were identified, leading to improved understanding and the suggestion of combined actions. Consequently, the barriers were classified into three dimensions based on the actions needed to overcome these challenges, as found in the literature review. This approach enhances the understanding of the root of the problem and supports the proposal of action.

Therefore, the dimensions in step 2 of Figure 3 are Strategy, Policies, and Standardization. These dimensions highlight the need for a more cohesive and unified approach to managing EoL LIBs. They also provide an overview of how inadequacies in strategic planning, policy formulation, and standard establishment hinder the effective management and recycling of these batteries.

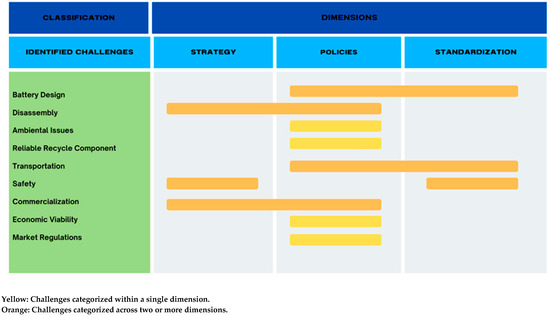

In order to facilitate the understanding, Figure 4 summarizes the challenges grouped by the dimensions of Strategy, Policies, and Standardization. It is worth noting that some challenges were classified into more than one dimension and are therefore identified in orange, while the challenges marked in yellow belong to just one dimension. In this context, based on the research consulted, a set of measures—initiatives that need to be taken to tackle challenges—is proposed and discussed as follows.

Figure 4.

Challenges grouped into dimensions.

- Strategy: For this research, strategy can be understood as well-defined plans and actions oriented toward results in the context of EoL batteries. Strategies include various approaches to address environmental concerns, optimize resource utilization, and promote a circular economy in EoL battery management. For this issue, several initiatives are proposed: (i) automating the testing process along with clear labeling [36]; (ii) ensuring easily accessible dedicated collection points to prevent incorrect waste streams [43]; (iii) providing clear disclosure of the recycling processes involved and the properties of the components is also necessary. Finally, iv) technological advances that impact both performance and safety while speeding up large-scale industrialization are essential requirements [40].

- Policies: Effective policies significantly influence the EoL management of LIBs. Establishing clear regulations, standards, and incentives is vital for encouraging sustainable practices. Developing specific policies for second-life battery applications can encourage their adoption, extend battery lifespan, and reduce waste [22]. Financial mechanisms such as tax credits, rebates, and subsidies should be implemented to support recycling initiatives and incentivize manufacturers and consumers to engage in responsible disposal and repurposing practices.

- Standardization: This involves establishing reliable procedures and standards at every stage of the LIB’s EoL. To achieve this, relevant information must be clearly disclosed, enabling the tracking of battery components throughout their entire life cycle as a fundamental requirement [34].

Classifying the challenges into dimensions made it possible to propose actions to overcome them. For this purpose, this research proposed a Causal Loop Diagram designed to improve understanding of the connection between challenges and actions. In other words, this approach was used to support the impact of each action. As shown in Figure 5, the blue boxes represent the challenges, while the green boxes indicate the actions to tackle these issues. The arrows indicate a direction from the actions to the barriers, illustrating that implementing these actions will contribute to minimizing the negative impact of the identified barriers.

Figure 5.

Causal Loop Diagram.

Based on the dimensions, the diagram in Figure 5 allows for visualizing the actions introduced in the classification mentioned earlier. Each of these is detailed as follows.

Battery Passport

Disassembly, safety, and commercialization are challenges that require a strategy, and one of the strategies suggested was clear labeling. The Digital Battery Passport (DBP) appears as a form of labeling since it can provide comprehensive information that enhances efficiency and effectiveness in managing batteries through their lifecycle stages, ultimately contributing to more sustainable battery management and recycling practices. Specifically, the information that can be provided is SoH, battery chemistry, life cycle information, material composition, upstream information, value chain information, and many others, which can be provided by the producer, assembler, and recycler [15].

The difficulty of implementing DBP due to the lack of interest in sharing information may be explained by the significant investment required for EV battery research and creating a unique selling proposition for EVs [51]. Therefore, due to intellectual property, some data, such as battery chemistry, incorporated materials, and product designs, may not be provided, interrupting the flow of information.

As suggested, introducing DBP can mitigate disassembly because this process requires extensive data—in other words, a lot of information—for optimal functionality [52]. Therefore, the challenge of disassembly can be overcome by introducing a DBP.

Additionally, the need for reliable information that can be addressed through the DBP implementation includes safety and commercialization. For example, DPB offers useful indicators for enhancing the safety of battery handling and disposal [53]. Meanwhile, the lack of information between academia and industry obstructs the development of technologies [33]. Therefore, the availability of battery data is crucial, and one method to accomplish this is by monitoring batteries from their initial lifecycle by implementing a program in the battery management system [20].

Automation

Based on the narrative review, the results demonstrate that automation can address barriers such as disassembly, safety, and commercialization, as illustrated in Figure 5. The introduction of DBP supports the same challenges since they share the same classification: lack of strategy, as presented in Figure 4. With automation as a strategy, the results indicate that numerous improvements could be achieved through automated disassembly, reducing costs and increasing material recovery value [12]. This outcome aligns with the work conducted by [52], which states that automation could signify a significant advancement in the disassembly of EVs.

Regarding safety, automation can serve as an alternative to improving safety protocols [54]. Increased automation may reduce the risk of human injury during disassembly, decrease costs, and possibly render recycling profitable [12].

According to [12], manual disassembly methods are challenging to scale up economically, which implies that automation will foster the scale of the LIBs EoL. From another point of view, Ref. [55] states that automated sorting technology significantly enhances mineral recovery rates, which attracts investments and fosters a robust recycling industry. Therefore, it is essential to note that high mineral recovery rates are vital for scaling up battery recycling. From both viewpoints, it is proposed that automation will increase the marketability of EoL processes by improving their economic viability and thus overcoming the commercialization barrier.

Regulation

Given the importance of a system of rules designed to manage and control practices in LIBs’ EoL to ensure their correct destination, this work recommends regulation as a key action. It aims to address most of the barriers identified, such as reliable components, economic viability, battery design, disassembly, commercialization, environmental aspects, market regulations, and transportation.

The results are also proposed by [56], who developed a robust and valuable review of regulations and standards for EoL batteries. They define regulations as authoritative instructions mandated by governmental or regulatory entities to ensure safety, reliability, and adherence to standards, and they attribute the difficulty in regulation to the heterogeneous battery composition.

The results from this research align with the work presented by [56], which emphasizes that regulations can provide a framework to ensure that EoL processes are conducted with the rigor necessary for high-quality recycling. This finding also supports [49], which proposed that strict regulations should be established to tackle the issue of reduced reliability, thereby addressing the challenge of dependable components. In terms of economic viability, public policies can assist participants in the second-life battery market in making informed decisions and developing sustainable business models [56]. Thus, by offering a clear regulatory framework, these regulations can enable businesses to create enduring enterprises with lasting economic viability.

For the case of battery design and disassembly, the results of this research point out that establishing legislation to regulate the layout of batteries could end their heterogeneity, making disassembly simpler. However, the literature adds that it remains uncertain how the legislation in each country will address the variability in useful lifespans, sizes, shapes, configurations, and safety levels of batteries produced by different manufacturers [56].

Related to market regulations and commercialization, the literature discusses that businesses can innovate while maintaining compliance and competitiveness with a clear understanding of performance, procedures, and measures. Therefore, a well-regulated market can ensure that second-life batteries meet the requirements, building consumer confidence [56]. Additionally, the lack of tangible legislation affects the stability of the battery supply chain, such as the absence of raw material production in certain countries. Based on these findings, this research proposes establishing a clear and comprehensive regulatory framework to ensure the economic availability of these critical inputs.

Regarding environmental aspects, findings indicate that the lack of strict regulatory standards established to protect human health and the environment prevents various hazards and pollution [56]. Additionally, inadequate laws and regulations commonly cause environmental safety issues related to EoL LIBs [46]. Thus, regulations could be adjusted to ensure that all retired LIBs can be treated to make them less environmentally harmful [57].

Regarding the transportation challenge, LIBs are classified as dangerous goods for transportation due to their potential hazards [58]. Moreover, international and national norms and regulations governing the transport of LIBs vary based on location, mode of transportation, and specific characteristics of batteries. However, national and international rules show inconsistencies in terminology, procedures, transport documentation, inner packaging requirements, and battery size classifications [59]. Therefore, this research recommends implementing standardized procedures that specifically govern the transportation and storage requirements of these batteries during their transit.

Extended Producer Responsibility

Extended producer responsibility (EPR) can be defined as a regulatory tool designed to address the potential environmental impacts of products, particularly when they reach the end of their useful life [60]. According to [54], EPR is essential for implementing the circular economy in the EV battery sector by encouraging manufacturers to take responsibility for the entire lifecycle of their products, from production to disposal. Thus, this research concludes that ERP acts as a mechanism for market regulation.

One of the objectives of EPR is to reduce environmental impact and influence the long-term design of a product by assigning responsibility throughout the whole lifecycle [60]. With this in mind, one of these responsibilities concerns the design restrictions. By implementing EPR, producers are encouraged to develop more environmentally friendly products, making them easier to disassemble and compatible with current recycling techniques and the environment.

Furthermore, the literature indicates that if producers design their products with the retirement phase in mind from the outset, EoL costs will be reduced [60], thereby aiding commercialization. This is consistent with [61], which argues that by assigning EoL management costs to producers, they are encouraged to achieve greater economic efficiencies throughout the product life cycle, from product and service design to the EoL management system.

The findings further indicate that an additional challenge that may be addressed through the implementation of EPR is the reliable recycling of components. The established closed-loop system, in which the producer assumes responsibility for the recycling process, ensures a supply of trustworthy materials for the producer. Based on the literature review, this work suggests implementing EPR as it represents an environmental policy that extends a producer’s responsibility beyond the consumer stage of a product’s lifecycle. This action can contribute to mitigating barriers related to environmental factors, battery design, disassembly, commercialization, and the reliability of recycling components.

Technology Advances

The literature reviewed shows that technological advancements are rapidly evolving in the EV retired battery industry, with machine learning and artificial intelligence (AI) playing vital roles in enhancing efficiency and sustainability. Consequently, these innovative technologies can significantly impact the industry by improving various aspects of the EoL [54].

Developing and implementing advanced technologies is essential for addressing commercialization, disassembly, and safety challenges, as illustrated in Figure 5. These challenges demand a strategic approach (see Figure 4), so this work recommends utilizing advanced technologies to tackle them.

Machine learning and AI can enhance LIB waste management by optimizing sorting and EoL processes through automated material classification, predictive maintenance, and efficiency-driven resource allocation. AI-powered systems can improve battery diagnostics, allowing for a more accurate assessment of SoH, which supports safer and more effective repurposing or recycling.

Concerning the safety challenge, technologies can track and mitigate safety risks. Nowadays, there are technological tools to predict and evaluate safety risks during EoL management, for example, blockchain and big data [58]. Blockchain, in particular, offers enhanced traceability and transparency in the LIB recycling chain, ensuring compliance with environmental regulations and preventing improper disposal. Smart contracts can further automate regulatory compliance, reducing human error and increasing operational efficiency.

Regarding the commercialization challenge, since technological advancements define the critical parameters of investment and industrial implementation decision-making (commercialization), there is a strong correlation between their technical performance and financial viability [62]. AI-driven market analytics can support investment decisions by predicting demand trends and optimizing supply chain logistics. Additionally, Ref. [38] highlights that while technology and battery design are still developing, the lack of agreement between the two makes disassembly challenging. AI-powered robotics and advanced automation solutions could significantly improve disassembly efficiency by identifying optimal dismantling procedures, reducing labor costs, and increasing material recovery rates.

By integrating these technological innovations, LIB waste management can become more cost-effective, environmentally friendly, and scalable, thereby accelerating the transition toward a circular economy in the battery industry.

Standardized procedures

Standardized procedures are systematic actions designed to overcome the challenges of safety, battery design, and transportation, which, as the name suggests, belong to the dimension of “standardization,” as represented in Figure 4 and Figure 5.

This research suggests the implementation of standardized procedures based on the literature, which states that there is no standardized design for automotive batteries at present [12]. However, to guarantee high-quality recovery, it is necessary to establish standards and regulations on the design of batteries and the intrinsic aspects of their design [63]. For example, establishing a universal labeling system for battery components could enable automated sorting and enhance recycling efficiency. Moreover, standardized disassembly protocols, like modular battery pack designs with easily detachable components, would streamline the dismantling process and cut labor costs. Finally, adopting uniform safety guidelines for battery handling and transportation would reduce risks related to hazardous material exposure.

Standardizing cell size and shape to a limited number of designs would further enhance the feasibility of dismantling and separation [23] and significantly improve efficiency [64]. By integrating these standardized procedures, the LIB industry can attain greater sustainability and cost-effectiveness in EoL battery management.

Regarding the transportation challenge, this work suggests implementing standardized procedures based on the literature, which indicates that standardization positively impacts transport performance [65] since packing, storing, and moving procedures vary from region to region [59].

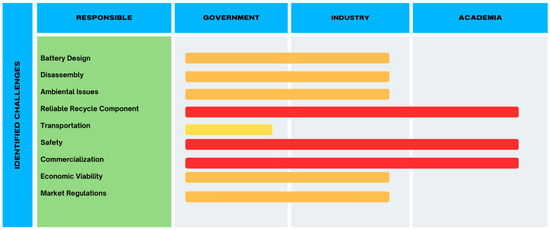

4.3. Addressing Responsibilities

This section presents the fourth step of the Causal Loop development Diagram shown in Figure 3. Its main purpose is to analyze and discuss who is responsible for the identified challenges of LIBs’ EoL.

The results showed that the legislation is a key aspect in tackling environmental and economic challenges in the growing EV market [56] and expanding the circular economy business model [66]. However, the legislation that drives automobiles and EV batteries has many gaps and is not designed to support proper EoL battery management [60]. It can be justified due to the absence of globally recognized standards for EV batteries, insufficient incentives for circular economy models, and inadequate support for technology innovation [54]. Due to its importance, this research considers it vital to assign responsibilities to the EoL scenario of LIBs to tackle challenges that may arise. Figure 6 addresses each organization’s role: government, academia (university and researchers), and industry (automotive and battery manufacturers, dismantlers).

Figure 6.

The role of government, academia, and industry in LIB waste management.

The colors of the lines represent responsibility distribution: the yellow line indicates a single organization′s responsibility, the orange line signifies shared responsibility between two organizations, and the red line denotes that all three organizations are responsible.

In Figure 6, the yellow line indicates the responsibility of a single organization, the orange line represents two organizations, and the challenge marked in red signifies that all three institutions are responsible. However, it is important to mention that some challenges are addressed by more than one organization.

The results indicate that the government plays a key role in developing policies to support initiatives for EoL batteries and to regulate the entire waste management LIB market. Additionally, to make establishing a large-scale, effective, and traceable LIB recycling management system easier, the government should actively expand the regulation and release corresponding guidance documents while permitting flexible implementation. Establishing pertinent organizations, stepping up public awareness and education campaigns, and raising public environmental literacy are also essential [22,40,43].

Moreover, due to its significant role in enhancing standards, laws, and regulations [46], the government should establish funding priorities for Research and Development (R&D), pilot project funding, and favorable market pull policies that can provide early incentives and subsidies to support the development of LIB recycling technologies, scale up, and optimize the recycling value chain [40].

The findings suggest that the academy addresses the responsibility for reliable recycling components, safety, and commercialization challenges. The literature indicates a recent surge in publications on LIB recycling; however, most suggested techniques still depend on large-scale experiments conducted in research conditions [43]. Therefore, it is essential for researchers to critically evaluate lab-scale processes and propose procedures that can be developed at an industrial level, including enhanced safety, scalability, and confidence in the recycled material [43].

This research suggested that the industry may be held responsible for most of the identified problems because battery manufacturers possess substantial information regarding battery history and current status. This knowledge would enable them to plan for second-life applications early in the design stage [48]. Furthermore, gaps in information between academia and industry may hinder further advancements [33]. This research advocates for universities and laboratories to work with industry and regulatory institutions to better understand and fulfill industry requirements.

The results from the narrative review indicated that for LIBs to reach the right destination, all three organizations must collaborate in a clear and cooperative manner [23,40]. The partnership between academia and industry will enhance academia’s understanding of the real needs of EoL, while industry will convert academic ideas into tangible processes and products [33]. Accordingly, public policies must be effective, and these three entities (the industrial sector, universities, and government agencies) must actively engage in their formulation [67].

In Figure 6, the government and industry are primarily responsible for many identified challenges. This aligns with the research from [66], which concluded that the government and industry (vehicle manufacturers) are the key stakeholders necessary to overcome the barriers.

5. Conclusions

As EVs gain popularity, the demand for LIBs continues to rise, mainly as they play a crucial role in reducing GHG emissions. This demand highlights the importance of proper EoL management for LIBs to mitigate environmental impacts and maximize opportunities for second use or recycling. This research analyzes the current challenges and solutions in EoL management of LIBs to emphasize the necessity of establishing procedures to handle their disposal, recycling, and repurposing sustainably and efficiently.

This work employs a narrative review to identify the pathways and challenges faced by LIBs in reaching these paths after their vehicular life ends, and it provides a foundation for proposing actions to overcome these challenges.

The narrative review is often used to identify and analyze relevant studies and uncover relationships between them, which is essential for developing the Causal Loop Diagram aimed at understanding the connection between actions and challenges. In this context, the results indicate that reuse, repurposing, recycling, and disposal are the main pathways. Reuse is a highly sustainable EoL option because it gives batteries a second chance and minimizes the environmental and economic impacts associated with other battery processes.

However, implementing these pathways encounters several challenges identified in this work, including battery design, environmental aspects, reliable recycling components, transportation, safety, commercialization, economic viability, and market regulation. To address these challenges, this research proposed classifying them into categories based on similarities among the identified issues. Therefore, based on the literature review, three types of similarities were identified: lack of standardization, lack of regulation, and lack of strategy. These categories emphasize how deficiencies in strategic planning, policy development, and standards establishment hinder the effectiveness of LIB waste management.

The proposed use of the Causal Loop Diagram, as the main result of this research, concludes that a Battery Digital Passport, automation, and advanced technologies are actions that can be used to overcome the challenges classified in the dimension “Strategy”. Additionally, implementing regulations and extended product responsibilities is recommended to address the challenges classified in the dimension “Policies”. For the challenges related to the dimension of “Standardization”, it is recommended to adopt standardized procedures, as the name suggests.

This research also aimed to identify key stakeholders in the LIB EoL scenario, along with the associated challenges: the government, academia, and industry. These stakeholders play a crucial role in developing legislation, new technologies, procedures, safety measures, and expanding markets. Therefore, it was concluded that the government and industry bear greater responsibility for the identified challenges.

Limitations and Directions for Future Research

Despite the importance of this research in contributing to a comprehensive understanding of the current challenges in LIB management and offering strategies to enhance the sustainability and efficiency of this process, it has limitations. For instance, there is a lack of literature on EoL challenges, as the existing literature primarily focuses on issues related to the production of new batteries, the introduction of EVs, and the supply chain. Additionally, the retired battery market is relatively new and booming. Moreover, there is a lack of empirical data on real-world applications, as many studies rely on theoretical models or projections rather than practical case studies. With this, coupled with the emergence of new technologies and legislation, there is ample opportunity for further research, such as comparing current and future challenges. Therefore, it is recommended that future research be conducted in partnership with industry to avoid bottlenecks between the literature and practice.

Author Contributions

Writing—original draft, A.L.S.; Writing—review & editing, W.A. and P.F.; Supervision, W.A. and P.F. All authors have read and agreed to the published version of the manuscript.

Funding

This paper is part of a PhD research. Please consider the following grant number: This work has been supported by FCT—Fundação para a Ciência e Tecnologia within the Project Scope: UIDB/04728/2020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial Intelligence |

| DBP | Digital Battery Passport |

| EoL | End-of-Life |

| ERP | Extended Producer Responsibility |

| EV | Electric Vehicle |

| GHC | Greenhouse Gas Emissions |

| LIB | Lithium-Ion Battery |

| OEMs | Original Equipment Manufacturers |

| R&D | Research and Development |

| SoH | State of Health |

| WoS | Web of Science |

References

- Martins, F.; Felgueiras, C.; Smitkova, M.; Caetano, N. Analysis of Fossil Fuel Energy Consumption and Environmental Impacts in European Countries. Energies 2019, 12, 964. [Google Scholar] [CrossRef]

- Zhang, L.; Long, R.; Li, W.; Wei, J. Potential for reducing carbon emissions from urban traffic based on the carbon emission satisfaction: Case study in Shanghai. J. Transp. Geogr. 2020, 85, 102733. [Google Scholar] [CrossRef]

- Abo-Khalil, A.G.; Abdelkareem, M.A.; Sayed, E.T.; Maghrabie, H.M.; Radwan, A.; Rezk, H.; Olabi, A. Electric vehicle impact on energy industry, policy, technical barriers, and power systems. Int. J. Thermofluids 2022, 13, 100134. [Google Scholar] [CrossRef]

- Wang, Y.; Gan, S.; Li, K.; Chen, Y. Planning for low-carbon energy-transportation system at metropolitan scale: A case study of Beijing, China. Energy 2022, 246, 123181. [Google Scholar] [CrossRef]

- Fang, D.; Wu, W.; Li, J.; Yuan, W.; Liu, T.; Dai, C.; Wang, Z.; Zhao, M. Performance simulation method and state of health estimation for lithium-ion batteries based on aging-effect coupling model. Green Energy Intell. Transp. 2023, 2, 100082. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, Y.; You, M.; Xiong, R.; Zhou, X. Two-stage aging trajectory prediction of LFP lithium-ion battery based on transfer learning with the cycle life prediction. Green Energy Intell. Transp. 2022, 1, 100008. [Google Scholar] [CrossRef]

- Zhang, C.; Luo, L.; Yang, Z.; Zhao, S.; He, Y.; Wang, X.; Wang, H. Battery SOH estimation method based on gradual decreasing current, double correlation analysis and GRU. Green Energy Intell. Transp. 2023, 2, 100108. [Google Scholar] [CrossRef]

- Linder, M.; Nauclér, T.; Nekovar, S.; Pfeiffer, A.; Vekić, N. The Race to Decarbonize Electric-Vehicle Batteries; McKinsey: New York, NY, USA, 2023. [Google Scholar]

- Bobba, S.; Carrara, S.; Huisman, J.; Mathieux, F.; Pavel, C. Critical Raw Materials for Strategic Technologies and Sectors in the EU. 2020. Available online: https://rmis.jrc.ec.europa.eu/uploads/CRMs_for_Strategic_Technologies_and_Sectors_in_the_EU_2020.pdf (accessed on 6 January 2025).

- Sommerville, R.; Zhu, P.; Rajaeifar, M.A.; Heidrich, O.; Goodship, V.; Kendrick, E. A qualitative assessment of lithium ion battery recycling processes. Resour. Conserv. Recycl. 2021, 165, 105219. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Li, Y.; Li, H.; Pan, X.; Mclellan, B. The social-economic-environmental impacts of recycling retired EV batteries under reward-penalty mechanism. Appl. Energy 2019, 251, 113313. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Kotak, Y.; Fernández, C.M.; Casals, L.C.; Kotak, B.S.; Koch, D.; Geisbauer, C.; Trilla, L.; Gómez-Núñez, A.; Schweiger, H.-G. End of electric vehicle batteries: Reuse vs. recycle. Energies 2021, 14, 2217. [Google Scholar] [CrossRef]

- Patel, A.N.; Lander, L.; Ahuja, J.; Bulman, J.; Lum, J.K.H.; Pople, J.O.D.; Hales, A.; Patel, Y.; Edge, J.S. Lithium-ion battery second life: Pathways, challenges and outlook. Front. Chem. 2024, 12, 1358417. [Google Scholar] [CrossRef]

- Ott, J.; Schoeggl, J.-P.; Baumgartner, R.J. End of life focused data model for a digital battery passport. Procedia CIRP 2024, 122, 277–281. [Google Scholar] [CrossRef]

- Bui, N.T.H. Methodology of the literature review: A comparison of systematic literature review and narrative literature review. Int. J. Econ. Commer. Manag. 2021, 9, 367–371. [Google Scholar]

- Jahan, N.; Naveed, S.; Zeshan, M.; Tahir, M.A. How to Conduct a Systematic Review: A Narrative Literature Review. Cureus 2016, 8, e864. [Google Scholar] [CrossRef]

- Ferrari, R. Writing narrative style literature reviews. Med. Writ. 2015, 24, 230–235. [Google Scholar] [CrossRef]

- Green, B.N.; Johnson, C.D.; Adams, A. Writing narrative literature reviews for peer-reviewed journals: Secrets of the trade. J. Chiropr. Med. 2006, 5, 101–117. [Google Scholar] [CrossRef]

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Sunny, M.S.H.; Mohammad, N. A Comprehensive Review on Second-Life Batteries: Current State, Manufacturing Considerations, Applications, Impacts, Barriers Potential Solutions, Business Strategies, and Policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar] [CrossRef]

- Moore, E.A.; Russell, J.D.; Babbitt, C.W.; Tomaszewski, B.; Clark, S.S. Spatial modeling of a second-use strategy for electric vehicle batteries to improve disaster resilience and circular economy. Resour. Conserv. Recycl. 2020, 160, 104889. [Google Scholar] [CrossRef]

- Gaines, L.; Richa, K.; Spangenberger, J. Key Issues for Li-Ion Battery Recycling; Springer Nature: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Chen, M.; Ma, X.; Chen, B.; Arsenault, R.; Karlson, P.; Simon, N.; Wang, Y. Recycling End-of-Life Electric Vehicle Lithium-Ion Batteries. Joule 2019, 3, 2622–2646. [Google Scholar] [CrossRef]

- Wilson, N.; Meiklejohn, E.; Overton, B.; Robinson, F.; Farjana, S.H.; Li, W.; Staines, J. A physical allocation method for comparative life cycle assessment: A case study of repurposing Australian electric vehicle batteries. Resour. Conserv. Recycl. 2021, 174, 105759. [Google Scholar] [CrossRef]

- Khatibi, H.; Hassan, E.; Frisone, D.; Amiriyan, M.; Farahati, R.; Farhad, S. Recycling and Reusing Copper and Aluminum Current-Collectors from Spent Lithium-Ion Batteries. Energies 2022, 15, 9069. [Google Scholar] [CrossRef]

- Guo, R.; Wang, F.; Rhamdhani, M.A.; Xu, Y.; Shen, W. Managing the surge: A comprehensive review of the entire disposal framework for retired lithium-ion batteries from electric vehicles. J. Energy Chem. 2024, 92, 648–680. [Google Scholar] [CrossRef]

- Woeste, R.; Drude, E.-S.; Vrucak, D.; Klöckner, K.; Rombach, E.; Letmathe, P.; Friedrich, B. A techno-economic assessment of two recycling processes for black mass from end-of-life lithium-ion batteries. Appl Energy 2024, 361, 122921. [Google Scholar] [CrossRef]

- Giza, K.; Pospiech, B.; Gęga, J. Future Technologies for Recycling Spent Lithium-Ion Batteries (LIBs) from Electric Vehicles—Overview of Latest Trends and Challenges. Energies 2023, 16, 5777. [Google Scholar] [CrossRef]

- Sharmili, N.; Nagi, R.; Wang, P. A review of research in the Li-ion battery production and reverse supply chains. J. Energy Storage 2023, 68, 107622. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward Sustainable Reuse of Retired Lithium-ion Batteries from Electric Vehicles. Resour. Conserv. Recycl. 2020, 168, 105249. [Google Scholar] [CrossRef]

- Costa, C.M.; Barbosa, J.C.; Gonçalves, R.; Castro, H.; Campo, F.J.D.; Lanceros-Méndez, S. Recycling and environmental issues of lithium-ion batteries: Advances, challenges and opportunities. Energy Storage Mater. 2021, 37, 433–465. [Google Scholar] [CrossRef]

- Mrozik, W.; Rajaeifar, M.A.; Heidrich, O.; Christensen, P. Environmental impacts, pollution sources and pathways of spent lithium-ion batteries. Energy Environ. Sci. 2021, 14, 6099–6121. [Google Scholar] [CrossRef]

- Ma, X.; Azhari, L.; Wang, Y. Li-ion battery recycling challenges. Chem 2021, 7, 2843–2847. [Google Scholar] [CrossRef]