The Effect of Chloride Ions Morphology on the Properties of Concrete Under Dry and Wet Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

- (1)

- Cement: Ji Dong Cement (P.O 42.5) from the Inner Mongolia region, specific surface area of 324 m2/kg, initial setting time of 180 min, final setting time of 385 min, and satisfactory volume stability.

- (2)

- Fly ash (FA): Class II fly ash provided by Jin Qiao Power Plant in Hohhot City, with a water requirement ratio of 101%, loss on ignition of 7.9%, and activity of 79%.

- (3)

- Fine aggregate: Includes aeolian sand (AS) selected from the Kubuqi Desert and basalt sand (BF) produced by mechanical crushing of basalt. The aeolian sand and basalt sand are mixed in a 1:1 ratio to form the mixed sand used as fine aggregate. The laser particle size test revealed that the main particle size distribution range of the aeolian sand is 4.5 μm to 255 μm, with a clay content of 1.39%. The basalt sand has a solidity index of 7% and a clay content of 0.872%. The particle gradation of the fine aggregate, as shown in Figure 1, has a bulk density, apparent density, and fineness modulus of 1578.68 kg/m3, 2764.21 kg/m3, and 1.64, respectively.

- (4)

- Coarse aggregate: Crushed stone with a particle size of 5.0 to 31.5 mm, with a bulk density of 1550 kg/m3 and an apparent density of 2680 kg/m3.

- (5)

- Mixing water: Tap water from the Inner Mongolia region, with a pH value of 7.0.

- (6)

- Admixture: A white powder-type polycarboxylate water reducer with a water reduction rate of 20%.

- (7)

- Epoxy resin: Bisphenol A type E51 epoxy resin, with a viscosity of 11,000–14,000 mpa·s, transparent color, and a usage temperature range of −50 to 150 °C.

2.2. Test Method

2.2.1. Macroscopic Performance Test

- (1)

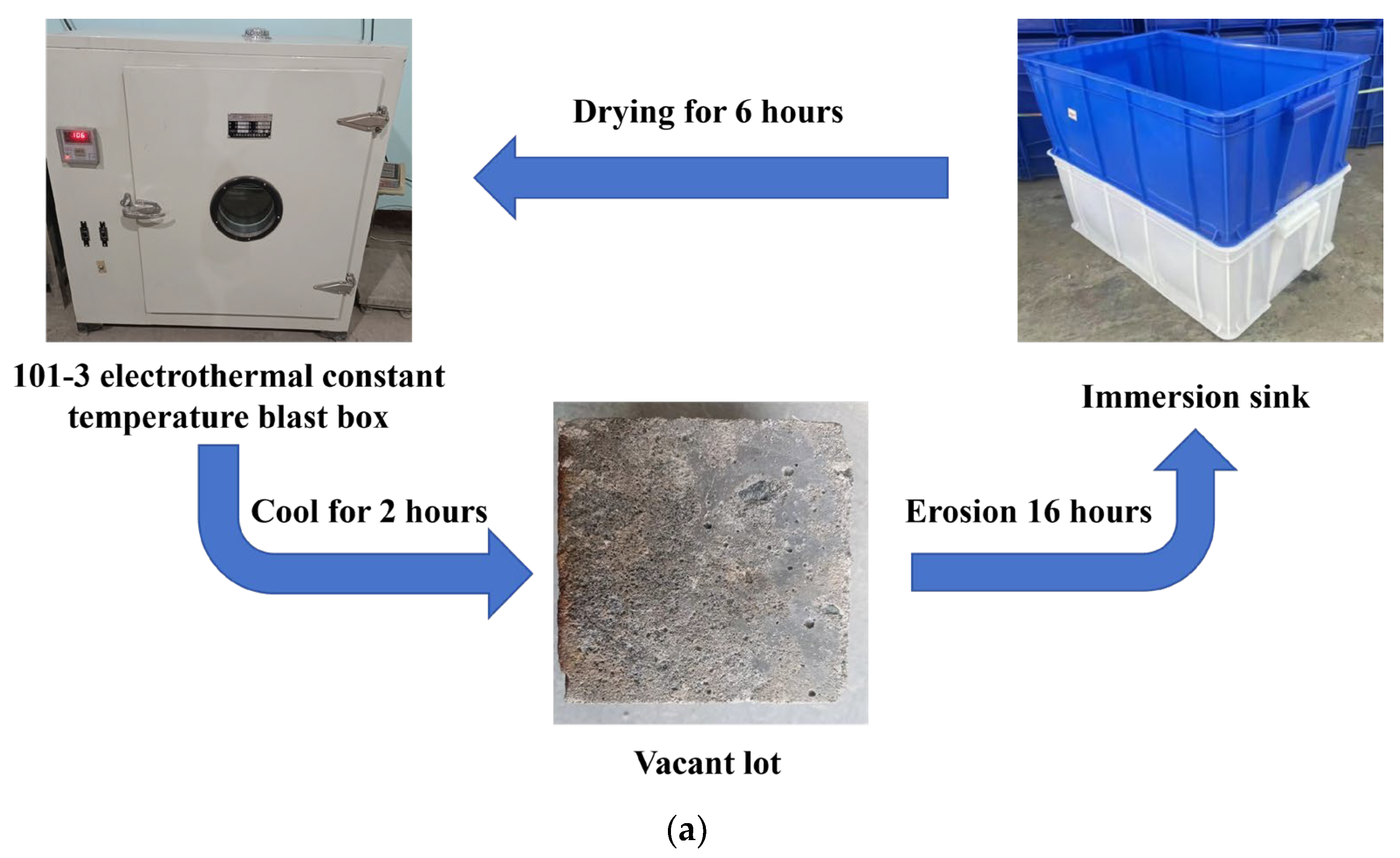

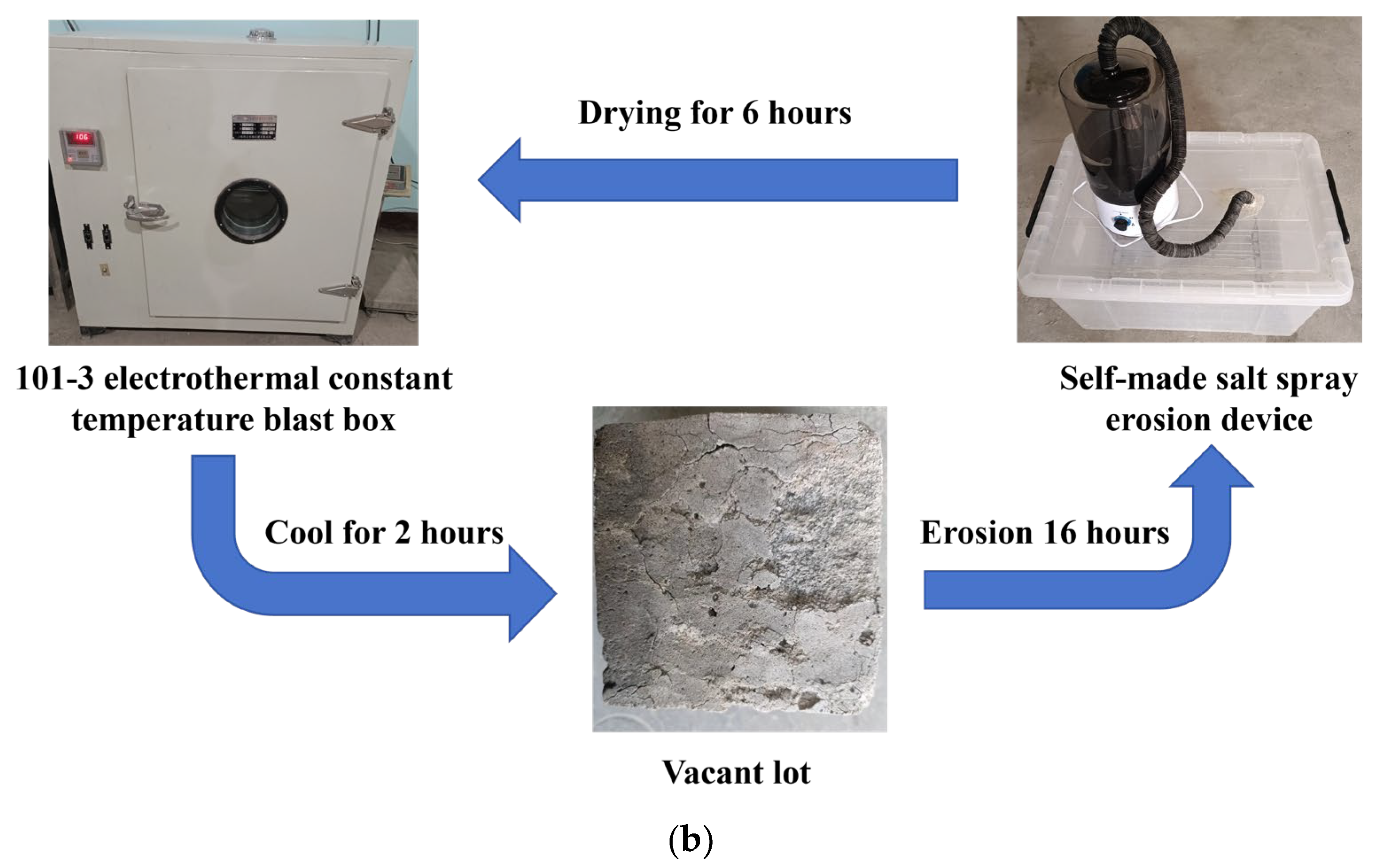

- Chloride Ion Erosion Test Under Dry–Wet Cycle

- (2)

- Compressive Strength and Penetration Depth Test

2.2.2. Microstructure Test

- (1)

- Scanning Electron Microscopy (SEM) Test

- (2)

- Nuclear Magnetic Resonance (NMR) Test

- (3)

- X-ray Diffraction (XRD) Test

- (4)

- Thermogravimetric (TG) Test

3. Results and Discussion

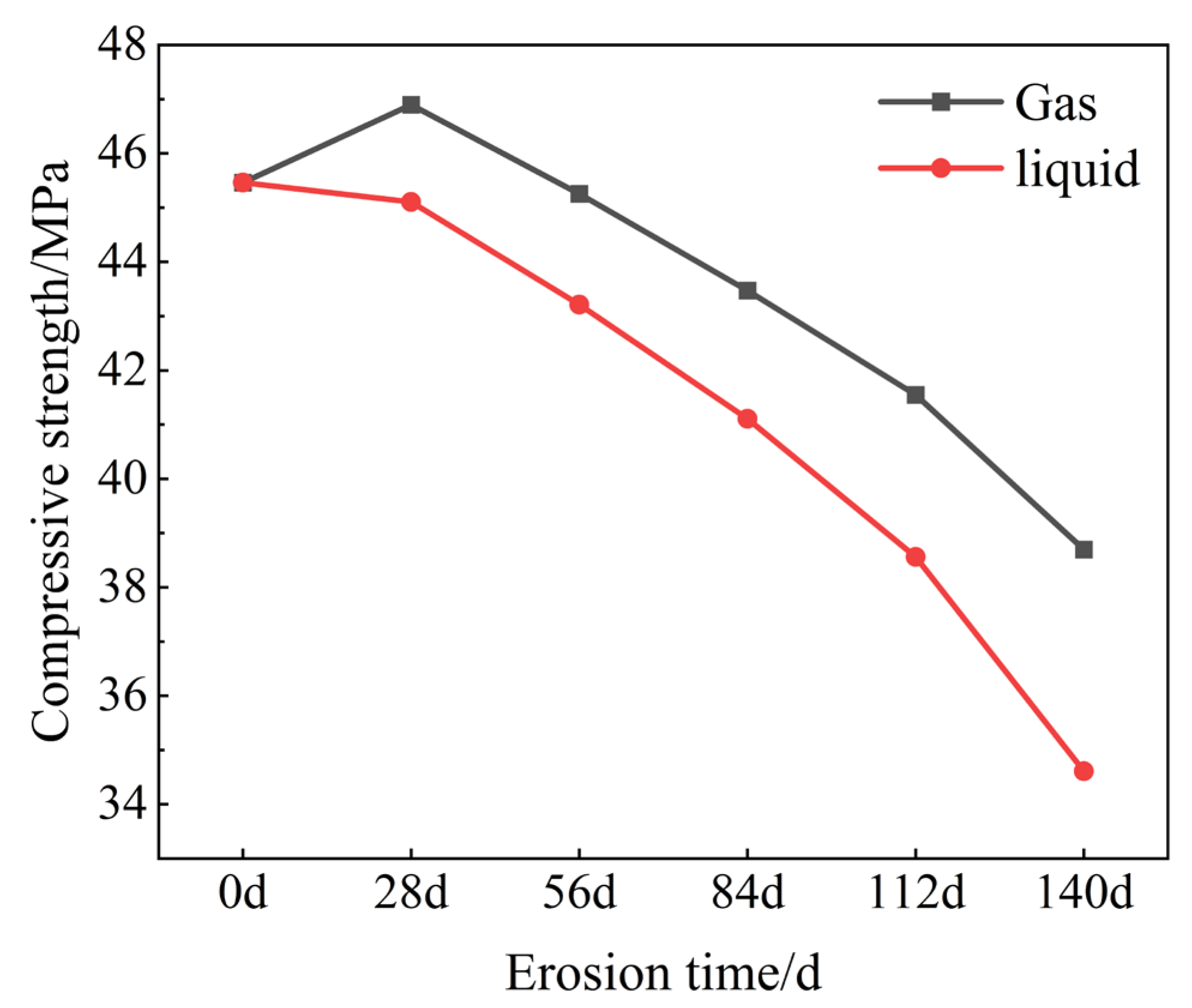

3.1. Compressive Strength

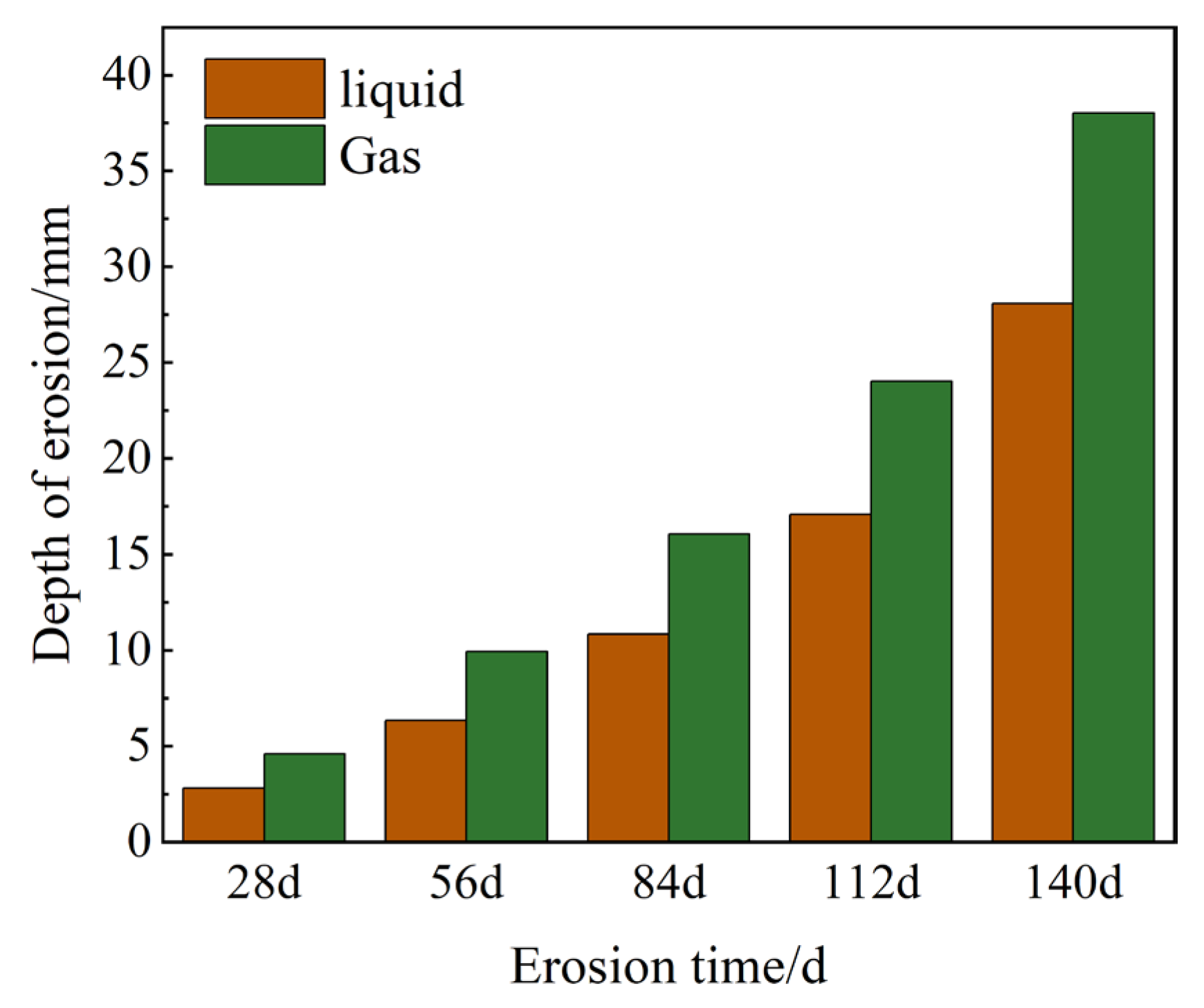

3.2. Penetration Depth

3.3. XRD

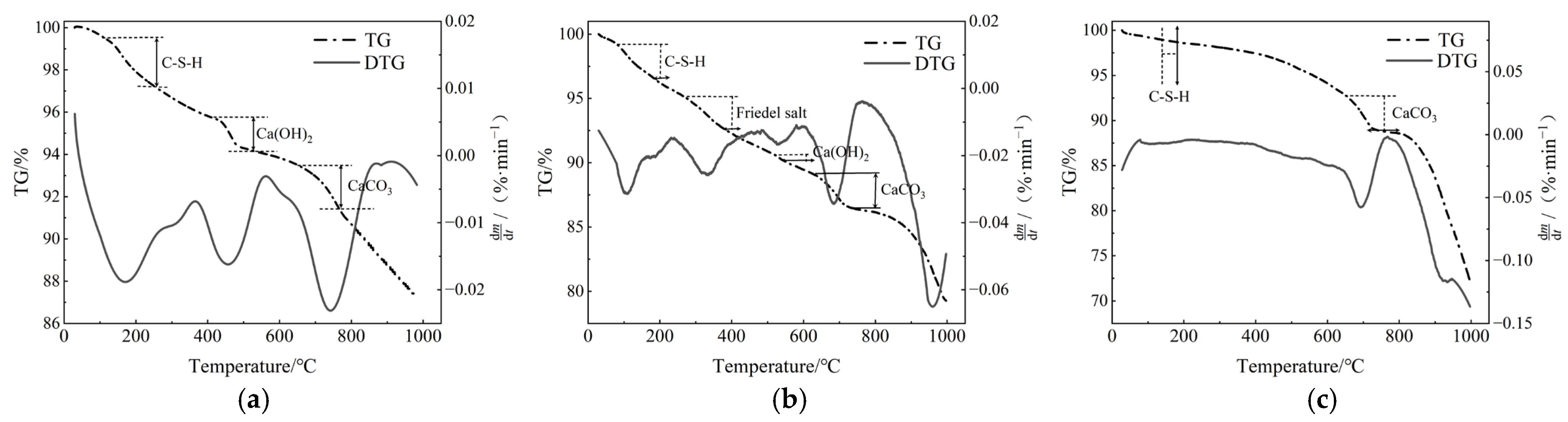

3.4. Thermogravimetric

- (1)

- Around 70 °C, the moisture in the sample and the air is thermally decomposed, which is not chemically bound.

- (2)

- Around 100 °C and 275 °C, a significant amount of initial dehydration of C-S-H gel occurs, as well as a small amount of secondary dehydration.

- (3)

- Around 330 °C, the eroded product Friedel’s salt undergoes thermal decomposition.

- (4)

- Around 400 °C, the hydration product calcium hydroxide (Ca(OH)2) undergoes thermal dehydration decomposition.

- (5)

- Around 600 °C to 700 °C, the calcium carbonate (CaCO3) in the aggregate undergoes thermal decomposition.

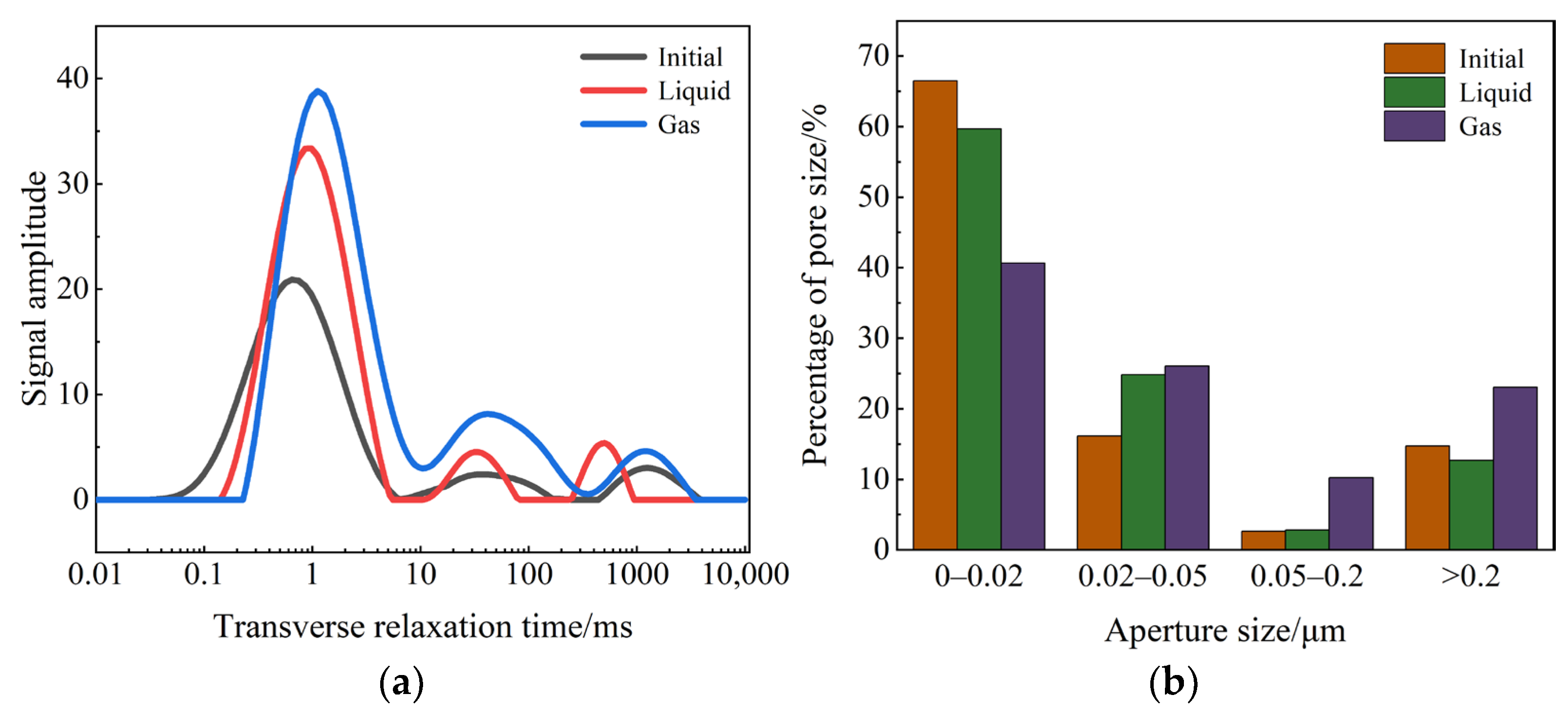

3.5. NMR

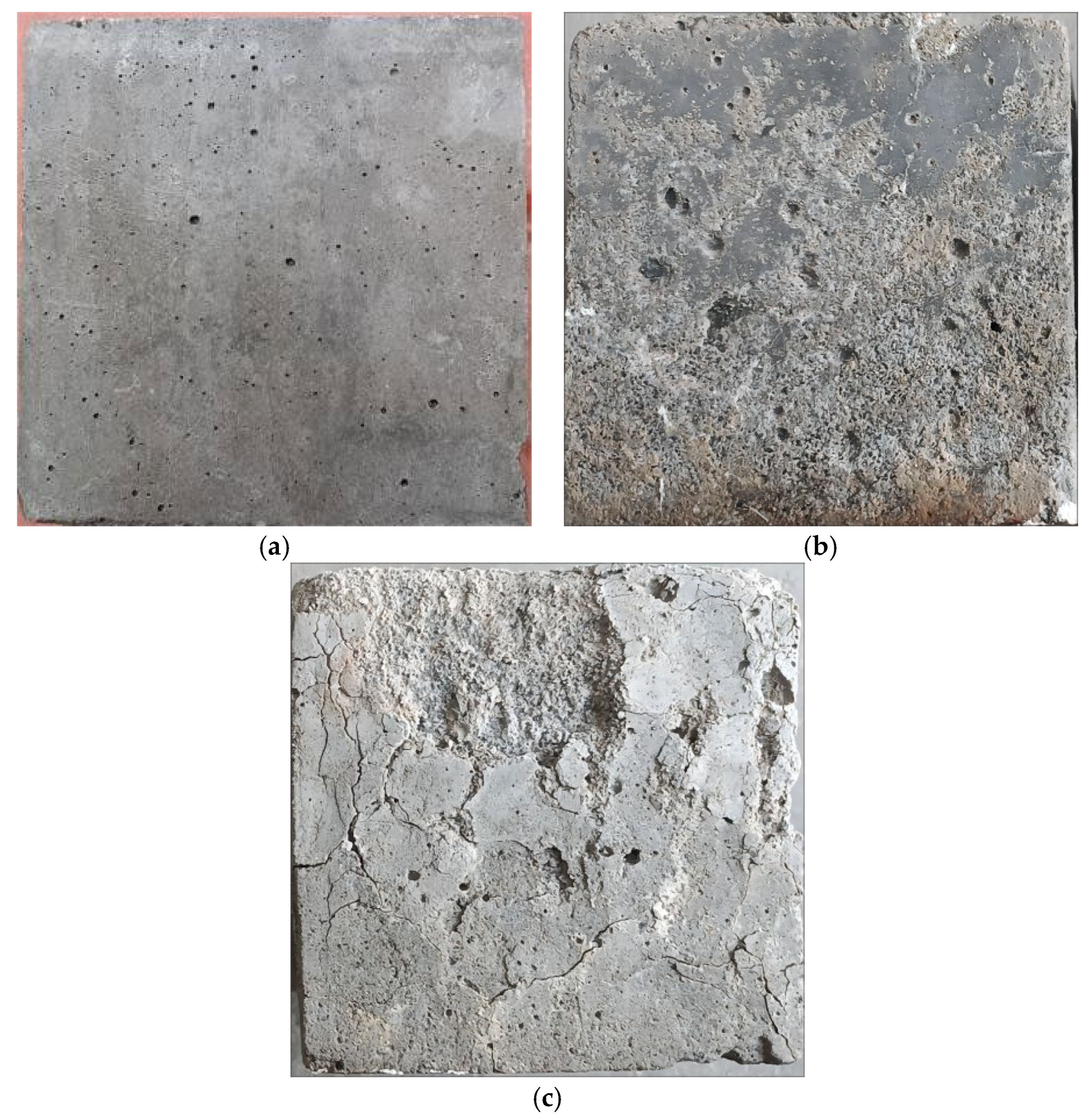

3.6. SEM

4. Conclusions

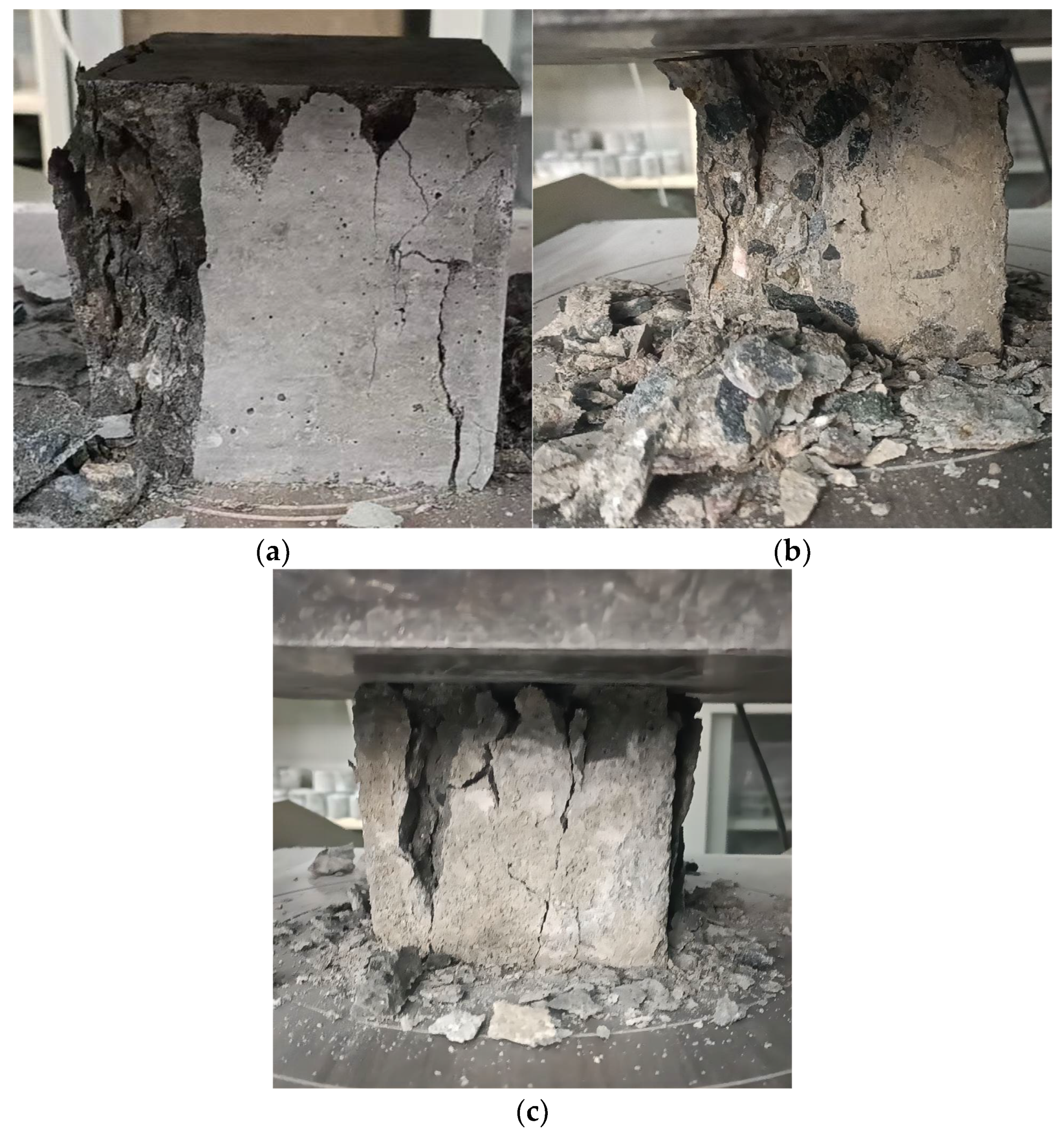

- (1)

- Under dry–wet cycling conditions, mixed sand concrete subjected to spray-born chloride ion erosion exhibits an 11.82% decrease in compressive strength and a 26.13% augmentation in erosion depth, in contrast to its performance under liquid chloride ion erosion. Notably, the degradation incurred under spray-born chloride erosion is more pronounced and progresses at a faster rate. Consequently, under compressive loading, the material demonstrates a failure mode characterized by extensive fragmentation, accompanied by a markedly shorter duration to failure.

- (2)

- Different forms of chloride ions have different erosion directions on concrete under the conditions of wet–dry cycles. The erosion direction of liquid chloride ions on mixed sand concrete is from the outside to the inside, while under the erosion of spray-born chloride, the chloride ions show bidirectional erosion within the mixed sand concrete.

- (3)

- Under the condition of wet–dry cycles, compared to the erosion of liquid chloride ions, the erosion of spray-born chloride exerts greater crystallization pressure on the structure of the mixed sand concrete. The micro-pore structure and the compact structure of the hydrated products inside the concrete are severely degraded, resulting in higher overall structural degradation and a faster degradation rate of the mixed sand concrete.

- (4)

- Under the coupling effect of wet–dry cycles and different forms of chloride ion erosion, the erosion and degradation mechanisms of the mixed sand concrete are different. Under the erosion of liquid chloride ions, the structural degradation of the mixed sand concrete is caused by the combined effects of wet–dry fatigue, crystallization pressure, chloride salt erosion, and leaching of calcium ions. Under the erosion of spray-born chloride, the structural degradation of the mixed sand concrete is caused by wet–dry fatigue, crystallization pressure, and leaching of calcium ions, with crystallization degradation playing a major role.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xue, H.L.; Chen, M.L.; Tang, Z.B. Macro-micro Mechanisms for the Effects of Stone Powder in Manufactured Sand on Physical and Mechanical Properties of Concrete. Adv. Eng. Sci. 2022, 55, 151–160. [Google Scholar] [CrossRef]

- Bendixen, M.; Best, J.; Hackney, C.; Iversen, L.L. Time is running out for sand. Nature 2019, 571, 29–31. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.Y.; Liu, M.H.; Liu, X. Study on mechanical properties and carbon emissions of desert sand and machine—Made sand concrete. China Civ. Eng. J. 2022, 55, 23–30. [Google Scholar]

- Sharma, R.; Senthil, K. Influence of manufactured sand, recycled aggregate, reinforcement ratio and wire mesh on the response of reinforced concrete slabs under impact loading. Constr. Build. Mater. 2024, 440, 137275. [Google Scholar] [CrossRef]

- Zou, Y.; Shen, X.; Zuo, X.; Xue, H.; Li, G. Experimental study on microstructure evolution of aeolian sand concrete under the coupling freeze–thaw cycles and carbonation. Eur. J. Environ. Civ. Eng. 2020, 26, 1267–1282. [Google Scholar] [CrossRef]

- Yang, H.; Jiao, Y.; Xing, J.; Liu, Z. Statistical model and fracture behavior of manufactured sand concrete with varying replacement rates and stone powder contents. J. Build. Eng. 2024, 95, 110102. [Google Scholar] [CrossRef]

- Dong, W.; Wang, X.S.; Ji, Y.J. Damage and deterioration mechanism and life prediction of aeolian sand concrete under carbonation salt freezing action. J. Build. Mater. 2023, 4, 20220188. [Google Scholar] [CrossRef]

- Lin, P.Z.; Wang, Z.Y. Study on durability of concrete bridge under chloride ion erosion in saline-alkali soil. Bridge Constr. 2022, 52, 73–78. [Google Scholar]

- Yu, Z.; Zhang, H.; Bao, J.; Zhang, P.; Ding, Y.; Chen, X.; Qin, L.; Sun, J.; Song, Q. Coupled effects of the freeze-thaw cycles and salt erosion on the performance of recycled aggregate concrete. J. Build. Eng. 2024, 95, 110212. [Google Scholar] [CrossRef]

- Su, L.; Niu, D.; Huang, D.; Luo, Y.; Qiao, H.; Zhang, Y. Chloride diffusion behavior and microstructure of basalt-polypropylene hybrid fiber reinforced concrete in salt spray environment. Constr. Build. Mater. 2022, 324, 126716. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, W.; Meng, Y.; Li, H. Deterioration of sea sand roller compacted concrete used in island reef airport runway under salt spray. Constr. Build. Mater. 2022, 322, 126523. [Google Scholar] [CrossRef]

- Xie, J.; Yang, Y.T.; Cheng, Y.H. Experimental study on bonding performance of UHPC-NC interface under chloride environment. J. Tianjin Univ. 2024, 57, 11–20. [Google Scholar]

- Hasan, T.M.; Allena, S.; Gilbert, L. Rapid chloride penetration test: An evaluation of corrosion resistance in ultra-high performance concrete. J. Build. Eng. 2024, 82, 108317. [Google Scholar] [CrossRef]

- Azar, P.; Samson, G.; Deby, F.; Trincal, V.; Lahalle, H.; Benavent, V.; Cyr, M. Transfer properties and chloride-induced corrosion resistance of GGBS and metakaolin alkali-activated materials. Cem. Concr. Compos. 2023, 142, 105182. [Google Scholar] [CrossRef]

- Wu, W.J.; Wang, N.; Zhu, C.Q. The effect of salt spray on the properties of coral aggregate concrete structures and its mechanism. J. Build. Mater. 2018, 21, 600–607. [Google Scholar]

- Xu, J.; Li, T.; Zhan, M.; Chen, X.; Xu, F.; Wang, S. Study on Erosion Characteristics and Mechanisms of Recycled Concrete with Tailings in Salt Spray Environments. Buildings 2022, 12, 446. [Google Scholar] [CrossRef]

- Li, L.; Ding, S.J.; Li, J.P. Chloride ion erosion experiment of concrete members under different environmental conditions. J. Harbin Inst. Technol. 2016, 48, 28–33. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2009.

- GB/T 50081-2019; Standard for Test Methods of Physical and Mechanical Properties of Concrete. China Construction Industry Press: Beijing, China, 2019.

- Jin, W.L.; Zhang, Y.; Lun, Z.Y. Mechanism and mathematic modeling of chloride permeation in concrete under unsaturated state. J. Chin. Ceram. Soc. 2008, 36, 8. [Google Scholar] [CrossRef]

- Shi, P.; Xiao, L.; Mei, G.; Wei, Y.; Zong, Y. Investigation of the chloride ion transport mechanism in unsaturated concrete considering the nonlinear seepage effect. Constr. Build. Mater. 2024, 418, 135383. [Google Scholar] [CrossRef]

- Jain, S.; Pradhan, B. Effect of cement type on hydration, microstructure and thermo-gravimetric behaviour of chloride admixed self-compacting concrete. Constr. Build. Mater. 2019, 212, 304–316. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Li, Y.G. Thermal analysis curves and characteristics of hydration products of silicate. J. Chongqing Jianzhu Univ. 1999, 21, 68–72. [Google Scholar] [CrossRef]

- Luo, D.M.; Zhou, M.; Li, F. Study on Chloride Transportation in Coral Aggregate Concrete Due to Wick Action. J. Build. Mater. 2023, 26, 1173–1182+1206. [Google Scholar] [CrossRef]

- Trancone, G.; Policastro, G.; Spasiano, D.; Race, M.; Parrino, F.; Fratino, U.; Fabbricino, M.; Pirozzi, F. Treatment of concrete waste from construction and demolition activities: Application of organic acids from continuous dark fermentation in moving bed biofilm reactors. Chem. Eng. J. 2025, 505, 159536. [Google Scholar] [CrossRef]

- Zhong, X.; Bi, J.; Zhao, Y.; Wang, C.; Zhang, Y. Research on the capillary absorption capacity of concrete of different particle sizes after high temperature based on nuclear magnetic resonance technology. J. Build. Eng. 2024, 95, 110064. [Google Scholar] [CrossRef]

- Elsayed, M.; Isah, A.; Hiba, M.; Hassan, A.; Al-Garadi, K.; Mahmoud, M.; El-Husseiny, A.; Radwan, A.E. A review on the applications of nuclear magnetic resonance (NMR) in the oil and gas industry: Laboratory and field-scale measurements. J. Pet. Explor. Prod. Technol. 2022, 12, 2747–2784. [Google Scholar] [CrossRef]

- Wang, Q.; Hu, Q.; Zhao, C.; Zhang, C.; Ilavsky, J.; Yu, L.; Ma, C.; Cheng, H.; Li, X.; Zhang, Y.; et al. Integrated experimental studies of pore structure and fluid uptake in the Bossier Shale in eastern Texas, USA. Fuel 2025, 384, 133926. [Google Scholar] [CrossRef]

- Bowers, M.; Ehrlich, R.; Howard, J.; Kenyon, W. Determination of porosity types from NMR data and their relationship to porosity types derived from thin section. J. Pet. Sci. Eng. 1995, 13, 1–14. [Google Scholar] [CrossRef]

- Huang, D.; Wang, X.; Li, X.; Su, L.; Tian, J. Advanced nuclear magnetic resonance technology analysis of hybrid fiber reinforced concrete for optimized pore structure and strength. Constr. Build. Mater. 2025, 467, 140383. [Google Scholar] [CrossRef]

- Huang, D.; Niu, D.; Su, L.; Liu, Y.; Guo, B.; Xia, Q.; Peng, G. Diffusion behavior of chloride in coral aggregate concrete in marine salt-spray environment. Constr. Build. Mater. 2022, 316, 125878. [Google Scholar] [CrossRef]

- Malathy, R.; Sentilkumar, S.R.R.; Prakash, A.R.; Das, B.B.; Chung, I.-M.; Kim, S.-H.; Prabakaran, M. Use of Industrial Silica Sand as a Fine Aggregate in Concrete—An Explorative Study. Buildings 2022, 12, 1273. [Google Scholar] [CrossRef]

- Dong, J.; Zong, Y.; Shang, X.; Chen, X.; Tu, Z.; Jiang, R.; Zhu, Z. Impact of Various Erosive Environments on the Durability of POM Fiber-Reinforced Ultra-High-Performance Concrete. Buildings 2024, 14, 4048. [Google Scholar] [CrossRef]

| Mix Ratio/(kg/m3) | Compressive Strength/(MPa) | |||||||

|---|---|---|---|---|---|---|---|---|

| Water | Cement | Fly Ash | Water-Reducing Agent | Aeolian Sand | Basalt Sand | Stone | 7 d | 28 d |

| 165.00 | 290.90 | 72.70 | 0.12 | 356.51 | 356.51 | 1163.30 | 32.26 | 44.19 |

| Classify | C-S-H/% | Ca(OH)2/% | Friedel Salt/% | CaCO3/% |

|---|---|---|---|---|

| Initial | 2.301 | 1.552 | 0.000 | 2.076 |

| Liquid | 1.591 | 0.686 | 1.941 | 2.959 |

| Gas | 0.284 | 0 | 0 | 3.947 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Yao, Z.; Gao, M.; Wang, H. The Effect of Chloride Ions Morphology on the Properties of Concrete Under Dry and Wet Conditions. Sustainability 2025, 17, 2884. https://doi.org/10.3390/su17072884

Zhang M, Yao Z, Gao M, Wang H. The Effect of Chloride Ions Morphology on the Properties of Concrete Under Dry and Wet Conditions. Sustainability. 2025; 17(7):2884. https://doi.org/10.3390/su17072884

Chicago/Turabian StyleZhang, Minhang, Zhanquan Yao, Meng Gao, and Hailong Wang. 2025. "The Effect of Chloride Ions Morphology on the Properties of Concrete Under Dry and Wet Conditions" Sustainability 17, no. 7: 2884. https://doi.org/10.3390/su17072884

APA StyleZhang, M., Yao, Z., Gao, M., & Wang, H. (2025). The Effect of Chloride Ions Morphology on the Properties of Concrete Under Dry and Wet Conditions. Sustainability, 17(7), 2884. https://doi.org/10.3390/su17072884