Integrating Building Information Modeling and Life Cycle Assessment to Enhance the Decisions Related to Selecting Construction Methods at the Conceptual Design Stage of Buildings

Abstract

1. Introduction

2. Literature Review

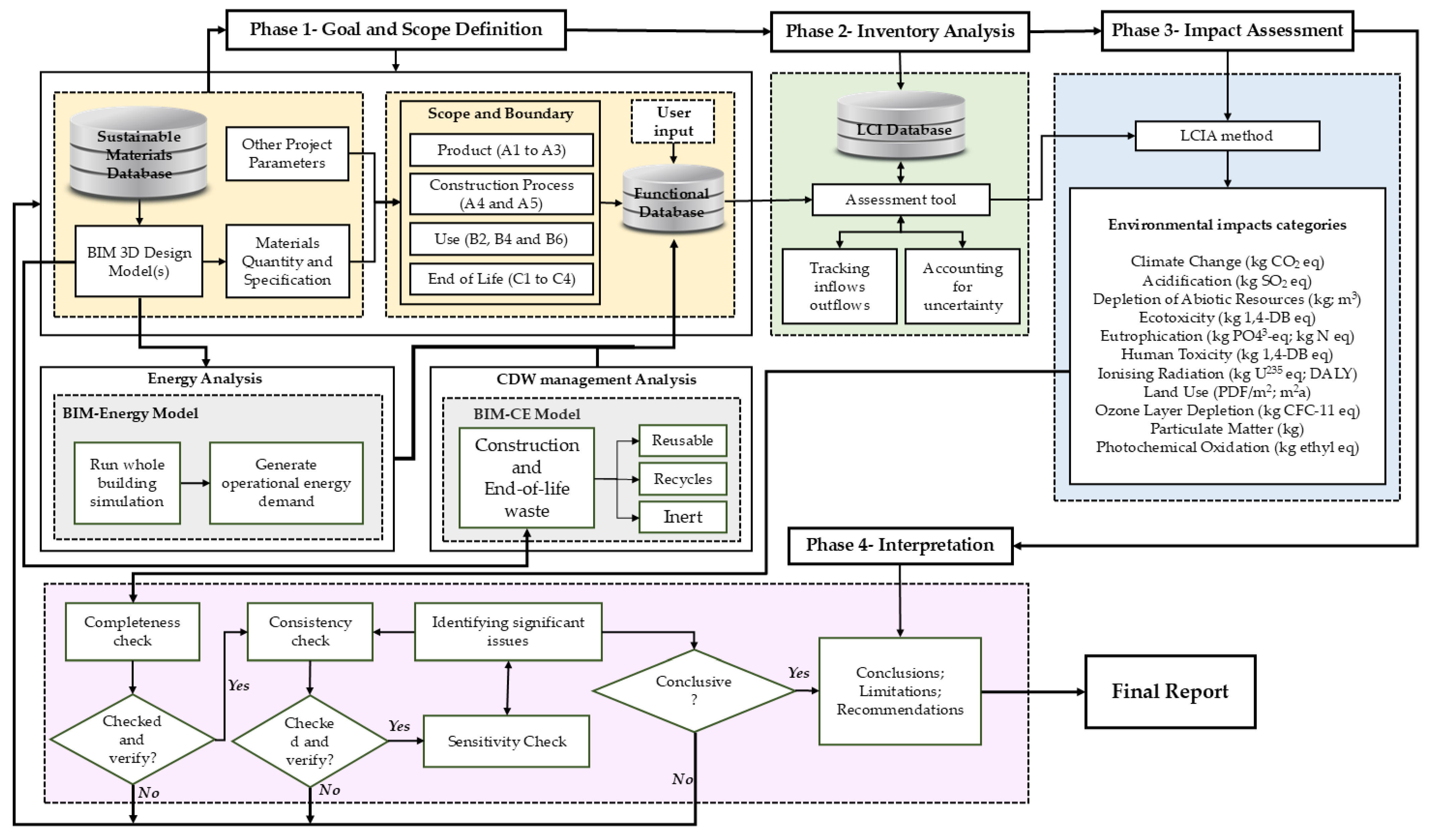

3. Development Methodology

3.1. Phase 1—Define the Study’s Goal and Scope

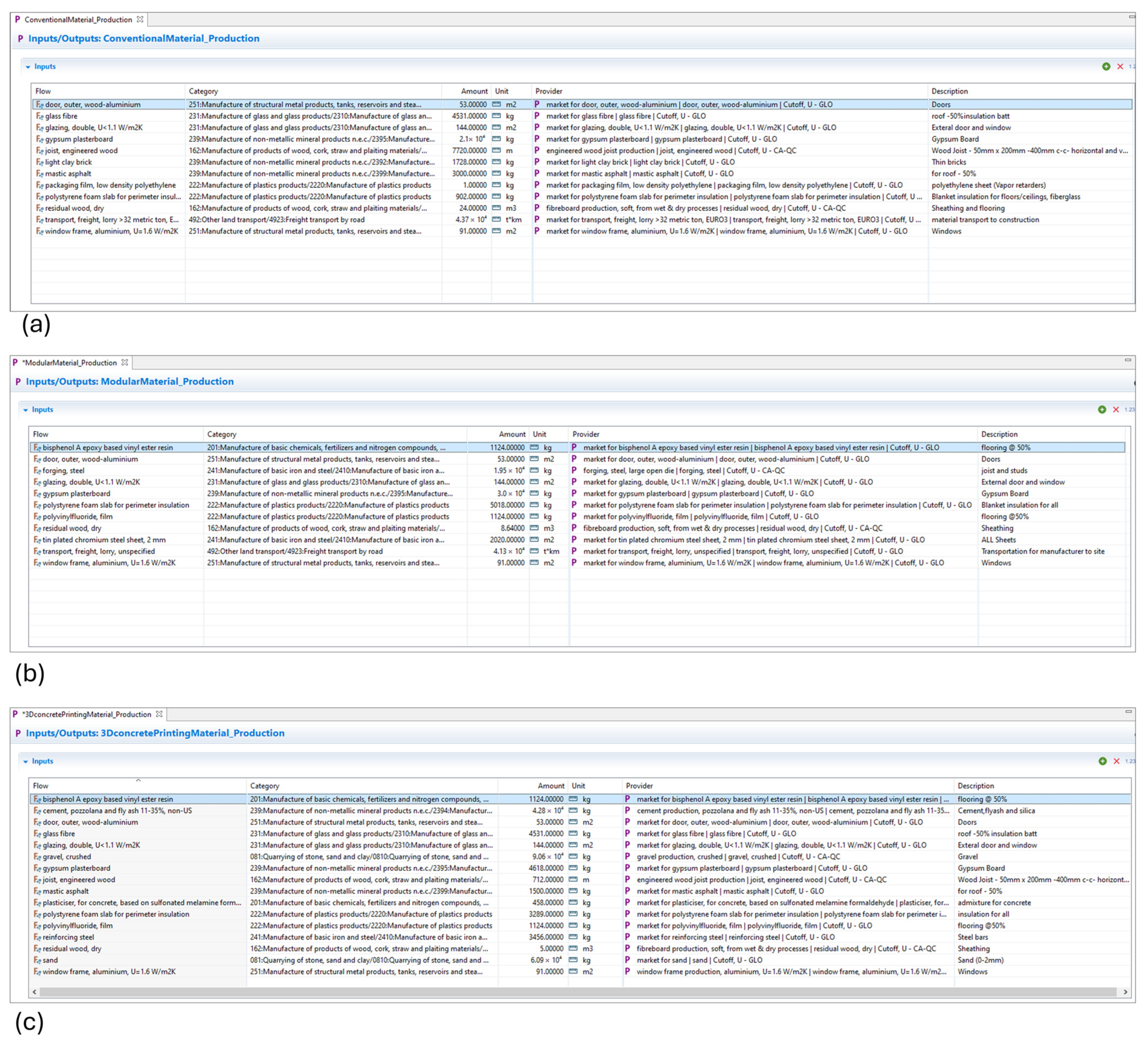

3.2. Phase 2—Data Extraction and Integration

3.3. Phase 3—Impact Assessment and Calculation

3.4. Phase 4—Interpretation

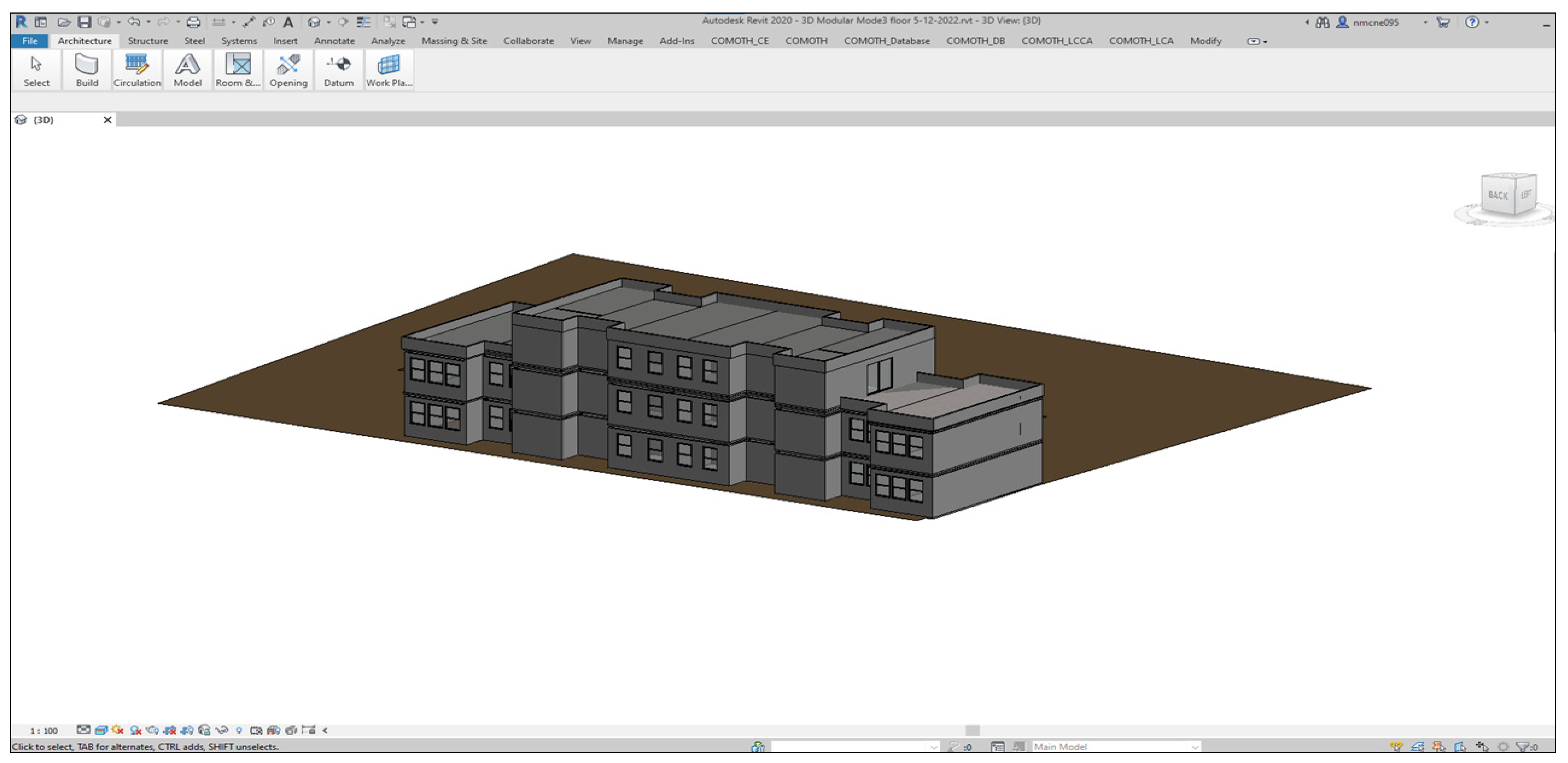

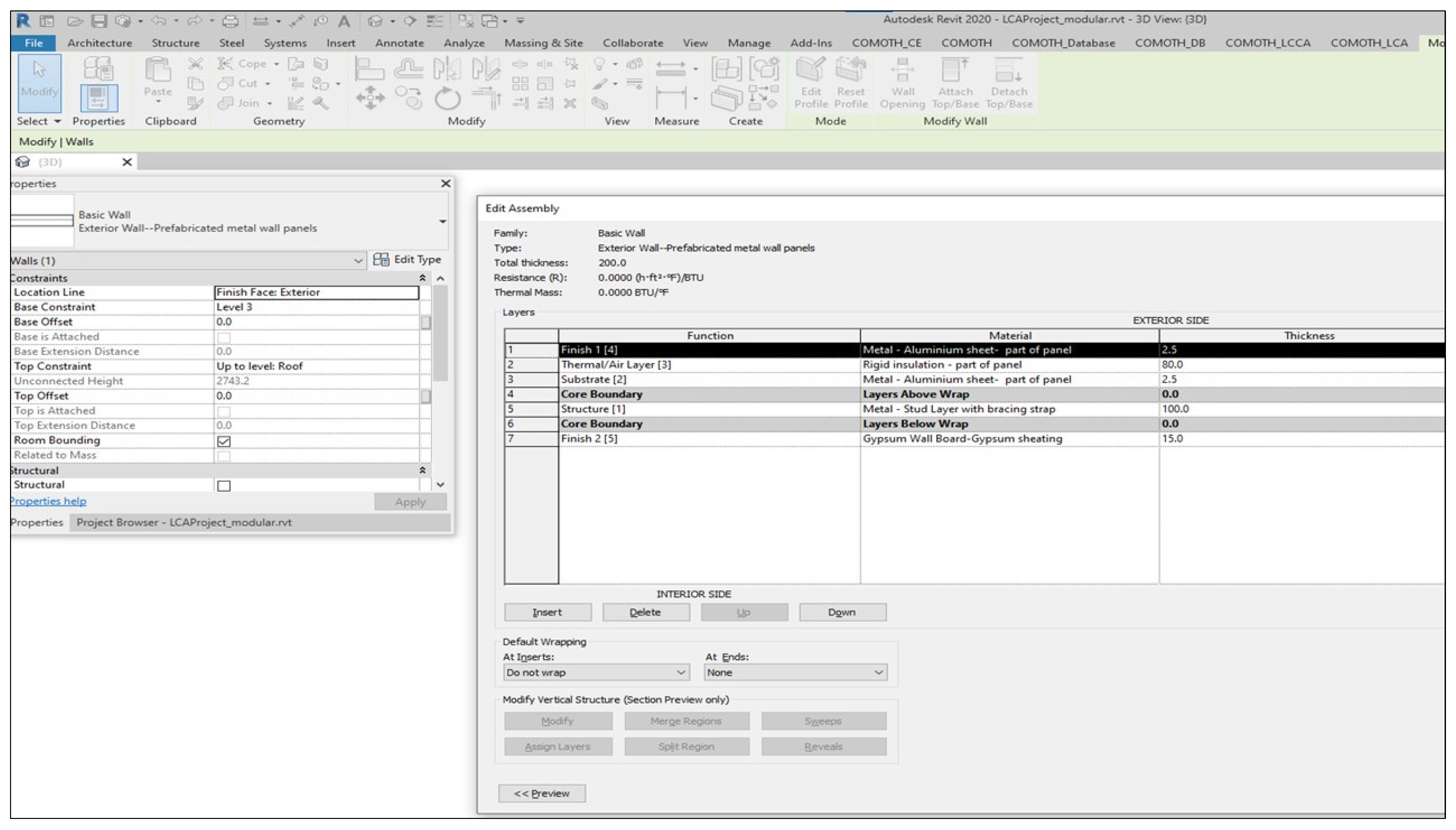

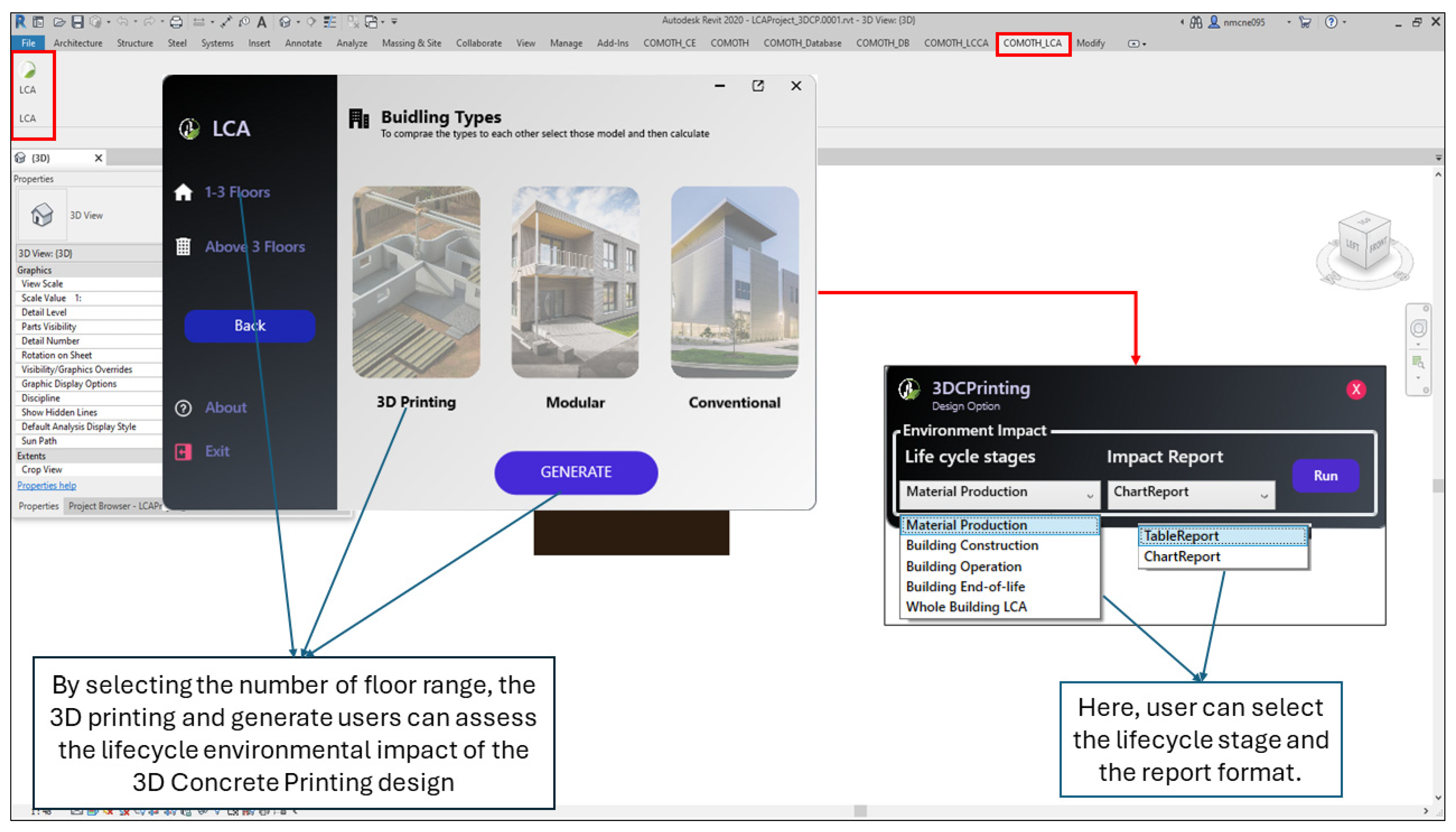

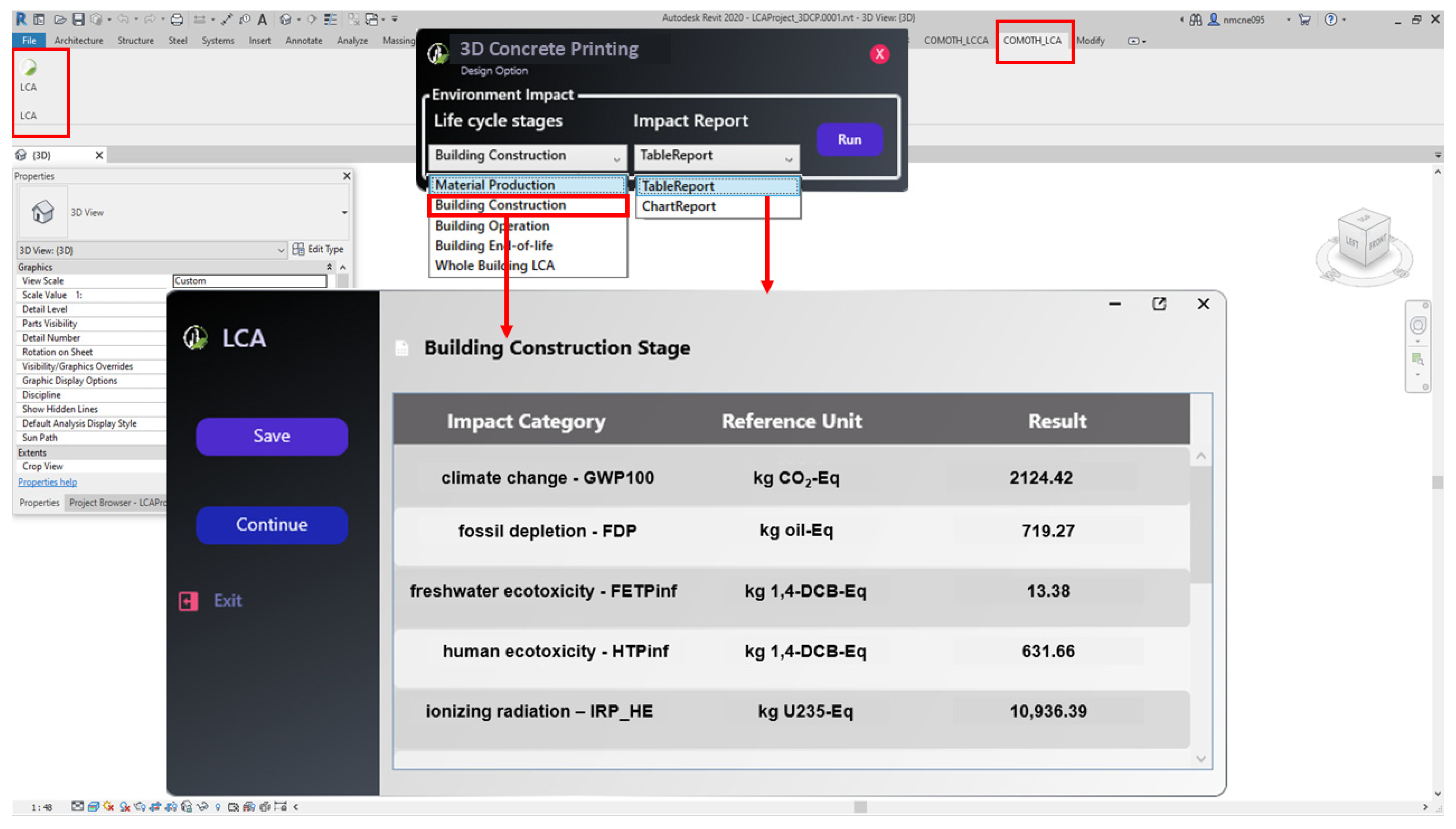

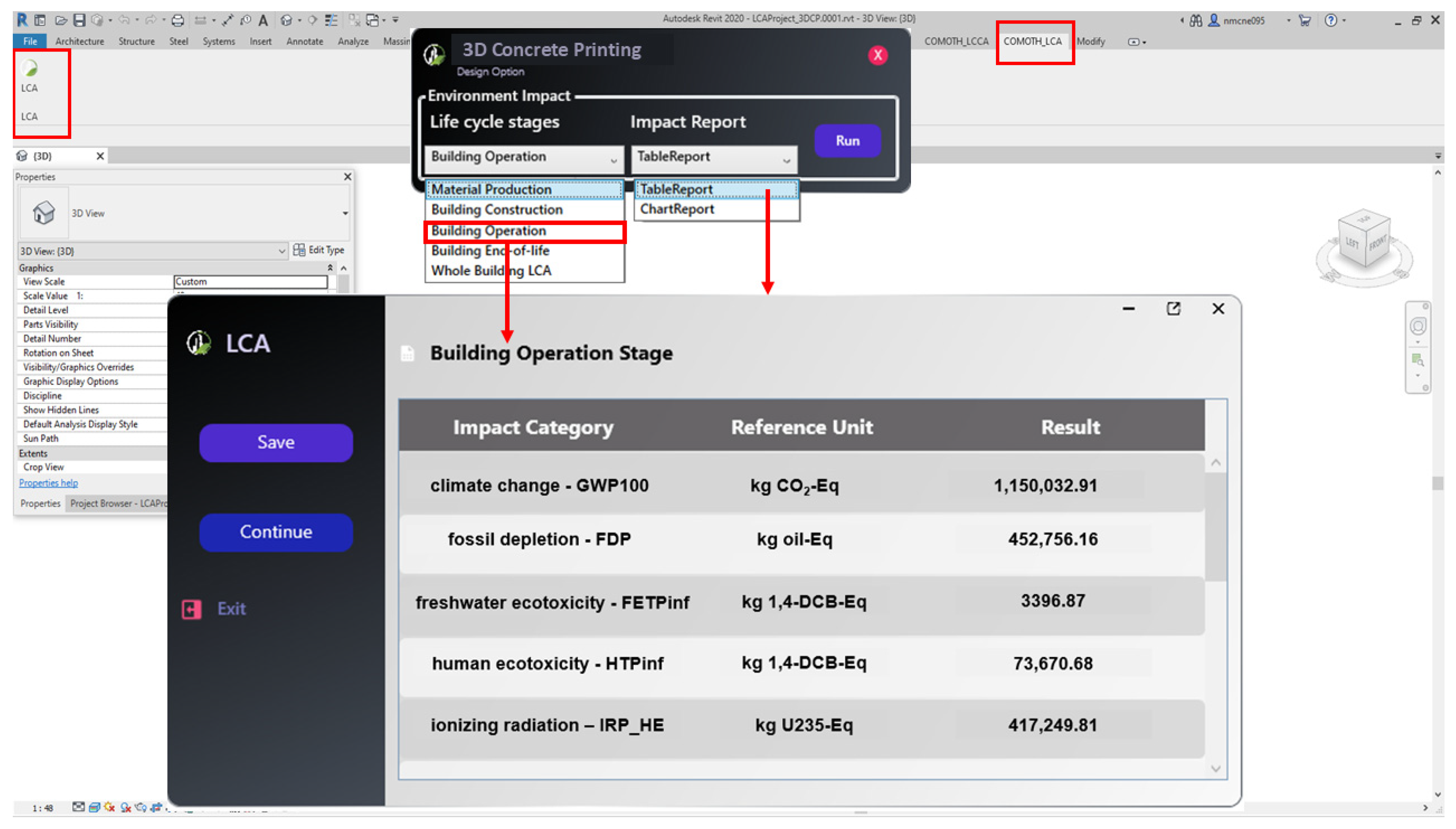

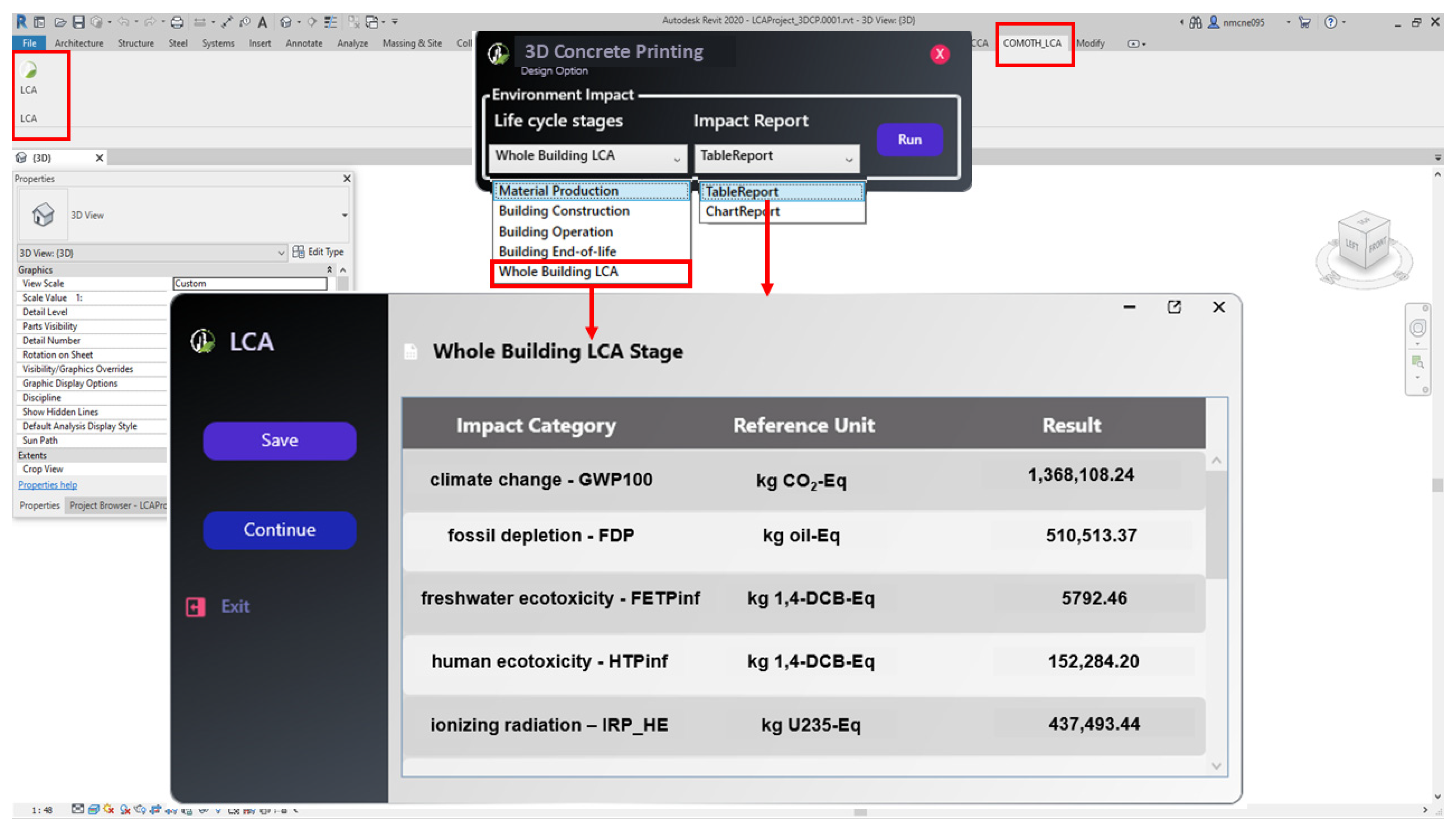

4. Model’s Development

5. Model Testing and Validation

6. Discussion

6.1. Model Evaluation and Comparative Analysis

6.2. Evaluation of the Life Cycle Impact Results Across the Different Construction Methods

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations, Department of Economic and Social Affairs, Population Division. World Population Prospects 2022; United Nations: New York, NY, USA, 2022; Available online: https://population.un.org/wpp/ (accessed on 29 September 2024).

- Antón, L.Á.; Díaz, J. Integration of life cycle assessment in a BIM environment. Procedia Eng. 2014, 85, 26–32. [Google Scholar] [CrossRef]

- Xue, K.; Hossain, M.U.; Liu, M.; Ma, M.; Zhang, Y.; Hu, M.; Chen, X.; Cao, G. BIM Integrated LCA for Promoting Circular Economy towards Sustainable Construction: An Analytical Review. Sustainability 2021, 13, 1310. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. 2020. Available online: https://www.ren21.net/gsr-2020/chapters/chapter_01/chapter_01/ (accessed on 12 February 2025).

- National Institute of Building Sciences, “Sustainable”, Whole Building Design Guide (WBDG). Available online: https://www.wbdg.org/do/sustainable (accessed on 2 February 2024).

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar]

- Kibert, C.J. Sustainable Construction: Green Building Design and Delivery, 4th ed.; Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 8–12. [Google Scholar]

- Ayarkwa, J.; Opoku, D.G.J.; Antwi-Afari, P.; Li, R.Y.M. Sustainable building processes’ challenges and strategies: The relative important index approach. Clean. Eng. Technol. 2022, 7, 100455. [Google Scholar]

- Ding, G.K.C. Life cycle assessment (LCA) of sustainable building materials: An overview. In Eco-Efficient Construction and Building Materials Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Elsevier: Amsterdam, The Netherlands, 2013; pp. 38–62. [Google Scholar]

- Love, P.E.D. Influence of Project Type and Procurement Method on Rework Costs in Building Construction Projects. J. Constr. Eng. Manag. 2002, 128, 18–29. [Google Scholar]

- McNeil-Ayuk, N.; Jrade, A. An Integrated Building Information Modeling (BIM) and Circular Economy (CE) Model for the Management of Construction and Deconstruction Waste Based on Construction Methods. Open J. Civ. Eng. 2024, 14, 168–195. [Google Scholar]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2019, 245, 118861. [Google Scholar]

- McNeil-Ayuk, N.; Jrade, A. Integrating building Information Modeling (BIM), GIS, and Circular Economy (CE) for the construction and deconstruction waste based on construction methods at the conceptual design stage of buildings. In Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2024; pp. 343–356. [Google Scholar]

- WBDG. Off-Site and Modular Construction Explained. WBDG. Published 2016. Available online: https://www.wbdg.org/resources/site-and-modular-construction-explained (accessed on 22 January 2024).

- Chauhan, K.; Peltokorpi, A.; Lavikka, R.; Seppänen, O. The Monetary and Non-Monetary Impacts of Prefabrication on Construction: The Effects of Product Modularity. Buildings 2022, 12, 459. [Google Scholar] [CrossRef]

- Chourasia, A.; Singhal, S.; Manivannan. Prefabricated Volumetric Modular Construction: A Review on Current Systems, Challenges, and Future Prospects. Pract. Period. Struct. Des. Constr. 2023, 28, 03122009. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q. Developing critical success factors for integrating circular economy into modular construction projects in Hong Kong. Sustain. Prod. Consum. 2022, 29, 574–587. [Google Scholar]

- Batikha, M.; Jotangia, R.; Baaj, M.Y.; Mousleh, I. 3D concrete printing for sustainable and economical construction: A comparative study. Autom. Constr. 2022, 134, 104087. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Holt, C.; Edwards, L.; Keyte, L.; Moghaddam, F.; Townsend, B. Construction 3D Printing. In 3D Concrete Printing Technology; Sanjayan, J.G., Nematollahi, B., Nazari, A., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 349–370. [Google Scholar]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Najjar, M.K.; Figueiredo, K.; Evangelista, A.C.J.; Hammad, A.W.A.; Tam, V.W.Y.; Haddad, A. Life cycle assessment methodology integrated with BIM as a decision-making tool at early-stages of building design. Int. J. Constr. Manag. 2022, 22, 541–555. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of construction materials: Methodologies, applications and future directions for sustainable decision-making. Case Stud. Constr. Mater. 2023, 19, e02326. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Li, X.J.; Xie, W.J.; Xu, L.; Li, L.L.; Jim, C.Y.; Wei, T.B. Holistic life-cycle accounting of carbon emissions of prefabricated buildings using LCA and BIM. Energy Build. 2022, 266, 112136. [Google Scholar] [CrossRef]

- Ströbele, B.; Lützkendorf, T. Communicating environmental information: Rethinking options for construction products. Build. Res. Inf. 2019, 47, 681–696. [Google Scholar] [CrossRef]

- Röck, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. Build. Environ. 2018, 140, 153–161. [Google Scholar]

- Jalaei, F.; Jrade, A. Integrating building information modeling (BIM) and LEED system at the conceptual design stage of sustainable buildings. Sustain. Cities Soc. 2015, 18, 95–107. [Google Scholar]

- McNeil-Ayuk, N.; Jrade, A. Integrating Building Information Modeling (BIM) and sustainability indicators and criteria to select associated construction method at the conceptual design stage of buildings. In Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2022; Volume 247, pp. 71–82. [Google Scholar]

- Hossain, M.U.; Ng, S.T. Critical consideration of buildings’ environmental impact assessment towards adoption of circular economy: An analytical review. J. Clean. Prod. 2018, 205, 763–780. [Google Scholar]

- BIM and Digital Transformation in AEC. Retrieved from Autodesk Official Website. Available online: https://www.autodesk.com/ca-en/industry/architecture-engineering-construction (accessed on 15 November 2024).

- Azhar, S. Building Information Modeling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar]

- Obrecht, T.P.; Röck, M.; Hoxha, E.; Passer, A. BIM and LCA integration: A systematic literature review. Sustainability 2020, 12, 5534. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A.; Vaiciunas, J.; Seduikyte, L. Integration of Building Information Modelling (BIM) and Life Cycle Assessment (LCA) for sustainable constructions. J. Sustain. Archit. Civ. Eng. 2016, 13, 28–38. [Google Scholar] [CrossRef][Green Version]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 175–227. [Google Scholar]

- Tam, V.W.; Zhou, Y.; Illankoon, C.; Le, K.N. A critical review on BIM and LCA integration using the ISO 14040 framework. Build. Environ. 2022, 213, 108865. [Google Scholar]

- Ecoinvent—Data with Purpose. Published 2024. Available online: https://ecoinvent.org/ (accessed on 6 July 2024).

- Golsteijn, L. Life Cycle Assessment (LCA) Explained. PRé Sustainability. Available online: https://pre-sustainability.com/about/our-team/#consultancy (accessed on 18 November 2024).

- Carlisle, S. Getting Beyond Energy: Environmental Impacts, Building Materials, and Climate Change. In Embodied Energy and Design: Making Architecture Between Metrics and Narratives; Columbia University Press: New York, NY, USA, 2017; pp. 165–177. [Google Scholar]

- Dervishaj, A.; Gudmundsson, K. From LCA to circular design: A comparative study of digital tools for the built environment. Resour. Conserv. Recycl. 2024, 200, 107291. [Google Scholar] [CrossRef]

- Felicioni, L.; Gaspari, J.; Veselka, J.; Malík, Z. A comparative cradle-to-grave life cycle approach for addressing construction design choices: An applicative case study for a residential tower in Aalborg, Denmark. Energy Build. 2023, 298, 113557. [Google Scholar]

- Moltesen, A.; Bjørn, A. LCA and Sustainability. In Life Cycle Assessment-Theory and Practice; Springer eBooks; Springer: Berlin/Heidelberg, Germany, 2017; pp. 43–55. [Google Scholar]

- Laurent, A.; Weidema, B.P.; Bare, J.; Liao, X.; de Souza, D.M.; Pizzol, M.; Sala, S.; Schreiber, H.; Thonemann, N.; Verones, F. Methodological review and detailed guidance for the life cycle interpretation phase. J. Ind. Ecol. 2020, 24, 986–1003. [Google Scholar]

- Najjar, M.; Figueiredo, K.; Palumbo, M.; Haddad, A. Integration of BIM and LCA: Evaluating the environmental impacts of building materials at an early stage of designing a typical office building. J. Build. Eng. 2017, 14, 115–126. [Google Scholar] [CrossRef]

- Jayathissa, P.; Jansen, M.; Heeren, N.; Nagy, Z.; Schlueter, A. Life cycle assessment of dynamic building integrated photovoltaics. Sol. Energy Mater. Sol. Cells 2016, 156, 75–82. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Embodied carbon mitigation and reduction in the built environment—What does the evidence say? J. Environ. Manag. 2016, 181, 687–700. [Google Scholar] [CrossRef]

- Royal Institution of Chartered Surveyors (RICS), Whole Life Carbon Assessment for the Built Environment: Professional Standard, Global. 2024. Available online: https://www.rics.org/content/dam/ricsglobal/documents/standards/Whole_life_carbon_assessment (accessed on 12 December 2024).

- Carbon Leadership Forum. 3—Building LCA 101: Embodied Carbon Accounting. Available online: https://carbonleadershipforum.org/building-lca-101/ (accessed on 20 December 2024).

- European Commission. International Reference Life Cycle Data System (ILCD) Handbook: General Guide for Life Cycle Assessment—Detailed Guidance; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- Ellen MacArthur Foundation. Designing Buildings for Adaptable Use, Durability, and Positive Impact; Ellen MacArthur Foundation: Cowes, UK, 2019. [Google Scholar]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Klöpffer, W.; Grahl, B. Life Cycle Assessment (LCA): A Guide to Best Practice; Wiley-VCH: Weinheim, Germany, 2014. [Google Scholar]

- Sameer, H.; Bringezu, S. Building information modelling application of material, water, and climate footprint analysis. Build. Res. Inf. 2021, 49, 593–612. [Google Scholar] [CrossRef]

- Bueno, C.; Fabricio, M.M. Comparative analysis between a complete LCA study and results from a BIM-LCA plug-in. Autom. Constr. 2018, 90, 188–200. [Google Scholar] [CrossRef]

- Simonen, K. Life Cycle Assessment, 1st ed.; Routledge: London, UK, 2014. [Google Scholar]

- Gantner, J.; Wittstock, B.; Lenz, K.; Fischer, M.; Sedlbauer, K.; Anderson, J.; Braune, A. EeBGuide Guidance Document Part B: Buildings. Operational Guidance for Life Cycle Assessment Studies of the Energy-Efficient Buildings Initative; Fraunhofer Institut für Bauphysik: Stuttgart, Germany, 2015. [Google Scholar]

- Curran, M.A. Life Cycle Assessment: A review of the methodology and its application to sustainability. Curr. Opin. Chem. Eng. 2013, 3, 273–277. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of bim-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- McNeil-Ayuk, N. COMOTH: A BIM- Sustainability Integrated Model to Select Associated Construction Methods at the Conceptual Design Stage of Buildings. Ph.D. Thesis, University of Ottawa, Ottawa, ON, Canada, 2024. Available online: https://ruor.uottawa.ca/bitstreams/e3abdd5c-eecb-4d59-9114-bbf9c4a9a8cf/download (accessed on 12 December 2024).

- Peuportier, B.; Scarpellini, S.; Glaumann, M.; Malmqvist, T.; Krigsvoll, G.; Wetzel, C.; Staller, H.; Szalay, Z.; Degiovanni, V.; Stoykova, E. State of the Art for Use of LCA in Building Sector: Deliverable D2 of the Project ENSLIC_BUILDING: Energy Saving Through Promotion of Life Cycle Assessment in Buildings. 2009. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-61118 (accessed on 12 December 2024).

- Li, Q.; Yang, W.; Kohler, N.; Yang, L.; Li, J.; Sun, Z.; Yu, H.; Liu, L.; Ren, J. A BIM–LCA Approach for the Whole Design Process of Green Buildings in the Chinese Context. Sustainability 2023, 15, 3629. [Google Scholar] [CrossRef]

- Tsikos, M.; Negendahl, K. Sustainable Design with Respect to LCA Using Parametric Design and BIM Tools Sustainable Design with Respect to LCA Using Parametric Design and BIM Tools. In Proceedings of the World Sustainable Built Environment Conference 2017, Hong Kong, China, 5–7 June 2017; pp. 1–9. [Google Scholar]

- Jalaei, F.; Jrade, A. An Automated BIM Model to Conceptually Design, Analyze, Simulate, and Assess Sustainable Building Projects. J. Constr. Eng. 2014, 73, 523–541. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Ceranic BGallanagh, M.; Kadiri, K.O. Lifecycle Environmental Performance of Materials Specifications: A BIM enhanced comparative assessment. Int. J. Sustain. Build. Technol. Urban Dev. 2015, 6, 14–24. [Google Scholar] [CrossRef]

- Kulahcioglu, T.; Dang, J.; Toklu, C. A 3D analyzer for BIM-enabled Life Cycle Assessment of the whole process of construction. HVAC&R Res. 2012, 18, 283–293. [Google Scholar]

- Kreiner, H.; Passer, A.; Wallbaum, H. A new systemic approach to improve the sustainability performance of office buildings in the early design stage. Energy Build. 2015, 109, 385–396. [Google Scholar] [CrossRef]

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar]

- Jayasinghe, L.B.; Waldmann, D. Development of a bim-based web tool as a material and component bank for a sustainable construction industry. Sustainability 2020, 12, 1766. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar]

- Acero, A.P.; Rodríguez, C.; Ciroth, A. LCIA methods: Impact assessment methods in life cycle assessment and their impact categories. GreenDelta 2015, 1–23. [Google Scholar]

- Meex, E.; Hollberg, A.; Knapen, E.; Hildebrand, L.; Verbeeck, G. Requirements for applying LCA-based environmental impact assessment tools in the early stages of building design. Build. Environ. 2018, 133, 228–236. [Google Scholar]

- EN 15978; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. British Standards Institution (BSI): Milton Keynes, UK, 2016.

- BS 5950-1:2000; The Standard for Structural Use of Steelwork in Building—Code of Practice for Design. Rolled and Welded Sections. British Standards Institution (BSI): Milton Keynes, UK, 2000.

- Canadian Institute of Steel Construction. CISC Code of Standard Practice for Structural Steel, 8th ed.; CISC: Markham, ON, Canada, 2016. [Google Scholar]

- Shrestha, P.; Speake, A.; Horowitz, S. Heating and Cooling Energy Modeling of 3D-Printed Concrete Construction of Residential Buildings; National Renewable Energy Laboratory: Applewood, CO, USA, 2022. Available online: https://www.nrel.gov/docs/fy22osti/82865.pdf (accessed on 15 June 2024).

- Xu, J.; Teng, Y.; Pan, W.; Zhang, Y. BIM-integrated LCA to automate embodied carbon assessment of prefabricated buildings. J. Clean. Prod. 2022, 374, 133894. [Google Scholar]

- Tam, V.W.; Zhou, Y.; Shen, L.; Le, K.N. Optimal BIM and LCA integration approach for embodied environmental impact assessment. J. Clean. Prod. 2023, 385, 135605. [Google Scholar]

| Impact Category Group | Name of the Impact | Hierarchist (H) * |

|---|---|---|

| Acidification | Terrestrial acidification | TAP100 EQ-H |

| Climate change | Climate change | GWP100 HH-H GWP100 EQ-H |

| Depletion of abiotic resources | Metal depletion Fossil depletion | MDP100 RD-H FDP100 RD-H |

| Ecotoxicity | Freshwater ecotoxicity Marine ecotoxicity Terrestrial ecotoxicity | FETP100 EQ-H METP100 EQ-H TETP100 EQ-H |

| Eutrophication | Freshwater | FEP100 EQ-H |

| Human toxicity | Human toxicity | HTP100 HH-H |

| Ionizing radiation | Ionizing radiation | IRP100 HH-H |

| Land use | Agricultural land occupation Urban land occupation Natural land transformation | ALOP100 EQ-H ULOP100 EQ-H LTP100 EQ-H |

| Ozone layer depletion | Ozone depletion | ODP100 HH-H |

| Particulate matter | Particulate matter formation | PMFP100 HH-H |

| Photochemical oxidation | Photochemical oxidant formation | POFP100 HH-H |

| Family Category | QTOs (m2) | Conventional Construction | Modular Construction | 3D Concrete Printing | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Thickness (mm) | U-Value (W/m2 K) | Material | Thickness (mm) | U-Value (W/m2 K) | Material | Thickness (mm) | U-Value (W/m2 K) | ||

| FLOOR | 576 | Wood flooring Floor tiles Sheathing—OSB Batt insulation Wood joist/rafter | 15 15 50 50 | 0.448 | Steel joist floor Vinyl composite tile Wood—sheathing Rigid insulation Steel bar joist layer Wood—sheathing | 15 15 50 100 15 | 0.328 | Precast concrete floor slabs Floor finish tile Precast slab | 15 100 | 0.338 |

| WALL | 540 | Brick veneer wall on wood Brick veneer Wall sheathing—OSB Air gap Wall insulation Wood—stud Gypsum board | 20 15 10 100 100 12 | 0.341 | Sandwich panel on mtl. stud Metal panel Rigid insulation Stud layers Metal panel Gypsum board | 2.5 80 100 2.5 12 | 0.268 | 3DC printing exterior wall Printed concrete (inner layer) Insulation—spray form Printed concrete (outer layer) | 50 50 50 | 0.361 |

| 751 | Interior wall Gypsum, board Wood—stud layer fiberglass batt Gypsum, board | 12 50 20 12 | 0.250 | Modular sandwich panels Gypsum wall board Metal stud layer Semirigid insulation Gypsum board | 12 25 25 12 | 0.227 | 3DC printing interior wall Printed concrete Insulation—spray form Printed concrete | 25 25 25 | 0.181 | |

| ROOF | 200 | Asphalt shingle on wood rafters Rigid insulation Wood joist/rafter Sheathing—OSB Water/vapor barrier Asphalt shingle | 100 50 15 6 3 | 0.213 | Steel truss on metal standing seam Metal—Sheeting Rigid insulation Steel structure Vapor barriers Metal seam | 6 100 25 10 25 | 0.370 | Asphalt shingle on wood rafters Rigid insulation Wood joist/rafter Sheathing—OSB Water/vapor barrier Asphalt shingle | 100 50 15 6 3 | 0.213 |

| Impact Category | Reference Unit | 3DCPrinting | Conventional Construction | Modular Construction |

|---|---|---|---|---|

| climate change—GWP100 | kg CO2-Eq | 210,160.47 | 136,965.92 | 374,750.32 |

| fossil depletion—FDP | kg oil-Eq | 54,765.60 | 38,489.79 | 106,749.04 |

| freshwater ecotoxicity—FETPinf | kg 1,4-DCB-Eq | 2360.37 | 1641.23 | 15,545.78 |

| human toxicity—HTPinf | kg 1,4-DCB-Eq | 76,208.03 | 62,810.39 | 169,141.51 |

| ionizing radiation—IRP_HE | kg U235-Eq | 8846.69 | 6523.82 | 19,542.24 |

| marine eutrophication—MEP | kg N-Eq | 201.51 | 164.77 | 383.33 |

| metal depletion—MDP | kg Fe-Eq | 25,808.55 | 5863.36 | 426,604.03 |

| ozone depletion—ODPinf | kg CFC-11-Eq | 0.01 | 0.01 | 0.02 |

| particulate matter formation—PMFP | kg PM10-Eq | 468.74 | 358.59 | 1330.11 |

| photochemical oxidant—POFP | kg NMVOC | 675.78 | 520.23 | 1297.19 |

| terrestrial acidification—TAP100 | kg SO2-Eq | 911.08 | 717.84 | 1802.38 |

| urban land occupation—ULOP | m2a | 3388.30 | 17,773.20 | 5284.88 |

| Impact Category | Reference Unit | 3DCPrinting | Conventional Construction | Modular Construction |

|---|---|---|---|---|

| climate change—GWP100 | kg CO2-Eq | 2124.41 | 1142.00 | 870.90 |

| fossil depletion—FDP | kg oil-Eq | 719.27 | 389.64 | 309.64 |

| freshwater ecotoxicity—FETPinf | kg 1,4-DCB-Eq | 13.38 | 6.52 | 36.78 |

| human toxicity—HTPinf | kg 1,4-DCB-Eq | 631.663 | 291.84 | 307.19 |

| ionizing radiation—IRP_HE | kg U235-Eq | 10,936.39 | 5473.10 | 3702.02 |

| marine eutrophication—MEP | kg N-Eq | 4.269 | 2.92 | 1.19 |

| metal depletion—MDP | kg Fe-Eq | 114.17 | 59.03 | 314.66 |

| ozone depletion—ODPinf | kg CFC-11-Eq | 0.00 | 0.00 | 0.00 |

| particulate matter formation—PMFP | kg PM10-Eq | 4.29 | 2.80 | 17.08 |

| photochemical oxidant—POFP | kg NMVOC | 11.89 | 8.29 | 6.11 |

| terrestrial acidification—TAP100 | kg SO2-Eq | 8.87 | 5.68 | 3.61 |

| urban land occupation—ULOP | m2a | 14.02 | 12.25 | 13.71 |

| Impact Category | Reference Unit | 3DCPrinting | Conventional Construction | Modular Construction |

|---|---|---|---|---|

| climate change—GWP100 | kg CO2-Eq | 1,150,032.91 | 1,130,020.31 | 1,084,769.99 |

| fossil depletion—FDP | kg oil-Eq | 452,756.16 | 444,596.45 | 426,979.33 |

| freshwater ecotoxicity—FETPinf | kg 1,4-DCB-Eq | 3396.87 | 3406.97 | 3197.07 |

| human toxicity—HTPinf | kg 1,4-DCB-Eq | 73,670.68 | 74,522.31 | 69,767.31 |

| ionizing radiation—IRP_HE | kg U235-Eq | 417,249.81 | 417,892.77 | 416,641.04 |

| marine eutrophication—MEP | kg N-Eq | 228.11 | 227.91 | 215.46 |

| metal depletion—MDP | kg Fe-Eq | 15,316.13 | 15,454.30 | 14,463.57 |

| ozone depletion—ODPinf | kg CFC-11-Eq | 0.14 | 0.14 | 0.14 |

| particulate matter formation—PMFP | kg PM10-Eq | 439.56 | 436.99 | 414.89 |

| photochemical oxidant—POFP | kg NMVOC | 1203.42 | 1186.43 | 1136.41 |

| terrestrial acidification—TAP100 | kg SO2-Eq | 1048.36 | 1039.54 | 990.36 |

| urban land occupation—ULOP | m2a | 1249.49 | 1244.54 | 1182.19 |

| Impact Category | Reference Unit | 3DCPrinting | Conventional | Modular |

|---|---|---|---|---|

| climate change—GWP100 | kg CO2-Eq | 5790.46 | 4204.42 | 4282.19 |

| fossil depletion—FDP | kg oil-Eq | 2272.35 | 805.45 | 1675.85 |

| freshwater ecotoxicity—FETPinf | kg 1,4-DCB-Eq | 21.84 | 13.17 | 15.85 |

| human toxicity—HTPinf | kg 1,4-DCB-Eq | 1773.83 | 1307.68 | 1269.97 |

| ionizing radiation—IRP_HE | kg U235-Eq | 460.56 | 167.93 | 338.46 |

| marine eutrophication—MEP | kg N-Eq | 11.65 | 4.39 | 9.06 |

| metal depletion—MDP | kg Fe-Eq | 175.80 | 107.13 | 130.68 |

| ozone depletion—ODPinf | kg CFC-11-Eq | 0.00 | 0.00 | 0.00 |

| particulate matter formation—PMFP | kg PM10-Eq | 14.41 | 5.40 | 10.94 |

| photochemical oxidant—POFP | kg NMVOC | 37.33 | 12.89 | 28.87 |

| terrestrial acidification—TAP100 | kg SO2-Eq | 25.19 | 8.97 | 19.25 |

| urban land occupation—ULOP | m2a | 526.60 | −151.41 | 374.29 |

| Impact Category | Reference Unit | 3DCPrinting | Conventional | Modular |

|---|---|---|---|---|

| climate change—GWP100 | kg CO2-Eq | 1,368,108.24 | 1,272,332.62 | 1,464,673.40 |

| fossil depletion—FDP | kg oil-Eq | 510,513.37 | 484,281.33 | 535,713.86 |

| freshwater ecotoxicity—FETPinf | kg 1,4-DCB-Eq | 5792.46 | 5067.89 | 18,795.48 |

| human toxicity—HTPinf | kg 1,4-DCB-Eq | 152,284.20 | 138,932.19 | 240,485.98 |

| ionizing radiation—IRP_HE | kg U235-Eq | 437,493.44 | 430,057.63 | 440,223.76 |

| marine eutrophication—MEP | kg N-Eq | 445.54 | 399.99 | 609.04 |

| metal depletion—MDP | kg Fe-Eq | 41,414.64 | 21,483.82 | 441,512.94 |

| ozone depletion—ODPinf | kg CFC-11-Eq | 0.15 | 0.15 | 0.16 |

| particulate matter formation—PMFP | kg PM10-Eq | 927.01 | 803.77 | 1773.02 |

| photochemical oxidant—POFP | kg NMVOC | 1928.42 | 1727.84 | 2468.58 |

| terrestrial acidification—TAP100 | kg SO2-Eq | 1993.50 | 1772.03 | 2815.60 |

| urban land occupation—ULOP | m2a | 5178.40 | 18,868.58 | 6855.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

McNeil-Ayuk, N.; Jrade, A. Integrating Building Information Modeling and Life Cycle Assessment to Enhance the Decisions Related to Selecting Construction Methods at the Conceptual Design Stage of Buildings. Sustainability 2025, 17, 2877. https://doi.org/10.3390/su17072877

McNeil-Ayuk N, Jrade A. Integrating Building Information Modeling and Life Cycle Assessment to Enhance the Decisions Related to Selecting Construction Methods at the Conceptual Design Stage of Buildings. Sustainability. 2025; 17(7):2877. https://doi.org/10.3390/su17072877

Chicago/Turabian StyleMcNeil-Ayuk, Nkechi, and Ahmad Jrade. 2025. "Integrating Building Information Modeling and Life Cycle Assessment to Enhance the Decisions Related to Selecting Construction Methods at the Conceptual Design Stage of Buildings" Sustainability 17, no. 7: 2877. https://doi.org/10.3390/su17072877

APA StyleMcNeil-Ayuk, N., & Jrade, A. (2025). Integrating Building Information Modeling and Life Cycle Assessment to Enhance the Decisions Related to Selecting Construction Methods at the Conceptual Design Stage of Buildings. Sustainability, 17(7), 2877. https://doi.org/10.3390/su17072877