Eco-Friendly Mining Practices: Field Test of Phosphogypsum Filling Based on Slag Powder in Dayukou Phosphate Mine

Abstract

1. Introduction

2. Problem Statement and Field Test Design

2.1. Engineering Background

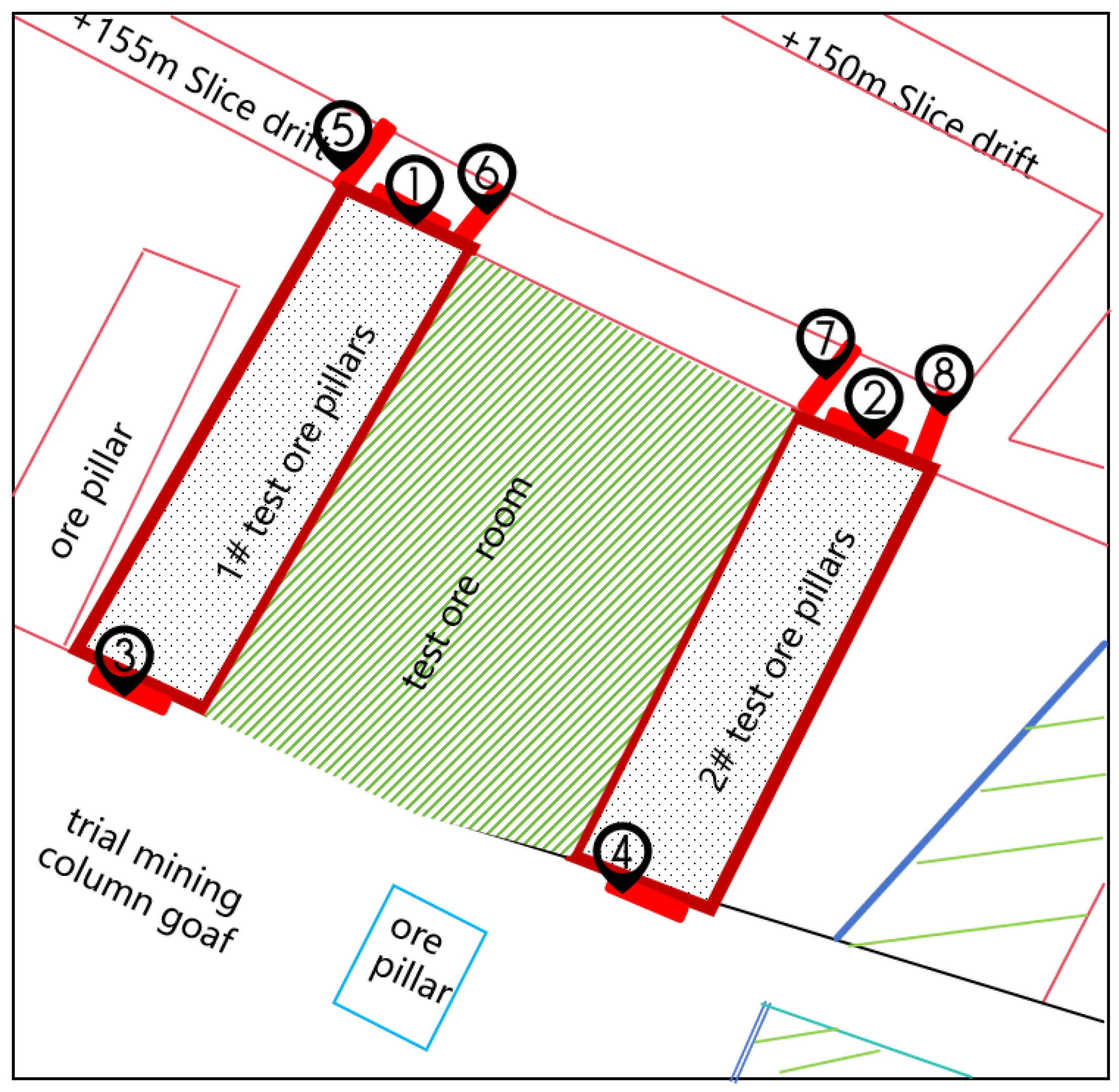

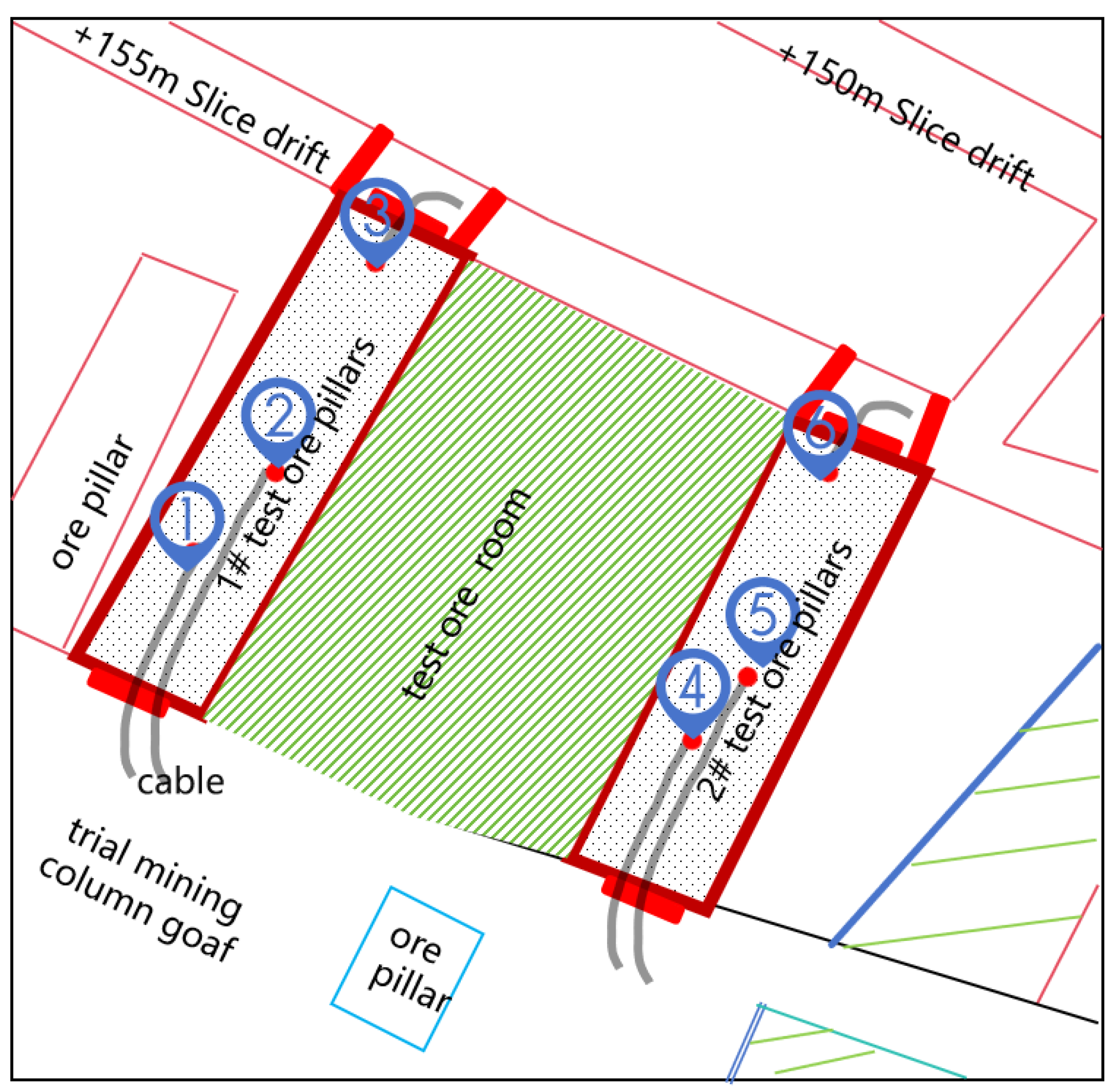

2.2. Field Test Design

2.2.1. Materials

2.2.2. Experimental Design

3. Field Test Results and Discuss

3.1. Backfilling Material Consumption

3.2. Backfilling Material Strength

3.3. Stress Variations

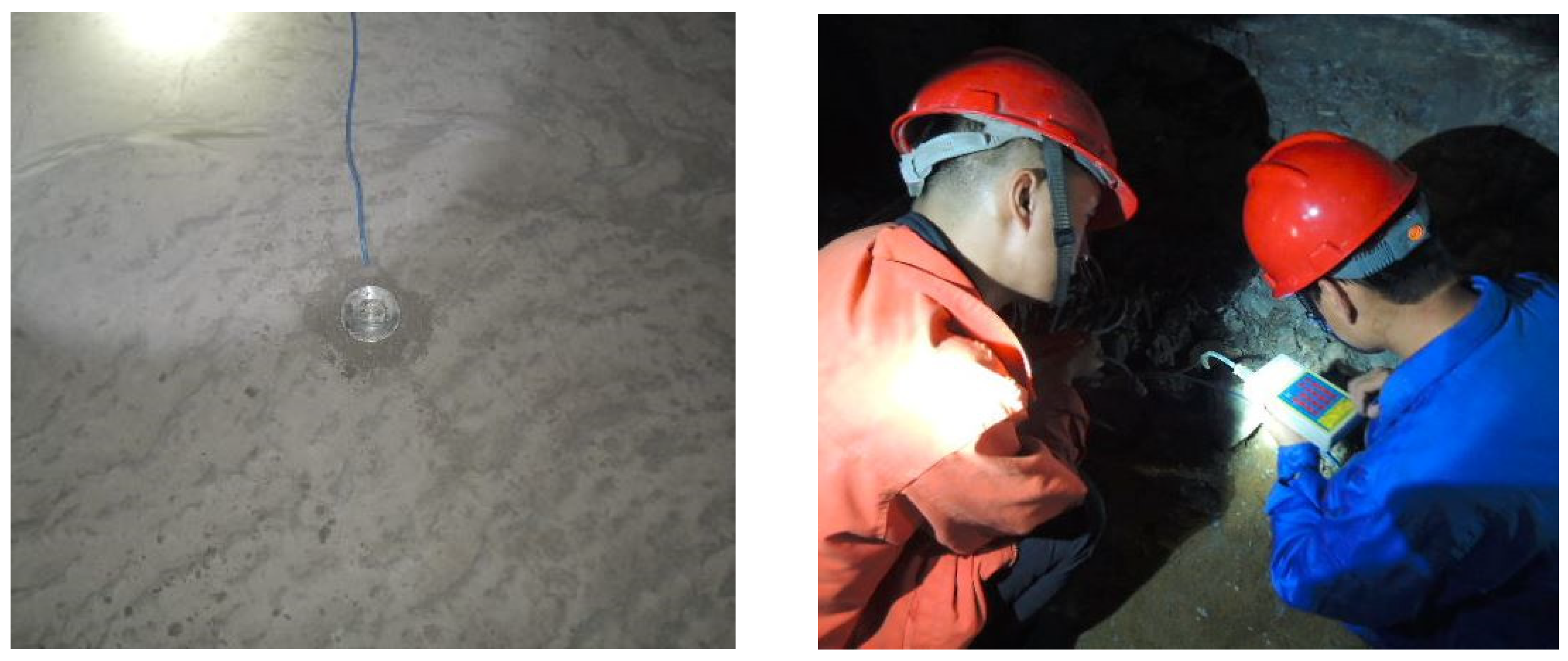

3.4. Backfill Permeability Analysis and Detection of Water Infiltration

4. Discussion

5. Conclusions

- (1)

- Both empty spaces in the two experimental mine columns have been completely filled through the self-flow transport of filling slurry, and the filling at the interface is in good condition. Phosphogypsum + cement + mine slag micro-powder is used for filling. The strength development at various stages of the filling body is normal, and the strength is relatively high. This filling method is reasonable and feasible.

- (2)

- Through monitoring the seepage and permeation water, the concentrations of major elements such as Cu, Zn, Mn, Pb, Cd, and Hg in the water samples meet the industrial wastewater discharge standards. The fluoride content complies with the national standard of China and falls within the groundwater quality classification index standard Class III. According to the standard limit of 50 mg/L in the (GB5085.3-1996 [34]), it is within the safe range.

- (3)

- The pH value of the backfilling seepage and permeation water is in the range of 8.85 to 10.3, but its yield is much smaller than that of natural spring water. It can be used to lower the pH value of mine drainage or spring water from 8.5 to 7.0. Additionally, a pH value greater than 7 mainly originates from the alkalinity in cement, which is a common issue in concrete construction. Its impact is limited, and the duration is short.

- (4)

- After the completion of backfilling in the experimental pillar void, all pressure chambers are functioning normally. According to the data received from the monitoring device, the fill body pressures in the two test mining areas are still undergoing changes, with pressures ranging between 0.11 and 2.53 MPa.

- (5)

- The experimental results demonstrate that the expansibility test of the backfilling material for the DaYukou phosphate mine is successful. The small-scale phosphate gypsum-like structure flowable backfilling self-flow conveying backfilling system used in the process is smooth and reliable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, Y.; Song, Y.; Min, C.; Du, J.; Wang, X.; Min, J.; Wang, S. Phosphogypsum pretreatment with CaCO3 to improve the backfill performance. Case Stud. Constr. Mater. 2023, 18, e01954. [Google Scholar] [CrossRef]

- Geraldo, R.H.; Costa, A.R.D.; Kanai, J.; Silva, J.S.; Souza, J.D.; Andrade, H.M.; Gonçalves, J.P.; Fontanini, P.S.; Camarini, G. Calcination parameters on phosphogypsum waste recycling. Constr. Build. Mater. 2020, 256, 119406. [Google Scholar] [CrossRef]

- Rashad, A.M. Phosphogypsum as a construction material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar]

- Chen, Q.; Zhang, Q.; Qi, C.; Fourie, A.; Xiao, C. Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact. J. Clean. Prod. 2018, 186, 418–429. [Google Scholar]

- Rongzheng, C. Status of comprehensive utilization of phosphogypsum in China in 2021 and suggestions. Phosphate Compd. Fertil. 2022, 37, 1–3. [Google Scholar]

- Kuzmanovic, P.; Todorovic, N.; Mrda, D.; Forkapić, S.; Petrović, L.F.; Miljević, B.; Hansman, J.; Knežević, J. The possibility of the phosphogypsum use in the production of brick: Radiological and structural characterization. J. Hazard. Mater. 2021, 413, 125343. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Chen, B.; Qu, G.; Liu, S.; Zhao, C.; Ren, Y.; Liu, X. Harmless treatment technology of phosphogypsum: Directional stabilization of toxic and harmful substances. J. Environ. Manag. 2022, 311, 114827. [Google Scholar]

- Li, B.; Li, L.; Chen, X.; Ma, Y.; Zhou, M. Modification of phosphogypsum using circulating fluidized bed fly ash and carbide slag for use as cement retarder. Constr. Build. Mater. 2022, 338, 127630. [Google Scholar]

- Chen, B.; Wu, F.; Qu, G.; Ning, P.; Ren, Y.; Liu, S.; Jin, C.; Li, H.; Zhao, C.; Liu, X.; et al. Waste control by waste: A comparative study on the application of carbide slag and quicklime in preparation of phosphogypsum-based ecological restoration materials. Chem. Eng. Process. Process Intensif. 2022, 178, 109051. [Google Scholar]

- Jin, Z.; Ma, B.; Su, Y.; Qi, H.; Lu, W.; Zhang, T. Preparation of eco-friendly lightweight gypsum: Use of beta-hemihydrate phosphogypsum and expanded polystyrene particles. Constr. Build. Mater. 2021, 297, 123837. [Google Scholar]

- Cao, W.; Yi, W.; Peng, J.; Li, G.; Yin, S. Preparation of anhydrite from phosphogypsum: Influence of phosphorus and fluorine impurities on the performances. Constr. Build. Mater. 2022, 318, 126021. [Google Scholar]

- Liu, Q. In-Depth Market Assessment and Investment Strategy Advisory Report of China Phosphate Industry 2023–2028; Changsha Mining Research Institute Co., Ltd.: Changsha, China, 2022. [Google Scholar]

- Wu, J.; Jing, H.; Yin, Q.; Meng, B.; Han, G. Strength and ultrasonic properties of cemented waste rock backfill considering confining pressure, dosage and particle size effects. Constr. Build. Mater. 2020, 242, 118132. [Google Scholar]

- Alainachi, I.; Fall, M. Chemically induced changes in the geotechnical response of cementing paste backfill in shaking table test. J. Rock Mech. Geotech. Eng. 2021, 13, 513–528. [Google Scholar]

- Qiu, H.; Zhang, F.; Liu, L.; Huan, C.; Hou, D.; Kang, W. Experimental study on acoustic emission characteristics of cemented rock-tailings backfill. Constr. Build. Mater. 2022, 315, 125278. [Google Scholar]

- Cullu, M.; Ertas, H. Determination of the effect of lead mine waste aggregate on some concrete properties and radiation shielding. Constr. Build. Mater. 2016, 125, 625–631. [Google Scholar]

- Nguyen, H.; Adesanya, E.; Ohenoja, K.; Kriskova, L.; Pontikes, Y.; Kinnunen, P.; Illikainen, M. Byproduct-based ettringite binder—A synergy between ladle slag and gypsum. Constr. Build. Mater. 2019, 197, 143–151. [Google Scholar]

- Gijbels, K.; Pontikes, Y.; Samyn, P.; Schreurs, S.; Schroeyers, W. Effect of NaOH content on hydration, mineralogy, porosity and strength in alkali/sulfate-activated binders from ground granulated blast furnace slag and phosphogypsum. Cem. Concr. Res. 2020, 132, 106054. [Google Scholar]

- Min, C.; Shi, Y.; Liu, Z. Properties of cemented phosphogypsum (PG) backfill in case of partially substitution of composite Portland cement by ground granulated blast furnace slag. Constr. Build. Mater. 2021, 305, 124786. [Google Scholar]

- Chen, Q.; Sun, S.; Wang, Y.; Zhang, Q.; Zhu, L.; Liu, Y. In-situ remediation of phosphogypsum in a cement-free pathway: Utilization of ground granulated blast furnace slag and NaOH pretreatment. Chemosphere 2023, 313, 137412. [Google Scholar]

- Liu, Y.; Wang, P.; Dalconi, M.C.; Molinari, S.; Valentini, L.; Wang, Y.; Sun, S.; Chen, Q.; Artioli, G. The sponge effect of phosphogypsum-based cemented paste backfill in the atmospheric carbon capture: Roles of fluorides, phosphates, and alkalinity. Sep. Purif. Technol. 2023, 315, 123702. [Google Scholar]

- Li, X.; Zhou, Y.; Shi, Y.; Zhu, Q. Fluoride immobilization and release in cemented PG backfill and its influence on the environment. Sci. Total Environ. 2023, 869, 161548. [Google Scholar]

- Satellite, L. Test Report on Filling Material of Dayyukou Phosphate Mine; Changsha Mining Research Institute Co., Ltd.: Changsha, China, 2020. [Google Scholar]

- Zhou, S.; Li, X.; Zhou, Y.; Min, C.; Shi, Y. Effect of phosphorus on the properties of phosphogypsum-based cemented backfill. J. Hazard. Mater. 2020, 399, 122993. [Google Scholar]

- Shi, Y.; Wang, X.; Qing, Z.; Song, Y.; Min, J.; Zhou, Y.; Du, J.; Wang, S. Using Iron Tailings for Phosphate Removal in Cemented Phosphogypsum (PG) Backfill. Materials 2022, 15, 8497. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Q.; Chen, Q.; Qi, C.; Su, Z.; Huang, Z. Utilisation of water-washing pretreated phosphogypsum for cemented paste backfill. Minerals 2019, 9, 175. [Google Scholar] [CrossRef]

- Cavusoglu, I.; Yilmaz, E.; Yilmaz, A.O. Sodium silicate effect on setting properties, strength behavior and microstructure of cemented coal fly ash backfill. Powder Technol. 2021, 384, 17–28. [Google Scholar]

- Ma, D.; Kong, S.; Li, Z.H.; Zhang, Q.; Wang, Z.; Zhou, Z. Effect of wetting-drying cycle on hydraulic and mechanical properties of cemented paste backfill of the recycled solid wastes. Chemosphere 2021, 282, 131163. [Google Scholar]

- Min, C.; Li, X.; He, S.; Zhou, S.; Zhou, Y.; Yang, S.; Shi, Y. Effect of mixing time on the properties of phosphogypsum-based cemented backfill. Constr. Build. Mater. 2019, 210, 564–573. [Google Scholar]

- Tayibi, H.; Choura, M.; Lopez, F.A.; Alguacil, F.J.; Lopez-Delgado, A. Environmental impact and management of phosphogypsum. J. Environ. Manag. 2009, 90, 2377–2386. [Google Scholar]

- Qasemi, M.; Afsharnia, M.; Farhang, M.; Ghaderpoori, M.; Karimi, A.; Abbasi, H.; Zarei, A. Spatial distribution of fluoride and nitrate in groundwater and its associated human health risk assessment in residents living in Western Khorasan Razavi, Iran. Desalin. Water Treat. 2019, 170, 176–186. [Google Scholar]

- GB/T14848-93; Quality Standard for Ground Water. Standardization Administration of the People’s Republic of China: Beijing, China, 1993.

- GB8978-1996; Comprehensive Sewage Discharge Standards. Standardization Administration of the People’s Republic of China: Beijing, China, 1996.

- GB5085.3-1996; Identification Standard for Hazardous Waste—Leaching Toxicity Identification. Administration of the People’s Republic of China: Beijing, China, 1996.

| Proportions (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mineral | SiO2 | Al2O3 | P2O5 | SO3 | CaO | MgO | MnO | Others | |

| Sample | (S P) | 26.24 | 14.13 | – | 2.72 | 36.35 | 8.74 | 0.27 | 11.55 |

| (P G) | 0.06 | 0.31 | 1.31 | 50.76 | 35.83 | 0.11 | – | 11.62 | |

| Unit/(μm) | (bar) | d10 | d30 | d50 | d60 | Cu | Cc | |

|---|---|---|---|---|---|---|---|---|

| Sample | (S P) | 9.68 | 2.01 | 5.56 | 8.89 | 11.94 | 5.94 | 1.29 |

| (P G) | 83.27 | 20.99 | 50.93 | 75.03 | 94.24 | 4.59 | 1.31 | |

| No. | Size (L × B × H) (m) | Hollow Brick (m3) | Cement Mortar (m3) | Concrete (m3) | Budgeted Costs (CNY) |

|---|---|---|---|---|---|

| 1# | 5 × 2.5 × 5 | 62.5 | 15.6 | 15.6 | 6250 |

| 2# | 5 × 2.5 × 5 | 62.5 | 15.6 | 15.6 | 6250 |

| 3# | 5 × 1.5 × 4.7 | 35.3 | 8.8 | 8.8 | 3000 |

| 4# | 5 × 1.5 × 4.7 | 35.3 | 8.8 | 8.8 | 3000 |

| 5# | 3.2 × 1 × 1 | 3.2 | 0.8 | 0.8 | 320 |

| 6# | 3.2 × 1 × 1 | 3.2 | 0.8 | 0.8 | 320 |

| 7# | 3.2 × 1 × 1 | 3.2 | 0.8 | 0.8 | 320 |

| 8# | 3.2 × 1 × 1 | 3.2 | 0.8 | 0.8 | 320 |

| Sum | 197.8 | 49.5 | 49.5 | 19,780 |

| Times | Section (m2) | Filling Quantity (m3) |

|---|---|---|

| 1st | 0.82 | 4.9 |

| 2nd | 1.874 | 11.2 |

| 3rd | 2.957 | 17.7 |

| 4th | 4.04 | 24.2 |

| 5th | 5.123 | 30.7 |

| 6th | 6.206 | 37.2 |

| 7th | 7.289 | 43.7 |

| Material Consumption | Filling Quantity (keg) | 425 Cement (t) | S95 Slag Micro-Powder (t) | Phosphogypsum (m3) |

|---|---|---|---|---|

| 1# (1:1:8) | 216 | 75.6 | 72.00 | 607 |

| 2# (1:1:12) | 176 | 52.8 | 44 | 586 |

| Sum | 392 | 128 | 116 | 1193 |

| No. | Ash–Sand Ratio (Cement–Fly Ash–Phosphogypsum) | Compressive Strength (MPa) | 28d Tensile Strength (MPa) | ||

|---|---|---|---|---|---|

| 7d | 14d | 28d | |||

| 1 | 1:1:8 | 1.26 | 2.62 | 3.24 | 0.32 |

| 2 | 1:1:12 | 0.92 | 2.13 | 2.69 | 0.21 |

| No. | Analysis Parameters and Detection Limits (mg/L) | Sample Name and Identification Results (mg/L) | ||||||

|---|---|---|---|---|---|---|---|---|

| 1# | 2# | 3# | 4# | 5# | 6# | |||

| 1 | PH | - | 9.35 | 8.85 | 9.42 | 10.27 | 10.30 | 10.27 |

| 2 | Total Phosphorus | 0.01 | 0.078 | 0.062 | 0.07 | 0.043 | 0.05 | 0.062 |

| 3 | Suspended solids | - | 35 | 34 | 39 | 10 | 26 | 24 |

| 4 | Sulfate | 8 | 827 | 797 | 969 | 1604 | 1313 | 1666 |

| 5 | Cr6+ | 0.004 | 0.046 | 0.08 | 0.307 | 0.319 | 0.3 | 0.3 |

| 6 | Fluoride | 0.05 | 3.28 | 3.74 | 6.9 | 5.21 | 6.16 | 5.09 |

| 7 | Cyanide | 0.004 | 0.005 | 0.004 | 0.005 | 0.011 | 0.011 | 0.013 |

| 8 | An-ionic surfactant | 0.05 | 0.12 | 0.12 | 0.14 | 0.21 | 0.15 | 0.16 |

| 9 | Chemical Oxygen Demand | 15 | 15 | 15 | 18 | 23 | 18 | 24 |

| 10 | Manganese (Mn) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| 11 | Cadmium (Cd) | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| 12 | Copper (Cu) | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| 13 | Zinc (Zn) | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| 14 | Lead (Pb) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 15 | Nickel (Ni) | 0.005 | 0.005 | 0.005 | 0.016 | 0.016 | 0.016 | 0.005 |

| 16 | Chromium (Cr) | 0.03 | 0.036 | 0.069 | 0.311 | 0.335 | 0.306 | 0.315 |

| 17 | Mercury (Hg) | 0.00001 | 0.00001 | 0.00001 | 0.00001 | 0.00001 | 0.00001 | 0.00001 |

| 18 | Arsenic (As) | 0.0002 | 0.00022 | 0.00164 | 0.0008 | 0.00177 | 0.00005 | 0.00178 |

| 19 | Selenium (Se) | 0.0003 | 0.0124 | 0.0069 | 0.0098 | 0.0079 | 0.0071 | 0.0059 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Kang, Q.; Ke, Y.; Zou, Y.; Liu, Q.; Wang, Z. Eco-Friendly Mining Practices: Field Test of Phosphogypsum Filling Based on Slag Powder in Dayukou Phosphate Mine. Sustainability 2025, 17, 2851. https://doi.org/10.3390/su17072851

Liu H, Kang Q, Ke Y, Zou Y, Liu Q, Wang Z. Eco-Friendly Mining Practices: Field Test of Phosphogypsum Filling Based on Slag Powder in Dayukou Phosphate Mine. Sustainability. 2025; 17(7):2851. https://doi.org/10.3390/su17072851

Chicago/Turabian StyleLiu, Houdong, Qian Kang, Yuxian Ke, Yi Zou, Qi Liu, and Zhongwei Wang. 2025. "Eco-Friendly Mining Practices: Field Test of Phosphogypsum Filling Based on Slag Powder in Dayukou Phosphate Mine" Sustainability 17, no. 7: 2851. https://doi.org/10.3390/su17072851

APA StyleLiu, H., Kang, Q., Ke, Y., Zou, Y., Liu, Q., & Wang, Z. (2025). Eco-Friendly Mining Practices: Field Test of Phosphogypsum Filling Based on Slag Powder in Dayukou Phosphate Mine. Sustainability, 17(7), 2851. https://doi.org/10.3390/su17072851