Abstract

The aim of this study is to evaluate the environmental impact of solar energy by analyzing its emissions, resource consumption, and waste generation throughout its life cycle. As one of the most widely adopted energy sources, solar power offers substantial benefits in reducing greenhouse gas emissions; however, its broader environmental footprint requires careful examination. The production, operation, and disposal of solar panels contribute to pollution, water consumption, and hazardous waste accumulation, with an estimated 250,000 tons of solar waste reported in 2016 alone. Furthermore, solar power generation requires significant water resources, averaging 650 gallons per megawatt-hour of electricity. A key focus of this study is the emissions associated with solar technology, particularly during panel manufacturing and operation. Using HOMER Pro software, this research quantifies the emissions from Trina Solar photovoltaic (PV) panels (345 Wp), revealing an annual output of 49,259 kg of carbon dioxide, 214 kg of sulfur dioxide, and 104 kg of nitrogen dioxide. This Study obtained using HOMER Pro primarily account for operational emissions and do not include full lifecycle impacts such as raw material extraction, transportation, and disposal. These findings highlight the trade-offs between solar energy’s environmental advantages and its indirect ecological costs. While solar systems contribute to energy security and long-term economic savings, their environmental implications must be factored into energy planning and sustainability strategies. This study underscores the importance of developing greener manufacturing processes, improving recycling strategies, and optimizing solar farm operations to reduce emissions and resource depletion. By providing a comprehensive assessment of solar energy’s environmental impact, this research contributes valuable insights for policymakers, researchers, and industry leaders seeking to balance the benefits of solar power with sustainable environmental management.

1. Introduction

1.1. The Importance of Energy in Economic and Social Development

Energy is not only crucial but also plays a central role in facilitating a nation’s economic and social development [1]. It acts as an essential catalyst, driving progress across various sectors and enabling the smooth operation of industries, households, and transportation systems. Without adequate and reliable energy sources, a nation’s growth potential can be hindered, affecting productivity, innovation, and overall quality of life. Industries heavily rely on energy to power their operations. Energy is equally crucial for the functioning of households [2]. It powers everyday activities, such as lighting, heating, cooking, and refrigeration. Reliable access to energy enhances the quality of life for individuals, providing comfort, convenience, and improved living standards. It enables people to stay connected through electronic devices, access information, and engage in educational, recreational, and professional activities. Transportation systems also heavily rely on energy sources. Whether it’s fueling vehicles or providing electricity for electric transportation, energy is vital for the movement of people and goods. Efficient and reliable energy sources are essential for maintaining an interconnected and functional transportation network, supporting commerce, trade, and mobility. Moreover, energy plays a significant role in mitigating environmental challenges and promoting sustainability [3,4,5]. The transition towards cleaner energy sources such as renewable energy and the adoption of energy-efficient technologies can reduce greenhouse gas emissions, conserve resources, and minimize environmental impacts. It paves the way for a more sustainable and resilient future, ensuring the well-being of present and future generations. Furthermore, a stable and reliable energy supply is paramount for fostering economic competitiveness, attracting investments, and creating employment opportunities. Therefore, recognizing the significance of energy in a nation’s progress is key to formulating effective policies, promoting sustainable practices, and achieving long-term prosperity. Over the past half-century, increases in population and corresponding economic growth have resulted in increases in the consumption of energy [6,7]. Research indicates that urbanization, while improving a population’s quality of life and promoting economic growth, significantly drives the demand for energy [8].

1.2. The Role of Renewable Energy in Sustainable Development

As the global quest for sustainable energy intensifies, photovoltaic (PV) systems are emerging as a cornerstone in reshaping our energy landscape. The unique blend of economic viability and environmental responsibility positions PV technology as a transformative force. Economically, PV systems offer an unprecedented opportunity for cost-effective power generation, contributing to a more resilient and diversified energy matrix. At the same time, their environmental impact is profound, offering a cleaner alternative that reduces greenhouse gas emissions and fosters a greener future. However, realizing the full potential of PV technology comes with its own set of challenges, from optimizing efficiency to addressing end-of-life considerations. In this study, we navigate the complex terrain of PV systems, highlighting their distinctive benefits and addressing the challenges head-on. By focusing on these nuanced aspects, we aim to provide a comprehensive understanding of the central role of PV technology in achieving a sustainable and environmentally friendly energy future. The ready availability of energy has fueled a massive transformation in human lifestyles over the past few centuries. Along with conventional fossil fuels, new energy sources have emerged, such as nuclear, solar, hydropower, and other renewables. Today’s global electricity consumption has risen to nearly 24,000 terawatt-hours [9,10,11]. In fact, between 1980 and 2019, there was a tripling of electricity consumption, even though the global population increased by 75% [10]. This indicates a massive growth not only in usage but in demand, mainly through widespread industrialization and improved access to electricity [12,13,14]. Increases in global energy consumption have remained high over the past two decades and are expected to grow even higher in the near future [15,16,17]. To be used as an alternative to conventional energy sources, solar energy needs to be collected and stored [18,19,20,21]. At present, solar power provides only 2% (~460 kWh) of global consumable energy [22], but its generation capacity is forecasted to reach up to 1200 GW by 2023 [23,24]. The solar photovoltaic sector has shown tremendous growth among all renewable energy forms. However, the increase in the end-of-life waste management of solar energy equipment and components is causing increasing concern for environmentalists and industry stakeholders [23].

1.3. Environmental and Economic Challenges of Solar Energy Production

While Solar energy is widely considered one of the most promising renewable energy sources due to its ability to generate electricity without contributing to greenhouse gas emissions. While solar power systems, particularly solar panels, play a vital role in reducing reliance on fossil fuels and combating climate change, their production and disposal present significant environmental and economic challenges. Despite the clean nature of solar power during operation, the manufacturing and end-of-life disposal processes require considerable resources and can result in environmental degradation. One of the primary challenges associated with solar panel production is the extraction of raw materials. Solar panels are made of materials such as silicon, copper, aluminum, and silver, which require intensive mining operations. The extraction of these materials can cause significant environmental damage, including habitat destruction, water contamination, and soil erosion. For example, quartz, the main raw material for silicon, must be mined and processed at high temperatures to produce the required electronic-grade silicon. This energy-intensive process, often powered by conventional fuels such as coal and natural gas, adds to the carbon footprint of solar panels. Furthermore, the transportation of raw materials and finished products across long distances adds another layer of environmental impact. Mining sites, processing plants, and manufacturing facilities are often located far apart, requiring extensive transportation. This reliance on global supply chains for solar panel production results in additional greenhouse gas emissions, further exacerbating the environmental footprint. The operational phase of solar energy systems, however, is much cleaner. Unlike fossil fuel-based power generation, solar panels produce electricity without emitting greenhouse gases or pollutants. The environmental impact of solar power systems mainly arises during the production and disposal phases. As solar panels have a lifespan of 20 to 30 years, their disposal at the end of their life cycle poses a significant challenge. If not properly recycled or disposed of, solar panels can release hazardous substances such as cadmium and lead into the environment, causing contamination. However, recycling solar panels is a complex and costly process that is not widely available, and many panels end up in landfills, contributing to waste management problems. The disposal and recycling challenges are compounded by the increasing volume of decommissioned panels. As the adoption of solar energy grows, the number of panels that need to be recycled will rise, creating a mounting waste management issue. This necessitates the development of more efficient recycling systems to minimize environmental harm. While solar energy is touted for its environmental benefits during its operational phase, it is essential to acknowledge the environmental costs associated with its production. The extraction and processing of raw materials, the energy-intensive manufacturing processes, and the disposal of solar panels contribute to the overall environmental footprint of solar power systems. These factors need to be carefully weighed in any analysis of the sustainability of solar energy.

In this study, the environmental impact of Trina Solar panels (345 Wp), a widely used brand in solar installations, is examined. By analyzing the emissions, energy consumption, and waste generation associated with their production, this research provides insight into the environmental consequences of solar panel manufacturing. Specialized commercial software will be used to quantify emissions and waste, allowing a detailed assessment of Trina Solar’s manufacturing processes. This analysis will focus on the energy consumption and emissions during the manufacturing stages, from raw material extraction to panel assembly. Waste management practices will also be examined to identify areas for improvement in the manufacturing process. By quantifying these impacts, the study aims to inform better practices within the solar industry, promoting more sustainable methods of solar panel production. The economic aspects of solar panel production must be considered. While the cost of solar energy generation has decreased significantly in recent years, making it more competitive with conventional energy sources, the production of solar panels still requires substantial investment. The economic costs of raw materials, labor, energy consumption, and waste management must be factored into any evaluation of the long-term benefits of solar energy. Furthermore, the economic benefits of solar energy, such as job creation, economic growth, and the reduction of external costs associated with pollution and environmental degradation, should also be considered. This study highlights the dual nature of sustainability in solar energy systems. Solar power offers substantial environmental benefits during operation, but the production and disposal of solar panels have notable environmental and economic impacts. By quantifying these impacts and exploring ways to mitigate them, this research aims to contribute to the development of more sustainable solar energy practices.

2. Materials and Methods

The area selected for this research is Tabuk, Saudi Arabia. Tabuk is situated in the Tabuk region in northwestern Saudi Arabia, as shown in the following map (Figure 1). The analysis and climate data for this study focus specifically on the Tabuk region, providing a detailed examination of solar activity, density of installed PV systems, and other relevant factors in this geographic area. Key climate data affecting PV energy production, such as solar irradiance, temperature variations, and weather patterns, are carefully considered in our analysis. These factors play a critical role in understanding the performance and efficiency of PV systems in a given region, ensuring a comprehensive assessment of economic and environmental impacts.

Figure 1.

Map of Saudi Arabia.

To ensure a well-defined scope for our analysis, we established specific system boundaries for evaluating the environmental and economic impacts of the PV system at Tabuk University. The boundaries included critical aspects of energy production, consumption profile, emissions analysis, economic assessment, and geographic scope. First, we focused on the energy production enabled by the Trina Solar (345 Wp) panels installed on the University of Tabuk building. In addition, we conducted a thorough assessment of the building’s daily power consumption, considering peak power demand and monthly load profiles. The emissions analysis considered greenhouse gas (GHG) emissions, comparing carbon dioxide (CO2) emissions from the PV system to those from power supplied solely by the utility grid. The economic assessment looked at factors such as levelized cost of energy (LCOE), net present cost (NPC), and overall financial feasibility, with a specific focus on the Tabuk University building. Geographically, our study was limited to Tabuk, Saudi Arabia, with meteorological data tailored to the unique conditions of this region. By clearly defining these system boundaries, we aimed to conduct a comprehensive analysis that would provide valuable insights into the localized impacts of the PV system.

HOMER Pro (Figure 2), a widely used software tool, provides a comprehensive platform for designing and analyzing hybrid power systems that integrate multiple energy sources like solar, wind, hydro, diesel, and batteries to offer sustainable electricity solutions. Users can model and optimize these systems based on specific requirements, considering factors such as energy demand, available resources, system components, and operational constraints. The software utilizes advanced algorithms to simulate various system configurations, identifying cost-effective designs and performing techno-economic analyses. This includes assessing financial feasibility, LCOE, payback period, and other metrics for informed decision-making. HOMER Pro also assists in optimizing system operation and control strategies by balancing energy production, storage, and consumption to enhance efficiency, reduce reliance on costly energy sources, and ensure reliable power supply. Besides, it offers robust analysis capabilities for evaluating scenarios, such as changes in energy demand or resource availability, facilitating risk management and informed decision-making for researchers, engineers, and policymakers interested in renewable energy systems’ technical and economic feasibility [25].

Figure 2.

Distinctive interface of HOMER Pro software.

One of the key equations used by HOMER Pro is the energy balance equation, which is used to calculate the energy production and consumption of the hybrid power system. The energy balance equation is given by:

where energy production is the sum of the energy produced by all renewable energy sources, energy consumption is the sum of the energy consumed by all loads, and energy storage is the energy stored in batteries.

Energy Production = Energy Consumption + Energy Storage + Energy Loss

Another important equation used by HOMER Pro is the net present cost (NPC) equation, which calculates the total cost of the hybrid power system over its lifetime. The NPC equation is given by:

where is the annual capital cost, is the discount rate, is the year of operation for which the annual capital cost is being calculated, is the annual operating cost, is the inflation rate, is the year of operation for which the annual operating cost is being calculated, is the salvage value at the end of the project, and represents the year in which the project ends and the salvage value of the system is determined.

HOMER Pro also calculates the LCOE for a given system design. LCOE is a commonly used metric for comparing different energy generation technologies and represents the cost of generating a unit of energy (e.g., $/kWh) over the lifetime of the system. The LCOE equation used by HOMER Pro is:

where FCR is the fixed charge rate, representing the annualized capital and operation and maintenance (O&M) costs of the system (expressed as a fraction of the initial capital cost); CRF is the capital recovery factor, which is a function of the discount rate and system lifetime; VOM is the variable operation and maintenance cost per unit of energy; E is the total energy produced by the system over its lifetime; and L is the lifetime of the system (in years).

The LCOE equation considers the capital cost, O&M cost, and energy production of the system, as well as the discount rate used to value future cash flows. By comparing the LCOE of different system designs, it is possible to determine the most cost-effective option for a given application. Moreover, the LCOE can be used to evaluate the environmental impact of a system by considering the emissions associated with energy production and comparing the LCOE of different technologies in terms of emissions per unit of energy.

Currently, there are two hypotheses being considered. Hypothesis 1 posits that leveraging HOMER Pro software for evaluating the economic advantages of solar photovoltaic panels will reveal a notable potential for cost savings and revenue generation. This hypothesis underscores the pivotal role that advanced simulation tools like HOMER Pro play in assessing the financial viability of investing in solar energy initiatives. By employing sophisticated modeling and analysis capabilities, stakeholders can gain insights into the economic benefits associated with the deployment of solar PV systems, thereby facilitating informed decision-making and strategic planning in the renewable energy sector. The significance of Hypothesis 1 lies in its premise that HOMER Pro, a widely utilized software platform for energy system optimization and analysis, can effectively quantify the financial returns and operational efficiencies of solar PV installations. Through detailed simulations and scenario-based assessments, HOMER Pro enables users to explore various configurations, system sizes, and economic parameters to determine the most cost-effective approach to incorporating solar energy into their energy mix. By utilizing data-driven analysis and forecasting tools, stakeholders can identify opportunities for reducing energy costs, maximizing return on investment, and potentially generating revenue through solar energy generation. On the other hand, Hypothesis 2 focuses on the environmental impact assessment conducted through HOMER Pro software specifically for Trina Solar PV panels [25]. This hypothesis anticipates that the analysis will uncover substantial emissions of carbon dioxide, sulfur dioxide, and nitrogen dioxide, highlighting the urgent need for sustainable practices to mitigate the environmental repercussions of solar energy production. This hypothesis underscores the dual imperative of advancing renewable energy deployment while concurrently addressing environmental concerns related to emissions and pollution associated with solar panel manufacturing and operation. The crux of Hypothesis 2 lies in acknowledging the environmental trade-offs inherent in solar energy production and the critical role of tools like HOMER Pro in quantifying and visualizing these impacts. By conducting a comprehensive environmental impact analysis using sophisticated modeling capabilities, stakeholders can gain a holistic understanding of the environmental footprint of solar PV systems, identify potential areas of improvement, and develop strategies to minimize adverse effects on air quality, climate change, and ecosystem health. The outcomes of this analysis have the potential to drive the adoption of sustainable practices, inform policy decisions, and shape the future trajectory of solar energy development towards greater environmental stewardship.

3. Results and Discussion

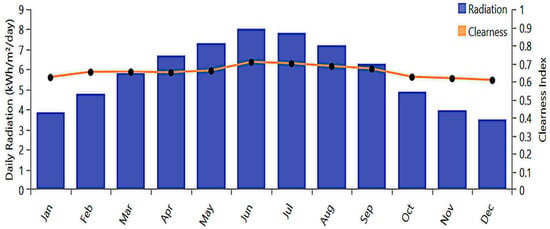

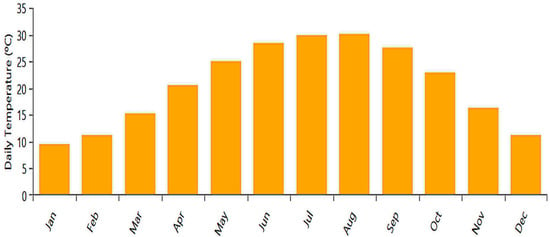

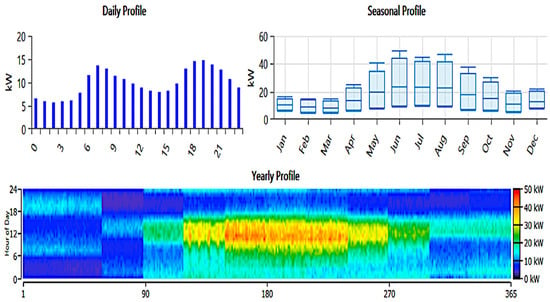

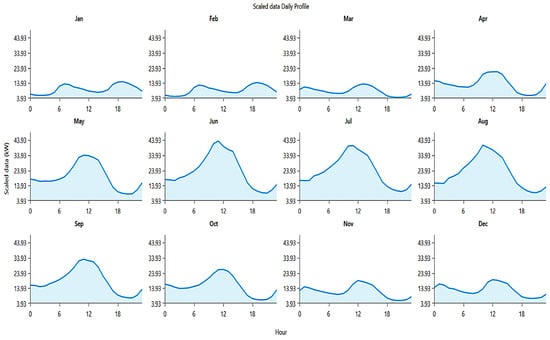

HOMER Pro software was used to perform an emissions analysis for a building at the University of Tabuk, in Tabuk, Saudi Arabia. HOMER Pro software, a powerful tool widely used for energy modeling and optimization, was specifically employed to conduct a comprehensive emissions analysis for a building located at the esteemed University of Tabuk in Tabuk, Saudi Arabia. This analysis played a crucial role in evaluating the building’s sustainability and identifying potential strategies for reducing carbon footprint. The utilization of HOMER Pro showcased the University of Tabuk’s commitment to sustainable practices and their proactive approach towards promoting a greener future. The building has a daily electricity consumption of 379.36 kWh and a peak power of 49.01 kW. The price of grid electricity is $0.0688/kWh and the sell-back price in Saudi Arabia is $0.021/kWh. Meteorological data such as temperature, clearness index, and daily radiation were provided by the HOMER Pro software and the consumption profile for each month was considered (Figure 3 and Figure 4). The hourly measured electricity consumption of the university building was provided to HOMER, which then provided the daily load profile and the consumption profiles for each month, as shown in Figure 5 and Figure 6.

Figure 3.

Monthly average global horizontal irradiance in Tabuk.

Figure 4.

Monthly average temperature in Tabuk.

Figure 5.

Daily, seasonal, and yearly load profiles.

Figure 6.

Monthly scaled load profile of the university building.

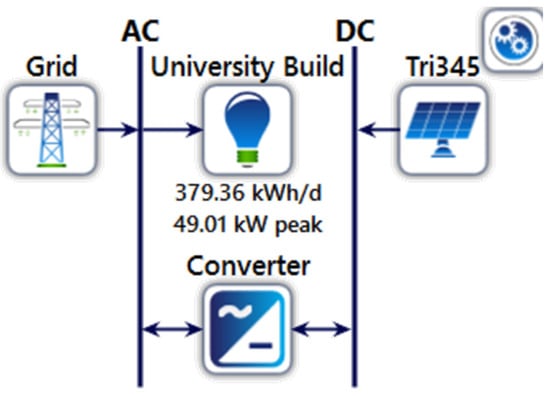

In the present study, TrinaSolar panels were selected for the PV system (Figure 7). The discount rate was set at 2.5% and the inflation rate at 1%. An economic analysis was performed using HOMER Pro to determine the LCOE for the PV system, which is a key metric for assessing the project’s economic viability.

Figure 7.

Topology of the PV installation.

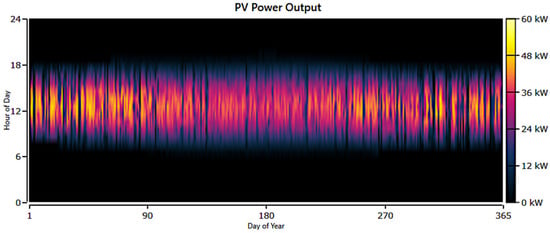

In addition to the economic analysis, an emissions analysis was performed using HOMER Pro. The software allows the comparison of emissions with and without a PV system. In this case, CO2 emissions with the PV system and grid power were 49,259 kg/year, while emissions with energy provided only from the utility grid were 87,511 kg/year. These results indicate that installing a PV system can significantly reduce greenhouse gas emissions. Furthermore, the results suggest that the PV system would not only contribute to the reduction in greenhouse gas emissions but also provide economic benefits through the production of clean energy instead of using local grid electricity. Figure 8 shows the intensity of energy produced by photovoltaic panels over the year.

Figure 8.

PV Power Output of TrinaSolar panels.

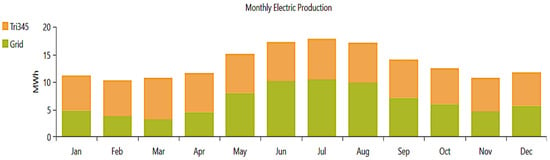

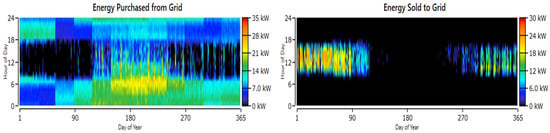

Figure 9 shows the monthly PV electricity production for each month, and Figure 10 represents the purchased energy as well as the energy sold to the grid over the course of a year.

Figure 9.

Monthly generated energy and utility grid-provided electricity.

Figure 10.

Purchased and sold energy.

The results clearly show that installing a PV system can significantly reduce greenhouse gas emissions and improve economic efficiency. With an LCOE of 0.0548 $/kWh, the PV system is a cost-effective option for the tested University of Tabuk building, optimizing the NPC from US $197,739 to $176,223. The LCOE highly depends on regional climatic conditions. Lower solar insolation zones may be experiencing higher LCOE due to lower energy production per installed capacity, whereas high humidity zones may be experiencing degradation in the PV panel performance due to soiling and efficiency due to humidity. Efficiency may also be influenced by the ambient temperature, as PV modules typically demonstrate lower efficiency at elevated temperatures. These factors point towards the requirement for site-specific analysis when using the findings of this work for other geographical locations. The use of HOMER Pro allowed for a comprehensive analysis of the economic and emissions impact of the PV system, making it a valuable tool for optimization and decision-making regarding renewable energy systems.

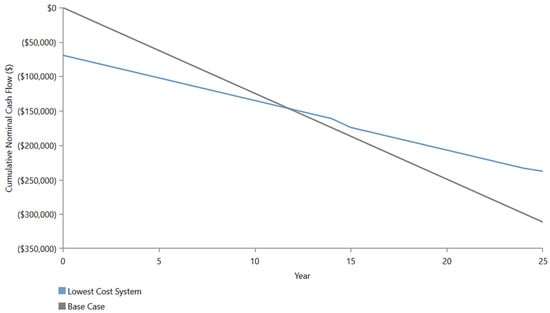

To place the findings in a broader context and enhance the depth of the research, a comparative analysis was conducted with a related study carried out at the Ibn Tofail University in Morocco. This comparison has played a crucial role in validating and corroborating the results, as well as in identifying areas of convergence and divergence between the two studies. The alignment of the findings with those obtained at the Ibn Tofail University underscores the reliability and consistency of the research methodology and outcomes. By showcasing similarities in the results with those of a separate research endeavor, the credibility of the findings has been bolstered and the overall validity of the study has been strengthened. Furthermore, the comparison with the study conducted at the Ibn Tofail University has not only served to validate the findings but has also opened new avenues for exploration and inquiry. This collaborative approach has enabled the identification of common threads and discrepancies between the two studies, prompting a deeper dive into specific aspects of the subject matter and the posing of new research questions. Ultimately, the comparison with the study conducted at the Ibn Tofail University in Morocco has enriched the research and broadened the understanding of the topic under investigation. This comparative analysis serves as a valuable tool in enhancing the robustness of the findings and in paving the way for further research and innovation in the field. In this study, the authors used HOMER Pro to evaluate and optimize photovoltaic systems in accordance with the new renewable energy law in the Kingdom of Morocco. While our focus was on the University of Tabuk, a comparison reveals interesting parallels and differences. Both studies underscore the potential of HOMER Pro as a valuable tool for optimizing photovoltaic systems. However, differences in geographic and climatic conditions, as well as local energy policies, contribute to the different results. Such comparative analyses contribute to a more nuanced understanding of the diverse applications and impacts of renewable energy systems in different contexts. Figure 11 shows the cumulative nominal cash flow over the lifetime of the photovoltaic system. The intersection of the graphs for the base case and the lowest cost system means that the system is expected to generate a return on investment (ROI) at this point. In this case, the simple payback period is 12 years and the ROI is 4.3%.

Figure 11.

Cumulative Nominal Cash Flow over the Lifetime.

Rising carbon and other anthropogenic greenhouse gas emissions have had a huge impact on climate change. The measurement of emission intensity is evaluated by taking the lifetime (i.e., total) carbon emissions per energy unit, as expressed in either grams of a CO2 equivalent per kilowatt-hour (gCO2e/kWh) or tons of a CO2 equivalent per megawatt-hour (tCO2/MWh). In general, lower emission intensities indicate lower environmental impacts because less CO2 is being emitted to create the same amount of power. However, carbon emissions are not the only factor considered when assessing how solar panels impact the environment. Generating solar energy may be non-polluting, but solar energy still uses non-renewable materials (metals and minerals) that require mining operations. These operations may cause loss of biodiversity or habitat through the construction of roads and mines and the transport of raw materials, equipment, and finished products. In other words, while PV systems in operation have negligible to zero carbon emissions, their manufacturing process does involve carbon emissions [26].

Despite the emissions produced during the pre-generation production phase, solar power is quite good at mitigating carbon and pollutants. For instance, dealing with waste and byproducts can be as easy as recycling solar panels and reselling the components’ base elements, though hazardous chemicals produced during the component manufacturing stage may require more diligent handling and disposal and greater oversight from the government. As in other forms of manufacturing, diligence in production and government oversight are heavily dependent on the manufacturing country of origin. Some countries are chosen by manufacturers specifically for their lax environmental laws, while others are preferred because of the standards they require, which boosts the reputability of their brand.

Not all companies engage in chemical dumping, but many unfortunately still do. Furthermore, because of the relative newness of the solar energy industry, solar panel recycling is not yet a major concern. However, when the solar panels need replacement in one or two decades, recycling may indeed become an issue, as solar modules cannot currently be combined with standard e-waste. This means that countries and regions that lack adequate e-waste disposal options could face recycling dilemmas in the near future. In fact, this is the main environmental concern of the PV industry. The silicon solar panel’s glass cover comprises approximately two-thirds of the panel’s weight, and when the panel has reached its end-of-life (EOL) stage, it will need recycling to mitigate its environmental impact as hazardous waste [27]. Analysis of the EOL stage of panels indicates that impacts are notably reduced by PV recycling, which also brings with it a decrease in freshwater ecotoxicity of around 78% [28].

To get a general idea of what potentially lies ahead with regard to solar energy-related pollution, researchers expect that, by 2030, global solar PV waste will be a modest 14% of total generation capacity, whereas by 2050, the waste will reach up to 80% (i.e., ~78 million tons) [29]. Already, the volume of solar PV waste exceeds 250,000 tons globally [29]. To get ahead of this startling potential waste disaster, the European Union (EU) included PV waste in their Waste of Electrical and Electronic Equipment (WEEE) classification as a means to slow the persistent growth of PV-related waste and encourage solar module recycling [29]. It is important to note that silicon wafers in standard solar modules are encapsulated in ethyl vinyl acetate (EVA). The EVA layer is intended to protect the silicon, but if these modules are improperly disposed of, they pose a hazard due to leaching [29]. According to the International Renewable Energy Agency (IRENA), global photovoltaic waste is expected to reach 78 million tons by 2050, driven by the rapid increase in solar installations. A significant portion of this waste will consist of glass, which makes up about 60–70% of PV panel material [30]. The potential value of recovered materials, such as glass, aluminum, copper, and silicon, could exceed 15 billion USD by 2050 [31,32]. Efficient recycling systems are crucial to address the environmental challenges of solar waste, and effective waste management strategies can contribute to a circular economy, minimizing the impact and maximizing the value of recycled materials.

Unless they become too costly to produce, fuel-free solar energy should be sustainable. The materials used for solar energy production, however, are not only depletable but are causing major environmental impacts [33]. Even so, solar energy remains an attractive alternative to conventional fuel sources, considering that buildings are responsible for nearly half of global energy consumption annually, with much of the power being used for heating, cooling, and lights [34,35]. This type of commercial, residential, and industrial consumption produces vast amounts of NOx and CO2 emissions [35]. The 1997 Montreal Protocol requires the phasing out of refrigerant chemicals that affect the stratosphere. To satisfy these requirements, signatory governments to the Montreal Protocol have agreed to a general reduction in their nations’ energy consumption as a way to cut their pollution levels [35]. The Kyoto Protocol likewise requires a decrease in the signatory nations’ emissions, with the overall aim of reducing the world’s greenhouse gas production.

To comply with the Kyoto Protocol, reduced energy consumption needs to be accompanied by an increase in energy efficiency, as well as other mechanisms such as moratoriums on deforestation and the development of sustainable energy alternatives [36]. To generate electricity at the utility-scale, solar energy requires vast expanses of area for the solar panels, set in arrays, to collect energy. Because of their size requirements, most arrays are set up in rural or wilderness locations where they could either impact wilderness and recreational areas or interfere with current land uses. At the same time, solar energy systems, like other energy production systems, have both direct and indirect impacts on land because of their inherent energy footprint (e.g., exploration, extraction, manufacturing, transportation, etc.). Specific to solar power, the impacts on the environment are mainly connected to water use, habitat loss through repurposing land use, and hazardous materials in the components. However, the extent of the impacts may greatly vary, depending on whether the energy is generated from concentrating solar thermal plants (CSP) or from photovoltaic solar cells.

The energy system’s scale likewise is significant to the degree of environmental impact. Smaller systems, such as PV arrays positioned on rooftops, will have a considerably smaller impact than CSP utility-scale projects. Depending on the specifications required (e.g., land mass, topography, intensity, etc.), large utility-scale solar energy producing sites may even cause concerns related to habitat loss and land degradation [37,38,39,40]. Utility-scale PV systems typically require 3.5–10 acres per megawatt, and CSP facilities require 4–16.5 acres per megawatt. These sites generally do not mix well with agricultural lands, which means they need to be situated on relatively remote low-quality land, such as abandoned mining sites, brownfields, and energy transmission corridors [41,42]. Conversely, small-scale solar PV array sites can be positioned on top of buildings in urban or suburban areas, making their environmental impact much less of an issue [43]. According to our investigations and personal communications, PV systems require around 5 acres per megawatt. Although solar PV cells do not require water to produce electricity, water is used in the manufacturing of the cells’ components. On the other hand, concentrating solar thermal plants, like other thermal electric plants, do need water for cooling. The amount of water required by CSP facilities is determined by the plant’s size, location, design, and cooling system. For example, the water requirement of wet-recirculating technology that uses cooling towers is around 650 gallons for each megawatt-hour of produced electricity [44,45]. Once-through cooling technology requires lower total water consumption, as the water is not dissipated through steam, and dry-cooling technology needs only about 10% of the amount of water consumed by wet-recirculating technology CSP plants [46,47,48,49]. However, dry-cooling technology functions much less effectively in temperatures above 100 °F [46,50]. Our investigations (personal communications) with the local industry in Tabuk reveal a water requirement of around 500 gallons for each megawatt-hour. Water consumption in energy production varies significantly across different technologies. For example, coal-fired plants require approximately 1000 gallons per megawatt-hour (MWh) of electricity produced for cooling, a considerably higher amount compared to PV [51]. Wet-recirculating technologies used in concentrated solar power (CSP) plants with cooling towers require around 650 gallons per MWh. In contrast, dry-cooling technologies in PV systems utilize only about 10% of the water consumed by wet-recirculating technologies, making them much more water-efficient. However, dry-cooling systems are less effective in higher temperatures, such as those exceeding 100°F, which may affect performance in some regions. For PV, water consumption is generally limited to cleaning the panels, not for the actual production of electricity. This further distinguishes PV from other energy sources that require significant amounts of water for cooling and electricity generation. Given the increasing concerns about water scarcity, PV, especially with the adoption of dry-cooling technologies and efficient water management, offers a clear advantage over conventional power plants in terms of water usage. Compared to fossil fuel-based energy sources, PV represents a more sustainable option in regions where water resources are limited.

4. Conclusions

The rapid expansion of photovoltaic (PV) energy generation is an exciting and essential step toward the transition to renewable energy. As nations around the world strive to reduce their carbon emissions and transition to more sustainable energy systems, solar power has emerged as a key technology in the clean energy landscape. Photovoltaic systems are particularly appealing due to their ability to harness solar energy without producing harmful emissions during operation. Solar energy promises to meet the growing global demand for energy while simultaneously mitigating climate change, reducing dependence on fossil fuels, and promoting environmental sustainability. However, the rapid adoption of PV technology also presents challenges that must be addressed to ensure its long-term success and sustainability. These challenges primarily revolve around the entire lifecycle of solar panels, from production to end-of-life disposal, and specifically focus on the need for effective recycling and resource recovery systems to manage the waste generated by decommissioned panels.

As the global deployment of solar panels continues to grow, it is crucial to consider the environmental and economic implications of their production, use, and disposal. While the benefits of solar energy are well-documented, the materials used in PV panel production present challenges. Materials such as silicon, aluminum, and copper are essential for the functioning of solar panels but require significant energy to extract and process. These materials are also finite resources, which raises concerns about their availability and the environmental costs associated with their extraction. The increased demand for solar panels will eventually lead to a significant amount of waste in the form of decommissioned panels. As solar energy adoption accelerates, so too will the volume of end-of-life panels, which will contribute to waste management challenges. If not properly managed, this waste could offset the environmental benefits of solar energy.

One of the primary barriers to addressing the issue of solar panel waste is the lack of a consistent and efficient recycling strategy. While some materials in PV panels, such as silicon, aluminum, and copper, are valuable and recyclable, current recycling efforts are inadequate in many regions. In many cases, decommissioned solar panels are sent to landfills, where they contribute to environmental pollution and the loss of valuable materials. The recycling process for these materials is complex and requires specialized infrastructure that many regions lack. Moreover, the economic viability of recycling is a challenge, as the cost of recycling often exceeds the value of the materials recovered. This economic hurdle makes it difficult to incentivize the widespread adoption of recycling systems.

The recycling lag in the PV industry is exacerbated by the slow pace of technological development in recycling methods. While advances have been made in the development of more efficient recycling processes, they are not yet widespread or standardized across the industry. Furthermore, there is a lack of coordinated efforts between governments, industries, and other stakeholders to address the challenges of PV panel waste. To overcome these issues, it is essential to invest in and promote innovations that can improve the recycling process. One promising solution lies in the development of robotic disassembly technologies, which can automate the process of dismantling panels and recover materials more efficiently. Robotic systems could significantly reduce labor costs and improve the speed and accuracy of the recycling process, making it more economically viable. In addition, “design-for-recycling” standards could be introduced, encouraging manufacturers to design panels with recycling in mind. This would make disassembly easier and more efficient, reducing the cost of recycling and increasing the overall effectiveness of material recovery.

Beyond the technological barriers, there is also a need for regulatory and financial incentives to support the growth of recycling infrastructure. Governments can play a crucial role in encouraging the development of recycling systems by introducing policies that require solar manufacturers to take responsibility for the end-of-life disposal of their products. Extended producer responsibility (EPR) programs, where manufacturers are held accountable for their products from production to disposal, could provide the necessary financial incentives to ensure that recycling systems are put in place. These programs could also involve the introduction of recycling fees, which would fund the development of recycling infrastructure and incentivize manufacturers to contribute to the cost of recycling. Mandatory recycling programs for solar panel manufacturers could further reinforce this responsibility and help to standardize recycling practices across the industry. Though EPR programs provide a systematized framework for waste management, their implementation differs geographically. The EU Waste Electrical and Electronic Equipment Directive has been a success model with the assurance that the producers bear the responsibility for recycling and disposal. In the developing nations, the same policy implementation is difficult due to the lack of regulation and the unavailability of finance. For these to be met, international coordination, economic incentives, and policy harmonization must be incorporated to ensure that equal and efficient implementation of EPR is available across the globe, providing sustainable recycling everywhere.

In parallel to improving the recycling infrastructure, it is also important to address the environmental risks associated with the production of solar panels. While PV technology is considered a clean energy source during its operational phase, the manufacturing process involves the use of hazardous chemicals that can pose significant environmental and human health risks. Some of these chemicals, such as cadmium in thin-film panels, are highly toxic and persistent in the environment. Cadmium can leach into soil and water if not properly disposed of, causing long-term contamination and environmental damage. Other substances, such as lead used in traditional soldering materials, also pose risks to human health and the environment. As the industry grows, it is important to identify and replace hazardous materials with safer alternatives to minimize the environmental footprint of PV production. Research into non-toxic materials, such as lead-free perovskites, could reduce the need for hazardous chemicals and improve the overall sustainability of solar technology.

In addition to replacing hazardous materials, efforts should also focus on improving the energy efficiency of the manufacturing process. While solar panels generate clean energy once installed, the production process itself is energy-intensive, which undermines some of the environmental benefits of solar energy. Research into more energy-efficient manufacturing methods and the use of renewable energy sources during production could help reduce the carbon footprint of PV production. Adopting cleaner production techniques would also reduce the industry’s reliance on harmful chemicals, further contributing to environmental sustainability.

Immediate action is necessary to ensure that the growth of the solar industry does not lead to environmental harm. As the volume of decommissioned panels increases, it is essential to develop the infrastructure and technologies needed to manage this waste stream effectively. Governments, industries, and stakeholders must collaborate to implement recycling initiatives that will minimize the environmental impact of solar panel waste. Failure to do so could undermine the long-term sustainability of solar energy, negating the environmental benefits of this important technology. A comprehensive approach to waste management that includes both recycling and the reduction of the environmental impact of production is necessary to ensure the future of solar energy.

In conclusion, the rapid expansion of photovoltaic energy offers tremendous promise for a sustainable energy future. However, to ensure the long-term success of solar power, it is critical to address the environmental and economic challenges associated with panel production, use, and disposal. Efficient recycling, improved manufacturing practices, and the reduction of hazardous materials are key components of a sustainable solar energy industry. By investing in technological innovations, regulatory measures, and financial incentives, we can build a more sustainable and circular solar energy system that minimizes waste and maximizes resource recovery. Through these efforts, the solar industry can continue to grow and contribute to a cleaner, more sustainable energy future.

Author Contributions

Conceptualization, A.L. and N.A.; methodology, A.L.; software, A.L. and C.E.M.; validation, A.L., N.A. and C.E.M.; formal analysis, A.L.; investigation, A.L.; resources, A.L.; data curation, A.L.; writing—original draft preparation, A.L. and C.E.M.; writing—review and editing, A.L., N.A., C.E.M. and H.H.; visualization, A.L.; supervision, A.L.; project administration, A.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be available based on a reasonable request to the corresponding author.

Acknowledgments

The author would like to acknowledge the Deanship of Scientific Research (DSR) at the University of Tabuk, Tabuk, Saudi Arabia.

Conflicts of Interest

The author declares no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

References

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Ali, B.M.; Algburi, S.; Alzoubi, H.M.; Al-Jiboory, A.K.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. The renewable energy role in the global energy Transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar]

- Zheng, J.; Dang, Y.; Assad, U. Household energy consumption, energy efficiency, and household income–Evidence from China. Appl. Energy 2024, 353, 122074. [Google Scholar]

- Salam, I.U.; Yousif, M.; Numan, M.; Billah, M. Addressing the challenge of climate change: The role of microgrids in fostering a sustainable future—A comprehensive review. Renew. Energy Focus 2024, 48, 100538. [Google Scholar]

- Usman, F.O.; Ani, E.C.; Ebirim, W.; Montero, D.J.P.; Olu-lawal, K.A.; Ninduwezuor-Ehiobu, N. Integrating renewable energy solutions in the manufacturing industry: Challenges and opportunities: A review. Eng. Sci. Technol. J. 2024, 5, 674–703. [Google Scholar]

- Adanma, U.M.; Ogunbiyi, E.O. A comparative review of global environmental policies for promoting sustainable development and economic growth. Int. J. Appl. Res. Soc. Sci. 2024, 6, 954–977. [Google Scholar]

- Kadoshin, S.; Nishiyama, T.; Ito, T. The trend in current and near future energy consumption from a statistical perspective. Appl. Energy 2000, 67, 407–417. [Google Scholar] [CrossRef]

- Raihan, A.; Tanchangya, T.; Rahman, J.; Ridwan, M. The Influence of Agriculture, Renewable Energy, International Trade, and Economic Growth on India’s Environmental Sustainability. J. Environ. Energy Econ. 2024, 3, 37–53. [Google Scholar]

- Franco, S.; Mandla, V.R.; Ram Mohan Rao, K. Urbanization, energy consumption and emissions in the Indian context A review. Renew. Sustain. Energy Rev. 2017, 71, 898–907. [Google Scholar] [CrossRef]

- Earnest, J.; Rachel, S. Wind Power Technology; PHI Learning Pvt. Ltd.: Delhi, India, 2019. [Google Scholar]

- Nalbandian, H. Climate Implications of Coal-to-Gas Substitution in Power Generation; IEA Clean Coal Centre: London, UK, 2015. [Google Scholar]

- Strielkowski, W.; Civín, L.; Tarkhanova, E.; Tvaronavičienė, M.; Petrenko, Y. Renewable Energy in the Sustainable Development of Electrical Power Sector: A Review. Energies 2021, 14, 8240. [Google Scholar] [CrossRef]

- Gibbons, J.H.; Blair, P.D.; Gwin, H.L. Strategies for energy use. Sci. Am. 1989, 261, 136–143. [Google Scholar]

- Murshed, M. Modeling primary energy and electricity demands in Bangladesh: An autoregressive distributed lag approach. Sustain. Prod. Consum. 2021, 27, 698–712. [Google Scholar]

- Shahbaz, M.; Lean, H.H. Does financial development increase energy consumption? The role of industrialization and urbanization in Tunisia. Energy Policy 2012, 40, 473–479. [Google Scholar]

- Agency, I.E. World Energy Outlook; OECD/IEA: Paris, France, 2009. [Google Scholar]

- Bradley, M.J.; Jones, B.M. Reducing global NOx emissions: Developing advanced energy and transportation technologies. Ambio J. Hum. Environ. 2002, 31, 141–149. [Google Scholar]

- Goswami, D.Y.; Kreith, F. Global Energy Systems. In Energy Conversion; CRC Press: Boca Raton, FL, USA, 2017; pp. 1–30. [Google Scholar]

- Jacobson, M.Z.; Delucchi, M.A. Providing all global energy with wind, water, and solar power, Part I: Technologies, energy resources, quantities and areas of infrastructure, and materials. Energy Policy 2011, 39, 1154–1169. [Google Scholar]

- Kalogirou, S.A. Solar Energy Engineering: Processes and Systems; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Kenisarin, M.; Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar]

- Mekhilef, S.; Saidur, R.; Safari, A. A review on solar energy use in industries. Renew. Sustain. Energy Rev. 2011, 15, 1777–1790. [Google Scholar]

- Kodali, R.K.; John, J. Smart Monitoring of Solar Panels Using AWS. In Proceedings of the 2020 International Conference on Power Electronics & IoT Applications in Renewable Energy and Its Control (PARC), Mathura, India, 28–29 February 2020; pp. 422–427. [Google Scholar]

- Nain, P.; Kumar, A. A state-of-art review on end-of-life solar photovoltaics. J. Clean. Prod. 2022, 343, 130978. [Google Scholar] [CrossRef]

- Salim, H.K.; Stewart, R.A.; Sahin, O.; Dudley, M. End-of-life management of solar photovoltaic and battery energy storage systems: A stakeholder survey in Australia. Resour. Conserv. Recycl. 2019, 150, 104444. [Google Scholar] [CrossRef]

- Çetinbaş, İ.; Tamyurek, B.; Demirtaş, M. Design, analysis and optimization of a hybrid microgrid system using HOMER software: Eskisehir osmangazi university example. Int. J. Renew. Energy Dev. IJRED 2019, 8, 65–79. [Google Scholar]

- Nian, V. Impacts of changing design considerations on the life cycle carbon emissions of solar photovoltaic systems. Appl. Energy 2016, 183, 1471–1487. [Google Scholar] [CrossRef]

- Belançon, M.P.; Sandrini, M.; Tonholi, F.; Dias, G.S. End-of-life of c-Si solar panels: Demonstrating the possibility to reuse the cover glass. arXiv 2021, arXiv:2111.09643. [Google Scholar]

- Daniela-Abigail, H.-L.; Tariq, R.; Mekaoui, A.E.; Bassam, A.; Vega De Lille, M.; Ricalde, L.J.; Riech, I. Does recycling solar panels make this renewable resource sustainable? Evidence supported by environmental, economic, and social dimensions. Sustain. Cities Soc. 2022, 77, 103539. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Bulińska, S.; Sujak, A.; Pyzalski, M. Sustainable Management of Photovoltaic Waste Through Recycling and Material Use in the Construction Industry. Materials 2025, 18, 284. [Google Scholar] [CrossRef]

- Zhdaneev, O.; Aleshkevich, T. Renewable energy waste recycling. Int. J. Hydrogen Energy 2024, 93, 499–512. [Google Scholar] [CrossRef]

- Preet, S.; Smith, S.T. A comprehensive review on the recycling technology of silicon based photovoltaic solar panels: Challenges and future outlook. J. Clean. Prod. 2024, 448, 141661. [Google Scholar] [CrossRef]

- Zendehdel, M.; Nia, N.Y.; Yaghoubinia, M. Emerging thin film solar panels. In Reliability and Ecological Aspects of Photovoltaic Modules; IntechOpen: Rijeka, Croatia, 2020. [Google Scholar]

- Guerra-Santin, O.; Itard, L. The effect of energy performance regulations on energy consumption. Energy Effic. 2012, 5, 269–282. [Google Scholar] [CrossRef]

- Omer, A.M. Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 2008, 12, 2265–2300. [Google Scholar] [CrossRef]

- Soytas, U.; Sari, R. Energy consumption and income in G-7 countries. J. Policy Model. 2006, 28, 739–750. [Google Scholar] [CrossRef]

- Hernandez, R.R.; Easter, S.; Murphy-Mariscal, M.L.; Maestre, F.T.; Tavassoli, M.; Allen, E.B.; Barrows, C.W.; Belnap, J.; Ochoa-Hueso, R.; Ravi, S. Environmental impacts of utility-scale solar energy. Renew. Sustain. Energy Rev. 2014, 29, 766–779. [Google Scholar] [CrossRef]

- Hernandez, R.R.; Hoffacker, M.K.; Murphy-Mariscal, M.L.; Wu, G.C.; Allen, M.F. Solar energy development impacts on land cover change and protected areas. Proc. Natl. Acad. Sci. USA 2015, 112, 13579–13584. [Google Scholar] [CrossRef] [PubMed]

- Klugmann-Radziemska, E.; Ostrowski, P. Chemical treatment of crystalline silicon solar cells as a method of recovering pure silicon from photovoltaic modules. Renew. Energy 2010, 35, 1751–1759. [Google Scholar]

- Klugmann-Radziemska, E. Environmental impacts of renewable energy technologies. In Proceedings of the 2014 5th International Conference on Environmental Science and Technology, IPCBEE, Singapore, 19–21 February 2014; pp. 104–109. [Google Scholar]

- Manikandan, P.; Umayal, S. A review on the various environmental impacts of renewable energy technologies. Int. J. Res. Comput. Appl. Robot. 2015, 3, 93–101. [Google Scholar]

- Nwaigwe, K.; Mutabilwa, P.; Dintwa, E. An overview of solar power (PV systems) integration into electricity grids. Mater. Sci. Energy Technol. 2019, 2, 629–633. [Google Scholar]

- Shahsavari, A.; Akbari, M. Potential of solar energy in developing countries for reducing energy-related emissions. Renew. Sustain. Energy Rev. 2018, 90, 275–291. [Google Scholar]

- Ebube, O.F.; Akan, E.E. The Other Side: Negative Impacts of Exploiting Renewable Energy Sources. Eur. J. Eng. Technol. Res. 2021, 6, 30–33. [Google Scholar]

- Tripathi, L.; Mishra, A.; Dubey, A.K.; Tripathi, C. Water pollution through energy sector. Int. J. Technol. Enhanc. Emerg. Eng. Res. 2015, 3, 2347–4289. [Google Scholar]

- Hooman, K.; Guan, Z.; Gurgenci, H. Advances in dry cooling for concentrating solar thermal (CST) power plants. In Advances in Concentrating Solar Thermal Research and Technology; Elsevier: Amsterdam, The Netherlands, 2017; pp. 179–212. [Google Scholar]

- Larson, D.; Lee, C.; Tellinghuisen, S.; Keller, A. California’s energy-water nexus: Water use in electricity generation. Southwest Hydrol. 2007, 6, 16–19. [Google Scholar]

- Talati, S.; Zhai, H.; Kyle, G.P.; Morgan, M.G.; Patel, P.; Liu, L. Consumptive water use from electricity generation in the southwest under alternative climate, technology, and policy futures. Environ. Sci. Technol. 2016, 50, 12095–12104. [Google Scholar]

- Turchi, C.S.; Wagner, M.J.; Kutscher, C.F. Water Use in Parabolic Trough Power Plants: Summary Results from WorleyParsons’ Analyses; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2010.

- Poullikkas, A.; Hadjipaschalis, I.; Kourtis, G. A comparative overview of wet and dry cooling systems for Rankine cycle based CSP plants. Trends Heat Mass. Transf. 2013, 13, 27–50. [Google Scholar]

- Braimah, M. Potential of Renewable Energy Technologies to Reduce Operational Water Consumption. Preprints 2024. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).