Nested Optimization Algorithms for Accurately Sizing a Clean Energy Smart Grid System, Considering Uncertainties and Demand Response

Abstract

1. Introduction

1.1. Intermittency Effect

1.2. Sizing of Smart Grid Components

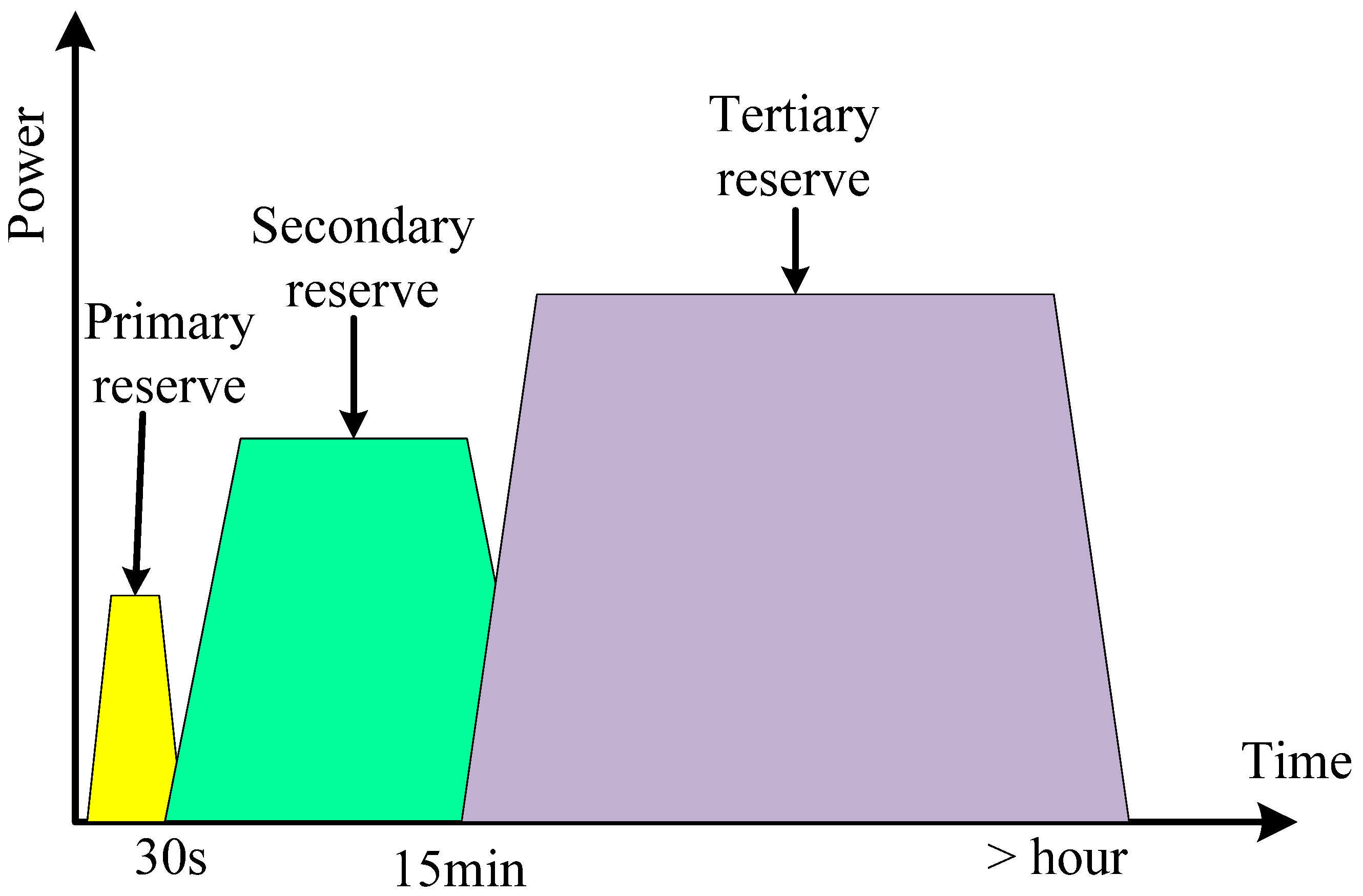

1.3. Energy Storage Systems

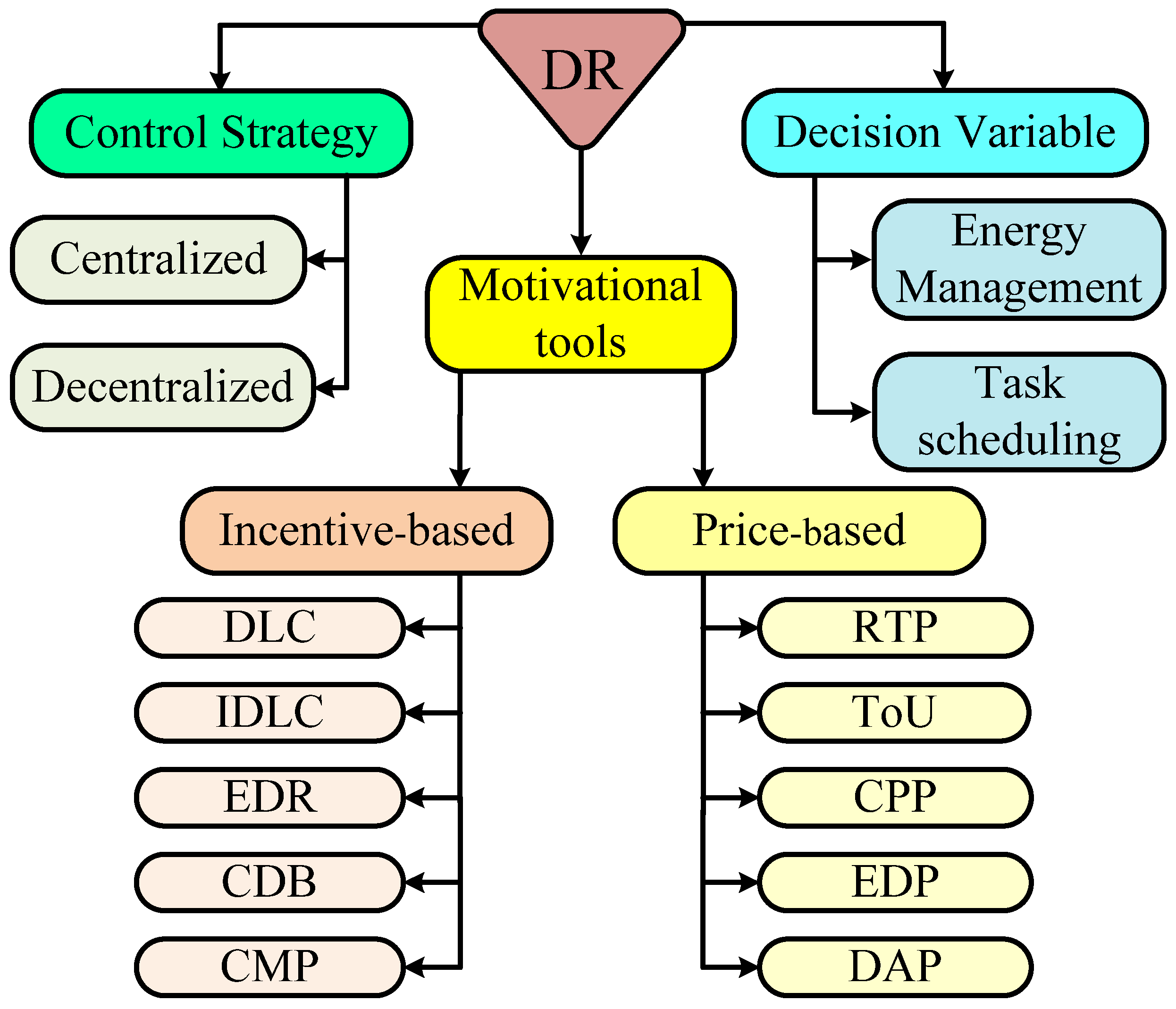

1.4. Demand Response

1.4.1. Decision Variables

1.4.2. Motivation Tools

1.5. Optimization Algorithms

1.6. Main Innovation and Contribution

- 1-

- Developing accurate CESG component models.

- 2-

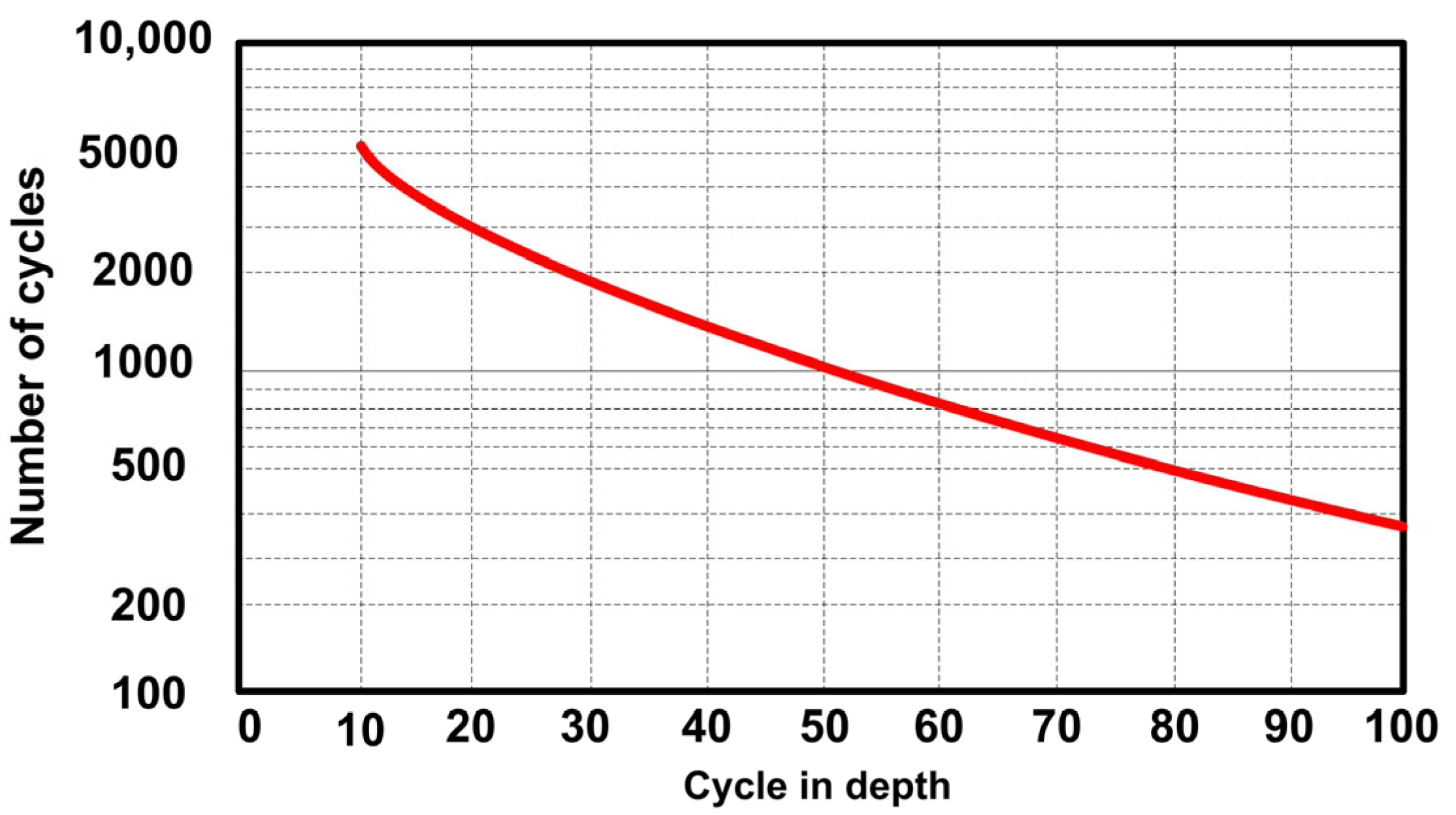

- Creating a new hourly model for LIB degradation.

- 3-

- Implementing a real DR strategy considering the current charge level (CCL) of the ESS, the day-ahead weather, and load levels.

- 4-

- Introducing optimal dispatch strategy for the power flow between the RESs, the loads, and the ESS.

- 5-

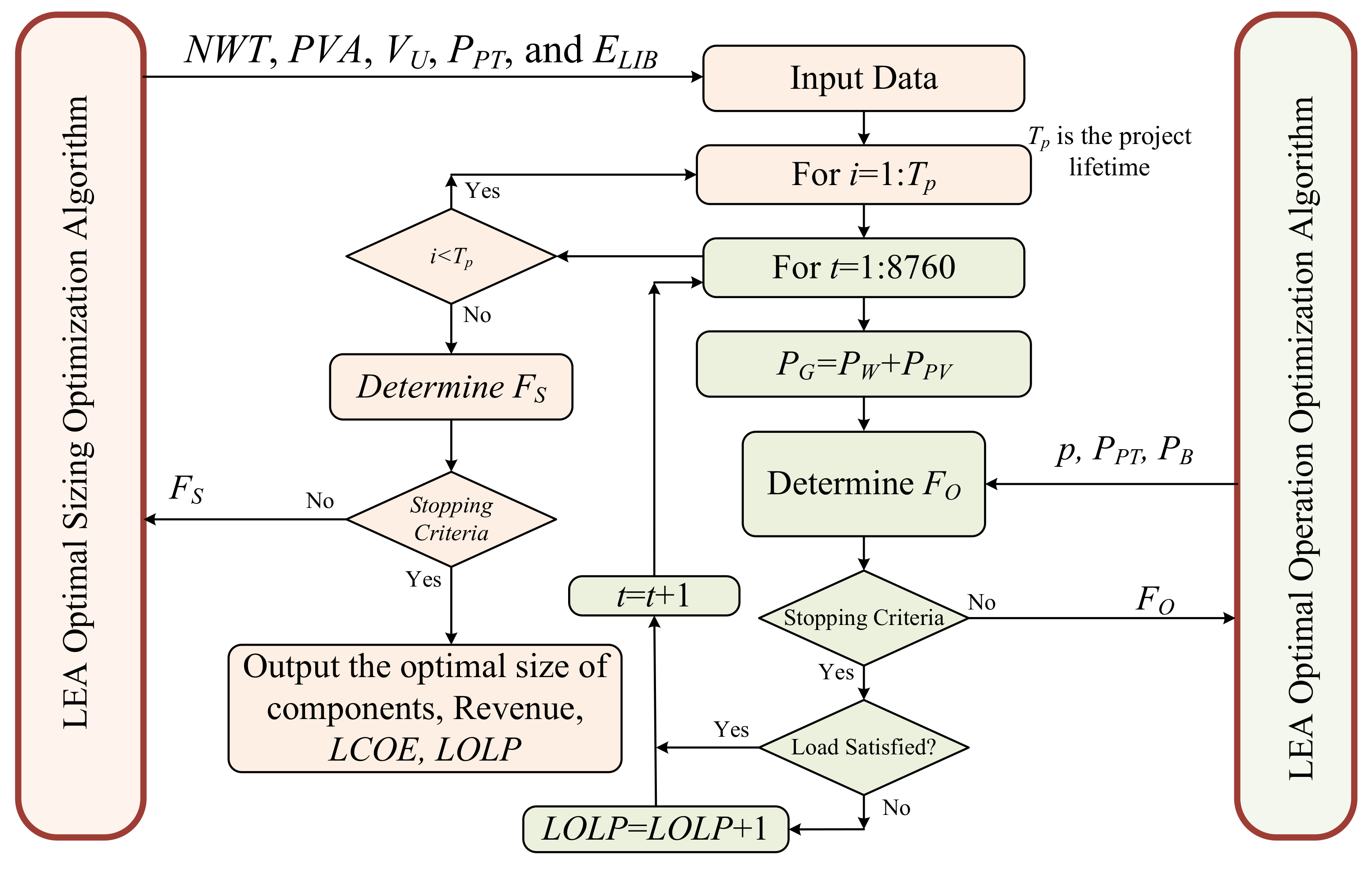

- Implementing a nested LEA for optimal operation in the inner optimization loop and optimal sizing in the outer loop.

- 6-

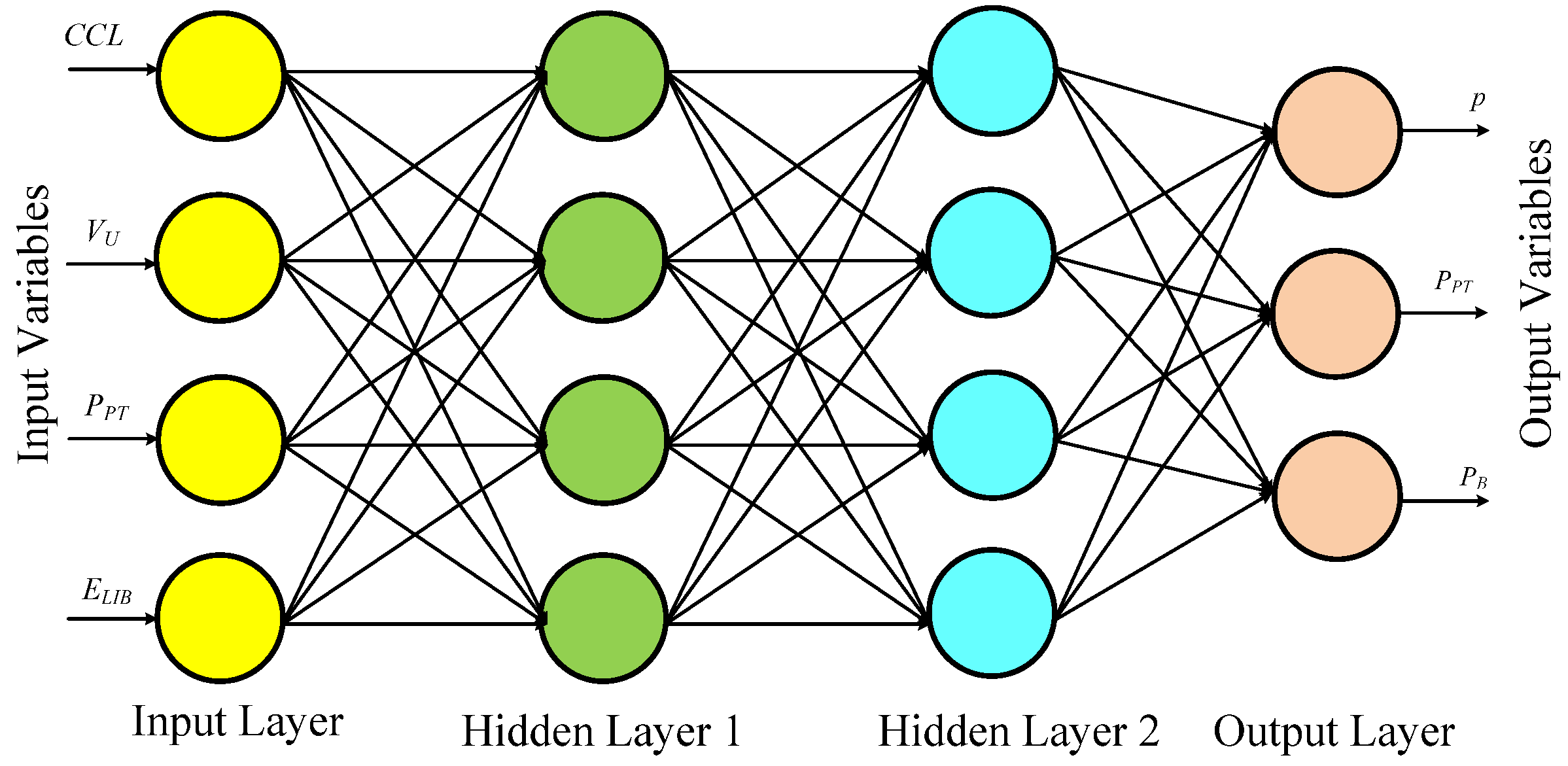

- Introducing an ANN strategy for replacing the inner optimization loop to substantially reduce the convergence time of the proposed sizing strategy.

1.7. Study Outlines

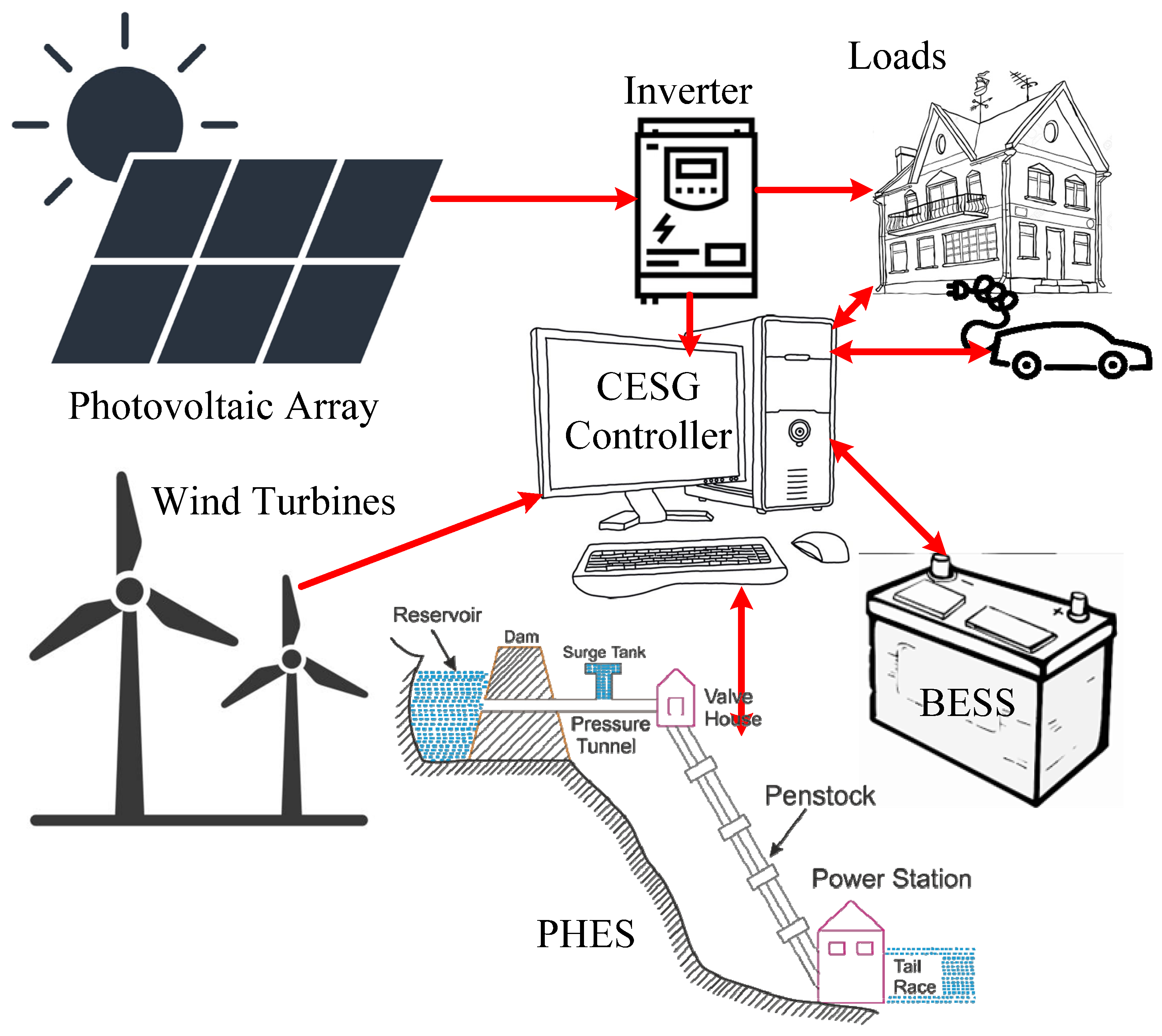

2. Smart Grid System Configuration

2.1. Modeling of CESG

2.1.1. Modeling of Wind Turbines

2.1.2. Modeling of the Photovoltaic System

2.1.3. Modeling of the BESS

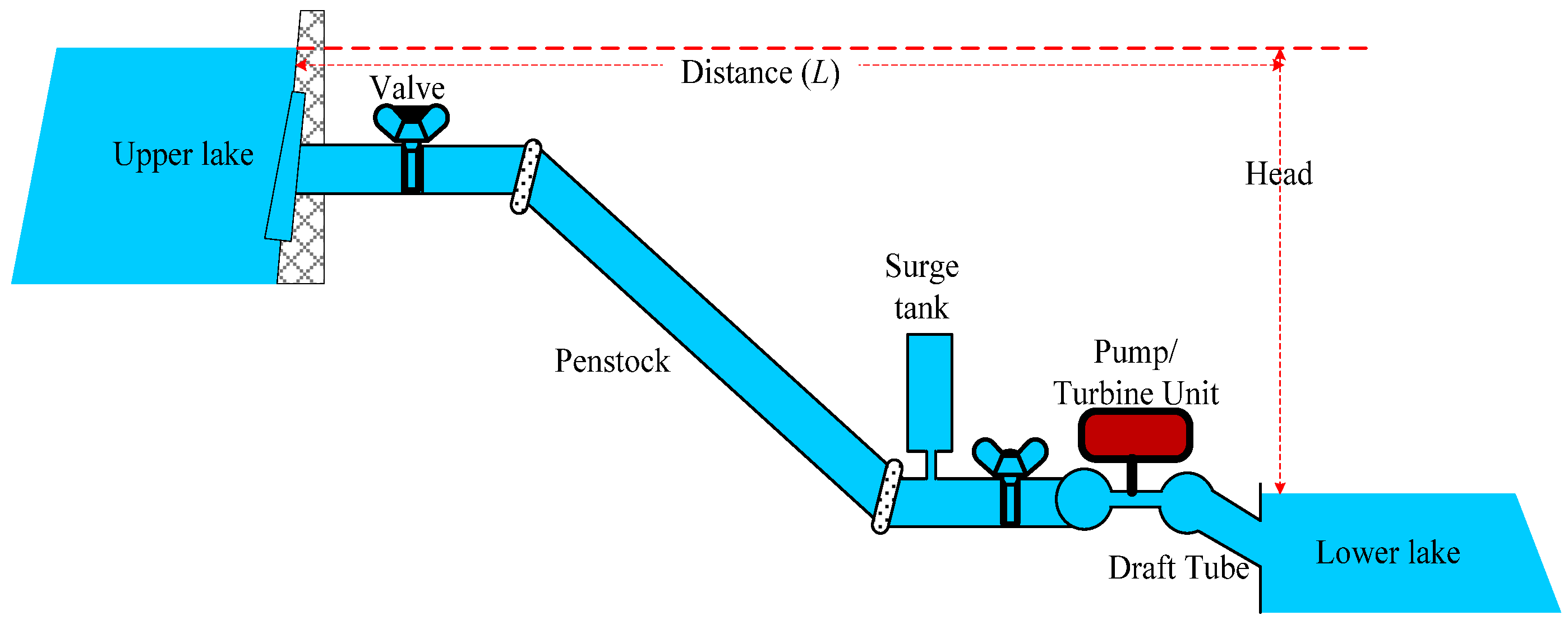

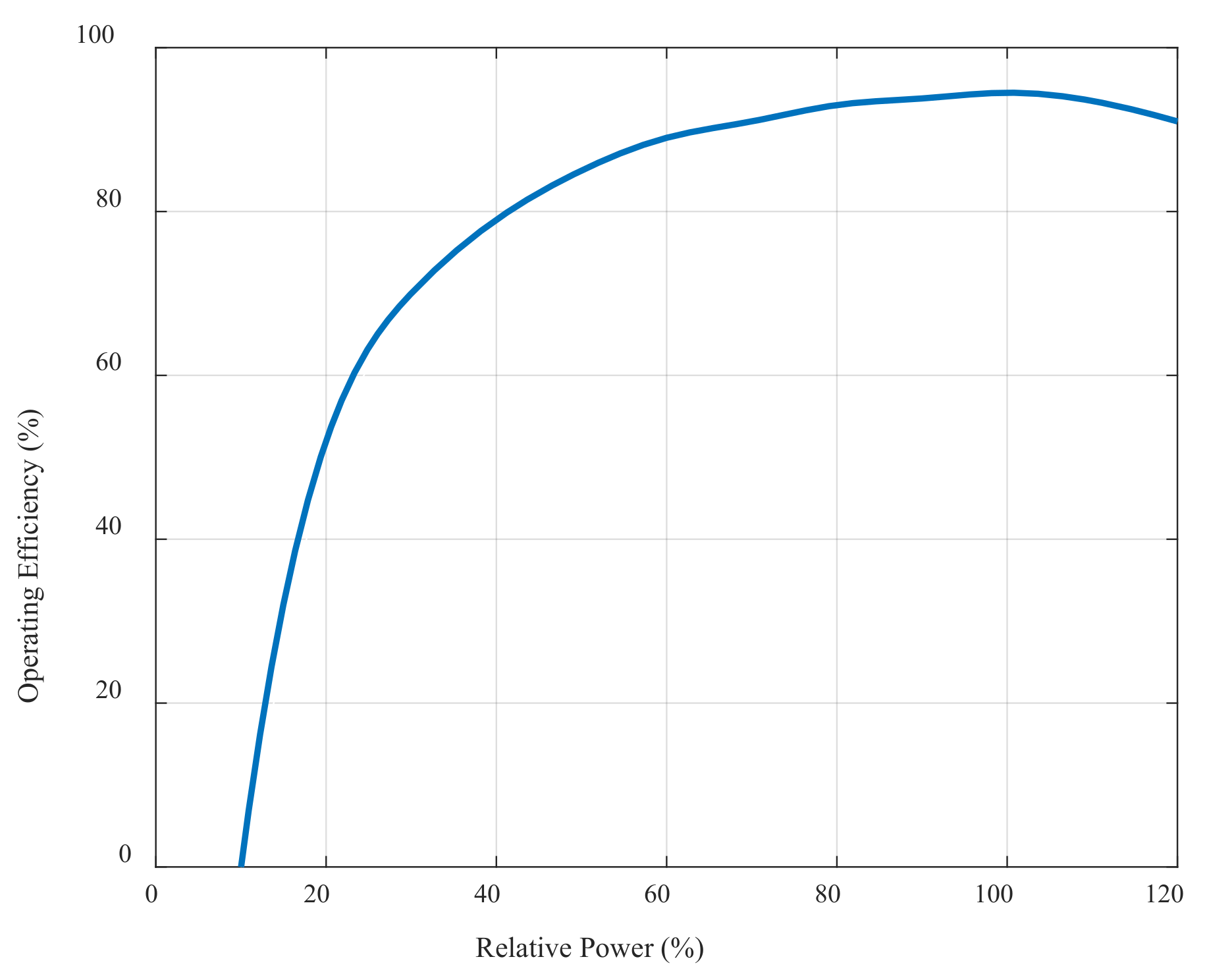

2.1.4. Modeling of PHES

2.2. Optimal Dispatch Strategy

2.2.1. Demand Response Implementation

2.2.2. Clean Energy Smart Grid Reliability

2.2.3. The Revenue of the CESG

2.2.4. Satisfaction Factor

2.2.5. Multi-Objective Functions

2.2.6. Energy Balance Modeling

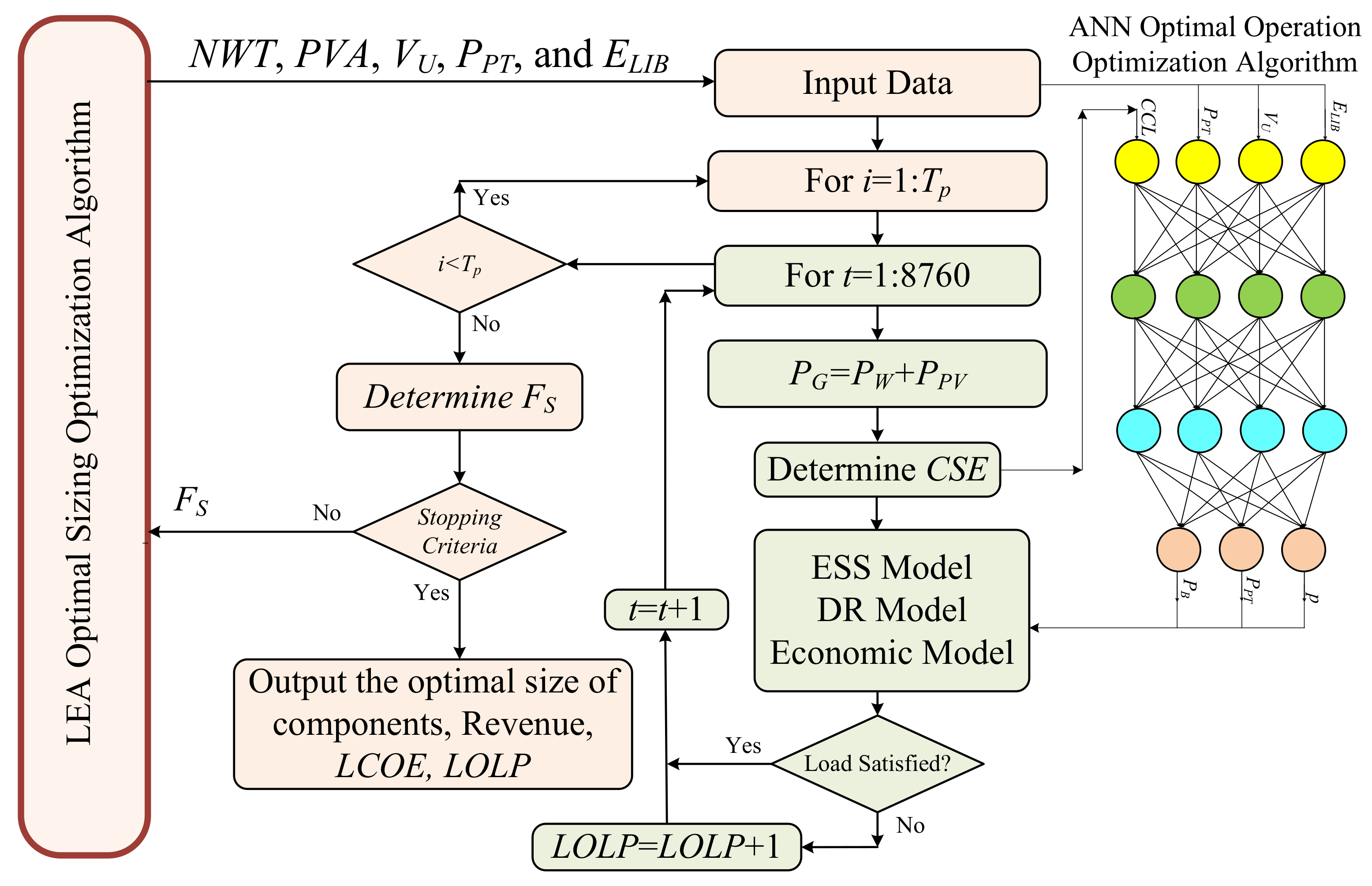

3. Optimization Algorithm

3.1. Lotus Effect Optimization Algorithm (LEA)

3.1.1. Exploration Phase (Pollination)

3.1.2. Extraction Phase (Self-Cleaning)

3.1.3. Benefits of the LEA

3.2. Replacing Internal LEA Using ANN

4. Software Implementation

5. Simulation Results

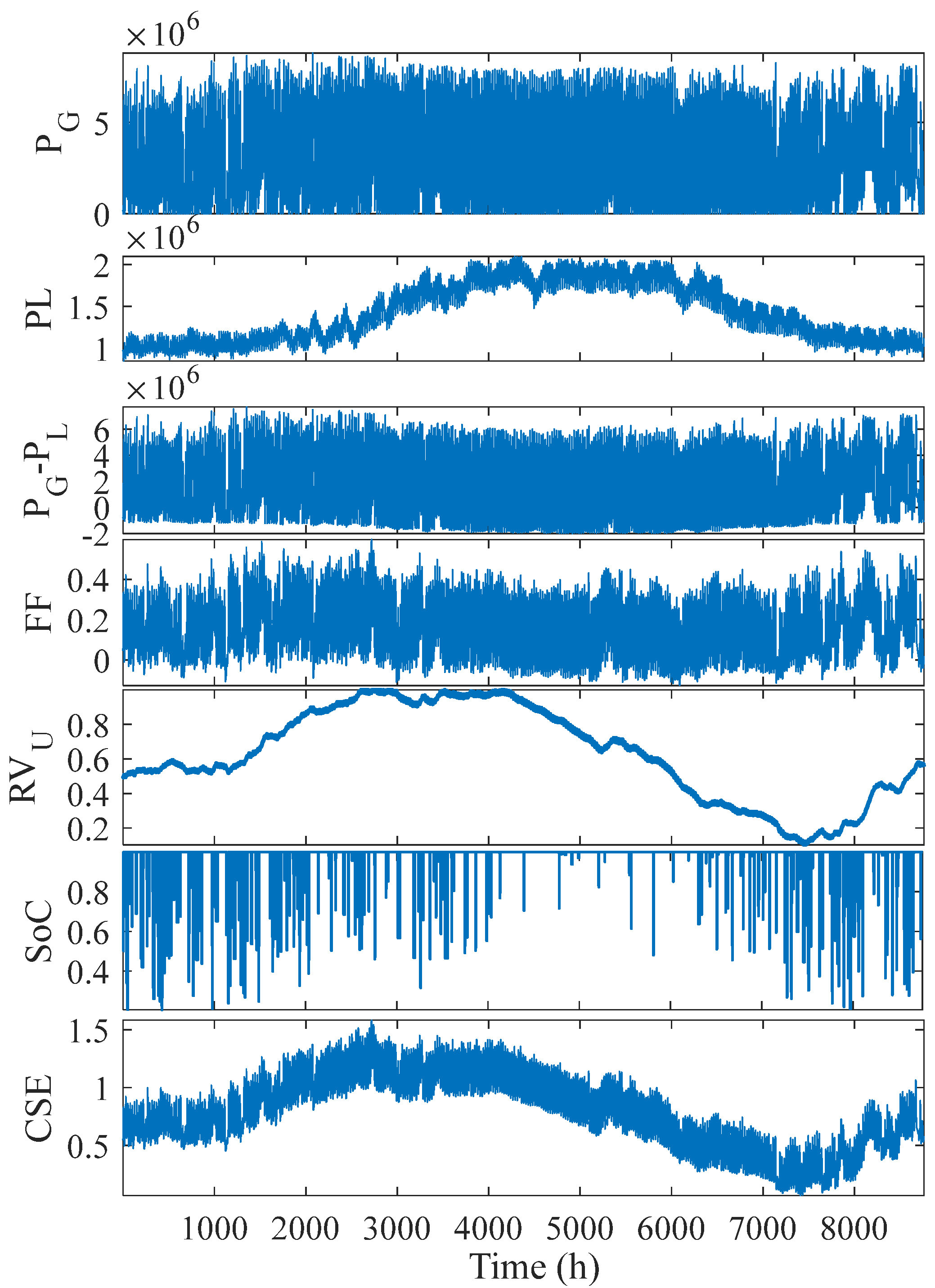

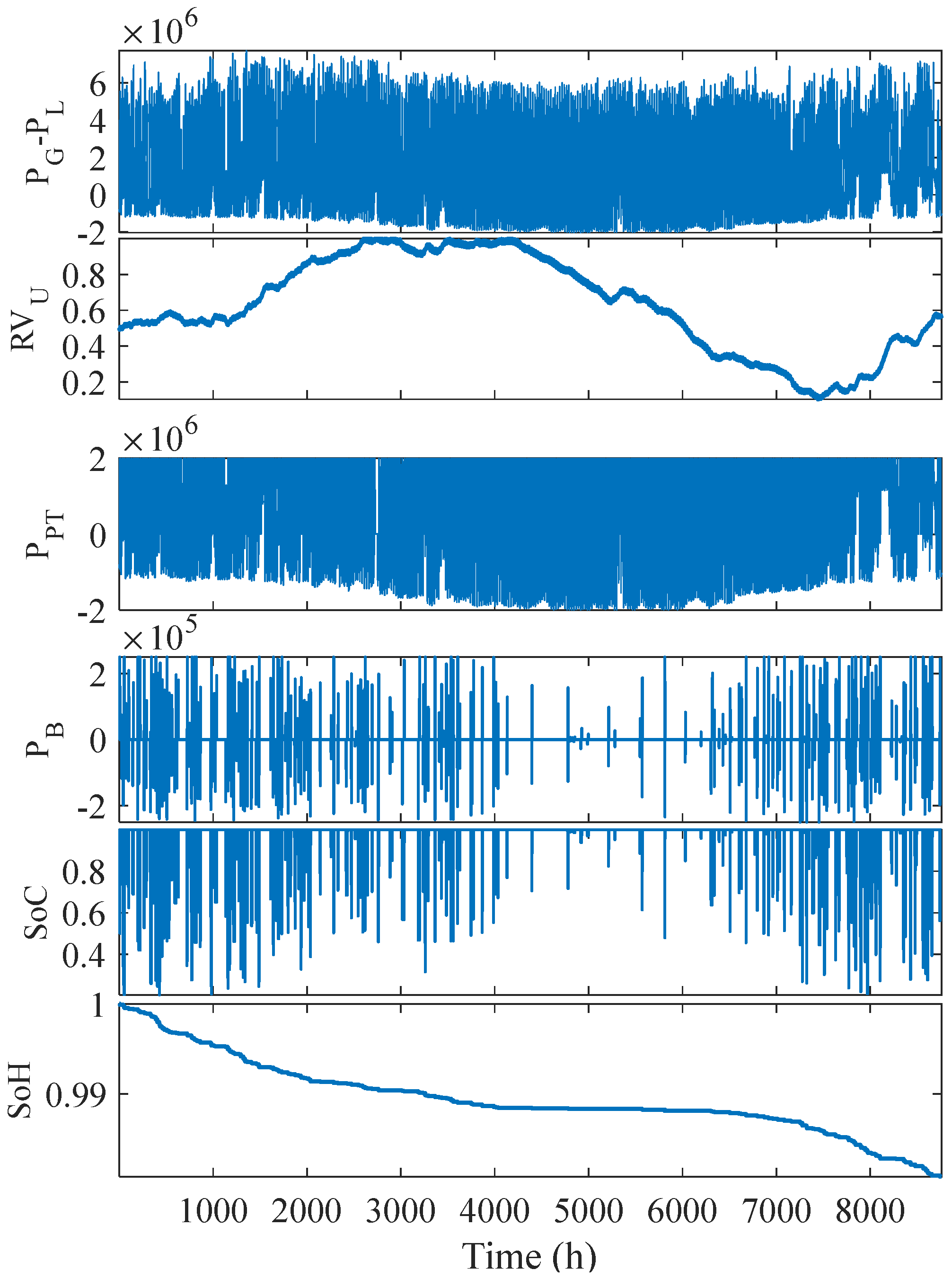

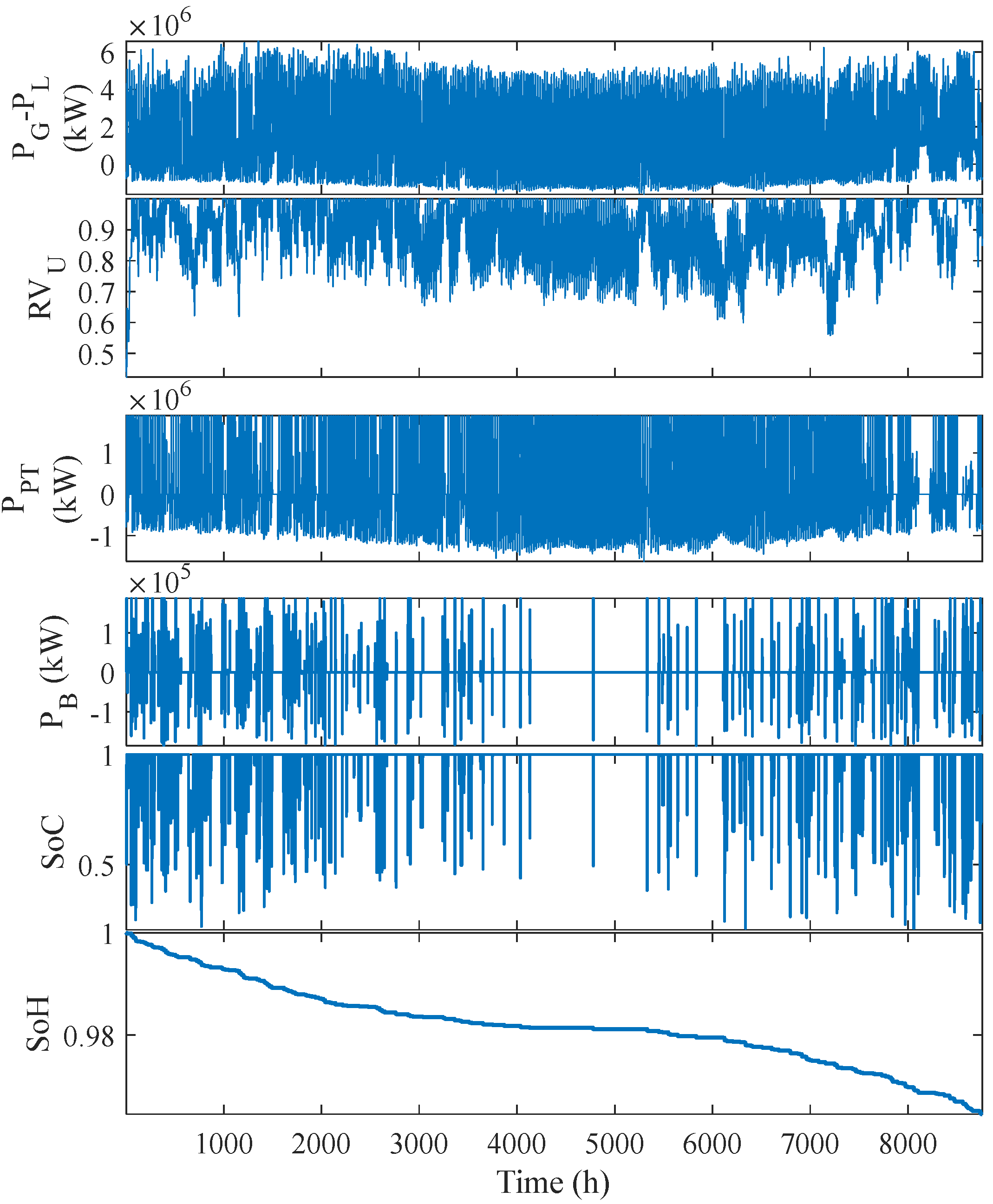

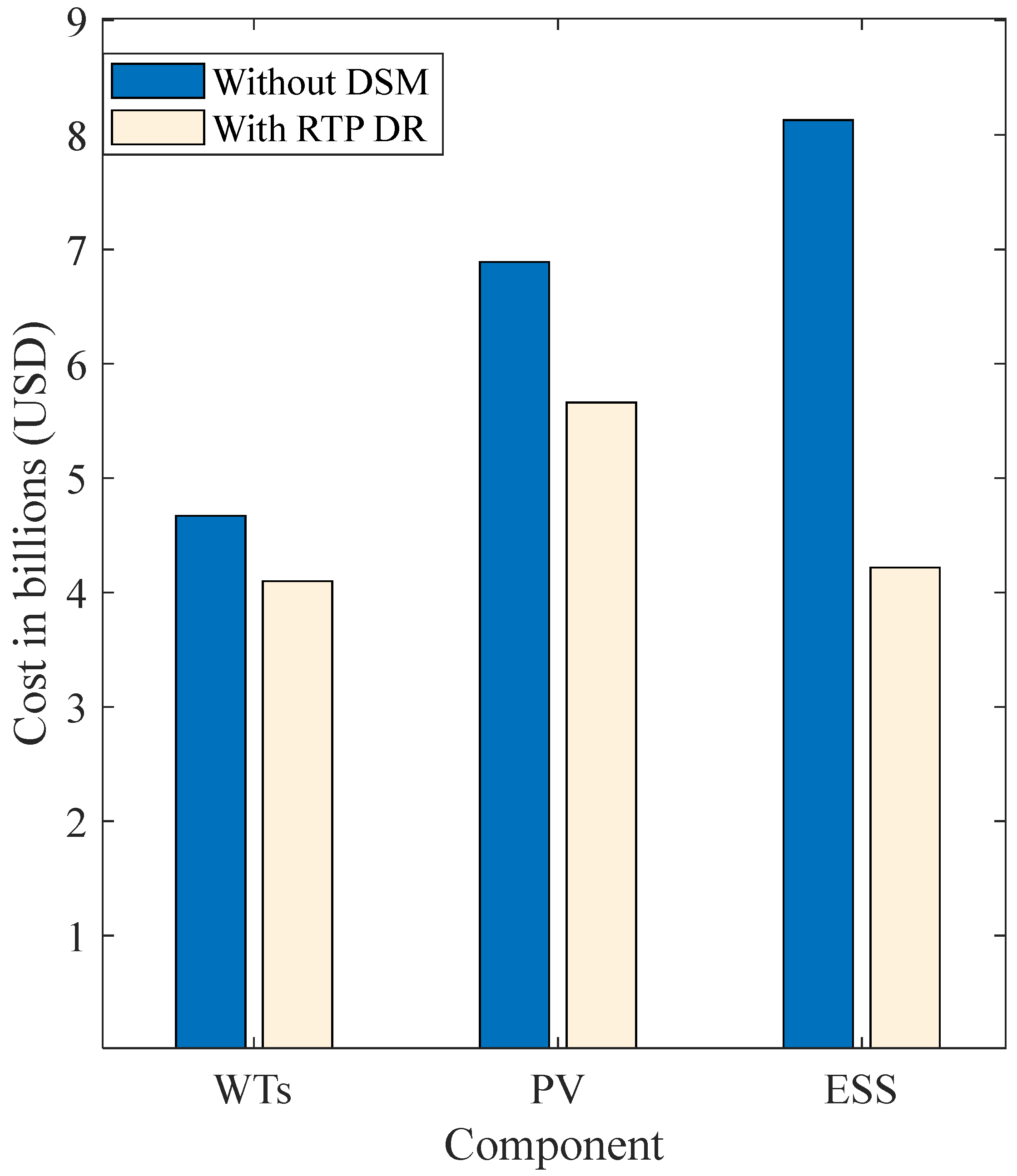

5.1. Importance of the DR Strategy

| Component | Without DSM | With RTP DR | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Item | WT | PV | ESS | LCOE USD/kW | WT | PV | ESS | LCOE USD/kW | |

| Size | 38,500 Units | 28.5 × 106 m2 | 7.65 × 106 kWh | 0.0792 | 33,803 Units | 23.4 × 106 m2 | 4.46 × 106 kWh | 0.0571 | |

| Cost | USD | 4.67 × 109 | 6.89 × 109 | 8.13 × 109 | 4.1 × 109 | 5.66 × 109 | 4.22 × 109 | ||

| % | 23.7 | 35 | 41.3 | 29.3 | 40.5 | 30.2 | |||

5.2. The Performance of Proposed Optimization Algorithm

| Algorithm | Tc (h) | tc ANN-LEA % of Others | LCOE USD/kWh | Fitness |

|---|---|---|---|---|

| ANN-LEA | 0.23 | -- | 0.057124 | 0.464628 |

| NLEA | 21.3 | 1.079812 | 0.057101 | 0.464628 |

| GWO [91] | 28.35 | 0.811287 | 0.057413 | 0.464659 |

| PSO [92] | 55.65 | 0.413297 | 0.057425 | 0.465125 |

| CS [93] | 93.45 | 0.246121 | 0.058234 | 0.467178 |

| BA [94] | 84.45 | 0.272351 | 0.059428 | 0.468637 |

| ABC [95] | 92.7 | 0.248112 | 0.058574 | 0.466674 |

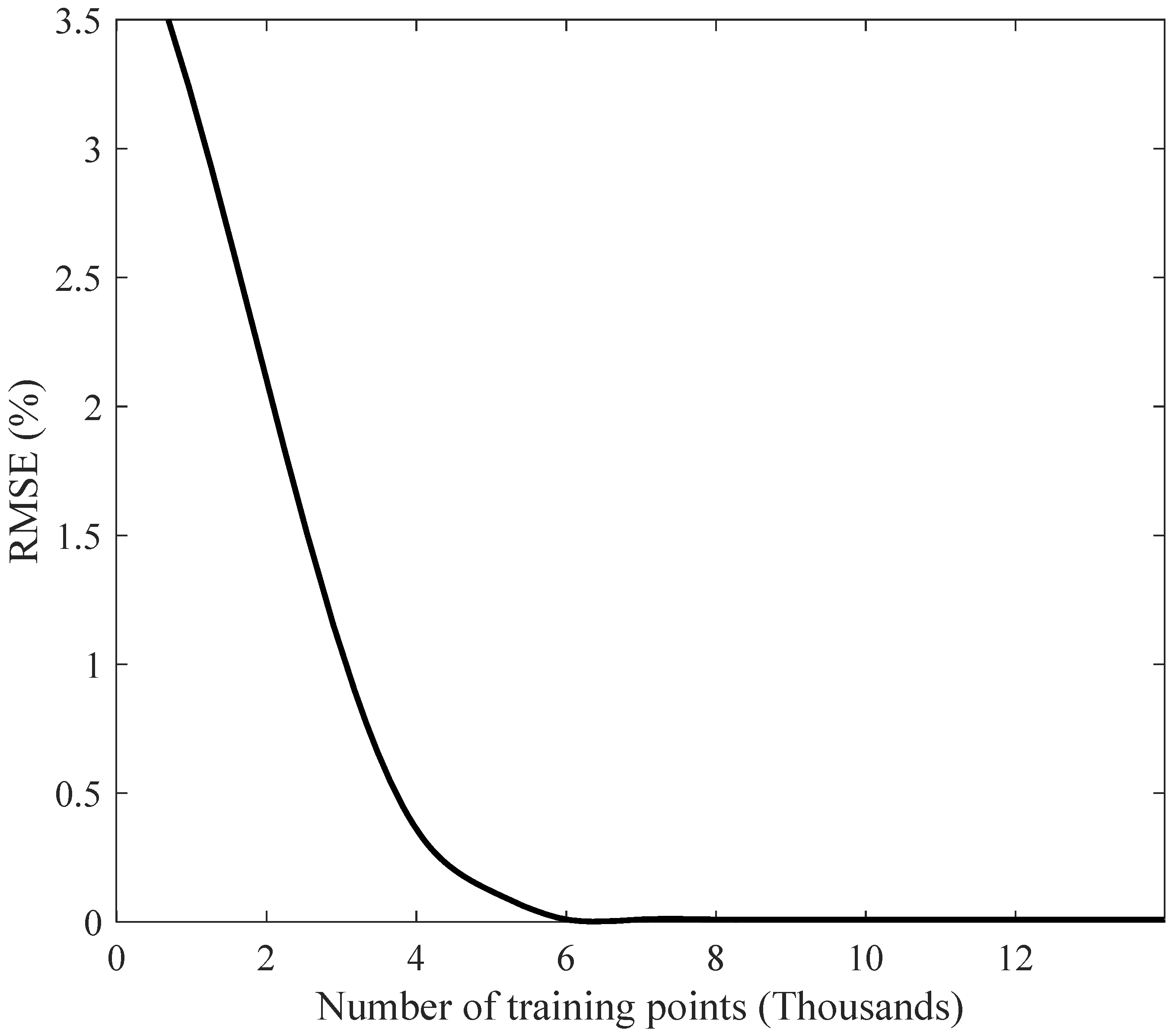

5.3. ANN-LEA Compared to a Nested LEA

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACC | Achievable Cycle Count | HRES | Hybrid Renewable Energy Systems |

| ANN | Artificial Neural Network | IDLC | Indirect–Direct Load Control |

| BA | Bat Algorithm | IEA | International Energy Agency |

| BESS | Battery Energy Storage System | LEA | Lotus Effect Optimization Algorithm |

| CCL | Current Charge Level | LIB | Lithium-Ion Battery |

| CDB | Customer Demand Bidding | LP | Linear Programming |

| CMP | Central Maine Power | MCA | Musical Chairs Algorithm |

| CPP | Critical Peak Pricing | MILP | Mixed-Integer Linear Programming |

| CS | Cuckoo Search | MPPT | Maximum Power Point Tracker |

| DAP | Day-ahead Pricing | NLEA | Nested LEA |

| DG | Distributed Generation | NLP | Non-Linear Programming |

| DLC | Direct Load Control | PED | Price elasticity of demand |

| DLC | Direct Load Control | PHES | Pumped Hydroelectric Energy Storage |

| DoD | Depth of Discharge | PSO | Particle Swarm Optimization |

| DR | Demand Response | PV | Photovoltaic |

| DSM | Demand-Side Management | PVA | PV Area |

| EDP | Extreme Day Pricing | RESs | Renewable Energy Sources |

| EDP | Extreme Day Pricing | RTP | Real-Time Pricing |

| EDR | Emergency DR | SGTs | Smart Grid Technologies |

| ESS | Energy Storage System | SoC | State of Charge of the Battery |

| FF | Forecast Factor | SoH | State of Health of the Battery |

| GA | Genetic Algorithm | ToU | Time of Use Pricing |

| GWO | Grey Wolf Optimization | WT | Wind Turbine |

| HESS | Hydrogen Energy Storage System | CESG | Clean energy smart grid |

References

- Santos, S.F.; Fitiwi, D.Z.; Shafie-Khah, M.; Bizuayehu, A.; Catalão, J. Optimal sizing and placement of smart-grid-enabling technologies for maximizing renewable integration. In Smart Energy Grid Engineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 47–81. [Google Scholar]

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Ali, B.M.; Algburi, S.; Alzoubi, H.M.; Al-Jiboory, A.K.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. The renewable energy role in the global energy Transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- Lu, B.; Blakers, A.; Stocks, M.; Chensg, C.; Nadolny, A. A zero-carbon, reliable and affordable energy future in Australia. Energy 2021, 220, 119678. [Google Scholar] [CrossRef]

- Eltamaly, A.M. A novel energy storage and demand side management for entire green smart grid system for NEOM city in Saudi Arabia. Energy Storage 2023, 6, e515. [Google Scholar] [CrossRef]

- Alzahrani, A.; Petri, I.; Rezgui, Y.; Ghoroghi, A. Developing Smart Energy Communities around Fishery Ports: Toward Zero-Carbon Fishery Ports. Energies 2020, 13, 2779. [Google Scholar] [CrossRef]

- Martinot, E. Grid integration of renewable energy: Flexibility, innovation, and experience. Annu. Rev. Environ. Resour. 2016, 41, 223–251. [Google Scholar] [CrossRef]

- Mannini, R.; Eynard, J.; Grieu, S. A survey of recent advances in the smart management of microgrids and networked microgrids. Energies 2022, 15, 7009. [Google Scholar] [CrossRef]

- Souza, M.E.T.; Freitas, L.C.G. Grid-connected and seamless transition modes for microgrids: An overview of control methods, operation elements, and general requirements. IEEE Access 2022, 10, 97802–97834. [Google Scholar] [CrossRef]

- Mansouri, S.A.; Ahmarinejad, A.; Nematbakhsh, E.; Javadi, M.S.; Nezhad, A.E.; Catalão, J.P. A sustainable framework for multi-microgrids energy management in automated distribution network by considering smart homes and high penetration of renewable energy resources. Energy 2022, 245, 123228. [Google Scholar] [CrossRef]

- Pommeret, A.; Schubert, K. Optimal energy transition with variable and intermittent renewable electricity generation. J. Econ. Dyn. Control 2022, 134, 104273. [Google Scholar] [CrossRef]

- Colbertaldo, P.; Agustin, S.B.; Campanari, S.; Brouwer, J. Impact of hydrogen energy storage on California electric power system: Towards 100% renewable electricity. Int. J. Hydrogen Energy 2019, 44, 9558–9576. [Google Scholar] [CrossRef]

- Elmorshedy, M.F.; Elkadeem, M.; Kotb, K.M.; Taha, I.B.; Mazzeo, D. Optimal design and energy management of an isolated fully renewable energy system integrating batteries and supercapacitors. Energy Convers. Manag. 2021, 245, 114584. [Google Scholar] [CrossRef]

- Tawfik, T.; Badr, M.; El-Kady, E.; Abdellatif, O. Optimization and energy management of hybrid standalone energy system: A case study. Renew. Energy Focus 2018, 25, 48–56. [Google Scholar] [CrossRef]

- Newbolt, T.M.; Mandal, P.; Wang, H. Implementation of Battery EVs and BESS into RAPSim Software to Enrich Power Engineering Education in DER-Integrated Distribution Systems. In Proceedings of the 2021 North American Power Symposium (NAPS), College Station, TX, USA, 14–16 November 2021; pp. 1–6. [Google Scholar]

- Sigurðsson, G.Á.; Abdel-Fattah, M.F. Smart grids simulation tools: Overview and recommendations. In Proceedings of the 2021 IEEE 62nd International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 15–17 November 2021; pp. 1–6. [Google Scholar]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.; Gholami, A. A systematic review of solar photovoltaic energy systems design modelling, algorithms, and software. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 6709–6736. [Google Scholar] [CrossRef]

- Ma, T.; Yang, H.; Lu, L.J.S.E. Development of a model to simulate the performance characteristics of crystalline silicon photovoltaic modules/strings/arrays. Sol. Energy 2014, 100, 31–41. [Google Scholar] [CrossRef]

- Luna-Rubio, R.; Trejo-Perea, M.; Vargas-Vázquez, D.; Ríos-Moreno, G. Optimal sizing of renewable hybrids energy systems: A review of methodologies. Sol. Energy 2012, 86, 1077–1088. [Google Scholar] [CrossRef]

- Gouda, N. Synergistic Integration of Demand Side Management, Renewable Energy Sources, Battery, and Hydrogen Storage in Hybrid Energy Systems. 2024. Available online: http://hdl.handle.net/10222/83876 (accessed on 1 October 2024).

- Ju, C.; Wang, P. Energy management system for microgrids including batteries with degradation costs. In Proceedings of the 2016 IEEE International Conference on Power System Technology (POWERCON), Wollongong, NSW, Australia, 28 September–1 October 2016; pp. 1–6. [Google Scholar]

- Eltamaly, A.M. Smart Decentralized Electric Vehicle Aggregators for Optimal Dispatch Technologies. Energies 2023, 16, 8112. [Google Scholar] [CrossRef]

- Talent, O.; Du, H. Optimal sizing and energy scheduling of photovoltaic-battery systems under different tariff structures. Renew. Energy 2018, 129, 513–526. [Google Scholar] [CrossRef]

- Tan, K.M.; Babu, T.S.; Ramachandaramurthy, V.K.; Kasinathan, P.; Solanki, S.G.; Raveendran, S.K. Empowering smart grid: A comprehensive review of energy storage technology and application with renewable energy integration. J. Energy Storage 2021, 39, 102591. [Google Scholar] [CrossRef]

- Wali, S.B.; Hannan, M.; Reza, M.; Ker, P.J.; Begum, R.; Abd Rahman, M.; Mansor, M. Battery storage systems integrated renewable energy sources: A biblio metric analysis towards future directions. J. Energy Storage 2021, 35, 102296. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Mohamed, M.A.; Al-Saud, M.S.; Alolah, A.I. Load management as a smart grid concept for sizing and designing of hybrid renewable energy systems. Eng. Optimiz. 2017, 49, 1813–1828. [Google Scholar] [CrossRef]

- Sheikhi, A.; Rayati, M.; Ranjbar, A.M. Energy Hub optimal sizing in the smart grid; machine learning approach. In Proceedings of the 2015 IEEE Power & Energy Society Innovative Smart Grid Technologies Conference (ISGT), Washington, DC, USA, 18–20 February 2015; pp. 1–5. [Google Scholar]

- Javadi, M.S.; Firuzi, K.; Rezanejad, M.; Lotfi, M.; Gough, M.; Catalão, J.P. Optimal sizing and siting of electrical energy storage devices for smart grids considering time-of-use programs. In Proceedings of the IECON 2019-45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 4157–4162. [Google Scholar]

- Zou, B.; Peng, J.; Li, S.; Li, Y.; Yan, J.; Yang, H. Comparative study of the dynamic programming-based and rule-based operation strategies for grid-connected PV-battery systems of office buildings. Appl. Energy 2022, 305, 117875. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Alotaibi, M.A. Novel Fuzzy-Swarm Optimization for Sizing of Hybrid Energy Systems Applying Smart Grid Concepts. IEEE Access 2021, 9, 93629–93650. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Alotaibi, M.A.; Elsheikh, W.A.; Alolah, A.I.; Ahmed, M.A. Novel Demand Side-Management Strategy for Smart Grid Concepts Applications in Hybrid Renewable Energy Systems. In Proceedings of the 2022 4th International Youth Conference on Radio Electronics, Electrical and Power Engineering (REEPE), Moscow, Russia, 17–19 March 2022; pp. 1–7. [Google Scholar]

- Almutairi, Z.A.; Eltamaly, A.M. Synergistic Effects of Energy Storage Systems and Demand-Side Management in Optimizing Zero-Carbon Smart Grid Systems. Energies 2024, 17, 5637. [Google Scholar] [CrossRef]

- Gatsis, N.; Giannakis, G.B. Cooperative multi-residence demand response scheduling. In Proceedings of the 2011 45th Annual Conference on Information Sciences and Systems, Baltimore, MD, USA, 23–25 March 2011; pp. 1–6. [Google Scholar]

- Samadi, P.; Mohsenian-Rad, A.-H.; Schober, R.; Wong, V.W.; Jatskevich, J. Optimal real-time pricing algorithm based on utility maximization for smart grid. In Proceedings of the 2010 First IEEE International Conference on Smart Grid Communications, Gaithersburg, MD, USA, 4–6 October 2010; pp. 415–420. [Google Scholar]

- Yu, M.; Hong, S.H. Supply–demand balancing for power management in smart grid: A Stackelberg game approach. Appl. Energy 2016, 164, 702–710. [Google Scholar] [CrossRef]

- Zamani, A.G.; Zakariazadeh, A.; Jadid, S. Day-ahead resource scheduling of a renewable energy based virtual power plant. Appl. Energy 2016, 169, 324–340. [Google Scholar] [CrossRef]

- Chang, T.-H.; Alizadeh, M.; Scaglione, A. Real-time power balancing via decentralized coordinated home energy scheduling. IEEE Trans. Smart Grid 2013, 4, 1490–1504. [Google Scholar] [CrossRef]

- Tindemans, S.H.; Trovato, V.; Strbac, G. Decentralized control of thermostatic loads for flexible demand response. IEEE Trans. Control. Syst. Technol. 2015, 23, 1685–1700. [Google Scholar] [CrossRef]

- Javanmard, B.; Tabrizian, M.; Ansarian, M.; Ahmarinejad, A. Energy management of multi-microgrids based on game theory approach in the presence of demand response programs, energy storage systems and renewable energy resources. J. Energy Storage 2021, 42, 102971. [Google Scholar] [CrossRef]

- Fang, X.; Zhao, Q.; Wang, J.; Han, Y.; Li, Y. Multi-agent deep reinforcement learning for distributed energy management and strategy optimization of microgrid market. Sustain. Cities Soc. 2021, 74, 103163. [Google Scholar] [CrossRef]

- Assad, U.; Hassan, M.A.S.; Farooq, U.; Kabir, A.; Khan, M.Z.; Bukhari, S.S.H.; Jaffri, Z.u.A.; Olah, J.; Popp, J. Smart grid, demand response and optimization: A critical review of computational methods. Energies 2022, 15, 2003. [Google Scholar] [CrossRef]

- Xu, B.; Wang, J.; Guo, M.; Lu, J.; Li, G.; Han, L. A hybrid demand response mechanism based on real-time incentive and real-time pricing. Energy 2021, 231, 120940. [Google Scholar] [CrossRef]

- Agnetis, A.; De Pascale, G.; Detti, P.; Vicino, A. Load scheduling for household energy consumption optimization. IEEE Trans. Smart Grid 2013, 4, 2364–2373. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Mohamed, M.A. Optimal sizing and designing of hybrid renewable energy systems in smart grid applications. In Advances in Renewable Energies and Power Technologies; Elsevier: Amsterdam, The Netherlands, 2018; pp. 231–313. [Google Scholar]

- Malik, A.; Ravishankar, J. A review of demand response techniques in smart grids. In Proceedings of the 2016 IEEE Electrical Power and Energy Conference (EPEC), Ottawa, ON, Canada, 12–14 October 2016; pp. 1–6. [Google Scholar]

- Balouch, S.; Abrar, M.; Abdul Muqeet, H.; Shahzad, M.; Jamil, H.; Hamdi, M.; Malik, A.S.; Hamam, H. Optimal scheduling of demand side load management of smart grid considering energy efficiency. Front. Energy Res. 2022, 10, 861571. [Google Scholar] [CrossRef]

- Eid, C.; Koliou, E.; Valles, M.; Reneses, J.; Hakvoort, R. Time-based pricing and electricity demand response: Existing barriers and next steps. Util. Policy 2016, 40, 15–25. [Google Scholar] [CrossRef]

- Poletti, S.; Wright, J. Real-Time Pricing and Imperfect Competition in Electricity Markets. J. Ind. Econ. 2020, 68, 93–135. [Google Scholar] [CrossRef]

- Kaabeche, A.; Ibtiouen, R. Techno-economic optimization of hybrid photovoltaic/wind/diesel/battery generation in a stand-alone power system. Sol. Energy 2014, 103, 171–182. [Google Scholar] [CrossRef]

- Smaoui, M.; Abdelkafi, A.; Krichen, L. Optimal sizing of stand-alone photovoltaic/wind/hydrogen hybrid system supplying a desalination unit. Sol. Energy 2015, 120, 263–276. [Google Scholar] [CrossRef]

- Fadaee, M.; Radzi, M.A.M. Multi-objective optimization of a stand-alone hybrid renewable energy system by using evolutionary algorithms: A review. Renew. Sustain. Energy Rev. 2012, 16, 3364–3369. [Google Scholar] [CrossRef]

- Bhandari, B.; Lee, K.-T.; Lee, G.-Y.; Cho, Y.-M.; Ahn, S.-H. Optimization of hybrid renewable energy power systems: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2015, 2, 99–112. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Jin, T.; Su, W. Multi-agent energy management of smart islands using primal-dual method of multipliers. Energy 2020, 208, 118306. [Google Scholar] [CrossRef]

- Borowy, B.S.; Salameh, Z.M. Methodology for optimally sizing the combination of a battery bank and PV array in a wind/PV hybrid system. IEEE Trans. Energy Convers. 1996, 11, 367–373. [Google Scholar] [CrossRef]

- Esmaeili, Z.; Hosseini, S.H. Optimal Energy Management of Microgrids using Quantum Teaching Learning Based Algorithm. AUT J. Electr. Eng. 2023, 55, 8. [Google Scholar]

- Branco, H.; Castro, R.; Lopes, A.S. Battery energy storage systems as a way to integrate renewable energy in small isolated power systems. Energy Sustain. Dev. 2018, 43, 90–99. [Google Scholar] [CrossRef]

- Babu, P.V.; Singh, S. Optimal Placement of DG in Distribution network for Power loss minimization using NLP & PLS Technique. Energy Procedia 2016, 90, 441–454. [Google Scholar]

- Torkan, R.; Ilinca, A.h.o.o.; Ghorbanzadeh, M. A genetic algorithm optimization approach for smart energy management of microgrids. Renew. Energy 2022, 197, 852–863. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Eltamaly, A.M.; Alolah, A.I. PSO-Based Smart Grid Application for Sizing and Optimization of Hybrid Renewable Energy Systems. PLoS ONE 2016, 11, e0159702. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Al-Saud, M.S. Nested multi-objective PSO for optimal allocation and sizing of renewable energy distributed generation. J. Renew. Sustain. Energy 2018, 10, 35302. [Google Scholar] [CrossRef]

- Arif, S.M.; Hussain, A.; Lie, T.T.; Ahsan, S.M.; Khan, H.A. Analytical hybrid particle swarm optimization algorithm for optimal siting and sizing of distributed generation in smart grid. J. Mod. Power Syst. Clean Energy 2020, 8, 1221–1230. [Google Scholar] [CrossRef]

- Hakimi, S.M.; Tafreshi, S.M.M. Optimal sizing of a stand-alone hybrid power system via particle swarm optimization for Kahnouj area in south-east of Iran. Renew. Energy Rev. 2009, 34, 1855–1862. [Google Scholar] [CrossRef]

- Duchaud, J.-L.; Notton, G.; Darras, C.; Voyant, C. Multi-Objective Particle Swarm optimal sizing of a renewable hybrid power plant with storage. Renew. Energy 2019, 131, 1156–1167. [Google Scholar] [CrossRef]

- Alotaibi, M.A.; Eltamaly, A.M. A Smart Strategy for Sizing of Hybrid Renewable Energy System to Supply Remote Loads in Saudi Arabia. Energies 2021, 14, 7069. [Google Scholar] [CrossRef]

- Nadjemi, O.; Nacer, T.; Hamidat, A.; Salhi, H. Optimal hybrid PV/wind energy system sizing: Application of cuckoo search algorithm for Algerian dairy farms. Renew. Sustain. Energy Rev. 2017, 70, 352–365. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Eltamaly, A.M.; Alolah, A.I.; Hatata, A.Y. A novel framework-based cuckoo search algorithm for sizing and optimization of grid-independent hybrid renewable energy systems. Int. J. Green Energy 2018, 16, 86–100. [Google Scholar] [CrossRef]

- Tabak, A.; Kayabasi, E.; Guneser, M.T.; Ozkaymak, M. Grey wolf optimization for optimum sizing and controlling of a PV/WT/BM hybrid energy system considering TNPC, LPSP, and LCOE concepts. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 44, 1508–1528. [Google Scholar] [CrossRef]

- Mahmoud, F.S.; Diab, A.A.Z.; Ali, Z.M.; El-Sayed, A.-H.M.; Alquthami, T.; Ahmed, M.; Ramadan, H.A. Optimal sizing of smart hybrid renewable energy system using different optimization algorithms. Energy Rep. 2022, 8, 4935–4956. [Google Scholar] [CrossRef]

- Pothireddy, K.M.R.; Vuddanti, S.; Salkuti, S.R. Impact of demand response on optimal sizing of distributed generation and customer tariff. Energies 2021, 15, 190. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Rabie, A.H. A Novel Musical Chairs Optimization Algorithm. Arab. J. Sci. Eng. 2023, 48, 10371–10403. [Google Scholar] [CrossRef]

- Dalirinia, E.; Jalali, M.; Yaghoobi, M.; Tabatabaee, H. Lotus effect optimization algorithm (LEA): A lotus nature-inspired algorithm for engineering design optimization. J. Supercomput. 2024, 80, 761–799. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Al-Shamma’a, A.A. Optimal configuration for isolated hybrid renewable energy systems. J. Renew. Sustain. Energy 2016, 8, 45502. [Google Scholar] [CrossRef]

- Skoplaki, E.; Boudouvis, A.G.; Palyvos, J.A. A simple correlation for the operating temperature of photovoltaic modules of arbitrary mounting. Sol. Energy Mater. Sol. Cells 2008, 92, 1393–1402. [Google Scholar] [CrossRef]

- Almutairi, Z.A.; Eltamaly, A.M.; El Khereiji, A.; Al Nassar, A.; Al Rished, A.; Al Saheel, N.; Al Marqabi, A.; Al Hamad, S.; Al Harbi, M.; Sherif, R. Modeling and Experimental Determination of Lithium-Ion Battery Degradation in Hot Environment. In Proceedings of the 2022 23rd International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 13–15 December 2022; pp. 1–8. [Google Scholar]

- Berrueta, A.; Heck, M.; Jantsch, M.; Ursúa, A.; Sanchis, P. Combined dynamic programming and region-elimination technique algorithm for optimal sizing and management of lithium-ion batteries for photovoltaic plants. Appl. Energy 2018, 228, 1–11. [Google Scholar] [CrossRef]

- Martins, R.; Hesse, H.C.; Jungbauer, J.; Vorbuchner, T.; Musilek, P. Optimal Component Sizing for Peak Shaving in Battery Energy Storage System for Industrial Applications. Energies 2018, 11, 2048. [Google Scholar] [CrossRef]

- Yao, L.W.; Aziz, J.A.; Kong, P.Y.; Idris, N.R.N. Modeling of lithium-ion battery using MATLAB/simulink. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 1729–1734. [Google Scholar]

- Mongird, K.; Viswanathan, V.; Balducci, P.; Alam, J.; Fotedar, V.; Koritarov, V.; Hadjerioua, B. An Evaluation of Energy Storage Cost and Performance Characteristics. Energies 2020, 13, 3307. [Google Scholar] [CrossRef]

- Eltamaly, A.M. Optimal Dispatch Strategy for Electric Vehicles in V2G Applications. Smart Cities 2023, 6, 3161–3191. [Google Scholar] [CrossRef]

- Eltamaly, A.M. An Accurate Piecewise Aging Model for Li-ion Batteries in Hybrid Renewable Energy System Applications. Arab. J. Sci. Eng. 2023, 49, 6551–6575. [Google Scholar] [CrossRef]

- Farzin, H.; Fotuhi-Firuzabad, M.; Moeini-Aghtaie, M. A practical scheme to involve degradation cost of lithium-ion batteries in vehicle-to-grid applications. Ieee Trans. Sustain. Energy 2016, 7, 1730–1738. [Google Scholar] [CrossRef]

- Kaunda, C.S.; Kimambo, C.Z.; Nielsen, T.K. Potential of small-scale hydropower for electricity generation in Sub-Saharan Africa. ISRN Renew. Energy 2012, 2012, 132606. [Google Scholar] [CrossRef]

- Botterud, A.; Levin, T.; Koritarov, V. Pumped Storage Hydropower: Benefits for Grid Reliability and Integration of Variable Renewable Energy; Argonne National Lab. (ANL): Argonne, IL, USA, 2014. [Google Scholar]

- Warnick, C.C.; Mayo, H.A., Jr. Hydropower Engineering; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 1984. [Google Scholar]

- Singhal, M.K.; Kumar, A. Optimum design of penstock for hydro projects. Int. J. Energy Power Eng. 2015, 4, 216. [Google Scholar]

- Emmanouil, S.; Nikolopoulos, E.I.; François, B.; Brown, C.; Anagnostou, E.N. Evaluating existing water supply reservoirs as small-scale pumped hydroelectric storage options—A case study in Connecticut. Energy 2021, 226, 120354. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Nayak, P.K. PV-pumped energy storage option for convalescing performance of hydroelectric station under declining precipitation trend. Renew. Energy 2019, 135, 288–302. [Google Scholar] [CrossRef]

- Kusakana, K. Feasibility analysis of river off-grid hydrokinetic systems with pumped hydro storage in rural applications. Energy Convers. Manag. 2015, 96, 352–362. [Google Scholar] [CrossRef]

- Singh, A.B.; Bala, A.S.; Kumar, K.S.; Ajaykumar, J. Internal Model Controller for Conical Tank System. J. Electron. Autom. Eng. 2024, 3, 1. [Google Scholar]

- Vallabhaneni, R.; Nagamani, H.; Harshitha, P.; Sumanth, S. Protecting the Cybersecurity Network Using Lotus Effect Optimization Algorithm Based SDL Model. In Proceedings of the 2024 International Conference on Distributed Computing and Optimization Techniques (ICDCOT), Bengaluru, India, 15–16 March 2024; pp. 1–7. [Google Scholar]

- Meraihi, Y.; Ramdane-Cherif, A.; Acheli, D.; Mahseur, M. Dragonfly algorithm: A comprehensive review and applications. Neural Comput. Appl. 2020, 32, 16625–16646. [Google Scholar] [CrossRef]

- Hadidian-Moghaddam, M.J.; Arabi-Nowdeh, S.; Bigdeli, M. Optimal sizing of a stand-alone hybrid photovoltaic/wind system using new grey wolf optimizer considering reliability. J. Renew. Sustain. Energy 2016, 8, 35903. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Eltamaly, A.M.; Alolah, A.I. Swarm intelligence-based optimization of grid-dependent hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2017, 77, 515–524. [Google Scholar] [CrossRef]

- Sanajaoba, S.; Fernandez, E. Maiden application of Cuckoo Search algorithm for optimal sizing of a remote hybrid renewable energy System. Renew. Energy 2016, 96, 1–10. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Alotaibi, M.A.; Alolah, A.I.; Ahmed, M.A. A Novel Demand Response Strategy for Sizing of Hybrid Energy System with Smart Grid Concepts. IEEE Access 2021, 9, 20277–20294. [Google Scholar] [CrossRef]

- Singh, S.; Singh, M.; Kaushik, S.C. Feasibility study of an islanded microgrid in rural area consisting of PV, wind, biomass and battery energy storage system. Energy Convers. Manag. 2016, 128, 178–190. [Google Scholar] [CrossRef]

| Training Points | Testing Points | RMSE (%) |

|---|---|---|

| 1000 | 14,000 | 3.2 |

| 2000 | 13,000 | 2.1 |

| 3000 | 12,000 | 1.05 |

| 4000 | 11,000 | 0.36 |

| 5000 | 10,000 | 0.12 |

| 6000 | 9000 | 0.01 |

| 7000 | 8000 | 0.01 |

| 8000 | 7000 | 0.01 |

| 9000 | 6000 | 0.01 |

| 10,000 | 5000 | 0.01 |

| 11,000 | 4000 | 0.01 |

| 12,000 | 3000 | 0.01 |

| 13,000 | 2000 | 0.01 |

| 14,000 | 1000 | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eltamaly, A.M.; Almutairi, Z.A. Nested Optimization Algorithms for Accurately Sizing a Clean Energy Smart Grid System, Considering Uncertainties and Demand Response. Sustainability 2025, 17, 2744. https://doi.org/10.3390/su17062744

Eltamaly AM, Almutairi ZA. Nested Optimization Algorithms for Accurately Sizing a Clean Energy Smart Grid System, Considering Uncertainties and Demand Response. Sustainability. 2025; 17(6):2744. https://doi.org/10.3390/su17062744

Chicago/Turabian StyleEltamaly, Ali M., and Zeyad A. Almutairi. 2025. "Nested Optimization Algorithms for Accurately Sizing a Clean Energy Smart Grid System, Considering Uncertainties and Demand Response" Sustainability 17, no. 6: 2744. https://doi.org/10.3390/su17062744

APA StyleEltamaly, A. M., & Almutairi, Z. A. (2025). Nested Optimization Algorithms for Accurately Sizing a Clean Energy Smart Grid System, Considering Uncertainties and Demand Response. Sustainability, 17(6), 2744. https://doi.org/10.3390/su17062744