Comprehensive Plastic Waste Characterisation to Enhance Landfill Diversion in New Zealand’s Construction Industry

Abstract

1. Introduction

2. Methodology

2.1. Site Selection and Setup

- 1.

- Pipes (PVC and HDPE);

- 2.

- Soft plastics (primarily LDPE);

- 3.

- Polystyrene (EPS);

- 4.

- Polypropylene (PP);

- 5.

- All other plastics.

2.2. Waste Separation, Auditing, and Recycling

2.3. Waste Categorisation

- 1.

- Product packaging—used for packaging componentry, materials, and tools (e.g., soft plastic bags, polystyrene, hard plastic packaging);

- 2.

- Building componentry—used within the building itself (e.g., pipes, reinforcing bar chairs, damp-proof course, polystyrene pods, vinyl flooring);

- 3.

- Building protection and/or tools—used to construct and protect the building (e.g., tools, shrink wrap, safety fences).

3. Results and Discussion

3.1. Qualitative Factors Impacting On-Site Waste Management

3.2. Plastic Waste Types and Quantities

3.3. Assessment of Plastic Polymer Type

3.4. Assessment of Plastic Material Functionality

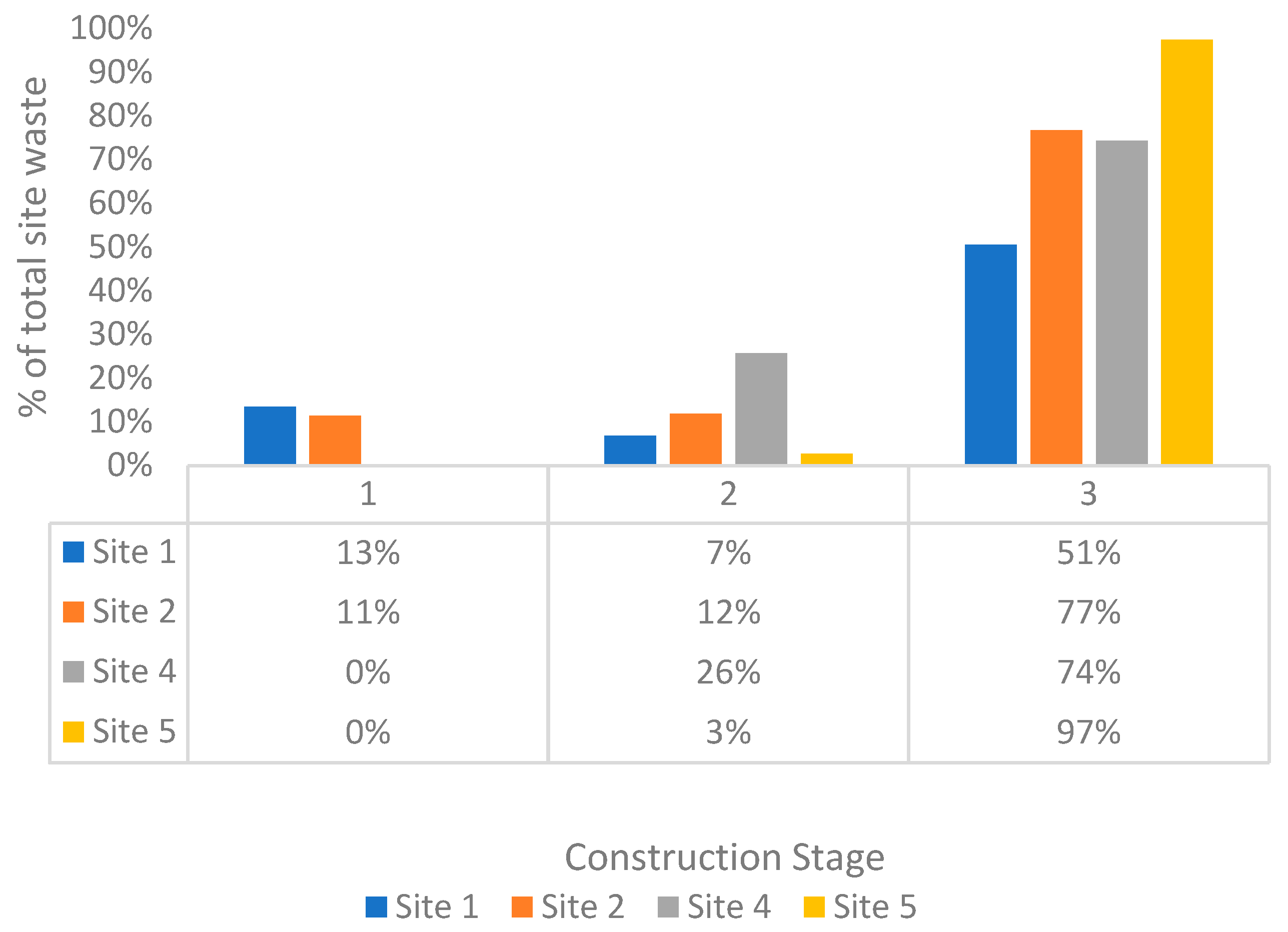

3.5. Impact of Construction Stage on Plastic Waste Generation

3.6. Impact of Building Type on Plastic Waste Generation

3.7. Study Limitations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Santos, G.; Esmizadeh, E.; Riahinezhad, M. Recycling Construction, Renovation, and Demolition Plastic Waste: Review of the Status Quo, Challenges and Opportunities. J. Polym. Environ. 2024, 32, 479–509. [Google Scholar] [CrossRef]

- Laadila, M.A.; LeBihan, Y.; Caron, R.-F.; Vaneeckhaute, C. Physical and chemical characterization of construction, renovation and demolition waste in the Quebec province. Clean. Waste Syst. 2022, 1, 100002. [Google Scholar] [CrossRef]

- Albsoul, H.; Doan, D.T.; GhaffarianHoseini, A. Estimating construction waste in New Zealand: A focus on urban areas, residential and non-residential building activities. Environ. Res. Commun. 2024, 6, 035009. [Google Scholar] [CrossRef]

- Nelson, J.M.B.; Elliot, G.; Pickering, K.L.; Beg, M.D. Preliminary Materials Flow Analysis for Aotearoa New Zealand’s Building Construction Sector; Āmiomio Aotearoa—The University of Waikato: Hamilton, New Zealand, 2022. [Google Scholar]

- Rohani, M.; Huang, T.; Hoffman, L.; Roberts, M.; Ribero, B. Cost Benefit Analysis of Construction and Demolition Waste Diversion from Landfill: A Case Study Based on HLC Ltd Development in Auckland (Technical Report TR2019/009). Auckland Council. 2019. Available online: https://knowledgeauckland.org.nz/media/fxwbvcbl/tr2019-009-cba-on-waste-diversion-from-landfill-homes-land-community-auckland.pdf (accessed on 12 March 2025).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Marston, N.; Jones, M. Weathering of Polymeric Materials in New Zealand; BRANZ Ltd.: Judgeford, New Zealand, 2007; Available online: https://www.branz.co.nz/pubs/research-reports/sr182/ (accessed on 29 January 2025).

- Ministry for the Environment. Targets in the New Zealand Waste Strategy: 2006 Review of Progress; ME 802; Ministry for the Environment: Wellington, New Zealand, 2007. Available online: https://environment.govt.nz/publications/targets-in-the-new-zealand-waste-strategy-2006-review-of-progress/ (accessed on 3 February 2023).

- Ratnasabapathy, S.; Perera, S.; Alashwal, A.; Lord, O. Assessment of Waste Generation and Diversion Rates in Residential Construction Projects in Australia. In Proceedings of the CIB World Building Congress 2019, Hong Kong, China, 17–21 June 2019; Available online: https://www.researchgate.net/publication/337721147 (accessed on 29 January 2025).

- Martínez Lage, I.; Martínez Abella, F.; Herrero, C.V.; Ordóñez, J.L.P. Estimation of the annual production and composition of C&D Debris in Galicia (Spain). Waste Manag. 2010, 30, 636–645. [Google Scholar] [CrossRef]

- Cochran, K.; Townsend, T.; Reinhart, D.; Heck, H. Estimation of regional building-related C&D debris generation and composition: Case study for Florida, US. Waste Manag. 2007, 27, 921–931. [Google Scholar] [CrossRef]

- Miliute-Plepiene, J.; Fråne, A.; Almasi, A.M. Overview of polyvinyl chloride (PVC) waste management practices in the Nordic countries. Clean. Eng. Technol. 2021, 4, 100246. [Google Scholar] [CrossRef]

- Ye, L.; Qi, C.; Hong, J.; Ma, X. Life cycle assessment of polyvinyl chloride production and its recyclability in China. J. Clean. Prod. 2017, 142, 2965–2972. [Google Scholar] [CrossRef]

- Nicholson, S.R.; Rorrer, N.A.; Carpenter, A.C.; Beckham, G.T. Manufacturing energy and greenhouse gas emissions associated with plastics consumption. Joule 2021, 5, 673–686. [Google Scholar] [CrossRef]

- Jankowska, E.; Gorman, M.R.; Frischmann, C.J. Transforming the Plastic Production System Presents Opportunities to Tackle the Climate Crisis. Sustainability 2022, 14, 6539. [Google Scholar] [CrossRef]

- Lamba, P.; Kaur, D.P.; Raj, S.; Sorout, J. Recycling/reuse of plastic waste as construction material for sustainable development: A review. Environ. Sci. Pollut. Res. Int. 2022, 29, 86156–86179. [Google Scholar] [CrossRef] [PubMed]

- Al-Sherrawi, M.H.; Edaan, I.M.; Al-Rumaithi, A.; Sotnik, S.; Lyashenko, V. Features of Plastics in Modern Construction Use. Int. J. Civ. Eng. Technol. (IJCIET) 2018, 9, 975–984. Available online: http://www.iaeme.com/ijciet/issues.asp?JType=IJCIET&VType=9&IType=4 (accessed on 1 February 2025).

- Jawaid, M.; Singh, B.; Kian, L.K.; Zaki, S.A.; Radzi, A.M. Processing techniques on plastic waste materials for construction and building applications. Curr. Opin. Green Sustain. Chem. 2023, 40, 100761. [Google Scholar] [CrossRef]

- Low, J.K.; Hernandez, G.; Berry, T.-A. Plastic waste characterisation to maximise landfill diversion from a New Zealand residential construction site. Front. Sustain. 2024, 5, 1455480. [Google Scholar] [CrossRef]

- Plastics, N.Z. Industrial & Commercial Recycling|Plastics New Zealand. Available online: https://www.plastics.org.nz/environment/recycling-disposal/industrial-recycling (accessed on 6 March 2025).

- Lahtela, V.; Hyvärinen, M.; Kärki, T. Composition of Plastic Fractions in Waste Streams: Toward More Efficient Recycling and Utilization. Polymers 2019, 11, 69. [Google Scholar] [CrossRef]

- Prestes, S.M.D.; Mancini, S.D.; Rodolfo, A.; Keiroglo, R.C. Construction and demolition waste as a source of PVC for recycling. Waste Manag. Res. 2012, 30, 115–121. [Google Scholar] [CrossRef]

- da Silva, L.P.; da Costa Marques Neto, J. Analysis and characterization of the Composition of construction waste in the city of Ribeirão Preto-SP. Gest. Prod. 2021, 28, e5237. [Google Scholar] [CrossRef]

- Katz, A.; Baum, H. A novel methodology to estimate the evolution of construction waste in construction sites | Elsevier Enhanced Reader. Waste Manag. 2011, 31, 353–358. [Google Scholar] [CrossRef]

- Llatas, C. A model for quantifying construction waste in projects according to the European waste list. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H.; Li, J.; Hao, J.J.L.; Mi, X.; Ding, Z. An empirical investigation of construction and demolition waste generation rates in Shenzhen city, South China. Waste Manag. 2011, 31, 680–687. [Google Scholar] [CrossRef]

- Kim, Y.-C.; Zhang, Y.-L.; Park, W.-J.; Cha, G.-W.; Kim, J.-W.; Hong, W.-H. Analysis of Waste Generation Characteristics during New Apartment Construction—Considering the Construction Phase. Int. J. Environ. Res. Public Health 2019, 16, 3485. [Google Scholar] [CrossRef] [PubMed]

- Domingo, N.; Batty, T. Construction waste modelling for residential construction projects in New Zealand to enhance design outcomes. Waste Manag. 2021, 120, 484–493. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Yu, A.T.W.; Poon, C.S. An off-site snapshot methodology for estimating building construction waste composition—A case study of Hong Kong. Environ. Impact Assess. Rev. 2019, 77, 128–135. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, L.; Hu, R.; Ren, Z.; He, Y.; Liu, D.; Zhou, Z. An empirical study on waste generation rates at different stages of construction projects in China. Waste Manag. Res. 2020, 38, 433–443. [Google Scholar] [CrossRef]

- Li, L.; Zuo, J.; Du, L.; Chang, R. What influences the on-site recycling behaviour of C&D plastic waste in Australia? An action determination model approach. J. Environ. Manag. 2024, 371, 123158. [Google Scholar] [CrossRef]

- González Pericot, N.; Villoria Sáez, P.; Del Río Merino, M.; Liébana Carrasco, O. Production patterns of packaging waste categories generated at typical Mediterranean residential building worksites. Waste Manag. 2014, 34, 1932–1938. [Google Scholar] [CrossRef]

- González Pericot, N.; Del Río Merino, M. Management of Waste from Packaging of Construction Materials in Building Construction Works. Open Constr. Build. Technol. J. 2011, 5, 149–155. [Google Scholar] [CrossRef]

- Chauhan, K.; Peltokorpi, A.; Seppänen, O. Analysing Film Plastic Waste in Residential Construction Project. In Proceedings of the 31st Annual Conference of the International Group for Lean Construction (IGLC 31), Lille, France, 26 June–2 July 2023; pp. 509–520. [Google Scholar] [CrossRef]

- Berry, T.-A.; Low, J.K.; Wallis, S.L.; Kestle, L.; Day, A.; Hernandez, G. Determining the Feasibility of a Circular Economy for Plastic Waste from the Construction Sector in New Zealand. IOP Conf. Ser. Earth Environ. Sci. 2022, 1122, 012002. [Google Scholar] [CrossRef]

- Hernandez, G.; Low, J.; Nand, A.; Bu, A.; Wallis, S.L.; Kestle, L.; Berry, T.-A. Quantifying and managing plastic waste generated from building construction in Auckland, New Zealand. Waste Manag. Res. 2023, 41, 205–213. [Google Scholar] [CrossRef]

- Jonsson, R. Prospects for Timber Frame in Multi-Storey House Building in England, France, Germany, Ireland, the Netherlands and Sweden; Växjö University: Växjö, Sweden, 2009; Available online: https://www.academia.edu/53904984/Prospects_for_timber_frame_in_multi_storey_house_building_in_England_France_Germany_Ireland_the_Netherlands_and_Sweden (accessed on 8 December 2023).

- Navaratnam, S.; Humphreys, M.; Mendis, P.; Nguyen, K.T.Q.; Zhang, G. Effect of roof to wall connection stiffness variations on the load sharing and hold-down forces of Australian timber-framed houses. Structures 2020, 27, 141–150. [Google Scholar] [CrossRef]

- Villoria Sáez, P.; del Río Merino, M.; San-Antonio González, A. Success Strategies for On-Site Waste Management in Spanish Construction Sites. In Proceedings of the Construction and Building Research; Llinares-Millán, C., Fernández-Plazaola, I., Hidalgo-Delgado, F., Martínez-Valenzuela, M.M., Medina-Ramón, F.J., Oliver-Faubel, I., Rodríguez-Abad, I., Salandin, A., Sánchez-Grandia, R., Tort-Ausina, I., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 19–25. [Google Scholar]

- Arshad, H.; Qasim, M.; Jamaluddin Thaheem, M.; Gabriel, H.F. (PDF) Quantification of Material Wastage in Construction Industry of Pakistan: An Analytical Relationship between Building Types and Waste Generation. J. Constr. Dev. Ctries. 2018, 22, 19–34. [Google Scholar] [CrossRef]

- Yuan, H.; Lu, W.; Jianli Hao, J. The evolution of construction waste sorting on-site. Renew. Sustain. Energy Rev. 2013, 20, 483–490. [Google Scholar] [CrossRef]

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Shanawaz Uddin, A.S.M.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Ministry for the Environment. Four New Plastic Innovation Fund Initiatives Announced. Available online: https://environment.govt.nz/news/four/ (accessed on 5 March 2025).

- BRANZ. About Us. Available online: https://www.branz.co.nz/about/ (accessed on 5 March 2025).

- Ministry for the Environment. Waste Disposal Levy Expansion. Available online: https://environment.govt.nz/what-government-is-doing/areas-of-work/waste/waste-disposal-levy/expansion/ (accessed on 13 February 2025).

- New Zealand Government. Building Act Changes Put the Environment at the Heart of How We Build. Available online: https://www.beehive.govt.nz/release/building-act-changes-put-environment-heart-how-we-build (accessed on 6 March 2025).

- New Plymouth District Council. Construction Waste Reduction Plan: A Guide. Available online: https://www.npdc.govt.nz/zero-waste/waste-minimisation/waste-minimisation-at-work/construction-waste/#:~:text=NPDC%20Construction%20Waste%20Reduction%20Plan%20%E2%80%93%20a%20requirement%20for%20commercial%20building%20projects&text=From%20August%202021%2C%20anyone%20applying,Plan%20to%20NPDC%20for%20approval (accessed on 4 October 2024).

- Wellington City Council. Solid Waste Management and Minimisation Bylaw 2020. Available online: https://wellington.govt.nz/your-council/plans-policies-and-bylaws/bylaws/solid-waste-bylaw-2020 (accessed on 4 October 2024).

- Li, Y.; Zhang, X.; Ding, G.; Feng, Z. Developing a quantitative construction waste estimation model for building construction projects. Resour. Conserv. Recycl. 2016, 106, 9–20. [Google Scholar] [CrossRef]

- Carpio, M.; Roldán-Fontana, J.; Pacheco-Torres, R.; Ordóñez, J. Construction waste estimation depending on urban planning options in the design stage of residential buildings. Constr. Build. Mater. 2016, 113, 561–570. [Google Scholar] [CrossRef]

| Site 1 | Site 2 | Site 3 | Site 4 | Site 5 | Site 6 | |

|---|---|---|---|---|---|---|

| Building Type | Institutional: school gym + teaching block, multiple storeys | Residential: terraced houses, two to three storeys | Residential: detached house, single-storey | Residential: 42-unit apartment block, three storeys | Institutional: extension of hospital building, four storeys | Institutional: school classroom teaching block, three storeys |

| Construction Timeframe | Late 2020– Late 2022 | September 2021–September 2022 | February 2022– November 2022 | Mid 2022– Late 2023 | Late 2022–Mid 2024 | Early 2023–October 2024 |

| Number of units | Gym and classrooms | 8 | 1 | 42 | 15 beds, consulting rooms, 3 procedure rooms, endoscopy suite | 30 classrooms |

| Site 1 | Site 2 | Site 3 * | Site 4 | Site 5 | Site 6 * | |

|---|---|---|---|---|---|---|

| Description | School gym + teaching block construction | Residential—terraced houses, 8 units | Residential—single-storey, detached house | Residential—42-unit apartment block | Hospital Building—4-storey block | School building—3-storey classroom block |

| Size (m2) | 4800 | 857 | 239 | 2400 | 4500 | 3224 |

| All plastic waste (kg) | 769 | 725 | 20 * | 1708 | 3140 | 843 * |

| % Plastic waste reused/recycled | NA * | 66% (wt.) 481 kg | 25% (wt.) 5 kg * | 62% (wt.) 1065 | 80% (wt.) 2515 kg | 45% (wt.) 378 kg |

| Plastic WGR (kg/m2) | 0.16 | 0.85 | 0.08 * | 0.71 | 0.70 | 0.26 * |

| Plastic % of total waste | 0.41% | 3.23% | 1.76% * | 1.98% | 1.70% | 0.52% |

| Soft plastic WGR (kg/m2) | 0.02 | 0.32 | NA | 0.11 | 0.25 | 0.08 |

| Plastic Type | Site 1 Mass (kg) | Site 2 Mass (kg) | Site 4 Mass (kg) | Site 5 Mass (kg) | Grand Total (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Total | L | R | Total | L | R | Total | L | R | Total | ||

| Soft plastic (LDPE) | 80.9 (11%) | 55.5 | 214.5 | 270 (37%) | 99.6 | 509.6 | 609.2 (36%) | 87.5 | 1056.8 | 1144.3 (36%) | 2363.1 (33%) |

| Pipes (HDPE and PVC) | 58.1 (8%) | 0.6 | 156.2 | 156.8 (22%) | 8.4 | 358.1 | 366.5 (21%) | 99.3 | 700.0 | 799.3 (25%) | 1394.6 (19%) |

| Shrink wrap (LDPE) | 20.6 | NA | NA | NA | NA | NA | NA | 70.0 | 642.3 | 712.3 (23%) | 732.9 (10%) |

| Woven plastic (LDPE and PP) | 2.0 | 15.2 | NA | 15.2 | 133.5 | NA | 133.5 (8%) | 45.6 | NA | 45.6 | 400.6 (6%) |

| Misc | 227.9 (30%) | NA | NA | NA | 10.7 | NA | 10.7 | 43.9 | NA | 43.9 | 360.2 (5%) |

| Expanded polystyrene (EPS) | 17.9 | NA | 94.9 | 94.9 (13%) | NA | 52.9 | 52.9 | 25.8 | 113.8 | 139.6 (4%) | 327.1 (5%) |

| Grand Total | 769.1 | 243.8 | 481.2 | 725.1 | 642.7 | 1065.2 | 1707.9 | 624.9 | 2515.3 | 3140.2 | 7205.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Low, J.K.; Berry, S.; Hernandez, G.; Thomson, P.; Steinhorn, G.; Waghela, H.; Briggs, C.; Berry, C.; Berry, T.-A. Comprehensive Plastic Waste Characterisation to Enhance Landfill Diversion in New Zealand’s Construction Industry. Sustainability 2025, 17, 2742. https://doi.org/10.3390/su17062742

Low JK, Berry S, Hernandez G, Thomson P, Steinhorn G, Waghela H, Briggs C, Berry C, Berry T-A. Comprehensive Plastic Waste Characterisation to Enhance Landfill Diversion in New Zealand’s Construction Industry. Sustainability. 2025; 17(6):2742. https://doi.org/10.3390/su17062742

Chicago/Turabian StyleLow, Joanne K., Samuel Berry, German Hernandez, Penelope Thomson, Gregor Steinhorn, Harshal Waghela, Cole Briggs, Ciarán Berry, and Terri-Ann Berry. 2025. "Comprehensive Plastic Waste Characterisation to Enhance Landfill Diversion in New Zealand’s Construction Industry" Sustainability 17, no. 6: 2742. https://doi.org/10.3390/su17062742

APA StyleLow, J. K., Berry, S., Hernandez, G., Thomson, P., Steinhorn, G., Waghela, H., Briggs, C., Berry, C., & Berry, T.-A. (2025). Comprehensive Plastic Waste Characterisation to Enhance Landfill Diversion in New Zealand’s Construction Industry. Sustainability, 17(6), 2742. https://doi.org/10.3390/su17062742