1. Introduction

Proper waste management in transition countries presents a significant challenge, especially considering the low level of public knowledge and the lack of a systematic approach to waste management [

1]. The absence of public awareness that waste is a raw material, not garbage, as well as the lack of modern and up-to-date machinery for sustainable waste management and inadequate transportation infrastructure, are among the country’s priorities [

2]. On the other hand, there are no clear and unified legal regulations regarding waste management in Bosnia and Herzegovina (B&H) due to the fact that the country is composed of two entities (Republic of Srpska and the Federation of Bosnia and Herzegovina) and the Brčko District [

3]. Most cities and municipalities in B&H, when viewed from the perspective of the entities, are in close proximity to one another and without a unified strategy and laws regarding waste management, causing a drift from the European Union’s unified approach. Therefore, the primary problem lies in the insufficient involvement of the state and all its stakeholders, in order to bring sustainable waste management closer to the developed practices of modern and advanced European and global environments. On the other hand, B&H, due to its disorganized internal politics and legal inconsistencies, is “losing” the race with the EU’s innovative policy in the field of adequate waste management, especially when it comes to grants for acquiring modern equipment for the collection, processing, and sorting of waste, and its further distribution to recycling centers, creating new value. The equipment used in Bosnia and Herzegovina for operations, including various types of utility vehicles and construction machines with special attachments, is 25 years old and more. In addition to the inefficiency in operation, and consequently the lack of competitiveness, the maintenance costs of the machinery are particularly concerning because, in most cases, they exceed the allocated funds for servicing and repairs on an annual basis, as well as through long-term set goals. Therefore, cities in transition countries, such as B&H, need modern machinery to manage not only non-hazardous municipal waste, but also bulky waste—the disposal of which often occurs due to the inertia of residents, resulting in improper disposal and the creation of illegal landfills which not only pollute the environment but also pose a health risk to all inhabitants [

4]. Developing countries lack a clear strategy to encourage every citizen to rationalize their thinking and adopt a clear stance on waste disposal in a prescribed manner [

5]. The waste management system, for the most part, is limited to traditional dumping [

6] at registered landfills, with the absence of intermediate treatment and the mechanical separation of useful waste [

7]. Legal principles, as well as rules established by local communities in terms of raising public awareness about waste as a resource, are priorities in comprehensive waste management [

8]. There are an immeasurable number of environmental management concepts, each associated with the same number of consultants, environmental experts, and other specialists in this field [

9]. This means that environmental management is neither a new concept nor a vision, but an interpretation of an already known model that needs to be adapted to the local level [

10].

On the other hand, despite strong environmental and public health awareness campaigns, developed European Union countries are still not at the desired level when it comes to sustainable waste management [

11,

12]. According to Wan et al. [

13], the lack of public awareness and insufficient involvement of all individuals in the waste management chain represents both a significant challenge and a threat to the potential success of a systemic approach [

14] to sustainable waste management. Separating mixed waste from waste with calorific value and secondary raw materials for new production cycles is a primary focus for EU countries [

15]. Waste management not only involves the collection and removal of waste by specialized trucks, but also includes maintaining cleanliness around municipal containers and city bins, as well as at all locations where municipal waste is disposed of, either properly or “improperly” [

16].

According to Bonet et al. [

17], developing countries are characterized by a poor waste management concept, primarily limited to traditional waste collection and transportation to landfills, with a scarce fleet of vehicles, while payment for these services from the population and businesses is often below 50%, and the recycling rate remains low. Simple waste disposal at landfills, with open-air burning, along with limited intermediate treatment and recycling management policies, is particularly characteristic of poor but also developing country economies [

18]. Open-air waste burning, in the absence of strict control, remains a major issue in developing countries [

19]. This further contributes to the deterioration of public health, the spread of potential viruses and infections from waste disposed of in uncontrolled conditions, with the main issue being the lack of a clear strategy for comprehensive waste management [

20,

21,

22]. Research has shown that solid waste management gains importance when the local community becomes involved in the process, through citizen education on sorting waste at the household level [

1]. Additionally, waste must be properly disposed of in municipal containers designated for recycling, as opposed to mixed municipal waste, which lacks the potential for creating new value, as well as bulky waste, which is treated separately, transported, and further processed at recycling centers and incinerators [

23,

24,

25,

26].

Numerous studies conducted in China have shown that the production of solid waste constantly increases with the growth of the urban population. However, the country has made significant efforts in building municipal infrastructure and establishing a successful system for useful waste separation, as well as a sustainable approach to constructing incinerators to create new value [

27,

28,

29]. On the other hand, China has implemented multiple effective practices [

30] for managing various types of waste, including bulky waste, and has developed various technological solutions for the optimal disposal of non-hazardous municipal waste [

31]. China has also developed a “zero waste emissions” model for cities [

32], which supports the circular economy, waste disposal, and recycling while creating new, usable value. This model is available for adoption by all interested countries worldwide.

The management of solid municipal waste, as a sustainable system in the long term, requires special attention and a series of actions: controlling waste generation activities, collection, transportation, storage, and disposal [

33,

34]. The growth of the urban population leads to increased solid waste generation, with greater community involvement in creating waste management policies [

35]. The essence of waste management is to reduce the amount of waste generated and its impact on the environment through separation and reuse. If this is not possible, recycling follows, and only as a last option comes disposal [

36]. Underdeveloped and developing countries with rapidly growing populations [

37] are put in a position where the huge amounts of bulky and mixed waste [

38] that are generated daily cannot be collected and properly managed, either mechanically or manually, due to a lack of necessary mechanization such as multifunctional machines for the management of particularly bulky waste [

39]. A sustainable system for comprehensive waste management implies a set of measures that must be feasible in practice as a written document, with the long-term goal being a healthy living environment and population, while promoting the “zero waste” practice [

40].

Developing countries are constantly searching for a sustainable system in the field of waste management [

41], which includes not only human resources but also appropriate machinery highly specialized to meet specific tasks—including waste mapping, collection, transportation, sorting, and recycling [

42]. Sustainable sanitary landfills [

43] in developing countries also constitute one of the main pillars of the sustainability of the waste management system, with the aim of disposing of only that waste which has no calorific value and cannot be properly managed in any other way. Landfills should be a short-term solution [

44], and with the development of specific social programs in the field of raising public awareness about proper waste disposal, along with economic improvements, a more rational flow of waste movement is achieved.

Vehicle optimization [

45], which also includes the selection of the best route [

46] for the collection of specific waste categories, such as bulky waste, not only helps to reduce the costs of the company but also aids in finding an optimal strategy for a sustainable concept [

47] of waste disposal. The use of modern machinery in the management of specific waste categories contributes to achieving optimal sustainable development goals [

48], as well as reducing the negative environmental impacts caused by waste [

49].

Today, the demand for multifunctional machines presents a great challenge, not only due to the increasingly demanding earthworks [

50] but also because of their energy efficiency and their environmental impact. Environmental protection has become an even greater priority in today’s conditions of rapid globalization, with particular concern focused on energy consumption, exhaust gas emissions from engines, fuel costs, and similar factors [

51]. On the other hand, when selecting vehicles with optimal characteristics, particular attention is paid to vehicle speed in the field, along with their specific maneuverability, both in urban and rural areas, considering factors such as slope, geographical position, soil compaction resistance, and others [

52,

53].

Often, when removing bulky and similar waste, which is directly related to the creation of illegal dumpsites [

54], the machine used for waste removal must also clear a significant portion of the area where the waste has accumulated. This area may contain loose soil that needs to be disposed of, and frequently includes construction waste that is illegally dumped [

55]. The creation of illegal dumpsites is primarily associated with locations that are either sparsely populated, near forests, or where the distance to municipal waste disposal bins is geographically dislocated [

56]. Construction waste [

57] also represents a significant issue for the circular economy, especially due to its natural inability to decompose within the Earth’s crust and the strain it places on the environment. Research has shown that when construction waste is properly managed, there is still a likelihood that an illegal dumpsite will be mapped at the same location again, primarily due to inadequate legal solutions and the lack of citizen education [

58].

The increasing amount of bulky waste [

59] worldwide highlights the need for greater efforts in managing this type of waste, which is primarily wood-based and a valuable raw material in the circular economy [

60]. The lack of public awareness regarding the improper disposal of solid and other types of waste (bulky, electronic, etc.) leads to soil contamination [

61] and the creation of leachate [

62] and poses a risk to human health [

63]. Special monitoring is needed to oversee and control illegal dumpsites [

64], as well as to take a clear stance on the uncontrolled disposal [

65] of bulky waste, its timely mapping, its transfer to recycling centers, and where appropriate, its regeneration and reuse. By designing a business model adapted to sustainable development [

66], it reduces the negative impact on the environment.

Recent studies have shown that backhoe loaders with all-wheel drive and diesel engines contribute to the optimization of daily operation tasks in a short time, while minimizing fuel consumption, due to the latest-generation diesel engines, and reducing harmful gas emissions in the environment [

67]. On the other hand, research on the efficiency of multifunctional machines under normal operating conditions for the disposal of waste materials and bulky waste revealed that hybrid machines perform as efficiently as the latest-generation diesel-powered vehicles. However, it should be noted that the exhaust gases emitted into the environment contribute to partial pollution, compared to advanced hybrid vehicles [

68]. Furthermore, it has been proven that multifunctional machines with newer-generation diesel engines reduce fuel consumption by approximately 22% and emit lower levels of harmful gases into the environment compared to machines manufactured two or more decades ago [

69]. Regarding the improved operational cycle of multifunctional machines produced in the last five years, compared to the same type that is over a decade and a half old, it has been demonstrated that operational efficiency has increased by more than 90% in performance, compared to older models that are more than 50% less efficient, according to the same comparison [

70]. A significant amount of construction waste [

71], which results from the demolition [

72,

73], renovation, and construction of various buildings, also contributes to the increased negative impact on the environment [

74]. For this reason, urgent measures for the removal and proper disposal of construction waste using specialized loader machines are essential. Construction waste, which includes a significant percentage of bulky waste, is not only a result of the demolition and renovation of buildings in urban areas, but also a consequence of negligence by private construction companies and individuals who do not dispose of construction waste properly (such as transporting it to sanitary landfills or crushing it with specialized machinery). Instead, they dump it in the outskirts of urban zones or, in the worst case, in rural areas along main roads, near forests, rivers, and similar locations [

75]. On the other hand, numerous studies [

76,

77,

78,

79,

80] have shown that heavy construction machinery, in addition to its efficiency in mapping and managing specific waste categories, also contributes to environmental pollution due to increased emissions of harmful gases. For this reason, it is necessary to plan the electrification of these machines in the context of hybridization, in the long term, with specific projections for the observed areas (the needs and budgets for financing the purchase of such machines in developed countries differ from those in developing countries). Thus, the latest-generation multifunctional machines significantly reduce environmental pollution, but there is a gradual preference for transitioning to those with 100% electric drive, which will not only be at the maximum level of task performance but will also gradually change public awareness, making people feel a sense of belonging to the utility company and the entire local community, as an important link in the preservation of natural resources and environmental protection.

The case study followed in this paper is highly relevant and its benefits are multiple, both for the utility company and for the local community and its entire population from a professional perspective. From a scientific perspective, it represents a study of global significance. It is focused on one of the 10 largest cities in B&H, the city of Doboj, and the selection of an optimal multifunctional machine for waste management, with particular emphasis on bulky waste. The research objective of this paper is to select the best multifunctional machine based on its performance, which will not only ease the daily operations of the utility company in mapping illegal dumpsites but also contribute to maintaining hygiene throughout the city of Doboj, thus protecting the environment.

There is insufficient public awareness and engagement to help citizens to understand that they must treat the environment and the local community they live in with the care of a responsible host. This has not been adequately implemented in the city of Doboj—nor, we can freely say, in all of Bosnia and Herzegovina. Citizens believe that all types of waste generated from daily activities can be disposed of next to municipal containers designated for waste disposal if they are unable to fit the waste into these containers due to its size. We have just outlined the main issue, which, in the long term, leads to the creation of illegal dumpsites and poses a threat to the health of the residents of the local community. Although bulky and solid waste should be removed by specialized utility vehicles for a fee, charged by a registered utility company, most citizens ignore this legal obligation and dispose of such waste next to municipal containers, along main and regional roads, in forests, rivers, and other similar areas. The utility company lacks the capacity to manage illegal dumpsites, nor is this its legal obligation. The competent municipal police also cannot fully address these issues despite their best efforts. For all these reasons, there is an escalating “red alert” regarding public health and the environment.

In parallel with encouraging citizens to properly dispose of waste according to its categories (mixed versus useful secondary raw materials), along with the so-called public awareness rising, which is the first and most fundamental step in sustainable waste management, it is necessary to actively remediate existing illegal dumpsites and create the conditions to prevent the emergence of new ones.

For this reason, this paper will analyze seven machines (from reputable manufacturers) designed for the removal of illegal dumpsites and the disposal of bulky and solid waste in the city of Doboj, along with a scientific and professional proposal for selecting a machine with optimal characteristics that meet the real needs of the local utility company.

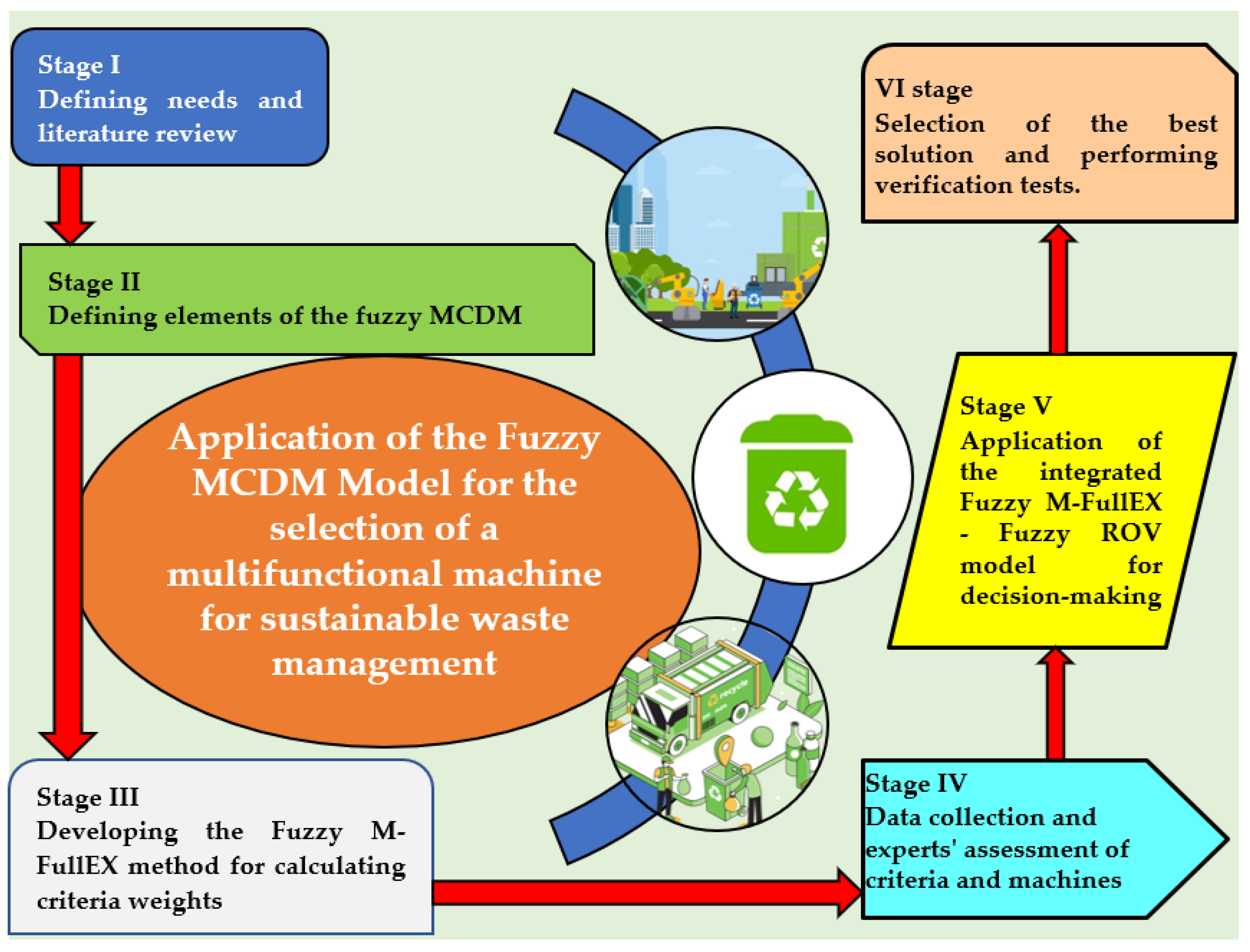

To meet the set goal, a unique Fuzzy M-FullEX-Fuzzy ROV model has been developed, which represents a significant scientific contribution for the following reasons:

- (1)

The FullEX method has been modified to M-FullEX due to the inconsistency observed between the initial expert evaluation and the weights of criteria after applying the established steps of the FullEX method.

- (2)

A flaw that caused inconsistency in the initial phase of evaluating the dominance of criteria in pairs and their final values has been eliminated by introducing new equations into the method.

- (3)

An extension with TFN (triangular fuzzy number) has been implemented, and the Fuzzy M-FullEX method for determining fuzzy criteria weights has been created, followed by integration into a unified model that also includes the Fuzzy ROV method.

3. Results

3.1. Case Study

The utility company Progres Ltd. (hereinafter referred to as Progres) serves the general public interest, particularly in terms of the collection and transportation of municipal waste in the city of Doboj. Progres is part of a group of companies that are responsible for ensuring the prerequisites for renewing their vehicle fleet and acquiring other municipal equipment necessary for daily operations, which are funded from their own revenue, in accordance with the local waste management law (Local Waste Management Plan for the City of Doboj for 2022–2027, 2021). The fleet includes various types of construction machinery, comprising both newer-generation machines and machines that are over two decades old. Progres specifically highlights an older model of multifunctional construction machinery, the Venieri, which has proven to be the most economical and practical option over the past 20 years, particularly in managing solid and bulky waste and removing illegal dumpsites.

In accordance with the Decision on the Municipal Order of the City of Doboj [

87], Progres has the legal obligation to transport non-hazardous municipal waste not only from the urban zone but also from rural areas, protecting the health and natural environment of all citizens. It is a significant challenge to cover all 64 local communities (outside the urban zone) with waste collection and transportation services in the city of Doboj, with a special focus on irresponsibly disposed bulky waste, which requires specialized machinery. Starting from 3 January 2024, Progres began parallel collection of municipal and bulky waste from rural areas (outlying zones), where a particular limitation is the resistance of residents, who are “accustomed” to burning waste or disposing of it improperly (along main roads, in forests, near rivers, etc.). On the other hand, in the absence of cooperation from the residents of the local communities targeted in this study, the local utility company also faces a limited budget for purchasing the appropriate machinery, which would be of general benefit for the observed area. For this reason, it is necessary to begin the process of procuring a multifunctional machine with optimal characteristics for handling specific categories of non-hazardous municipal waste, such as bulky waste. The machine must be highly adaptable to inaccessible terrain, as well as capable of navigating narrow and steep roads, especially in winter but also in autumn, when roads are less passable. This could potentially lead to the failure to transport waste during the observed period, which may further result in the creation of potential viruses and diseases from the waste, as well as an increase in the number of illegal landfills. Therefore, the goal of procuring a multifunctional machine is to create conditions for a clean living environment, which means living both in urban and rural areas without illegal landfills and waste that threatens both plant and animal life. This further means that, with the support of the relevant department of the city of Doboj and the municipal police, all illegal landfills in all 64 local communities will be mapped, both mechanically and manually, and a clear schedule for the collection of municipal and bulky waste will be defined, for a fee. The population of the observed local communities must be motivated in such a way that they are provided with the service of removing illegal landfills in the area where they live, or that the necessary conditions will be created to provide waste disposal equipment (e.g., 140 L municipal bins), which will be provided for use free of charge. Furthermore, it is necessary to define the dynamics of collecting and transporting municipal, bulky, and solid waste for a fee, so that the population feels a sense of belonging to the local community and fulfills their legally defined obligation, which is the proper disposal of the aforementioned categories of waste. The goal is to cover all 64 local communities with waste collection services and proper disposal at a sanitary landfill by 2030. Only in the previously described manner, including all the aforementioned stakeholders, can a sustainable waste management system be created in the city of Doboj, with a special emphasis on a healthy environment.

Irresponsible individuals or certain groups of citizens improperly dispose of various types of waste (such as household furniture, white goods, car tires, waste oils, etc.) not only in the inner city area but also in rural areas, directly contributing to the pollution of the environment and posing a threat to public health. For this reason, Progres needs a new, modern, and efficient machine to sustainable manage these types of waste in the fastest possible manner while adhering to all environmental principles and public health standards. Therefore, until the 3R strategy (Reduce, Reuse, and Recycle) is fully implemented in the city of Doboj and until citizens’ awareness is raised beyond its current level, which involves understanding that they are the true owners of a healthy environment and that they must preserve it, they must comply with its laws and rules.

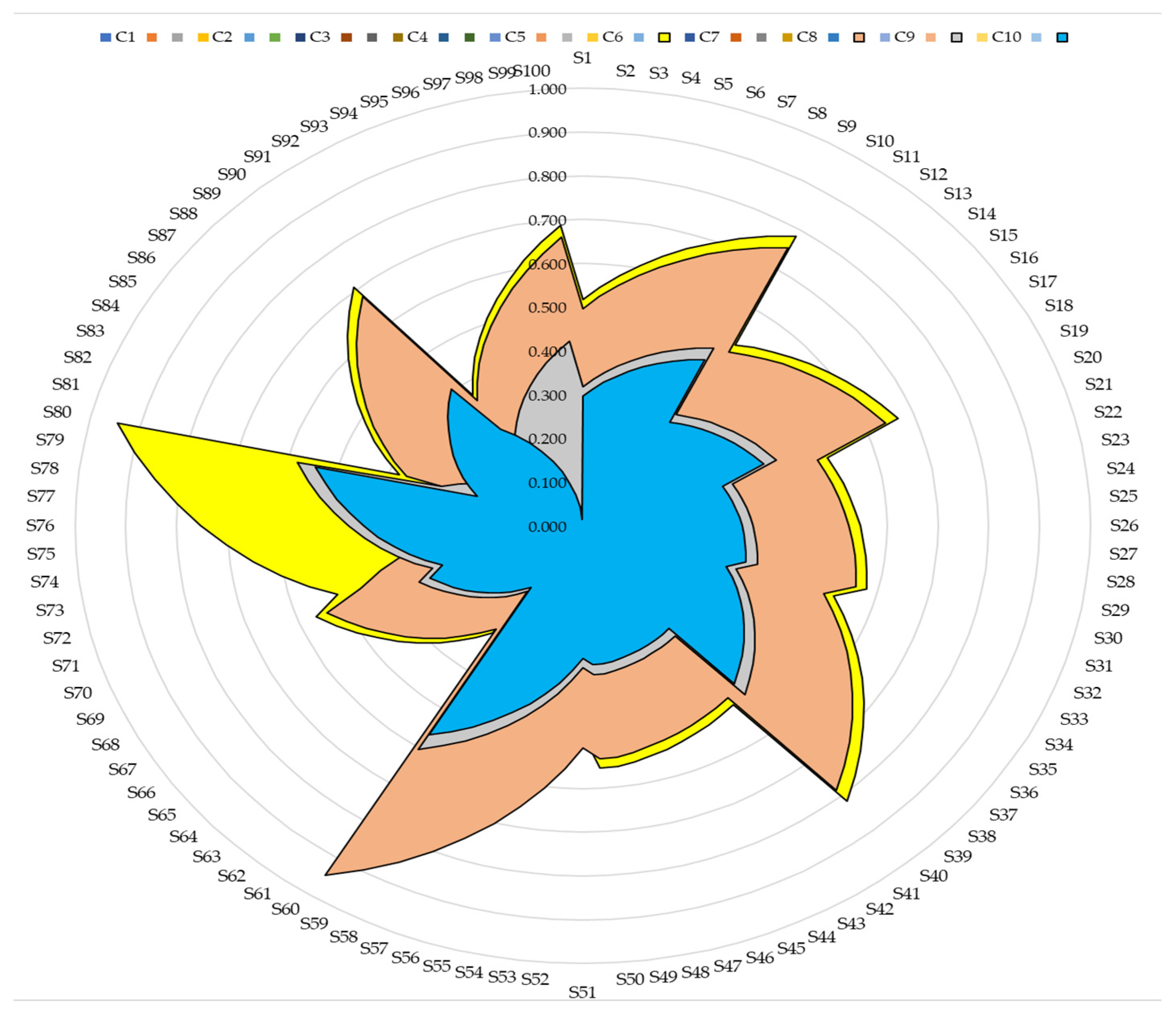

3.2. Description of Input Parameters for the MCDM Model

In this paper, we analyzed seven renowned multifunctional machines that meet the potential needs of Progres, for the purpose of optimal waste management, with a focus on bulky waste. Based on market research of the available machines in Bosnia and Herzegovina, including the availability of service centers, spare parts, and necessary logistics, the analysis included the following machines: M1—Venieri, M2—JCB, M3—Komatsu, M4—CAT, M5—Case, M6—Hidromek, and M7—Bull HD. We set 10 criteria to evaluate these machines and provide Progres with a recommendation for the selection of the optimal one. For the selection of six multifunctional machines for sustainable waste management, the following criteria were defined:

C1—Articulated chassis and maneuverability for business operations.

C2—Hydrostatic transmission and the maximum degree of power transfer from the hydro drive to the drive axles.

C3—System for using additional working tools on the loading arm (asphalt grinders, snow plows, crane mowers, etc.).

C4—Towing power on all four wheels.

C5—Layout of controls in the driver’s cabin and visibility while performing operational tasks.

C6—Machine operation in place during material collection (soil and other) with a bucket, as opposed to multiple movements for a single operation.

C7—Euro standard of the drive unit.

C8—Material spill outside the bucket during work tasks.

C9—Availability of service centers and spare parts in the territory of B&H.

C10—Cost price of the machine.

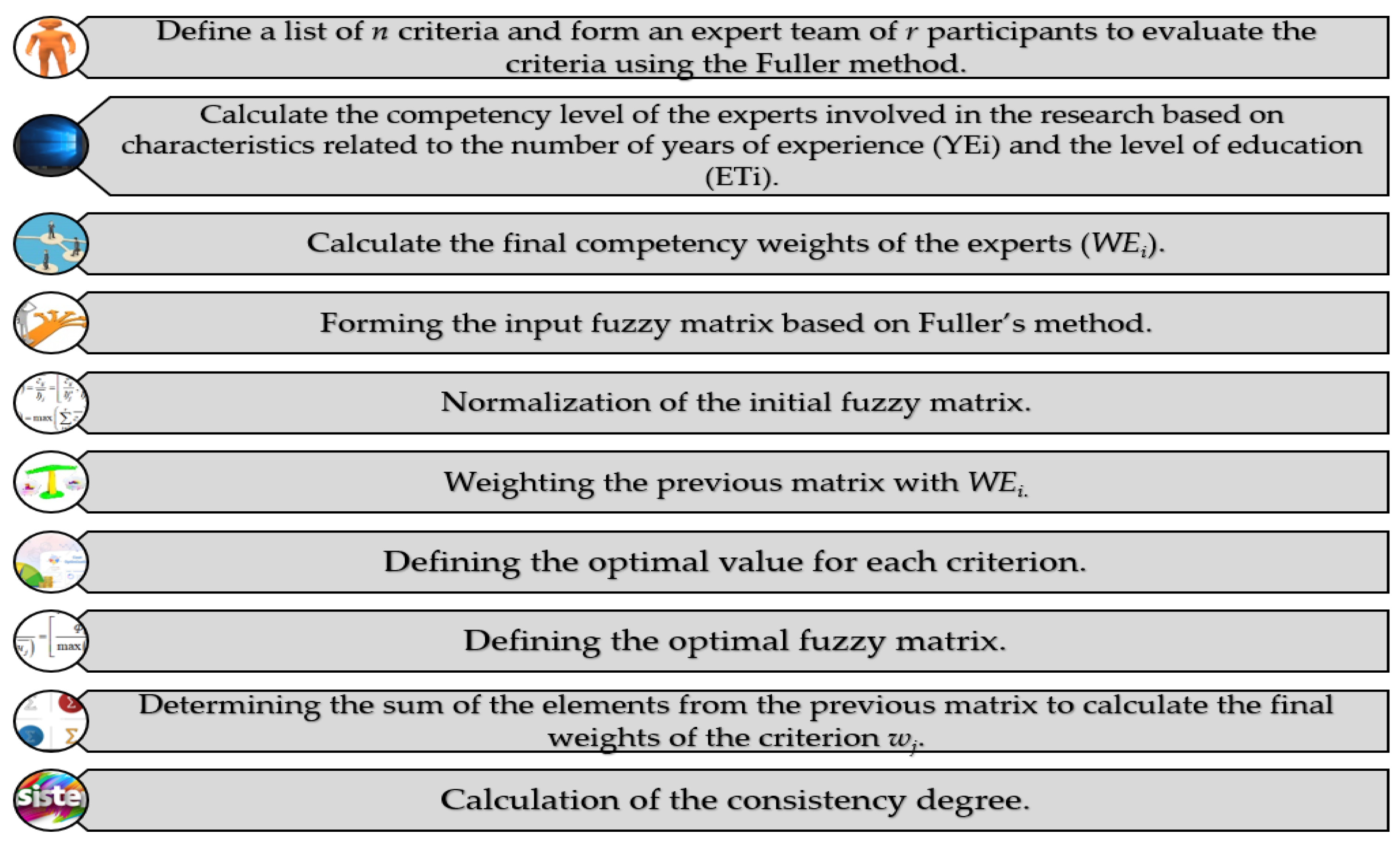

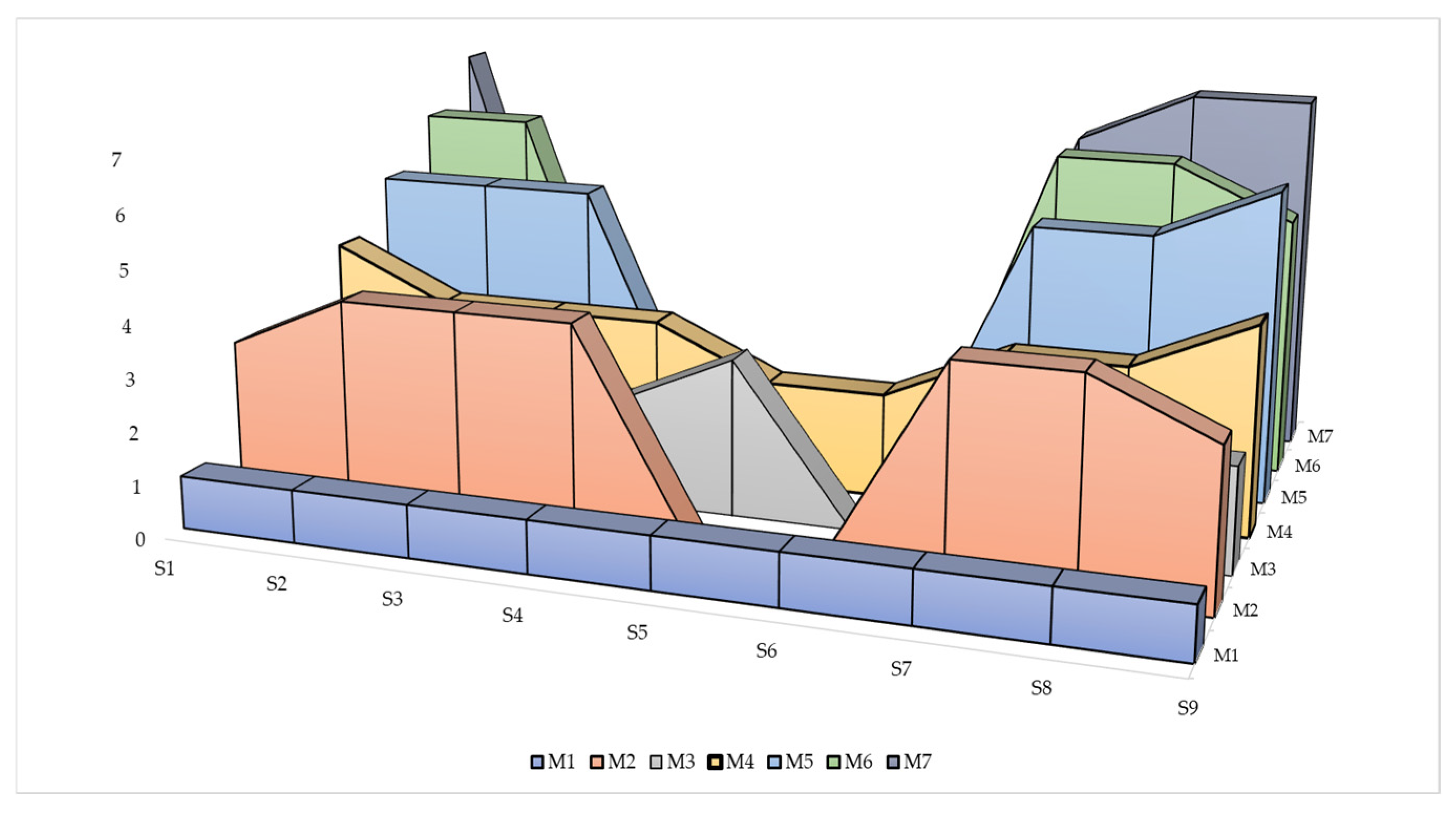

3.3. Determining Criteria Weights Using the Fuzzy M-FullEX Method

For the purposes of evaluating criteria and alternative solutions, a total of three experts were engaged with the following characteristics: E1—22 years of experience (YE) and a bachelor’s level of education (ED), E2—13 years of experience with a master’s degree, E3—10 years of experience with a bachelor’s level of education. The expert team selected for this study consists of two waste management experts, who are also decision-makers and have been appointed by the City Administration of the City of Doboj (Bosnia and Herzegovina) for waste management. The third expert is a technical professional with 22 years of experience in the field and an in-depth understanding of the strategy for selecting multifunctional machines for sustainable waste management. The first two experts have participated in international waste management projects and have received numerous awards for enhancing the waste management system in Doboj, as well as across Bosnia and Herzegovina. Additionally, one of these two experts holds internationally recognized certificates for developing recycling policies and for managing integrated waste management systems.

The experts’ competencies were calculated as follows:

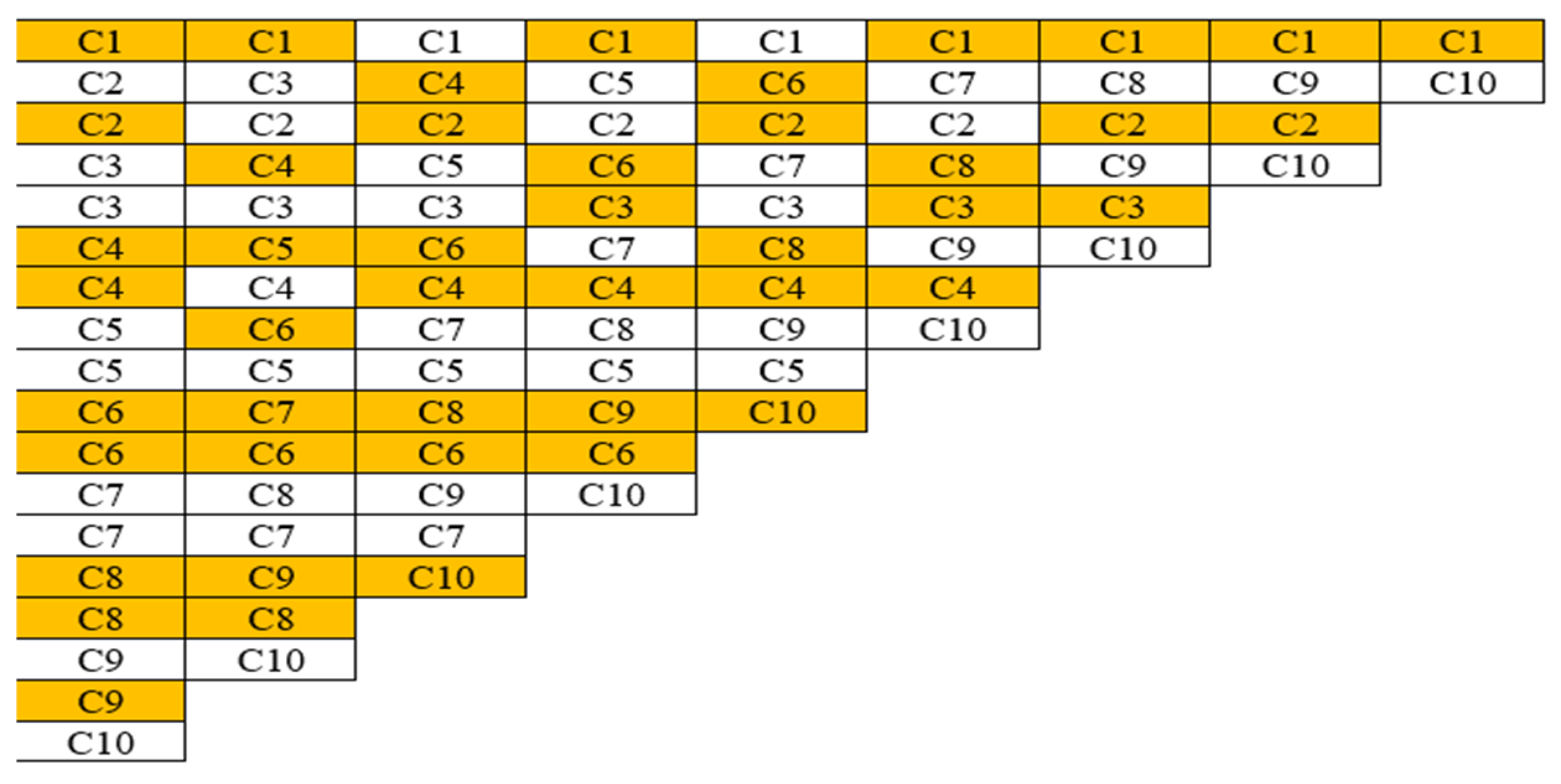

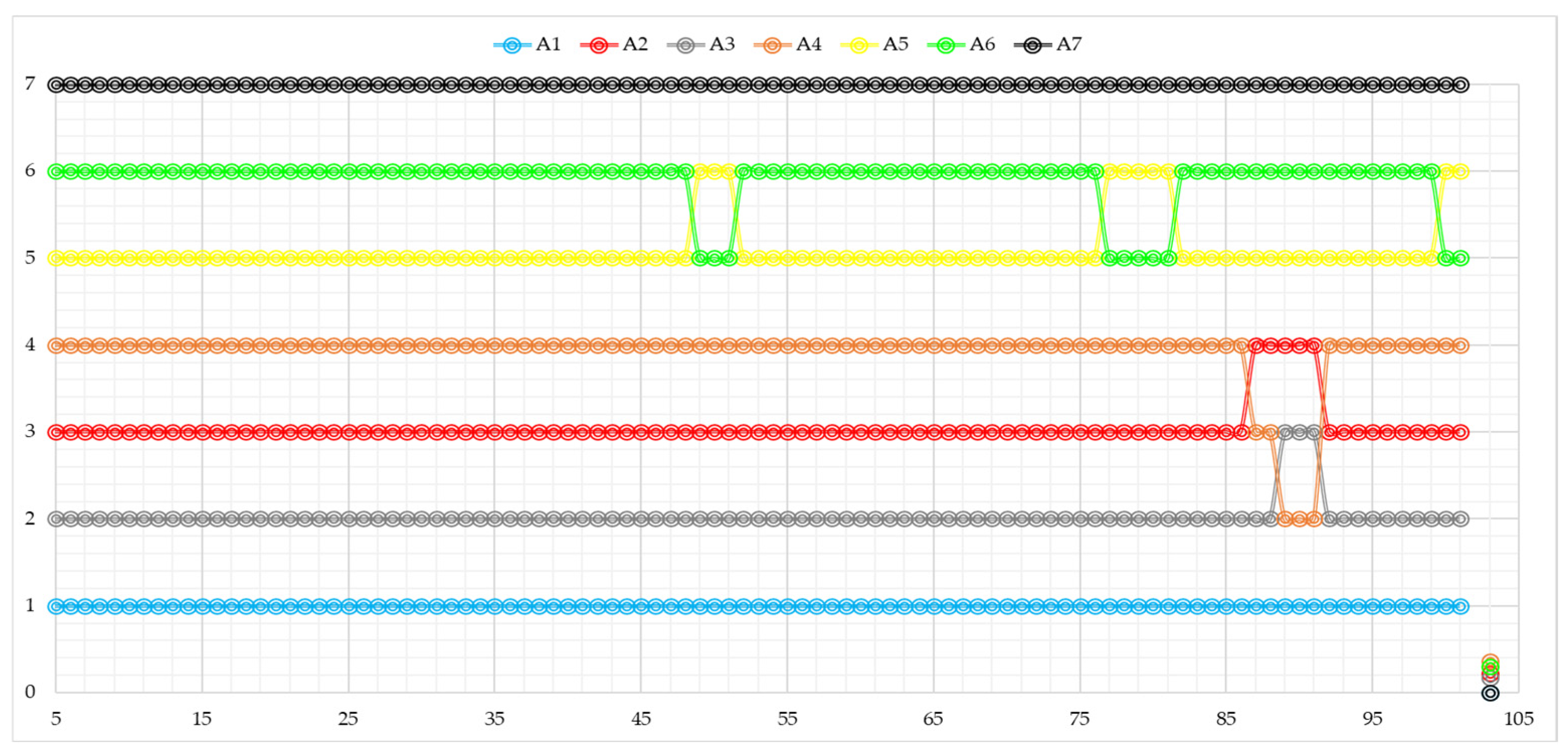

The next step involves the pairwise comparison of the criteria and obtaining the total number of dominations in fuzzy form, as shown in

Table 1. An example of the evaluation of the criteria by the second expert is presented in

Figure 4.

The initial fuzzy matrix is formed as follows:

, and for the first criterion, the values are 6, 7, and 5, respectively, for each expert individually. The fuzzy form is obtained by applying (3) and

, but

,

, and

. For the fifth criterion,

b is one, so the left side of the fuzzy number is equal to one according to the first condition of Equation (3). TFN (22, 25, 28) represents the

needed for the normalization process, as shown in the example:

and the normalized fuzzy matrix is shown in

Table 2.

When the process of normalizing the initial fuzzy matrix is completed, the next step is to weight it (

Table 3) with the experts’ competence values, i.e., Equation (6) is applied.

After the matrix

is formed, the maximum values of this matrix are selected in order to define the optimal values, i.e., the matrix

. Out of all the values of matrix

, the maximum value is selected (in this case

, in order to calculate the optimal fuzzy matrix, as shown in

Table 4, as follows:

In the ninth step, the summation elements

of the previous matrix are determined in order to calculate the final criterion weights

wj as follows:

According to the final results after the application of the Fuzzy M-FullEX method, the most important criterion is C6 with a crisp value of 0.220, which confirms the alignment with the initial evaluation by the experts, as C6 has the highest b value of 25, while the least important criterion is C5, with b = 3.

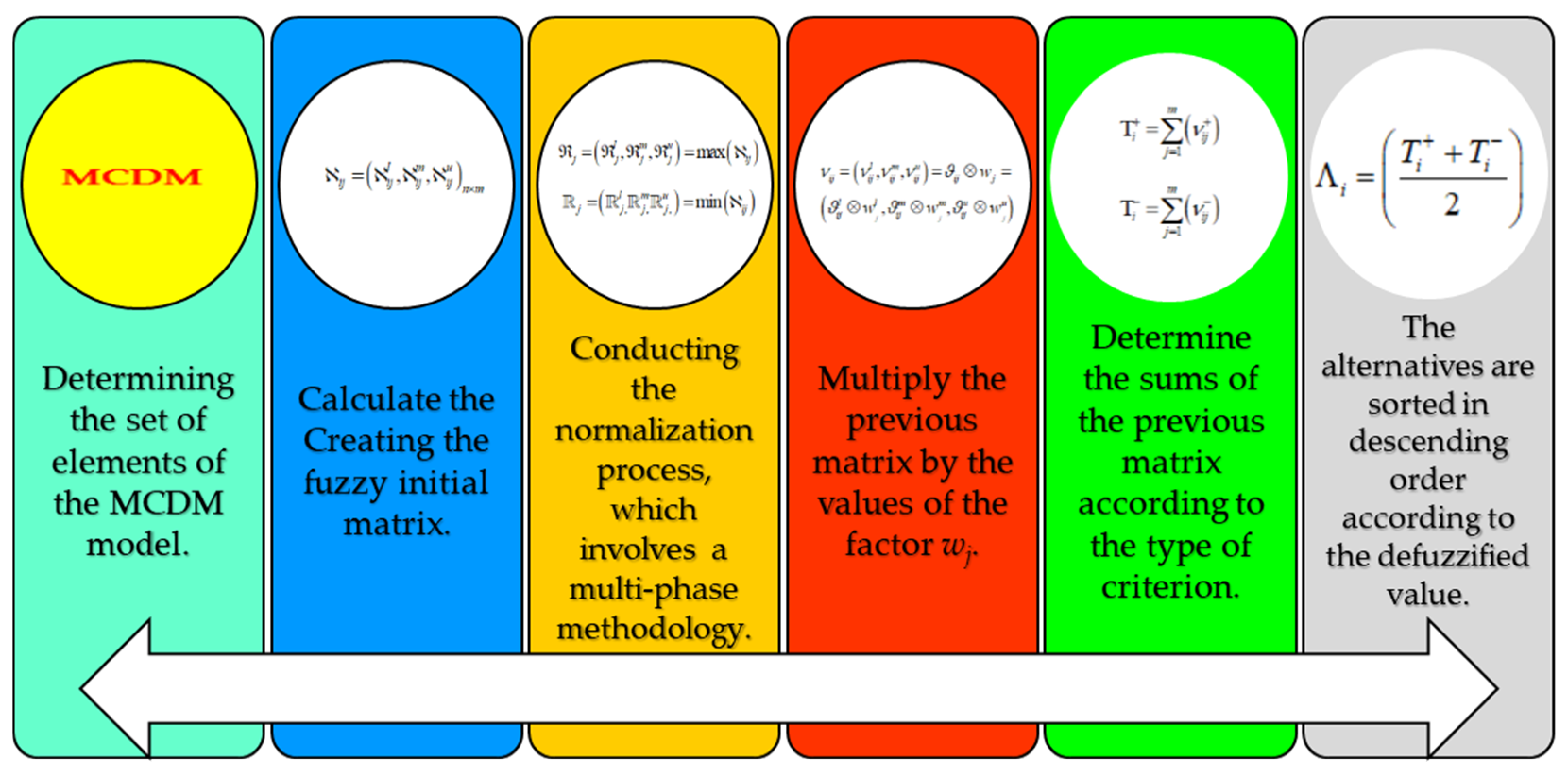

3.4. Evaluation of Multifunctional Machines Using the Fuzzy ROV Method

Three experts also evaluated the multifunctional machines for waste management, and their averaging was carried out using the Bonferroni operator, after which the initial aggregated fuzzy matrix was obtained in the Fuzzy ROV method (

Table 5).

The normalized Fuzzy ROV matrix (

Table 6) was obtained by applying the equations for the benefit criteria.

In the normalized matrix, the values of

and

are first determined, which for C1 are

and

, and then the values of

, and

are calculated:

Then, the final normalized fuzzy values are obtained by applying the following equation:

The formation of the weighted normalized Fuzzy ROV matrix is shown in

Table 7.

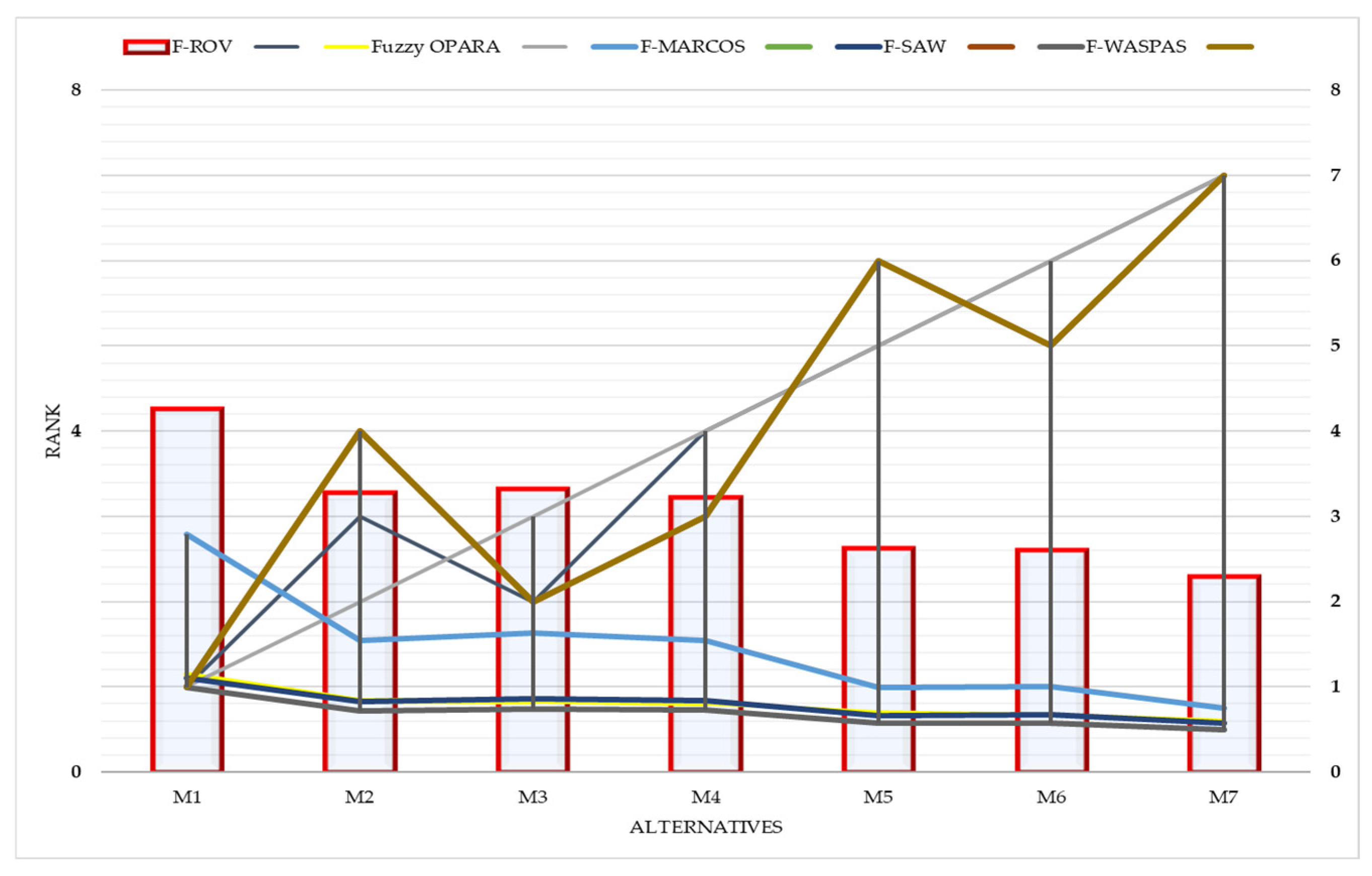

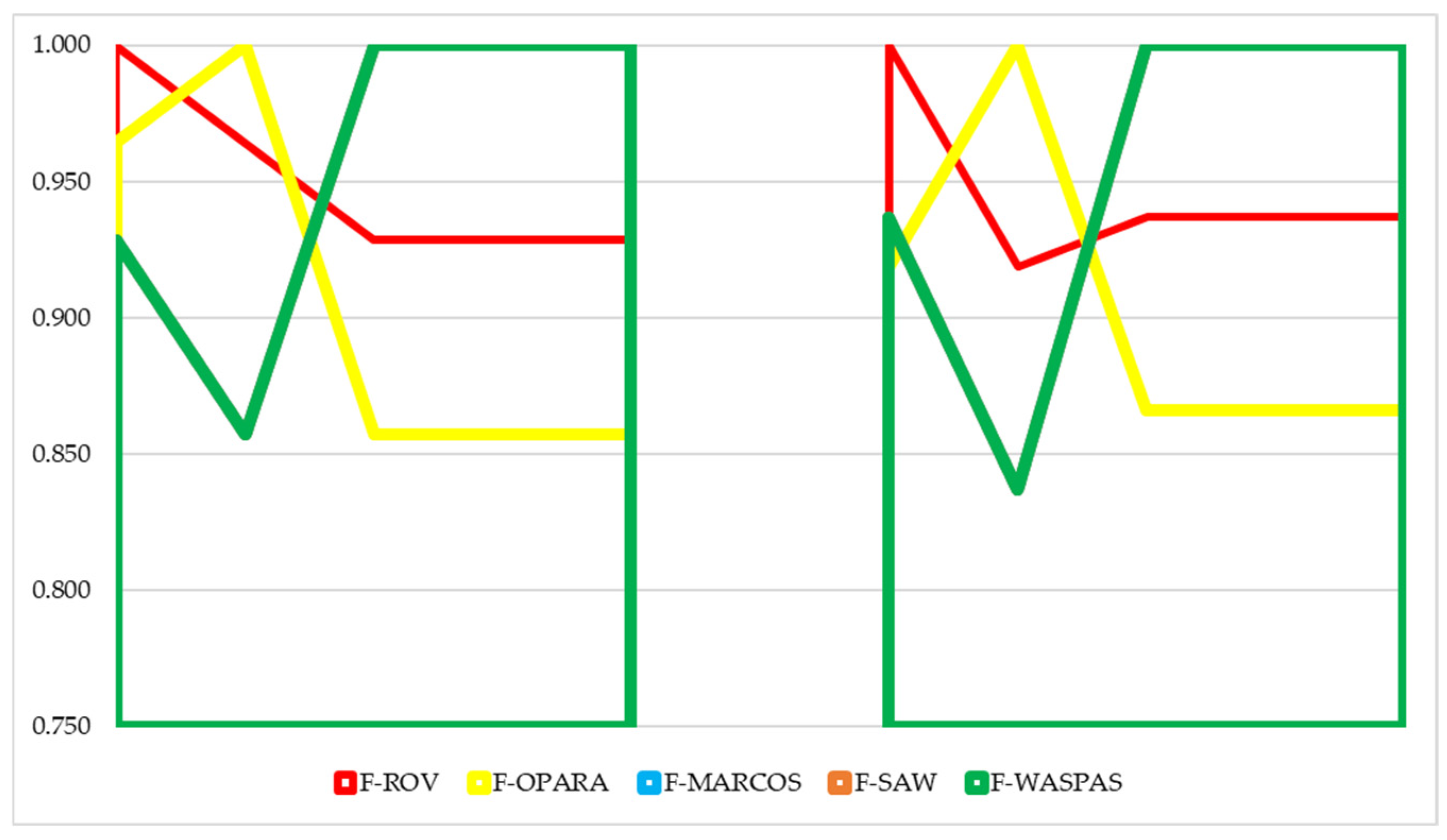

By completing the Fuzzy ROV method, the final results presented in

Table 8 were obtained.

The results show the following: M1 > M3 > M2 > M4 > M5 > M6 > M7. This indicates that the Venieri machine was selected. The Italian machine, the Venieri backhoe loader, represents a specific concept in terms of multifunctional applications across various sectors of business activity, with a special focus on sustainable waste management and the removal of illegal dumpsites, which are created daily, often due to the lack of education among the population and the negligence of some individuals when it comes to the disposal of non-hazardous and similar categories of waste. A distinctive feature of the Venieri machine is its articulated chassis, which sets it apart from all other machines with a similar performance on the market in terms of its construction. The articulated chassis allows for exceptional maneuverability compared to the tractor chassis, which is commonly used in most competing machines of this type. The maneuverability that the Venieri offers allows it to achieve the maximum utilization of the loading bucket, as well as remarkable features for loading/unloading activities.

The main characteristic of the multifunctional Venieri machine is its hydrostatic transmission, which ensured the maximum degree of efficiency in power transmission (piston–axial pump/hydraulic motors). This allows the machine to achieve an exceptional performance in the transmission of power from the hydraulic drive to the drive axles. The hydrostatic transmission in this type of machine enables it to be the only one with such a system for using additional tools on the loading arm, which utilize hydraulic motors as drive devices for specialized attachments, such as crane mowers for grass, cutting discs for micro and midi excavators, asphalt grinders, and others.

The Venieri multifunctional machine contributes to the sustainability of the waste management system in the city of Doboj. The layout of the controls on the dashboard and the visibility from the cabin, especially when performing maneuvering activities (such as collecting and loading bulky waste into trucks, particularly in the outskirts of the city and in hard-to-reach rural areas, which contribute to the optimization of the total waste collected), make the machine highly efficient, and help to avoid idle time during operations. The speed at which the Venieri machine moves across difficult terrain makes it lighter and more adaptable for the tasks that need to be performed. This is mainly due to its articulated chassis, which is more flexible compared to the rigid models of competing types that resemble tractors, thus reducing work efficiency. One of the experts, who actively participated in this study and has over two decades of experience in the field, compared all the machines available on the market based on the need for bulky waste disposal, as well as the machine economy, durability, and other criteria. He concluded that the Venieri machine offers exceptional maneuverability with maximum utilization during loading/unloading activities, especially focusing on the degree of utilization of the bucket for collecting and loading bulky waste. In addition, in developing countries like Bosnia and Herzegovina, when collecting bulky waste in rural areas, it is necessary to clean the entire area where the waste is collected. This is because a portion of the waste is still irresponsibly burned, which is illegal. To prevent damage to future plant crops during potential planting, it is necessary to remove thoroughly the soil layer and load it into another vehicle with an open container, which will take the soil and other waste material to the landfill. The Venieri machine also proves to be the best possible option for this purpose, compared to all other available machines, such as backhoe loaders on the market. The same expert also assessed the Venieri as the best option for the needs of the local company Progres, analyzing the geographical location of the 64 local communities, where 72% of the total sample is located in predominantly hilly areas with underdeveloped infrastructure and road network, as well as scattered households, which complicates the door-to-door waste collection strategy, with the ultimate goal of reducing waste collection costs along the defined transport route. On the other hand, the Venieri multifunctional machine is characterized by its adaptability to the working environment, especially in conditions of highly demanding operations in a short time. Namely, the 360-degree visibility from the cabin allows for easy and simple maneuvering during operations, especially during bulky waste loading and cleaning of scattered waste. Furthermore, due to the Z-joint, the Venieri easily allows for the installation of a large number of attachments, which enables more efficient completion of daily tasks. The new generation of electrically controlled cooling fans, with two speeds, reduces fuel costs by 10% and decreases noise intensity during operation.

On the other hand, compared to competing manufacturers such as JCB, CAT, Komatsu, Case, Hidromak, and others, which feature “rigid” tractor chassis, hydrodynamic transmission, and are unable to perform the wide range of tasks required daily by the utility company Progres Ltd. Doboj, and do not possess specialized tools that can be mounted on the loading arm, the Venieri machine stands out as a unique multifunctional machine with optimal characteristics, making it the most desirable and best choice for Progres. Additionally, another feature of the Venieri is the towing power on all four wheels, which is especially noticeable in hard-to-reach areas (rural and hilly regions, both in winter conditions and during intense autumn rains when the transport infrastructure is mostly damaged). On the other hand, another positive feature of the multifunctional Venieri machine is its ability to perform tasks faster and more easily when working in place and at a specific position (such as collecting bulky waste at one or more interconnected locations) in such a way that there is no idling or redundant maneuvering during operation.

5. Conclusions

Appropriate and sustainable waste management is a challenge that receives significant attention, regardless of whether it concerns developing countries or global economic powers. The aim is certainly to achieve sustainability in the greatest possible form and to strive toward sustainable development goals. This paper considers a set of multifunctional machines that can contribute to sustainable waste management. A total of 10 criteria were defined on the basis of which the machines, a total of seven, were evaluated.

This study contributes to the sustainable development of waste management systems, not only in Bosnia and Herzegovina, but also in the countries in the region, as well as globally, thanks to a new model and a systemic approach in motivating the rural population to adopt the new image of proper waste management today, compared to the image from two or more decades ago. Therefore, all residents, both in urban and rural areas, are obliged to comply with the legal requirement to dispose of all types of waste properly and, for a fee, to an authorized utility company. Specifically, all Balkan countries share the same mentality when it comes to waste disposal, where waste is mostly disposed of by inertia, meaning improperly, even when there is a clear textual and visual illustration showing which type of waste belongs in which container. However, this awareness is being raised, both through the tightening of fines for offenders and through specific penalties that individuals are required to carry out, which involve compulsory labor on a daily or multi-day basis, related to cleaning up waste in the city or rural areas that they themselves have caused. Therefore, most transition countries face a similar issue regarding the selection of an appropriate strategy for a sustainable waste management system, with particular emphasis on rural areas, which are hard to access (narrow roads, inadequate transport infrastructure, scattered households that are mostly hard to reach), as well as the lack of awareness among residents that waste is a resource that must be properly disposed of and landfilled, not garbage, and that they must cooperate with all stakeholders in the chain to create a sustainable waste management system. From this case study, as well as from Bosnia and Herzegovina as a country, numerous lessons can be drawn, and a structural discussion can be initiated for new, similar studies. Therefore, the procurement of a multifunctional machine for the disposal of specific categories of waste, such as bulky waste and related waste categories, along with available municipal vehicles and trained auxiliary workers, will contribute to the better cleaning of “critical” points where this waste is improperly disposed of, creating the preconditions for a sustainable and healthy living environment. The goal is to first create the conditions for the collection and transportation of municipal and bulky waste from inaccessible rural areas, and only after that to seriously approach the aforementioned service. This study has shown that the population is more accessible and open to compromise if visible improvements are made to the area where they live, such as the removal of illegal dumpsites and all critical points where waste is improperly disposed of, as well as the collection of municipal waste from door to door, with a regular waste collection schedule. Furthermore, better cooperation with the local utility company is achieved when the population receives material satisfaction, which is reflected in the provision of municipal equipment for use, rather than having to purchase it themselves, especially in rural areas, such as 120 or 140 L bins and larger 1100 L containers.

The research carried out with a clearly created and newly defined model represents a dual contribution from both a professional and scientific perspective.

- (1)

From a professional perspective, the defined model can be used to achieve a sustainable waste management system through appropriate waste treatment. Also, the model can be useful for all stakeholders in the field of waste management and can help decision-makers and local governments to create appropriate strategies for sustainable waste management.

- (2)

From a scientific standpoint, the contribution lies in the simultaneous modification of the FullEX method and its extension with TFNs. It was observed that in the previous model of the original method, there was a discrepancy between the expert evaluations and the final criterion weights, which has been completely addressed and overcome with the development of the Fuzzy M-FullEX method.

- (3)

Furthermore, integration with the Fuzzy ROV method was carried out to enable the ranking of multifunctional machines for waste treatment, which represents a unique model.

The results of the defined Fuzzy M-FullEX-Fuzzy ROV model show that M1, representing the Venieri manufacturer, is the best solution, which was later confirmed through extensive analyses in terms of matrix size, changes in fuzzy criterion weights, comparative fuzzy analysis, and the calculation of correlation coefficients.

Further research based on the study conducted in this paper represents, from a professional standpoint, the pursuit of achieving the 3R concept, or from a scientific perspective, the presentation of new models or the integration of existing methods into unique MCDM models.