A Two-Layer Cooperative Optimization Approach for Coordinated Photovoltaic-Energy Storage System Sizing and Factory Energy Dispatch Under Industrial Load Profiles

Abstract

1. Introduction

- (1)

- A two-layer cooperative optimization model integrating GA and MILP is proposed. The model incorporates source and load uncertainties as well as time-of-use electricity prices, with the objective of minimizing the economic costs. It simultaneously determines the optimal capacity of the PV-ESS and performs fine-grained scheduling of industrial load energy allocation.

- (2)

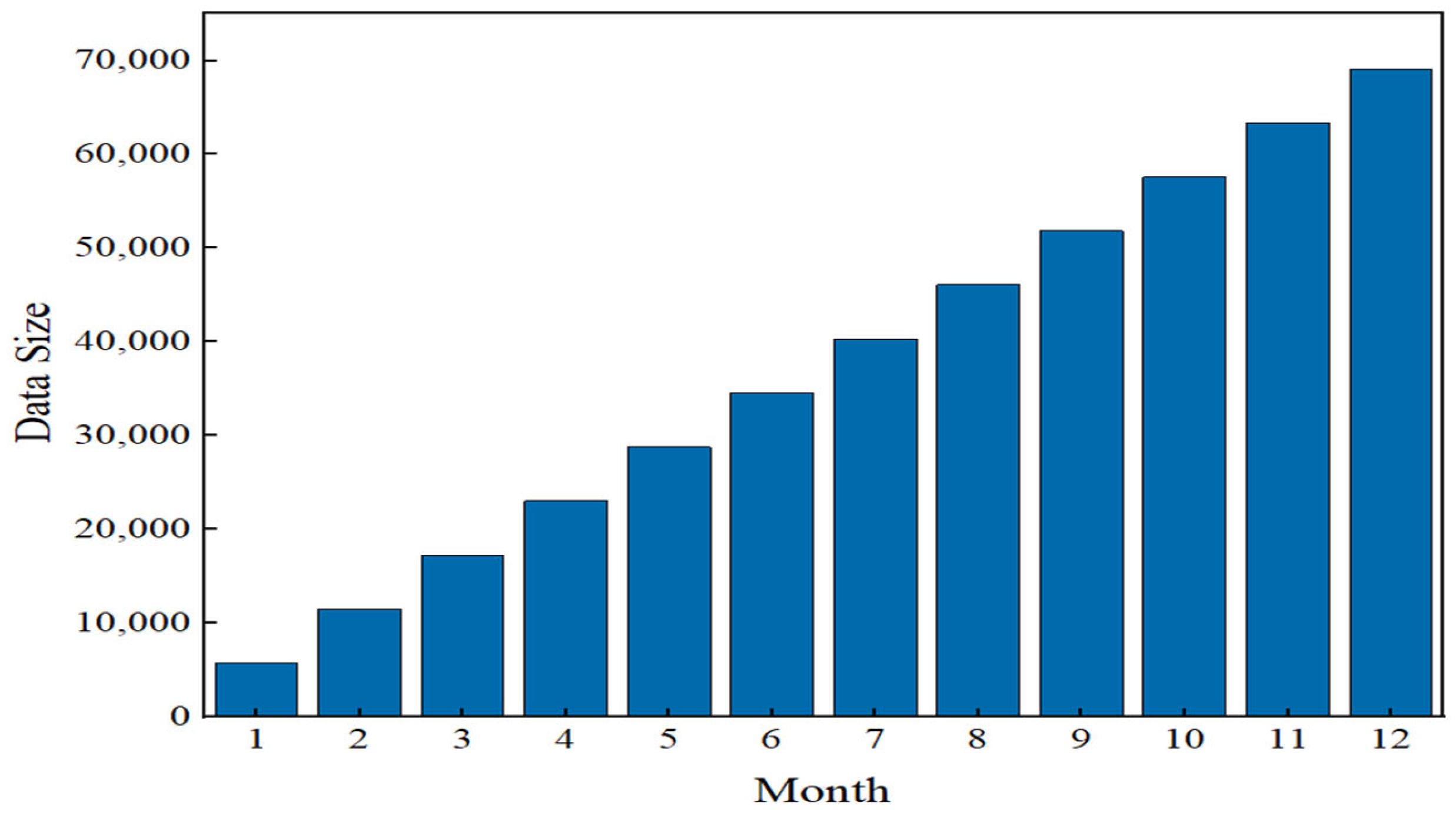

- Enhanced computational efficiency is accomplished through multi-process parallel computing. To address the challenges of large-scale and high-dimensional industrial load scheduling data, the RG (Random Generation), HG (Heuristic Generation), and LHS (Latin Hypercube Sampling) methods are integrated to enhance the population diversity and expand the solution space. Furthermore, multi-process parallel computing is implemented to accelerate fitness evaluation, significantly improving the computational efficiency of the optimal solution search using massive datasets.

- (3)

- Comprehensive experimental validation with real-world data was achieved. The proposed algorithm was rigorously validated using real-world factory load and power market data. Its feasibility and adaptability in complex industrial environments were demonstrated through multiple metrics, including the economic cost reduction, renewable energy utilization rate, and energy exchange efficiency with the grid.

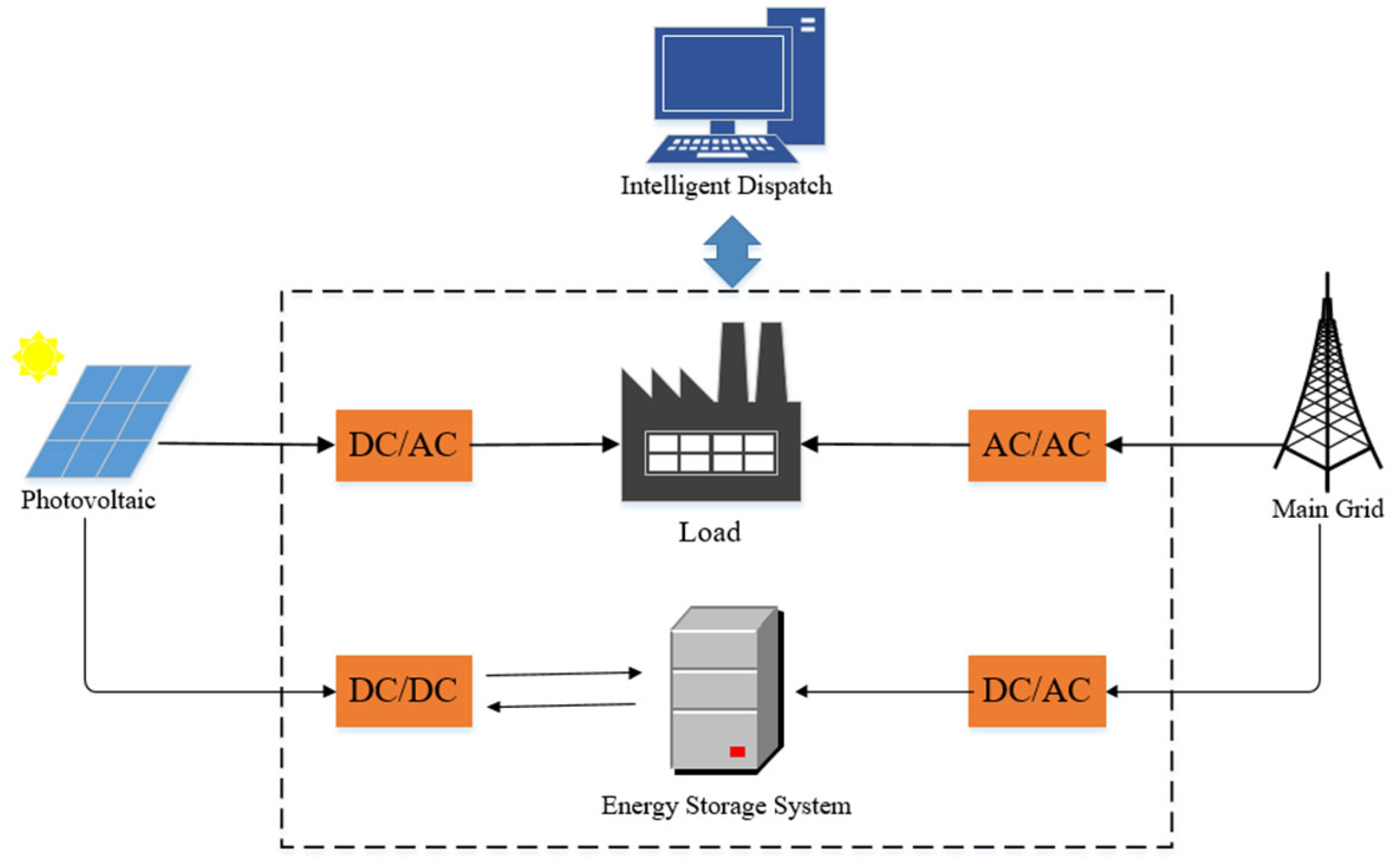

2. Problem Formulation and System Modeling

2.1. Energy Storage Systems

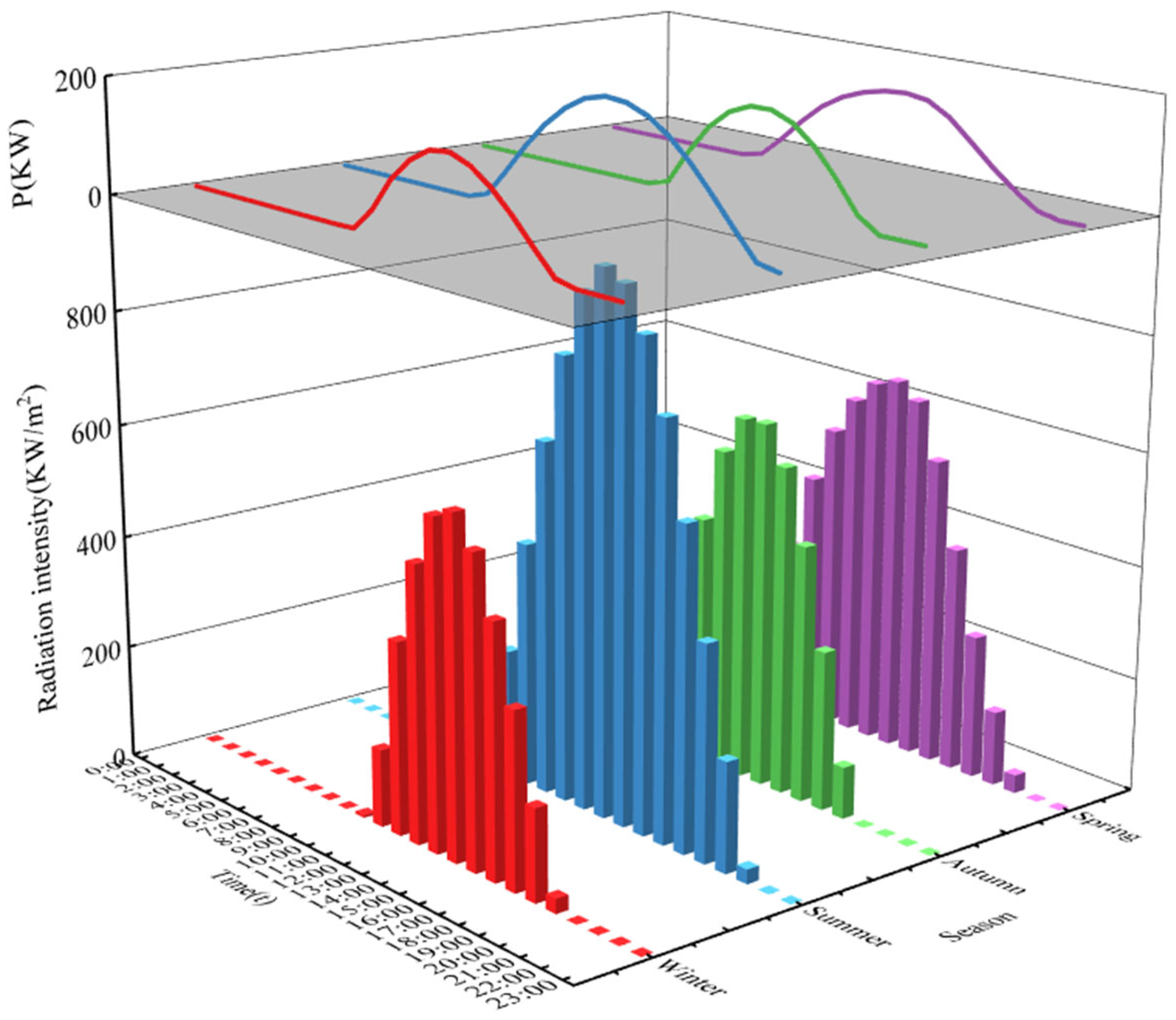

2.2. Photovoltaics

2.3. Main Grid

3. Solution Methodology

3.1. Decision Variables

3.2. Constraints

3.3. Objective Function

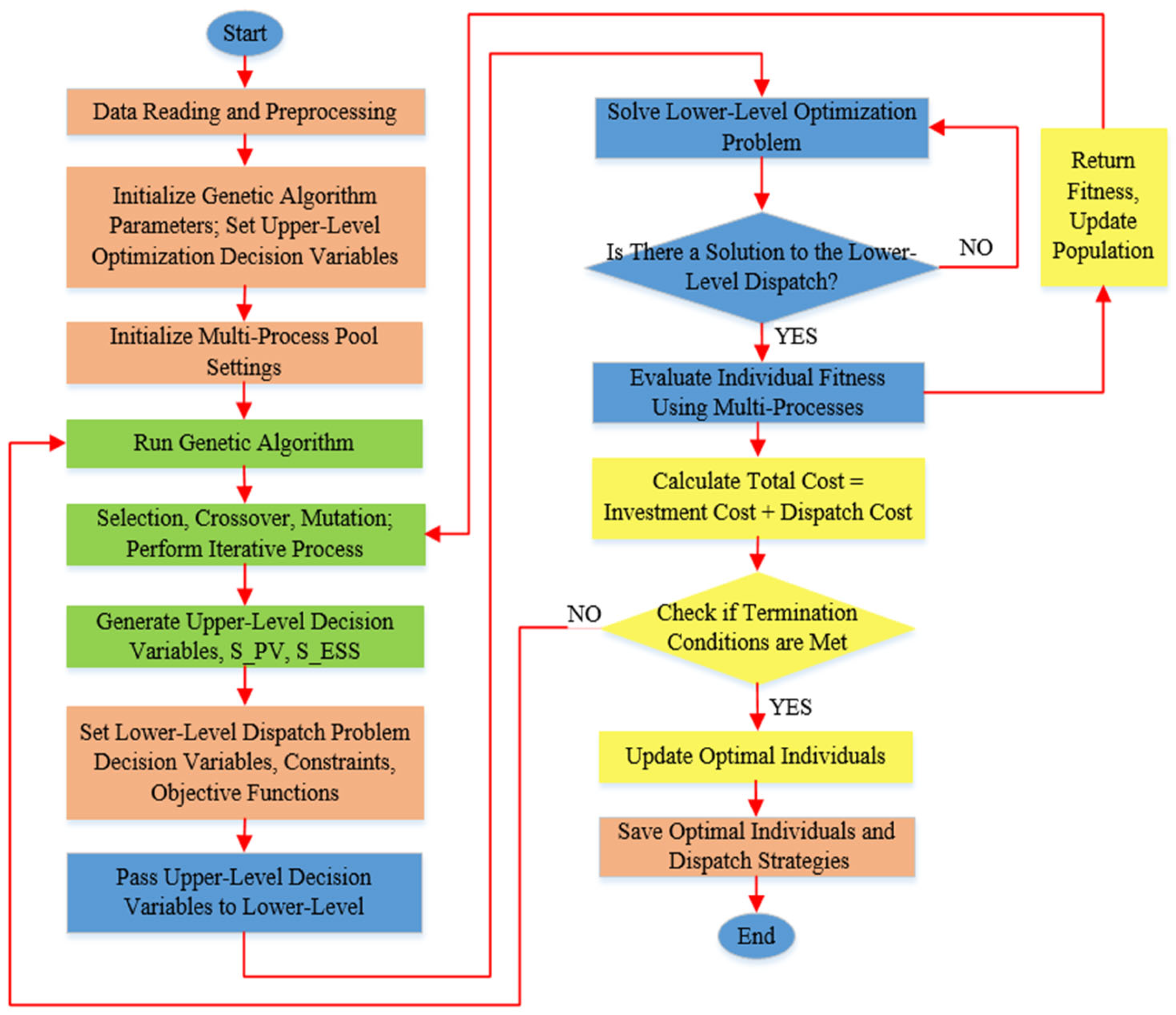

3.4. The Specific Solution Process

3.4.1. Overall Framework of TLCOA and Algorithm Flow

3.4.2. Upper-Layer GA for PV–ESS Capacity Optimization

3.4.3. Lower-Layer MILP for Energy Dispatch

3.4.4. Implementation Details and Parallel Computing

| Algorithm 1. TLCOA: Two-Layer Cooperative Optimization for PV–ESS Sizing and Dispatch |

| # Upper Layer: Genetic Algorithm (GA) # Lower Layer: Mixed-Integer Linear Programming (MILP) # Parallel Fitness Evaluation: each population member is evaluated in parallel. Procedure TLCOA_Main: 1. (prices_df, pv_output_df, load_df) ← read_and_preprocess(“data_file.csv”) 2. Initialize global data for parallel processes (init_pool_globals). 3. (toolbox, var_bounds, avg_load, pool) ← setup_genetic_algorithm() 4. (best_ind, logbook, hof) ← run_genetic_algorithm(toolbox) 5. extract_and_visualize_results(best_ind) 6. pool.close(), pool.join() End Procedure -------------------------------------------------------------------------------- Function run_genetic_algorithm(toolbox) → (best_ind, logbook, hof): 1. population ← toolbox.population() 2. ngen ← 500, cxpb ← 0.7, mutpb ← 0.2 3. hof ← HallOfFame(1) 4. stats ← define_statistics(…) 5. (population, logbook) ← eaSimple( population, toolbox, cxpb = cxpb, mutpb = mutpb, ngen = ngen, stats = stats, halloffame = hof, verbose = True ) 6. best_ind ← hof[0] # best (S_PV, S_ESS) solution 7. return (best_ind, logbook, hof) End Function -------------------------------------------------------------------------------- Function evaluate(individual) → fitness: # individual = (S_PV, S_ESS) 1. investment_cost ← compute_investment(S_PV, S_ESS) 2. (dispatch_cost, _) ← optimize_dispatch(S_PV, S_ESS, global_data, …) 3. if dispatch_cost = ∞ then return large_value 4. total_cost ← investment_cost + dispatch_cost 5. return total_cost End Function -------------------------------------------------------------------------------- Function optimize_dispatch(S_PV, S_ESS, prices_df, pv_output_df, load_df, …) → (cost, dispatch_df): 1. prob ← create MILP problem (MINIMIZE total electricity cost) 2. for each time slot t in load_df: - Define variables: P_PV_load[t], P_grid_load[t], P_ESS_load[t], etc. - Enforce constraints: (a) Load balance: P_PV_load[t] + P_grid_load[t] + P_ESS_load[t] = Load[t] (b) PV allocation: P_PV_load[t] + P_PV_ESS[t] ≤ S_PV * PV_output[t] (c) ESS SOC: E_ESS[t+1] = E_ESS[t] + … (d) Charge/discharge limits and binary constraints for mutual exclusivity 3. Add objective function: minimize ∑(price[t] × grid_power[t]) [± any sell/buy terms] 4. prob.solve() 5. if solution is not Optimal: return (∞, None) 6. cost ← value(prob.objective) 7. dispatch_df ← extract_decision_variables(prob) 8. return (cost, dispatch_df) End Function |

4. Validation and Analysis of Case Studies

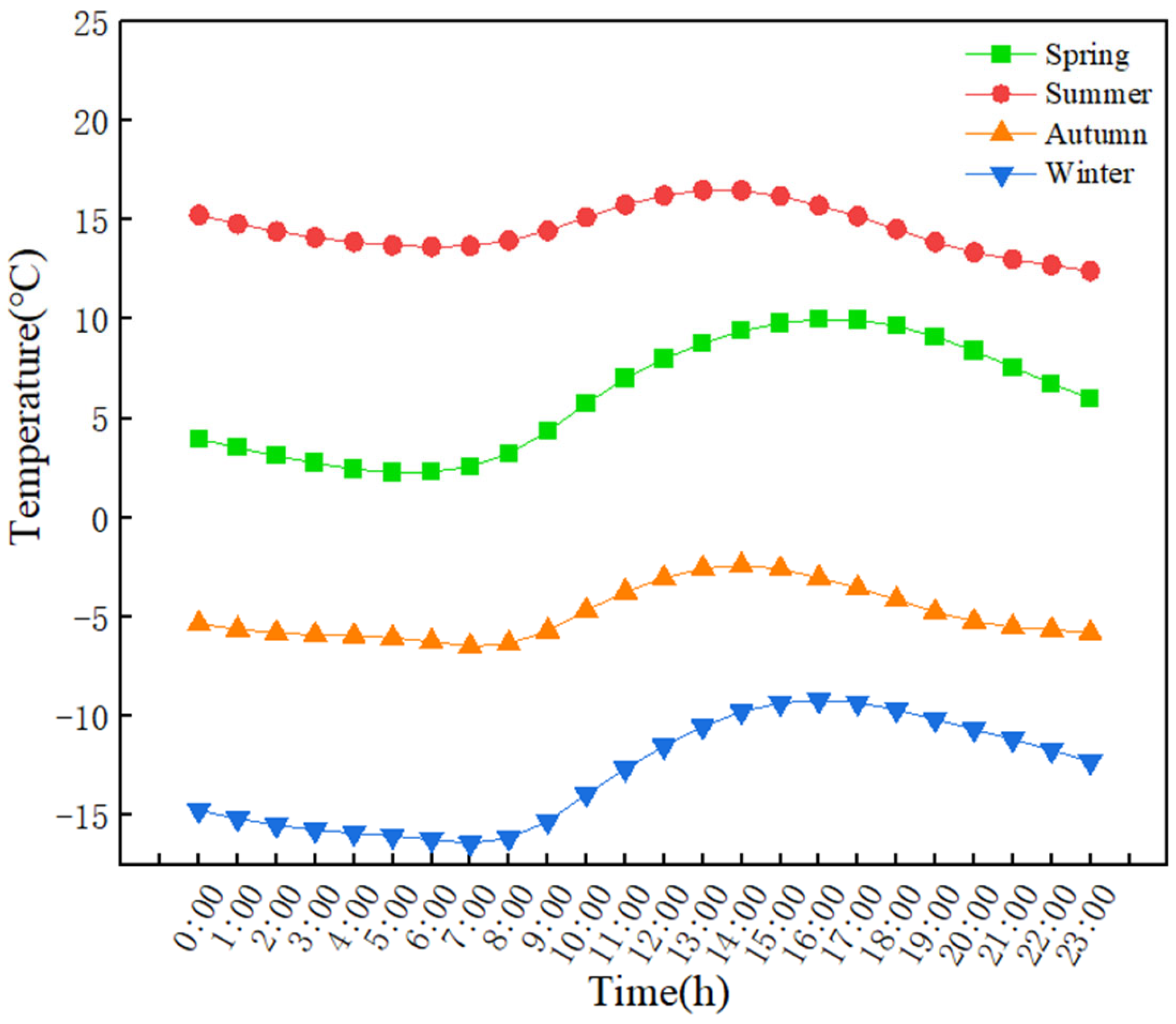

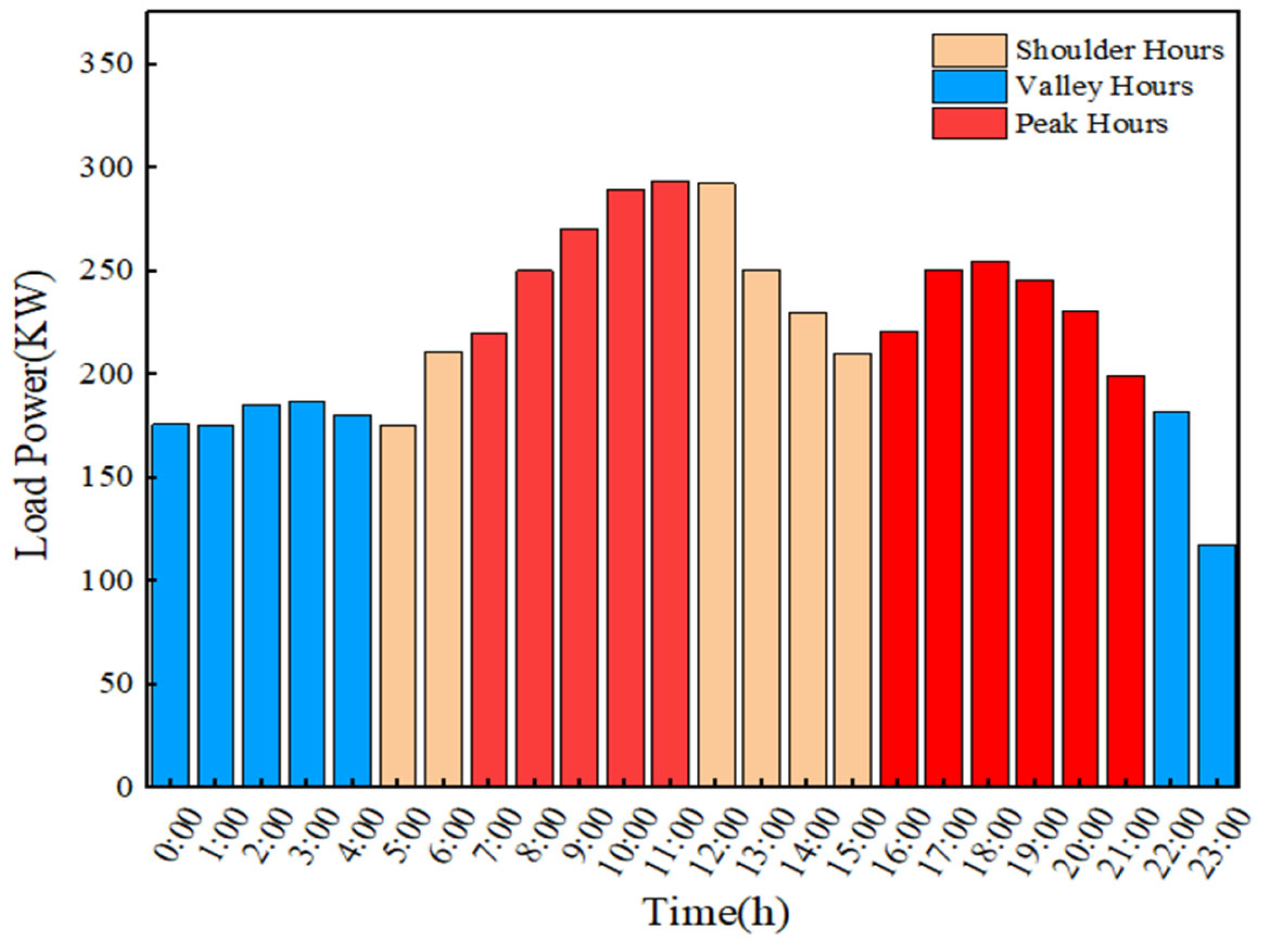

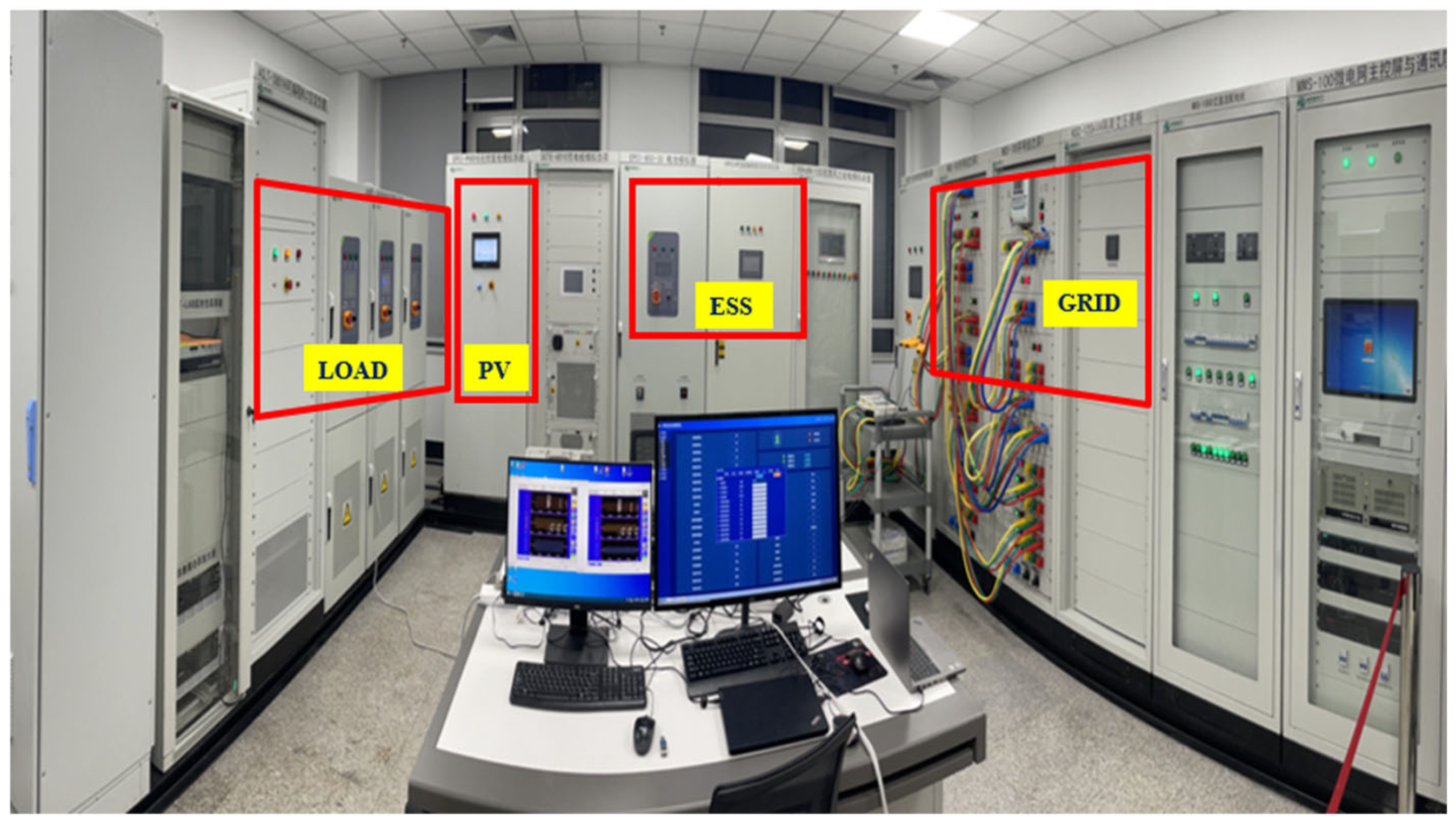

4.1. Case Description

4.2. Validation of the TLCOA

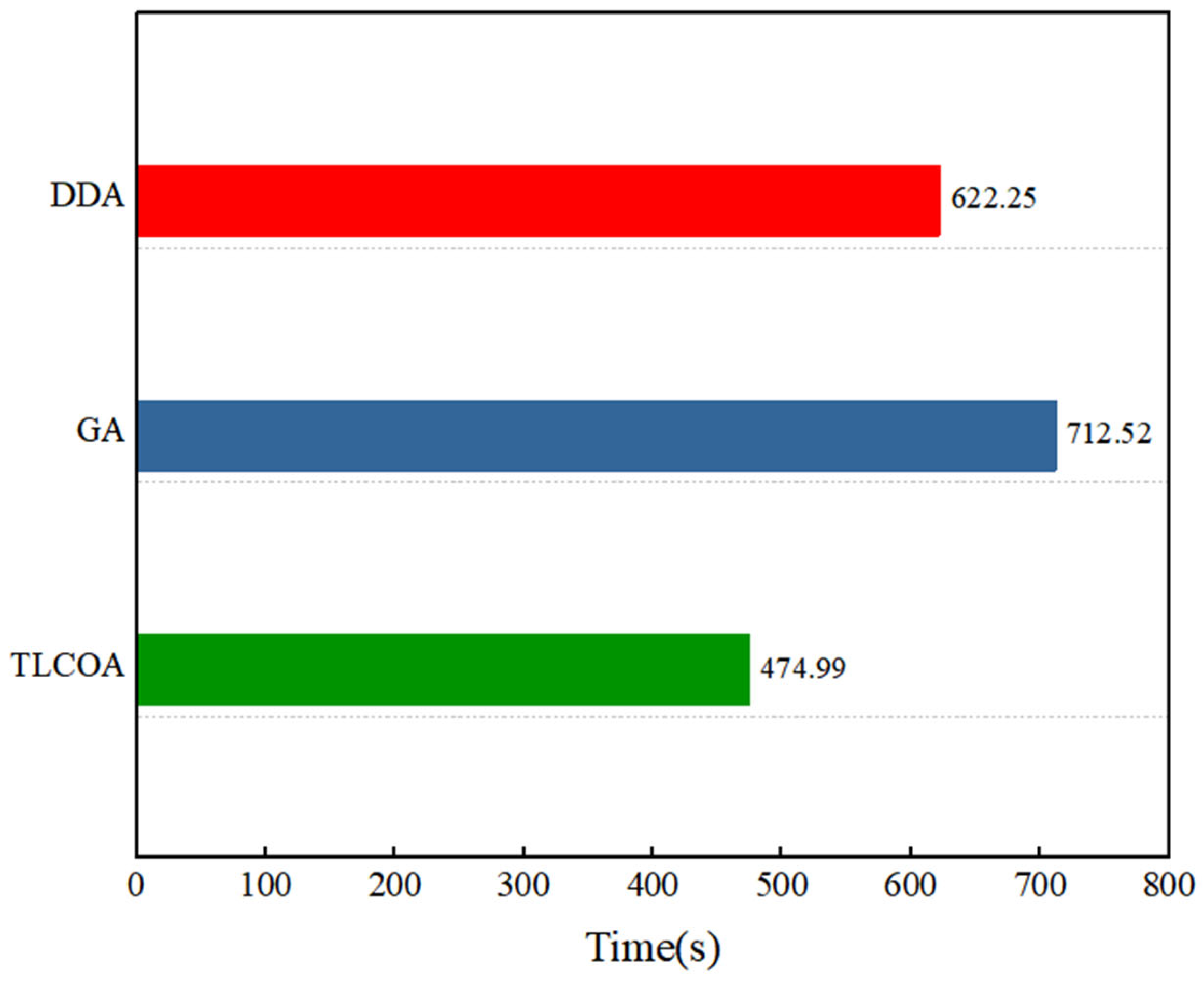

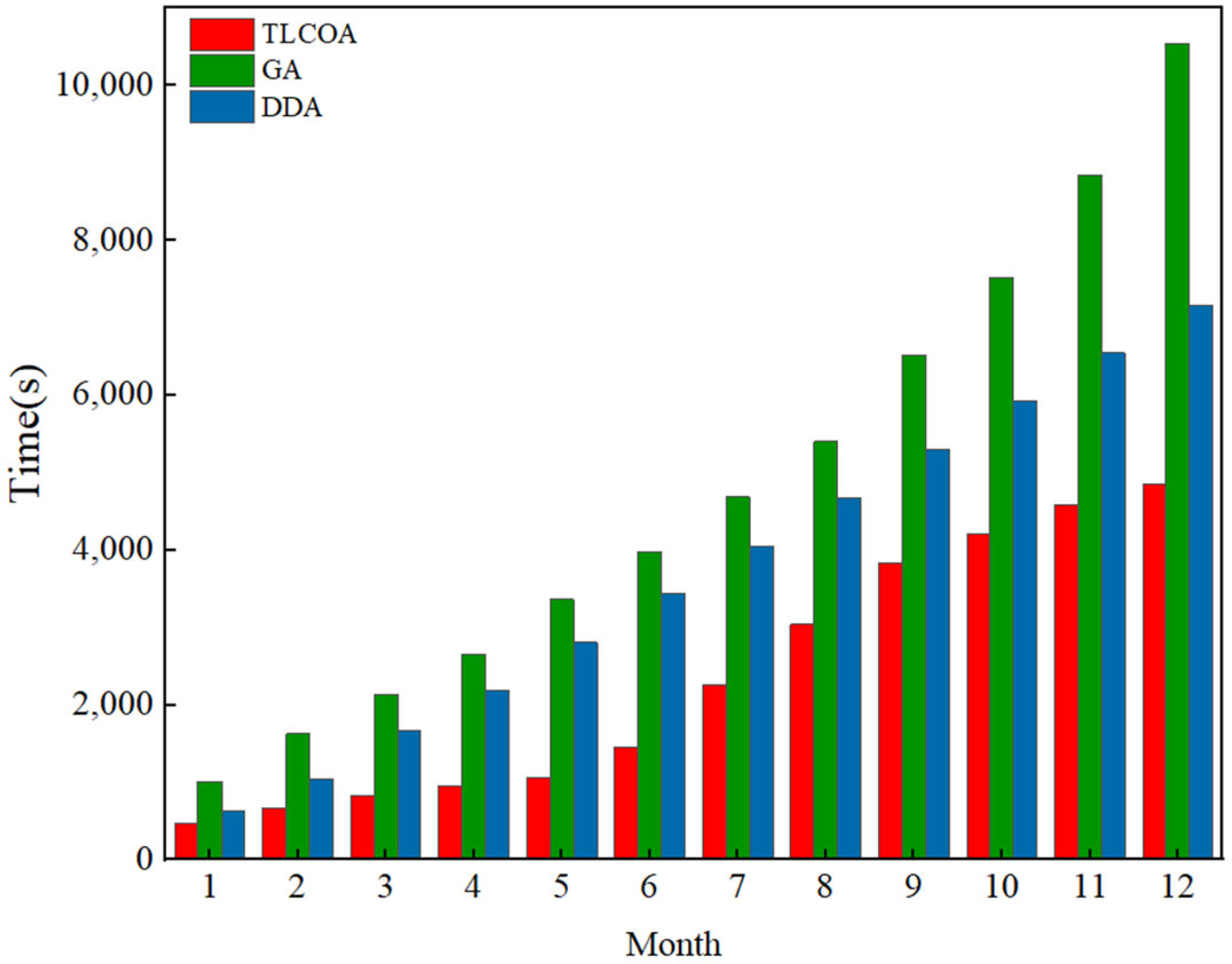

4.2.1. Comparison of Solution Time

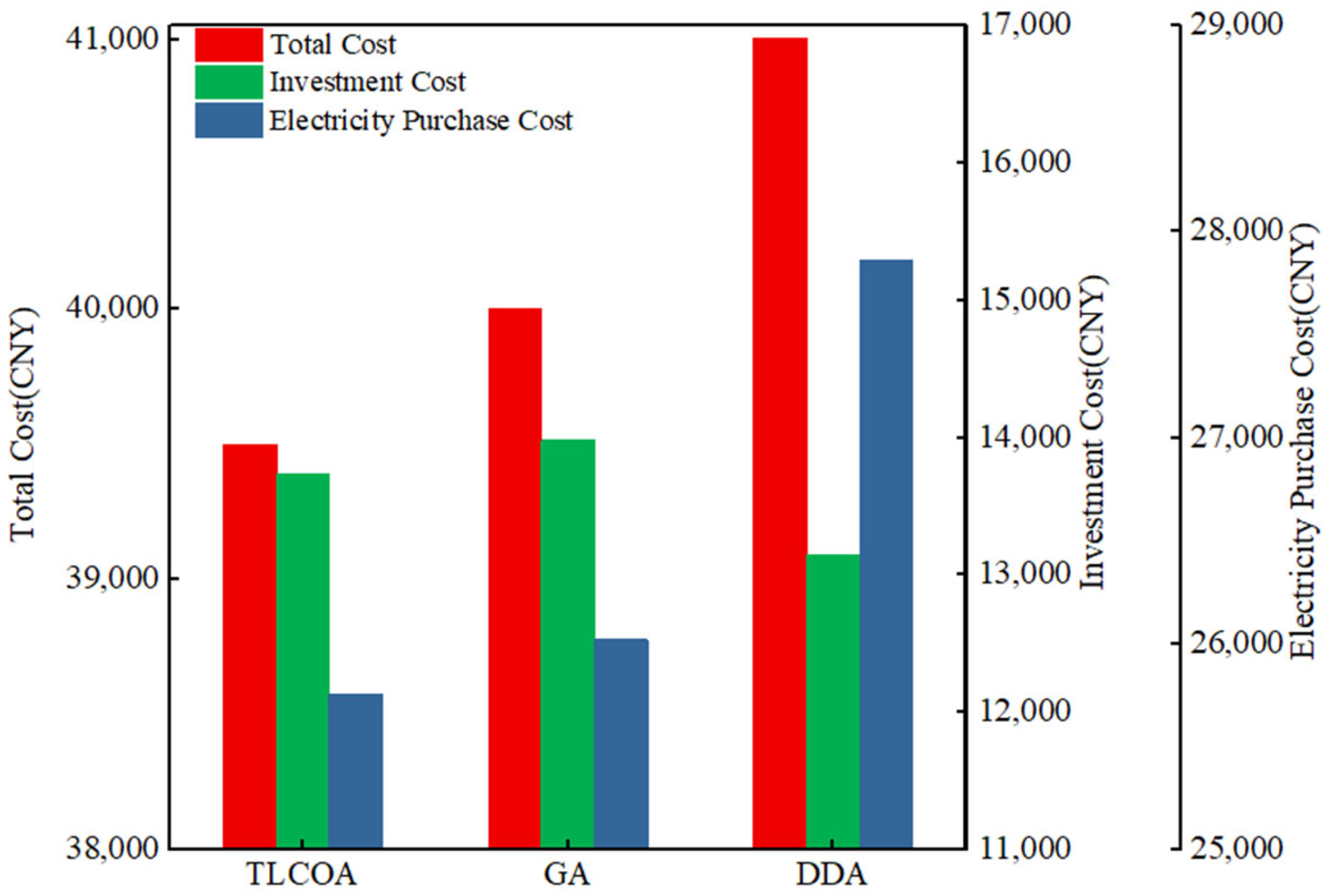

4.2.2. Comparison of Economic Benefits

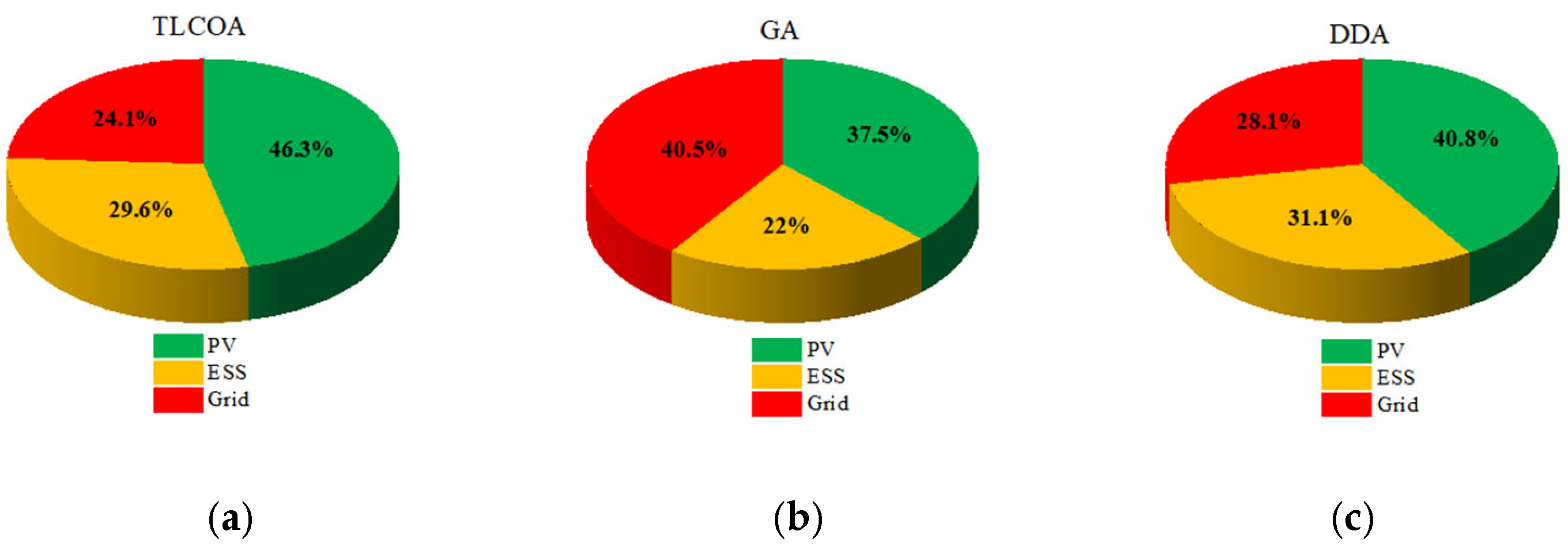

4.2.3. Comparison of Renewable Energy Utilization Rate

4.2.4. Analysis of System Stability

5. Conclusions

- (1)

- By employing a parallel multi-process solving strategy in the TLCOA, the time required to find the optimal scheduling solution was reduced by 33.33% and 23.68%, compared to the GA and DDA, significantly improving the solving efficiency.

- (2)

- The experimental results showed that, compared to the single-layer GA algorithm and the DDA algorithm, TLCOA exhibited significant advantages in handling large-scale datasets. Nonetheless, given the high efficiency required for industrial energy dispatch, there remains room for further enhancement of the TLCOA algorithm. Future studies could explore reinforcement learning-based search strategies or other hybrid methods to improve the energy dispatch efficiency.

- (3)

- A TLCOA was used to model the investment in the PV-ESS for the plant. The PV area was 1376 m2 and the ESS capacity was 998 kWh, resulting in a 1.73% reduction in investment costs and a 7.55% reduction in purchased power costs. As a result, the economic cost of energy use in the plant was significantly reduced.

- (4)

- From a long-term economic perspective, this study analyzed the payback period for a factory’s investment in a PV–ESS system. With the TLCOA, the payback period was 3.22 years, after which, the factory attained the greatest savings in electricity purchases, thus maximizing economic returns. This study offers a reliable plan for implementing PV–ESS systems in industrial facilities.

- (5)

- By scheduling the load energy supply using the TLCOA, the PV, ESS, and MG supplied 46.34%, 29.59%, and 24.07% of the load, respectively. The PV power supply increased by 8.79%, significantly improving the utilization rate of renewable energy.

- (6)

- Based on the comprehensive system performance analysis, after adopting the TLCOA, the S-G-L-S system provided a stable power supply to the loads and could adjust the power supply strategy according to time-of-day tariffs, achieving “peak shaving and valley filling”.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameter | Value/Range | Rationale and Justification |

|---|---|---|

| Population Size (GA) | 100 |

|

| Number of Generations (GA) | 50 |

|

| Crossover Probability (GA) | 0.7 |

|

| Mutation Probability (GA) | 0.2 |

|

| Time Horizon and Step | 24 h @ 1 h step |

|

| 0.95, 0.95 |

|

References

- Zhao, X.; Ma, X.; Chen, B.; Shang, Y.; Song, M. Challenges toward Carbon Neutrality in China: Strategies and Countermeasures. Resour. Conserv. Recycl. 2022, 176, 105959. [Google Scholar] [CrossRef]

- Shao, T.; Pan, X.; Li, X.; Zhou, S.; Zhang, S.; Chen, W. China’s Industrial Decarbonization in the Context of Carbon Neutrality: A Sub-Sectoral Analysis Based on Integrated Modelling. Renew. Sustain. Energy Rev. 2022, 170, 112992. [Google Scholar] [CrossRef]

- Wang, S.; Yue, Y.; Cai, S.; Li, X.; Chen, C.; Zhao, H.; Li, T. A Comprehensive Survey of the Application of Swarm Intelligent Optimization Algorithm in Photovoltaic Energy Storage Systems. Sci. Rep. 2024, 14, 17958. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Xu, Q.; Yang, Y.; Xia, Y.; Hua, K. Study on Distributed Renewable Energy Generation Aggregation Application Based on Energy Storage. Int. J. Electr. Power Energy Syst. 2024, 158, 109935. [Google Scholar] [CrossRef]

- Yang, C.; Lin, Z.; Huang, K.; Wu, D.; Gui, W. Manifold Embedding Stationary Subspace Analysis for Nonstationary Process Monitoring with Industrial Applications. J. Process Control 2024, 140, 103262. [Google Scholar] [CrossRef]

- Fan, G.-F.; Feng, Y.-W.; Peng, L.-L.; Huang, H.-P.; Hong, W.-C. Uncertainty Analysis of Photovoltaic Power Generation System and Intelligent Coupling Prediction. Renew. Energy 2024, 234, 121174. [Google Scholar] [CrossRef]

- Xie, L.; Xiang, Y.; Xu, X.; Wang, S.; Li, Q.; Liu, F.; Liu, J. Optimal Planning of Energy Storage in Distribution Feeders Considering Economy and Reliability. Energy Tech. 2024, 12, 2400200. [Google Scholar] [CrossRef]

- Jiang, C.; Mao, Y.; Chai, Y.; Yu, M. Day-ahead Renewable Scenario Forecasts Based on Generative Adversarial Networks. Int. J. Energy Res. 2021, 45, 7572–7587. [Google Scholar] [CrossRef]

- Zhu, D.; Liu, W.; Hu, Y.; Wang, W. A Practical Load-Source Coordinative Method for Further Reducing Curtailed Wind Power in China with Energy-Intensive Loads. Energies 2018, 11, 2925. [Google Scholar] [CrossRef]

- Xu, M.; Li, W.; Feng, Z.; Bai, W.; Jia, L.; Wei, Z. Economic Dispatch Model of High Proportional New Energy Grid-Connected Consumption Considering Source Load Uncertainty. Energies 2023, 16, 1696. [Google Scholar] [CrossRef]

- Li, L.; Cao, X. Comprehensive Effectiveness Assessment of Energy Storage Incentive Mechanisms for PV-ESS Projects Based on Compound Real Options. Energy 2022, 239, 121902. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, X.; Li, M.; Wang, H.; Han, F.; Fu, X.; Wang, J. Control and Capacity Planning for Energy Storage Systems to Enhance the Stability of Renewable Generation Under Weak Grids. EBSCOhost. Available online: https://openurl.ebsco.com/contentitem/doi:10.1049%2Frpg2.12424?sid=ebsco:plink:crawler&id=ebsco:doi:10.1049%2Frpg2.12424 (accessed on 11 February 2025).

- Zamanpour, K.; Vaziri Rad, M.A.; Saberi, N.; Fereidooni, L.; Kasaeian, A. Techno-Economic Comparison of Dispatch Strategies for Stand-Alone Industrial Demand Integrated with Fossil and Renewable Energy Resources. Energy Rep. 2023, 10, 2962–2981. [Google Scholar] [CrossRef]

- Tan, Q.; Mei, S.; Ye, Q.; Ding, Y.; Zhang, Y. Optimization Model of a Combined Wind–PV–Thermal Dispatching System under Carbon Emissions Trading in China. J. Clean. Prod. 2019, 225, 391–404. [Google Scholar] [CrossRef]

- Li, Y.; Hou, J.; Yan, G. Exploration-Enhanced Multi-Agent Reinforcement Learning for Distributed PV-ESS Scheduling with Incomplete Data. Appl. Energy 2024, 359, 122744. [Google Scholar] [CrossRef]

- Babu, C.A.; Ashok, S. Optimal Utilization of Renewable Energy-Based IPPs for Industrial Load Management. Renew. Energy 2009, 34, 2455–2460. [Google Scholar] [CrossRef]

- Guo, J.; Wu, D.; Wang, Y.; Wang, L.; Guo, H. Co-Optimization Method Research and Comprehensive Benefits Analysis of Regional Integrated Energy System. Appl. Energy 2023, 340, 121034. [Google Scholar] [CrossRef]

- Yan, R.; Wang, J.; Lu, S.; Ma, Z.; Zhou, Y.; Zhang, L.; Cheng, Y. Multi-Objective Two-Stage Adaptive Robust Planning Method for an Integrated Energy System Considering Load Uncertainty. Energy Build. 2021, 235, 110741. [Google Scholar] [CrossRef]

- Yang, M.; Wang, J.; Zhou, Y.; Han, G.; Kang, J. Optimal Configuration of Integrated Energy System Based on Multiple Energy Storage Considering Source-Load Uncertainties under Different Risk Tendencies. J. Energy Storage 2025, 109, 115220. [Google Scholar] [CrossRef]

- Gibilisco, P.; Ieva, G.; Marcone, F.; Porro, G.; Tuglie, E.D. Day-Ahead Operation Planning for Microgrids Embedding Battery Energy Storage Systems. A Case Study on the PrInCE Lab Microgrid. In Proceedings of the 2018 AEIT International Annual Conference, Bari, Italy, 3–5 October 2018; IEEE: Bari, Italy, 2018; pp. 1–6. [Google Scholar]

- Bai, Z.; Gu, Y.; Wang, S.; Jiang, T.; Kong, D.; Li, Q. Applying the Solar Solid Particles as Heat Carrier to Enhance the Solar-Driven Biomass Gasification with Dynamic Operation Power Generation Performance Analysis. Appl. Energy 2023, 351, 121798. [Google Scholar] [CrossRef]

- Wang, T.; Lin, C.; Zheng, K.; Zhao, W.; Wang, X. Research on Grid-Connected Control Strategy of Photovoltaic (PV) Energy Storage Based on Constant Power Operation. Energies 2023, 16, 8056. [Google Scholar] [CrossRef]

- Tercan, S.M.; Demirci, A.; Gokalp, E.; Cali, U. Maximizing Self-Consumption Rates and Power Quality towards Two-Stage Evaluation for Solar Energy and Shared Energy Storage Empowered Microgrids. J. Energy Storage 2022, 51, 104561. [Google Scholar] [CrossRef]

- Silva, J.A.A.; López, J.C.; Arias, N.B.; Rider, M.J.; Da Silva, L.C.P. An Optimal Stochastic Energy Management System for Resilient Microgrids. Appl. Energy 2021, 300, 117435. [Google Scholar] [CrossRef]

- Luna, A.C.; Diaz, N.L.; Graells, M.; Vasquez, J.C.; Guerrero, J.M. Mixed-Integer-Linear-Programming-Based Energy Management System for Hybrid PV-Wind-Battery Microgrids: Modeling, Design, and Experimental Verification. IEEE Trans. Power Electron. 2017, 32, 2769–2783. [Google Scholar] [CrossRef]

- Al Essa, M.J.M. Management of Charging Cycles for Grid-Connected Energy Storage Batteries. J. Energy Storage 2018, 18, 380–388. [Google Scholar] [CrossRef]

- Turdybek, B.; Tostado-Véliz, M.; Mansouri, S.A.; Rezaee Jordehi, A.; Jurado, F. A Local Electricity Market Mechanism for Flexibility Provision in Industrial Parks Involving Heterogenous Flexible Loads. Appl. Energy 2024, 359, 122748. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Z.; Wu, X.; Wu, D.; Zhang, S.; Yang, X.; Ge, H.; Zhang, P. Two-Layer Co-Optimization Method for a Distributed Energy System Combining Multiple Energy Storages. Appl. Energy 2022, 322, 119486. [Google Scholar] [CrossRef]

| No. | Variable | Meaning |

|---|---|---|

| 1 | Installed capacity of the PV | |

| 2 | Installed capacity of the ESS | |

| 3 | Power from the PV to the load at time t | |

| 4 | Power from the PV to the ESS at time t | |

| 5 | Power from the MG to the ESS at time t | |

| 6 | Power from the MG to the ESS at time t | |

| 7 | Power from the ESS to the load at time t | |

| 8 | Load power consumption at time t | |

| 9 | Photovoltaic generation power at time t | |

| 10 | ESS charging/discharging power at time t | |

| 11 | Maximum power limit of the ESS | |

| 12 | Grid-supplied power at time t |

| Equipment Name | Optimization Scope | Construction Cost | Tenure (Years) |

|---|---|---|---|

| PV | 20 | ||

| ESS | 10 | ||

| CONV | 10 |

| Parameter | TLCOA | GA | DDA |

|---|---|---|---|

| ) | 998 | 1000 | 1099 |

| ) | 1376 | 1444 | 921 |

| Method | TLCOA | GA | DDA |

|---|---|---|---|

| Investment Cost (103 CNY) | 2199.57 | 2255.68 | 1946.00 |

| Annual Operational Cost (CNY) | 309.09 | 312.23 | 334.33 |

| Annual Maintenance Cost (CNY) | 2474.93 | 2544.6 | 2130.22 |

| Payback Period (Years) | 3.22 | 3.31 | 2.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Cui, S.; Dong, Q. A Two-Layer Cooperative Optimization Approach for Coordinated Photovoltaic-Energy Storage System Sizing and Factory Energy Dispatch Under Industrial Load Profiles. Sustainability 2025, 17, 2713. https://doi.org/10.3390/su17062713

Wang X, Cui S, Dong Q. A Two-Layer Cooperative Optimization Approach for Coordinated Photovoltaic-Energy Storage System Sizing and Factory Energy Dispatch Under Industrial Load Profiles. Sustainability. 2025; 17(6):2713. https://doi.org/10.3390/su17062713

Chicago/Turabian StyleWang, Xiaohui, Shijie Cui, and Qingwei Dong. 2025. "A Two-Layer Cooperative Optimization Approach for Coordinated Photovoltaic-Energy Storage System Sizing and Factory Energy Dispatch Under Industrial Load Profiles" Sustainability 17, no. 6: 2713. https://doi.org/10.3390/su17062713

APA StyleWang, X., Cui, S., & Dong, Q. (2025). A Two-Layer Cooperative Optimization Approach for Coordinated Photovoltaic-Energy Storage System Sizing and Factory Energy Dispatch Under Industrial Load Profiles. Sustainability, 17(6), 2713. https://doi.org/10.3390/su17062713