Abstract

Marine microplastic pollution has emerged as a pressing environmental issue, with significant implications for aquatic ecosystems, human health and global biodiversity. Ports, acting as semi-enclosed environments, are critical zones where plastic waste, including microplastics, plastic fragments smaller than 5 mm, tend to accumulate. These settings provide controlled conditions that are ideal for deploying innovative solutions to monitor and mitigate the impact of microplastic pollution. This paper presents the design, development and initial testing of an autonomous surface drone engineered specifically to monitor and collect microplastics in port environments. Unlike traditional marine drones, this device operates exclusively at the water surface, leveraging mechanical filtration systems to capture and quantify microplastic fragments. Designed for cost-efficiency, ease of manufacturing and operational simplicity, this drone aligns with principles of environmental sustainability and scalability. By integrating readily available materials and modular components, it offers a replicable model for addressing microplastic pollution in localized aquatic systems.

1. Introduction

Marine environments are increasingly burdened by the proliferation of microplastics, a form of pollution that poses multifaceted risks to organisms and ecosystems [1,2]. Microplastics pose a growing environmental threat with widespread impacts on aquatic and terrestrial ecosystems. Recent studies highlight their presence even in the most remote and theoretically pristine areas of the planet, such as Antarctica, where they are transported through marine and atmospheric currents [3,4,5]. These particles, resulting from the fragmentation of larger plastic waste or industrial consumer products, have been detected in water, sediments and marine organisms, including Antarctic krill, a key species in the polar food chain [6]. Their spread poses serious risks to biodiversity and ecosystem stability, as well as to human health. However, understanding of their impact, especially on the smallest particles, is still limited. Therefore, the need to monitor the concentration, distribution and characteristics of these particles is increasingly evident [7,8,9,10].

These plastic particles, often originating from degraded waste or industrial byproducts, infiltrate aquatic food chains and disrupt natural processes [11]. While open oceans receive significant attention, ports represent a unique and underexplored context for studying and mitigating microplastic pollution [12]. As semi-enclosed systems, ports serve as accumulation zones where hydrodynamic conditions concentrate debris, making them ideal testbeds for targeted intervention strategies [13,14,15]. Existing microplastic remediation methods are often complex, expensive and unable to adapt to dynamic aquatic environments [4,5,6,7]. Autonomous technologies, particularly surface drones, offer promising avenues to address these challenges [16,17,18].

The use of drones for environmental monitoring is emerging as an innovative solution to address the challenges of microplastic pollution in marine environments. Currently, the detection of microplastics in the sea is a complex and costly process, requiring sampling with specialist networks such as the Manta net and lengthy laboratory analyses to obtain reliable results. Existing technologies do not allow for fast and efficient measurements, and conventional multiparameter sensors are ineffective in determining the presence of microplastics in water. However, recent studies suggest that the evolution of hardware and software tools for holographic imaging and their subsequent processing represents a promising method for real-time detection of microplastics at sea, applications already tested in contexts such as the Adriatic Sea. At the same time, new methodologies for collecting and analyzing microplastics are being developed through the use of marine drones. A recent study has adapted an aquatic drone, the Jellyfishbot®, for microplastic sampling, comparing it with the traditional Manta net. The results showed that the drone provides comparable data in terms of abundance, shape and color of collected particles, with a higher degree of reproducibility and a better ability to sample smaller, lighter microplastics [19,20,21].

However, the existing solutions frequently emphasize high-tech configurations that may not align with the accessibility and scalability required for widespread adoption. To bridge this gap, this study introduces a novel autonomous surface drone designed with a deliberate focus on simplicity, modularity and environmental responsibility. This research extends beyond traditional engineering paradigms by incorporating principles of circular economy and sustainable design [22,23,24,25]. It addresses key practical considerations such as material selection, structural stability and ease of deployment while ensuring compatibility with variable operational conditions typical of port environments. Through rigorous testing in controlled and real-world settings, the drone demonstrates the feasibility of combining environmental monitoring with actionable waste collection in a single, integrated platform. This paper explores the interdisciplinary challenges and solutions inherent in designing such a system, offering insights into its potential applications and scalability for broader environmental impact.

1.1. TRIZ Methodology

A pivotal aspect of the project’s success lies in the application of the Theory of Inventive Problem Solving (TRIZ) methodology, which played a critical role in driving innovation throughout the design process [26]. TRIZ is a systematic approach to innovation that originates from the analysis of thousands of patents to uncover universal principles of problem-solving. Developed by the Soviet engineer Genrich Altshuller, this methodology provides a structured framework for addressing engineering challenges by identifying and resolving contradictions, i.e., situations where improving one aspect of a system leads to a compromise in another [26,27,28]. Unlike trial-and-error approaches, TRIZ offers tools and strategies to systematically generate innovative solutions [29]. The advantages lie in its ability to guide the creative process while reducing reliance on intuition alone [30,31,32]. By offering a toolkit that includes the 40 inventive principles, the contradiction matrix, and the ideal final result (IFR) concept, the use of this framework helps designers reframe problems and explore unconventional solutions. This method fosters efficiency in problem-solving by highlighting potential breakthroughs that align with overarching project goals [10,11,12,13,14,15,16]. In the context of this work, this approach enabled the team to reconcile conflicting requirements, such as maximizing buoyancy while minimizing material use, or achieving structural rigidity without compromising modularity. Its application ensured that innovation was both systematic and aligned with the sustainable and operational priorities of the project.

In this work, we adopted this systematic approach to identifying and resolving engineering contradictions, enabling the team to balance competing requirements such as structural simplicity and operational robustness. By applying innovative problem-solving principles, the design process explored creative solutions that minimized material usage while enhancing functionality. This structured methodology not only streamlined decision-making but also led to an efficient and sustainable drone configuration, specifically tailored to address the challenges of microplastic remediation in port environments.

1.2. Objectives and Design Philosophy

The design process adhered to several core objectives:

- Affordability and Accessibility: The drone was engineered using low-cost, easily sourced materials and components to ensure broad accessibility and reproducibility.

- Stability and Resilience: A stable configuration was prioritized to handle variable conditions within ports, such as sudden changes in currents or wave motion caused by moving vessels.

- Modular and Sustainable Design: The system employs principles of design for assembly/disassembly and additive manufacturing, emphasizing recyclability and minimal environmental impact.

- Quantifiable Outcomes: Equipped with calibrated filtration systems, the drone facilitates precise measurement of microplastic concentrations, aiding in the assessment of port water quality.

By rejecting complex geometries and intricate setups, the drone achieves a broad operational window, making it suitable for diverse conditions in semi-enclosed aquatic environments.

1.3. Context: The MARLESS Project

This research aligns with the objectives of the European MARLESS project, which seeks to address marine litter through integrated strategies of monitoring, management, prevention and removal. MARLESS emphasizes circular economic principles, aiming to convert plastic waste into valuable resources. Within this framework, the drone serves as a practical and innovative tool for microplastic mitigation, bridging the gap between experimental technology and actionable environmental interventions [33].

1.4. Key Features and Innovations

The drone is designed for simplicity and functionality, utilizing a stable catamaran configuration suited for semi-enclosed port environments. The hulls, made from durable PVC pipes, are sealed with 3D-printed hydrodynamic caps—hemispherical at the front to reduce drag and flat at the rear for ease of assembly. This design provides ample buoyancy, accommodating payload variations from plastic accumulation.

The frame consists of lightweight aluminum extrusions, selected for their strength-to-weight ratio, recyclability and modular adaptability. PLA 3D-printed joints enable rapid prototyping and customization, while tensioned steel cables enhance structural rigidity. This balance of flexibility and durability supports diverse operational needs.

The filtration system employs a cascading filter assembly: a coarse metal mesh for large debris, followed by finer conical and cup filters to isolate microplastics. This modular system ensures quick maintenance and adaptability.

Electronics are housed in a transparent, waterproof PVC tube, allowing visual inspection of system indicators. The system includes an Arduino microcontroller, dual-motor control and connectivity for remote and autonomous operation. Two 10,000 mAh batteries are integrated within the hulls, optimizing weight distribution and enhancing stability.

1.5. Operational Capabilities and Potential Applications

The drone is equipped to operate autonomously or via remote control, providing flexibility in deployment. For remote operations, it relies on a joystick interface linked to a laptop, while autonomous functionality is enabled through pre-loaded navigation paths. This dual-mode capability ensures the drone can adapt to various operational requirements, from systematic surveying to focused interventions in areas of high microplastic concentration. The propulsion system, driven by two rear-mounted motors, is designed to balance efficiency with power, enabling the drone to maintain consistent performance even against moderate currents or wave action within port environments.

Extensive testing in diverse water conditions, including open sea trials, confirmed the drone’s ability to maintain stability and operational integrity. Even in challenging scenarios, such as strong crosscurrents or significant wave activity, the design’s low center of gravity and rigid frame ensured reliable performance. The inclusion of modular batteries also allows for extended missions through rapid battery swaps, enhancing the system’s versatility for continuous operations.

While the current implementation prioritizes microplastic monitoring and collection, the modular design positions the drone as a flexible platform for future innovations. Advanced sensors, such as LiDAR for collision avoidance or enhanced filtration technologies, could be integrated to broaden its scope of applications. These capabilities align the drone with the growing demand for adaptive tools in environmental monitoring and remediation efforts.

1.6. Broader Implications and Contribution to Marine Litter Mitigation

The development of this drone contributes to addressing one of the most critical aspects of marine litter: microplastic pollution. Its specific focus on port environments fills a crucial niche, as these areas often serve as hubs for plastic debris accumulation. The ability to quantify microplastic concentrations in real time offers valuable insights for environmental management, enabling stakeholders to measure the effectiveness of mitigation strategies and refine their approaches accordingly.

From a broader perspective, the drone represents a tangible step toward integrating technology with sustainability. Its reliance on recyclable materials and modular construction underscores the potential for environmentally responsible engineering. By adopting readily available and low-cost components, the project also demonstrates how cutting-edge solutions can be democratized, ensuring accessibility for a wide range of users, including smaller municipalities and research institutions.

Furthermore, the drone’s alignment with the MARLESS project highlights its role within a larger framework of initiatives aimed at combating marine litter. By bridging monitoring and removal activities with a focus on circular economy principles, the drone offers a scalable model for addressing plastic pollution holistically. This alignment not only enhances the impact of the MARLESS project but also serves as a blueprint for similar efforts worldwide.

In summary, this study provides a detailed exploration of the design, testing and potential applications of an autonomous surface drone for microplastic remediation. It addresses key challenges in marine pollution management, offering an innovative and scalable solution that balances environmental responsibility with operational practicality. As marine litter continues to pose a global threat, such innovations are critical to fostering sustainable interactions between technology and ecosystems.

2. Materials and Methods

2.1. Project Goals and Design Constraints

As established in the preceding chapters, the drone’s design was guided by principles of simplicity, modularity and eco-compatibility, adhering to the philosophies of design for assembly/disassembly and design for additive manufacturing. The primary objective was to develop a replicable product utilizing readily available materials and accessible industrial processes while minimizing environmental impact through the use of recyclable and biodegradable components.

To optimize the drone’s design and address key technical and operational challenges identified during development, a methodological framework based on TRIZ and the OTSM (General Theory of Powerful Thinking) approach was employed. This framework enabled the systematic and creative resolution of physical and technical contradictions, which will be detailed in the following sections, avoiding suboptimal compromises.

2.2. Design Approach and Contradiction Analysis

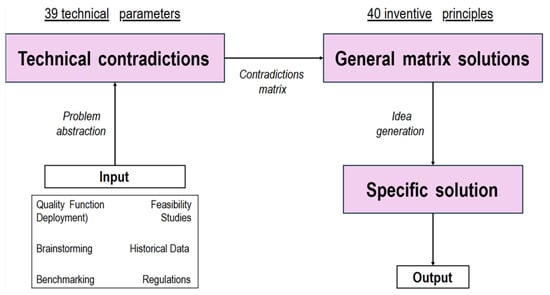

The TRIZ methodology addresses critical physical and technical contradictions emerging during the design process through the application of the OTSM approach. According to the OTSM framework, a physical contradiction inherently gives rise to at least two relevant technical contradictions. This principle is central to Altshuller’s “Hill Model”, which serves as the theoretical foundation of TRIZ and it is represented in Figure 1. This model is built upon a rich database of inventive solutions that can be broadly applied across a wide range of engineering and design challenges.

Figure 1.

Triz method—scheme of Altshuller’s “Hill Model”.

This approach represents how the method is applied to a given problem. After identifying the inputs, features that are intended to be implemented or enhanced in the product, based on methodologies widely discussed in the literature, a decision is made regarding which aspects to improve [34,35,36]. However, at this stage, contradictions may arise when attempting to optimize all parameters simultaneously without adopting compromise solutions. To address this, the process follows the method outlined in the schematic, beginning with problem abstraction, formulating a general question while temporarily disregarding the specific case. The Altshuller matrix is then employed, as explained later, to identify a generalized solution to the defined problem. Once a general solution is found, it must be assessed for applicability to the specific case [37,38].

In this work, we focused on resolving engineering contradictions to achieve an optimal balance between structural simplicity and operational robustness. By adopting a structured problem-solving approach, we systematically analyzed design challenges and identified innovative solutions that minimized material consumption without compromising performance. This method allowed for a more efficient exploration of alternatives, leading to a drone configuration that enhances functionality while remaining lightweight and durable. The resulting design not only improves overall efficiency but also ensures the drone’s effectiveness in addressing the specific challenges of microplastic remediation in port environments.

2.3. Investigation of Contradictions in the Design Process

A physical contradiction occurs when optimizing one product parameter, such as weight, speed or battery capacity, negatively impacts others. For instance, increasing battery size in an electric vehicle enhances range but also adds weight, which in turn reduces speed and acceleration. These conflicting requirements create technical contradictions that need to be addressed early in the design phase to achieve an optimal balance between competing factors.

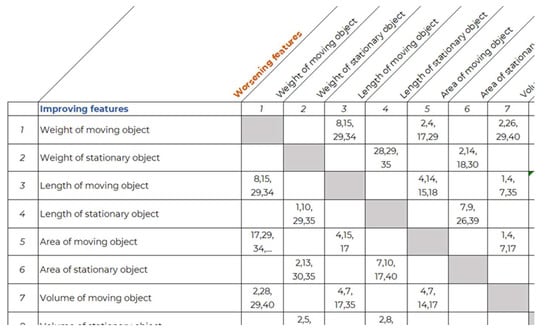

In the TRIZ methodology, technical contradictions are resolved by identifying the key product parameters that exhibit conflicting behaviors. For instance, parameters like weight, speed, capacity and temperature may be subject to trade-offs during the design process. These parameters are represented in the “contradiction matrix”, where the rows correspond to improving features and the columns to deteriorating ones. By finding the intersection of the relevant parameters, a series of numbers corresponding to Altshuller’s 40 inventive principles is generated, offering systematic solutions to the identified contradictions.

Figure 2 presents an extract from the Altshuller contradiction matrix, while Figure 3 shows a diagram illustrating the key design choices for the drone, made through the application of TRIZ principles.

Figure 2.

Extract from Altshuller’s matrix.

Figure 3.

Scheme of application of TRIZ on some of the design contradictions.

The application of TRIZ in the design process involved critical decisions regarding the drone’s configuration, such as the selection between monohull and multi-hull designs, the material choice for the hull support structure (aluminum versus composite) and the determination of the optimal placement and quantity of batteries and electric motors. Each of these decisions had a direct impact on various design parameters and the search for the most efficient configuration is explored in the following section.

2.3.1. Geometric and Structural Design

The number of hulls significantly influences drone configuration. The design could involve a single hull for simplicity or multiple hulls for enhanced stability. Typically, adopting a dual-hull structure delivers superior stability but introduces extra weight.

The drone’s stability was evaluated using Siemens NX, where the mass distribution of all components was precisely calculated to optimize the center of gravity and buoyancy; this analysis is reported in Section 3 after illustrating all the components chosen for the drone. The catamaran configuration was selected to enhance stability, reducing roll and pitch under operational conditions. Key design parameters, including hull dimensions and weight placement, were systematically analyzed to ensure balanced flotation and controlled hydrodynamics. While this study focuses on the drone’s overall development and application, a detailed computational analysis of its stability is available in a separate investigation.

From the analysis of contradictions related to this topic, four inventive principles emerged: pulling away, fast crossing, changing parameters and inert atmosphere (Figure 3). Not all principles demonstrate the same level of relevance: inert atmosphere and fast crossing were deemed unsuitable by the authors for the specific application; on the other hand, the principles of pulling away and changing parameters offer potential avenues for exploration in the drone’s design. This outcome highlights the generalized nature of the conceptual process described here, which retains its abstraction until later stages.

A similar approach was applied to the drone’s frame. The use of bolts instead of welds facilitates faster part replacement in case of damage, aligning with the principle of segmentation. Moreover, this choice is feasible given that the drone is designed for operation in controlled environments, such as ports, rather than chaotic or open sea conditions. Prefabricated aluminum extrusions were selected for the frame, which simplifies assembly and eliminates the need for welding. The detachable frame design also provides flexibility during development, particularly when the final architecture (motor positioning, wiring layout and joint connections) has not been fully finalized. This modular approach simplifies assembly and allows for iterative improvements based on operational testing.

2.3.2. Power Systems and Energy Management

Regarding the drone’s power system, the first component analyzed was the battery pack. While increasing the number of batteries improves operational autonomy, it also leads to a significant increase in weight. Two primary charging strategies were considered: one involving onboard charging and the other using dedicated charging stations along the drone’s route. The concept of battery swapping proved to be the most efficient solution and was incorporated into the final design. To resolve the trade-off between the drone’s battery capacity (mAh) and overall weight, design decisions were guided by principles derived from Altshuller’s contradiction matrix, specifically pulling away, exact opposite, multiple dynamics and self-service. Among these, the principle of “separation” directly inspired the integration of the battery-swapping mechanism into the final system design.

In the finalized design, batteries were placed in a sealed electronics tube above the frame, ensuring protection from water without compromising hull integrity. A rear flap on the tube allows for quick battery replacement, minimizing downtime. Power continuity during swaps was achieved through two parallel circuits: one powers critical systems, including the control module (Pixhawk), GPS and telemetry, while another supports motor operation. This setup ensures uninterrupted functionality, as a low-consumption battery independently powers control and monitoring systems. Additional measures, such as waterproof casings and composite materials, were explored to enhance durability and lightweight construction.

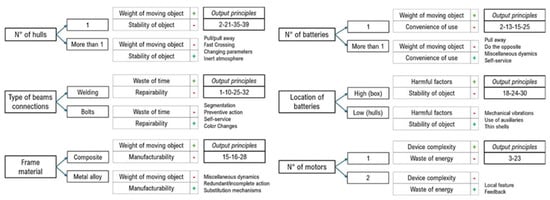

After finalizing the battery architecture, attention shifted to the analysis of the propulsion system. A dual-motor configuration, utilizing Thruster T-200 units (BlueRobotics, St. Torrance, CA, USA), was chosen to replace the traditional rudder mechanism. The system utilizes varying propeller speeds to create steering moments, enhancing maneuverability and simplifying the design. The final drone, shown in Figure 4 and Figure 5, demonstrates both stability and functionality during operational testing.

Figure 4.

Overview of the final drone structure.

Figure 5.

Details of the motors and electronics package.

To address stability challenges, control electronics were implemented using the autopilot module Pixhawk 2.4.8. This system enables trajectory and roll corrections when paired with firmware compatible with marine drones, such as ArduPilot (ArduRover—https://ardupilot.org). The Mission Planner software (version 4.1.0) was employed to configure the drone’s mission parameters, including autonomous navigation modes. The Pixhawk features an integrated IMU (Inertial Measurement Unit) with accelerometers and gyroscopes, essential for accurately monitoring the drone’s orientation and movement. This allowed precise roll and trajectory corrections during operation. Furthermore, the GPS connected to Pixhawk provided reliable location data, supporting the maintenance of stable and accurate flight paths. Finally, telemetry modules enabled control of the drone in manual mode up to a range of 200–250 m from the coast, ensuring sufficient operational coverage while conducting tests and performing mission operations.

2.3.3. Microplastic Collection Module

Several components of the filtration system were fabricated using PLA through 3D printing, allowing for precise customization of the geometries to meet specific design requirements. This approach aligns with examples in the literature that highlight the effectiveness of 3D printing in similar applications [39]. To enhance durability and resistance, the PLA components were coated with resin and multiple layers of protective paint.

We acknowledge the importance of long-term durability testing, especially for 3D-printed components in saline environments. Since the drone was recently developed, we have conducted initial stress tests to ensure structural integrity and functional performance. However, assessing long-term wear requires extended real-world deployment, which we plan to carry out as the project progresses.

To improve durability while maintaining a low-budget approach, we are considering cost-effective material alternatives that offer better resistance to marine conditions. PETG and ASA, for instance, provide increased UV and moisture resistance compared to PLA while remaining affordable and compatible with standard FDM printing. Additionally, coating critical components with epoxy resin or marine-grade sealants could enhance longevity without significantly increasing costs. For structural elements exposed to high stress, replacing standard aluminum with anodized aluminum profiles—readily available at hardware stores—can improve corrosion resistance at minimal extra expense.

These practical solutions align with the project’s low-cost philosophy while offering a feasible path for enhancing the drone’s durability in the near future. As more operational data become available, we will refine material choices to further optimize long-term performance.

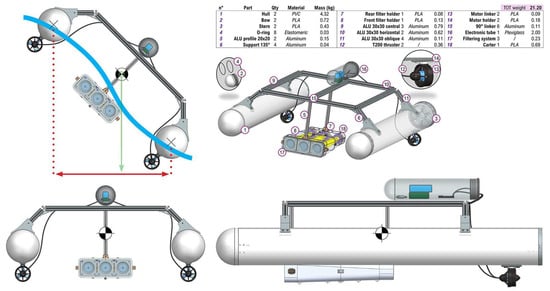

The filtration system employs three parallel filters to ensure continuous functionality. These filters are equipped with nets of varying mesh sizes: 1 mm at the inlet and 0.1 mm at the outlet. This configuration was chosen to capture fragments, including polymer-based particles, within a dimensional range consistent with the technical specifications. The conical design of the filter facilitates the rapid evacuation of processed water, improving operational efficiency. To securely integrate the filter with the drone’s structure, two vertical trabecular elements were incorporated, enabling attachment to the drone’s frame and allowing adjustments to the filter’s immersion depth. A detailed schematic of the filtration system is shown in Figure 6.

Figure 6.

Details of the filtration system—complete assembly (left), half-disassembled view (center) and close-up of the microplastic mesh (right).

3. Results and Validation

To evaluate the effectiveness of the project, the drone underwent a series of tests aimed at identifying potential issues and performing post-design validation. The initial tests focused on verifying whether the structural and buoyancy calculations simulated using CAD software (Siemens NX, version 2007 Series) corresponded to real-world conditions. This stage ensured that any discrepancies could be addressed before proceeding with further testing.

The results of the software analysis are presented in Figure 7. In addition to the bill of materials, which includes specifications regarding material and weight, the figure illustrates how the center of gravity remains within the drone’s structure even at a 45° tilt, an intentionally exaggerated stress condition, far from the typical operating scenario in port environments.

Figure 7.

Visualization of the drone’s center of gravity (CG) position, accompanied by a comprehensive breakdown of all individual components and their respective mass distributions.

Subsequently, the drone was tested at the University of Bologna’s facilities, specifically in a freshwater pool designed to simulate the operational environment. The pool provided a controlled setting, including narrow spaces and artificial obstacles mimicking a port environment, combined with calm water conditions. Additionally, the pool was equipped with an artificial wave generator, allowing the team to evaluate the drone’s performance under varying surface conditions, such as those caused by nearby boat traffic. Following the success of these initial tests, the project advanced to full-scale operational trials.

The test basin used for the drone’s initial evaluation is capable of generating waves up to 0.5 m in height, simulating the conditions typically encountered in small port environments (Figure 8). During testing, the drone demonstrated stability under these conditions, with the catamaran configuration providing sufficient resistance to tipping. The double-hull design was specifically chosen for its ability to handle small to medium waves typically found in sheltered port environments, ensuring operational stability even when exposed to occasional wave action. While the drone is designed to operate in relatively calm conditions, as expected in port environments, testing with higher waves was conducted to assess its behavior under unexpected disturbances, including lateral currents (Figure 9). These evaluations confirmed that the design maintains stability within the expected range of operational conditions.

Figure 8.

The drone enduring a testing phase at a pool facility.

Figure 9.

The drone in a marine environment, testing its maneuverability capabilities against sea tide and waves.

The operational testing phase introduced several significant challenges that were absent in the controlled pool environment. Firstly, the corrosive nature of saltwater posed a potential risk to small components, such as screws and fasteners, highlighting possible weak points in the drone’s structural design. Secondly, unlike the controlled conditions of the pool, the marine environment presented inherent currents and multidimensional wave movements. These factors not only tested the drone’s buoyancy but also its directional control and operational reliability. Remote operation functionality was also evaluated during this phase, with the drone controlled via a computer at a distance.

To ensure safety and flexibility, the trials were conducted near the shore. This allowed for close monitoring of adverse events and exposed the drone to more turbulent and unpredictable water conditions. Additionally, by varying the distance between the drone and the shore, the team was able to dynamically alter water depth and further simulate diverse scenarios. On a particularly windy day, the drone was subjected to a challenging operational environment, testing its buoyancy, movement and maneuverability. These trials yielded valuable data for subsequent refinement.

Overall, the drone performed exceptionally well. No key issues or uncertainties were observed during the operation. One key outcome of this phase was the calibration of motor power, allowing the team to determine the ideal power levels required for real-world scenarios. As anticipated, a significant power reserve proved essential in marine environments, enabling the drone to counteract strong currents and avoid deviations from its planned trajectory—or, in worst-case scenarios, being carried off course entirely.

Outcomes and Future Considerations

The results of these tests were highly satisfactory. The drone demonstrated excellent buoyancy and seaworthiness, exceeding expectations across all operational scenarios, including tight maneuvers in crosscurrents and other challenging conditions that surpassed its intended operational requirements. These outcomes are particularly significant as they validate the drone’s ability to reliably carry out its intended functions, including the effective operation of its filtration system. During testing, the filter, positioned on the underside of the drone, successfully captured debris even in a cleaner test environment that differed significantly from the pollution levels expected in actual operational zones.

The analysis of the extracted samples is beyond the scope of this study, as it will be conducted later within the MARLESS project through periodic assessments in a selected environment. Experts in the field will evaluate the collected samples and determine whether adjustments to the mesh size are necessary, either to refine filtration capabilities further or to allow for larger particles to pass through.

Structurally, the drone exhibited exceptional rigidity while maintaining a favorable strength-to-weight ratio. This rigidity, combined with its deliberately oversized dimensions, contributed to its stability, buoyancy and effective filtration performance during testing. However, these tests also provided valuable insights into areas for improvement. Specifically, the generous dimensions, initially chosen to maximize stability and operational reliability, can be reduced in future iterations to achieve a more compact and lightweight design without compromising performance.

In conclusion, the drone’s success in these trials establishes a solid foundation for its deployment in real-world scenarios and paves the way for further optimization. The lessons learned from these tests will inform future iterations, ensuring a balance between compactness, efficiency and the operational requirements of autonomous microplastic monitoring and remediation.

4. Discussion

The development of the autonomous surface drone presented in this study aligns with the growing need for efficient and scalable solutions to monitor microplastic pollution in marine environments. The design successfully integrates simplicity, modularity and functionality, addressing some of the key limitations associated with traditional sampling methods such as the Manta net [20]. Previous studies on marine drones for pollution monitoring have focused primarily on high-tech, high-cost solutions that may not be accessible for widespread deployment [19,21]. For instance, recent research has demonstrated the use of remotely operated vehicles and aerial drones for monitoring floating and submerged plastic debris. While these approaches provide valuable spatial and temporal data, their cost-efficiency remains an issue, and their applicability is often limited to specific environmental conditions.

The Jellyfishbot® aquatic drone (IADYS—Interactive Autonomous DYnamic Systems, Roquefort-la-Bédoule, France), for example, has been tested as an alternative to traditional microplastic sampling methods, demonstrating comparable efficiency to the Manta net in capturing microplastic particles. However, its reliance on proprietary technology and specific configurations may limit its adaptability for different operational contexts. In contrast, our proposed drone emphasizes open-source, modular construction with accessible materials, making it easier to reproduce and adapt for diverse monitoring scenarios.

One of the primary advantages of our drone lies in its structural stability, achieved through a dual-hull configuration that enhances buoyancy and maneuverability. Unlike conventional single-hull designs, which may struggle in dynamic port environments, the dual-hull approach provides resilience against wave disturbances while maintaining precise control. Although this design choice increased the overall weight, the integration of dual T-200 thrusters ensured efficient propulsion and navigation. The use of prefabricated aluminum extrusions and bolted connections enables easy assembly and disassembly, facilitating maintenance and adaptability for future improvements. This feature is particularly valuable for research applications, where iterative modifications are often required to optimize performance based on evolving project needs. The drone’s stable dual-hull design ensures optimal conditions for the filtration system, allowing the filters to operate efficiently without excessive flexion or structural stress. This stability enhances the consistency and reliability of microplastic collection, even in variable water conditions. Additionally, the modular filtration system enables easy adaptation by allowing researchers to swap or adjust mesh sizes, tailoring the sampling process to different particle dimensions.

A key advantage of the proposed drone is its low production cost, which makes it an accessible and scalable solution for widespread deployment. Unlike many existing marine monitoring technologies, which often rely on specialized materials, high-performance sensors and complex manufacturing processes, our design emphasizes affordability without compromising functionality [40].

For confidentiality reasons, it is not possible to disclose the total cost of the specific project. However, we have provided an overview of the materials used to highlight the economic feasibility of the model (Table 1). In a fully developed project, additional costs must be considered, such as the acquisition of equipment (e.g., 3D printers) and design-related expenses. The use of readily available and affordable materials, such as PVC hulls, 3D-printed components and aluminum extrusions, contributes to keeping production costs low while maintaining the drone’s functionality and durability.

Table 1.

Estimated cost breakdown of the marine drone, based on typical market prices for materials and components. Figures are approximate and subject to variations in supplier pricing and availability.

Despite its strengths, the prototype revealed several areas for potential enhancement. The increased weight associated with the dual-hull design, while beneficial for stability, may impact energy efficiency, particularly for extended missions. Future iterations could explore alternative materials or structural optimizations to reduce weight without compromising performance. Another limitation is the durability of components in saline environments. The use of 3D-printed PLA parts, while cost-effective and environmentally sustainable, demonstrated vulnerabilities under prolonged exposure to seawater.

5. Conclusions

This study demonstrates the feasibility of a low-cost, modular and sustainable autonomous surface drone for microplastic monitoring in port environments. By prioritizing structural stability, adaptability and eco-compatible materials, the design ensures both efficiency and replicability. The integration of a customizable filtration system further enhances its versatility for diverse research applications.

Future developments should focus on optimizing weight, improving material durability and integrating advanced sensing technologies to expand the drone’s functionality. This work highlights the potential of autonomous solutions in environmental monitoring, paving the way for scalable and accessible technologies to combat marine plastic pollution.

Author Contributions

Conceptualization, D.F.; methodology, C.P. and D.F.; validation, G.G.; investigation, C.P.; resources, D.F.; writing—original draft preparation, C.P. and G.G.; writing—review and editing G.G. and C.P.; supervision, D.F.; project administration D.F.; funding acquisition, D.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded in part by the European Regional Development Fund, 2014–2020, 471 Interreg V-A Italy–Croatia CBC Programme Call for proposal 2019 Strategic—MARLESS 472.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to privacy reasons.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Schernewski, G.; Escobar Sánchez, G.; Wandersee, P.; Lange, X.; Haseler, M.; Nassour, A. Marine Macro-Litter (Plastic) Pollution of German and North African Marina and City-Port Sea Floors. Appl. Sci. 2023, 13, 11424. [Google Scholar] [CrossRef]

- Liu, B.; Lu, Y.; Deng, H.; Huang, H.; Wei, N.; Jiang, Y.; Jiang, Y.; Liu, L.; Sun, K.; Zheng, H. Occurrence of microplastics in the seawater and atmosphere of the South China Sea: Pollution patterns and interrelationship. Sci. Total Environ. 2023, 889, 164173. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Liu, W.; Chen, Y.; Liao, K.; Yu, W.; Jin, H. Microplastics in Antarctic krill (Euphausia superba) from Antarctic region. Sci. Total Environ. 2023, 870, 161880. [Google Scholar] [CrossRef]

- Tian, W.; Song, P.; Zhang, H.; Duan, X.; Wei, Y.; Wang, H.; Wang, S. Microplastic materials in the environment: Problem and strategical solutions. Prog. Mater. Sci. 2023, 132, 101035. [Google Scholar] [CrossRef]

- Materić, D.; Kjær, H.A.; Vallelonga, P.; Tison, J.-L.; Röckmann, T.; Holzinger, R. Nanoplastics measurements in Northern and Southern polar ice. Environ. Res. 2022, 208, 112741. [Google Scholar] [CrossRef]

- Xiao, S.; Cui, Y.; Brahney, J.; Mahowald, N.M.; Li, Q. Long-distance atmospheric transport of microplastic fibres influenced by their shapes. Nat. Geosci. 2023, 16, 863–870. [Google Scholar] [CrossRef]

- Bhardwaj, L.K.; Sharma, S.; Jindal, T. Estimation of Physico-Chemical and Heavy Metals in the Lakes of Grovnes & Broknes Peninsula, Larsemann Hill, East Antarctica. Chem. Afr. 2023, 6, 2677–2694. [Google Scholar] [CrossRef]

- Bhardwaj, L.K. Evaluation of Bis (2-ethylhexyl) Phthalate (DEHP) in the PET Bottled Mineral Water of Different Brands and Impact of Heat by GC–MS/MS. Chem. Afr. 2022, 5, 929–942. [Google Scholar] [CrossRef]

- Bhardwaj, L.K. Occurrence of microplastics (MPs) in Antarctica and its impact on the health of organisms. Marit. Technol. Res. 2024, 6, 265418. [Google Scholar] [CrossRef]

- Caruso, G.; Bergami, E.; Singh, N.; Corsi, I. Plastic occurrence, sources, and impacts in Antarctic environment and biota. Water Biol. Secur. 2022, 1, 100034. [Google Scholar] [CrossRef]

- Abessa, D.M.S.; Gonçalves, A.R.N.; de Carvalho, M.U.; Spanghero, N.; Do Nascimento, N.S.S.; Fornari, M.; Perina, F.C.; Cruz, A.C.F. Not all that glitters is gold: Glitter causes acute toxicity to nauplii of Artemia sp. Marit. Technol. Res. 2024, 6, 270722. [Google Scholar] [CrossRef]

- Johnson, G.; Bailey, T.; Hatinoglu, D.; Nwachukwu, O.; Peller, J.; Doudrick, K.; Van Dam, B.; Smith, S.M.; Ross, L.; Apul, O. Land–Sea Connection of Microplastic Fiber Pollution in Frenchman Bay, Maine. Environ. Eng. Sci. 2024, 41, 584–596. [Google Scholar] [CrossRef]

- Belioka, M.P.; Achilias, D.S. Microplastic Pollution and Monitoring in Seawater and Harbor Environments: A Meta-Analysis and Review. Sustainability 2023, 15, 9079. [Google Scholar] [CrossRef]

- Petrelli, V.; Ferraro, A.; Fratino, U.; Mali, M.; Spasiano, D.; Dell’anna, M.M. Microplastic pollution in Italian South Adriatic Harbor Areas. In Proceedings of the 2023 IEEE International Workshop on Metrology for the Sea; Learning to Measure Sea Health Parameters (MetroSea), Portorose, Slovenia, 4–6 October 2023; pp. 269–273. [Google Scholar] [CrossRef]

- Rabari, V.; Rakib, M.R.J.; Patel, H.; Idris, A.M.; Malafaia, G.; Trivedi, J. Microplastic prevalence in epipelagic layer: Evidence from epipelagic inhabiting prawns of north-west Arabian Sea. Mar. Pollut. Bull. 2024, 200, 116137. [Google Scholar] [CrossRef]

- Schernewski, G.; Sánchez, G.E.; Felsing, S.; Rebours, M.G.; Haseler, M.; Hauk, R.; Lange, X.; Piehl, S. Emission, Transport and Retention of Floating Marine Macro-Litter (Plastics): The Role of Baltic Harbor and Sailing Festivals. Sustainability 2024, 16, 1220. [Google Scholar] [CrossRef]

- Gutsa, T.; Trois, C.; de Vries, R.; Mani, T. Wasted shores: Using drones to monitor the spatio-temporal evolution of debris accumulation hotspots on South Africa’s Umgeni River. Sci. Total Environ. 2024, 955, 176791. [Google Scholar] [CrossRef] [PubMed]

- Manzolli, R.P.; Portz, L. Use of Drone Remote Sensing to Identify Increased Marine Macro-Litter Contamination following the Reopening of Salgar Beach (Colombian Caribbean) during Pandemic Restrictions. Sustainability 2024, 16, 5399. [Google Scholar] [CrossRef]

- Calore, D.; Fraticelli, N. State of the Art Offshore In Situ Monitoring of Microplastic. Microplastics 2022, 1, 640–650. [Google Scholar] [CrossRef]

- Pasquier, G.; Doyen, P.; Carlesi, N.; Amara, R. An innovative approach for microplastic sampling in all surface water bodies using an aquatic drone. Heliyon 2022, 8, e11662. [Google Scholar] [CrossRef]

- Escobar-Sánchez, G.; Markfort, G.; Berghald, M.; Ritzenhofen, L.; Schernewski, G. Aerial and underwater drones for marine litter monitoring in shallow coastal waters: Factors influencing item detection and cost-efficiency. Environ. Monit. Assess. 2022, 194, 863. [Google Scholar] [CrossRef]

- Figge, F.; Thorpe, A.S.; Gutberlet, M. Definitions of the circular economy: Circularity matters. Ecol. Econ. 2023, 208, 107823. [Google Scholar] [CrossRef]

- Mihelcic, J.R.; Zimmerman, J.B. Environmental Engineering: Fundamentals, Sustainability, Design, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Frizziero, L.; Donnici, G.; Venditti, G.; Freddi, M. Design of an innovative sanitation system for bike-sharing service. Heliyon 2024, 10, e26595. [Google Scholar] [CrossRef]

- Donnici, G.; Freddi, M.; Liverani, A. RSM applied to lattice patterns for stiffness optimization. Rapid Prototyp. J. 2024, 30, 345–356. [Google Scholar] [CrossRef]

- Ekmekci, I.; Nebati, E.E. TRIZ Methodology and Applications. Procedia Comput. Sci. 2019, 158, 303–315. [Google Scholar] [CrossRef]

- Ilevbare, I.M.; Probert, D.; Phaal, R. A review of TRIZ, and its benefits and challenges in practice. Technovation 2013, 33, 30–37. [Google Scholar] [CrossRef]

- Chang, D.; Li, F.; Xue, J.; Zhang, L. A TRIZ-inspired knowledge-driven approach for user-centric smart product-service system: A case study on intelligent test tube rack design. Adv. Eng. Inform. 2023, 56, 101901. [Google Scholar] [CrossRef]

- Yao, K.-C.; Huang, W.-T.; Xu, J.-R.; Huang, S.-H.; Tsai, C.-T.; Ho, W.-S.; Liao, C.-C. Application of the TRIZ Innovation System Method to Bicycle Handlebars. Machines 2023, 11, 507. [Google Scholar] [CrossRef]

- Rau, H.; Wu, J.J.; Procopio, K.M. Exploring green product design through TRIZ methodology and the use of green features. Comput. Ind. Eng. 2023, 180, 109252. [Google Scholar] [CrossRef]

- Francia, D.; Caligiana, G.; Liverani, A.; Frizziero, L.; Donnici, G. PrinterCAD: A QFD and TRIZ integrated design solution for large size open moulding manufacturing. Int. J. Interact. Des. Manuf. 2018, 12, 81–94. [Google Scholar] [CrossRef]

- Molina, G.J.; Desai, A. Recent developments on integration of QFD, TRIZ and other quality and concept-design techniques: A case-study based review. Int. J. Des. Eng. 2023, 12, 145–169. [Google Scholar] [CrossRef]

- Interreg Italy—Croatia. MARLESS Project. Available online: https://programming14-20.italy-croatia.eu/web/marless (accessed on 9 September 2024).

- Frizziero, L.; Donnici, G.; Caligiana, G.; Liverani, A.; Francia, D. Project of Inventive Ideas Through a TRIZ Study Applied to the Analysis of an Innovative Urban Transport Means. Int. J. Manuf. Mater. Mech. Eng. 2018, 8, 35–62. [Google Scholar] [CrossRef]

- Donnici, G.; Frizziero, L.; Francia, D.; Liverani, A.; Caligiana, G. Innovation design driven by QFD and TRIZ to develop new urban transportation means. Aust. J. Mech. Eng. 2021, 19, 300–316. [Google Scholar] [CrossRef]

- Frizziero, L.; Donnici, G.; Dhaimini, K.; Liverani, A.; Caligiana, G. Advanced Design Applied to an Original Multi-Purpose Ventilator Achievable by Additive Manufacturing. Appl. Sci. 2018, 8, 2635. [Google Scholar] [CrossRef]

- Altshuller, G. 40 Principles: TRIZ Keys to Technical Innovation; Technical Innovation Center, Inc.: Worcester, UK, 2002. [Google Scholar]

- Dave, H.P. TRIZ: 40 principles and their ranking by contradiction matrix. In Proceedings of the 2017 2nd International Conference for Convergence in Technology (I2CT), Mumbai, India, 7–9 April 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1258–1261. [Google Scholar] [CrossRef]

- Ciccone, F.; Bacciaglia, A.; Ceruti, A. Optimization with artificial intelligence in additive manufacturing: A systematic review. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 303. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, K.; Xing, W.; Li, H.; Yang, Z. Applications, Evolutions, and Challenges of Drones in Maritime Transport. J. Mar. Sci. Eng. 2023, 11, 2056. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).