India’s Transition to a Circular Economy Towards Fulfilling Agenda 2030: A Critical Review

Abstract

1. Introduction

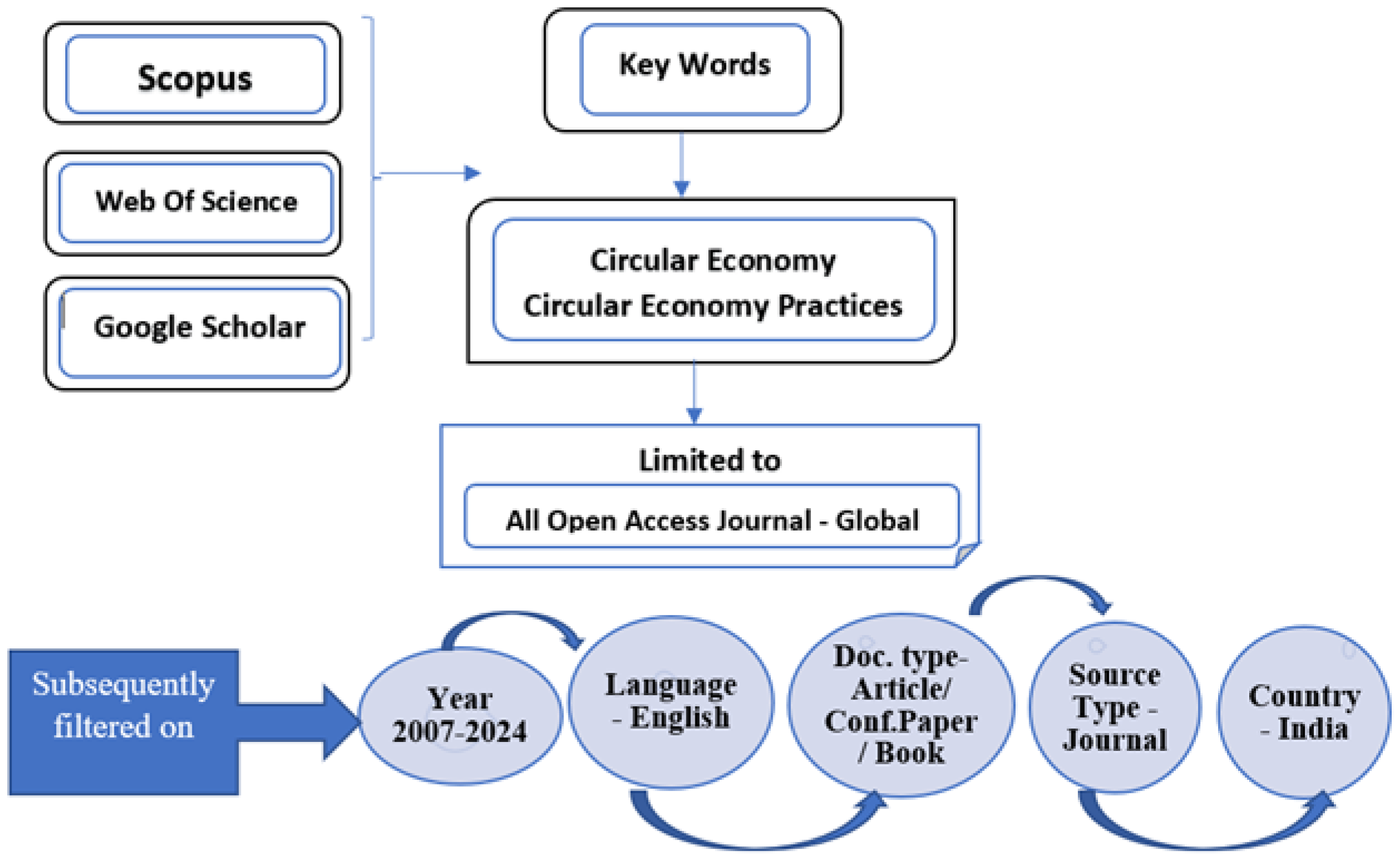

1.1. Objectives, Data and Methods

1.2. Data, Methodology, and Approach

2. Emergence of Circular Economy: A Global Perspective

3. Working of Circular Economy in India: A Sectoral View

3.1. CE and Bio-Energy Sector

3.2. CE Model for Waste Management and Material and Energy Recovery

3.3. CE Through Remanufacturing and Reverse Logistics

3.4. CE Practices as Applied by Industrial Sectors in India

3.5. CE Policies for Energy Efficiency and Sustainable Businesses

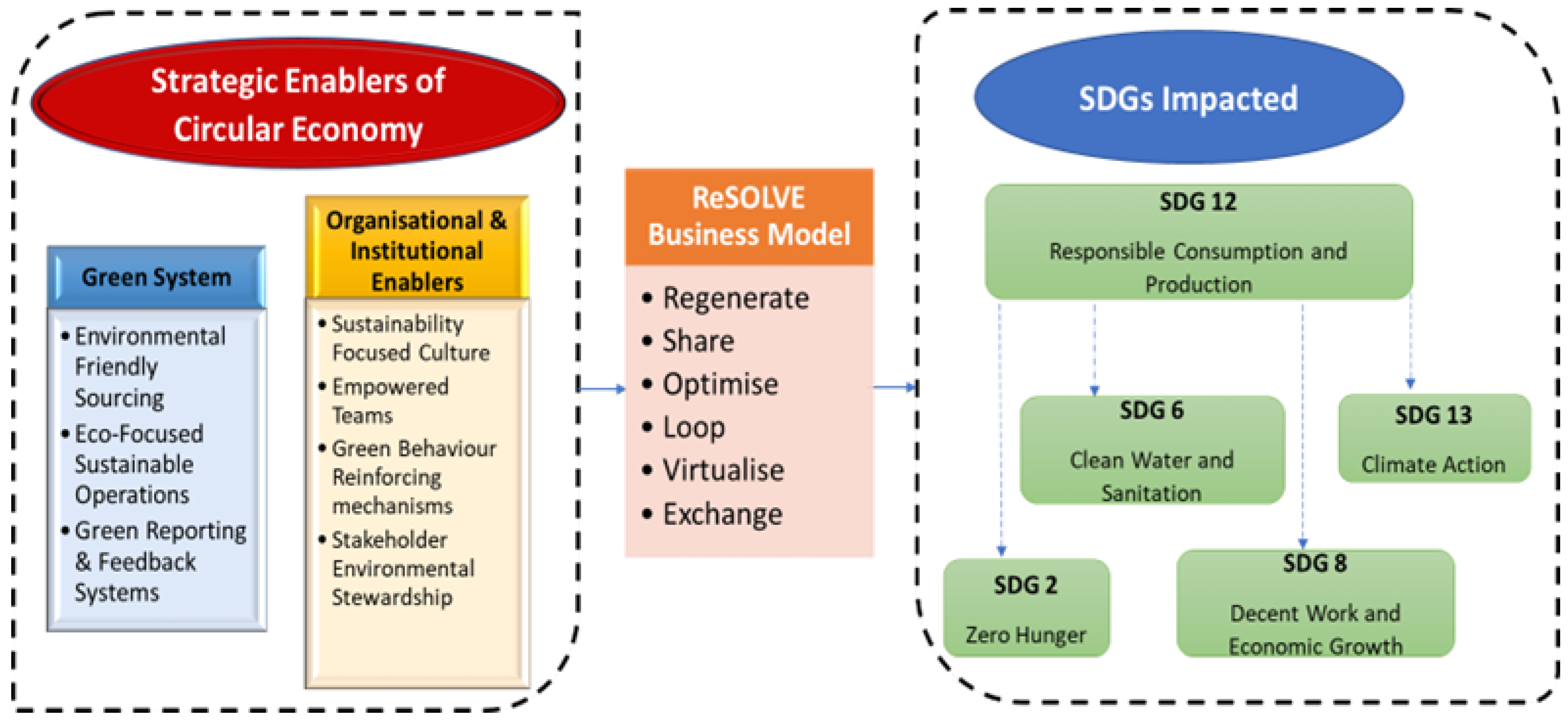

4. Exploring Circular Economy Pathways to Achieve SDGs in India

4.1. Strategic Enablers of Circular Economy: Green Systems

- (a)

- Environmentally Friendly Sourcing: Due to regulatory requirements and stakeholder scrutiny, firms are increasingly pressurised to ensure environmentally friendly supply chains [124]. Therefore, choosing “green” suppliers becomes crucial for firms aiming to establish themselves as sustainable entities. Research has well-documented the positive impact of green suppliers on profitability and sustainability metrics [125,126]. While a considerable body of research has investigated various aspects of supplier selection from a sustainability perspective [57,127,128,129,130], it appears skewed against developing markets. Specifically, we concur with Ghosh et al.’s [124] cognisance of the need for a modus of selecting green suppliers in developing markets and find their suggested multi-criteria decision-making (MCDM) framework appropriate to the context of this paper. Ghosh et al. [124] situated their study in India, and their MCDM framework considered the economic–social–environmental costs and benefits of supplier actions. The geographical context of their study led us to consider their supplier benchmarking modus a suitable starting point for organisations transitioning to CE in the Indian context.

- (b)

- Eco-Focused Sustainable Operations: According to Kleindorfer et al. [130], sustainable operations involve integrating traditional efficiency measures with the environmental impact of a firm’s production operations. Of the three components of sustainable operations identified by [130], logistics decisions impact the aforementioned green supplier selection directly, and production/process decisions impact indirectly. Jabbour et al. [29] recommend the ReSOLVE model for organisations that seek to transition to CE. While they mapped the ReSOLVE model to the Internet of Things (IoT), we opine that this may be inappropriate in the context of developing markets, such as India. Further, we extend their model and posit that an eco-friendly focus is also required to ensure a more seamless fit with green supplier selection. However, we concur that technology and information systems are expected to play a significant role. Particularly in a developing market setting, we posit that achieving sustainable operations requires sharing information among players within the same industry. An association of industry members could maintain, for example, best CE practices, preferred sources of materials, pricing structures, sustainability programs, etc. in a database. These data could be made available to all registered members, which would help to ensure optimal synergising of sustainability operations across different firms.

- (c)

- Green Reporting and Feedback Systems: Martin and Moser [131] reported that disclosing green activities leads to favourable investor reactions. Indeed, they discovered that managers, in response to investor reactions, would rather reveal the absence of any green investment than make no disclosure at all. This, along with the stakeholder and regulatory influences mentioned earlier, could explain the finding by KPMG that sustainability reporting has steadily increased over the years [132]. Therefore, it is suggested that consistent disclosures of measures taken by firms towards achieving CE would enhance the effectiveness of the ReSOLVE model. Martin and Moser’s [131] findings are based on voluntary disclosures in a developed market and therefore may not seem to be easily extendable to an emerging market with mandatory CSR disclosure. However, our position is justifiable because, firstly, compliance with mandatory disclosure requirements does not dilute the favourable disposition of investors. Further, if the mandatory requirements are buttressed with additional (hence, voluntary) information, it could still appeal to investors. Secondly, we posit that, in an increasingly globalised economy, such disclosures could be instrumental in attracting investments abroad.

4.2. Strategic Enablers of Circular Economy: Organisational and Institutional Enablers

- (a)

- Sustainability-Focused Culture: Extant circumstances demand that, to be successful, firms diligently put forth systematic efforts towards fostering an organisational culture that embraces sustainability at all levels [133]. Despite the widespread recognition of sustainability’s importance and relevance, developing markets often lag in its implementation. Altering this would most likely call for cultural change. Following prior literature [134,135], we suggest that demonstrating the significance that sustainability holds for organisations is a top-down (albeit non-linear) exercise. This entails a sustainability-focused culture to be visible from a firm’s mission statement through to its performance management modus. This implies that recruitment, training, appraisal, and retention policies and practices unequivocally spell out the firm’s commitment to sustainability. This is crucial because employee expectations have the potential to shape their attitudes, which could then infiltrate the organisational culture. Galpin et al. [133] suggest that employee engagement in the firm’s sustainability programs could also lead them to replicate this sentiment in their non-official social interactions as well. In that case, it is reasonable to expect that they will demonstrate this in an official milieu, which could have a favourable impact on green supplier selection and also encourage the transition to CE.

- (b)

- Empowered Teams: We suggest that teams empowered to initiate and implement sustainability and CE measures should supplement the integration of sustainability and CE aspirations into the organisational culture. If human resource (HR) policies are driven by the ethos of sustainability, it is reasonable to expect that employees will place trust in their ability to not only continue existing programs, but also take the initiative to institute new measures aligned with sustainability and CE. In the absence of empowered teams, despite the best intentions, an organisation is liable to significantly trail best practices. Corporate history is replete with examples of best-in-class companies falling behind the competition due to an inability to match metamorphosing circumstances. In contrast, companies that have incorporated circular economy principles have thrived. Globally, Patagonia stands out for its commitment to sustainability through initiatives like garment repair services and recycling programs, which have strengthened its market position and customer relationships [135]. India also presents several successful examples of companies and sectors embedding CE, facilitating significant business growth with sustainability. For instance, it is reported that Indian agribusiness companies have embraced circular economy (CE) principles by forming collaborative partnerships, designing products for longevity, minimising waste, promoting recycling, and enhancing resource efficiency. These initiatives are influenced by sociocultural, economic, technological, strategic, organisational, and supply chain factors [136]. Similarly, the Indian rubber industry employs a hybrid methodology integrating the analytic hierarchy process (AHP) with the grey-based ELECTRE technique to identify and address challenges in circular supply chain management (CSCM). This approach has helped the industry to prioritise its strategies to promote CE adoption [137]. It is also important that a transition to CE requires constant examination of the status quo, as well as systems that accommodate multiple paths of communication flows. This implies an agile organisation with an appetite for innovative and adaptive mindsets. Empowered teams form such an organisation and are arguably best-suited to achieve CE with a focus on sustainability.

- (c)

- Green Behaviour-Reinforcing Mechanisms: While this may seem like an extension or even repetition of the previous two cornerstones of organisational and institutional enablers, we intend it to imply a much wider scope. Here, the emphasis is not just on employee behaviour; rather, we envision an organisation that rewards and reinforces green behaviour throughout its value chain. This includes the supply chain. Thus, we support organisations that recognise and, probably, reward stakeholders’ measures towards CE. Once the corporate culture and team dynamics discussed earlier materialise, it is conceivable that inter-organisational collaborations will occur and that there will be spillovers of learning and experience. At this point, we argue that, as long as the long-term viability of the firm is not jeopardised, leadership ought not to be overly constrained by thoughts of porous confidentiality and potential weakening of tactical positioning. Martin and Moser [131] state that the pecuniary cost of investing in sustainability always exceeds the pecuniary benefit, but not necessarily the societal benefit. Considering the umbilical link between sustainability and CE, it is reasonable to extend the ambit of Martin and Moser’s [131] statement to include CE.

- (d)

- Stakeholder Environmental Stewardship: Our conception of environmental stewardship aligns with that of Bennett et al. [138], as they considered the influence of stakeholders on an organisation’s social impact (which we extend to include the impact of sustainability programs). We advocate the use of Bacq and Eddleston’s [139] framework as a template for policy developers and practitioners. The interdisciplinary scope of this framework, which incorporates evidence from studies in environmental stewardship, management, and governance, motivates our choice. Any organisation can likely adapt Bacq and Eddleston’s [139] framework, acknowledging that the context (socio-economic, politico-cultural, and environmental) shapes stakeholders whose motivations and abilities align with the organisation’s sustainability goals. We are aware that small firms may not have the wherewithal to actively employ sustainable operations and hence suggest that larger firms could assist them in transitioning to such operations. These larger firms could include such assistance in their CSR projects. Martin and Moser [131] use CSR disclosures to reach their conclusions, supporting our proposal to classify larger firms’ efforts to help smaller firms transition to CE as CSR.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Crocker, R.; Saint, C.; Chen, G.; Tong, Y. Unmaking Waste in Production and Consumption: Towards the Circular Economy|Emerald Insight. Available online: https://www.emerald.com/insight/publication/doi/10.1108/9781787146198 (accessed on 25 December 2024).

- Koech, M.K.; Munene, K.J. Circular Economy in Kenya. In Circular Economy: Global Perspective; Ghosh, S.K., Ed.; Springer: Singapore, 2020; pp. 223–239. ISBN 978-981-15-1052-6. [Google Scholar]

- Garcia-Saravia Ortiz-de-Montellano, C.; Samani, P.; van der Meer, Y. How can the circular economy support the advancement of the Sustainable Development Goals (SDGs)? A comprehensive analysis. Sustain. Prod. Consum. 2023, 40, 352–362. [Google Scholar] [CrossRef]

- Rabbi, M.F.; Amin, M.B. Circular economy and sustainable practices in the food industry: A comprehensive bibliometric analysis. Clean. Responsible Consum. 2024, 14, 100206. [Google Scholar] [CrossRef]

- Rodriguez-Anton, J.M.; Rubio-Andrada, L.; Celemín-Pedroche, M.S.; Alonso-Almeida, M.D.M. Analysis of the relations between circular economy and sustainable development goals. Int. J. Sustain. Dev. World Ecol. 2019, 26, 708–720. [Google Scholar] [CrossRef]

- Yasmin, T.; Refae, G.A.E.; Eletter, S. Highlighting the Role of UAE’s Government Policies in Transition Towards “Circular Economy”. In Artificial Intelligence and Transforming Digital Marketing; Hamdan, A., Aldhaen, E.S., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 723–735. ISBN 978-3-031-35828-9. [Google Scholar]

- Lindner, P.; Mooij, C.; Rogers, H. Circular Economy in Cities: A Strategic Approach Towards a Sustainable Society? Master’s Thesis, Department of Strategic Sustainable Development, Blekinge Institute of Technology, Karlskrona, Sweden, 2017; 66p. Available online: https://www.diva-portal.org/smash/get/diva2:1108675/FULLTEXT02.pdf (accessed on 16 November 2024).

- Oliveira, M.; Miguel, M.; van Langen, S.K.; Ncube, A.; Zucaro, A.; Fiorentino, G.; Passaro, R.; Santagata, R.; Coleman, N.; Lowe, B.; et al. Circular Economy and the Transition to a Sustainable Society: Integrated Assessment Methods for a New Paradigm. Circ. Econ. Sustain. 2021, 1, 99–113. [Google Scholar] [CrossRef]

- Cahyadi, E.R.; Hidayati, N.; Zahra, N.; Arif, C. Integrating Circular Economy Principles into Agri-Food Supply Chain Management: A Systematic Literature Review. Sustainability 2024, 16, 7165. [Google Scholar] [CrossRef]

- Pacurariu, R.L.; Vatca, S.D.; Lakatos, E.S.; Bacali, L.; Vlad, M. A Critical Review of EU Key Indicators for the Transition to the Circular Economy. Int. J. Environ. Res. Public Health 2021, 18, 8840. [Google Scholar] [CrossRef]

- Cao, Y.; Lu, H.; Zhu, C. Consumer Preference for End-of-Life Scenarios and Recycled Products in Circular Economy. Sustainability 2022, 14, 12129. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- MacArthur, E. Towards the Circular Economy Vol. 2 Opportunities for the Consumer Goods Sector. Ellen MacArthur Foundation, Pre-Printed Online Version—References—Scientific Research Publishing. 2013. Available online: https://www.scirp.org/reference/referencespapers?referenceid=1766959 (accessed on 12 November 2024).

- Towards the Circular Economy Vol 1 an Economic and Business Rationale for an Accelerated Transition.pdf. Available online: https://emf.thirdlight.com/file/24/xTyQj3oxiYNMO1xTFs9xT5LF3C/Towards%20the%20circular%20economy%20Vol%201%3A%20an%20economic%20and%20business%20rationale%20for%20an%20accelerated%20transition.pdf (accessed on 13 November 2024).

- Going Circular: A Future with Zero Waste. Available online: https://www.ikea.com/in/en/this-is-ikea/sustainable-everyday/a-circular-ikea-making-the-things-we-love-last-longer-pub9750dd90/ (accessed on 19 December 2024).

- Circular Economy. Available online: https://www.philips.com/a-w/about/environmental-social-governance/environmental/circular-economy.html (accessed on 19 December 2024).

- Business-Responsibility-and-Sustainability-Report.pdf. Available online: https://www.tatasteel.com/media/21242/business-responsibility-and-sustainability-report.pdf (accessed on 18 December 2024).

- ITC-Sustainability-Integrated-Report-2022.pdf. Available online: https://www.itcportal.com/sustainability/sustainability-integrated-report-2022/ITC-Sustainability-Integrated-Report-2022.pdf (accessed on 18 December 2024).

- JSW. JSW-Energy-Sustainability-Framework-Measuring-Success-Waste. Available online: https://www.jsw.in/groups/jsw-energy-sustainability-framework-measuring-success-waste (accessed on 18 December 2024).

- Circular Economy in Action|Stories|Aditya Birla Group. Available online: https://www.adityabirla.com/en/media/stories/circular-economy-in-action/ (accessed on 18 December 2024).

- Acerbi, F.; Taisch, M. A literature review on circular economy adoption in the manufacturing sector. J. Clean. Prod. 2020, 273, 123086. [Google Scholar] [CrossRef]

- Liu, B.; Chen, D.; Zhou, W.; Nasr, N.; Wang, T.; Hu, S.; Zhu, B. The effect of remanufacturing and direct reuse on resource productivity of China’s automotive production. J. Clean. Prod. 2018, 194, 309–317. [Google Scholar] [CrossRef]

- Sitcharangsie, S.; Ijomah, W.; Wong, T.C. Decision makings in key remanufacturing activities to optimise remanufacturing outcomes: A review. J. Clean. Prod. 2019, 232, 1465–1481. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Rapsikevičienė, J.; Gurauskienė, I.; Jučienė, A. Model of Industrial Textile Waste Management. Environ. Res. Eng. Manag. 2019, 75, 43–55. [Google Scholar] [CrossRef]

- Elkington, J. Enter the Triple Bottom Line. In The Triple Bottom Line; Routledge: London, UK, 2004; ISBN 978-1-84977-334-8. [Google Scholar]

- Wang, P.; Kara, S.; Hauschild, M.Z. Role of manufacturing towards achieving circular economy: The steel case. CIRP Ann. 2018, 67, 21–24. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Chiappetta Jabbour, C.J.; Sarkis, J.; Lopes de Sousa Jabbour, A.B.; Scott Renwick, D.W.; Singh, S.K.; Grebinevych, O.; Kruglianskas, I.; Filho, M.G. Who is in charge? A review and a research agenda on the ‘human side’ of the circular economy. J. Clean. Prod. 2019, 222, 793–801. [Google Scholar] [CrossRef]

- The Contribution of Organizational Learning and Green Human Resource Management Practices to the Circular Economy: A Relational Analysis—Evidence from Manufacturing SMEs (Part II)|Emerald Insight. Available online: https://www.emerald.com/insight/content/doi/10.1108/tlo-06-2022-0068/full/html (accessed on 13 November 2024).

- Subramanian, N.; Gunasekaran, A.; Wu, L.; Shen, T. Role of traditional Chinese philosophies and new product development under circular economy in private manufacturing enterprise performance. Int. J. Prod. Res. 2019, 57, 7219–7234. [Google Scholar] [CrossRef]

- Batista, L.; Gong, Y.; Pereira, S.; Jia, F.; Bittar, A. Circular supply chains in emerging economies—A comparative study of packaging recovery ecosystems in China and Brazil. Int. J. Prod. Res. 2019, 57, 7248–7268. [Google Scholar] [CrossRef]

- Steinmann, Z.J.N.; Huijbregts, M.A.J.; Reijnders, L. How to define the quality of materials in a circular economy? Resour. Conserv. Recycl. 2019, 141, 362–363. [Google Scholar] [CrossRef]

- Conceptualizing a Circular Framework of Supply Chain Resource Sustainability|Emerald Insight. Available online: https://www.emerald.com/insight/content/doi/10.1108/ijopm-02-2016-0078/full/html (accessed on 13 November 2024).

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Scarano, P.; Sciarrillo, R.; Tartaglia, M.; Zuzolo, D.; Guarino, C. Circular economy and secondary raw materials from fruits as sustainable source for recovery and reuse. A review. Trends Food Sci. Technol. 2022, 122, 157–170. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Camacho-Otero, J.; Boks, C.; Pettersen, I.N. Consumption in the Circular Economy: A Literature Review. Sustainability 2018, 10, 2758. [Google Scholar] [CrossRef]

- de Jesus, A.; Antunes, P.; Santos, R.; Mendonça, S. Eco-innovation in the transition to a circular economy: An analytical literature review. J. Clean. Prod. 2018, 172, 2999–3018. [Google Scholar] [CrossRef]

- Yu, Y.; Junjan, V.; Yazan, D.M.; Iacob, M.-E. A systematic literature review on Circular Economy implementation in the construction industry: A policy-making perspective. Resour. Conserv. Recycl. 2022, 183, 106359. [Google Scholar] [CrossRef]

- Kakwani, N.S.; Kalbar, P.P. Review of Circular Economy in urban water sector: Challenges and opportunities in India. J. Environ. Manag. 2020, 271, 111010. [Google Scholar] [CrossRef]

- Sarja, M.; Onkila, T.; Mäkelä, M. A systematic literature review of the transition to the circular economy in business organizations: Obstacles, catalysts and ambivalences. J. Clean. Prod. 2021, 286, 125492. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Chiaroni, D.; Del Vecchio, P.; Urbinati, A. Designing business models in circular economy: A systematic literature review and research agenda. Bus. Strategy Environ. 2020, 29, 1734–1749. [Google Scholar] [CrossRef]

- Kukreja, K.; Sharma, P.; Mohapatra, B.; Saxena, A. Indian Cement Industry: A Key Player in the Circular Economy of India. In Enhancing Future Skills and Entrepreneurship; Sangwan, K.S., Herrmann, C., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 181–192. [Google Scholar]

- Sousa-Zomer, T.T.; Magalhães, L.; Zancul, E.; Cauchick-Miguel, P.A. Exploring the challenges for circular business implementation in manufacturing companies: An empirical investigation of a pay-per-use service provider. Resour. Conserv. Recycl. 2018, 135, 3–13. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Ritala, P.; Mäkinen, S.J. Exploring institutional drivers and barriers of the circular economy: A cross-regional comparison of China, the US, and Europe. Resour. Conserv. Recycl. 2018, 135, 70–82. [Google Scholar] [CrossRef]

- Mendoza, J.M.F.; Sharmina, M.; Gallego-Schmid, A.; Heyes, G.; Azapagic, A. Integrating Backcasting and Eco-Design for the Circular Economy: The BECE Framework. J. Ind. Ecol. 2017, 21, 526–544. [Google Scholar] [CrossRef]

- Stål, H.I.; Corvellec, H. A decoupling perspective on circular business model implementation: Illustrations from Swedish apparel. J. Clean. Prod. 2018, 171, 630–643. [Google Scholar] [CrossRef]

- Singh, M.P.; Chakraborty, A.; Roy, M. Developing an extended theory of planned behavior model to explore circular economy readiness in manufacturing MSMEs, India. Resour. Conserv. Recycl. 2018, 135, 313–322. [Google Scholar] [CrossRef]

- Scheepens, A.E.; Vogtländer, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- Zamfir, A.-M.; Mocanu, C.; Grigorescu, A. Circular Economy and Decision Models among European SMEs. Sustainability 2017, 9, 1507. [Google Scholar] [CrossRef]

- de Abreu, M.C.S.; Ceglia, D. On the implementation of a circular economy: The role of institutional capacity-building through industrial symbiosis. Resour. Conserv. Recycl. 2018, 138, 99–109. [Google Scholar] [CrossRef]

- Pan, S.-Y.; Du, M.A.; Huang, I.-T.; Liu, I.-H.; Chang, E.-E.; Chiang, P.-C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- The Circular Economy and Circular Economic Concepts—A Literature Analysis and Redefinition—Geisendorf—2018—Thunderbird International Business Review—Wiley Online Library. Available online: https://onlinelibrary.wiley.com/doi/10.1002/tie.21924 (accessed on 14 November 2024).

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- ‘Decarbonising’ UK Industry: Towards a Cleaner Economy|Proceedings of the Institution of Civil Engineers—Energy. Available online: https://www.icevirtuallibrary.com/doi/10.1680/jener.18.00007 (accessed on 14 November 2024).

- Khan, M.A.; Mittal, S.; West, S.; Wuest, T. Review on upgradability—A product lifetime extension strategy in the context of product service systems. J. Clean. Prod. 2018, 204, 1154–1168. [Google Scholar] [CrossRef]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Franco, M.A. Circular economy at the micro level: A dynamic view of incumbents’ struggles and challenges in the textile industry. J. Clean. Prod. 2017, 168, 833–845. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Mäkinen, S.J. Creating value in the circular economy: A structured multiple-case analysis of business models. J. Clean. Prod. 2018, 201, 988–1000. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Kumar, A.; Gaur, D.; Liu, Y.; Sharma, D. Sustainable waste electrical and electronic equipment management guide in emerging economies context: A structural model approach. J. Clean. Prod. 2022, 336, 130391. [Google Scholar] [CrossRef]

- Leong, Y.K.; Chew, K.W.; Chen, W.-H.; Chang, J.-S.; Show, P.L. Reuniting the Biogeochemistry of Algae for a Low-Carbon Circular Bioeconomy. Trends Plant Sci. 2021, 26, 729–740. [Google Scholar] [CrossRef]

- Jurgutis, L.; Šlepetienė, A.; Šlepetys, J.; Cesevičienė, J. Towards a Full Circular Economy in Biogas Plants: Sustainable Management of Digestate for Growing Biomass Feedstocks and Use as Biofertilizer. Energies 2021, 14, 4272. [Google Scholar] [CrossRef]

- Luo, F.; Li, X.; Peng, C. Study on the decoupling effect of energy consumption and economic growth in the construction industry of Guangxi (People’s Republic of China) from the perspective of the circular economy. SN Appl. Sci. 2020, 2, 1025. [Google Scholar] [CrossRef]

- Werning, J.P.; Spinler, S. Transition to circular economy on firm level: Barrier identification and prioritization along the value chain. J. Clean. Prod. 2020, 245, 118609. [Google Scholar] [CrossRef]

- Venkata Mohan, S.; Nikhil, G.N.; Chiranjeevi, P.; Nagendranatha Reddy, C.; Rohit, M.V.; Kumar, A.N.; Sarkar, O. Waste biorefinery models towards sustainable circular bioeconomy: Critical review and future perspectives. Bioresour. Technol. 2016, 215, 2–12. [Google Scholar] [CrossRef]

- Savini, F. The circular economy of waste: Recovery, incineration and urban reuse. J. Environ. Plan. Manag. 2021, 64, 2114–2132. [Google Scholar] [CrossRef]

- Hsu, W.-T.; Domenech, T.; McDowall, W. How circular are plastics in the EU?: MFA of plastics in the EU and pathways to circularity. Clean. Environ. Syst. 2021, 2, 100004. [Google Scholar] [CrossRef]

- Mohammadi, E.; Singh, S.; Habib, K. How big is circular economy potential on Caribbean islands considering e-waste? J. Clean. Prod. 2021, 317, 128457. [Google Scholar] [CrossRef]

- Guerra-Rodríguez, S.; Oulego, P.; Rodríguez, E.; Singh, D.N.; Rodríguez-Chueca, J. Towards the Implementation of Circular Economy in the Wastewater Sector: Challenges and Opportunities. Water 2020, 12, 1431. [Google Scholar] [CrossRef]

- Nurdiana, J.; Franco-Garcia, M.L.; Heldeweg, M.A. How Shall We Start? The Importance of General Indices for Circular Cities in Indonesia. Sustainability 2021, 13, 11168. [Google Scholar] [CrossRef]

- Mutz, D.; Roy, M.; Paillé, P. Circular Economy and Informal Waste Management in India—A Contradiction? In Resource Politics 2015. 2015. Available online: https://resourcepolitics2015.wordpress.com/wp-content/uploads/2015/09/mutz.pdf (accessed on 14 November 2024).

- Conlon, K. Emerging Transformations in Material Use and Waste Practices in the Global South: Plastic-Free and Zero Waste in India. Urban Sci. 2023, 7, 47. [Google Scholar] [CrossRef]

- Alka, T.A.; Raman, R.; Suresh, M. Research trends in innovation ecosystem and circular economy. Discov. Sustain. 2024, 5, 323. [Google Scholar] [CrossRef]

- Singh, R. Solid Waste Management: Why Integrating Informal Sector Is a Must. Available online: https://www.downtoearth.org.in/waste/solid-waste-management-why-integrating-informal-sector-is-a-must-83841 (accessed on 17 November 2024).

- Sengupta, D.; Ilankoon, I.M.S.K.; Dean Kang, K.; Nan Chong, M. Circular economy and household e-waste management in India: Integration of formal and informal sectors. Miner. Eng. 2022, 184, 107661. [Google Scholar] [CrossRef]

- Gautam, A.; Shankar, R.; Vrat, P. Managing end-of-life solar photovoltaic e-waste in India: A circular economy approach. J. Bus. Res. 2022, 142, 287–300. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; Chowdhury, S.; Saha, K.; Budhwar, P.; De, D. Adoption of circular economy practices in small and medium-sized enterprises: Evidence from Europe. Int. J. Prod. Econ. 2022, 248, 108496. [Google Scholar] [CrossRef]

- Möllemann, D. Framing the Climate Change Policies and Circular Economy Tenets for SMEs. 2016. Available online: https://www.semanticscholar.org/paper/Framing-the-climate-change-policies-and-circular-M%C3%B6llemann/8c825da2a7b89bb28fc9f351115351e6ae5b329e (accessed on 15 November 2024).

- The Circular Economy: Barriers and Opportunities for SMEs—CEPS. Available online: https://www.ceps.eu/ceps-publications/circular-economy-barriers-and-opportunities-smes/ (accessed on 15 November 2024).

- tata-steel-ir-2021-22.pdf. Available online: https://www.tatasteel.com/media/15928/tata-steel-ir-2021-22.pdf (accessed on 6 January 2025).

- Narayana, A.; Verma, U.; Vijayvargy, L.; Kumar, R. Network Building Capabilities for a Sustainable and Circular Economy. Int. J. Math. Eng. Manag. Sci. 2024, 9, 305–322. [Google Scholar] [CrossRef]

- Pereira, V.; Nandakumar, M.K.; Sahasranamam, S.; Bamel, U.; Malik, A.; Temouri, Y. An exploratory study into emerging market SMEs’ involvement in the circular Economy: Evidence from India’s indigenous Ayurveda industry. J. Bus. Res. 2022, 142, 188–199. [Google Scholar] [CrossRef]

- Sohal, A.; Nand, A.A.; Goyal, P.; Bhattacharya, A. Developing a circular economy: An examination of SME’s role in India. J. Bus. Res. 2022, 142, 435–447. [Google Scholar] [CrossRef]

- Venugopal, P.; Kour, H. Integrating the circular economy into engineering programs in India: A study of students’ familiarity with the concept. Ind. High. Educ. 2021, 35, 264–269. [Google Scholar] [CrossRef]

- Bist, N.; Sircar, A.; Yadav, K. Holistic review of hybrid renewable energy in circular economy for valorization and management. Environ. Technol. Innov. 2020, 20, 101054. [Google Scholar] [CrossRef]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Sengupta, S.; Gupta, A.; Kumar, S.S.; Vijay, V.; Kumar, V.; Kumar Vijay, V.; Pant, D. Valorization of agricultural waste for biogas based circular economy in India: A research outlook. Bioresour. Technol. 2020, 304, 123036. [Google Scholar] [CrossRef]

- Mandpe, A.; Paliya, S.; Gedam, V.V.; Patel, S.; Tyagi, L.; Kumar, S. Circular economy approach for sustainable solid waste management: A developing economy perspective. Waste Manag. Res. 2023, 41, 499–511. [Google Scholar] [CrossRef]

- Rathi, R.; Sabale, D.B.; Antony, J.; Kaswan, M.S.; Jayaraman, R. An Analysis of Circular Economy Deployment in Developing Nations’ Manufacturing Sector: A Systematic State-of-the-Art Review. Sustainability 2022, 14, 11354. [Google Scholar] [CrossRef]

- Sahu, A.; Agrawal, S.; Kumar, G. Integrating Industry 4.0 and circular economy: A review. J. Enterp. Inf. Manag. 2022, 35, 885–917. [Google Scholar] [CrossRef]

- Sharma, N.; Kalbar, P.P.; Salman, M. Global review of circular economy and life cycle thinking in building Demolition Waste Management: A way ahead for India. Build. Environ. 2022, 222, 109413. [Google Scholar] [CrossRef]

- Subbarao, P.M.V.; D’ Silva, T.C.; Adlak, K.; Kumar, S.; Chandra, R.; Vijay, V.K. Anaerobic digestion as a sustainable technology for efficiently utilizing biomass in the context of carbon neutrality and circular economy. Environ. Res. 2023, 234, 116286. [Google Scholar] [CrossRef]

- Chaudhary, V.P.; Chandra, R.; Denis, D.M.; D’Silva, T.C.; Isha, A. Agri-biomass-based bio-energy supply model: An inclusive sustainable and circular economy approach for a self-resilient rural India. Biofuels Bioprod. Biorefining 2022, 16, 1284–1296. [Google Scholar] [CrossRef]

- Tayal, S.; Das, S. Economic viability of marketing bio-methane: A case study in India to promote circular economy. Clean Technol. Environ. Policy 2023, 25, 507–518. [Google Scholar] [CrossRef]

- Härri, A.; Levänen, J.; Koistinen, K. Marginalized Small-Scale Farmers as Actors in Just Circular-Economy Transitions: Exploring Opportunities to Circulate Crop Residue as Raw Material in India. Sustainability 2020, 12, 10355. [Google Scholar] [CrossRef]

- Bakshi, P.; Pappu, A.; Gupta, M.K. A review on calcium-rich industrial wastes: A sustainable source of raw materials in India for civil infrastructure—Opportunities and challenges to bond circular economy. J. Mater. Cycles Waste Manag. 2022, 24, 49–62. [Google Scholar] [CrossRef]

- Debnath, B.; Das, A.; Das, A. Chapter 29—Towards circular economy in e-waste management in India: Issues, challenges, and solutions. In Circular Economy and Sustainability; Stefanakis, A., Nikolaou, I., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 523–543. ISBN 978-0-12-821664-4. [Google Scholar]

- Dasalukunte Ananda, K.; Sompura Vishwanath, P.; Ramesh, J.; Puradahalli Muthanarasimha, A. Assessment and management of construction and demolition waste in tier 2 cities of Karnataka, India: A case study of Hubli-Dharwad and Davanagere. Environ. Monit. Assess. 2024, 196, 1022. [Google Scholar] [CrossRef]

- Narang, S.; Vij, D. The COVID-19 Pandemic: An analytical study on opportunities for circular economy practices in India’s healthcare sector. Asia Pac. J. Health Manag. 2021, 16, 236–242. [Google Scholar] [CrossRef]

- Hossain, R.; Islam, M.T.; Shanker, R.; Khan, D.; Locock, K.E.S.; Ghose, A.; Schandl, H.; Dhodapkar, R.; Sahajwalla, V. Plastic Waste Management in India: Challenges, Opportunities, and Roadmap for Circular Economy. Sustainability 2022, 14, 4425. [Google Scholar] [CrossRef]

- Kamble, C.B.; Raju, R.; Vishnu, R.; Rajkanth, R.; Pariatamby, A. A circular economy model for waste management in India. Waste Manag. Res. J. Sustain. Circ. Econ. 2021, 39, 1427–1436. [Google Scholar] [CrossRef]

- Sharma, H.B.; Vanapalli, K.R.; Samal, B.; Cheela, V.R.S.; Dubey, B.K.; Bhattacharya, J. Circular economy approach in solid waste management system to achieve UN-SDGs: Solutions for post-COVID recovery. Sci. Total Environ. 2021, 800, 149605. [Google Scholar] [CrossRef]

- Fiksel, J.; Sanjay, P.; Raman, K. Steps toward a resilient circular economy in India. Clean Technol. Environ. Policy 2021, 23, 203–218. [Google Scholar] [CrossRef]

- Gautam, P.; Behera, C.K.; Sinha, I.; Gicheva, G.; Singh, K.K. High added-value materials recovery using electronic scrap-transforming waste to valuable products. J. Clean. Prod. 2022, 330, 129836. [Google Scholar] [CrossRef]

- Ghosh, S. Circular Economy: Global Perspective; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 978-981-15-1051-9. [Google Scholar]

- Chaudhary, K.; Vrat, P. Circular economy model of gold recovery from cell phones using system dynamics approach: A case study of India. Environ. Dev. Sustain. 2020, 22, 173–200. [Google Scholar] [CrossRef]

- Yaduvanshi, N.; Myana, R.; Krishnamurthy, S. Circular Economy for Sustainable Development in India. Indian J. Sci. Technol. 2016, 9, 1–9. [Google Scholar] [CrossRef]

- Priyadarshini, P.; Abhilash, P. Circular Economy Practices within Energy and Waste Management Sectors of India: A Meta-Analysis. Bioresour. Technol. 2020, 304, 123018. [Google Scholar] [CrossRef]

- Noble, P. Circular economy and inclusion of informal waste pickers. In The Circular Economy and the Global South: Sustainable Lifestyles and Green Industrial Development; Taylor & Francis: Abingdon, UK, 2019; pp. 57–74. ISBN 978-0-429-43400-6. [Google Scholar]

- Goyal, S.; Esposito, M.; Kapoor, A. Circular economy business models in developing economies: Lessons from India on reduce, recycle, and reuse paradigms. Thunderbird Int. Bus. Rev. 2018, 60, 729–740. [Google Scholar] [CrossRef]

- Singhal, D.; Tripathy, S. Acceptance of remanufactured products in the circular economy: An empirical study in India. Manag. Decis. 2019, 57, 953–970. [Google Scholar] [CrossRef]

- Dutta, P.; Talaulikar, S.; Xavier, V.; Kapoor, S. Fostering reverse logistics in India by prominent barrier identification and strategy implementation to promote circular economy. J. Clean. Prod. 2021, 294, 126241. [Google Scholar] [CrossRef]

- Prashar, A. Heavy Lifters, India: Towards a Circular Economy Era. Vis. J. Bus. Perspect. 2021, 28, 097226292110435. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Kandasamy, J.; Gite, V. A framework to assess circularity across product-life cycle stages—A case study. Procedia CIRP 2021, 98, 442–447. [Google Scholar] [CrossRef]

- Gowd, K.; Kumar, D.; Lin, R.; Rajendran, K. Nutrient recovery from wastewater in India: A perspective from mass and energy balance for a sustainable circular economy. Bioresour. Technol. Rep. 2022, 18, 101079. [Google Scholar] [CrossRef]

- Gowd, K.; Ramakrishna, S.; Rajendran, K. Wastewater in India: An untapped and under-tapped resource for nutrient recovery towards attaining a sustainable circular economy. Chemosphere 2021, 291, 132753. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, A.; Pandit, R. Smart Cities in India: Linkages with Circular Economy. In Sustainability in the Built Environment in the 21st Century: Lessons Learned from INDIA and the Region; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; pp. 185–200. ISBN 978-3-030-61890-2. [Google Scholar]

- Goldar, A.; Dasgupta, D. Material Efficiency Approach towards Reducing Emissions: G20 Experiences and Lessons for India—ICRIER. Available online: https://icrier.org/publications/material-efficiency-approach-towards-reducing-emissions-g20-experiences-and-lessons-for-india/ (accessed on 16 November 2024).

- Sawhney, A. Striving towards a circular economy: Climate policy and renewable energy in India. Clean Technol. Environ. Policy 2021, 23, 491–499. [Google Scholar] [CrossRef]

- Ahmed, J.; Islam, Q.; Ahmed, A.; Amin, S. Extending Resource Value-Based Circular Economy Business Model in Emerging Economies: Lessons from India. Bus. Perspect. Res. 2022, 11, 227853372110703. [Google Scholar] [CrossRef]

- Nair, R.; Viswanathan, P.K.; Bastian, B.L. Reprioritising Sustainable Development Goals in the Post-COVID-19 Global Context: Will a Mandatory Corporate Social Responsibility Regime Help? Adm. Sci. 2021, 11, 150. [Google Scholar] [CrossRef]

- Castro, A.; Iglesias, V.; Vijande, M. Organizational capabilities and institutional pressures in the adoption of circular economy—ScienceDirect. J. Bus. Res. 2023, 161, 113823. [Google Scholar] [CrossRef]

- Ghosh, S.; Mandal, M.; Ray, A. Selection of environmental-conscious sourcing: An empirical investigation. Benchmarking Int. J. 2021; ahead-of-print. [Google Scholar] [CrossRef]

- Singh, A.; Trivedi, A. Sustainable Green Supply Chain Management: Trends and Current Practices|Emerald Insight. Competitiveness Review. Available online: https://www.emerald.com/insight/content/doi/10.1108/cr-05-2015-0034/full/html (accessed on 16 November 2024).

- Khaksar, E.; Abbasnejad, T.; Esmaeili, A.; Tamošaitienė, J. The Effect of Green Supply Chain Management Practices on Environmental Performance and Competitive Advantage: A Case Study of the Cement Industry. Technol. Econ. Dev. Econ. 2015, 22, 293–308. [Google Scholar] [CrossRef]

- Singh, N.; Jain, D.S.; Sharma, P. Environmental benchmarking practices in Indian industries: Evidences from an empirical study. Benchmarking Int. J. 2016, 23, 1132–1146. [Google Scholar] [CrossRef]

- Tuni, A.; Rentizelas, A.; Duffy, A. Environmental performance measurement for green supply chains: A systematic analysis and review of quantitative methods. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 765–793. [Google Scholar] [CrossRef]

- Kleindorfer, P.R.; Singhal, K.; Van Wassenhove, L.N. Sustainable Operations Management. Prod. Oper. Manag. 2005, 14, 482–492. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Irani, Z.; Papadopoulos, T. Modelling and analysis of sustainable operations management: Certain investigations for research and applications. J. Oper. Res. Soc. 2014, 65, 806–823. [Google Scholar] [CrossRef]

- Martin, P.R.; Moser, D.V. Managers’ green investment disclosures and investors’ reaction. J. Account. Econ. 2016, 61, 239–254. [Google Scholar] [CrossRef]

- Key Global Trends in Sustainability Reporting. Available online: https://kpmg.com/xx/en/our-insights/esg/survey-of-sustainability-reporting-2022/global-trends.html (accessed on 16 November 2024).

- Galpin, T.; Whitttington, J.; Bell, G. Is your sustainability strategy sustainable? Creating a culture of sustainability. Corp. Gov. Int. J. Bus. Soc. 2015, 15, 1–17. [Google Scholar] [CrossRef]

- Coates, D.; Atkinson, P. Creating Culture Change: The Key to Successful Total Quality Management. J. Oper. Res. Soc. 1993, 44, 525. [Google Scholar] [CrossRef]

- “WEF_No-Excuse” Opportunities_to_Tackle_Scope_3_Emissions_in_Manufacturing_and_Value_Chains_2023.pdf. Available online: https://www3.weforum.org/docs/WEF_No-Excuse%E2%80%9D_Opportunities_to_Tackle_Scope_3_Emissions_in_Manufacturing_and_Value_Chains_2023.pdf (accessed on 25 December 2024).

- Khan, M.A.; Mahajan, R. Exploring factors influencing circular economy adoption and firm-level practices in the agribusiness sector: An exploratory study of Indian firms. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef]

- Conception of Circular Economy Obstacles in Context of Supply Chain: A Case of Rubber Industry|Emerald Insight. Available online: https://www.emerald.com/insight/content/doi/10.1108/ijppm-12-2020-0686/full/html (accessed on 25 December 2024).

- Bennett, N.J.; Whitty, T.S.; Finkbeiner, E.; Pittman, J.; Bassett, H.; Gelcich, S.; Allison, E.H. Environmental Stewardship: A Conceptual Review and Analytical Framework. Environ. Manag. 2018, 61, 597–614. [Google Scholar] [CrossRef]

- Bacq, S.; Eddleston, K. A Resource-Based View of Social Entrepreneurship: How Stewardship Culture Benefits Scale of Social Impact. J. Bus. Ethics 2018, 152, 589–611. [Google Scholar] [CrossRef]

- Harris, S.; Martin, M.; Diener, D. Circularity for circularity’s sake? Scoping review of assessment methods for environmental performance in the circular economy. Sustain. Prod. Consum. 2021, 26, 172–186. [Google Scholar] [CrossRef]

- Dalmia, N. What Is Circular Economy and Why Is It Important for India? Econ. Times 2022. Available online: https://economictimes.indiatimes.com/news/how-to/what-is-circular-economy-and-why-is-it-important-for-india/articleshow/92255753.cms?from=mdr (accessed on 17 November 2024).

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Yakovleva, N.; Camacho-Ferre, F. Analysis of the Circular Economic Production Models and Their Approach in Agriculture and Agricultural Waste Biomass Management. Int. J. Environ. Res. Public Health 2020, 17, 9549. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’Amico, M. Circular Economy Models in Agro-Food Systems: A Review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- Canet-Martí, A.; Pineda-Martos, R.; Junge, R.; Bohn, K.; Paço, T.A.; Delgado, C.; Alenčikienė, G.; Skar, S.L.G.; Baganz, G.F. Nature-based solutions for agriculture in circular cities: Challenges, gaps, and opportunities. Water 2021, 13, 2565. [Google Scholar] [CrossRef]

- Jesus, G.M.K.; Jugend, D.; Paes, L.A.B.; Siqueira, R.M.; Leandrin, M.A. Barriers to the adoption of the circular economy in the Brazilian sugarcane ethanol sector. Clean Technol. Environ. Policy 2023, 25, 381–395. [Google Scholar] [CrossRef]

- Nizami, A.S.; Rehan, M.; Waqas, M.; Naqvi, M.; Ouda, O.K.; Shahzad, K.; Miandad, R.; Khan, M.Z.; Syamsiro, M.; Ismail, I.M.I.; et al. Waste biorefineries: Enabling circular economies in developing countries. Bioresour. Technol. 2017, 241, 1101–1117. [Google Scholar] [CrossRef] [PubMed]

- Kiselev, A.; Magaril, E.; Magaril, R.; Panepinto, D.; Ravina, M.; Zanetti, M.C. Towards Circular Economy: Evaluation of Sewage Sludge Biogas Solutions. Resources 2019, 8, 91. [Google Scholar] [CrossRef]

- Bakan, B.; Bernet, N.; Bouchez, T.; Boutrou, R.; Choubert, J.M.; Dabert, P.; Duquennoi, C.; Ferraro, V.; Garcia-Bernet, D.; Gillot, S.; et al. Circular Economy Applied to Organic Residues and Wastewater: Research Challenges. Waste Biomass Valoriz. 2022, 13, 1267–1276. [Google Scholar] [CrossRef]

- Okafor, C.; Madu, C.; Ajaero, C.; Ibekwe, J.; Otunomo, F. Situating coupled circular economy and energy transition in an emerging economy. AIMSE 2021, 9, 651–675. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Schroeder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Barros, M.V.; Salvador, R.; do Prado, G.F.; de Francisco, A.C.; Piekarki, C.M. Circular economy as a driver to sustainable businesses. Clean. Environ. Syst. 2021, 2, 100006. [Google Scholar] [CrossRef]

- Shevchenko, T.; Vavrek, R.; Danko, Y.; Gubanova, O.; Chovancová, J.; Mykhailova, L. Clarifying a Circularity Phenomenon in a Circular Economy under the Notion of Potential. Probl. Ekorozwoju 2021, 16, 79–89. [Google Scholar] [CrossRef]

- Corvellec, H.; Stowell, A.F.; Johansson, N. Critiques of the circular economy. J. Ind. Ecol. 2022, 26, 421–432. [Google Scholar] [CrossRef]

- Adami, L.; Schiavon, M. From Circular Economy to Circular Ecology: A Review on the Solution of Environmental Problems through Circular Waste Management Approaches. Sustainability 2021, 13, 925. [Google Scholar] [CrossRef]

- Savini, F. The economy that runs on waste: Accumulation in the circular city. J. Environ. Policy Plan. 2019, 21, 675–691. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001:2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Markic, D.N.; Carapina, H.S.; Bjelic, D.; Bjelic, L.S.; Ilic, P.; Pesic, Z.S.; Kikanovicz, O. Using Material Flow Analysis for Waste Management Planning. Pol. J. Environ. Stud. 2019, 28. [Google Scholar] [CrossRef]

- Gottinger, A.; Ladu, L.; Quitzow, R. Studying the Transition towards a Circular Bioeconomy—A Systematic Literature Review on Transition Studies and Existing Barriers. Sustainability 2020, 12, 8990. [Google Scholar] [CrossRef]

- Juan, R.; Domínguez, C.; Robledo, N.; Paredes, B.; Galera, S.; García-Muñoz, R.A. Challenges and Opportunities for Recycled Polyethylene Fishing Nets: Towards a Circular Economy. Polymers 2021, 13, 3155. [Google Scholar] [CrossRef]

- Majeed, M.T.; Luni, T. Renewable energy, circular economy indicators and environmental quality: A global evidence of 131 countries with heterogeneous income groups. Pak. J. Commer. Soc. Sci. (PJCSS) 2020, 14, 866–912. [Google Scholar]

- Bassi, F.; Dias, J.G. The use of circular economy practices in SMEs across the EU. Resour. Conserv. Recycl. 2019, 146, 523–533. [Google Scholar] [CrossRef]

- Vaskalis, I.; Skoulou, V.; Stavropoulos, G.; Zabaniotou, A. Towards Circular Economy Solutions for The Management of Rice Processing Residues to Bioenergy via Gasification. Sustainability 2019, 11, 6433. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; De, D.; Budhwar, P.; Chowdhury, S.; Cheffi, W. Circular economy to enhance sustainability of small and medium-sized enterprises. Bus. Strategy Environ. 2020, 29, 2145–2169. [Google Scholar] [CrossRef]

- Magazzino, C.; Mele, M.; Schneider, N.; Sarkodie, S.A. Waste generation, wealth and GHG emissions from the waste sector: Is Denmark on the path towards circular economy? Sci. Total Environ. 2021, 755, 142510. [Google Scholar] [CrossRef] [PubMed]

- Langergraber, G.; Castellar, J.A.; Andersen, T.R.; Andreucci, M.B.; Baganz, G.F.; Buttiglieri, G.; Canet-Marti, A.; Carvalho, P.N.; Finger, D.C.; Bulc, T.G.; et al. Towards a Cross-Sectoral View of Nature-Based Solutions for Enabling Circular Cities. Water 2021, 13, 2352. [Google Scholar] [CrossRef]

- Sehnem, S.; Jabbour, C.J.C.; Pereira, S.C.F.; de Sousa Jabbour, A.B.L. Improving sustainable supply chains performance through operational excellence: Circular economy approach. Resour. Conserv. Recycl. 2019, 149, 236–248. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Philippidis, G.; Sartori, M.; Ferrari, E.; M’Barek, R. Waste not, want not: A bio-economic impact assessment of household food waste reductions in the EU. Resour. Conserv. Recycl. 2019, 146, 514–522. [Google Scholar] [CrossRef]

- Chen, C.C.; Pao, H.T. The causal link between circular economy and economic growth in EU-25. Environ. Sci. Pollut. Res. 2022, 29, 76352–76364. [Google Scholar] [CrossRef]

- Ddiba, D.; Andersson, K.; Koop, S.H.; Ekener, E.; Finnveden, G.; Dickin, S. Governing the circular economy: Assessing the capacity to implement resource-oriented sanitation and waste management systems in low- and middle-income countries. Earth Syst. Gov. 2020, 4, 100063. [Google Scholar] [CrossRef]

- Kaffashi, S.; Shamsudin, M.N. Transforming to a low carbon society; an extended theory of planned behaviour of Malaysian citizens. J. Clean. Prod. 2019, 235, 1255–1264. [Google Scholar] [CrossRef]

| Citation No. | Application of CE Principles |

|---|---|

| [94] | Promoting organic alternatives for cooking and fertilisers; utilising crop and livestock residues in biogas plants. |

| [67] | Biorefineries act as alternatives to petrochemical refineries, utilising agri-biomass waste for value-added products. |

| [88,94,95] | Biorefineries offer a variety of value-added products from agri-biomass waste, particularly biogas/compressed bio-methane (CBM) gas. |

| [88] | Widespread promotion and adoption of CE guidelines in the bioenergy field by farm households can also have a positive environmental impact by reducing emissions from burning agri-waste. |

| [95] | Enhancing sewage treatment plants (STPs) with biofuel production for clean, self-sustaining operations. The revenue from biofuel production enables the STPs to transition to a clean technology-based CE domain, thereby becoming self-sustaining entities in the long run. |

| [96] | Supporting marginalised farmers and integrating institutional factors to address gaps in biomass-based energy systems. |

| Citation | CE Principles |

|---|---|

| [78] | CE processing of end-of-life (EOL) solar PV panels enables material recovery. Forecasts indicate 2.95 billion metric tonnes of solar e-waste by 2047, with a potential 70% recovery rate using advanced CE recycling technologies. |

| [92] | CE-based waste management offers immense potential for stimulating green recovery and achieving SDGs. |

| [101] | Converting marble waste and FGD gypsum into construction materials to achieve sustainability in the construction industry. |

| [102] | Applying CE for managing municipal garbage in India, reducing residual waste generation. Identified 30 factors for CE application and nine critical success factors for implementation. |

| [103] | Establishing formal waste management systems with organised collection, recycling technologies, enhanced regulatory oversight, and mobile monitoring for construction and demolition waste. |

| [104] | Case studies demonstrate CE benefits for rural and urban communities in managing solid and electronic waste, improving sanitation, protecting the environment, generating income, and fostering cleaner community habits. |

| [106] | Achieving CE in India requires legislative frameworks, government support, best practices, plans, targets, and learning from cross-country experiences. |

| [105,107] | A system dynamics (SD) model demonstrates circular recycling of gold flakes from mobile phones, with nine simulated scenarios providing policy insights for CE in electronic waste. Nanotechnology has lately been employed to extract basic metals, hazardous metals, and precious metals from waste printed circuit boards (PCBs). |

| [108] | Waste management (WM) in India faces inefficiencies due to a silo mentality. Promoting CE-integrated WM practices through community education and awareness is crucial. |

| [109] | Explores the link between CE, waste management, and renewable energy. Government efforts and frameworks are essential to encourage circularity and sustainability. |

| [110] | Informal waste pickers in Delhi (India) and São Paulo (Brazil) contribute to recycling and closing the waste management loop. Organised cooperatives address waste challenges. A detailed analysis of their living conditions, potentials, and needs is essential for CE transformation. |

| [111] | Transitioning from a linear economy (take-make-use-dispose) to a circular model (reduce–reuse–recycle) requires reverse logistics, creative design, shared ecosystems, and innovative business models. Resource management flows across product value chains must align for CE success. |

| Citation | CE Principles |

|---|---|

| [112] | Studied consumers’ purchase intentions (PIs) towards refurbished products using a structural equation model (SEM). Identified factors influencing PI: market strategy, attitude, personal advantages, product knowledge, risk perception, and subjective norms. Emphasised the need for a positive consumer attitude towards remanufactured products through better product information dissemination. |

| [113] | Explored reverse logistics (RL) as a strategic tool for promoting CE and enhancing operational effectiveness. Identified obstacles such as a lack of management initiative and accountability, and proposed strategies such as customer education, utilising logistics networks, and effective warehousing to overcome them. |

| Citation | CE Principles |

|---|---|

| [41] | Systematically reviews global CE adoption in the urban water sector, examining 6R principles (reduce, reuse, recycle, reclaim, recover, and restore). Identifies challenges in India’s water sector, including technological, economic, institutional, and social barriers. Opportunities include wastewater treatment, resource recovery, and decentralised wastewater collection for agricultural and industrial reuse. |

| [44] | The cement industry supports CE via circular supply chains and waste recovery. High-temperature incineration processes enable environmentally sustainable waste utilisation with no residue, contributing to CE in waste-generating industries. |

| [84] | Investigates SMEs’ capacity to adapt CE practices in emerging markets, focusing on the Indian Ayurveda industry. Emerging themes related to CE are identified, offering insights into causes, catalysts, and motivations for SMEs to support CE transitions. |

| [85] | The skewed structure of India’s SMEs poses challenges for CE adoption due to their informal nature and lack of institutional support. Promoting CE requires a culture of waste reduction, recycling, repairing, refurbishing, and reuse. Societal, technical, and environmental factors influencing CE are explored using the sociotechnical systems (STS) framework, highlighting key enablers and motivations for SMEs. |

| [96] | Promotes biofuel production from sewage treatment plants (STPs) as an alternative clean technology. Revenue from biofuel sales can finance STPs, advancing India’s CE transition. |

| [114] | CE adoption in heavy-duty and off-road industrial sectors impacts product design, planning, and control. The study explored circular business models and challenges in remanufacturing businesses. Industry 4.0 technologies significantly influence green procurement and remanufacturing processes, enhancing CE performance. |

| [115] | Proposes a product circularity assessment system, with a case study on elastic product manufacturing in Gujarat. Introduces the sustainable product circularity index (SPCI), evaluating circularity across environmental, economic, material, and sociological dimensions. |

| [116,117] | Highlights nutrient recovery from wastewater using techniques like ion exchange, microalgae production, and chemical precipitation. Discusses the potential of struvite as a phosphate fertiliser, reducing emissions and enhancing sustainability. Recovery from sewage can replace imports and reduce CO2 emissions by 663.2 kg/ha. |

| [118] | Examines CE opportunities in India’s Smart City Mission (SCM) using the ReSOLVE framework to map CE prospects in urban areas. Recommendations are provided for efficient CE implementation in SCM projects, aligning with sustainability goals. |

| Citation | Adoption of CE Policies |

|---|---|

| [49] | Explores CE readiness of small firms using the expanded theory of planned behaviour (ETPB) model. Finds that mindset, societal pressure, environmental commitment, and economic incentives significantly influence CE adoption. Provides strategic insights to promote CE in small manufacturing businesses. |

| [103] | Reviews the current state of plastic waste (PW) management in India. Highlights inefficiencies in solid waste systems and the need for reverse supply chain management, better regulations, and EPR. Suggests policies to achieve SDGs and sustainable PW management. |

| [119] | Reviewed policies adopted by G20 nations for material efficiency in CE transitions, comparing India’s policies with those of China and Germany. Highlights India’s potential for increasing material productivity and engaging with G20 for resource efficiency measures. |

| [120] | Discusses integrating CE strategies into energy-efficient policies in India to address energy scarcity. Emphasises the need for legal reforms to restructure the power sector and promote clean renewable energy, ensuring universal clean energy access. |

| [121] | Examines the Paperman Foundation’s circularity-based business model for sustainable resource recovery from post-consumer plastics. Demonstrates the model’s impact on reducing CO2 emissions and emphasises scaling such CE business models in transitional economies, like India. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajayya, A.; Nair, R.; Karthiayani, V.P. India’s Transition to a Circular Economy Towards Fulfilling Agenda 2030: A Critical Review. Sustainability 2025, 17, 2667. https://doi.org/10.3390/su17062667

Rajayya A, Nair R, Karthiayani VP. India’s Transition to a Circular Economy Towards Fulfilling Agenda 2030: A Critical Review. Sustainability. 2025; 17(6):2667. https://doi.org/10.3390/su17062667

Chicago/Turabian StyleRajayya, Ananthi, Rajiv Nair, and Viswanathan Pozhamkandath Karthiayani. 2025. "India’s Transition to a Circular Economy Towards Fulfilling Agenda 2030: A Critical Review" Sustainability 17, no. 6: 2667. https://doi.org/10.3390/su17062667

APA StyleRajayya, A., Nair, R., & Karthiayani, V. P. (2025). India’s Transition to a Circular Economy Towards Fulfilling Agenda 2030: A Critical Review. Sustainability, 17(6), 2667. https://doi.org/10.3390/su17062667