1. Introduction

Risk arises from the intricacy of the supply chain, the state of the markets, and outside factors. These factors that pose a danger to global supply chain sustainability include trade disputes involving China, the U.S., and Europe; the impact of COVID-19; conflicts between Ukraine and Russia; and the ongoing issue of global warming [

1]. These factors can disrupt supply chains, leading to material shortages, delays, and significant impacts on supply chain performance. In turn, these disruptions emphasize the need for supply chain resilience—the ability to recover quickly, adapt, and continue delivering value despite challenges [

2].

The Fast-Moving Consumer Goods (FMCG) sector is anticipated to expand at a Compound Annual Growth Rate (CAGR) of 5.4% from 2018 to 2025, accompanied by a significant growth in marketing expenditures, forecasted to increase from

$58 billion in 2022 to

$138 billion by 2027 [

3,

4]. According to Kenton [

5], FMCG are distinguished by their high demand, inexpensive prices, and rapid consumption rates. According to

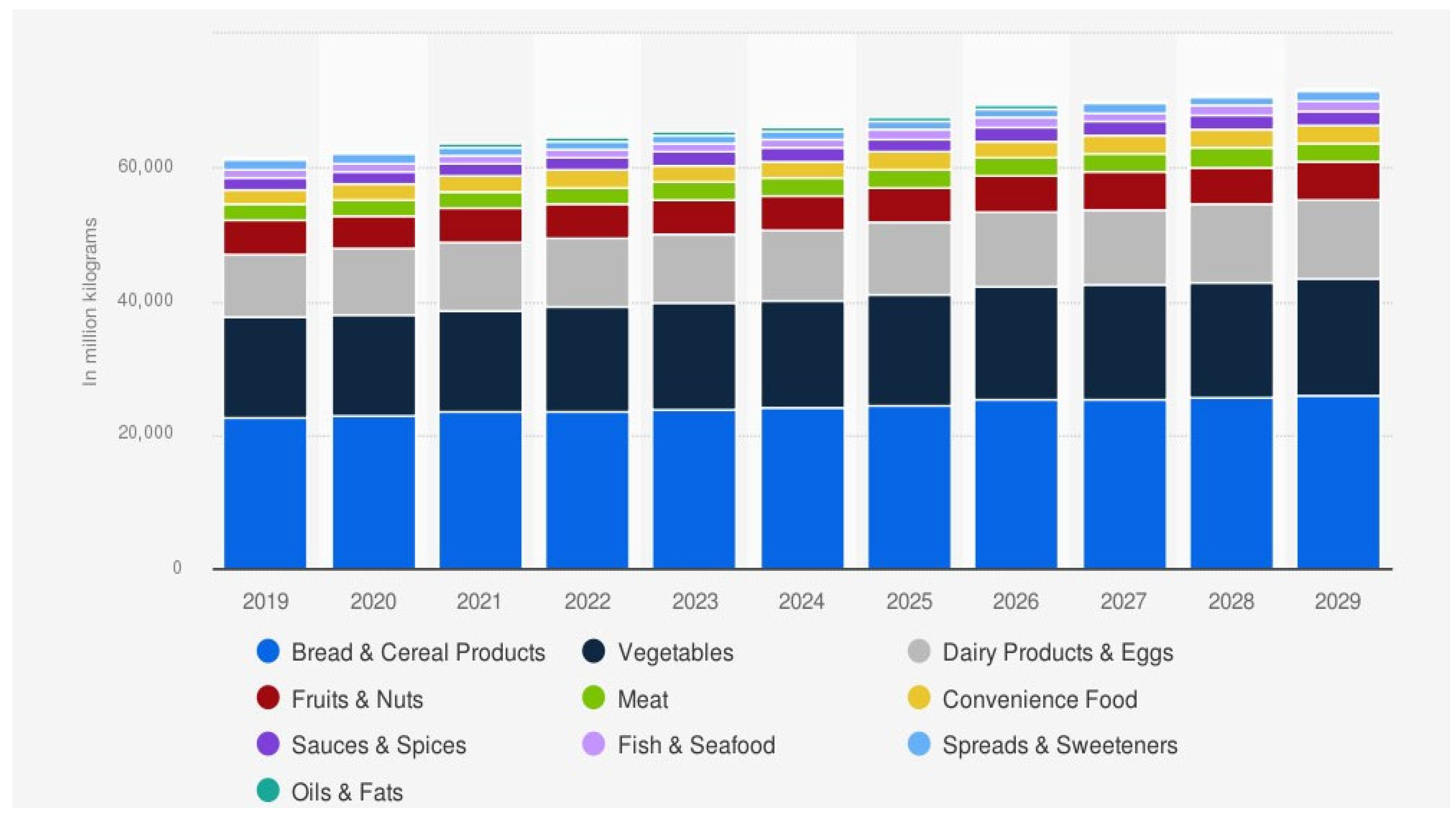

Figure 1, it was anticipated that the volume of the FMCG (food market) in Pakistan would continue to expand, reaching a total of 6.2 billion kilograms, or an increase of 9.08 percent between the years 2024 and 2029 [

6].

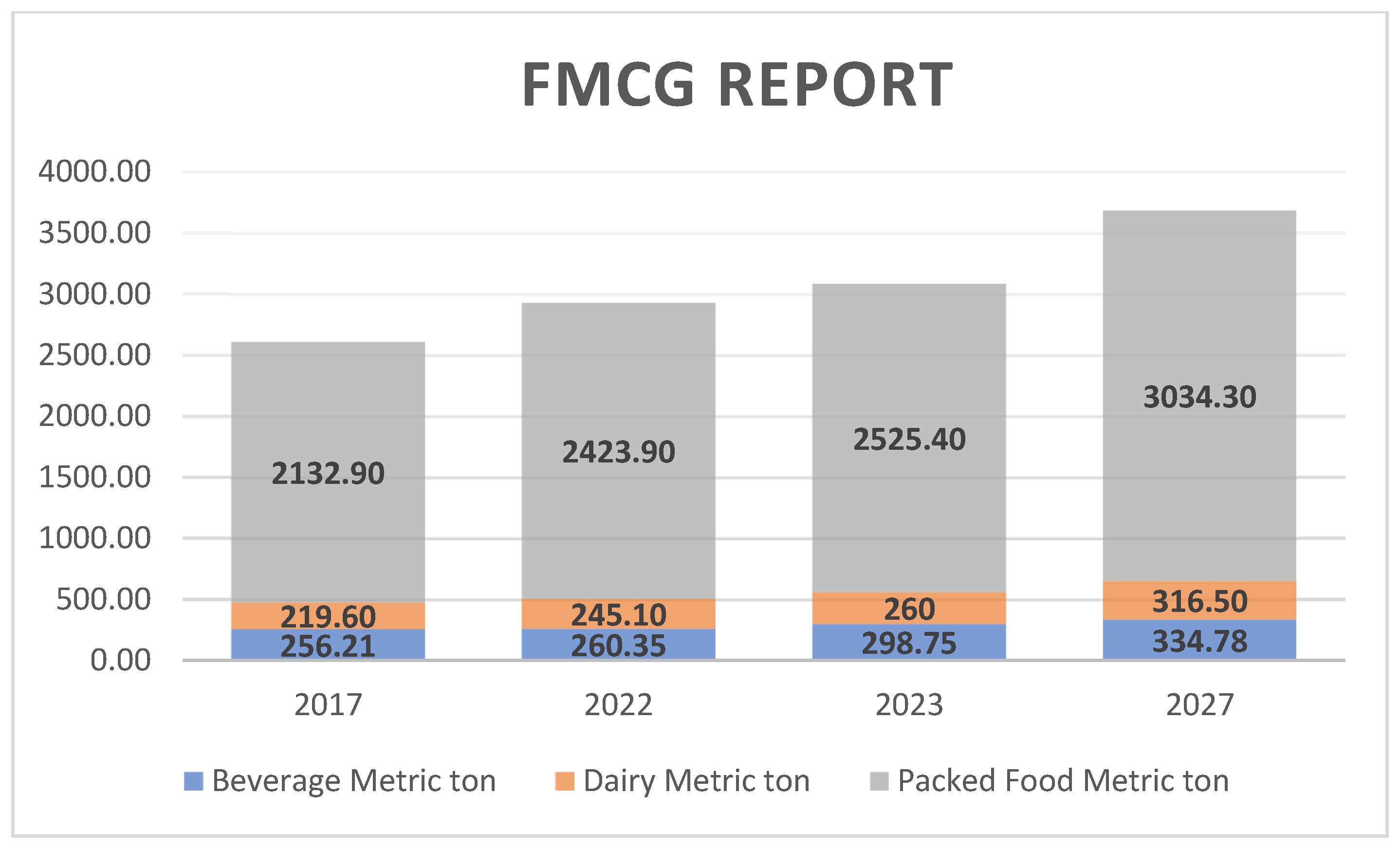

Figure 2 presents the growth in the FMCG sector of Saudi Arabia [

7]. FMCG companies in Pakistan and Saudi Arabia have promising opportunities as the FMCG sector grows, but a strong supply chain is needed to meet expanding demand and avoid interruptions. FMCG companies must cultivate robust, enduring connections with local and global suppliers that can swiftly respond to supply disruptions caused by natural catastrophes, geopolitical crises, or economic instability [

8], and organizations are required to adapt robust strategies and reaction tactics [

9].

Resilient suppliers (RSs) consistently uphold product quality while emphasizing sustainability and ethical sourcing procedures, guaranteeing that the produced food is both responsible and dependable [

10]. Furthermore, transportation capacity (TC) is a critical component of supply chain resilience, particularly in a nation such as Pakistan, where infrastructural obstacles may hinder the efficient movement of commodities. Heightened consumption necessitates that FMCG firms engage in the expansion of transportation networks capable of accommodating the increasing volume of commodities, hence ensuring the timely delivery of food products to retail outlets and consumers [

11]. The Flexibility (FLEX) of the supply chain network is crucial for responding to evolving market circumstances. The FMCG market in Pakistan and Saudi Arabia has variable customer tastes, seasonal demand variations, and evolving import–export regulations, necessitating agility in the operations of FMCG companies [

12]. The degree of flexibility enables FMCG companies to satisfy consumer demands without straining their resources or undertaking imprudent investments [

13].

The intricacy of the supply chain network in both countries presents an additional barrier for FMCG companies. As the network’s complexity (NC) increases, so does the likelihood of disruptions, delays, or miscommunications. Consequently, FMCG companies must prioritize the establishment of an integrated, collaborative network that enables fluid communication and the efficient transportation of goods [

14]. Supply chain dynamism (SPD) denotes the capacity of the supply chain to adjust and progress in reaction to internal and external influences. This may encompass alterations in consumer behavior, governmental modifications, or environmental influences such as climate change [

15]. To maintain competitiveness, FMCG companies must have a dynamic supply chain that not only responds to disturbances but also predicts them [

16].

Due to growing importance and the wider spectrum of disruptions and risks, supply chain resilience is under study. Various researchers studied supply chain resilience from multiple perspectives, which highlights its importance, e.g., viable sourcing strategies and resilience [

17], the capacity of transportation is helpful to enhance resilience [

18], product flow optimization through TC [

19], mitigating internal and external uncertainty through flexibility [

20], optimizing responsiveness through flexibility [

21], the impact of NC on supply chain performance [

22], NC decreases operational performance [

23], the importance of artificial intelligence and information for resilience [

24], and the impact of improved visibility and primary suppliers on resilience [

25]. This study introduces a novel approach by utilizing Necessity Condition Analysis (NCA) to determine benchmark levels of key variables (RS, TC, FLEX, and SPD) required to achieve optimal supply chain resilience (SRES). To the best of our knowledge, no previous study has applied NCA in this context. Previous studies have focused on the effects of RS and TC on SRES, but there is a lack of information on SPD and NC, especially in the FMCG industry. This work combines the Theory of Constraints and Systems Theory to identify SRES bottlenecks. It shows how these factors enhance SRES, offering new insights into resilience-building.

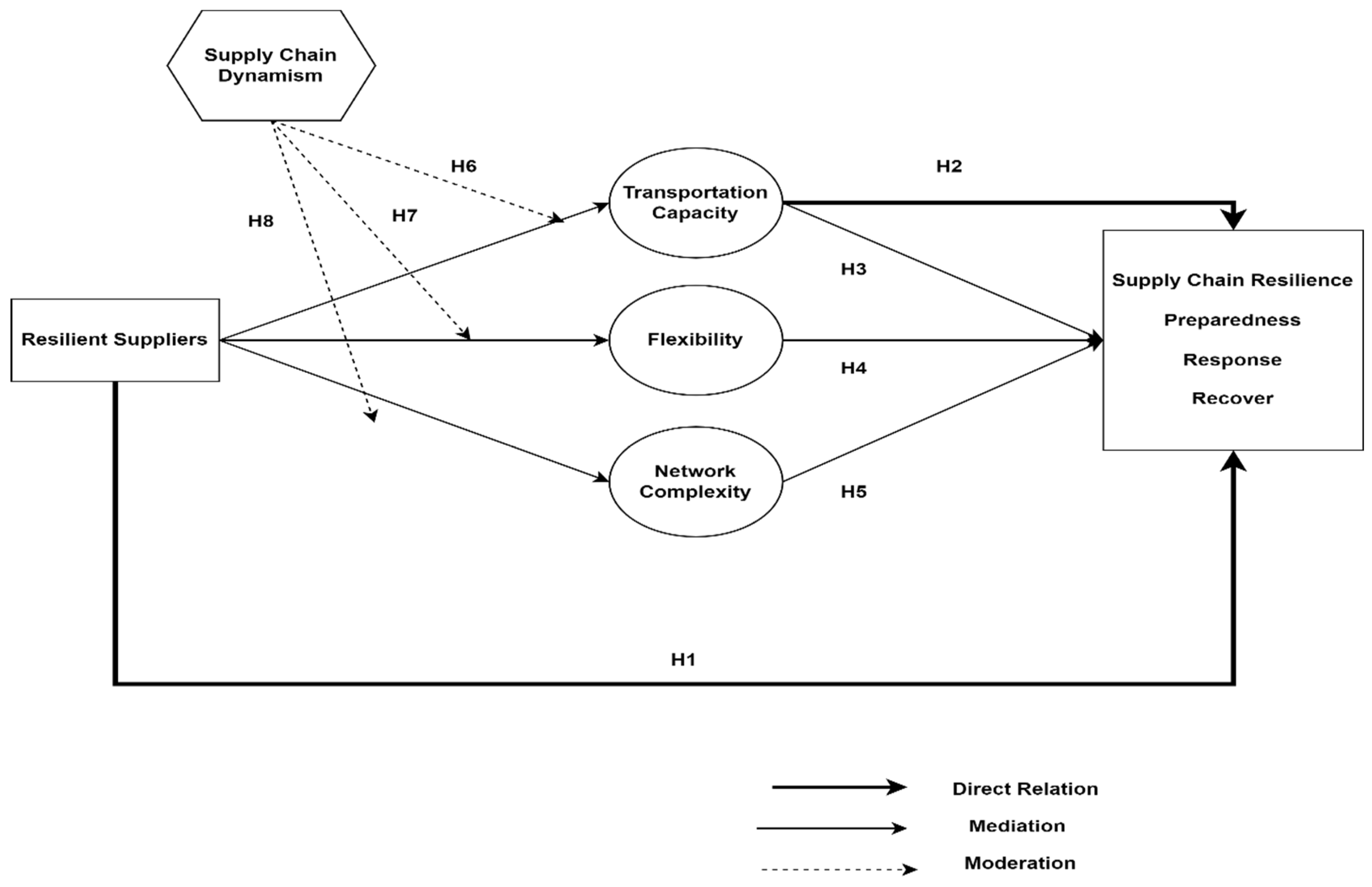

RQ1. How do resilient suppliers (RSs) and transportation capacity contribute to enhancing supply chain resilience in the FMCG sector?

RQ2. How do transportation capacity, flexibility, and network complexity mediate the relationship between RS and SRES?

RQ3. What role does supply chain dynamism play to moderate the relationship between RS, transportation capacity, network complexity, and supply chain resilience?

RQ4. What are the minimum performance thresholds for RS, TC, FLEX, NC, and SPD necessary to ensure optimal operational excellence of supply chain resilience, as determined by NCA?

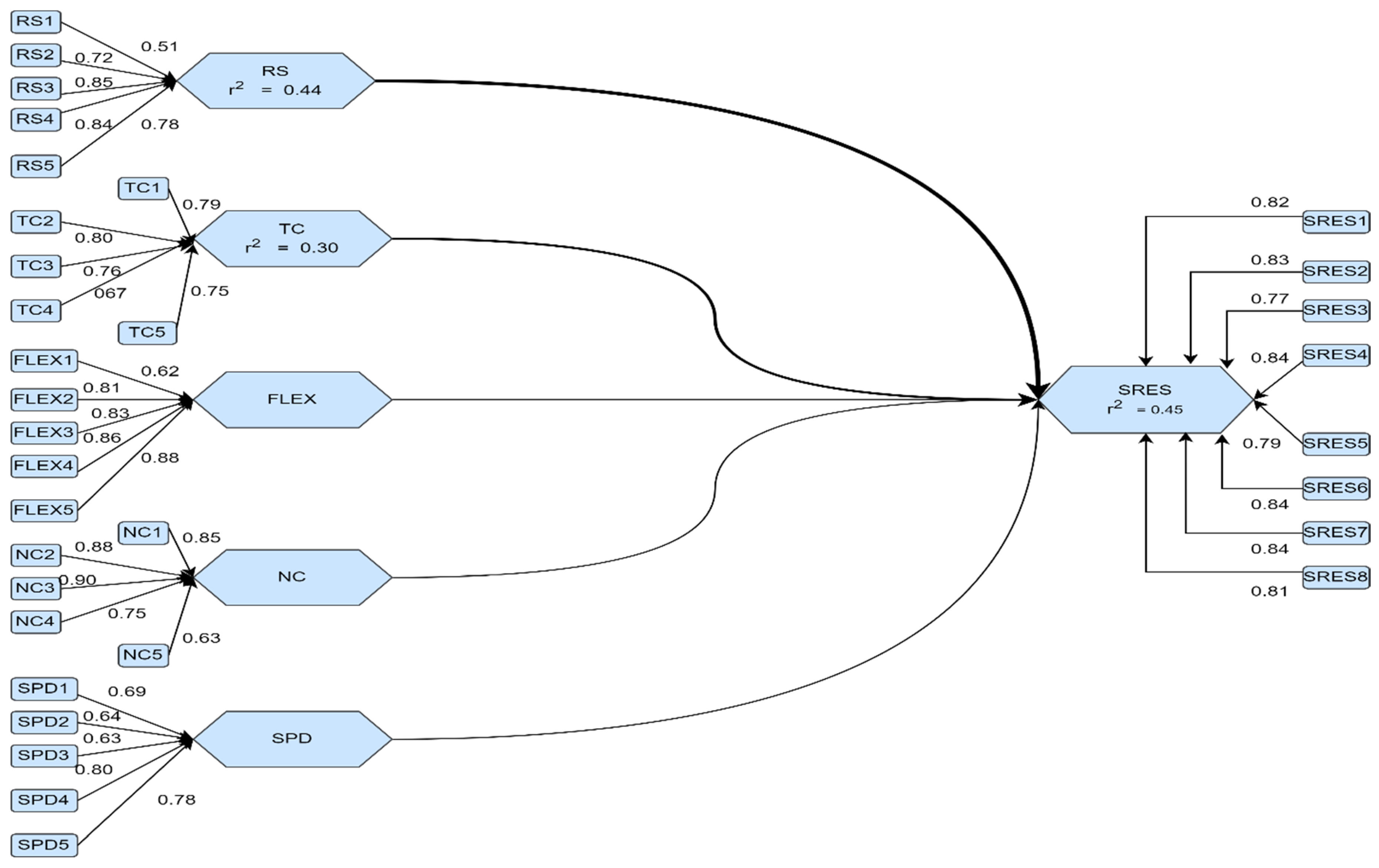

This research utilizes Partial Least Squares Structural Equation Modeling (PLS-SEM) and Necessary Condition Analysis (NCA) to investigate the interconnections among critical variables RS, TC, FLEX, NC, SPD, and their critical role in enhancing SRES. This study employs these approaches to ascertain the essential conditions for improving supply network resilience and analyzes the interactions of these variables on overall supply chain performance.

To understand their resilience-building role, FLEX, NC, and TC mediation effects are extensively explored. The NCA gives managers clear performance standards to boost resilience. The standards help supply chain managers assess their operations’ resilience. They can identify underperforming components against these requirements, enabling proactive vulnerability mitigation. Managers may properly allocate resources and prioritize operational continuity and disruption prevention using this knowledge. The remaining article is as follows:

Section 2: Literature Review and Hypotheses Development;

Section 3: Methodology;

Section 4: Results;

Section 5: Discussion; and

Section 6: Conclusions.

5. Discussion

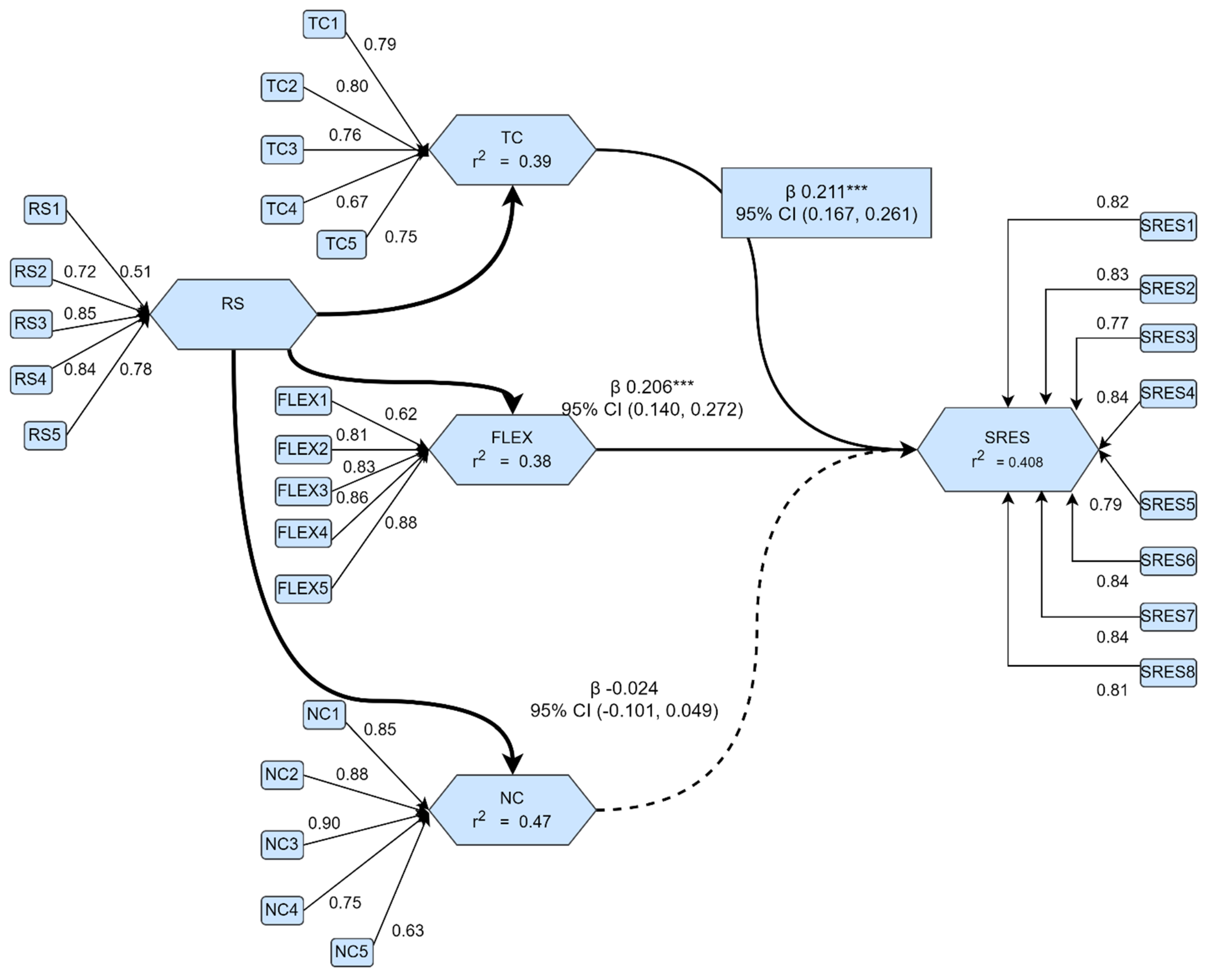

The outcomes of the hypothesis testing on RS and TC in augmenting SRES within the FMCG sector yield substantial insights into the principal determinants of resilience in this business. Hypothesis H1, which asserts a positive correlation between RS and SRES, received robust support with a β value of 0.436 and a highly significant

p-value of 0.000. The confidence interval (0.354 to 0.523) reinforces the robustness of this association, showing that resilient providers are essential in enhancing supply chain resilience. RS facilitates an uninterrupted supply of goods and reduces disruptions, so strengthening the overall resilience of the supply chain [

53]. Likewise, Hypothesis H2, which investigates the effect of TC on SRES, was accepted with a β value of 0.295 and a

p-value of 0.000. The confidence interval for TC (0.179 to 0.400) indicates that transportation capacity is a significant factor influencing supply chain resilience. As supply chains grow increasingly intricate and geographically widespread, adequate transportation capacity is essential to sustain the flow of commodities and respond to interruptions, hence enhancing resilience [

39]. These findings answer RQ1 of this study. The findings of H3, H4, and H5 answer RQ2, which indicates that RS and TC are crucial in augmenting SRES within the FMCG sector. RS significantly influences SRES (H3) by fortifying the supply chain, assuring a steady flow of goods during disruptions, and so enhancing overall resilience. The results indicate that RS indirectly improves SRES by positively affecting FLEX (H4). RS provides flexibility by providing options in sourcing or delivery timelines, enabling the supply chain to rapidly adjust to fluctuations in demand or supply circumstances. Conversely, NC does not significantly influence SRES (H5), indicating that, in this case, streamlining the network does not inherently improve resilience. Enhancing the supply chain via RS, sufficient transportation capacity, and adaptability fosters a more flexible and robust system, proficient in successfully addressing disturbances. These aspects collaboratively strengthen the supply chain, guaranteeing its stability and adaptability amid adversities [

22,

35,

49].

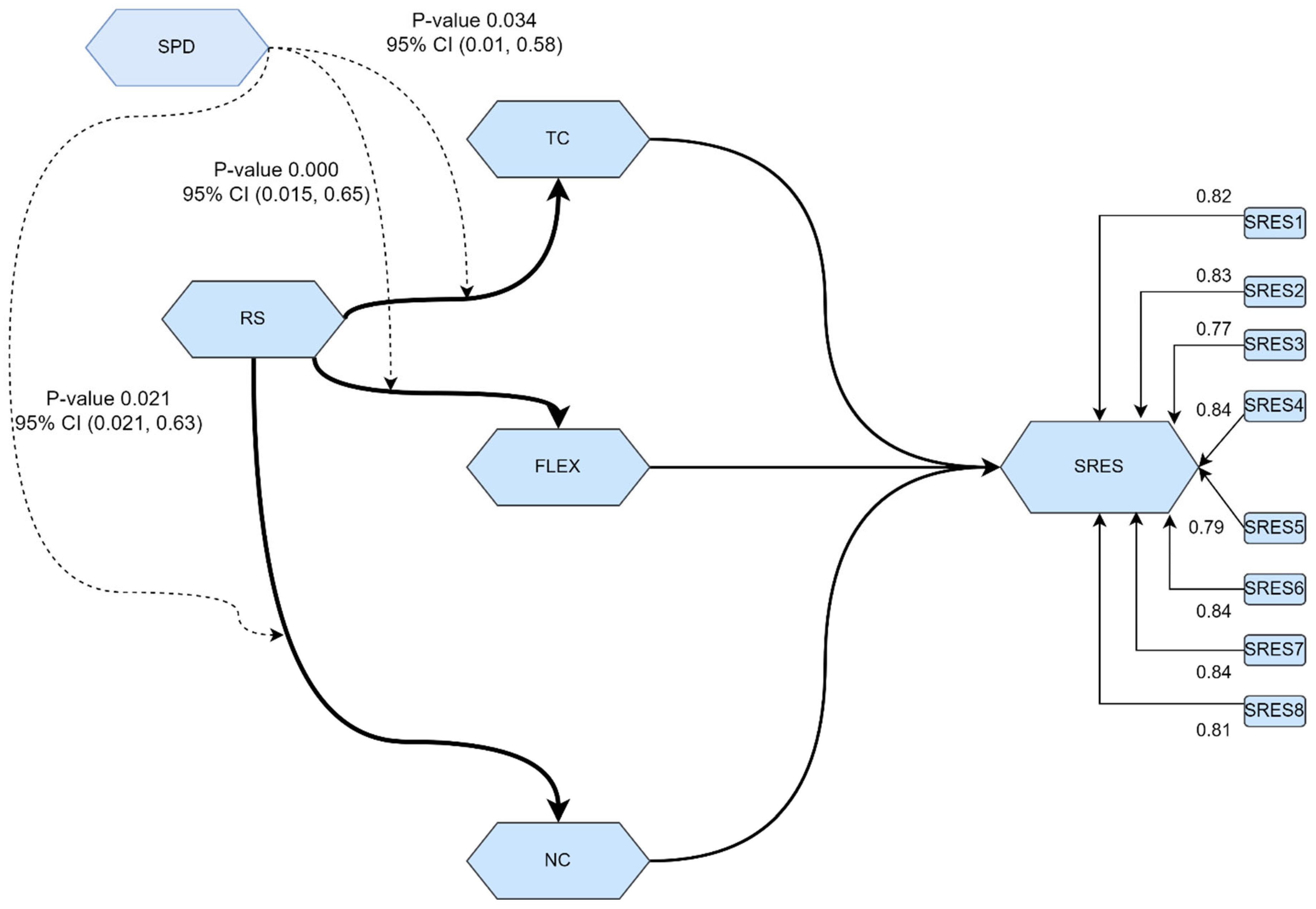

The findings of RQ3 demonstrate how the interplay between SPD and RS augments SRES via several mediating elements. Hypothesis H6 indicates that the synergistic effect of SPD and RS enhances TC, hence reinforcing SRES. A dynamic supply chain, bolstered by robust suppliers, enhances transportation infrastructure, allowing the supply chain to better withstand disturbances and improve its resilience.

Hypothesis H7 indicates that the connection between SPD and RS favorably affects FLEX, hence enhancing SRES. This underscores the essential function of adaptability in a robust supply chain. The capacity to swiftly adjust to variations in demand, supply, and other operational issues is heightened when resilient suppliers collaborate with supply chain dynamism, resulting in improved overall resilience. Hypothesis H8 indicates that the relationship between SPD and RS positively affects NC, which subsequently influences SRES. Although network complexity is a minor contributing component, its association with SPD and RS facilitates the optimization of network design, diminishes inefficiencies, and enhances the supply chain’s responsiveness to interruptions [

106,

107].

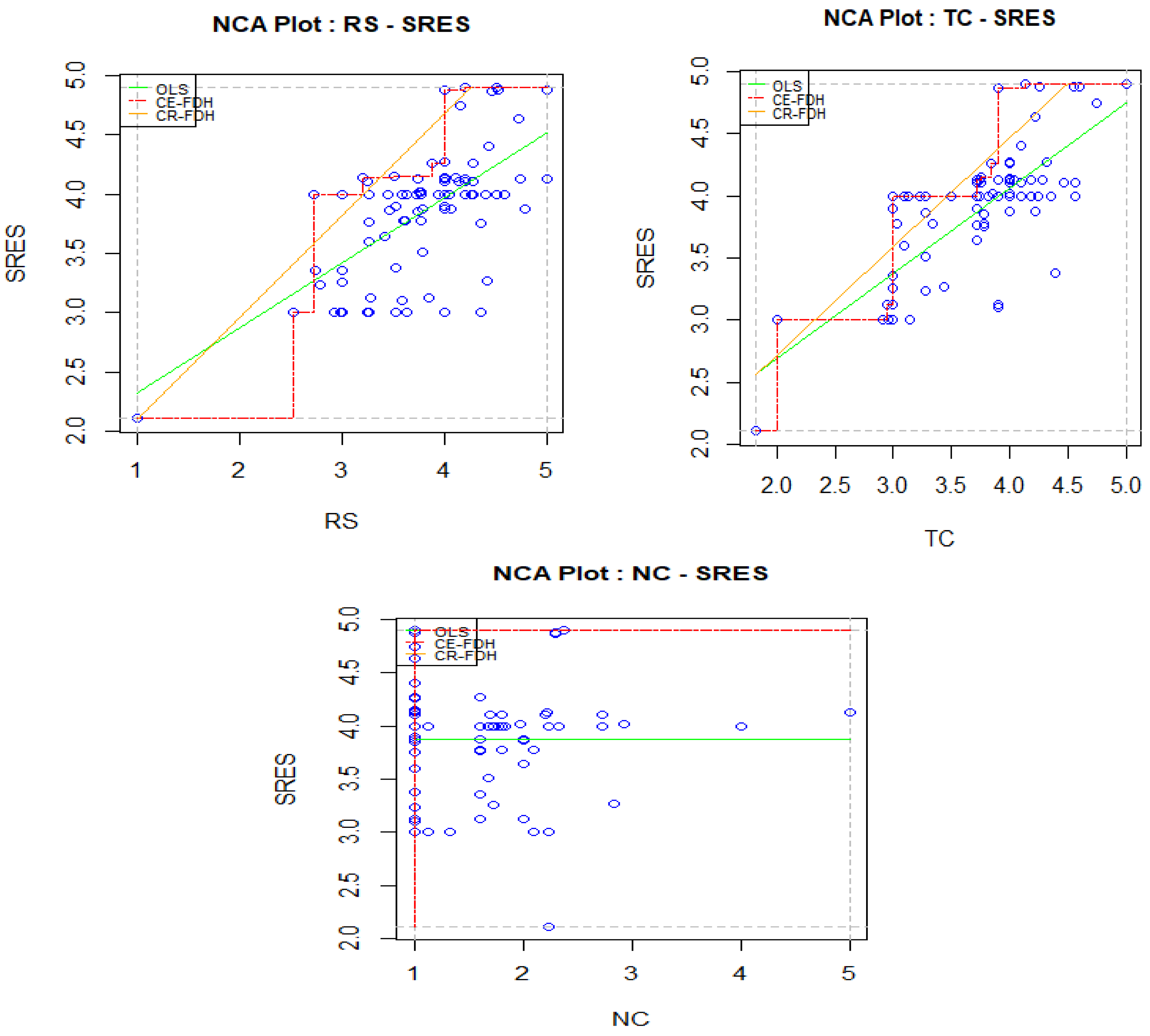

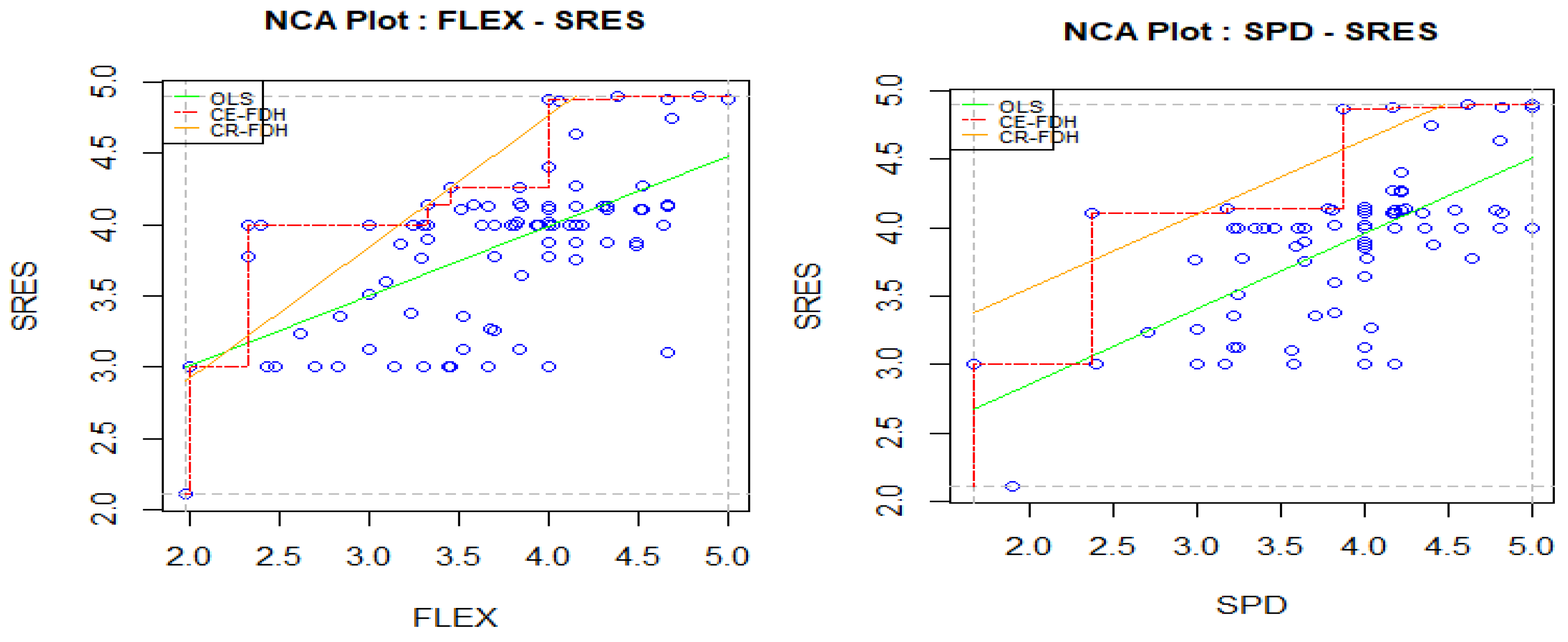

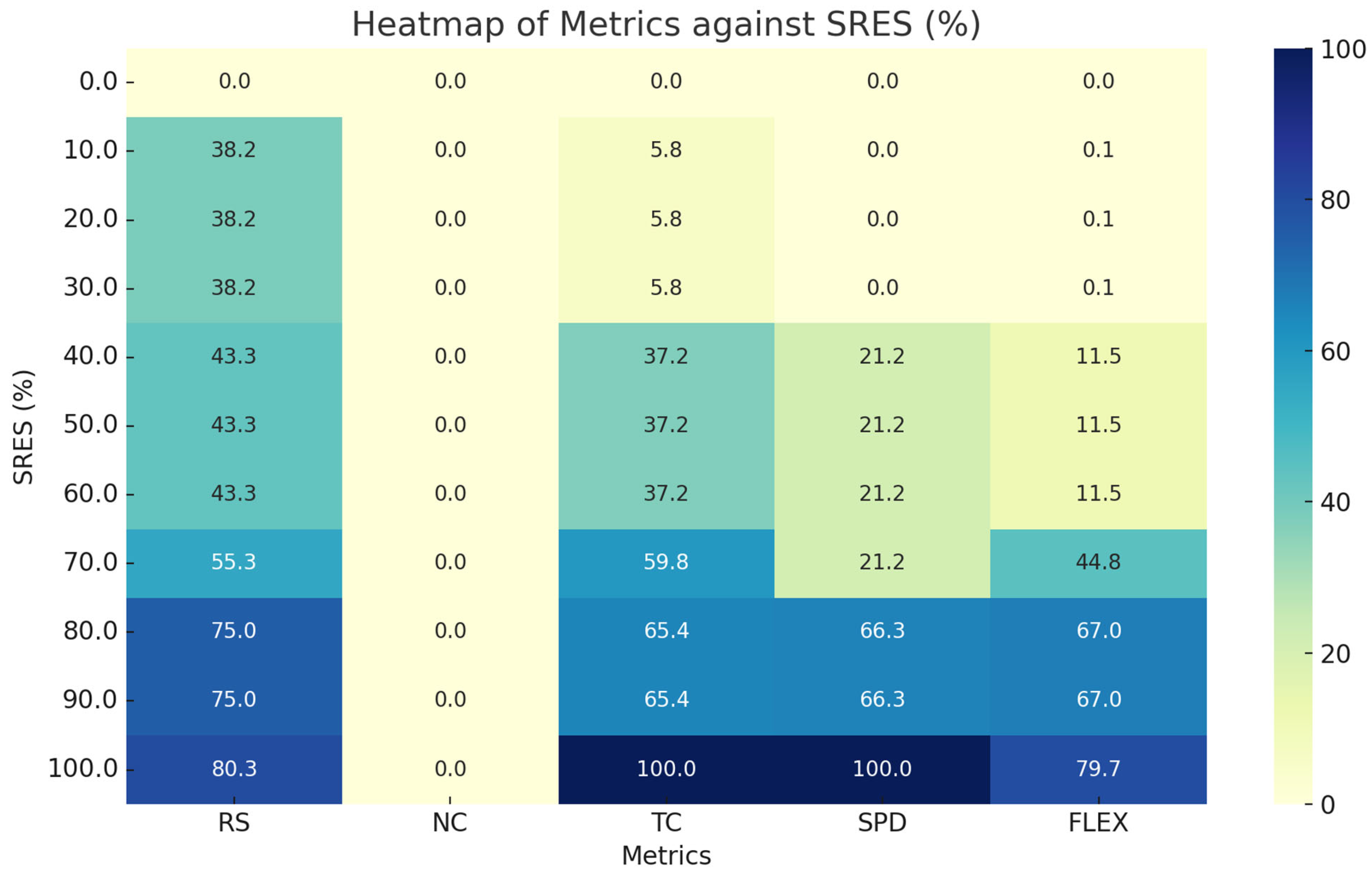

The examination of the bottleneck table yields critical insights into the minimal performance standards required for optimal operational excellence in SRES. Hence, answering RQ 4 Achieving 80% SRES necessitates a balanced and strategic emphasis on RS, TC, FLEX, and SPD. The results indicate that RS and TC are essential at this juncture, with RS attaining a minimum of 75 and TC at 65.4, highlighting the crucial importance of supplier resilience and transportation infrastructure in maintaining overall supply chain stability. RS guarantees a consistent supply of materials despite disruptions, while sufficient transportation capacity is essential to accommodate the heightened needs of a robust supply chain. FLEX and SPD are significant factors, with thresholds of 67% for FLEX and 66.3% for SPD, underscoring the necessity of operational agility and the capacity to adjust dynamically to variations and uncertainties. These features facilitate the supply chain’s effective response to interruptions, guaranteeing uninterrupted operations and minimizing the likelihood of bottlenecks.

Conversely, NC does not provide a substantial impediment to operational excellence, remaining consistently at zero across all benchmarks. This indicates that, in this scenario, NC does not impede the attainment of optimal resilience. To further strengthen resilience, managers should prioritize the cultivation of robust supplier relationships, the assurance of sufficient transportation capacity, and the promotion of operational flexibility and dynamism. Proper alignment of these components can greatly improve supply chain resilience, allowing them to endure and recuperate from disturbances while sustaining operational excellence. In a nutshell, RS, effective TC, operational FLEX, and SPD constitute the fundamental elements of a resilient supply chain. By deliberately concentrating on these domains, businesses can establish a resilient framework that guarantees both stability and adaptation, allowing them to confront future challenges with enhanced resilience and efficiency [

60,

66].

5.1. Theoretical Implications

This study validates the application of systems theory in the context of supply chain resilience, emphasizing the interdependence of a variety of factors in the supply chain. The research demonstrates that SRES is not the outcome of isolated enhancements in individual components, such as TC, FLEX, RS, or SPD. Rather, it is the result of the dynamic interactions among these factors. Systems theory demonstrates that modifications to a single component, such as RS, can have a cascading effect on others, including TC and FLEX, thereby increasing the system’s overall resilience. This comprehensive, systems-based management approach underscores the significance of observing supply chain resilience as an integrated outcome, where the strengthening of one aspect of the system can have a positive impact on the entire supply chain’s capacity to adapt to change and withstand disruptions.

Furthermore, the recognition of NC as a possible limitation is consistent with TOC, highlighting that excessive complexity might serve as a bottleneck that undermines resilience. Streamlining networks, enhancing coordination, and minimizing redundancies can mitigate these constraints, resulting in more efficient and resilient supply chains. The research illustrates the significance of feedback loops, wherein resilient providers and adaptability enhance information flow and coordination, hence generating a positive reinforcement effect within the supply chain.

5.2. Implications for Management

Managers must first maximize RS and TC if they want to create a strong supply chain. Beyond an ideal level, nevertheless, more investment produces declining benefits. Once these sectors approach efficiency, focus should move to improving FLEX, raising dynamism, and lowering NC for additional resilience increases. Secondly, once these areas are efficient, the focus should shift to improving FLEX, increasing SPD, and reducing NC for additional resilience improvements. FLEX becomes more important as resilience improves, necessitating adaptive production schedules, sourcing strategies, and logistics to ensure rapid reaction to shocks. This study discovered that NC has little effect under moderation on resilience, indicating the need to streamline processes and minimize complexity. As resilience grows, SPD, particularly in decision-making and adaptability, is critical. Managers should invest in systems that allow for speedy decision-making and response. Understanding how these aspects interact allows managers to optimize supply chain operations, ensuring agility and robustness in the face of unanticipated interruptions.

6. Conclusions

The challenges presented by unforeseen disruptions, market fluctuations, and escalating complexity underscore the necessity of enhancing SRES in the contemporary global landscape. This study sought to investigate the influence of critical elements, including RS, TC, FLEX, NC, and supply SPD, on the enhancement of supply chain resilience within the FMCG sector in Pakistan and Saudi Arabia and collect data from 611 respondents. The paper demonstrates, through extensive empirical analysis, the essential function of RS and TC in strengthening SRES, with FLEX and SPD further augmenting adaptability and responsiveness.

This study utilized a systems theory framework, highlighting the interdependence of several supply chain elements, and employed the TOC to NC as a possible impediment. This study utilized a unique and novel dual methodology (PLS-SEM and NCA). The findings of this study indicate that although RS and TC are essential factors in supply chain resilience, the enhancement of flexibility and dynamism is equally significant. Additionally, NC, albeit less critical, was recognized as a limitation inside the system, indicating that prioritizing complexity management is essential to prevent unwanted interruptions and inefficiencies. The findings emphasize the necessity for managers to concentrate on both individual supply chain components and their interconnections. This comprehensive strategy enhances resilience by maximizing the entire system. Establishing a balanced and integrated supply chain, focusing on RS, TC, and FLEX, is essential for enhancing resilience and adaptability to disturbance.

Limitations and Future Directions

This work offers significant insights into supply chain resilience; yet, it possesses some shortcomings that future research could rectify. The research was confined to the FMCG sector in Pakistan and Saudi Arabia, perhaps limiting the generalizability of the results. Subsequent research may investigate supply chain resilience in additional sectors and geographies to augment the generalizability of the findings.

A further limitation is the exclusive reliance on system theory and the TOC to examine the interconnections among supply chain components. Subsequent studies may incorporate additional theories, such as network theory or risk management frameworks, to provide a more holistic understanding of resilience dynamics.

This study’s cross-sectional design restricts its capacity to monitor temporal variations in supply chain resilience. Longitudinal research may yield profound insights into the development and adaptation of resilience during and following disturbances, elucidating the enduring impacts of resilience-building techniques. Finally, the research did not investigate the potential influence of future technologies, such as artificial intelligence, machine learning, and blockchain, on improving supply chain resilience. Future research may investigate the interaction between these technologies and conventional supply chain elements, presenting novel options for improving agility and resilience.