Lignocellulosic Biomass Gasification: Perspectives, Challenges, and Methods for Tar Elimination

Abstract

1. Introduction

2. Biomass and Bioenergy

2.1. Lignocellulosic Biomass

2.2. Biomass Conversion Approaches

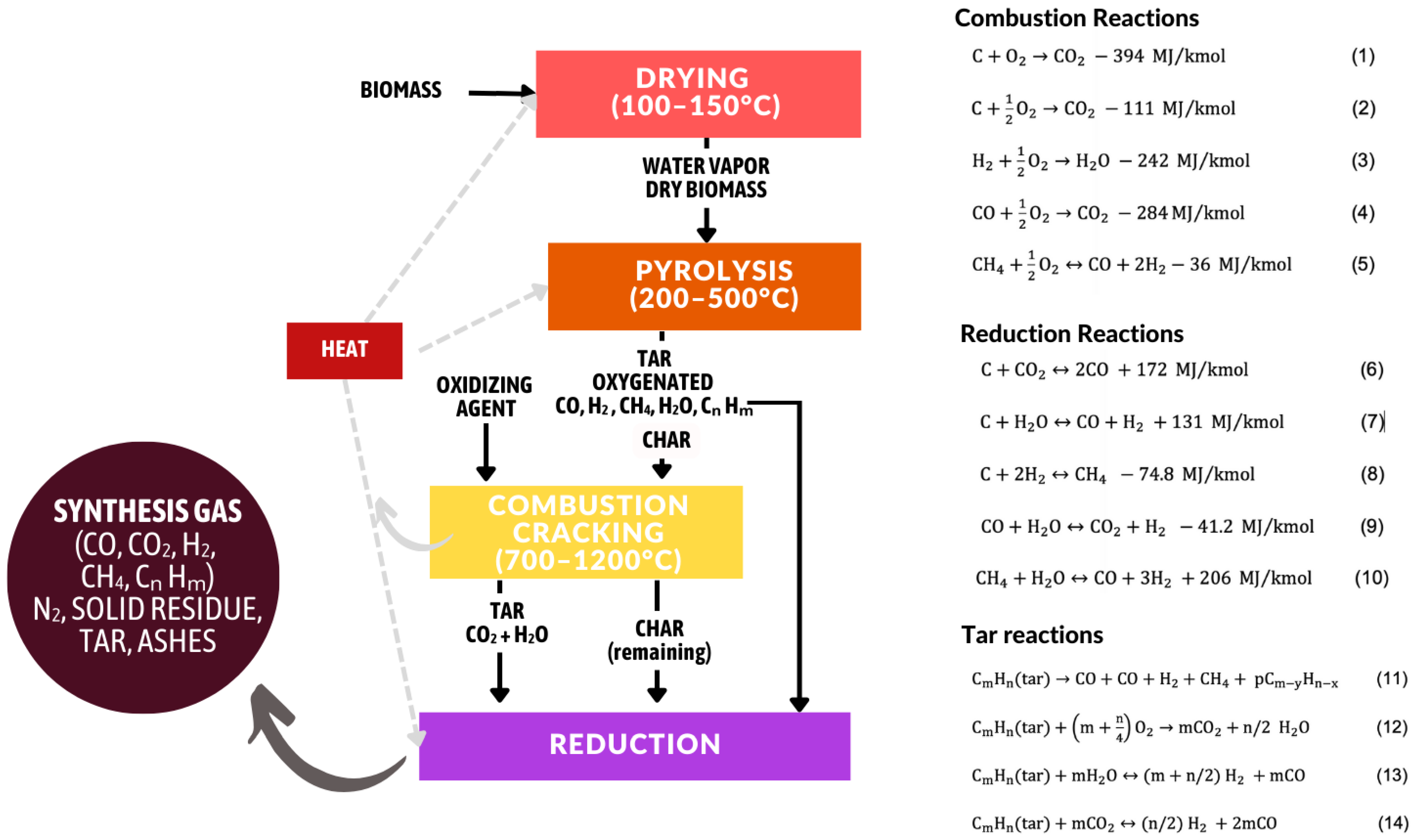

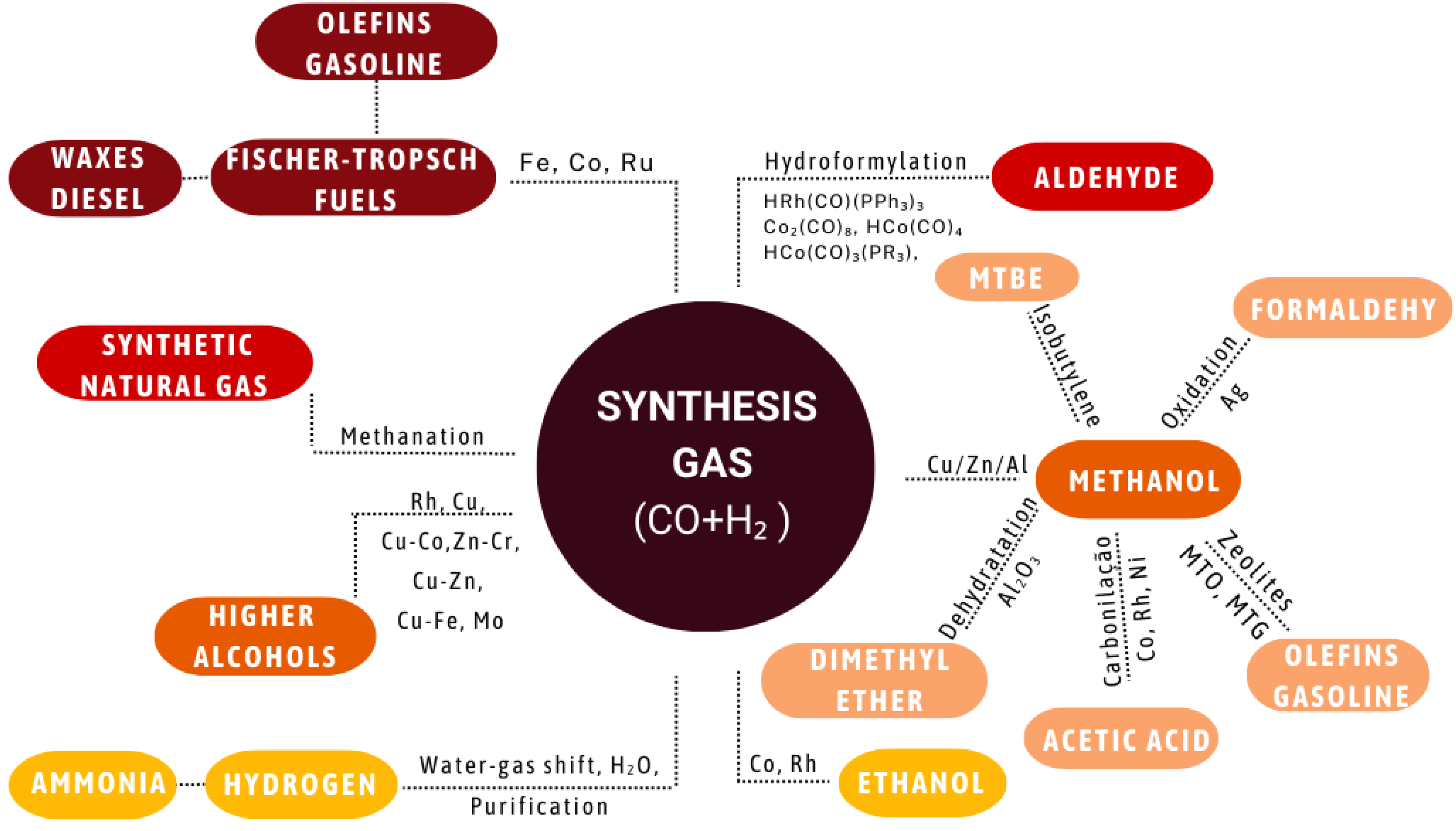

3. Thermochemical Conversion: Gasification

4. Tar Chemistry and Removal Methods

4.1. Tar Classification

4.2. Tar Formation and Evolution from Lignocellulosic Biomass

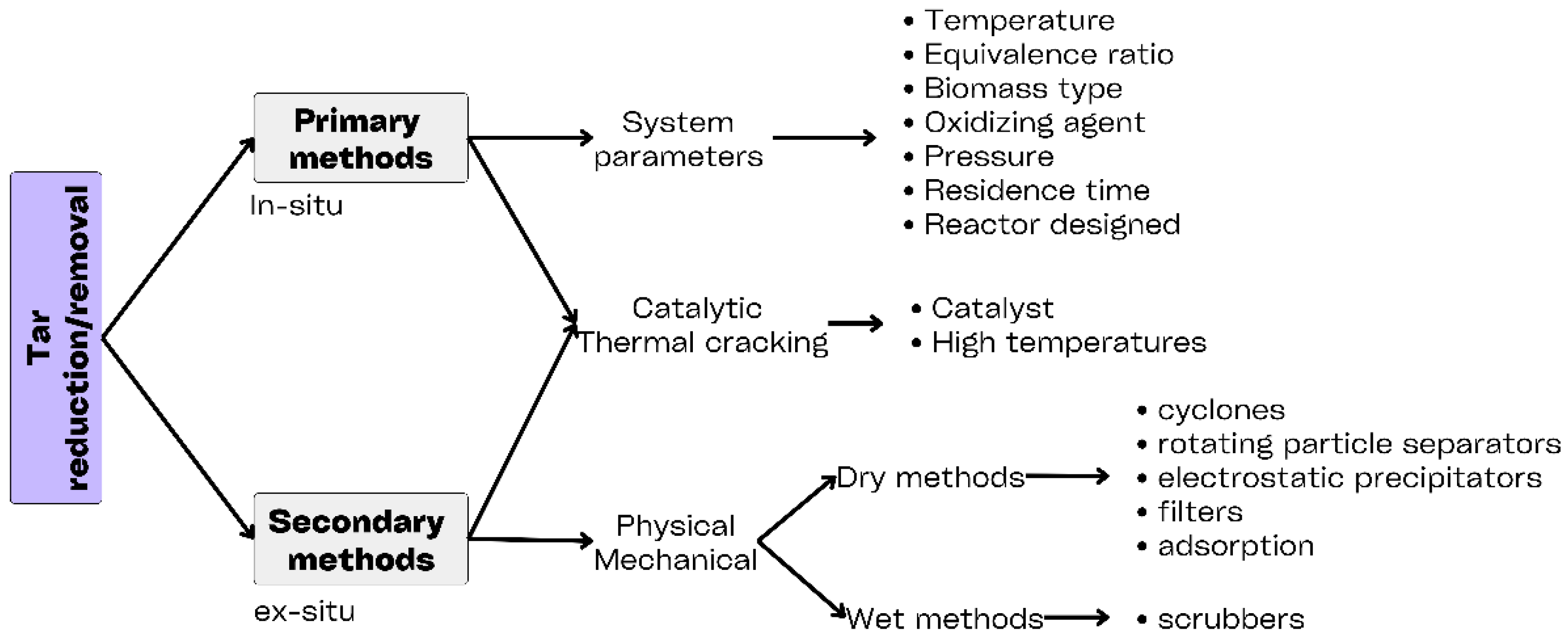

4.3. Tar Destruction and Removal

4.3.1. Biomass Gasification Parameters

Temperature

Oxidizing Agent

Gasifier Design

4.3.2. Thermal Cracking

4.3.3. Gasification Catalyst

Natural Catalyst

Akali and Alkaline Earth

Transition Metals

Zeolites

Carbon-Based Materials

Nanocatalyst

4.3.4. Physical and Mechanical Methods for Tar Removal

4.3.5. Advanced Methods for Tar Removal

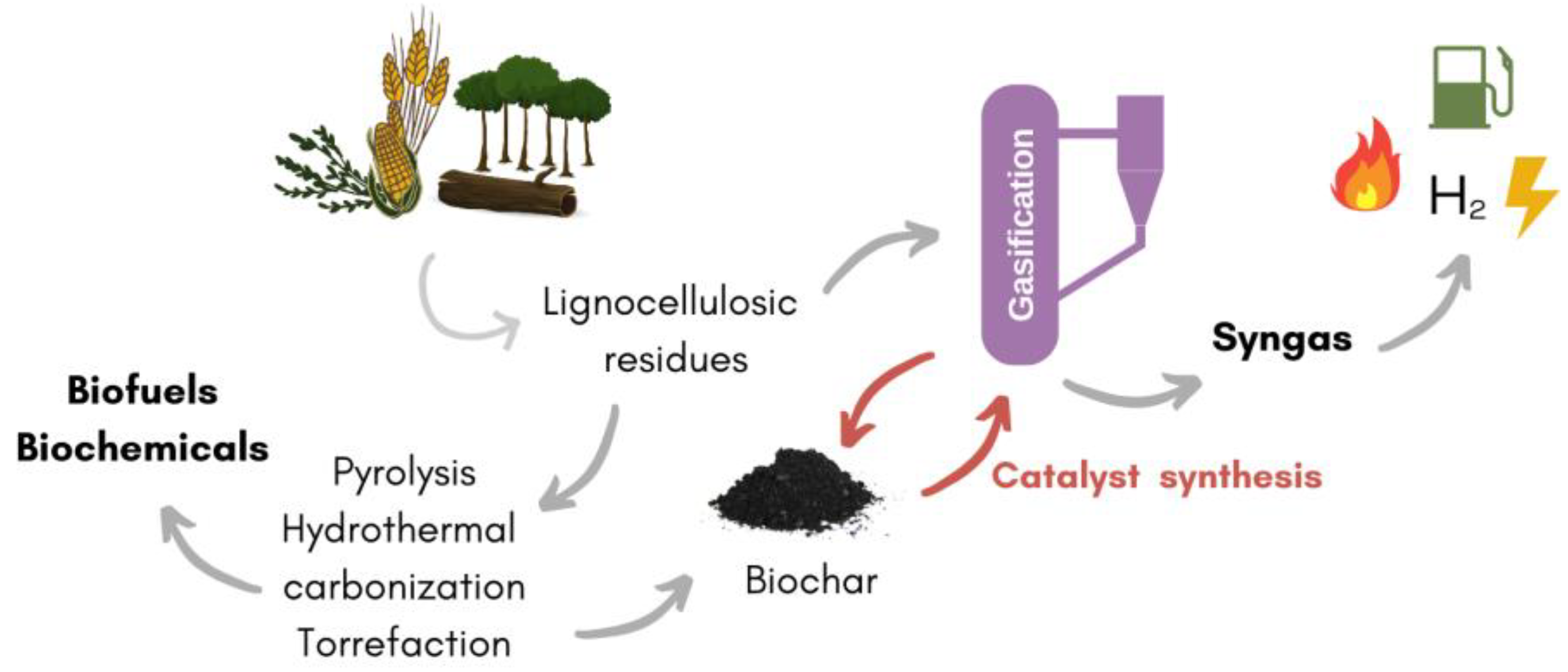

5. Tar Removal in the Path of Circular Economy Approach

5.1. Biochars

5.2. Alternative Materials

6. Conclusions and Prospects

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IPCC. Global Warming of 1.5 °C; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Energy Institute (EI). Energy Institute (EI). Energy Outlook 2024. In Statistical Review of World Energy; EI: London, UK, 2024; pp. 1–53. [Google Scholar]

- REN21. Renewables 2022 Global Status; UN: New York, NY, USA, 2022; ISBN 9783948393045. [Google Scholar]

- Gross, S. The Challenge of Decarbonizing Heavy Industry. Brookings Foreing Policy 2021; pp. 1–28. Available online: https://www.brookings.edu/articles/the-challenge-of-decarbonizing-heavy-industry/ (accessed on 20 January 2024).

- De Dieu Ufitikirezi, J.M.; Filip, M.; Ghorbani, M.; Zoubek, T.; Olšan, P.; Bumbálek, R.; Strob, M.; Bartoš, P.; Umurungi, S.N.; Murindangabo, Y.T.; et al. Agricultural waste valorization: Exploring environmentally friendly approaches to bioenergy conversion. Sustainability 2024, 16, 3617. [Google Scholar] [CrossRef]

- Verma, S.; Dregulo, A.M.; Kumar, V.; Bhargava, P.C.; Khan, N.; Singh, A.; Sun, X.; Sindhu, R.; Binod, P.; Zhang, Z.; et al. Reaction engineering during biomass gasification and conversion to energy. Energy 2023, 266, 126458. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory, 3rd ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 1–564. [Google Scholar] [CrossRef]

- Harb, R.; Rivera-Tinoco, R.; Nemer, M.; Zeghondy, B.; Bouallou, C. Towards synthetic fuels production from biomass gasification: Tar content at low temperatures. Biomass Bioenergy 2020, 137, 105540. [Google Scholar] [CrossRef]

- De Oliveira, D.C.; De Rezende, T.T.G.; Lora, E.E.S.; Venturini, O.J.; Maya, D.M.Y. Tar removal from biomass-derived syngas for hydrogen production: Oil absorption process considering brazilian sources. Int. J. Hydrogen Energy, 2024; in press. [Google Scholar] [CrossRef]

- Murri, A.N.; Papa, E.; Medri, V.; Miccio, F.; Landi, E. Fe/Mn oxide-based foams via geopolymerization process as novel catalysts for tar removal in biomass gasification. J. Eur. Ceram. Soc. 2024, 44, 2560–2570. [Google Scholar] [CrossRef]

- Dou, X.; Yue, J.; Guan, Y.; Liu, W.; Zhang, Y.; Chen, Z.; Luo, G.; Xu, G. Characteristics and kinetics of in-situ catalytic cracking of biomass tar in a micro dual bed reactor. Energy 2024, 306, 132470. [Google Scholar] [CrossRef]

- Bonechi, C.; Consumi, M.; Donati, A.; Leone, G.; Magnani, A.; Tamasi, G.; Rossi, C. Biomass: An Overview; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 9780081010266. [Google Scholar]

- Basu, P. Biomass characteristics. In Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory; Elsevier: Amsterdam, The Netherlands, 2018; pp. 49–91. ISBN 9780128129920. [Google Scholar]

- Bar-On, Y.M.; Phillips, R.; Milo, R. The biomass distribution on earth. Proc. Natl. Acad. Sci. USA 2018, 115, 6506–6511. [Google Scholar] [CrossRef] [PubMed]

- Kumar Gupta, P.; Sai Raghunath, S.; Venkatesh Prasanna, D.; Venkat, P.; Shree, V.; Chithananthan, C.; Choudhary, S.; Surender, K.; Geetha, K. An update on overview of cellulose, its structure and applications. In Cellulose; Intech Open: London, UK, 2019; pp. 1–21. [Google Scholar] [CrossRef]

- Heinze, T.; El Seoud, O.A.; Koschella, A. Structure and Properties of Cellulose and Its Derivatives; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9783319731681. [Google Scholar]

- Nishiyama, Y.; Langan, P.; Wada, M.; Forsyth, V.T. Looking at Hydrogen Bonds in Cellulose. Biol. Crystallogr. 2010, 66, 1172–1177. [Google Scholar] [CrossRef] [PubMed]

- Kammoun, M.; Ayeb, H.; Bettaieb, T.; Richel, A. chemical characterisation and technical assessment of agri-food residues, marine matrices, and wild grasses in the south mediterranean area: A considerable inflow for biorefineries. Waste Manag. 2020, 118, 247–257. [Google Scholar] [CrossRef]

- Lepage, T.; Kammoun, M.; Schmetz, Q.; Richel, A. Biomass-to-hydrogen: A review of main routes production, processes evaluation and techno-economical assessment. Biomass Bioenergy 2021, 144, 105920. [Google Scholar] [CrossRef]

- Gomes de Oliveira Paranhos, A.; Herrera Adarme, O.F.; Fernandes Barreto, G.; de Queiroz Silva, S.; de Aquino, S.F. Methane Production by Co-Digestion of Poultry Manure and Lignocellulosic Biomass: Kinetic and Energy Assessment. Bioresour. Technol. 2020, 300, 122588. [Google Scholar] [CrossRef]

- Raj, T.; Kapoor, M.; Gaur, R.; Christopher, J.; Lamba, B.; Tuli, D.K.; Kumar, R. Physical and chemical characterization of various indian agriculture residues for biofuels production. Energy Fuels 2015, 29, 3111–3118. [Google Scholar] [CrossRef]

- Hatakeyama, H.; Hatakeyama, T. Lignin structure, properties, and applications. Adv. Polym. Sci. 2010, 232, 1–63. [Google Scholar] [CrossRef]

- Mathew, A.K.; Abraham, A.; Mallapureddy, K.K.; Sukumaran, R.K. Lignocellulosic Biorefinery Wastes, or Resources? Elsevier B.V.: Amsterdam, The Netherlands, 2018; ISBN 9780444639929. [Google Scholar]

- Flórez-Pardo, L.M.; González-Córdoba, A.; López-Galán, J.E. characterization of hemicelluloses from leaves and tops of the CC 8475, CC 8592, and V 7151 varieties of sugarcane (Saccharum officinarum L.). Dyna 2019, 86, 98–107. [Google Scholar] [CrossRef]

- Zhou, X.; Li, W.; Mabon, R.; Broadbelt, L.J. A Critical review on hemicellulose pyrolysis. Energy Technol. 2017, 5, 52–79. [Google Scholar] [CrossRef]

- Wang, T.P.; Li, H.; Yuan, J.M.; Li, W.X.; Li, K.; Huang, Y.B.; Xiao, L.P.; Lu, Q. Structures and pyrolytic characteristics of organosolv lignins from typical softwood, hardwood and herbaceous biomass. Ind. Crops Prod. 2021, 171, 113912. [Google Scholar] [CrossRef]

- Zong, P.; Jiang, Y.; Tian, Y.; Li, J.; Yuan, M.; Ji, Y.; Chen, M.; Li, D.; Qiao, Y. Pyrolysis behavior and product distributions of biomass six group components: Starch, cellulose, hemicellulose, lignin, protein and oil. Energy Convers. Manag. 2020, 216, 112777. [Google Scholar] [CrossRef]

- Yeo, J.Y.; Chin, B.L.F.; Tan, J.K.; Loh, Y.S. Comparative studies on the pyrolysis of cellulose, hemicellulose, and lignin based on combined kinetics. J. Energy Inst. 2019, 92, 27–37. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, Z.; Li, Z.; Chen, D. Characteristics of tar formation during cellulose, hemicellulose and lignin gasification. Fuel 2014, 118, 250–256. [Google Scholar] [CrossRef]

- Michailof, C.; Sfetsas, T.; Stefanidis, S.; Kalogiannis, K.; Theodoridis, G.; Lappas, A. Quantitative and qualitative analysis of hemicellulose, cellulose and lignin bio-oils by comprehensive two-dimensional gas chromatography with time-of-flight mass spectrometry. J. Chromatogr. A 2014, 1369, 147–160. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Cen, K.; Zhuang, X.; Gan, Z.; Zhou, J.; Zhang, Y.; Zhang, H. Insight into biomass pyrolysis mechanism based on cellulose, hemicellulose, and lignin: Evolution of volatiles and kinetics, elucidation of reaction pathways, and characterization of gas, biochar and bio-oil. Combust. Flame 2022, 242, 112142. [Google Scholar] [CrossRef]

- Mukarakate, C.; Evans, R.J.; Deutch, S.; Evans, T.; Starace, A.K.; Ten Dam, J.; Watson, M.J.; Magrini, K.; Yu, J.; Paterson, N.; et al. Cellulose, xylan and lignin interactions during pyrolysis of lignocellulosic biomass. Fuel 2017, 191, 3212–3224. [Google Scholar] [CrossRef]

- Ahmad, F.B.; Zhang, Z.; Doherty, W.O.S.; O’Hara, I.M. The outlook of the production of advanced fuels and chemicals from integrated oil palm biomass biorefinery. Renew. Sustain. Energy Rev. 2019, 109, 386–411. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Jagtap, S.S.; Bedekar, A.A.; Bhatia, R.K.; Rajendran, K.; Pugazhendhi, A.; Rao, C.V.; Atabani, A.E.; Kumar, G.; Yang, Y.H. Renewable biohydrogen production from lignocellulosic biomass using fermentation and integration of systems with other energy generation technologies. Sci. Total Environ. 2021, 765, 144429. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Krishna, B.B.; Bhaskar, T.; Perkins, G. Advances in the thermo-chemical production of hydrogen from biomass and residual wastes: Summary of recent techno-economic analyses. Bioresour. Technol. 2020, 299, 122557. [Google Scholar] [CrossRef] [PubMed]

- Garba, A. biomass conversion technologies for bioenergy generation: An introduction. In Biotechnological Applications of Biomass; Basso, T.P., Basso, T.O., Basso, L.C., Eds.; IntechOpen: London, UK, 2020; Volume 1, p. 13. [Google Scholar]

- Razeghi, M.; Hajinezhad, A.; Naseri, A.; Noorollahi, Y.; Moosavian, S.F. An overview of Renew. Energytechnologies for the simultaneous production of high-performance power and heat. Future Energy 2023, 2, 1–11. [Google Scholar] [CrossRef]

- Horvat, I.; Dović, D.; Filipović, P. Numerical and experimental methods in development of the novel biomass combustion system concept for wood and agro pellets. Energy 2021, 231, 120929. [Google Scholar] [CrossRef]

- Abhijeet, P.; Swagathnath, G.; Rangabhashiyam, S.; Asok Rajkumar, M.; Balasubramanian, P. Prediction of pyrolytic product composition and yield for various grass biomass feedstocks. Biomass Convers. Biorefinery 2020, 10, 663–674. [Google Scholar] [CrossRef]

- Hameed, S.; Sharma, A.; Pareek, V.; Wu, H.; Yu, Y. A review on biomass pyrolysis models: Kinetic, network and mechanistic models. Biomass Bioenergy 2019, 123, 104–122. [Google Scholar] [CrossRef]

- Fan, Y.; Cai, Y.; Li, X.; Jiao, L.; Xia, J.; Deng, X. Effects of the cellulose, xylan and lignin constituents on biomass pyrolysis characteristics and bio-oil composition using the simplex lattice mixture design method. Energy Convers. Manag. 2017, 138, 106–118. [Google Scholar] [CrossRef]

- Hwang, J.G.; Choi, M.K.; Choi, D.H.; Choi, H.S. Quality improvement and tar reduction of syngas produced by bio-oil gasification. Energy 2021, 236, 121473. [Google Scholar] [CrossRef]

- Xu, C.C.; Liao, B.; Pang, S.; Nazari, L.; Mahmood, N.; Tushar, M.S.H.K.; Dutta, A.; Ray, M.B. Biomass energy. Compr. Energy Syst. 2018, 1–5, 770–794. [Google Scholar] [CrossRef]

- Nanda, S.; Mohanty, P.; Kozinski, J.A.; Dalai, A.K. Physico-chemical properties of bio-oils from pyrolysis of lignocellulosic biomass with high and slow heating rate. Energy Environ. Res. 2014, 4, 21–32. [Google Scholar] [CrossRef]

- de Caprariis, B.; De Filippis, P.; Petrullo, A.; Scarsella, M. Hydrothermal liquefaction of biomass: Influence of temperature and biomass composition on the bio-oil production. Fuel 2017, 208, 618–625. [Google Scholar] [CrossRef]

- Hognon, C.; Delrue, F.; Texier, J.; Grateau, M.; Thiery, S.; Miller, H.; Roubaud, A. comparison of pyrolysis and hydrothermal liquefaction of chlamydomonas reinhardtii. Growth studies on the recovered hydrothermal aqueous phase. Biomass Bioenergy 2015, 73, 21–31. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, H.; Li, H.; Han, X.; Zhang, M.; Sun, Y.; Fan, X.; Tu, R.; Zeng, Y.; Xu, C.C.; et al. Applications of catalysts in thermochemical conversion of biomass (pyrolysis, hydrothermal liquefaction and gasification): A critical review. Renew. Energy 2022, 196, 462–481. [Google Scholar] [CrossRef]

- Kim, S.H.; Kumar, G.; Chen, W.H.; Khanal, S.K. Renewable hydrogen production from biomass and wastes (ReBioH2-2020). Bioresour. Technol. 2021, 331, 125024. [Google Scholar] [CrossRef]

- Molino, A.; Chianese, S.; Musmarra, D. Biomass gasification technology: The state of the art overview. J. Energy Chem. 2016, 25, 10–25. [Google Scholar] [CrossRef]

- Huang, F.; Jin, S. Investigation of biomass (pine wood) gasification: Experiments and aspen plus simulation. Energy Sci. Eng. 2019, 7, 1178–1187. [Google Scholar] [CrossRef]

- Ferreira, S.; Monteiro, E.; Brito, P.; Vilarinho, C. A holistic review on biomass gasification modified equilibrium models. Energies 2019, 12, 160. [Google Scholar] [CrossRef]

- Trubetskaya, A.; Souihi, N.; Umeki, K. Categorization of tars from fast pyrolysis of pure lignocellulosic compounds at high temperature. Renew. Energy 2019, 141, 751–759. [Google Scholar] [CrossRef]

- Guo, F.; Dong, Y.; Dong, L.; Guo, C. Effect of design and operating parameters on the gasification process of biomass in a downdraft fixed bed: An experimental study. Int. J. Hydrogen Energy 2014, 39, 5625–5633. [Google Scholar] [CrossRef]

- Brequigny, P.; Pacaud, E.; Mounaïm-Rousselle, C. Performances of a producer gas from sewage sludge gasification enriched with ammonia in a spark-ignition engine. Biomass Bioenergy 2023, 171, 106731. [Google Scholar] [CrossRef]

- Zhang, S.; Gu, H.; Qian, J.; Wang, Y.; Wu, Q.; Zhao, H. techno-economic assessment of high-safety and cost-effective syngas produced by O 2 -enriched air gasification with 40–70% O2 purity. Energies 2023, 16, 3414. [Google Scholar] [CrossRef]

- Glushkov, D.; Nyashina, G.; Shvets, A.; Pereira, A.; Ramanathan, A. Current status of the pyrolysis and gasification mechanism of biomass. Energies 2021, 14, 7541. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Fennell, P.S.; Shah, N.; Anthony, E.J. Progress in biofuel production from gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Rakesh, N.; Dasappa, S. A Critical assessment of tar generated during biomass gasification - formation, evaluation, issues and mitigation strategies. Renew. Sustain. Energy Rev. 2018, 91, 1045–1064. [Google Scholar] [CrossRef]

- Ciferno, J.P.; Marano, J.J. Benchmarking Biomass Gasification Technologies for Fuels, Chemicals and Hydrogen Production; U.S. Department of Energy, National Energy Technology Laboratory: Washington, DC, USA, 2002; 58p.

- Valderrama Rios, M.L.; González, A.M.; Lora, E.E.S.; Almazán del olmo, o.a. reduction of tar generated during biomass gasification: A review. Biomass Bioenergy 2018, 108, 345–370. [Google Scholar] [CrossRef]

- Woolcock, P.J.; Brown, R.C. A review of cleaning technologies for biomass-derived syngas. Biomass Bioenergy 2013, 52, 54–84. [Google Scholar] [CrossRef]

- Milne, T.A.; Evans, R.J.; Abatzaglou, N. Biomass Gasifier “Tars”: Their Nature, Formation, and Conversion; National Renewable Energy Laboratory: Golden, CO, USA, 1998.

- Zhou, B.; Dichiara, A.; Zhang, Y.; Zhang, Q.; Zhou, J. Tar formation and evolution during biomass gasification: An experimental and theoretical study. Fuel 2018, 234, 944–953. [Google Scholar] [CrossRef]

- Cerciello, F.; Senneca, O.; Russo, C.; Apicella, B. Comparison of primary volatiles from coal and biomass pyrolysis in N2 and CO2. Energy Fuels 2019, 33, 12822–12829. [Google Scholar] [CrossRef]

- Horvat, A.; Kwapinska, M.; Xue, G.; Rabou, L.P.L.M.L.M.; Pandey, D.S.; Kwapinski, W.; Leahy, J.J. Tars from fluidized bed gasification of raw and torrefied miscanthus x giganteus. Energy Fuels 2016, 30, 5693–5704. [Google Scholar] [CrossRef]

- Yang, K.; Huang, J.; Dong, B.; Liu, P.; Chen, L.; Wang, Z.; Jia, L. Secondary reactions of primary tar from biomass pyrolysis: Characterization of heavy products by FT-ICR MS. Energy Fuels 2021, 35, 13191–13199. [Google Scholar] [CrossRef]

- Nguyen, H.N.T.; Seemann, M.; Thunman, H. Fate of polycyclic aromatic hydrocarbons during tertiary tar formation in steam gasification of biomass. Energy Fuels 2018, 32, 3499–3509. [Google Scholar] [CrossRef]

- Rabou, L.P.L.M.; Zwart, R.W.R.; Vreugdenhil, B.J.; Bos, L. Tar in biomass producer gas, the energy research centre of the Netherlands (ECN) experience: An enduring challenge. Energy Fuels 2009, 23, 6189–6198. [Google Scholar] [CrossRef]

- Pan, Y.; Abulizi, A.; Talifu, D.; Tursun, Y.; Xu, S. Catalytic gasification of biomass and coal blend with Fe2O3/Olivine in a decoupled triple bed. Fuel Process. Technol. 2019, 194, 106121. [Google Scholar] [CrossRef]

- Awais, M.; Li, W.; Munir, A.; Omar, M.M.; Ajmal, M. Experimental investigation of downdraft biomass gasifier fed by sugarcane bagasse and coconut shells. Biomass Convers. Biorefinery 2021, 11, 429–444. [Google Scholar] [CrossRef]

- Yan, B.; Jia, X.; Li, J.; Li, Z.; Che, Y.; Zhou, Z.; Zhao, J.; Zhou, S.; Chen, G. In-situ elimination of biomass gasification tar based on the understanding of tar formation process: A review. J. Energy Inst. 2023, 112. [Google Scholar] [CrossRef]

- Guo, Q.; Qin, Y.; Wang, Y.; Du, Y.; Yuan, M.; He, C.; Wei, Y.; Liu, X. Numerical study on kinetics of tar production and mechanism of benzene formation during corn straw gasification. J. Energy Inst. 2024, 114, 101635. [Google Scholar] [CrossRef]

- Qin, Y.; Campen, A.; Wiltowski, T.; Feng, J.; Li, W. The influence of different chemical compositions in biomass on gasification tar formation. Biomass Bioenergy 2015, 83, 77–84. [Google Scholar] [CrossRef]

- Fu, W.; Zhang, Y.; Cui, L.; Liu, H.; Maqsood, T. Experimental microwave-assisted air gasification of biomass in fluidized bed reactor. Bioresour. Technol. 2023, 369, 128378. [Google Scholar] [CrossRef]

- Billaud, J.; Valin, S.; Peyrot, M.; Salvador, S. Influence of H2O, CO2 and O2 addition on biomass gasification in entrained flow reactor conditions: Experiments and modelling. Fuel 2016, 166, 166–178. [Google Scholar] [CrossRef]

- Tursun, Y.; Xu, S.; Wang, G.; Wang, C.; Xiao, Y. Tar formation during co-gasification of biomass and coal under different gasification condition. J. Anal. Appl. Pyrolysis 2015, 111, 191–199. [Google Scholar] [CrossRef]

- Palma, C.F. Modelling of tar formation and evolution for biomass gasification: A review. Appl. Energy 2013, 111, 129–141. [Google Scholar] [CrossRef]

- Kaiser, R.I.; Zhao, L.; Lu, W.; Ahmed, M.; Zagidullin, M.V.; Azyazov, V.N.; Mebel, A.M. Formation of benzene and naphthalene through cyclopentadienyl-mediated radical–radical reactions. J. Phys. Chem. Lett. 2021, 13, 208–213. [Google Scholar] [CrossRef]

- Surjosatyo, A.; Anggriawan, M.B.; Hermawan, A.A.; Dafiqurrohman, H. Comparison between secondary thermal cracking methods and venturi scrubber filtering in order to reduce tar in biomass gasification. Energy Procedia 2019, 158, 749–754. [Google Scholar] [CrossRef]

- Lotfi, S.; Ma, W.; Austin, K.; Luque, L.; Littlejohns, J.V.; Butler, J. Tar removal from the producer gas of a small scale downdraft gasifier using a fatty acid based, wet packed-bed scrubber. Can. J. Chem. Eng. 2024, 102, 607–621. [Google Scholar] [CrossRef]

- Waluyo, J.; Ruya, P.M.; Hantoko, D.; Rizkiana, J.; Makertihartha, I.; Yan, M.; Susanto, H. Utilization of modified zeolite as catalyst for steam gasification of palm kernel shell. Bull. Chem. React. Eng. Catal. 2021, 16, 623. [Google Scholar] [CrossRef]

- Vecchione, L.; Cossio, F.; Longo, L. Comparison of different systems for tar removal for Renew. Energyderivation from biomass gasification. Contemp. Eng. Sci. 2016, 9, 413–423. [Google Scholar] [CrossRef]

- Yang, H.M.; Liu, J.G.; Zhang, H.; Han, X.X.; Jiang, X.M. Experimental research for biomass steam gasification in a fluidized bed. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 1993–2006. [Google Scholar] [CrossRef]

- Rapagna, S.; Gallucci, K.; Di Marcello, M.; Matt, M.; Foscolo, P.U.; Nacken, M.; Heidenreich, S. Characterisation of tar produced in the gasification of biomass with in situ catalytic reforming. Int. J. Chem. React. Eng. 2010, 8, 2188. [Google Scholar] [CrossRef]

- Udomsirichakorn, J.; Basu, P.; Salam, P.A.; Acharya, B. Effect of CaO on tar reforming to hydrogen-enriched gas with in-process CO2 capture in a bubbling fluidized bed biomass steam gasifier. Int. J. Hydrogen Energy 2013, 38, 14495–14504. [Google Scholar] [CrossRef]

- Di Carlo, A.; Papa, A.A.; Nacken, M. Comparison of novel and commercial catalysts for the steam reforming of tar obtained from biomass gasification. Chem. Eng. Trans. 2024, 109, 115–120. [Google Scholar]

- Liu, S.; Mei, D.; Wang, Y.; Ma, Y.; Tu, X. Plasma reforming of toluene as a model tar compound from biomass gasification: Effect of CO2 and steam. Waste Dispos. Sustain. Energy 2019, 1, 133–141. [Google Scholar] [CrossRef]

- Oni, B.A.; Sanni, S.E.; Tomomewo, O.S.; Ibegbu, A.J. Gasification of egusi melon (citrullus lanatus) shell over a novel Ni/Dolomite/MgO/Γ− Al2O3 catalyst for the production of H2-Rich gas. Process Saf. Environ. Prot. 2024, 183, 446–458. [Google Scholar] [CrossRef]

- Garcia, L.; Cordoba, M.; Dosso, L.; Nardi, F.; Vera, C.; Quiroga, M.; Busto, M.; Badano, J. Catalytic gasification and reforming of residual biomass in a bench scale system with low cost catalysts. ChemPlusChem 2023, 88, e202300376. [Google Scholar] [CrossRef] [PubMed]

- Cerón, A.L.; Konist, A.; Lees, H.; Järvik, O. Effect of Woody Biomass Gasification Process Conditions on the Composition of the Producer Gas. Sustainability 2021, 13, 11763. [Google Scholar] [CrossRef]

- Briesemeister, L.; Kremling, M.; Fendt, S.; Spliethoff, H. Air-blown entrained-flow gasification of biomass: Influence of operating conditions on tar generation. Energy Fuels 2017, 31, 10924–10932. [Google Scholar] [CrossRef]

- Diyoke, C.; Gao, N.; Aneke, M.; Wang, M.; Wu, C. Modelling of down-draft gasification of biomass – an integrated pyrolysis, combustion and reduction process. Appl. Therm. Eng. 2018, 142, 444–456. [Google Scholar] [CrossRef]

- Gai, C.; Dong, Y. Experimental study on non-woody biomass gasification in a downdraft gasifier. Int. J. Hydrogen Energy 2012, 37, 4935–4944. [Google Scholar] [CrossRef]

- Liu, W.; Tian, Y.; Yan, H.; Zhou, X.; Tan, Y.; Yang, Y.; Li, Z.; Yuan, L. Gasification of biomass using oxygen-enriched air as gasification agent: A simulation study. Biomass Convers. Biorefinery 2021, 13, 15993–16000. [Google Scholar] [CrossRef]

- Zhao, J.; Xie, D.; Wang, S.; Zhang, R.; Wu, Z.; Meng, H.; Chen, L.; Wang, T.; Guo, Y. Hydrogen-rich syngas produced from co-gasification of municipal solid waste and wheat straw in an oxygen-enriched air fluidized bed. Int. J. Hydrogen Energy 2021, 46, 18051–18063. [Google Scholar] [CrossRef]

- Hernández, J.J.; Aranda, G.; Barba, J.; Mendoza, J.M. Effect of steam content in the air–steam flow on biomass entrained flow gasification. Fuel Process. Technol. 2012, 99, 43–55. [Google Scholar] [CrossRef]

- Cerone, N.; Zimbardi, F.; Contuzzi, L.; Prestipino, M.; Carnevale, M.O.; Valerio, V. Air-steam and oxy-steam gasification of hydrolytic residues from biorefinery. Fuel Process. Technol. 2017, 167, 451–461. [Google Scholar] [CrossRef]

- Nakyai, T.; Authayanun, S.; Patcharavorachot, Y.; Arpornwichanop, A.; Assabumrungrat, S.; Saebea, D. Exergoeconomics of hydrogen production from biomass air-steam gasification with methane co-feeding. Energy Convers. Manag. 2017, 140, 228–239. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, Q.; Wang, Y.; Guo, P.; Wang, Z.; Liu, H.; Akbari, A. Investigation of biomass gasification potential in syngas production: Characteristics of dried biomass gasification using steam as the gasification agent. Energy Fuels 2019, 34, 1033–1040. [Google Scholar] [CrossRef]

- Mayerhofer, M.; Mitsakis, P.; Meng, X.; de Jong, W.; Spliethoff, H.; Gaderer, M. Influence of pressure, temperature and steam on tar and gas in allothermal fluidized bed gasification. Fuel 2012, 99, 204–209. [Google Scholar] [CrossRef]

- Tian, Y.; Zhou, X.; Lin, S.; Ji, X.; Bai, J.; Xu, M. Syngas production from air-steam gasification of biomass with natural catalysts. Sci. Total Environ. 2018, 645, 518–523. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.W. Effect of different gasifying agents (Steam, H2O2, Oxygen, CO2, and Air) on gasification parameters. Int. J. Hydrogen Energy 2020, 45, 31760–31774. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, M.; Raheem, A.; Wang, F.; Wei, J.; Xu, D.; Song, X.; Bao, W.; Huang, A.; Zhang, S. Syngas production from biomass gasification: Influences of feedstock properties, reactor type, and reaction parameters. ACS Omega 2023, 8, 31620–31631. [Google Scholar] [CrossRef]

- Sookramoon, K. Syngas from Updraft Gasifier Incineration for Internal Combustion Engine Power Generation in Klongluang PathumThani Thailand. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Bandung, Indonesia, 2018; Volume 187, p. 3002. [Google Scholar]

- Cerinski, D.; Ferreiro, A.I.; Baleta, J.; Costa, M.; Zimbardi, F.; Cerone, N.; Wang, J. Modelling the biomass updraft gasification process using the combination of a pyrolysis kinetic model and a thermodynamic equilibrium model. Energy Rep. 2021, 7, 8051–8061. [Google Scholar] [CrossRef]

- Silva, I.P.; Lima, R.M.A.A.; Silva, G.F.; Ruzene, D.S.; Silva, D.P. Thermodynamic equilibrium model based on stoichiometric method for biomass gasification: A review of model modifications. Renew. Sustain. Energy Rev. 2019, 114, 109305. [Google Scholar] [CrossRef]

- Susastriawan, A.A.P.; Saptoadi, H. Purnomo small-scale downdraft gasifiers for biomass gasification: A review. Renew. Sustain. Energy Rev. 2017, 76, 989–1003. [Google Scholar] [CrossRef]

- Nguyen, N.M.; Alobaid, F.; May, J.; Peters, J.; Epple, B. Experimental Study on steam gasification of torrefied woodchips in a bubbling fluidized bed reactor. Energy 2020, 202, 117744. [Google Scholar] [CrossRef]

- Hanchate, N.; Ramani, S.; Mathpati, C.S.; Dalvi, V.H. Biomass gasification using dual fluidized bed gasification systems: A review. J. Clean. Prod. 2021, 280, 123148. [Google Scholar] [CrossRef]

- Parrillo, F.; Ardolino, F.; Calì, G.; Marotto, D.; Pettinau, A.; Arena, U. Fluidized bed gasification of eucalyptus chips: Axial profiles of syngas composition in a pilot scale reactor. Energy 2021, 219, 119604. [Google Scholar] [CrossRef]

- Chutichai, B.; Patcharavorachot, Y.; Assabumrungrat, S.; Arpornwichanop, A. Parametric analysis of a circulating fluidized bed biomass gasifier for hydrogen production. Energy 2015, 82, 406–413. [Google Scholar] [CrossRef]

- Kraft, S.; Kuba, M.; Hofbauer, H. The behavior of biomass and char particles in a dual fluidized bed gasification system. Powder Technol. 2018, 338, 887–897. [Google Scholar] [CrossRef]

- Kremling, M.; Briesemeister, L.; Gaderer, M.; Fendt, S.; Spliethoff, H. Oxygen-blown entrained flow gasification of biomass: Impact of fuel parameters and oxygen stoichiometric ratio. Energy Fuels 2017, 31, 3949–3959. [Google Scholar] [CrossRef]

- Meng, J.; Wang, X.; Zhao, Z.; Zheng, A.; Huang, Z.; Wei, G.; Lv, K.; Li, H. Highly abrasion resistant thermally fused olivine as in-situ catalysts for tar reduction in a circulating fluidized bed biomass gasifier. Bioresour. Technol. 2018, 268, 212–220. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Liao, Y.; Liu, G.; Ma, X. Syngas production by chemical looping gasification of biomass with steam and CaO additive. Int. J. Hydrogen Energy 2018, 43, 19375–19383. [Google Scholar] [CrossRef]

- Khajeh, A.; Masoumi, S.; Wang, L.; Shahbazi, A. Effects of various carbon-supported iron catalysts on tar removal efficiency and syngas yield during catalytic biomass gasification. J. Environ. Chem. Eng. 2023, 11, 110884. [Google Scholar] [CrossRef]

- Kumar, A. experimental investigation of a dual stage ignition biomass downdraft gasifier for deriving the engine quality gas. Ain Shams Eng. J. 2023, 14, 101912. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, L.; Zhang, M.; Han, Z.; Jia, X.; Bai, D.; Duo, W.; Bi, X.; Abudula, A.; Guan, G. A Two-stage circulated fluidized bed process to minimize tar generation of biomass gasification for fuel gas production. Appl. Energy 2022, 323, 119639. [Google Scholar] [CrossRef]

- Khan, M.J.; Al-attab, K.A.; Wai, C.K. New Annular steam-biomass reactor design for hydrogen-enriched producer gas production. Renew. Energy 2023, 214, 154–167. [Google Scholar] [CrossRef]

- Rahman, M.D.M.; Henriksen, U.B.; Ahrenfeldt, J.; Arnavat, M.P. Design, construction and operation of a low-tar biomass (LTB) gasifier for power applications. Energy 2020, 204, 117944. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, F.; Sun, Y.; Zhang, J.; Tang, S.; Xu, G. Characteristics of tar abatement by thermal cracking and char catalytic reforming in a fluidized bed two-stage reactor. Fuel 2018, 231, 18–25. [Google Scholar] [CrossRef]

- Zhai, M.; Wang, X.; Zhang, Y.; Dong, P.; Qi, G.; Huang, Y. Characteristics of rice husk tar secondary thermal cracking. Energy 2015, 93, 1321–1327. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, L.; Shen, B.; Wu, C. Preparation, modification and development of ni-based catalysts for catalytic reforming of tar produced from biomass gasification. Renew. Sustain. Energy Rev. 2018, 94, 1086–1109. [Google Scholar] [CrossRef]

- Narnaware, S.L.; Panwar, N.L. Catalysts and Their Role in Biomass Gasification and Tar Abetment: A Review; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 0123456789. [Google Scholar]

- Hu, D.; Zeng, X.; Wang, F.; Adamu, M.H.; Xu, G.; Haruna Adamu, M.; Xu, G. Comparison of tar thermal cracking and catalytic reforming by char in a micro fluidized bed reaction analyzer. Fuel 2021, 290, 120038. [Google Scholar] [CrossRef]

- Wang, J.; Kang, D.; Shen, B.; Sun, H.; Wu, C. Enhanced hydrogen production from catalytic biomass gasification with in-situ CO2 capture. Environ. Pollut. 2020, 267, 115487. [Google Scholar] [CrossRef] [PubMed]

- Soomro, A.; Chen, S.; Ma, S.; Xiang, W. Catalytic activities of nickel, dolomite, and olivine for tar removal and H2-enriched gas production in biomass gasification process. Energy Environ. 2018, 29, 839–867. [Google Scholar] [CrossRef]

- Al-Obaidi, M.M.A.; Ishak, N.S.; Ali, S.; Arifin, N.A.; Raja Shahruzzaman, R.M.H.; Wan Abdul Karim Ghani, W.A.; Yun Hin, T.-Y.; Shamsuddin, A.H.; Shafizah, I.N.; Salmiaton, A.; et al. H2-rich and tar-free downstream gasification reaction of EFB by using the malaysian dolomite as a secondary catalyst. Catalysts 2021, 11, 447. [Google Scholar] [CrossRef]

- Cao, Y.; Bai, Y.; Du, J. Air-gasification of pine sawdust using dolomite as in-bed material: Effects of gasification conditions on product characteristics. J. Energy Inst. 2021, 95, 187–192. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, H.; Wang, J.; Wu, B. Catalytic gasification characteristics of rice husk with calcined dolomite. Energy 2018, 165, 1173–1177. [Google Scholar] [CrossRef]

- Cortazar, M.; Santamaria, L.; Lopez, G.; Alvarez, J.; Amutio, M.; Bilbao, J.; Olazar, M. Fe/Olivine as primary catalyst in the biomass steam gasification in a fountain confined spouted bed reactor. J. Ind. Eng. Chem. 2021, 99, 364–379. [Google Scholar] [CrossRef]

- Tuomi, S.; Kaisalo, N.; Simell, P.; Kurkela, E. Effect of pressure on tar decomposition activity of different bed materials in biomass gasification conditions. Fuel 2015, 158, 293–305. [Google Scholar] [CrossRef]

- Soomro, A.; Chen, S.; Ma, S.; Xu, C.; Sun, Z.; Xiang, W. Elucidation of syngas composition from catalytic steam gasification of lignin, cellulose, actual and simulated biomasses. Biomass Bioenergy 2018, 115, 210–222. [Google Scholar] [CrossRef]

- Li, B.; Magoua Mbeugang, C.F.; Xie, X.; Wei, J.; Zhang, S.; Zhang, L.; El Samahy, A.A.; Xu, D.; Wang, Q.; Zhang, S.; et al. Catalysis/CO2 sorption enhanced pyrolysis-gasification of biomass for H2-rich gas production: Effects of activated carbon, NiO Active component and calcined dolomite. Fuel 2023, 334, 126842. [Google Scholar] [CrossRef]

- Zhou, L.; Yang, Z.; Tang, A.; Huang, H.; Wei, D.; Yu, E.; Lu, W. Steam-gasification of biomass with CaO as catalyst for hydrogen-rich syngas production. J. Energy Inst. 2019, 92, 1641–1646. [Google Scholar] [CrossRef]

- Xu, G.; Yang, P.; Yang, S.; Wang, H.; Fang, B. Non-natural catalysts for catalytic tar conversion in biomass gasification technology. Int. J. Hydrogen Energy 2022, 47, 7638–7665. [Google Scholar] [CrossRef]

- Vivanpatarakij, S.; Rulerk, D.; Assabumrungrat, S. Removal of tar from biomass gasification process by steam reforming over nickel catalysts. Chem. Eng. Trans. 2014, 37, 205–210. [Google Scholar]

- Wu, Y.; Liu, S.; Chen, Y.; Yang, Y.; Yang, H. Alkali and alkaline earth metals catalytic steam gasification of ashless lignin: Influence of the catalyst type and loading amount. Fuel 2024, 356, 129549. [Google Scholar] [CrossRef]

- Jiang, L.; Hu, S.; Wang, Y.; Su, S.; Sun, L.; Xu, B.; He, L.; Xiang, J. Catalytic effects of inherent alkali and alkaline earth metallic species on steam gasification of biomass. Int. J. Hydrogen Energy 2015, 40, 15460–15469. [Google Scholar] [CrossRef]

- Yuan, H.; Wu, S.; Yin, X.; Huang, Y.; Guo, D.; Wu, C. Adjustment of biomass product gas to raise H2/CO ratio and remove tar over sodium titanate catalysts. Renew. Energy 2018, 115, 288–298. [Google Scholar] [CrossRef]

- Yip, K.; Tian, F.; Hayashi, J.; Wu, H. Effect of alkali and alkaline earth metallic species on biochar reactivity and syngas compositions during steam gasification. Energy Fuels 2010, 24, 173–181. [Google Scholar] [CrossRef]

- Bach-Oller, A.; Furusjö, E.; Umeki, K. On the role of potassium as a tar and soot inhibitor in biomass gasification. Appl. Energy 2019, 254, 113488. [Google Scholar] [CrossRef]

- Berguerand, N.; Berdugo Vilches, T. Alkali-feldspar as a catalyst for biomass gasification in a 2-MW indirect gasifier. Energy Fuels 2017, 31, 1583–1592. [Google Scholar] [CrossRef]

- Lysne, A.; Saxrud, I.; Snidaro, R.L.G.; Blekkan, E.A. Noble metal (Pt, Pd and Rh) promoted Ni-Co/Mg (Al) O catalysts for steam reforming of tar impurities from biomass gasification. J. Catal. 2024, 436, 115567. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, J.; Ye, L.; Li, S.; Su, Y.; Zhang, H. Investigation into biochar supported Fe-Mo carbides catalysts for efficient biomass gasification tar cracking. Chem. Eng. J. 2023, 454, 140072. [Google Scholar] [CrossRef]

- Tian, Y.; Ma, X.; Chen, X.; Zhang, C. Effect of Ni-Co bimetallic core-shell catalyst for coke resistance in CO2 reforming of biomass tar. J. Anal. Appl. Pyrolysis 2022, 164, 105539. [Google Scholar] [CrossRef]

- Tian, B.; Mao, S.; Guo, F.; Bai, J.; Shu, R.; Qian, L.; Liu, Q. Monolithic biochar-supported cobalt-based catalysts with high-activity and superior-stability for biomass tar reforming. Energy 2022, 242, 122970. [Google Scholar] [CrossRef]

- Cheng, L.; Wu, Z.; Zhang, Z.; Guo, C.; Ellis, N.; Bi, X.; Paul Watkinson, A.; Grace, J.R.; Watkinson, A.P.; Grace, J.R. Tar elimination from biomass gasification syngas with bauxite residue derived catalysts and gasification char. Appl. Energy 2020, 258, 114088. [Google Scholar] [CrossRef]

- Shen, Y.; Zhao, P.; Shao, Q.; Ma, D.; Takahashi, F.; Yoshikawa, K. In-Situ catalytic conversion of tar using rice husk char-supported nickel-iron catalysts for biomass pyrolysis/gasification. Appl. Catal. B Environ. 2014, 152, 140–151. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, H.; Chao, H.; Chen, D. A Novel nickel catalyst supported on activated steel slags for syngas production and tar removal from biomass pyrolysis. Int. J. Hydrogen Energy 2021, 46, 37268–37280. [Google Scholar] [CrossRef]

- Acevedo-Paez, J.C.; Arenas-Castiblanco, E.; Posso, F.; Alarcón, E.; Villa, A.L.; Jahromi, H.; Adhikari, S. Effect of calcium and potassium on activity of mordenite-supported nickel catalyst for hydrogen production from biomass gasification. Int. J. Hydrogen Energy 2024, 52, 1248–1262. [Google Scholar] [CrossRef]

- Huang, S.; Xu, H.; Li, H.; Guo, Y.; Sun, Z.; Du, Y.; Li, H.; Zhang, J.; Pang, R.; Dong, Q. Preparation and characterization of char supported nicu nanoalloy catalyst for biomass tar cracking together with syngas-rich gas production. Fuel Process. Technol. 2021, 218, 106858. [Google Scholar] [CrossRef]

- Hossain, M.Z.; Chowdhury, M.B.I.; Charpentier, P.A. Effect of surface acidity of al2o3 supported metal catalysts on catalytic activity and carbon deposition during scwg of glucose. Biomass Bioenergy 2019, 124, 142–150. [Google Scholar] [CrossRef]

- Zhang, D.; Wei, W.; Lu, L.; Jin, H.; Guo, L. Variation of pore structure in zhundong coal particle with stepped K2CO3 loading during supercritical water gasification. Fuel 2021, 305, 121457. [Google Scholar] [CrossRef]

- Mazumder, J.; De Lasa, H. Fluidizable Ni/La2O3-ΓAl2O3 Catalyst for steam gasification of a cellulosic biomass surrogate. Appl. Catal. B Environ. 2014, 160–161, 67–79. [Google Scholar] [CrossRef]

- Ravenni, G.; Elhami, O.H.; Ahrenfeldt, J.; Henriksen, U.B.; Neubauer, Y. Adsorption and Decomposition of Tar Model Compounds over the Surface of Gasification Char and Active Carbon within the Temperature Range 250–800 °C. Appl. Energy 2019, 241, 139–151. [Google Scholar] [CrossRef]

- Claude, V.; Mahy, J.G.; Tilkin, R.G.; Lambert, S.D. Enhancement of the catalytic performances and lifetime of Ni/γ-Al2O3 catalysts for the steam toluene reforming via the combination of dopants: Inspection of Cu, Co, Fe, Mn, and Mo species addition. Mater. Today Chem. 2020, 15, 100229. [Google Scholar] [CrossRef]

- Santamaria, L.; Artetxe, M.; Lopez, G.; Cortazar, M.; Amutio, M.; Bilbao, J.; Olazar, M. Effect of CeO2 and MgO promoters on the performance of a Ni/Al2O3 catalyst in the steam reforming of biomass pyrolysis volatiles. Fuel Process. Technol. 2020, 198, 106223. [Google Scholar] [CrossRef]

- Tang, W.; Cao, J.; He, Z.; Jiang, W.; Wang, Z.; Zhao, X. Recent progress of catalysts for reforming of biomass Tar/Tar models at low temperatures–A short review. ChemCatChem 2023, 15, e202300581. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, H.; Xiong, Q.; Di, Y.; Yin, L.; Zuo, W.; Tian, Y. Biomass-derived bimetallic Ni-Fe catalyst with enhanced tar removal performance. SSRN Electron. J. 2022, 4050293. [Google Scholar] [CrossRef]

- Tamošiūnas, A.; Gimžauskaitė, D.; Aikas, M.; Uscila, R.; Snapkauskienė, V.; Zakarauskas, K.; Praspaliauskas, M. Biomass Gasification to Syngas in Thermal Water Vapor Arc Discharge Plasma. Biomass Convers. Biorefinery 2023, 13, 16373–16384. [Google Scholar] [CrossRef]

- Ruivo, L.C.M.; Pio, D.T.; Yaremchenko, A.A.; Tarelho, L.A.C.; Frade, J.R.; Kantarelis, E.; Engvall, K. Iron-Based Catalyst (Fe2-XNixTiO5) for Tar Decomposition in Biomass Gasification. Fuel 2021, 300, 120859. [Google Scholar] [CrossRef]

- El-Rub, Z.A.; Halawa, D.; Alqudah, I.; Nasr, A.; Naqvi, M. Natural Zeolite Catalyst for Tar Removal in Biomass Gasification Systems: Kinetics and Effectiveness Evaluation. Fuel 2023, 346, 128393. [Google Scholar] [CrossRef]

- Awais, M.; Li, W.; Arshad, A.; Haydar, Z.; Yaqoob, N.; Hussain, S. Evaluating Removal of Tar Contents in Syngas Produced from Downdraft Biomass Gasification System. Int. J. Green Energy 2018, 15, 724–731. [Google Scholar] [CrossRef]

- Yang, H.; Ye, C.; Wang, J.; Jin, H.; Zhang, J.; Wang, X.; Dong, C.; Li, G.; Tang, Y.; Luo, G. Mechanism Study of Toluene Removal Using Iron/Nickel Bimetallic Catalysts Supported on Biochar. Sci. Total Environ. 2024, 925, 171732. [Google Scholar] [CrossRef] [PubMed]

- Fuentes-Cano, D.; von Berg, L.; Diéguez-Alonso, A.; Scharler, R.; Gómez-Barea, A.; Anca-Couce, A. Tar Conversion of Biomass Syngas in a Downstream Char Bed. Fuel Process. Technol. 2020, 199, 106271. [Google Scholar] [CrossRef]

- Cortazar, M.; Santamaria, L.; Lopez, G.; Alvarez, J.; Zhang, L.; Wang, R.; Bi, X.; Olazar, M. A Comprehensive Review of Primary Strategies for Tar Removal in Biomass Gasification. Energy Convers. Manag. 2023, 276, 116496. [Google Scholar] [CrossRef]

- Numberi, J.J.; Tambing, E.; Siregar, S.P.; Setiawan, R.P.A.; Tambunan, A.H.; Siregar, K. Evaluating the Application of Bubble Wet Scrubber Systems for Gas Cleaning in Gasification. Instrum. Mes. Metrol. 2023, 22, 21. [Google Scholar]

- Mussatti, D.; Hemmer, P. Wet Scrubbers for Particulate Matter. In EPA Air Pollution Control Cost Manual, 6th ed.; EPA: Washington, DC, USA, 2002; 6p. [Google Scholar]

- Sultan, S.H.; Palamanit, A.; Techato, K.; Amin, M.; Ahmed, K.; Asadullah, A. Syngas Production from Rubberwood Biomass in Downdraft Gasifier Combined with Wet Scrubbing: Investigation of Tar and Solid Residue. Sains Malays. 2020, 49, 1729–1743. [Google Scholar] [CrossRef]

- Unyaphan, S.; Tarnpradab, T.; Takahashi, F.; Yoshikawa, K. Effect of Emulsified Absorbent for Tar Removal in Biomass Gasification Process. Biofuels 2016, 7, 233–243. [Google Scholar] [CrossRef]

- Calì, G.; Deiana, P.; Bassano, C.; Meloni, S.; Maggio, E.; Mascia, M.; Pettinau, A. Syngas Production, Clean-up and Wastewater Management in a Demo-Scale Fixed-Bed Updraft Biomass Gasification Unit. Energies 2020, 13, 2594. [Google Scholar] [CrossRef]

- Peck, D.; Holmes, W.; Zappi, M.; Hernandez, R.; Gang, D.; Buchireddy, P. Novel Nickel Ceramic Filter for Hot Gas Cleanup of Tars from Syngas. Fuel Process. Technol. 2023, 244, 107708. [Google Scholar] [CrossRef]

- Papa, A.A.; Savuto, E.; Di Carlo, A.; Tacconi, A.; Rapagnà, S. Synergic Effects of Bed Materials and Catalytic Filter Candle for the Conversion of Tar during Biomass Steam Gasification. Energies 2023, 16, 595. [Google Scholar] [CrossRef]

- Shen, Y. Chars as Carbonaceous Adsorbents/Catalysts for Tar Elimination during Biomass Pyrolysis or Gasification. Renew. Sustain. Energy Rev. 2015, 43, 281–295. [Google Scholar] [CrossRef]

- Singh, S.; Bhaumik, S.K.; Dong, L.; Vuthaluru, H. Enhanced Tar Removal in Syngas Cleaning through Integrated Steam Catalytic Tar Reforming and Adsorption Using Biochar. Fuel 2023, 331, 125912. [Google Scholar] [CrossRef]

- Paethanom, A.; Nakahara, S.; Kobayashi, M.; Prawisudha, P.; Yoshikawa, K. Performance of Tar Removal by Absorption and Adsorption for Biomass Gasification. Fuel Process. Technol. 2012, 104, 144–154. [Google Scholar] [CrossRef]

- Guo, F.; Liang, S.; Jia, X.; Peng, K.; Jiang, X.; Qian, L. One-Step Synthesis of Biochar-Supported Potassium-Iron Catalyst for Catalytic Cracking of Biomass Pyrolysis Tar. Int. J. Hydrogen Energy. 2020, 45, 16398–16408. [Google Scholar] [CrossRef]

- Zhang, W.; Fang, Y.; Qian, S.; Chen, Y.; Li, X.; Liu, N. Biomass Gasification to Syngas of Phosphogypsum as Gasification Agent: Thermogravimetric Analysis and Gasification Performance. Fuel 2025, 385, 134065. [Google Scholar] [CrossRef]

- Gao, N.; Milandile, M.H.; Quan, C.; Rundong, L. Critical Assessment of Plasma Tar Reforming during Biomass Gasification: A Review on Advancement in Plasma Technology. J. Hazard. Mater. 2022, 421, 126764. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Dai, D.; Lu, Y.; Chen, J.; Mei, D.; Fang, Z.; Tu, X. Tailoring Performance for Biomass Tar Reforming Using Magnetically Assisted Gliding Arc Discharges. Chem. Eng. J. 2024, 498, 155364. [Google Scholar] [CrossRef]

- Cimerman, R.; Račková, D.; Hensel, K. Tars Removal by Non-Thermal Plasma and Plasma Catalysis. J. Phys. D Appl. Phys. 2018, 51, 274003. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, R.; Zhou, R.; Zou, J.; Long, Y.; Zhang, Y.; Gao, L.; Yan, J.; Li, X.; Huang, Q. Plasma-Catalytic Reforming of Complex Tar over Ni-Cu Bimetallic Catalysts. Renew. Energy 2024, 240, 122258. [Google Scholar] [CrossRef]

- Pan, W.; Meng, J.; Gu, T.; Zhang, Q.; Zhang, J.; Wang, X.; Bu, C.; Liu, C.; Xie, H.; Piao, G. Plasma-Catalytic Steam Reforming of Benzene as a Tar Model Compound over Ni-HAP and Ni-ΓAl2O3 Catalysts: Insights into the Importance of Steam and Catalyst Support. Fuel 2023, 339, 127327. [Google Scholar] [CrossRef]

- Xu, B.; Xie, J.; Wang, N.; Huang, Y.; Liu, H.; Yin, X.; Wu, C.; Tu, X. Plasma-Enabled Catalytic Steam Reforming of Toluene as a Biomass Tar Surrogate: Understanding the Synergistic Effect of Plasma Catalysis. Chem. Eng. J. 2023, 464, 142696. [Google Scholar] [CrossRef]

- Chen, H.; Meng, J.; Tang, J.; Wang, X.; Liu, Y.; Bu, C.; Zhang, J.; Liu, C.; Xie, H.; Piao, G. Overcoming Carbon Deposition in Non-Thermal Plasma Catalyzed Biomass Tar Reforming: Innovative Strategies Employed by GPPC Systems. Fuel 2025, 381, 133649. [Google Scholar] [CrossRef]

- Catizzone, E.; Freda, C.; Villone, A.; Romanelli, A.; Cornacchia, G. Gasification of Olive Tree Pruning in a Rotary Kiln Reactor Integrated with Radio Frequency Plasma Torch. Fuel 2025, 381, 133480. [Google Scholar] [CrossRef]

- Saleem, F.; Rehman, A.; Hussain, H.; Saeed, A.; Farooq, M.; Zhang, K.; Harvey, A. Biomass Gasification Tar Removal Using Dielectric Barrier Discharge Reactor: Effect of Reactor Geometry and Carrier Gases. J. Energy Inst. 2024, 117, 101776. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, L.; Deng, W.; Ge, Y.; Wang, H.; Li, X. Catalytic Gasification of Rice Hull by Dielectric Barrier Discharge Non-Thermal Plasma over Potassium Catalyst. Int. J. Hydrogen Energy 2023, 48, 6947–6958. [Google Scholar] [CrossRef]

- Saleem, F.; Khoja, A.H.; Sharif, R.; Rehman, A.; Naqvi, S.R.; Qazi, U.Y.; Zhang, K.; Harvey, A. Synergistic Effect of Plasma Power and Temperature on the Cracking of Toluene in the N2 Based Product Gas. Heliyon 2023, 9, e14237. [Google Scholar] [CrossRef]

- Mei, D.; Liu, S.; Yanik, J.; Lopez, G.; Olazar, M.; Fang, Z.; Tu, X. Plasma-Catalytic Reforming of Naphthalene and Toluene as Biomass Tar over Honeycomb Catalysts in a Gliding Arc Reactor. ACS Sustain. Chem. Eng. 2022, 10, 8958–8969. [Google Scholar] [CrossRef]

- Guo, F.; Jia, X.; Liang, S.; Zhou, N.; Chen, P.; Ruan, R. Development of Biochar-Based Nanocatalysts for Tar Cracking/Reforming during Biomass Pyrolysis and Gasification. Bioresour. Technol. 2020, 298, 122263. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Ye, C.; Ye, Z.; Zhu, Z.; Wang, Q.; Tang, Y.; Luo, G.; Guo, W.; Dong, C.; Li, G.; et al. Catalytic Cracking and Catalyst Deactivation/Regeneration Characteristics of Fe-Loaded Biochar Catalysts for Tar Model Compound. Fuel 2023, 334, 126810. [Google Scholar] [CrossRef]

- Muzyka, R.; Misztal, E.; Hrabak, J.; Banks, S.W.; Sajdak, M. Various Biomass Pyrolysis Conditions Influence the Porosity and Pore Size Distribution of Biochar. Energy 2023, 263, 126128. [Google Scholar] [CrossRef]

- Dieguez-Alonso, A.; Vu-Han, T.L.E.; Almuina-Villar, H.; Fuentes, J.J.R.; Hilfert, L.; Dernbecher, A.; de la Rosa, J.M.; Behrendt, F. Tailored Production and Application of Biochar for Tar Removal. Fuel 2023, 348, 128306. [Google Scholar] [CrossRef]

- Magoua Mbeugang, C.F.; Mahmood, F.; Ali, M.; Tang, J.; Li, B. H2-Rich Syngas Production and Tar Removal over Biochar-Supported Ni-Fe Bimetallic Catalysts during Catalytic Pyrolysis-Gasification of Biomass. Renew. Energy 2025, 243, 122547. [Google Scholar] [CrossRef]

- Bhandari, R.; Trudewind, C.A.; Zapp, P. Life Cycle Assessment of Hydrogen Production via Electrolysis—A Review. J. Clean. Prod. 2014, 85, 151–163. [Google Scholar] [CrossRef]

- Abdelaal, A.; Villot, A.; Patuzzi, F.; Baratieri, M.; Gerente, C. Steam Reforming of Main Tar Compounds over Industrial Gasification Char. Fuel 2025, 384, 133986. [Google Scholar] [CrossRef]

- Bai, J.; He, Z.; Yang, L.; Wei, X.; Hu, J.; Li, P.; Yan, Z.; Chen, Z.; Chang, C. Preparation and Characterization of Furfural Residue Derived Char-Based Catalysts for Biomass Tar Cracking. Waste Manag. 2024, 179, 182–191. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.; Shafique, O.; Mahmood, S.; Mahmood, T.; Khan, B.A.; Ahmad, I. Biofuels Production from Weed Biomass Using Nanocatalyst Technology. Biomass Bioenergy 2020, 139, 105595. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, Y.; Zhao, Y.; Sun, S.; Wu, J.; Tan, H. Mechanism of In-Situ Dynamic Catalysis and Selective Deactivation of H2O-Activated Biochar for Biomass Tar Reforming. Fuel 2020, 279, 118450. [Google Scholar] [CrossRef]

- Han, L.; Wu, Y.; Rong, N.; Ma, K.; Wu, P.; Qi, Z.; Ding, H.; Zhao, J.; Xin, C. Biomass Calcium Looping Gasification via Cement-Modified Carbide Slag in Fluidized Bed: An Examination on Enhanced Multi-Cycle CO2 Capture and Hydrogen Production. Biomass Convers. Biorefinery 2024, 14, 20485–20497. [Google Scholar] [CrossRef]

- Niu, Y.-H.; Chi, Z.-Y.; Wang, Z.-Q.; Yang, M.; Han, F.-T. Mechanistic Analysis of Hydrogen-Rich Co-Gasification of Pine Wood and Polypropylene-Based Waste Masks Using Fe/Dol Catalyst. J. Energy Inst. 2024, 117, 101801. [Google Scholar] [CrossRef]

- Sui, M.; Li, G.Y.; Guan, Y.L.; Li, C.M.; Zhou, R.Q.; Zarnegar, A.M. Hydrogen and Syngas Production from Steam Gasification of Biomass Using Cement as Catalyst. Biomass Convers. Biorefinery 2020, 10, 119–124. [Google Scholar] [CrossRef]

- Parrillo, F.; Ardolino, F.; Boccia, C.; Arconati, V.; Ruoppolo, G.; Arena, U. Waste-Derived Catalysts for Tar Cracking in Hot Syngas Cleaning. Waste Manag. 2024, 179, 163–174. [Google Scholar] [CrossRef]

- Abedin, A.; Bai, X.; Muley, P. Microwave-Assisted Catalytic Gasification of Mixed Plastics and Corn Stover for Low Tar, Hydrogen-Rich Syngas Production. Int. J. Hydrogen Energy 2024, 77, 69–83. [Google Scholar] [CrossRef]

| Destination 1 | GT | FT | Methanol | IC | BH2 |

|---|---|---|---|---|---|

| Compounds | |||||

| Tar (mg/Nm3) | <0.5 | <0.1 | <1 | <100 | Low |

| Sulfur (ppmv) | <20 | 0.01 | <1 4 | Low | |

| Nitrogen (ppmv) | <50 | 0.02 | 0.1 4 | Low | |

| Alkali (ppmv) | <0.02 | 0.01 | <10 5 | Low | |

| Halogens (ppmv) | <1 | 0.01 | 0.1 | Low | |

| Particulate 6 (mg/Nm3) | <30 | <0.02 | <0.02 | <50 | Low |

| H2/CO | NR 2 | 2 | 2 | NR | High |

| CO2 | NC 3 | Low | Low | NC | NR |

| N2 | NC | Low | Low | NC | Low |

| CH4 | High | Low | Low | High | Low |

| Sample | Process | Cleaning/Removal Method | Tar (g/Nm3) BC/AF Efficiency | Ref |

|---|---|---|---|---|

| Spruce wood | Air gasification Downdraft reactor T: 850 °C | Cyclone and packed bed filled with pine chips | 1.6–1.4 12.5% | [80] |

| Pine 8% moisture | Cyclone and packed bed filled with pine chips | 3.9–2.5 35% | ||

| Pine chips | Wet packed bed scrubber using chips as the packing material and waste cooking oil as the media | 1.4–0.3 78.5% | ||

| Palm kernel shell | Steam gasification T 750 °C S/B: 2.25 | In situ catalyst zeolite | 0.7 98% | [81] |

| T: 850 °C S/B: 2.25 | 0.12 | |||

| T: 750 °C S/B: 1.5 | In situ catalyst zeolite acid leaching | 4.6–1.9 57% | ||

| In situ catalyst zeolite impregnation 5% Ni | 4.6–3.5 23.9% | |||

| Corylus avellana shells syngas | Fluidized bed reactor | Steam reforming 5% Ni-mayenite at 700 °C | 27.7–8.17 69% | [82] |

| Steam reforming 5% Ni-mayenite at 800 °C | 27.7–4.1 86% | |||

| Scrubber with food waste oil as a fluid absorber | 18.4 33% | |||

| Scrubber with food water as a fluid absorber | 9.3 67% | |||

| Cotton stalk | Steam gasification Fluidized bed reactor T: 600 °C S/B: 0.9 | Olivine as bed material | 452.07 | [83] |

| T: 800 °C S/B: 0.9 | Olivine as bed material | 19.7 | ||

| T: 700 °C S/B: 0.9 | Olivine as bed material | 52.14–39.2 24% (compared to quartz sand) | ||

| T: 700 °C S/B: 0.9 | Dolomite as bed material | 52.14–31.34 39% (compared to quartz sand) | ||

| Crushed almond shells | Steam gasification Bubbling fluidized bed reactor T: 830 °C S/B: 0.9 | In situ catalytic ceramic filter candle with olivine as bed | 0.72 | [84] |

| T: 830 °C S/B: 1.4 | 0.92 | |||

| T: 830 °C S/B: 0.9 | In situ commercial filter candle olivine as bed | 1.9 | ||

| Pine wood sawdust | Air/Steam gasification Bubbling fluidized bed reactor T: 610 °C S/B: 3.41 | In situ limestone calcinated at 900 °C as bed materials | 83 | [85] |

| T: 650 °C S/B: 3.41 | 26.7 | |||

| T: 700 °C S/B: 3.41 | 8 | |||

| T: 610 °C S/B: 3.41 | In situ silica sand and limestone calcinated at 900 °C as bed materials | 62 | ||

| Naphthalene, toluene, and thiophene | Steam reforming laboratory-scale packed bed reactor T: 700 °C | Catalyst 31% NiO-40% MgO-30% Al2O3 | 100% | [86] |

| T: 750 °C | ||||

| T: 800 °C | ||||

| T: 700 °C | Commercial Ni-catalyst | 13–4.11 70% | ||

| T: 750 °C | 13–2.74 80% | |||

| T: 800 °C | 13–1.09 92% | |||

| Toluene | Gliding arc discharge reactor | Plasma reforming 3% CO2 | 16.1–6.1 62% | [87] |

| Plasma reforming 9% CO2 | 16.1–6.6 59% | |||

| Egusi melon shell | Air/steam gasification Fixed bed reactor T: 700 °C S/B: 1 | 0.2wt% Ni/dolomite/MgO /Al2O3 dolomite calcinated at 850 °C | 32–17 47% | [88] |

| T: 800 °C S/B: 1 | 32–16 50% | |||

| T: 900 °C S/B: 1 | 32–15 54% | |||

| T: 1000 °C S/B: 1 | 32–14 57% | |||

| Pine sawdust and bituminous coal | Steam gasification Decoupled triple-bed gasification T: 850 °C S/B: 1.3 | In situ olivine calcinated at 900 °C | 25.35–5.87 76% (compared to quartz) | [69] |

| In situ olivine calcinated at 900 °C 5wt% Fe2O3/olivine | 25.35–4.87 80% (compared to quartz) | |||

| Sugarcane bagasse | Air/steam gasification Downdraft T: 843 °C ER: 0.3 S/B: 0.24 | Cyclone separator | 4.4–1.7 60% | [70] |

| Wet scrubber | 1.7–0.75 54.2% | |||

| Biomass filter | 0.75–0.3 56% | |||

| Auxiliary filter | 0.3–0.2 45.7% | |||

| Pine sawdust | Catalyst Reforming Fixed-bed downstream T: 650 °C ER: 0.35 | Pyrolysis char | 43.9–9.3 | [89] |

| Natural dolomite | 43.9–11 | |||

| NiMo/Al | 43.9–11.8 | |||

| Fe/activated carbon | 43.9–16 | |||

| T: 750 °C ER: 0.45 | Pyrolysis char | 28.8–12.1 | ||

| Natural dolomite | 28.8–11.7 | |||

| NiMo/Al | 28.8–1 | |||

| Fe/activated carbon | 28.8–11.4 | |||

| T: 750 °C ER: 0.45 S/B: 0.006 | Pyrolysis char | 15.9–3.4 | ||

| Natural dolomite | 15.9–4.8 | |||

| NiMo/Al | 15.9–5.2 | |||

| Fe/activated carbon | 15.9–0.6 |

| Sample | Catalyst | Operational Conditions | Tar Conv. (%) | Tar Yield (g/Nm3) | Ref. |

|---|---|---|---|---|---|

| Pine sawdust tar | Pine sawdust char | Fluidized bed reactor Downstream 750 °C | 65.7 | [125] | |

| 950 °C | 79.1 | ||||

| Empty fruit bunch | Malaysian dolomite | Fixed bed reactor Downstream 900 °C | 94–99% | [128] | |

| Pine sawdust | 10 wt% dolomite Calcined at 900 °C | Air gasification Fluidized bed reactor 700 °C | ~9.5 | [129] | |

| 10 wt% Calcined at 900 °C | 850 °C | ~6.5 | |||

| 50 wt% dolomite Calcined at 900 °C | 850 °C | 4.6 | |||

| Rice husk | Dolomite Calcinated at 830 °C | Air gasification Fluidized bed reactor 950 °C | 1.8 | [130] | |

| Raw dolomite | 950 °C | 4.1 | |||

| Cotton stalk | Olivine | Steam Fluidized bed reactor 600 °C | 452.07 | [83] | |

| 800 °C | 19.72 | ||||

| 700 °C | 39.2 | ||||

| Dolomite | 700 °C | 31.3 | |||

| Bark pellets | Dolomite | Air/steam Fluidized bed reactor 850 °C | 87 | 0.48 | [132] |

| Olivine B/kaolin | 54 | 1.67 | |||

| MgO | 83 | 0.63 | |||

| Pine sawdust | Olivine | Fluidized bed reactor Air 850 °C | 4.49 | [114] | |

| Olivine calcinated at 900 °C | 2.14 | ||||

| Olivine calcinated at 1000 °C | 1.98 | ||||

| 5% Ni-Fe/olivine calcinated at 1100 °C | 0.83 | ||||

| 5% Ni-Fe/olivine calcinated at 1400 °C | 0.77 | ||||

| Wood sawdust | 4Na2O·5TiO2/char | Reforming Fixed bed reactor 850 °C | 99.6 | 0.93 | [140] |

| Na2O·3TiO2 char | 96 | 3.2 | |||

| Toluene | Co/biochar | Steam reformer Fixed bed reactor | 62–70 | [147] | |

| Co-Ni/biochar | 95–97 | ||||

| Co-Fe/biochar | 80–90 | ||||

| Pinewood tar | Co-Ni/biochar | Steam reforming Fixed bed reactor 700 °C | 91 | [147] | |

| Naphthalene | Reduced bauxite residue | Fixed bed reactor Steam reforming | 55–90 | [148] | |

| HCl-activated bauxite residue | 55–97 | ||||

| Gasification biochar | 50–85 | ||||

| Biochar-activated bauxite residue | 95 | ||||

| Rice husk tar | Ni-Fe-char | Reforming 800 °C Air | 92.3 | [149] | |

| Aspen wood sawdust | Ni/char | Two-staged fixed bed reactor 700 °C | 93 | [152] | |

| Char | 42 | ||||

| Fe/char | 82.6 | ||||

| Biochar | 55 | ||||

| Cu/ biochar | 65 | ||||

| Ni/ biochar | 80 | ||||

| 0.5Ni-Cu/ biochar | 82 | ||||

| Ni-Cu/ biochar | 90 | ||||

| Ni-0.5Cu/biochar | 87 | ||||

| Toluene | 10 wt% Ni/γ-Al2O3 dopped 2wt% Mo | 650 °C | 55 | [164] | |

| 10 wt% Ni/γ-Al2O3 dopped 2 wt% Mn | 38 | ||||

| 10 wt% Ni/γ-Al2O3 | 50 | ||||

| Toluene | 2.5% Fe-2.5% Ni/calcinated biochar | Catalytic cracking 800 °C | 92.7 | [165] | |

| 5% Fe/calcinated biochar | 88.5 | ||||

| 5% Ni/calcinated biochar | 89.4 | ||||

| Biomass-derived tar | 5% Ni-Fe-Ti | 900 °C | 84.6 | [162] | |

| 10% Ni-Fe-Ti | 99 | ||||

| Toluene | Natural zeolite | 800 °C | 63 | [163] | |

| 900 °C | 79 | ||||

| Spruce wood pellets | Biochar | 875 °C Fluidized bed Steam downstream operation | 64–70 | [166] |

| Plasma Technology | Objective of the Study | Findings | Ref. |

|---|---|---|---|

| Graded post-plasma | Thermal plasma biomass tar reforming using Ni-Fe supported with hydroxyapatite as catalyst | Benzene conversion of 84.8% at the discharge power of 100 W | [186] |

| Radio frequency plasma torch | Gasification of olive tree pruning in a rotary kiln reactor integrated with plasma torch | Integration of plasma decreased the benzene/toluene content from 8.3 g/Nm3 to 2.2 g/Nm3 | [187] |

| Dielectric barrier discharge | Decomposition of toluene using 30 mm and 15 mm in length external electrodes at ambient temperature | Toluene decomposition >97% for 40 W of input power | [188] |

| Dielectric barrier discharge | Steam reforming of toluene in plasma reactor combined with Ni/γ-Al2O3 catalysts | Toluene conversion of 87.1%, total gas yield of 72.6%, and an energy efficiency of 18.2 g/kWh at 450 °C | [185] |

| Direct current thermal arc plasma | Wood pellet gasification in plasma torch using vapor as a main gasifying agent and a plasma-forming gas | Producer gas composed of H2 (43.86 vol.%) and CO (30.93 vol.%), H2/CO ratio of 1.42 and LHV of 10.23 MJ/Nm3 The tar content was in the range of 9.937 to 13.81 g/Nm3 | [161] |

| Dielectric barrier discharge | Catalytic gasification of rice hull by plasma over potassium catalyst | Gasification efficiency of 96.51% in the atmosphere of CO2 No tar was formed during gasification | [189] |

| Dielectric barrier discharge | Cracking of the toluene into C1–C6 hydrocarbons | Toluene removal efficiency of 92.8–98.4% using 10–40 W input power | [190] |

| Gliding arc discharge | Plasma reforming of biomass gasification tar coupled with honeycomb catalysts | Toluene and naphthalene conversion of 86.3% and 75.5% using honeycomb material coated with Ni/γ-Al2O3 | [191] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santana, H.E.P.; Jesus, M.; Santos, J.; Rodrigues, A.C.; Pires, P.; Ruzene, D.S.; Silva, I.P.; Silva, D.P. Lignocellulosic Biomass Gasification: Perspectives, Challenges, and Methods for Tar Elimination. Sustainability 2025, 17, 1888. https://doi.org/10.3390/su17051888

Santana HEP, Jesus M, Santos J, Rodrigues AC, Pires P, Ruzene DS, Silva IP, Silva DP. Lignocellulosic Biomass Gasification: Perspectives, Challenges, and Methods for Tar Elimination. Sustainability. 2025; 17(5):1888. https://doi.org/10.3390/su17051888

Chicago/Turabian StyleSantana, Hortência E. P., Meirielly Jesus, Joana Santos, Ana Cristina Rodrigues, Preciosa Pires, Denise S. Ruzene, Isabelly P. Silva, and Daniel P. Silva. 2025. "Lignocellulosic Biomass Gasification: Perspectives, Challenges, and Methods for Tar Elimination" Sustainability 17, no. 5: 1888. https://doi.org/10.3390/su17051888

APA StyleSantana, H. E. P., Jesus, M., Santos, J., Rodrigues, A. C., Pires, P., Ruzene, D. S., Silva, I. P., & Silva, D. P. (2025). Lignocellulosic Biomass Gasification: Perspectives, Challenges, and Methods for Tar Elimination. Sustainability, 17(5), 1888. https://doi.org/10.3390/su17051888