1. Introduction

In an effort to address the global energy security issue and decrease reliance on fossil fuels, there is a global transition towards renewable energy systems [

1]. The utilization of solar energy in electricity generation has emerged as a compelling choice among many renewable energy technologies in recent years [

2]. In 2021, solar energy accounted for 28% (849 GW) of the global renewable energy capacity, which totaled 3064 GW [

3]. The main driver for the substantial installation capacity is the affordable cost of solar PV, which has had a considerable decline over the years. As a result, the use of solar PV has become less expensive than fossil fuel in some countries [

4] The global market for solar PV is primarily dominated by two technologies: crystalline silicon (c-Si) modules, which account for 95% of global output, and cadmium telluride (CdTe) thin-film PV technology, which makes up the remaining 5% [

5]. The typical longevity of these panels is from 20 to 30 years [

6].

As PV deployment increases, the number of modules reaching the EOL will also rise due to decreased efficiency over time. This decrease in efficiency leads to decreased electricity production until it reaches 80% of the total production capacity. When this level is reached, the solar panel cannot keep up with operating costs, resulting in its EOL and being considered a waste [

7]. Although manufacturers offer a guarantee for the 20–30 years lifespan of PV modules, waste can still be generated before the EOL period due to manufacturing defects, poor design, extreme weather conditions, corroded electrical units, changes in manufacturer metal color, transportation and installation defects, and other operational conditions [

7,

8,

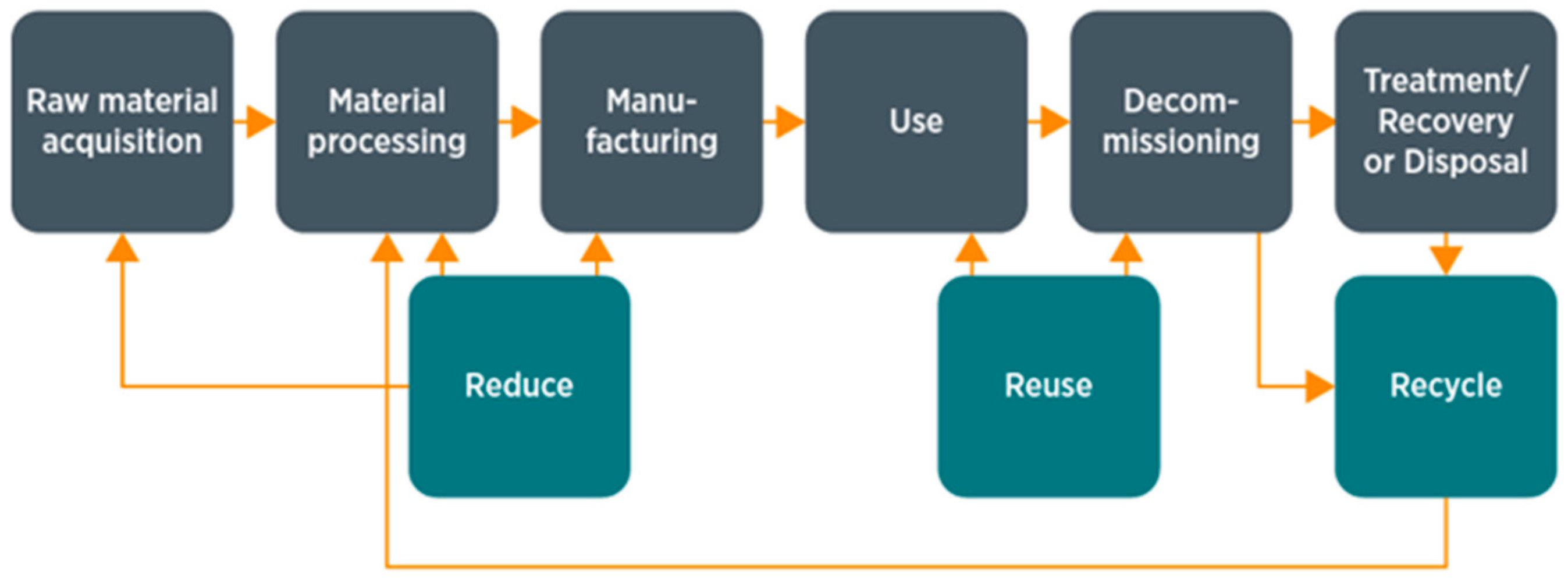

9]. From this, different waste management approaches have been developed for managing the EOL of solar panels, starting with raw material extraction and ending with disposal or recycling, reuse, and recovery of material, as illustrated in

Figure 1.

Thus, due to the involvement of several parties in the EOL management process for solar PV panels, it is important to understand how to effectively manage the EOL of those panels. This understanding is necessary for making better decisions for EOL that can minimize any unwanted consequences on the life cycle of PV panels [

11]. The available alternatives for EOL PV waste include disposal, recycling, reuse, and recovery. However, given the diversity of drivers and stakeholders, a comprehensive decision-making strategy is necessary to assess the EOL strategies from several viewpoints, such as economic, environmental, sociological, technological, regulatory, and business perspectives [

12,

13]. Therefore, this research seeks to comprehend the decision-making environment from various stakeholder viewpoints by examining their decision options according to different criteria. This study aims to employ a multi-decision-making approach to prioritize decisions and thereafter apply the results to formulate a policy proposal for EOL management of solar PV.

The objective of this research is to develop a comprehensive, holistic decision-making framework for the end-of-life (EOL) management of solar photovoltaic (PV) modules. This framework aims to incorporate the perspectives of various stakeholders, evaluate all possible alternatives, and address the multi-faceted nature of the decision-making environment to ensure sustainable and efficient EOL strategies. The following research questions will be addressed:

What are the key factors influencing the decision-making process for the EOL management of solar PV modules?

How do the perspectives of different stakeholders impact the overall decision-making environment for solar PV EOL strategies?

What are the current gaps in the literature regarding holistic decision-making for the EOL disposition of solar PV modules?

What are the most sustainable and efficient EOL strategies for solar PV modules based on a comprehensive evaluation of all possible alternatives?

This research aims to fill the existing gap in the literature by providing a comprehensive approach to EOL decision-making for solar PV systems, ultimately contributing to more sustainable and effective management practices.

2. Literature Review

2.1. Alternatives Disposition Strategies for Solar Panels at End-of-Life

In 2016, photovoltaic (PV) waste was estimated at 250,000 tons, but it is projected to surge to 78 million tons by 2050, creating significant economic and environmental challenges [

14,

15,

16]. The term “end of life” refers to a product’s disposal at the end of its useful life, which can be managed through reuse, minor repairs, or recycling [

17]. Decisions for PV panel disposal at EOL can be divided into three main categories: landfill disposal, recycling, or reuse/recovery for similar or other applications [

18]. Disposal to landfill is a common practice due to its simplicity and affordability compared to expensive recycling processes [

19,

20]. It occurs when decision-makers decide there is no longer value in reusing or recycling waste material and should only occur as a last resort when other options are no longer available [

21].

Recycling solar panels involves various techniques, such as mechanical removal of the aluminum frame and junction box, thermal, chemical, or mechanical treatment of delaminate or encapsulant material (EVA), and recovery of some material. Mechanical recycling of a C-SI panel can recover almost 80% of the material, while a combination of mechanical and thermal treatment can result in a 96% recovery rate. However, toxic gases can be released during thermal treatment, requiring careful treatment. On the other hand, reuse/recovery of wasted solar panels is a popular choice in waste management, but it requires repair. Repaired C-SI panels can have a new guarantee and a lifetime of 15 years, but their efficiency and performance may be lower than the original product. The issue with panel reuse is that it will eventually reach EOL. Therefore, it’s not solving the problem entirely but delaying it for some time [

20].

2.2. Disposition Decision Factors

The EOL phase of solar PV modules poses a complex decision-making challenge, driven by multiple factors that require careful consideration to guarantee sustainable and efficient management. With the increasing use of solar energy systems, it is becoming more and more important to manage the PV EOL. Various key factors significantly influence these decisions, including environmental, economic, regulatory, technical, and social factors. This section offers a comprehensive examination of those factors, providing valuable insights into their influence on the decision-making process for PV EOL. By comprehending and incorporating all of these factors, relevant stakeholders may create comprehensive plans that not only reduce the negative effects on the environment but also maximize economic results and comply with regulations, thereby guaranteeing a sustainable lifecycle for solar PV technology.

2.2.1. Technical-Related Factors

From a technological perspective, several aspects impact the decision-making process for managing the EOL of solar panels. Solar panels capture solar energy and transform it into electricity using the photovoltaic effect in the semiconductor material of the panels. Solar panels are classified into three generations based on the materials used in their production: crystalline silicon (monocrystalline or multicrystalline), thin film (including amorphous silicon, cadmium telluride (CdTe), and copper indium gallium selenide (CIGS)), and concentrator photovoltaics. Additionally, emerging technologies, such as organic solar panels, hybrid panels, and dye-sensitized solar panels, are gaining attention for their potential applications [

14]. The material composition differs across various photovoltaic technologies [

22]. Each form of PV technology has a different material content and composition, leading to a diversity in PV module technology [

23]. Furthermore, the design of solar panels has a substantial impact on their EOL management. Certain components of photovoltaic panels can be readily extracted, while others have more difficulty. The recyclability of the modules is an issue because of the variations in PV technologies, which affect their structure, size, characteristics, and weight [

24]. As solar panel designs progress, the amount of waste produced will vary over time. As a result, the proportion and quantity of materials that are recovered or recycled will also differ, which makes it challenging to implement a uniform EOL management approach. Moreover, the amount of waste produced can have a significant impact on decision-making results, especially in relation to investment and government regulations [

25].

2.2.2. Environment-Related Factors

Environmental factors are linked to the influence on the environment, policies related to the environment, as well as concerns and knowledge regarding the environment. Disposing of end-of-life PV panels in landfills can lead to the loss of valuable conventional materials such as glass and aluminum, as well as rare metals including silver, indium, gallium, and germanium [

15]. The main environmental concern in this context is the ability to recover and reuse conventional materials instead of just disposing of them in a landfill. Furthermore, the limited availability of the material comprises only around 1% of the panel volume. Despite their high value, these materials have extremely low recycling rates. Consequently, the inability to retrieve and reuse them might result in significant losses for manufacturers and the industry [

26].

In addition to material recovery challenges, the environmental impact of end-of-life PV panels also includes significant carbon emissions associated with their disposal or recycling processes. For instance, improper handling of panels can contribute to greenhouse gas emissions during landfill decomposition or inefficient recycling operations. Hence, incorporating strategies to minimize carbon footprints is essential for sustainable PV end-of-life management [

27,

28].

In addition, the release of toxic metals such as cadmium (Cd) and lead (Pb) through leaching when the photovoltaic (PV) glass is fractured or damaged can be harmful to wildlife and fish and can result in respiratory, kidney, and bone damage in humans. On the other hand, incorrect disposal of solar panels results in the release of harmful substances, such as hydrofluoric acid, into the environment. Furthermore, it has the potential to emit toxic elements such as cadmium, lead, tellurium, and selenium into the nearby environment [

26].

2.2.3. Economic-Related Factors

Factors related to economic conditions are frequently mentioned as crucial considerations for making effective disposition decisions [

21]. Investing in the construction of PV treatment facilities and infrastructures is a highly profitable alternative for managing significant quantities of PV waste. Recycling PV panels at the end of their life can release a significant amount of raw materials and valuable substances that can be reintroduced into the economy. This process enhances the future availability of natural resources and strengthens resource security [

22]. According to statistics, if the waste panel is processed appropriately, it is predicted that 90% of the initial investment cost for the raw material will be recovered from crystalline silicon PV modules [

29].

In addition to the high global demand for raw materials, the limited availability of the original material and substance plays a crucial role in determining the market price of raw materials. This scarcity may also serve as a motivator and incentive for generating potential revenue from the secondary materials recovered at the end of their useful life. Thus, in order to make a decision on EOL management, decision makers must guarantee the profitability of PV treatment across the whole life cycle of the solar panels [

30].

Additionally, the expenses associated with the logistics of collecting and transporting garbage, such as EOL solar panels, can significantly influence decision-making processes. The cost of this service is dependent upon the selected system and the distance between the collecting site and EOL treatment centers. On the other hand, the cost of recycling varies depending on the technology used for solar PV. Conversely, the estimation of revenue is based on the selling of the recovered material at the current market price [

25].

2.2.4. Social-Related Factors

The PV EOL operations, including generation, collection, transportation, treatment, and disposal, are the responsibility of three key stakeholders: society, consumers, and producers [

25]. In order to efficiently manage the EOL of PV systems, it is essential to have a comprehensive understanding of the points of view of the key stakeholders in the industry regarding waste management. Furthermore, the readiness of both manufacturers for EOL treatment and the knowledge of customers are critical aspects to consider for the safe management of PV systems at the EOL [

31].

Social behavior has a notable impact on the EOL PV program and the growth of the second-use market [

32]. Inadequate handling of PV waste might result in significant societal repercussions, perhaps leading to the rejection of the PV market by society [

33]. Conversely, the consumer who creates the waste panel is accountable for managing the waste that is produced at the end of its life [

25]. Consumers have an essential role in the EOL of any product. The success of a product on a wide scale depends on the customer’s desire to recycle and reuse it. Consumers drive the market and their willingness to participate in decreasing the negative effect of PV waste is a determining factor [

34]. Alternatively, the management of EOL products can create fresh employment prospects for society and facilitate the emergence of new markets [

25].

EOL is founded on the notion of extended producer responsibility (EPR) from the perspective of the producer. In this scenario, the producer has the responsibility for the environmental effect at the end of the product’s life cycle, both in terms of physical consequences and financial obligations. Government subsidies can provide financial assistance and motivation for producers to create environmentally friendly products [

25]. Implementing effective EOL management practices for solar PV support enhances manufacturers’ environmental reputation and elevates their social standing [

35].

In order to comprehend the social standing of PV EOL, ref. [

30] conducted a social study to get insight into the knowledge, behavior, and perspective of various stakeholders on the recycling regulations of PV. The survey primarily aimed to gather information regarding (1) the sociodemographic and socioeconomic characteristics of the respondents, (2) the assessment of the respondents’ knowledge regarding sustainable development and renewable energy, and (3) the examination of whether the respondents have photovoltaic (PV) installations, including inquiries about installation limitations and waste management. In addition, [

31] conducted a study to investigate the waste management methods of the respondents, their readiness to contribute financially to recycling efforts, and their attitudes towards the issue of future solar waste.

2.2.5. Regulation and Legislation-Related Factors

The absence or lack of regulation, inadequate infrastructure, and insufficient environmental laws can have a substantial impact on the targeted disposal of PV waste [

24]. Regulation and law refer to the legal requirements imposed by governing bodies on enterprises and end-users to ensure the retrieval, recycling, or reutilization of EOL products. The waste management strategy may encompass activities such as collection, reuse, transferring the financial burden of waste management to producers, reducing the amount of trash generated, and promoting the use of recovered materials [

13]. From other viewpoints, it is important for decision-makers to provide an economic framework that guarantees the profitability of PV treatment through the implementation of regulations, financial incentives, and research and development assistance programs [

30]. In the European Union, South Korea, and Japan, laws are implemented to encourage producers to create PV designs that are easily recoverable at the end of their life cycle (EEE) and to bear the costs of recovery at the EOL [

36].

In summary, the main factors impacting the decision environment, as identified from the above analysis and literature review, include technical, legislative, environmental, social, and economic factors. These are the primary influences on decision-makers regarding the disposition of solar panels at EOL. Each factor and its sub-factors, as emerged from the literature, are presented in

Table 1.

2.3. End of Life Decision Methods

Various research has employed a broad range of EOL decision techniques. The EOL decision-making methodologies may be classified into three primary types: optimization methods, multi-criteria decision methodology, and empirical methods [

17]. Optimization approaches rely on mathematical techniques to maximize or minimize a specific problem. For instance, the study conducted by [

38] investigates the economic aspects of PV recycling by analyzing both the macro-level reverse logistics planning and the micro-level process planning of the c-Si recycling process. A mathematical model was employed to assess the profitability of recycling technology by optimizing the profits generated from the sale of materials obtained from the collected PV modules. The economic decision was to evaluate the marginal capital cost of each PV take-back center (PVTBC), the cost of reverse logistics, the distance traveled, and the quantity of PV trash collected from different locations.

From multi-criteria decision methodology, according to [

39], the most suitable approach for identifying the optimal way to treat PV waste is multi-criteria analysis (MCA). This is due to the intricate nature of the waste flow. Additionally, [

40] confirmed that Multi-Criteria Decision Making (MCDM) is a robust method for making decisions regarding waste management. This technique allows for the consideration of several criteria that are relevant to waste management issues, hence addressing the complexity of decision-making in this subject. Moreover, the MCDM method can serve as a valuable tool for group decision-making in the context of the waste management system, which is characterized by its intricate nature and various hierarchical levels encompassing waste treatment, disposal, recycling, technology selection, landfill location selection, treatment plant location selection, and waste treatment scenario. Due to the intricate nature of the system, the presence of many stakeholder opinions may lead to ambiguities in the ultimate outcomes. Consequently, academics mostly employ fuzzy set theory as a means of addressing this ambiguity. However, the Analytic Hierarchy Process (AHP) is utilized in waste management for tasks such as choosing technologies, selecting locations, and conducting assessments of both environmental and economic factors. Lastly, in empirical methods, the judgment in this circumstance relies on the information and experience acquired from examining the problem using empirical techniques [

17].

In the context of solar PV waste, various factors and methods have been employed to address different research objectives. For instance, the optimal collection strategy in reverse logistics for the downstream part of the Taiwan PV industry has been evaluated using economic and technical factors through AHP and Fuzzy AHP methods [

41]. Another study ranked solar manufacturers based on their outlook towards EOL for solar PV in India, considering social, technical, and regulatory factors, and employing AHP and Fuzzy AHP methods [

42]. The management practices of PV waste in Australia have been explored, focusing on technical factors using the Fuzzy Delphi method [

43]. Furthermore, the impact of consumer decision-making on the replacement or disposal of house-installed PV panels before failure was analyzed using social and technical factors through ANP methods [

44]. Simplifying decision-making via a user-friendly interface for stakeholders to experience different EOL decisions related to PV involves economic, social, and technical factors, utilizing serious games and ELECTRE III methods [

45]

The research objectives in the context of solar PV waste management involve various factors and methods. One objective is to evaluate the optimal collection strategy (CS) in reverse logistics (RL) for the downstream part of the Taiwan PV industry, focusing on economic factors using AHP and Topsis methods [

41]. Another objective is to rank solar manufacturers based on their outlook toward EOL for solar PV in India, considering social, and regulatory factors, and employing AHP and Topsis methods [

42]. Additionally, the management practices of PV waste in Australia are explored, focusing on technical and regulatory factors using the Fuzzy Delphi method [

43]. The impact of consumer decision-making on the replacement or disposal of house-installed PV panels before failure is analyzed using social, regulatory, and technical factors through BDF methods [

44]. Finally, simplifying decision-making via a user-friendly interface that enables stakeholders to experience different decisions related to PV EOL involves economic, regulatory, and technical factors, utilizing serious games methods [

45]

The literature reveals a variety of methods and factors considered for waste EOL decision-making across different industries. Evaluating and ranking waste collection methods often focuses on environmental factors using fuzzy TOPSIS methods [

46]. Environmental factors are assessed in waste management decision models utilizing the consensus analysis model (CAM) method [

47]. Alternatives for sorting the optimal process or strategy for reverse logistics are ranked based on economic factors through ANP methods [

48]. Selecting the most appropriate reuse, recovery, and recycling options in the shoe waste industry involves a comprehensive consideration of environmental, economic, social, technical, and regulatory factors using methods such as the AHP method [

49]. EOL alternative options for food waste management, including landfill, composting, hog feeding, and anaerobic digestion, are analyzed using multiple factors through AHP and ANP methods [

47]. The proper healthcare waste disposal or treatment system is chosen by evaluating environmental, economic, and technical factors through ANP and ELECTRE III methods [

50]. Different ways of disposing of plastic waste are evaluated using environment, economic, and social factors, employing THOR methods [

51]. Eight solid waste management scenarios are analyzed considering environmental, economic, social, and technical factors using multiple methods, including fuzzy TOPSIS and fuzzy AHP [

52]. The circular economy and solid waste agendas are studied focusing on social and regulation factors through game theory methods [

53]. The most preferred ‘end-of-life’ handling alternatives for batteries are identified by considering environment, economic, and social factors using Topsis methods [

54]. Lastly, factors influencing the feasibility of alternative fuel vehicles (AFVs) adoption are screened using a comprehensive approach that includes environmental, economic, social, technical, and regulatory factors through Topsis and DEMATEL methods [

55].

2.4. Interested Parties and Their Drivers in EOL of Solar Panel Disposition Options

To obtain a comprehensive understanding of the factors that contribute to the EOL of solar panels, there are several stakeholders that play a significant role in determining the disposal alternatives for these panels. The PV EOL activities, including generation, collection, transportation, treatment, and disposal, are the responsibility of three key stakeholders: society, consumers, and producers [

25]. Furthermore, the producer, end user, government, researcher, and municipality are involved in the EOL process for every given product. Hence, the involvement of many decision-makers can influence the development of policies regarding the EOL disposal of any product. Due to this variety, a comprehensive decision method is needed [

12].

Based on the above, determining the appropriate EOL strategy for solar PV systems is complex due to the involvement of multiple stakeholders and processes. This literature review reveals a significant gap in the EOL decision-making research for solar panels, as no studies have thoroughly investigated the holistic decision-making environment. Understanding the perspectives of various stakeholders on the overall decision-making process and evaluating all possible alternatives is essential. The primary reason for this gap is the complexity of the decision-making environment, which encompasses multiple aspects and involves many stakeholders. Furthermore, existing research on EOL decision-making for solar panels tends to focus on specific parts or topics, rather than the overall decision environment. Therefore, a holistic decision-making approach is necessary to address this challenge effectively to address the research objective

3. Methodology

3.1. Method Selection

For this research, the focus and objective are on ranking the alternatives based on the preferences of stakeholders. The data for this research is qualitative and measured. The decision-makers in this study are mainly individuals classified into groups (social representatives, industry users, manufacturers, regulators, researchers, and municipalities). This variation in the types of users suggests the use of a tool that does not require users to have extensive knowledge of how the method works and can handle a wide range of user priorities and preferences. Therefore, the Analytic Hierarchy Process (AHP) has been chosen for this research due to its advantages over other MCDA tools such as Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) and Analytic Network Process (ANP). AHP is selected because it is easy to use and understand, with results that can be explained and justified. ANP requires several pairwise comparison matrices, adding complexity to the survey process, while TOPSIS has limited acceptance among scientific communities [

56]. The main reasons for choosing AHP for this research are its ability to decompose complex decision problems into many subproblems with hierarchical levels, where each level represents a set of criteria and sub-criteria related to each other; its simplicity, logical consistency, and flexibility; and its ability to quantify expert judgments and determine priority weights [

57].

3.2. Data Collection Tool

3.2.1. AHP Procedure

This section will provide a detailed overview of the AHP procedure. It will elaborate on each step of the AHP procedure, from defining the problem and structuring the hierarchy to conducting pairwise comparisons and deriving priority weights.

Step 1: Hierarchy Construction

Figure 2 presents a graphical representation of the AHP model and decision environment. At Level 1, the primary objective is to rank the disposition alternatives for solar waste at the end of its life (EOL), using the factors outlined in the literature, which are categorized into five dimensions at Level 2. Level 3 consists of subfactors that impact Level 2 and may lead to different decisions from various stakeholders. The alternatives are placed at the lowest level of the hierarchy, Level 4, where they will be evaluated to rank the disposition alternatives in a specific context.

Step 2: Pairwise Comparison and Construction of the Pair-Wise Comparison Matrix

In this step, data is collected from experts according to the hierarchical structure using a survey. Each participant conducts pairwise comparisons among the alternatives and criteria, or between the criteria and their sub-criteria, using Saaty’s scale [

58,

59,

60,

61] as shown in

Table 2. Subsequently, the pairwise comparison values of the criteria will be translated into a square matrix. The diagonal elements of the matrix are always set to one, reflecting their equal importance when comparing the criteria to itself [

62].

Step 3: Find the Priorities of Each Criterion

The normalized priority of each criterion is determined in this study using the Row Geometric Mean Method (RGMM). This strategy is employed because of its ease in identifying the largest eigenvalue, its simplicity, and its capacity to reduce the inconsistency value. It is computed using the Equations (1) and (2) [

62]:

Step 4: Calculation of the Consistency Ratio

The consistency ratio (CR) is calculated to assess the level of consistency in the results. Saaty argues that a satisfactory CR should be less than 0.1, while a number below 0.20 is still considered acceptable [

64]. Furthermore, when the consistency ratio is equal to zero, the matrix is said to be completely consistent [

65]. When employing eigenvalue EGNM prioritizing, the consistency index (CI) and consistency ratio (CR) are calculated, with the threshold values for inconsistency defined as follows: CR < 0.05 for n = 3, CR < 0.08 for n = 4, and CR < 0.1 for n > 4 [

65]. The calculation of the CR is determined by utilizing the (CI) and the random index (RI) based on Equations (3) and (4) [

65].

The RI values for matrix sizes 1 to 10 are as follows: for sizes 1 and 2, the RI value is 0.00; for size 3, the RI value is 0.58; for size 4, the RI value is 0.90; for size 5, the RI value is 1.12; for size 6, the RI value is 1.24; for size 7, the RI value is 1.32; for size 8, the RI value is 1.41; for size 9, the RI value is 1.45; and for size 10, the RI value is 1.49 [

66].

Alternatively, when employing the RGMM prioritizing approach, the group consistency is determined by calculating the Geometric Consistency Index (GCI) as shown in Equation (5) below [

64,

67].

The related thresholds for GCI are as follows: GCI = 0.031 for n = 3, GCI = 0.35 for n = 4, and GCI = 0.37 for n more than or equal to 4 [

67]. In addition, Both [

68,

69] claimed that there exists a theoretical correlation between the Geometric Consistency Index (GCI) and the Consistency Ratio (CR) when the priority vector is derived using the Row Geometric Mean Method (RGMM). By applying RGMM, the GCI can be calculated by analyzing the k(n) correlation between CGI and CR, as expressed in Equation (6). The value of K corresponds to the RI and n values as detailed in

Table 3:

Step 5: Group Decision Making Aggregation

By using AHP, decision-makers are assisted in choosing the optimal scenario according to their preferences. Nevertheless, the AHP frequently entails the participation of several decision-makers, including customers, users, specialists, and others, each of whom has their own differing perspectives and biases. This leads to varying viewpoints and perspectives on the significance of the criterion and sub-criteria in the AHP model. Hence, it is crucial to meticulously consolidate the outcome to establish a unified collective choice that may be employed in the AHP model to accomplish the objective of picking the most suitable alternative [

70]. To perform the aggregation, there are several different methods, including:

- (1)

Aggregating the Individual Judgments (AIJ) for each set of pairwise comparisons into an aggregate hierarchy. AIJ is used if the group structure is homogeneous and the decision-makers are prepared to function as a unified entity. In this case, each decision maker individually conducts pairwise comparisons, and then, the Weighted Geometric Mean Method (WGMM) is employed to calculate the group judgment for each element in the comparison matrix. The calculation is performed using Equation (7) [

71,

72].

- (2)

Aggregating Individual Priorities (AIP): AIP is used when the decision environment has the potential for conflicts of interest, where group members behave as separate systems with their own values and interests. In this scenario, after each decision-maker provides their independent AHP rating, the individual priorities are aggregated to determine the final group preference. This aggregation can be performed using either the WGMM or the Weighted Arithmetic Mean Method (WAMM) [

71,

72]. Both studies [

73,

74] assess the performance of WAMM and WGMM via various tests and determine that aggregation should be carried out using WGMM. This is because WGMM aligns more consistently with the preceding phases in the AHP. On the other hand, while WAMM offers a straightforward aggregation method, it introduces an issue referred to as “eclipsing”. Hence, the calculation of the WGMM in the AIP is derived from Equation (8) provided in the references [

67,

75].

- (3)

Aggregating the individual-derived priority in each node [

76]

Therefore, based on the outlined steps and research aim, it has been demonstrated that both AIJ and AIP approaches produce identical results when the RGMM is used for prioritization and the WGMM is applied for aggregation [

67,

77]. Hence, given the information provided, the objective of this study is to comprehend the various viewpoints of different shareholder groups about the possible methods of disposing of photovoltaic end-of-life materials. This study will focus on AIP aggregation. Since this study uses RGMM as the prioritization procedure and WGMM as the aggregation method, the GCI and CR are used to check for consistency.

3.3. Questionnaire and Survey

A survey was designed with the primary aim of evaluating three choices (landfill disposal, recycling, and reuse) based on five main criteria. Furthermore, the survey also evaluates the rankings of the key factors by analyzing the subfactors (level 3) to provide insight into the elements influencing the decision-making process for each set of participants. The questionnaire was designed to comply with the criteria for using AHP as an analytical tool.

3.4. Study Sample

In order to guarantee an unbiased analysis, participants were carefully selected based on their expertise and direct involvement in the PV field. This study engaged stakeholders whose opinions can significantly influence solar PV EOL strategies, including social representatives, industry users, manufacturers, regulators, researchers, and municipal representatives. Each stakeholder group was limited to a maximum of three participants to ensure equitable representation and prevent any potential bias.

The inclusion criteria focused on individuals with practical experience, decision-making roles, or research contributions related to PV EOL management. The target sample size was set between 15 and 30 participants, with equal distribution across stakeholder groups to capture a balanced range of perspectives. This approach ensured that the analysis reflected the diverse interests and expertise of individuals in the PV field, providing valuable insights for informed decision-making.

3.5. Data Analysis

The data are structured into two levels or sections. Firstly, analyzing the alternatives in accordance with the main criteria, and secondly, analyzing the primary criteria by considering the sub-criteria. Upon gathering the data from the participants via the survey, the data analysis was conducted with an Excel spreadsheet. Surveys that were not finished or included errors were not included in this study. The AHP tool was developed in a Microsoft Excel spreadsheet, where the findings were combined and consolidated using AIP. The analysis is divided into two sections:

Firstly, the method involves examining and consolidating the preferences and priorities of each stakeholder group separately to gain a comprehensive understanding of their perspectives. To illustrate, in order to gain insight into the preferences and priorities of society as a whole, the data gathered from specialists who represent various segments of society will be carefully reviewed and consolidated. Likewise, the data obtained from specialists who represent manufacturers will be examined and combined to comprehend the preferences and priorities of the manufacturing group and so on. This facilitates understanding of each stakeholder’s viewpoint, hence helping in the definition of different needs and perspectives in the subsequent policy formulation.

Secondly, a comprehensive analysis and aggregation will be conducted for all participants, regardless of their stakeholder group. It is important to have a clear understanding of the ranking priorities for all participants.

AIP aggregation is utilized for both parts of this study. The gathered findings are subsequently utilized to formulate a policy for the EOL disposition options for Solar PV waste, which is the primary objective of this study.

4. Results and Data Analysis

The survey was circulated to the specialists in the field of solar panel technology. A total of 37 responses was received from the participants. After performing data cleaning, the incomplete responses and inaccurate answers were eliminated, namely those where the same response was given for all questions. A total of 18 replies were included in this study, with each stakeholder group contributing three responses.

Table 4 displays the number of years of experience for all participants where the majority of specialists have 6–15 years of expertise.

The AHP calculations were conducted using the “Business Performance Management Singapore (BPMSG)” template developed by D. Klaus Goepel, and implemented in an Excel spreadsheet. This template includes an input page for pairwise comparisons from up to 20 participants. Each participant’s priorities were calculated using the RGMM. Additionally, the template computes two consistency measures: the CR and GCI. The BPMSG AHP tool employs the WGMM for AIJ [

78]. To perform the final aggregation for group decision-making, the BPMSG AHP template does not provide functionality for including the hierarchy of the decision problem or the final aggregation that incorporates the weights. Therefore, this step was performed manually using Microsoft Excel.

As previously stated, this study began by examining the alternatives based on the primary criteria. Furthermore, an analysis of the primary criteria using the sub-criteria was conducted. To achieve this, the data acquired for each aim were examined together as aggregated data for all 18 participants using AIP aggregation. Subsequently, the results from each stakeholder group, consisting of three participants, were combined to determine the preference for each individual stakeholder group.

4.1. First Objective: Examining the Alternatives Based on the Primary Criteria

The primary objective of this study consists of two tasks. The first task involves ranking the disposition alternatives for solar PV waste—disposal, recycling, and reuse (Level 4)—based on five key criteria: environmental, economic, social, policy and legislation, and technical factors (Level 1). The second task focuses on determining both the overall aggregated ranking and the preference rankings for each stakeholder group individually.

4.1.1. Task 1: Rank the Disposition Alternatives

In the beginning, the survey gathered individual priorities for the primary five categories (environmental, economic, social, policy and law, and technological) through pairwise comparison. Subsequently, the BPMSG template was employed to collect RGMM for each response.

Table 5 displays the RGMM outcome along with its matching CR and GCI.

By utilizing AIP WGMM aggregation and normalizing the outcome, a result that is almost identical to the AIJ aggregation from the BPMSG-developed excel sheet is achieved. The rationale for this is as previously mentioned. It has been demonstrated that when WGMM is employed as an aggregate technique and RGMM is utilized as the prioritizing procedure, the weight result of AIJ is equal to the weight result of AIP [

67,

77].

The findings reveal that regulation and legislative factors carry the highest weight at 30.7%, followed by environmental factors at 21.8% and economic factors at 21.5%. Technical factors contribute 15.9%, while social factors account for 10%. Additionally, the results demonstrate the reliability of the pairwise comparisons, with a GCI = 0.37 for n ≥ 4 and a CR value of less than 0.01.

After that, each participant evaluated the alternatives—disposal, recycling, and reuse—against the five criteria: environmental, economic, social, policy and legislation, and technical. A total of 18 responses were collected for each criterion. The results were then aggregated using the AIP WGMM method and subsequently normalized.

Using the weight results presented in

Table 5 and the AIP WGMM aggregation for all factors, the overall final ranking of the alternatives, based on participant input, is as follows: recycling at 40.5%, reuse at 34.5%, and disposal at 24.8%, as detailed in

Table 6.

4.1.2. Task 2: Understanding the Preference Disposition for Each Stakeholder Group

The second part of the first objective focuses on understanding the preferences of each stakeholder group. Accordingly, AIP aggregation, as shown in

Table 7, was conducted for the three individuals within each group and evaluated based on the main criteria factors.

Based on the overall weight ranking, the results reveal notable differences in preferences among stakeholder groups for solar PV end-of-life (EOL) strategies. Industry users prioritize recycling, followed by reuse and disposal. Conversely, manufacturers and regulators rank the alternatives as recycling, disposal, and reuse. Municipality representatives, society, and researchers favor reuse as their top choice, followed by recycling and disposal. This variation in preferences underscores the differing opinions and interests of stakeholder groups regarding solar PV EOL management. A more detailed analysis of the preferences for each group across the main criteria is as follows:

Economic Factors: Manufacturers, regulators, and society prioritize recycling as the preferred alternative when considering economic factors. Industry users and researchers, however, favor reuse as their top priority, while municipality representatives rank both recycling and reuse equally, with disposal as their top priority.

Environmental Factors: All groups, except society representatives, recommend recycling as the best alternative for managing solar PV waste. Society representatives, however, believe reuse is a better option.

Regulation and Legislation: Researchers, society, and municipality representatives rank reuse as the top EOL strategy, whereas other groups select recycling as their highest choice. Notably, regulators rank disposal as the second alternative after recycling.

Social Factors: Industry users, manufacturers, regulators, and society representatives identify recycling as the top option. Researchers prioritize reuse, while municipality representatives rank both recycling and disposal equally.

Technical Factors: Industry users and regulators rank disposal as the highest priority. Society and municipality representatives favor reuse, while researchers and manufacturers select recycling as the top alternative.

The analysis highlights several noteworthy trends. Society representatives demonstrate a stronger preference for reuse compared to other groups. Municipality representatives uniquely prioritize disposal for economic and social factors. Interestingly, regulators rank disposal as the second option after recycling when considering regulation and legislation factors. Additionally, the preference for disposal by industry users and regulators in relation to technical factors may indicate specific concerns within the industry about technical challenges. These findings emphasize the diverse priorities and interests among stakeholder groups, providing valuable insights for policy development in solar PV EOL management.

4.2. Second Objective: Analyze Main Criteria Based on the Sub-Criteria/Subfactors

The second objective of this study is to examine the main criteria using the sub-criteria or subfactors at level 2 and level 3. The data were obtained from the same 18 experts and aggregated using the same approach as previously, which is the AIP-WGMM based on the RGMM. Furthermore, each of those components was examined based on the findings of the different representative groups and then combined using AIP for three persons per group.

Overall, the comparison matrix is very consistent, with the exception of a few specific responses that have an 11% CR, one with a 14% CR, and another with a 12% CR. For the purpose of this study, those values are deemed acceptable, and the analysis will proceed with them, taking into account the large number of participants and data collected. The next section provides a comprehensive analysis of the data for each individual main criteria group.

4.2.1. Economic Factors

The economic factors were assessed using the four previously defined criteria outlined in the literature. All participants ranked these factors according to their relative significance to the main criteria (economic). This study reveals the aggregated ranking for the economic aspects based on AIP aggregation, as shown in

Table 8:

However, the data also indicate that this ranking varies across different stakeholders (

Table 9). The manufacturer’s priority aligns with the overall priority. This demonstrates the manufacturer’s concern for the revenue generated from selling second-hand PV materials, as well as the expenses associated with its recycling, which necessitates the manufacturer to invest in infrastructure. Subsequently, the amount of garbage created must be sufficient to warrant the investment in recycling infrastructure, and lastly, the logistics must be considered. Both the municipality representative and regulator concur that their primary objective is to generate revenue from the sale of second-hand PV materials. The majority of stockholders concur that logistic costs are of minimal importance to them. However, society regards logistic costs as a high priority, whereas the revenue generated by selling second-hand PV products is ranked as the lowest priority.

When comparing the findings with the main alternative disposition option, as indicated in

Table 7, the manufacturer, regulator, and society all acknowledge that recycling is a key option, particularly when economic reasons are taken into consideration. Industry users and researchers prioritize reuse as their top concern, whereas municipality representatives assign equal importance to both recycling and reuse. The manufacturer and regulator’s high ranking for recycling is justified based on the economic aspect. It is evident from the table that the high ranking is due to the cash generated from selling second-hand materials, which might potentially affect the decision-making of both groups. Industry users emphasize their preference for reusing PV waste material, which is influenced by their high ranking in terms of waste generation amount.

4.2.2. Environmental-Related Factors

The environmental factors were assessed from several perspectives, using four established criteria from the literature. Participants ranked these aspects based on their relative significance as shown in

Table 10.

According to

Table 11, all groups except the municipality representatives consider the ecological impact of wasted PV as the lowest compared to other criteria. However, the municipality representatives consider it to be the top priority. The response of the municipality representatives may be justified since their primary objective is to protect the surrounding environment. From another perspective, industry users, manufacturers, and regulators prioritize the impact on rare materials as their highest concern when considering environmental factors. The impact on health was of major significance to both researchers and society.

4.2.3. Regulation and Legislation

The participants assess the availability of regulations, infrastructure, environmental regulations, and economic support in connection to PV waste at the EOL, taking into account their relative significance compared to each other. The analysis shows the ranking of the participants for the factors after AIP aggregate, as shown in

Table 12:

Within different participant groups, the ranking of these elements varies among stakeholder groups as shown in

Table 13. Municipality representatives prioritize economic support as the highest priority compared to others who consider it as the lowest. Furthermore, industry users, researchers, and manufacturers assert that the availability of infrastructure is the essential component in determining regulatory and legislative requirements. Furthermore. The regulator and society both consider the availability of regulation to be of utmost importance.

By comparing the findings with the primary alternative disposition selection, as indicated in

Table 7, the municipality and social representatives prioritize environmental regulation, putting it as their second highest concern. They also support the use of reuse as a primary waste disposal technique for protecting the environment. The regulator representative’s choice of regulatory availability and infrastructure availability as the two most relevant reasons may explain their decision to choose disposal as the second option for disposition.

4.2.4. Technical Factors

The ranking of the technical factors, as determined by the total aggregate of the findings in the AIP, indicates that the most significant aspect is the recyclability of the panel and ease of recovery. Following closely in second place is the technology type, material content, and composition. The amount of created and most recently produced panels is also considered.

Table 14 illustrates the ranking of the subfactors.

The ranking varies among participant groups, as indicated in

Table 15. The top-ranked factors for both regulator and industry users were the recyclability of the panel and the simplicity of recovery. However, the quantity of garbage created was evaluated as the highest by both the manufacturer and municipality representatives. Furthermore, researchers and representatives of society have put technology type and material content/composition as the top priority.

By comparing the findings with the primary alternative disposition selection, as indicated in

Table 7, industry users and regulators have chosen disposal as the primary method of disposition. It is evident that they prioritize the recyclability of the panel and the simplicity of recovery as the key elements influencing their decision. These technical criteria serve as the basis for their selection. On the other hand, manufacturers prioritize recycling as their foremost priority in terms of technical aspects. They also prioritize the quantity of waste created, since it has a significant influence on these technical elements. This suggests that the recycling market for EOL products, from the perspective of manufacturers, is influenced by the presence of a sufficient number of waste materials. Municipality representatives emphasize that their main focus is on reuse, which is reasonable considering their responsibility for waste management. Nevertheless, they prioritized the quantity of created waste as the primary element influencing the technical aspects, suggesting that the market’s growth will be determined by the amount of waste produced. Given that both researchers and representatives of society prioritize technological selection, it is crucial to consider the creation of a more sustainable PV model as a lasting solution to PV waste.

4.2.5. Social Factors

The social factors have been ranked based on the overall aggregation of the AIP findings. The most important factor is stakeholders’ engagement, followed by society’s awareness and knowledge in second place. After that is customer willingness to recycle and reuse, followed by society acceptance. Lastly, employment is ranked last as shown in

Table 16.

The ranking of these factors varies across different stakeholder groups as shown in

Table 17. Stakeholders’ engagement was identified as the most significant aspect by the regulator, researcher, and manufacturer. The municipality representative prioritized employment as a major factor. Furthermore, the industry users ranked customer readiness to recycle and reuse as their highest priority. Finally, the society representative had the highest rank for awareness and knowledge among society members.

When comparing the findings with the main alternative disposition options, as indicated in

Table 7, the decision made by both the regulator and manufacturer to choose recycling alternatives is influenced by stakeholder participation and is primarily motivated by social factors. Industry users claim that the willingness of customers to recycle is a crucial factor in driving solar waste recycling. Society considers reusing as the most important alternative and emphasizes that society’s awareness and knowledge are crucial factors in promoting this alternative from a social perspective. Finally, the municipality official considered disposal and recycling to be equally important. However, the research on social factors reveals that employment is a crucial determinant influencing their decision-making process. It might potentially indicate a need for jobs in the market, as it represents the creation of a new industry.

5. Discussion and Policy Recommendations

The AHP research reveals that recycling is the most highly ranked method for disposing of solar PV waste at the end of its life, based on the collective opinions of 18 experts from various sectors. Recycling received an overall aggregate score of 40.5%, followed by reuse at 34%, and disposal at 24.8%. While recycling is widely recognized as the most environmentally beneficial EOL strategy, the use of AHP in this study provides new insights by systematically quantifying stakeholder preferences across environmental, economic, social, and technical dimensions. The analysis highlights variations in stakeholder priorities, which may be attributed to the different interests of these groups, offering actionable insights for tailoring EOL strategies to specific contexts. This approach adds novelty by identifying trade-offs and drivers behind stakeholder preferences, contributing to more effective and inclusive decision-making for PV EOL management. Based on that, the following policy recommendations may be derived:

In relation to economic factors:

There is a need to develop a market for second-used solar panels with proper guidelines and regulations that manage the business model and encourage the involvement of all industry representatives.

National laws should be in place to manage the second-use PV panel waste market with a focus on economical value, and environmental and public health protection.

Involvement of society in the process of collection and transportation of the PV waste to its EOL destination should ensure covering all related aspects of the process, including but not limited to the logistic arrangements, economic intensives/revenue, and awareness.

Ensure tracking of the quantity of the sold PV module in the market in order to project and forecast the quantity of generated waste. This will help in developing the required infrastructure and projecting the potential revenue from different PV EOL disposition alternatives.

In relation to environmental factors:

Ensure protection of the surrounding environment to reduce the ecological impacts by introducing regulations and legislation that prohibit throwing PV waste in uncontrolled places and introducing a penalty system for violators.

Establish a program for managing and controlling rare materials in order to ensure proper handing for solar PV EOL.

Partnership with the health sector is necessary in order to manage the health impact of waste PV on society and the people who will deal with the waste.

Develop an environmental policy that ensures the environmental responsibility of the producer and post-consumer stage of the solar PV life cycle.

In relation to regulation and legislation:

In order to establish the recycle and reuse market and encourage the end users to participate, it is recommended to establish economic support for the industry by both the government and private sector.

Ensure the availability of infrastructure as a necessary factor that will support the market establishment.

Design and establish a policy and regulation that will cover the whole industry participants from the generation of the waste to proper handing at EOL, considering the impact of the waste on humans, the economy, and the environment.

In relation to technical factors

Ensure ease of recovery and recyclability from manufacturers and product producers by updating the standard to ensure that the products entering the market are capable of being recycled and reused at their EOL.

In order to establish a market for recycling and reuse, there is a need for a proper business case analysis that considers all involved parties’ perspectives.

It is recommended to study and evaluate the quality of generated waste and include it in the business model in order to allow all participants from the economy to gain maximum benefit from EOL disposition of solar waste.

Encourage the PV industry to propose and develop more sustainable PV panels and develop better technology to deal with EOL products.

In relation to social factors

A multi-sector and multi-stakeholder coordinated approach is needed among various stakeholders in the industry in order to manage the EOL disposition option properly.

There is a need for skilled employees who will participate in the market and enable the development of the second-hand market of solar PV modules.

Encourage participation of the whole society in the EOL of solar panels through awareness programs that will support raising society’s acceptance and willingness to any solar EOL plan in the future.

The criteria and recommendations proposed in this study are derived from widely recognized frameworks and expert insights, ensuring their relevance to diverse contexts. However, we acknowledge that the applicability of these criteria may vary across regions depending on local policies, technological capabilities, and socio-economic conditions. Countries with robust recycling infrastructures and environmental policies, such as those in Europe, are well-positioned to adopt these recommendations. Similarly, nations with emerging solar energy markets, including those in Asia and the Middle East, may leverage these criteria by tailoring them to regional conditions. This paper highlights the adaptability of the proposed framework and emphasizes its potential to guide decision-making globally while allowing for customization to meet specific national or regional needs.

6. Conclusions

With the increasing adoption of solar panels, a substantial accumulation of solar panel waste is expected as panels reach their EOL. The conventional EOL options include disposal, recycling, or reuse of the discarded PV panels. However, selecting the optimal EOL strategy involves multiple stakeholders across the industry. This study utilizes the AHP model to analyze and prioritize these disposition alternatives. The application of AHP in this study not only simplified the decision-making process but also provided a structured framework for capturing and quantifying diverse stakeholder preferences. This novelty lies in the ability to systematically rank alternatives and identify variations in priorities across stakeholder groups, offering valuable insights for shaping targeted policies and strategies for PV EOL management.

The alternatives were evaluated from diverse stakeholder viewpoints, including five key criteria derived from the literature: environment, economic, social, technological, and policy and regulation factors. All of these factors might influence the decision of stakeholders about the optimal EOL approach. Furthermore, this study establishes subfactors for each of the main factors to determine the primary elements that drive or impact stakeholder perspectives for each main criterion.

The analysis employed the AHP method with a sample size of 18 participants representing various sectors including sociality, industry users, manufacturers, regulators, researchers, and municipality representatives. Each group had a maximum of three participants to guarantee fair participation. The analysis was conducted in two phases. Firstly, the major criterion was assessed using the three primary alternatives. Secondly, the main criteria were assessed using subordinate criteria. Each step examined the outcomes from two perspectives: first, the overall ranking of all participants, and then the evaluation of each stakeholder group individually (each group evaluated separately). The findings were then compared with each other.

The AHP research identifies recycling as the most preferred method for disposing of solar PV waste at the end of its life, with an aggregate score of 40.5%, followed by reuse at 34%, and disposal at 24.8%. This study reveals variations in preferences among different stakeholder groups, reflecting their diverse interests. Based on these findings, several policy recommendations have been proposed. Moreover, while the criteria used in this study are widely recognized, their applicability may vary globally due to differences in policies, infrastructure, and socioeconomic contexts. For instance, countries with advanced recycling systems may adopt these criteria readily, while others may need adaptations.

As a future recommendation, it is suggested to conduct the analysis using the eigenvalue approach and then compare the findings with the results obtained via the WGMM method. Furthermore, it is advisable to incorporate other variables into the study and seek input from a broader range of individuals. Furthermore, it is recommended to conduct an interview to gather further input from specialists on the findings of this research.

Author Contributions

Conceptualization, W.A. and M.N.; methodology, W.A. and M.N.; software, W.A.; validation, W.A. and M.N.; formal analysis, W.A. and M.N.; investigation, W.A.; resources, W.A. and M.N.; data curation, W.A. and M.N.; writing—original draft preparation W.A.; writing—review and editing, W.A. and M.N.; visualization, W.A. and M.N.; supervision, M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was approved by the Institutional Review Board (or Ethics Committee) of the American University of Sharjah (Protocol# 23-063 dated: 12 April 2023).

Informed Consent Statement

Participant consent was waived because this study involved minimal risk to participants.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rabaia, M.K.H.; Semeraro, C.; Olabi, A. Modeling photovoltaics’ waste projection and waste management optimization. J. Clean. Prod. 2023, 388, 135947. [Google Scholar] [CrossRef]

- Gangwar, P.; Kumar, N.M.; Singh, A.K.; Jayakumar, A.; Mathew, M. Solar photovoltaic tree and its end-of-life management using thermal and chemical treatments for material recovery. Case Stud. Therm. Eng. 2019, 14, 100474. [Google Scholar] [CrossRef]

- IRENA. Renewable Capacity Highlights 2022; IRENA, 2022. Available online: https://www.irena.org/-/media/Irena/Files/Statistical-Notes-and-Methodology/IRENA_-RE_Capacity_Highlights_2022.pdf (accessed on 25 November 2024).

- Helveston, J.P.; He, G.; Davidson, M.R. Quantifying the cost savings of global solar photovoltaic supply chains. Nature 2022, 612, 83–87. [Google Scholar] [CrossRef]

- IEA. Special Report on Solar PV Global Supply Chains; IEA: Paris, France, 2022. [Google Scholar]

- Hoseinpur, A.; Tang, K.; Ulyashin, A.; Palitzsch, W.; Safarian, J. Toward the recovery of solar silicon from end-of-life PVs by vacuum refining. Solar Energy Mater. Solar Cells 2023, 251, 112181. [Google Scholar] [CrossRef]

- Al-Aqqad, A.O.G.; Menyhart, J. Solar panels problem after end-of-life and waste management (SWOT analysis for the global directives of PV’s waste management). Int. Rev. Appl. Sci. Eng. 2023, 14, 220–229. [Google Scholar]

- Vargas, C.; Chesney, M. End of life decommissioning and recycling of solar panels in the United States. A real options analysis. J. Sustain. Financ. Invest. 2021, 11, 82–102. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Weckend, S.; Wade, A.; Heath, G.A. End of Life Management: Solar Photovoltaic Panels; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016.

- Salim, H.K.; Stewart, R.; Sahin, O.; Dudley, M. Systems approach to end-of-life management of residential photovoltaic panels and battery energy storage system in Australia. Renew. Sustain. Energy Rev. 2020, 134, 110176. [Google Scholar] [CrossRef]

- Ziout, A.; Azab, A.; Atwan, M. A holistic approach for decision on selection of end-of-life products recovery options. J. Clean. Prod. 2014, 65, 497–516. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R.; Tiwari, M.K. Analyzing alternatives in reverse logistics for end-of-life computers: ANP and balanced scorecard approach. Comput. Ind. Eng. 2005, 48, 327–356. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global status of recycling waste solar panels: A review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef]

- Seo, B.; Kim, J.Y.; Chung, J. Overview of global status and challenges for end-of-life crystalline silicon photovoltaic panels: A focus on environmental impacts. Waste Manag. 2021, 128, 45–54. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Behnia, M. Environmental impacts and economic feasibility of end of life photovoltaic panels in Australia: A comprehensive assessment. J. Clean. Prod. 2020, 260, 120996. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Circular economy assessment tool for end of life product recovery strategies. J. Remanuf. 2019, 9, 169–185. [Google Scholar] [CrossRef]

- Fthenakis, V.M. End-of-life management and recycling of PV modules. Energy Policy 2000, 28, 1051–1058. [Google Scholar] [CrossRef]

- Singh, J.K.D.; Molinari, G.; Bui, J.; Soltani, B.; Rajarathnam, G.P.; Abbas, A. Life cycle assessment of disposed and recycled end-of-life photovoltaic panels in Australia. Sustainability 2021, 13, 11025. [Google Scholar] [CrossRef]

- Lunardi, M.M.; Alvarez-Gaitan, J.P.; Bilbao, J.I.; Corkish, R. Comparative life cycle assessment of end-of-life silicon solar photovoltaic modules. Appl. Sci. 2018, 8, 1396. [Google Scholar] [CrossRef]

- Badenhorst, A. What practice can learn from theory: The potential impact of disposition decision factors on organisational performance. J. Transp. Supply Chain. Manag. 2018, 12, 1–16. [Google Scholar] [CrossRef]

- Divya, A.; Adish, T.; Kaustubh, P.; Zade, P. Review on recycling of solar modules/panels. Sol. Energy Mater. Sol. Cells 2023, 253, 112151. [Google Scholar] [CrossRef]

- Domínguez, A.; Geyer, R. Photovoltaic waste assessment in Mexico. Resour. Conserv. Recycl. 2017, 127, 29–41. [Google Scholar] [CrossRef]

- Farrell, C.C.; Osman, A.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Harrison, J.; Vennard, A.; Kumaravel, V.; Al-Muhtaseb, A.; et al. Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules. Renew. Sustain. Energy Rev. 2020, 128, 109911. [Google Scholar] [CrossRef]

- Monier, V.; Hestin, M. Study on Photovoltaic Panels Supplementing the Impact Assessment for a Recast of the WEEE Directive; Final Report; European Commission DG ENV: Brussels, Belgium, 2011; Volume 6. [Google Scholar]

- Sharma, A.; Mahajan, P.; Garg, R. End-of-life solar photovoltaic panel waste management in India: Forecasting and environmental impact assessment. Int. J. Environ. Sci. Technol. 2024, 21, 1961–1980. [Google Scholar] [CrossRef]

- Oteng, D.; Zuo, J.; Sharifi, E. An evaluation of the impact framework for product stewardship on end-of-life solar photovoltaic modules: An environmental lifecycle assessment. J. Clean. Prod. 2023, 411, 137357. [Google Scholar] [CrossRef]

- Franco, M.A.; Groesser, S.N. A systematic literature review of the solar photovoltaic value chain for a circular economy. Sustainability 2021, 13, 9615. [Google Scholar] [CrossRef]

- Gönen, C.; Kaplanoğlu, E. Environmental and economic evaluation of solar panel wastes recycling. Waste Manag. Res. 2019, 37, 412–418. [Google Scholar] [CrossRef] [PubMed]

- Mahmoudi, S.; Huda, N.; Behnia, M. Multi-levels of photovoltaic waste management: A holistic framework. J. Clean. Prod. 2021, 294, 126252. [Google Scholar] [CrossRef]

- Nain, P.; Kumar, A. Understanding manufacturers’ and consumers’ perspectives towards end-of-life solar photovoltaic waste management and recycling. Environ. Dev. Sustain. 2023, 25, 2264–2284. [Google Scholar] [CrossRef]

- Walzberg, J.; Carpenter, A.; Heath, G.A. Role of the social factors in success of solar photovoltaic reuse and recycle programmes. Nat. Energy 2021, 6, 913–924. [Google Scholar] [CrossRef]

- Daniela-Abigail, H.; Tariq, R.; El Mekaoui, A.; Bassam, A.; De Lille, M.V.; Ricalde, L.J.; Riech, I. Does recycling solar panels make this renewable resource sustainable? Evidence supported by environmental, economic, and social dimensions. Sustain. Cities Soc. 2022, 77, 103539. [Google Scholar] [CrossRef]

- El-Khawad, L.; Bartkowiak, D.; Kümmerer, K. Improving the end-of-life management of solar panels in Germany. Renew. Sustain. Energy Rev. 2022, 168, 112678. [Google Scholar] [CrossRef]

- Deng, R.; Chang, N.L.; Ouyang, Z.; Chong, C.M. A techno-economic review of silicon photovoltaic module recycling. Renew. Sustain. Energy Rev. 2019, 109, 532–550. [Google Scholar] [CrossRef]

- Besiou, M.; Van Wassenhove, L.N. Closed-loop supply chains for photovoltaic panels: A case-based approach. J. Ind. Ecol. 2016, 20, 929–937. [Google Scholar] [CrossRef]

- Khawaja, M.K.; Ghaith, M.; Alkhalidi, A. Public-private partnership versus extended producer responsibility for end-of-life of photovoltaic modules management policy. Sol. Energy 2021, 222, 193–201. [Google Scholar] [CrossRef]

- Choi, J.; Fthenakis, V. Crystalline silicon photovoltaic recycling planning: Macro and micro perspectives. J. Clean. Prod. 2014, 66, 443–449. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, T.; Gupta, A.K. End-of-life management of solar PV waste in India: Situation analysis and proposed policy framework. Renew. Sustain. Energy Rev. 2022, 153, 111774. [Google Scholar] [CrossRef]

- Torkayesh, A.E.; Rajaeifar, M.A.; Rostom, M.; Malmir, B.; Yazdani, M.; Suh, S.; Heidrich, O. Integrating life cycle assessment and multi criteria decision making for sustainable waste management: Key issues and recommendations for future studies. Renew. Sustain. Energy Rev. 2022, 168, 112819. [Google Scholar] [CrossRef]

- Hsueh, J.; Lin, C. Integrating the AHP and TOPSIS decision processes for evaluating the optimal collection strategy in reverse logistic for the TPI. Int. J. Green Energy 2017, 14, 1209–1220. [Google Scholar] [CrossRef]

- Chaudhary, M.K.; Vrat, P. Analysis of long term impact of the end of life solar panels as e-waste in India. Ind. Eng. J. 2017, 1, 10. [Google Scholar] [CrossRef]

- Oteng, D.; Zuo, J.; Sharifi, E. An expert-based evaluation on end-of-life solar photovoltaic management: An application of Fuzzy Delphi Technique. Sustain. Horiz. 2022, 4, 100036. [Google Scholar] [CrossRef]

- Murakami, S.; Yamamoto, H.; Toyota, T. Potential Impact of Consumer Intention on Generation of Waste Photovoltaic Panels: A Case Study for Tokyo. Sustainability 2021, 13, 10507. [Google Scholar] [CrossRef]

- Salim, H.; Stewart, R.A.; Sahin, O.; Sagstad, B.; Dudley, M. R3SOLVE: A Serious Game to Support End-of-Life Rooftop Solar Panel Waste Management. Sustainability 2021, 13, 12418. [Google Scholar] [CrossRef]

- Ulukan, H.Z.; Kop, Y. Multi-criteria decision making (MCDM) of solid waste collection methods using life cycle assessment (LCA) outputs. In Proceedings of the 2009 International Conference on Computers & Industrial Engineering, Troyes, France, 6–9 July 2009. [Google Scholar]

- Hung, M.; Ma, H.; Yang, W. A novel sustainable decision making model for municipal solid waste management. Waste Manag. 2007, 27, 209–219. [Google Scholar] [CrossRef] [PubMed]

- Hsueh, J.; Lin, C. Constructing a network model to rank the optimal strategy for implementing the sorting process in reverse logistics: Case study of photovoltaic industry. Clean Technol. Environ. Policy 2015, 17, 155–174. [Google Scholar] [CrossRef]

- Staikos, T.; Rahimifard, S. A decision-making model for waste management in the footwear industry. Int J Prod Res. 2007, 45, 4403–4422. [Google Scholar] [CrossRef]

- Özkan, A. Evaluation of healthcare waste treatment/disposal alternatives by using multi-criteria decision-making techniques. Waste Manag. Res. 2013, 31, 141–149. [Google Scholar] [CrossRef] [PubMed]

- Gomes, C.F.S.; Nunes, K.R.A.; Xavier, L.H.; Cardoso, R.; Valle, R. Multicriteria decision making applied to waste recycling in Brazil. Omega 2008, 36, 395–404. [Google Scholar] [CrossRef]

- Gaur, A.; Prakash, H.; Anand, K.; Kumar, G.; Hussain, A. Evaluation of municipal solid waste management scenarios using multi-criteria decision making under fuzzy environment. Process Integr. Optim. Sustain. 2022, 6, 307–321. [Google Scholar] [CrossRef]

- Palafox-Alcantar, P.G.; Hunt, D.V.L.; Rogers, C.D.F. The complementary use of game theory for the circular economy: A review of waste management decision-making methods in civil engineering. Waste Manag. 2020, 102, 598–612. [Google Scholar] [CrossRef]

- Babatunde, O.M.; Munda, J.L.; Hamam, Y. Triangular Intuitionistic Fuzzy Aggregating and Ranking Function Approach for the Rating of Battery ‘End-of-Life’Handling Alternatives. Energies 2022, 15, 2248. [Google Scholar] [CrossRef]

- Raj, A.; Dan, A.; Kumar, P. A Comparative Study of the Feasibility of Alternative Fuel Vehicles for Sustainable Transportation in India: A Hybrid Approach of DEMATEL and TOPSIS. Transp. Dev. Econ. 2023, 9, 2. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; Haq, A.N. Pressure analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Res. 2014, 52, 188–202. [Google Scholar] [CrossRef]

- Saaty, T.L. Axiomatic foundation of the analytic hierarchy process. Manag. Sci. 1986, 32, 841–855. [Google Scholar] [CrossRef]

- Etim, M.; Academe, S.; Emenike, P.; Omole, D. Application of multi-criteria decision approach in the assessment of medical waste management systems in Nigeria. Sustainability 2021, 13, 10914. [Google Scholar] [CrossRef]

- Alrawad, M.; Lutfi, A.; Almaiah, M.A.; Alsyouf, A.; Al-Khasawneh, A.L.; Arafa, H.M.; Ahmed, N.A.; AboAlkhair, A.M.; Tork, M. Managers’ Perception and Attitude toward Financial Risks Associated with SMEs: Analytic Hierarchy Process Approach. J. Risk Financ. Manag. 2023, 16, 86. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Analytic hierarchy process and expert choice: Benefits and limitations. Oper. Res. Insight 2009, 22, 201–220. [Google Scholar] [CrossRef]

- Roy, B. Multicriteria Methodology for Decision Aiding. J. Oper. Res. Soc. 1997, 48, 1257. [Google Scholar]

- Awang, A.; Mohd, W.R.W.; Abdullah, L.; Lee, S.T. Assessing the sustainable fishery-based industry in malaysia using the analytic hierarchy process (AHP). IOP Conf. Ser. Earth Environ. Sci. 2020, 494, 012005. [Google Scholar] [CrossRef]

- Cavallo, B.; Ishizaka, A. Evaluating scales for pairwise comparisons. Ann. Oper. Res. 2022, 325, 951–965. [Google Scholar] [CrossRef]

- Wedley, W.C. Consistency prediction for incomplete AHP matrices. Math. Comput. Model. 1993, 17, 151–161. [Google Scholar] [CrossRef]

- Supraja, S.; Kousalya, P. A comparative study by AHP and TOPSIS for the selection of all round excellence award. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016. [Google Scholar] [CrossRef]

- Khoshand, A.; Kamalan, H.; Rezaei, H. Application of analytical hierarchy process (AHP) to assess options of energy recovery from municipal solid waste: A case study in Tehran, Iran. J. Mater. Cycles Waste Manag. 2018, 20, 1689–1700. [Google Scholar] [CrossRef]

- Ssebuggwawo, D.; Hoppenbrouwers, S.; Proper, E. Group Decision Making in Collaborative Modeling: Aggregating Individual Preferences with AHP; TUE: Eindhoven, The Netherlands, 2009. [Google Scholar]

- Pascoe, S. A Simplified Algorithm for Dealing with Inconsistencies Using the Analytic Hierarchy Process. Algorithms 2022, 15, 442. [Google Scholar] [CrossRef]

- Aguarón, J.; Moreno-Jiménez, J.M. The geometric consistency index: Approximated thresholds. Eur. J. Oper. Res. 2003, 147, 137–145. [Google Scholar] [CrossRef]