Circular Economy: Literature Review on the Implementation of the Digital Product Passport (DPP) in the Textile Industry

Abstract

1. Introduction

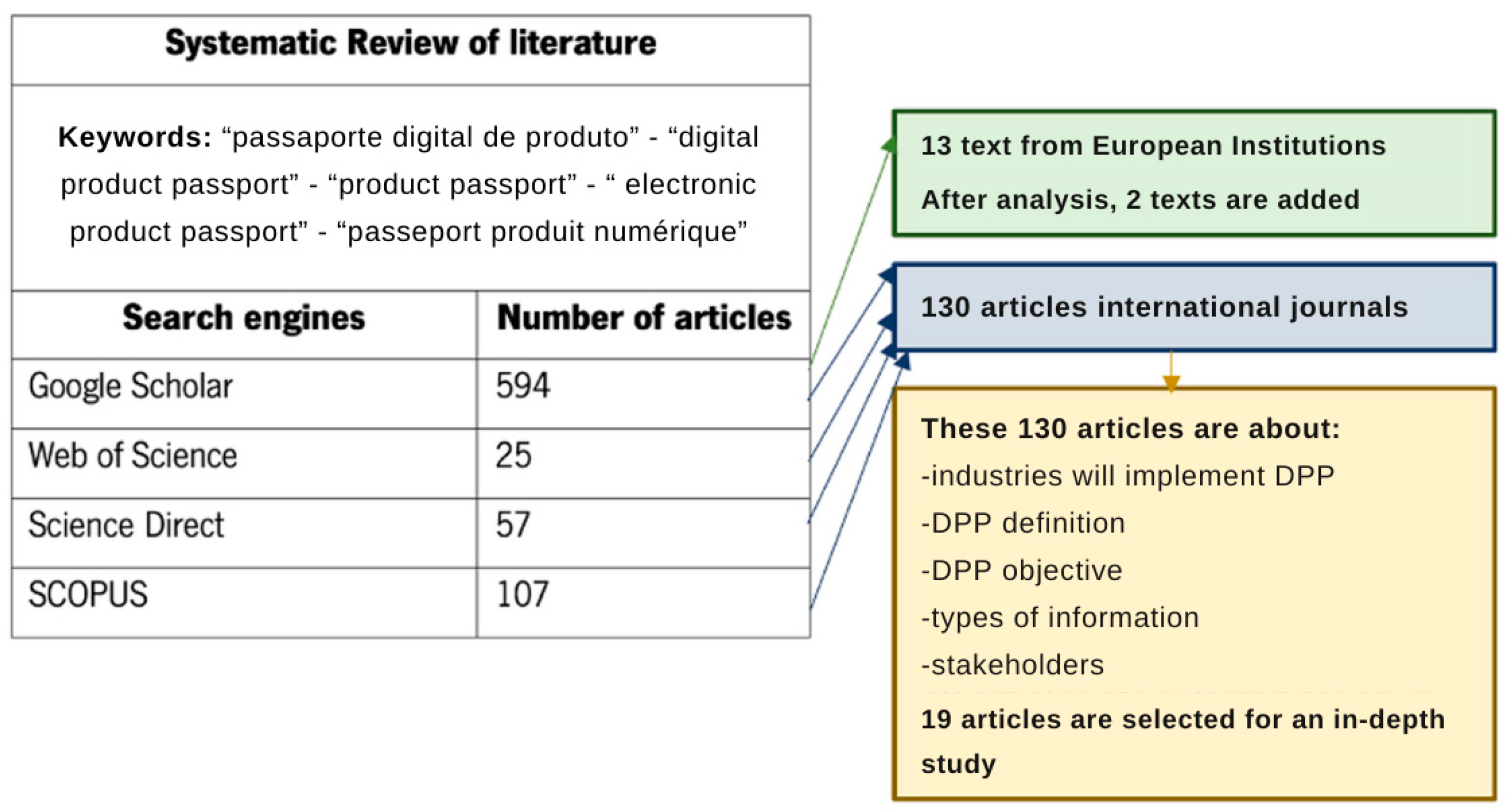

2. Methodology

3. State of the Art

3.1. Impact of the Textile Industry on the Environment

3.2. Circular Economy

3.3. Textile Circular Economy

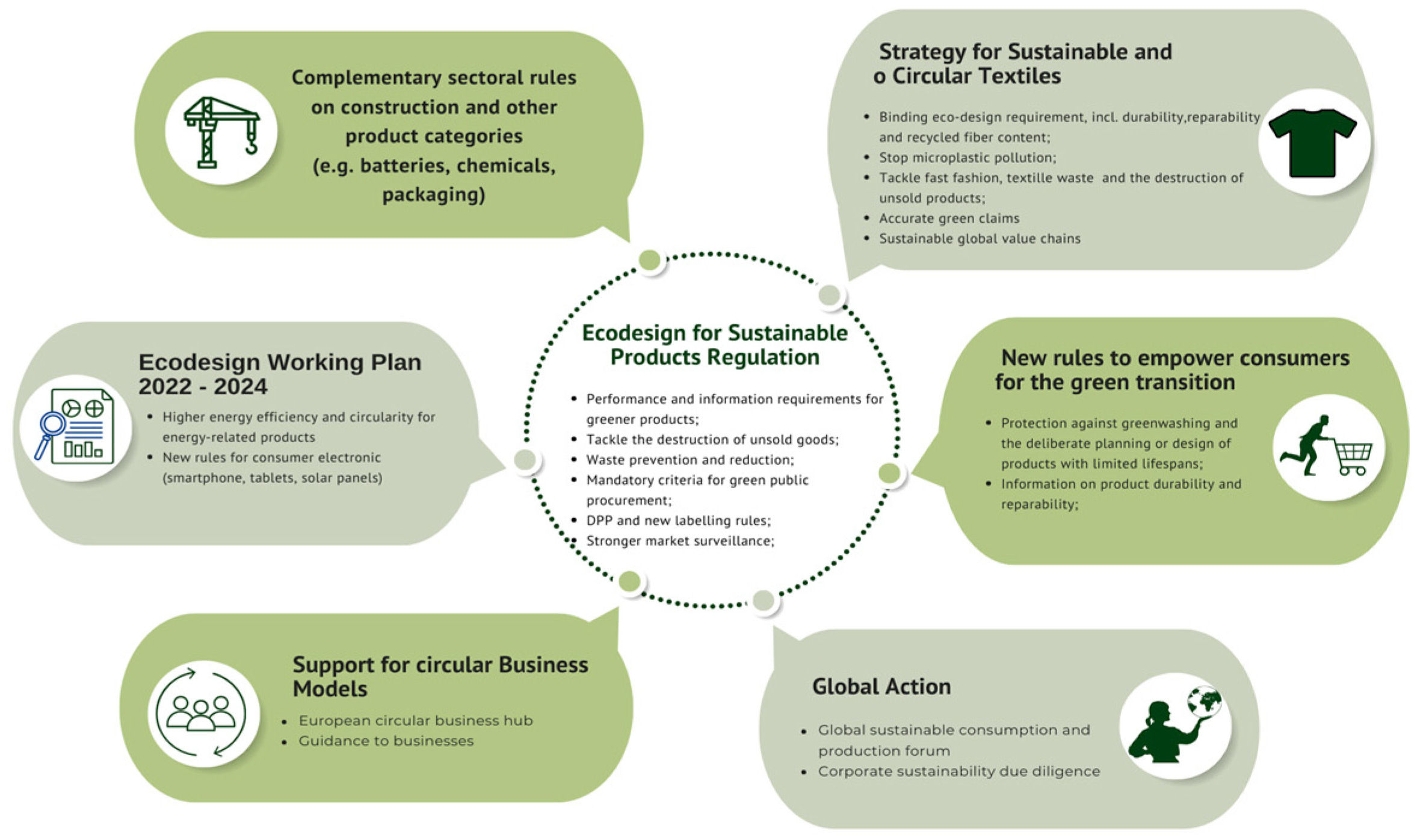

3.4. Context for the Introduction of the Digital Product Passport (DPP)

3.5. Definition of DPP

- Designers and management: The DPP enables the inclusion of detailed feedback on the environmental impact and end-of-life disposal of products, facilitating the development of design solutions that maximize recyclability and maintenance, contributing to product longevity.

- Manufacturers: By accessing a comprehensive digital archive of each product’s lifecycle, manufacturers can effectively trace component provenance, improve accuracy in warranty claims and recalls, and implement predictive maintenance strategies by correlating failures with operational parameters.

- Repairers and maintenance service providers: They benefit from detailed technical information on spare parts, usage history, and maintenance logs, improving the accuracy and quality of the services provided.

- Remanufacturers: They gain access to important data on the condition of components, enabling them to optimize the remanufacturing and reuse of strategic parts. This improves the production cycle and reduces the need for new material resources.

- Recyclers: The availability of detailed data on product composition, including information on hazardous or valuable materials, will improve the efficiency and safety of recycling processes.

- Consumers: They receive comprehensive information about products, including the carbon footprint, the presence of allergens, and the availability of spare parts, so that they can make purchasing decisions based on environmental and sustainability criteria.

3.6. Objectives for Implementing Digital Product Passports (DPPs) in the Textile Industry

“The introduction of a digital product passport as a tool aimed at significantly improving the traceability of textile products throughout their value chain can empower consumers to make informed choices by providing better access to information about products concerning end-of-life management. It will also enable economic operators to accurately track the amount of textile waste produced and assist Member States in implementing and monitoring selective textile collection obligations for reuse, preparation for reuse, and recycling, in accordance with this regulation.”—EU to Directive 2008/98/EC on Waste (13 March 2024)—P9_TA(2024)0145.

- Facilitate Traceability: The DPP supports product tracking throughout its lifecycle, helping stakeholders to verify authenticity, ethical sourcing, and regulatory compliance.

- Support Circular Economy Initiatives: The DPP encourages the circular economy by sharing details on repair, maintenance, and recycling, promoting the reuse and refurbishment of products to cut down on waste and resource depletion.

- Promote Sustainable Practices: The DPP champions sustainability by spotlighting eco-friendly materials and providing insights into the environmental impact of products, guiding consumers toward greener choices.

- Ensure Product Safety: The DPP provides critical safety details, including potential risks, recall notices, and certifications, to protect consumers and uphold safety standards.

- Empower Consumer Choice: By offering customized information on product usage, features, and personalization options, the DPP enhances the consumer experience and encourages active engagement.

- Streamline Supply Chain Operations: The DPP boosts supply chain efficiency by refining inventory management, curbing counterfeit risks, and improving communication among all parties involved in the product’s lifecycle.

- Foster Innovation: The DPP creates a platform for innovative business models and collaboration, paving the way for sustainable solutions and new industry practices.

- Simplify Regulatory Compliance: The DPP helps meet legal requirements by providing a reliable, decentralized platform for accessing product data, easing the process of demonstrating regulatory compliance.

- Build Trust and Responsibility: The DPP enhances trust through greater transparency, traceability, and accountability, promoting responsible practices throughout the supply chain [59].

3.7. Requirements and Data to Be Included in the DPP

- Product Identification: Implements distinct identifiers like serial numbers or QR codes, ensuring accurate tracking and identification of each product across its entire lifecycle.

- Origin Details: Provides precise information on the manufacturer, production site, and supply chain, enhancing transparency and supporting ethical procurement practices.

- Material Composition Analysis: Offers a detailed breakdown of the materials and components used, including their chemical makeup, relevant certifications, and associated environmental impacts.

- Manufacturing Data: Delivers insights into production methods, techniques, and energy requirements, shedding light on the processes involved and their environmental implications.

- Repair and Maintenance Guidance: Includes detailed instructions on repair procedures, spare part availability, and access to certified service providers to help prolong product use and minimise waste.

- Performance Metrics: Provides key data on product efficiency and performance, including energy ratings and testing results, allowing for informed and evidence-based consumer decisions.

- Ownership Tracking: Maintains a record of ownership history and transfers, ensuring full transparency and aiding in verification of authenticity.

- End-of-Life Strategies: Offers clear, practical guidance on the proper disposal, recycling, or repurposing of products, aiming to minimize waste and support sustainable practices.

- Compliance and Certifications: Lists the product’s certifications and regulatory compliance status, ensuring it meets industry standards and legal requirements for safety and quality.

- Warranty and Service Details: Provides comprehensive information on warranty terms, service history, and access to approved repair providers, facilitating efficient product support.

- Safety Alerts and Recalls: Shares updates on any product safety issues, including potential risks and recalls, ensuring consumers are informed and protected.

- Recycling and Disposal Instructions: Offers detailed recommendations on the correct disposal and recycling methods, highlighting suitable facilities and designated drop-off points.

- Intellectual Property: Documents information on the product’s patents, trademarks, and copyrights, protecting its intellectual property rights and ensuring proper recognition.

3.8. Brands and Initiatives Advancing Digital Product Passports (DPPs)

4. Discussion

4.1. Opportunities for Implementing Digital Product Passports (DPPs)

4.2. Challenges for Implementing the DPP

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Environment Agency. Textiles. Available online: https://www.eea.europa.eu/en/topics/in-depth/textiles (accessed on 10 September 2024).

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The Environmental Price of Fast Fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Fletcher, K. Sustainable Fashion and Textiles: Design Journeys, 2nd ed.; Earthscan: London, UK, 2014. [Google Scholar]

- Roy Choudhury, A.K. Environmental Impacts of the Textile Industry and Its Assessment Through Life Cycle Assessment. In Roadmap to Sustainable Textiles and Clothing, Textile Science and Clothing Technology; Muthu, S.S., Ed.; Springer: Singapore, 2014; pp. 1–39. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0098 (accessed on 10 September 2024).

- European Environment Agency. Textiles and the Environment: The Role of Design in Europe’s Circular Economy. Publications Office. 2022. Available online: https://www.eea.europa.eu/publications/textiles-and-the-environment-the (accessed on 12 September 2024).

- Alves, L.; Sá, M.; Cruz, E.F.; Alves, T.; Alves, M.; Oliveira, J.; Santos, M.; Rosado da Cruz, A.M. A Traceability Platform for Monitoring Environmental and Social Sustainability in the T&C Value Chain: Towards a Digital Passport for Textiles and Clothing. Sustainability 2024, 16, 82. [Google Scholar] [CrossRef]

- Andrade, M.M. Introduction to the Methodology of Scientific Work: Elaboration of Undergraduate Work; Atlas: São Paulo, Brazil, 2010. [Google Scholar]

- Grant, M.J.; Booth, A. A typology of reviews: An analysis of 14 review types and associated methodologies. Health Inf. Libr. J. 2009, 26, 91–108. [Google Scholar] [CrossRef]

- Coscieme, L.; Salvatore, A.; Sutton, P. EU Textiles Strategy and the Role of Sustainable Practices; European Environment Agency Report; European Environment Agency: Copenhagen, Denmark, 2022. [Google Scholar]

- Choudhury, K.; Tsianou, M.; Alexandridis, P. Recycling of Blended Fabrics for a Circular Economy of Textiles: Separation of Cotton, Polyester, and Elastane Fibers. Sustainability 2024, 16, 6206. [Google Scholar] [CrossRef]

- Muthu, S.S. Sustainable Fibres for Fashion Industry; Woodhead Publishing: Cambridge, UK, 2017. [Google Scholar]

- Cesa, F.S.; Turra, A.; Baruque-Ramos, J. Synthetic fibers as microplastics in the marine environment: A review from textile perspective with a focus on domestic washings. Sci. Total Environ. 2017, 598, 1116–1129. [Google Scholar] [CrossRef]

- Harsanto, B.; Primiana, I.; Sarasi, V.; Satyakti, Y. Sustainability Innovation in the Textile Industry: A Systematic Review. Sustainability 2023, 15, 1549. [Google Scholar] [CrossRef]

- Mishra, P.K.; Izrayeel, A.M.D.; Mahur, B.K.; Ahuja, A.; Rastogi, V.K. A comprehensive review on textile waste valorization techniques and their applications. Environ. Sci. Pollut. Res. 2022, 29, 65962–65977. [Google Scholar] [CrossRef] [PubMed]

- Wagaw, A.; Babu, B. The compostability of denim fabrics dyed with various indigos. BioResources 2024, 19, 2685–2700. [Google Scholar] [CrossRef]

- Stone, C.; Windsor, F.M.; Munday, M.; Durance, I. Natural or synthetic—How global trends in textile usage threaten freshwater environments. Sci. Total Environ. 2020, 718, 134689. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future. Ellen MacArthur Foundation. 2017. Available online: http://www.ellenmacarthurfoundation.org/publications (accessed on 10 September 2024).

- McKinsey & Company. The State of Fashion 2024: Navigating the Winds of Change. McKinsey Report. 2024. Available online: https://www.mckinsey.com/industries/retail/our-insights/the-state-of-fashion (accessed on 10 September 2024).

- Hedrich, S.; Janmark, J.; Langguth, N.; Magnus, K.H.; Strand, M. Scaling Textile Recycling in Europe—Turning Waste into Value; McKinsey & Company: New York, NY, USA, 2023. [Google Scholar]

- Textile Exchange. Preferred Fibre & Materials Market Report 2023. Available online: https://textileexchange.org/knowledge-center/reports/materials-market-report-2023/ (accessed on 11 September 2024).

- Dahmani, M.; Garcia, C.; Lema, R. Design Strategies for Sustainable Textiles: A Review. J. Text. Des. Technol. 2021, 34, 120–135. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2016, 143, 757–768. [Google Scholar] [CrossRef]

- Giannetti, B.; Agostinho, F.; Eras, J.C.; Yang, Z.; Almeida, C. Cleaner production for achieving the sustainable development goals. J. Clean. Prod. 2020, 271, 122127. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2015; Available online: https://www.ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 14 September 2024).

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Carreón, J.R.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; The Johns Hopkins University Press: Baltimore, MD, USA, 1991. [Google Scholar]

- Stahel, W.R.; Reday, G. The Potential for Substituting Manpower for Energy; Report to the European Commission; Battelle, Geneva Research Centre: Geneva, Switzerland, 1976. [Google Scholar]

- Stahel, W.R. The Performance Economy: The Role of Closed-Loop Materials Management; Springer: Berlin/Heidelberg, Germany, 1982. [Google Scholar]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Commoner, B. The Closing Circle: Nature, Man, and Technology; Alfred A. Knopf: New York, NY, USA, 1971. [Google Scholar]

- Graedel, T.E.; Allenby, B.R. Industrial Ecology; Prentice Hall: Saddle River, NJ, USA, 1995. [Google Scholar]

- Benyus, J.M. Biomimicry: Innovation Inspired by Nature; HarperCollins: New York, NY, USA, 2002. [Google Scholar]

- Pauli, G. The Blue Economy: 10 Years, 100 Innovations, 100 Million Jobs; Paradigm Publications: Boulder, CO, USA, 2010. [Google Scholar]

- Lahti, T.; Wincent, J.; Parida, V. A Definition and Theoretical Review of the Circular Economy, Value Creation, and Sustainable Business Models: Where Are We Now and Where Should Research Move in the Future? Sustainability 2018, 10, 2799. [Google Scholar] [CrossRef]

- Business Council for Sustainable Development. The Business Case for a Circular Economy; Business Council for Sustainable Development: Geneva, Switzerland, 2015. [Google Scholar]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving ‘leapfrog development’. J. Clean. Prod. 2008, 15, 231–239. [Google Scholar] [CrossRef]

- Rizos, V.; Centre for European Policy Studies; Tuokko, K.; Centre for European Policy Studies; Behrens, A.; CEPS—Centre for European Policy Studies. The Circular Economy: A Review of Definitions, Processes and Impacts. CEPS Research Reports, No 2017/08. 2017; Available online: https://www.researchgate.net/publication/315837092 (accessed on 10 September 2024).

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Tichoniuk, M. Digital product passport (DPP) as an important mechanism supporting the circular economy. In Current Trends in Quality Science. Innovative and Sustainable Products, Materials, and Technologies; The Poznań Society for the Advancement of Arts and Sciences: Poznań, Poland, 2024; Available online: https://www.researchgate.net/publication/379692684_Digital_Product_Passport_DPP_as_an_Important_Mechanism_Supporting_the_Circular_Economy (accessed on 12 September 2024).

- European Commission. Circular Economy Action Plan: Closing the Loop; European Union: Brussels, Belgium, 2015. [Google Scholar]

- Badhwar, A.; Islam, S.; Tan, C.S.L.; Panwar, T.; Wigley, S.; Nayak, R. Unraveling Green Marketing and Greenwashing: A Systematic Review in the Context of the Fashion and Textiles Industry. Sustainability 2024, 16, 2738. [Google Scholar] [CrossRef]

- Business Insider. The Staggering Environmental Impact of Clothing Discarded Every Year. Available online: https://www.businessinsider.com/environmental-impact-of-discarded-clothing (accessed on 10 September 2024).

- Dragomir, V.D.; Dumitru, M. Practical solutions for circular business models in the fashion industry. Clean. Logist. Supply Chain. 2022, 4, 100040. [Google Scholar] [CrossRef]

- Hendriksz, V. Best of: Fashion United’s Top 6 Series from 2016. FashionUnited, 30 December 2016. Available online: https://fashionunited.com/news/fashion/best-of-fashionunited-s-top-6-series-from-2016/2016123014110 (accessed on 10 September 2024).

- Jia, F.; Yin, S.; Chen, L.; Chen, X. Circular Economy in Textile and Apparel Industry: A systematic Literature review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Laitala, K. Clothing Consumption: An Interdisciplinary Approach to Design for Environmental Improvement. 2014. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/229724 (accessed on 11 September 2024).

- Saha, K.; Dey, P.K.; Kumar, V. A comprehensive review of circular economy research in the textile and clothing industry. J. Clean. Prod. 2024, 444, 141252. [Google Scholar] [CrossRef]

- Coscieme, L.; Manshoven, S.; Gillabel, J.; Grossi, F.; Mortensen, L.F. A framework of circular business models for fashion and textiles: The role of business-model, technical, and social innovation. Sustain. Sci. Pract. Policy 2022, 18, 451–462. [Google Scholar] [CrossRef]

- Remy, N.; Speelman, E.; Swartz, S. The Circular Economy in the Textile Industry. European Environment Agency. 2016. Available online: https://www.eea.europa.eu/publications (accessed on 10 September 2024).

- Wicker, L. Textiles in a Circular Economy: An Assessment of the Current Landscape, Challenges, and Opportunities in the United States; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016. Available online: https://www.nist.gov/publications/textiles-circular-economy-assessment-current-landscape-challenges-and-opportunities (accessed on 14 September 2024).

- Adisorn, N.; Tholen, L.; Götz, S. Towards a Digital Product Passport Fit for Contributing to a Circular Economy. Energies 2021, 14, 8. [Google Scholar] [CrossRef]

- Saari, L.; Heilala, J.; Heikkila, T.; Kääriäinen, J.; Pulkkinen, A.; Rantala, T. Digital Product Passport Promotes Sustainable Manufacturing: Whitepaper; VTT Technical Research Centre of Finland: Espoo, Finland, 2022. [Google Scholar]

- WBCSD (World Business Council for Sustainable Development). Advancing the Digital Product Passport: Challenges and Opportunities. WBCSD Report 2023. 2023. Available online: https://www.wbcsd.org/ (accessed on 10 September 2024).

- Jensen, S.F.; Kristensen, J.H.; Adamsen, S.; Christensen, A.; Wæhrens, B.V. Digital product passports for a circular economy: Data needs for product life cycle decision-making. Sustain. Prod. Consum. 2023, 37, 242–255. [Google Scholar] [CrossRef]

- European Parliamentary Research Service. Artificial Intelligence and the Rule of Law: The Implications for Human Rights, Democracy, and the Legal System; European Union: Brussels, Belgium, 2024; Available online: https://www.europarl.europa.eu/RegData/etudes/STUD/2024/757808/EPRS_STU(2024)757808_EN.pdf (accessed on 10 September 2024).

- Plociennik, C.; Pourjafarian, M.; Nazeri, A.; Windholz, W.; Knetsch, S.; Rickert, J.; Ciroth, A.; Lopes, A.D.C.P.; Hagedorn, T.; Vogelgesang, M.; et al. Towards a Digital Lifecycle Passport for the Circular Economy. Procedia CIRP 2022, 105, 122–127. [Google Scholar] [CrossRef]

- Re-Tek. Exploring the Role of the Digital Product Passport in Circular Textiles. Re-Tek. Initiative Report. 2019. Available online: https://www.retek.org/reports (accessed on 12 September 2024).

- Jansen, M.; Meisen, T.; Plociennik, C.; Berg, H.; Pomp, A.; Windholz, W. Stop guessing in the dark: Identified requirements for digital product passport systems. Systems 2023, 11, 123. [Google Scholar] [CrossRef]

- Hedberg, A.; Šipka, S. Toward a Circular Economy: The Role of Digitalization. One Earth 2020, 4, 783–785. [Google Scholar] [CrossRef]

- Durand, A.; Goetz, T.; Hettesheimer, T.; Tholen, L.; Hirzel, S.; Adisorn, T. Enhancing evaluations of future energy-related product policies with the digital product passport. In Proceedings of the 2022 Energy Evaluation Europe Conference, Paris, France, 28–30 September 2022. [Google Scholar] [CrossRef]

- Koppelaar, R.H.E.M.; Pamidi, S.; Hajósi, E.; Herreras, L.; Leroy, P.; Jung, H.Y.; Concheso, A.; Daniel, R.; Francisco, F.B.; Parrado, C.; et al. A digital product passport for critical raw materials reuse and recycling. Sustainability 2023, 15, 1405. [Google Scholar] [CrossRef]

- Patagonia. Regenerative Organic Certified™: Beyond Sustainable Farming. Available online: https://www.patagonia.com/roc (accessed on 10 September 2024).

- Adidas. Impact: Our Planet. Available online: https://www.adidas.pt/go/campaign/impact/planet (accessed on 13 September 2024).

- Sofić, J. Circular Innovation Challenge: Transforming Textiles. H&M Foundation, 23 October 2024. Available online: https://hmfoundation.com/2024/10/23/new-round-of-global-change-award-launched-with-a-mission-to-accelerate-innovation-for-a-net-zero-textile-industry-by-2050/ (accessed on 10 September 2024).

- ENGIE. Integrated Report 2023. ENGIE. 2024. Available online: https://www.engie.com/en/csr/integrated-report (accessed on 10 September 2024).

- CIRPASS Project. Digital Product Passport (DPP). Available online: https://cirpassproject.eu/ (accessed on 12 September 2024).

- DPP40. DPP 4.0: Digital Product Passport for the Future. Available online: https://dpp40.eu/ (accessed on 10 September 2024).

- TRICK Project. News. TRICK Project. 2024. Available online: https://www.trick-project.eu/news (accessed on 11 September 2024).

- STVGO Digital. STVGO Digital—Projeto. STVGO Digital. Available online: http://www.stvgodigital.pt/stvgodigital-projeto/ (accessed on 10 September 2024).

- Voulgaridis, K.; Lagkas, T.; Angelopoulos, C.M.; Boulogeorgos, A.-A.A.; Argyriou, V.; Sarigiannidis, P. Digital product passports as enablers of digital circular economy: A framework based on technological perspective. Telecommun. Syst. 2024, 85, 699–715. [Google Scholar] [CrossRef]

- Walden, J.; Steinbrecher, A.; Marinkovic, M. Digital product passports as enabler of the circular economy. Chem. Ing. Tech. 2021, 93, 1717–1727. [Google Scholar] [CrossRef]

- Luoma, P.; Penttinen, E.; Tapio, P.; Toppinen, A. Future images of data in circular economy for textiles. Technol. Forecast. Soc. Change 2022, 182, 121859. [Google Scholar] [CrossRef]

- Stahel, W.R. The Performance Economy; Palgrave Macmillan: London, UK, 2010. [Google Scholar] [CrossRef]

| Brands | Innovation Projects |

|---|---|

| Patagônia | Patagonia was one of the first companies to implement DPPs on some of its products, offering consumers detailed information on the environmental and social impacts, from the origin of the materials to the production process. In this way, consumers have information about the development and creation of the brand’s products [68]. |

| Adidas | Adidas uses DPPs to increase transparency in the complex resource chain, offering consumers information about the materials used in products, such as the working conditions in factories and the environmental impact of their production [69]. |

| H&M | H&M is adopting DPPs with the aim of providing consumers with more information about the origin, production, and environmental impact of products marketed by the brand. As such, it hopes that the PDP will help build a more sustainable and transparent resource chain [70]. |

| Engie | Engie is using DPPs to track the environmental impact of work uniforms. The main aim of this initiative is to reduce the environmental impact of the company’s supply chain and promote more sustainable practices [71]. |

| Project | Country | Description | Technology |

|---|---|---|---|

| CIRPASS | Europe (financed by the European Commission) | It lays the foundations for the gradual implementation and piloting of DPPs. The first focus is on three priority areas, electrical devices and electronics, batteries, and the textile industry, while establishing the basis for a cross-sectoral DPP based on shared rules, principles, and taxonomy [72]. | The technologies used in this DPP: cross-sector definition and description of the DPP; intersectoral product data model for DPPs; open DPP data exchange protocol; building consensus among stakeholders on essential data for circularity; development of use cases and roadmaps for piloting and deployment [72]. |

| DPP 4.0 | Germany | The aim is to create a concept for sharing product information so that it can be used to figure out the legal criteria needed to create DPPs and achieve circular economy objectives [73]. | Creation of a demonstration website (front-end) that meets the data interface requirements of the stakeholders [73]. |

| TRICK | Italian | This project aims to develop DPPs for textile articles and provide information on the environmental impact and sustainability of a product throughout its existence [74]. | The core of the project is the development of complete, reliable access for PMEs and a standardized platform for data storage, protected by blockchain, to allow companies to obtain protected data for products, combined with a marketplace that includes the necessary services and the data generated [74]. |

| STVgoDigital | Portugal | This project encompasses R&D initiatives with a strong collective character and high inductive and demonstrative effects, with the central involvement of companies in the textile and clothing sector, to promote the adoption and transition to the new Industry 4.0 paradigm in order to promote the digitalization of the entire value chain and increase the productivity and efficiency of each company, and consequently the supply chain, making them more transparent, agile, and flexible [75]. | It aims to create an online platform with resources available for PMEs to begin their journey in adopting solutions based on artificial intelligence (AI). It is focused on an area that is representative of the interests of the national cluster, which is guaranteeing the quality of textile and clothing materials and products. It is an area that cuts across the cluster and makes intensive use of image processing and AI techniques and algorithms [75]. |

| Advantages for Companies | Advantages for Consumers |

|---|---|

|

|

| Disadvantages for Companies | Disadvantages for Consumers |

|---|---|

|

|

| SWOT Analysis of the Digital Product Passport (DPP) | |

|---|---|

| Strengths | Weaknesses |

| Complete traceability of product manufacturing Creating more transparency in business models. Detailed information about products, materials used, production processes, environmental and social impacts—combating greenwashing. Efficient management of resources and reduction of waste. Promotes the circular economy, encouraging more sustainable business models. Compliance with environmental and social regulations. Development of new, more sustainable, and personalized products. Access to new markets that value transparency and sustainability. Better collaboration between the different actors in the value chain. | The development and implementation of a DPP system require investments in technology, employees, and internal processes. Integrating the tool with existing management systems can be complex and take longer. Storing and managing large volumes of data throughout the supply chain require specialized tools and software. The lack of legislation on global standards for DPPs can make interoperability between different systems and companies difficult. Companies in the sector can be hesitant to adopt innovative technologies. The protection of sensitive data stored along the supply chain is essential to prevent the loss of information and fraud. The growing threat of cyberattacks requires robust security measures to protect DPP data. Small companies may face difficulties in implementing DPP due to a lack of financial resources and technical ability. |

| Opportunities | Threats |

| It will be possible to know the origin of the products, the materials used, the production processes, and the environmental impact. It will be possible to make more conscious choices, opting for products with a lower environmental impact and that promote the circular economy. It will be possible to check the quality and durability of the items and safety/health standards. From raw materials to disposal, facilitating reuse, recycling, and repair. Simply scanning the QR code will provide details such as washing and drying instructions and composition. Consumers will be able to make more informed purchasing decisions that contribute to a more sustainable future. | Consumers may not have smartphones/tablets with internet, thus limiting access to the information in the DPP. The amount of technical data in this tool may be difficult for the average consumer to understand. The implementation of the DPP could increase the costs of products, which could reduce purchasing power. There is concern that the storage of consumers’ personal data could violate their privacy if there is not adequate security. The lack of legislation on international standards for implementing DPPs could make it difficult to compare products. Consumers may be sceptical about the information contained in the DPP or feel that the amount of information available may be overwhelming. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvalho, C.; Silva, C.J.; Abreu, M.J. Circular Economy: Literature Review on the Implementation of the Digital Product Passport (DPP) in the Textile Industry. Sustainability 2025, 17, 1802. https://doi.org/10.3390/su17051802

Carvalho C, Silva CJ, Abreu MJ. Circular Economy: Literature Review on the Implementation of the Digital Product Passport (DPP) in the Textile Industry. Sustainability. 2025; 17(5):1802. https://doi.org/10.3390/su17051802

Chicago/Turabian StyleCarvalho, Catarina, Carla Joana Silva, and Maria José Abreu. 2025. "Circular Economy: Literature Review on the Implementation of the Digital Product Passport (DPP) in the Textile Industry" Sustainability 17, no. 5: 1802. https://doi.org/10.3390/su17051802

APA StyleCarvalho, C., Silva, C. J., & Abreu, M. J. (2025). Circular Economy: Literature Review on the Implementation of the Digital Product Passport (DPP) in the Textile Industry. Sustainability, 17(5), 1802. https://doi.org/10.3390/su17051802