Investigation of Uneven Gas Emission Mechanisms with Hard Roofs and Control Strategies by Ground Fracturing

Abstract

1. Introduction

2. Gas Emission in Extra-Thick Coal Seam Working Faces with Hard Roofs

2.1. Gas Occurrence Characteristics

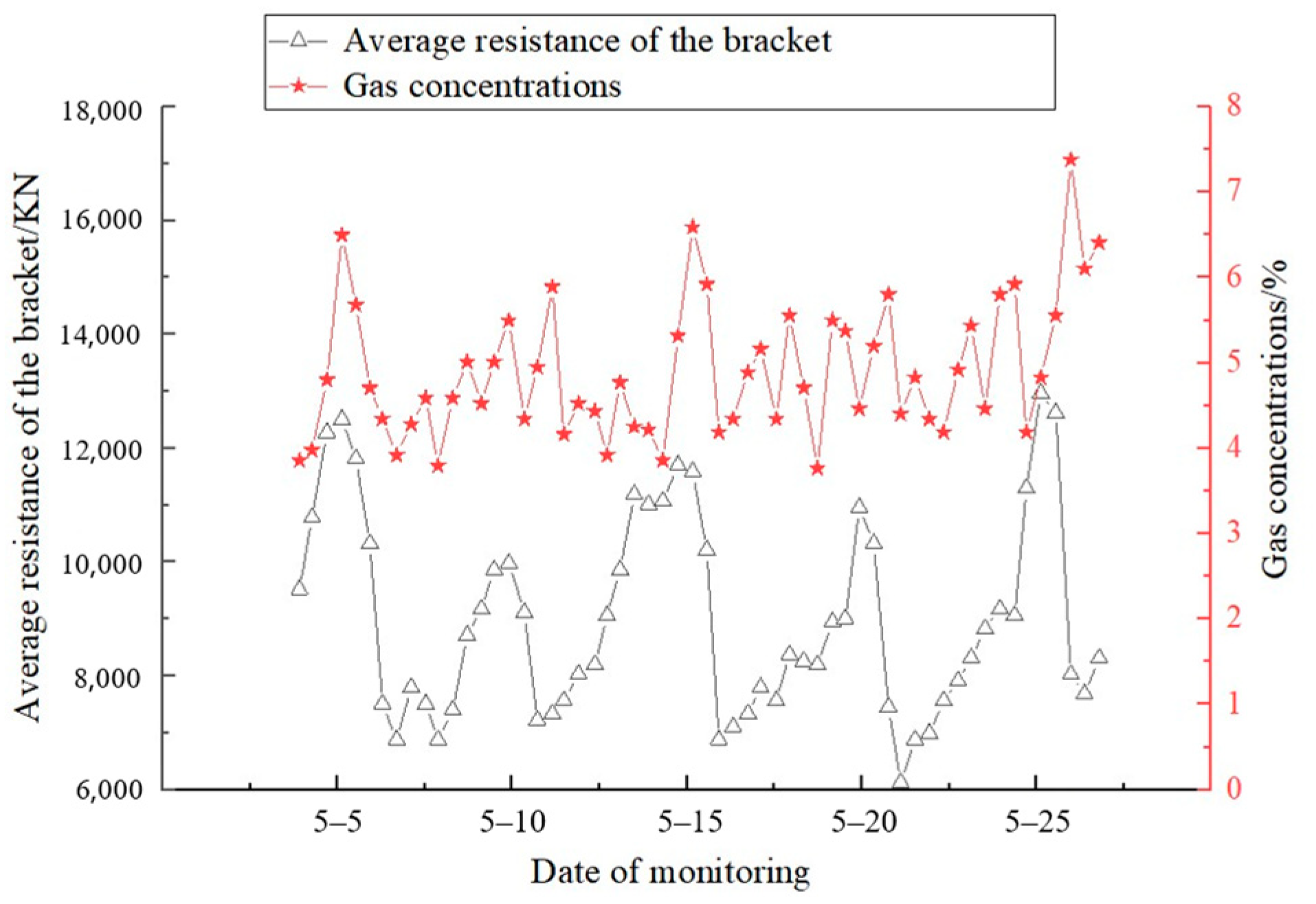

2.2. Gas Emission Law

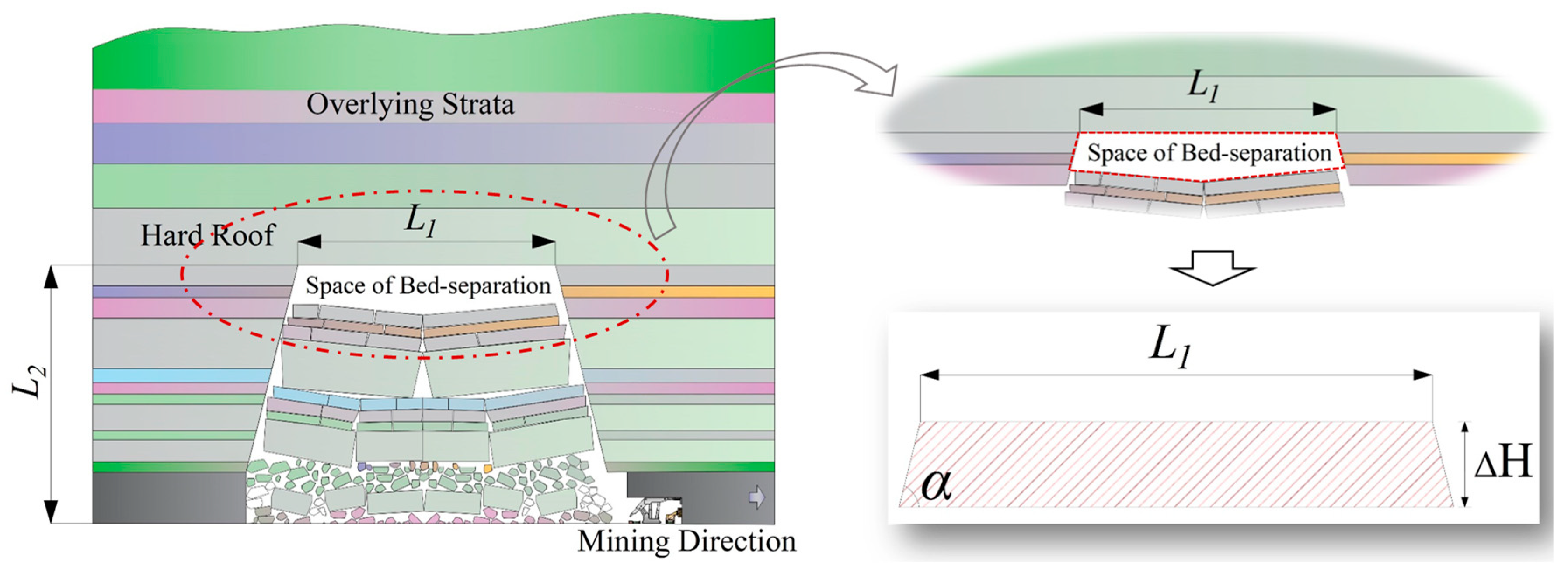

3. Mechanism of Unbalanced Gas Emission Due to Roof Breaking

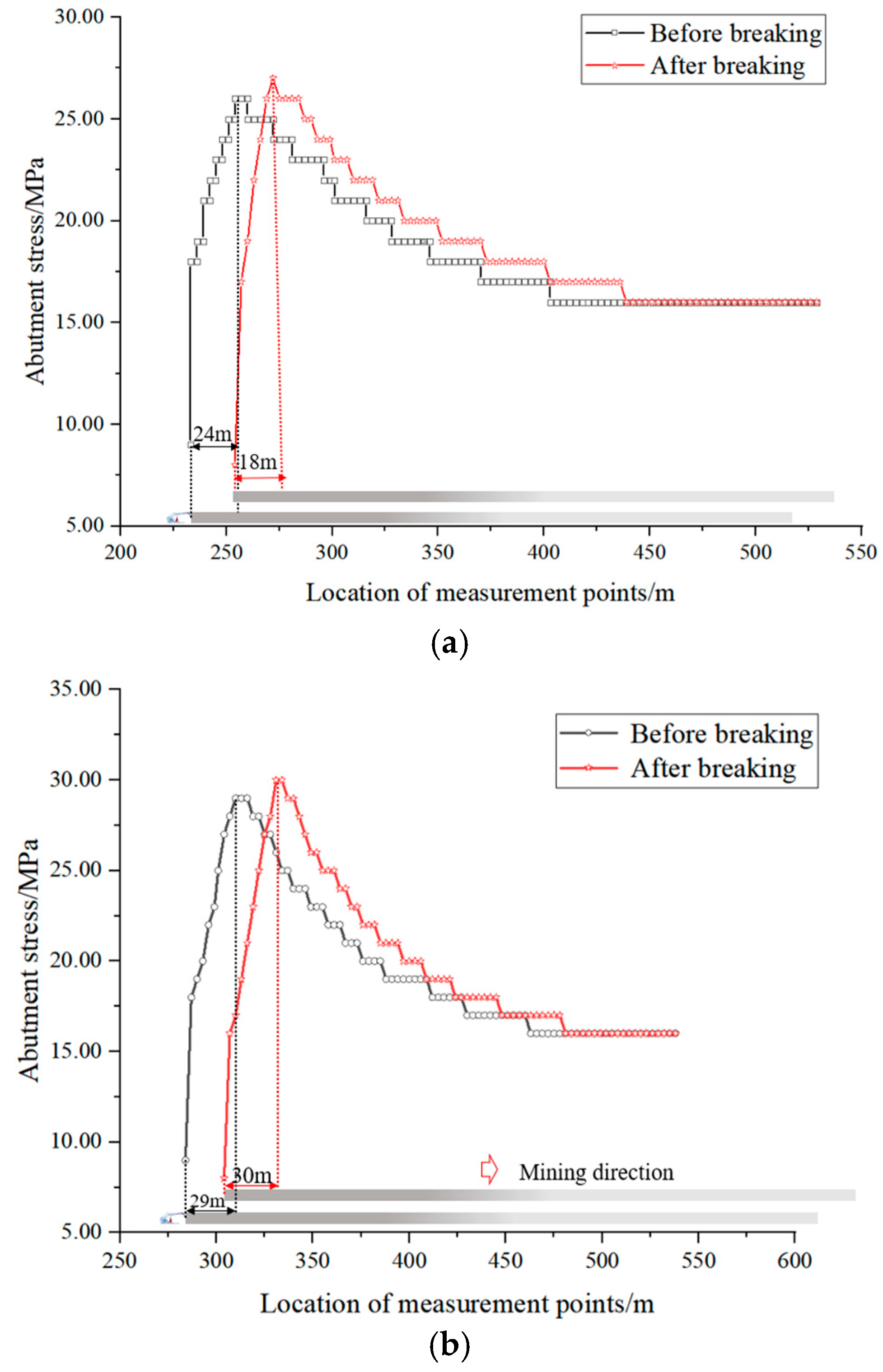

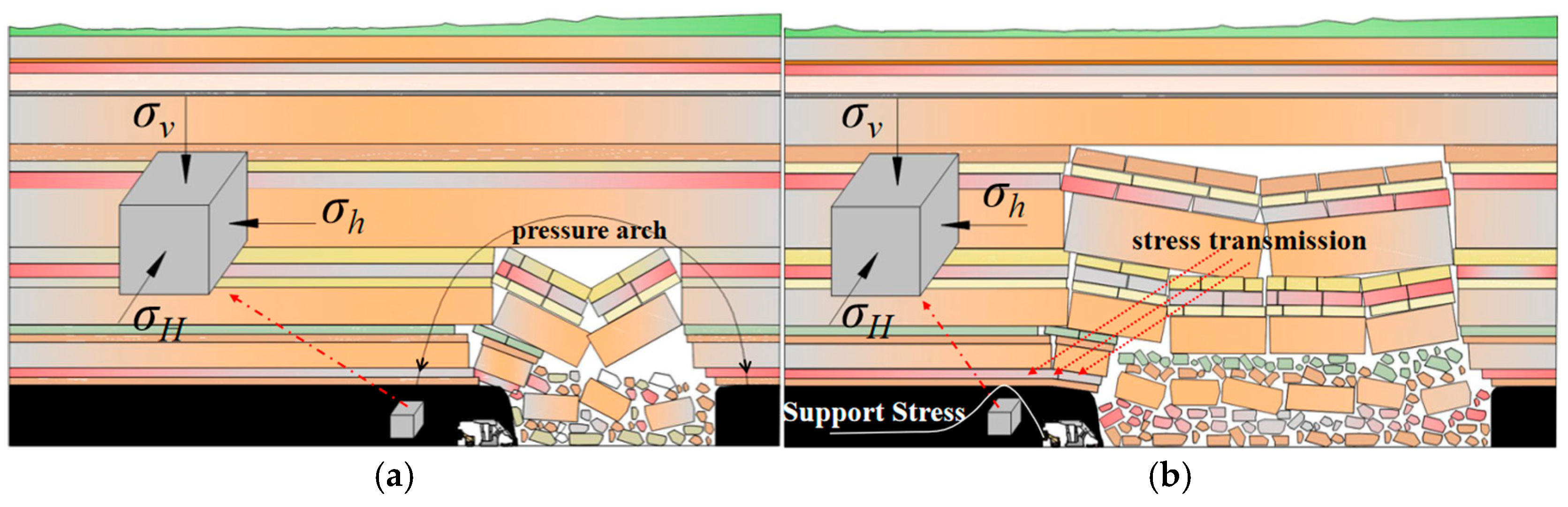

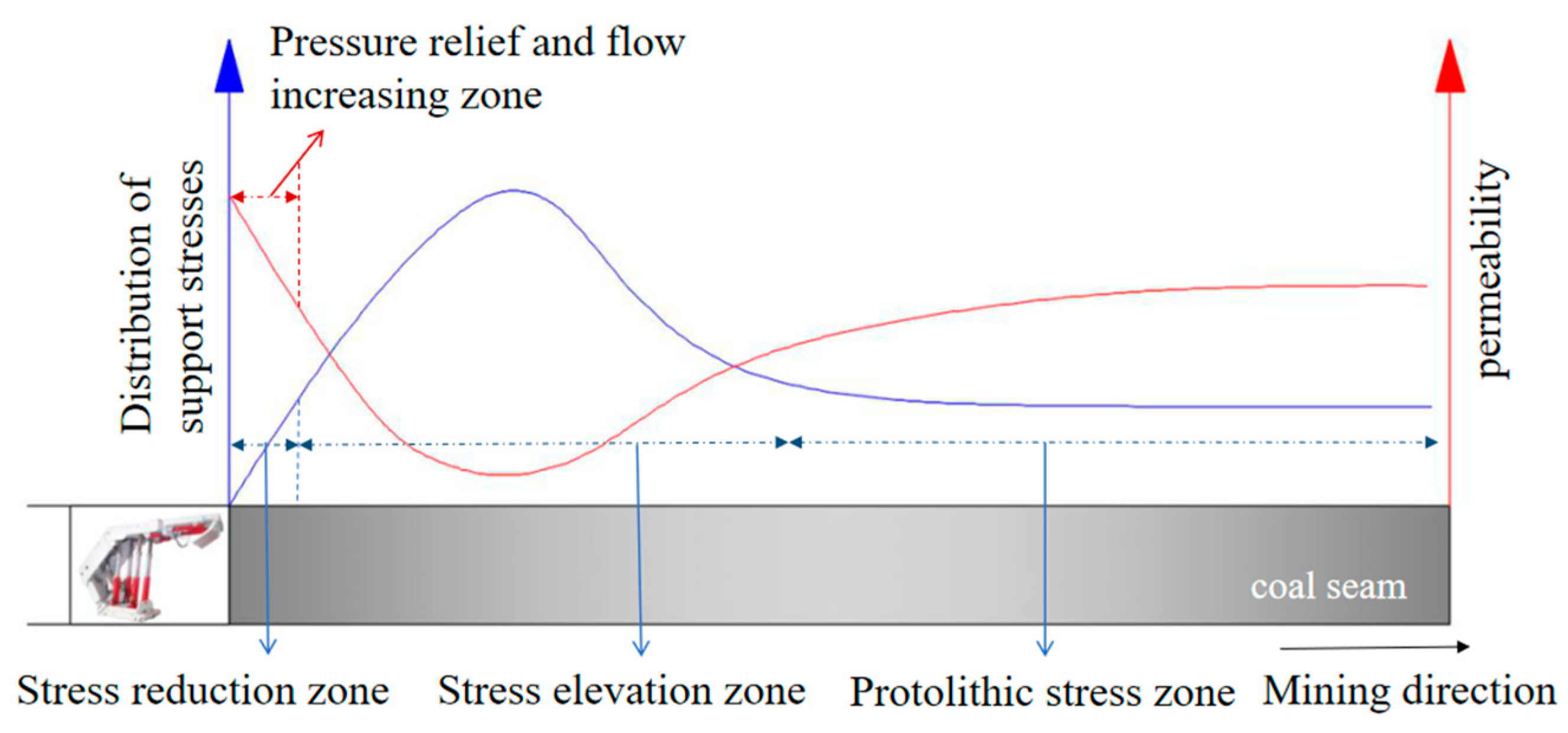

3.1. Stress Evolution on Hard Roofs Affecting Gas Desorption

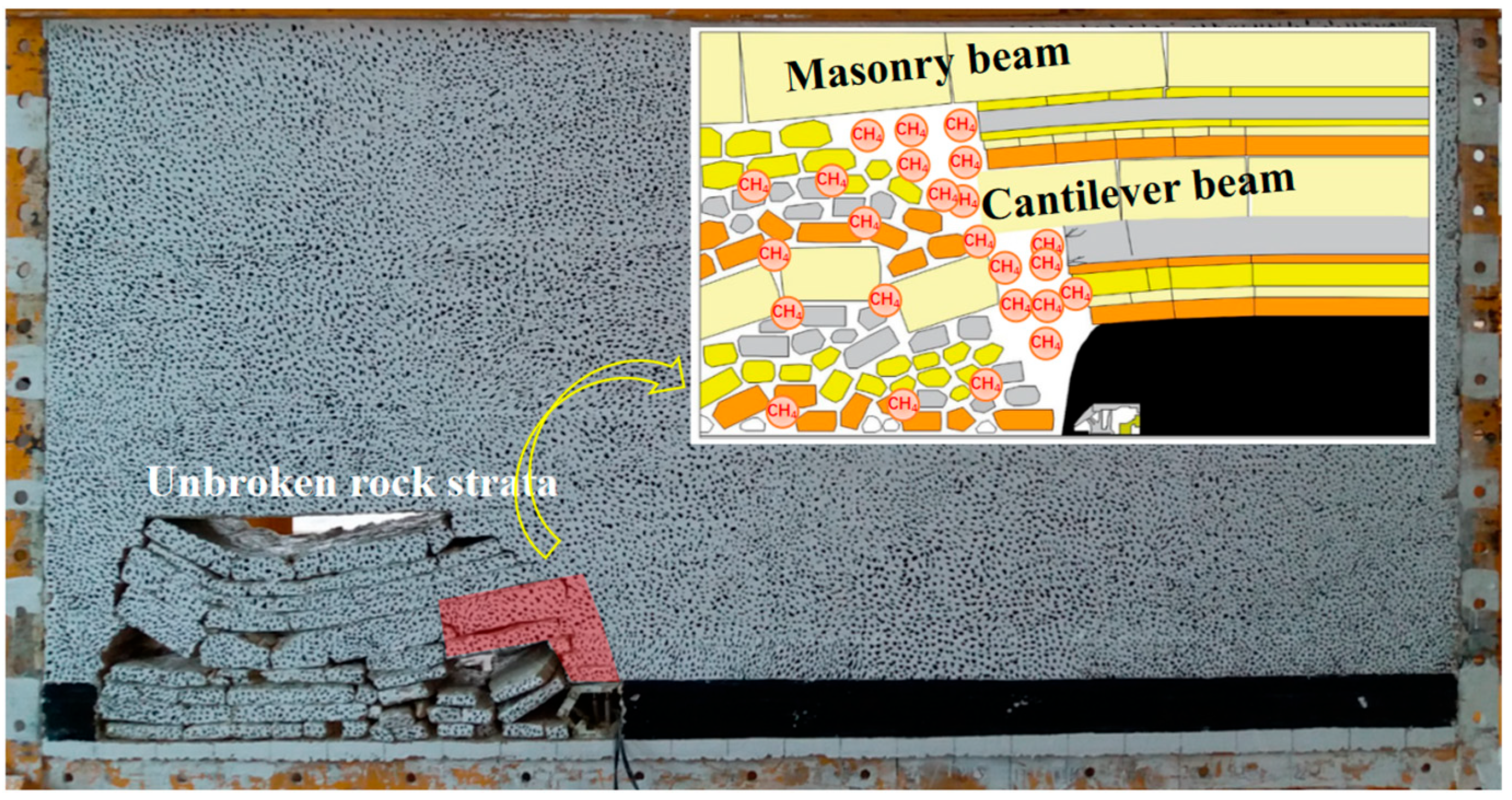

3.2. Gas Enrichment Characterization Based on Roof Breaking

3.3. The Effect of Roof Breaking on Gas Emission

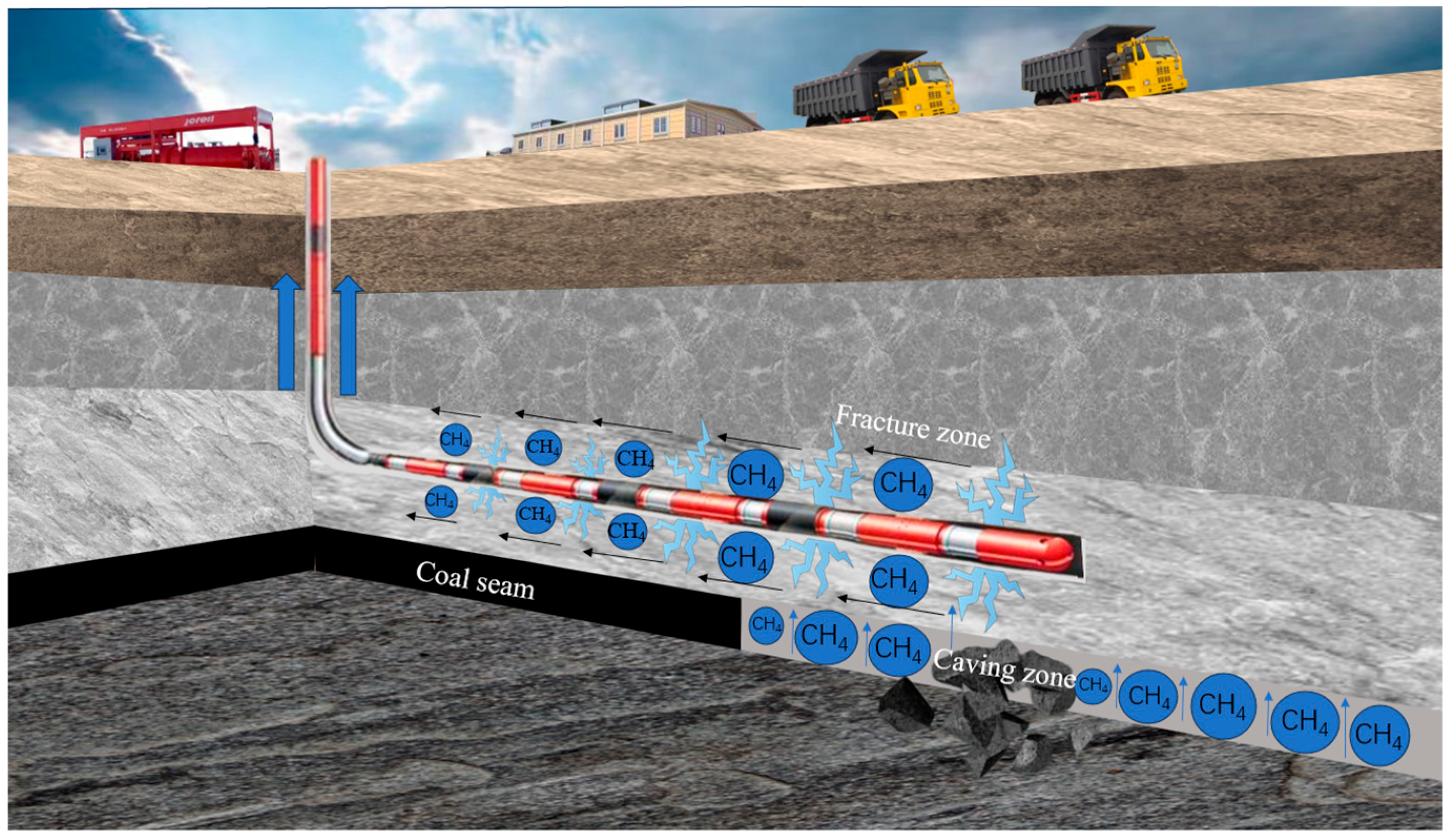

4. Gas Emission Control by Ground Fracturing

4.1. Rock Formations Weakening Based on Ground Fracturing

4.2. Roof Fracturing Modification Affects Gas Emission

4.3. Characterization of Full Time-Space Pumping in Fracturing Wells

5. Engineering Practice

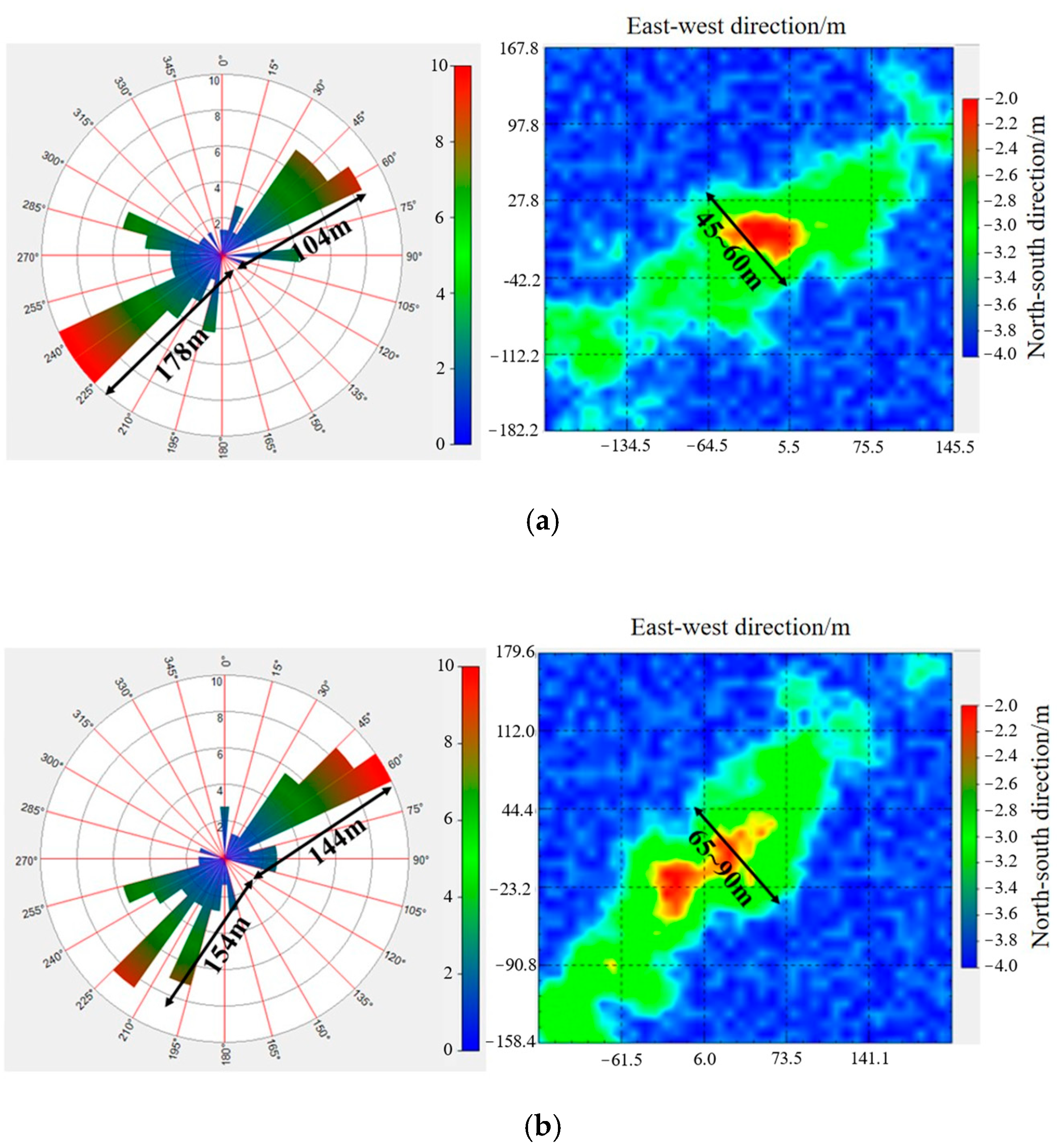

5.1. Extraction Effect of Vertical Fracturing Well

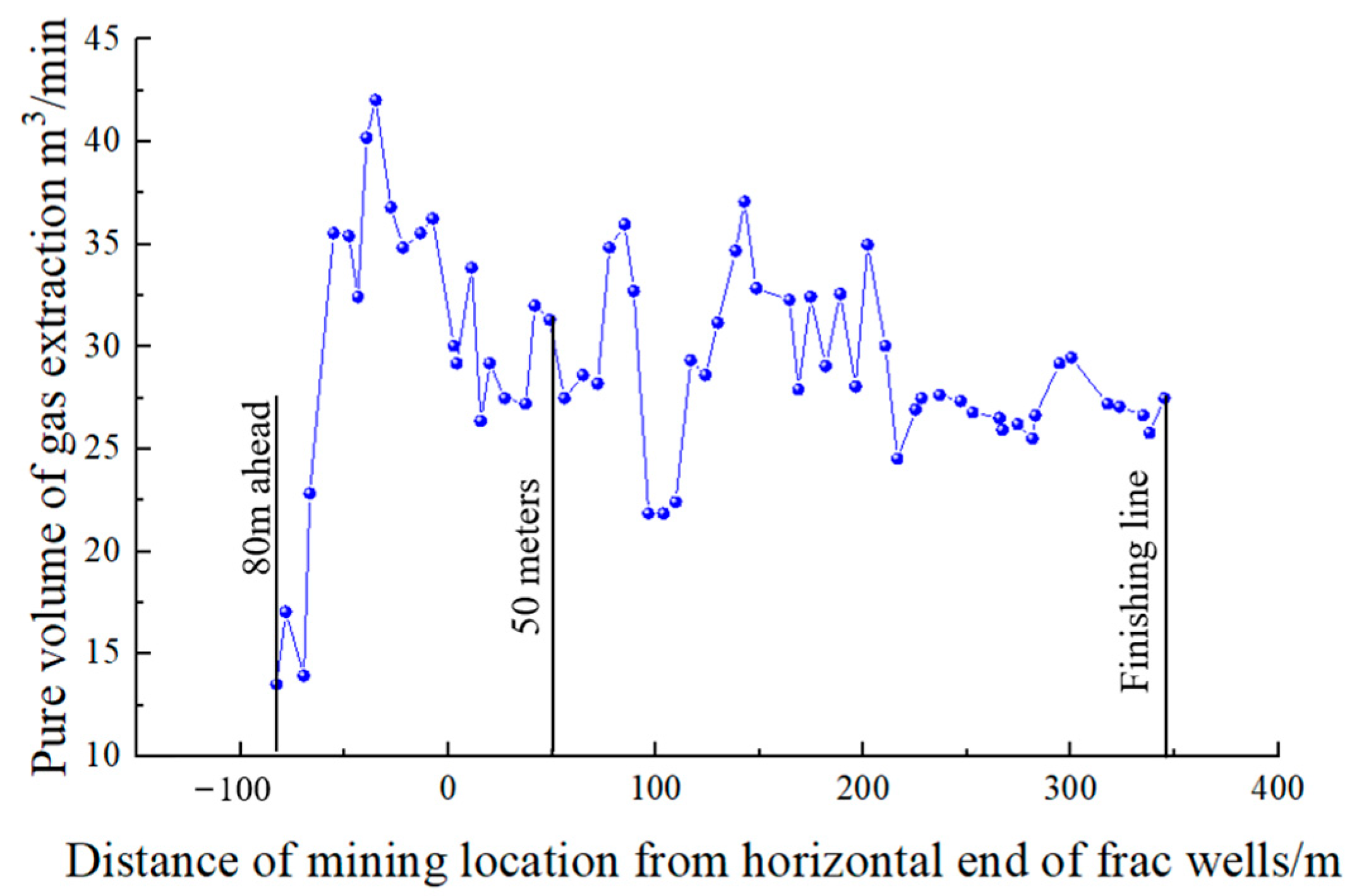

5.2. Extraction Effect of Horizontal Well Fracturing

6. Conclusions

- (1)

- The technology of “ground fracturing + gas extraction” is applied to improve the efficiency of gas extraction. This technology takes into account the characteristics of the ground fracturing seam network and analyzes the mechanisms of pressure relief and permeability enhancement through fracturing wells. Additionally, the full-time and spatial extraction characteristics of this technology have been thoroughly examined.

- (2)

- The field monitoring results have revealed a strong correlation between the concentration of gas extraction and the characteristics of roof breaking. The cycles of pressure exerted by the roof, both large and small, result in varying degrees of gas emission. During normal mining operations, the gas emission rate ranges from 35 to 45 m3/min. However, during periods of pressure exerted by the roof plate, the absolute gas emission rate can reach up to 55 to 75 m3/min, with individual peaks reaching 84 m3/min. This represents an increase of 20 to 30 m3/min compared to the gas emission rate during normal mining operations.

- (3)

- The characteristics of gas extraction under different conditions were analyzed in the 8101 working face using vertical well fracturing and in the 8204 working face using horizontal well fracturing in the Tashan Mine. The presence of a large-scale seam network resulting from ground fracturing weakened the stress concentration environment of the advancing coal body. This large-area seam network within the rock stratum facilitated the extraction of gas in the entire space. As a result, the application of “ground fracturing + gas extraction” by ground fracturing technology yielded positive results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, E.; Zhang, G.; Zhang, C.; Li, Z. Progress and prospect of theoretical and technical research on coal and gas outburst prevention in China. J. China Coal Soc. 2022, 47, 297–322. [Google Scholar]

- Liu, T.; Zhao, Y.; Lin, B. Mechanical behavior response of coal and its influence on permeability under double pressure relief effect. J. China Coal Soc. 2022, 47, 2656–2667. [Google Scholar]

- Yu, B.; Xia, B.; Yu, P. Influence of Hard Roof Fracture on gas emission in Fully mechanized caving of super Thick Coal Seam. J. China Coal Soc. 2018, 43, 2243–2249. [Google Scholar]

- Zhang, M.; Deng, W.; Tan, Z.; Tang, K.; Jiang, S.; Shang, Z. Research on filtering methane with spatial reticular stucture in coal seam roof fracture zone. Coal Sci. Technol. 2023, 51, 96–103. [Google Scholar]

- Pan, J.; Nie, H. Analysis on influencing factors and countermeasures of gas emission in high yield and high efficiency fully mechanized mining face. China Coal 2022, 48, 68–75. [Google Scholar]

- Meng, X.; Zhao, P.; Wang, X.; Liu, L.; Yang, J. Microseismic monitoring and gas extraction effect of mining overburden “three zones” in high gas seam with large dip Angle. Coal Sci. Technol. 2022, 50, 177–185. [Google Scholar]

- Liu, T.; Lin, B.; Shi, Y.; Liu, T. Dynamic Response of Gas Recovery Enhancement Efficiency in Coalbed Methane Displacement by Hot Flue Gas: From the Perspective of Thermo-Hydro-Mechanical-Chemical Coupling. Energy Fuels 2024, 38, 6962–6981. [Google Scholar] [CrossRef]

- Kędzior, S.; Dreger, M. Geological and Mining Factors Controlling the Current Methane Conditions in the Rydułtowy Coal Mine (Upper Silesian Coal Basin, Poland). Energies 2022, 15, 6364. [Google Scholar] [CrossRef]

- Leśniak, G.; Brunner, D.J.; Topór, T.; Słota-Valim, M.; Cicha-Szot, R.; Jura, B.; Skiba, J.; Przystolik, A.; Lyddall, B. Application of long-reach directional drilling boreholes for gas drainage of adjacent seams in coal mines with severe geological conditions. Int. J. Coal Sci. Technol. 2022, 9, 88. [Google Scholar] [CrossRef]

- Qu, Q.; Guo, H.; Balusu, R. Methane emissions and dynamics from adjacent coal seams in a high permeability multi-seam mining environment. Int. J. Coal Geol. 2022, 253, 103969. [Google Scholar] [CrossRef]

- Zheng, C.; Kizil, M.; Chen, Z.; Aminossadati, S. Effects of coal damage on permeability and gas drainage performance. Int. J. Min. Sci. Technol. 2017, 27, 783–786. [Google Scholar] [CrossRef]

- Chen, D.; Pan, Z.; Liu, J.; Connell, L.D. An improved relative permeability model for coal reservoirs. Int. J. Coal Geol. 2013, 109–110, 45–57. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Yang, W.; Liu, T.; Xiao, W.; Zha, W. Study of Effects of Hard Thick Roof on Gas Migration and Field Experiment of Roof Artificially Guided Pre-Splitting for Efficient Gas Control. Nat. Resour. Res. 2020, 29, 1819–1841. [Google Scholar] [CrossRef]

- Ren, F.; Ge, L.; Rufford, T.E.; Xing, H.; Rudolph, V. Permeability enhancement of coal by chemical-free fracturing using high-voltage electrohydraulic discharge. J. Nat. Gas Sci. Eng. 2018, 57, 1–10. [Google Scholar] [CrossRef]

- Song, J.; Zhang, H.; Yu, S.; Su, X. Application of integrated drilling and stamping technology in gas extraction through layer drilling. Energy Explor. Exploit. 2022, 40, 1113–1130. [Google Scholar] [CrossRef]

- Chen, Y.B.; Li, D.Q.; Wang, S.R.; Zou, Z.S.; Rabe, M. Study on mechanism of pressure relief and permeability enhancement in soft-hard composite coal seam by directional hydraulic flushing technology. Acta Montan. Slovaca 2022, 27, 522–536. [Google Scholar] [CrossRef]

- Li, C. Application of outburst risk analysis in the selection of liberated layer. Coal Technol. 2020, 39, 111–114. [Google Scholar]

- Xiao, F.; Duan, L.; Ge, Z. Fracture law of floor and application of gas drainage in Coal face. J. China Coal Soc. 2010, 35, 417–419. [Google Scholar]

- Yu, Y. Practice of long distance lower free layer mining in deep mine. Coal Technol. 2016, 35, 85–87. [Google Scholar]

- Slastunov, S.; Kolikov, K.; Batugin, A.; Sadov, A.; Khautiev, A. Improvement of Intensive In-Seam Gas Drainage Technology at Kirova Mine in Kuznetsk Coal Basin. Energies 2022, 15, 1047. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, M.; Kong, D.; Shang, Y.; Li, F. Optimization of drilling parameters for coal seam gas extraction considering fluid–solid coupling and field application. Energy Sci. Eng. 2024, 12, 657–669. [Google Scholar] [CrossRef]

- Jia, X. Research on gas extraction technology of high directional long borehole in Laochang Mining area “replacing roadway with hole”. Min. Saf. Environ. Prot. 2021, 48, 103–107. [Google Scholar]

- Gao, R.; Bai, D.; Yu, B.; Tai, Y.; Meng, X.; Zhang, W. Ground fracturing of multi-strata for strong ground pressure control in extra-thick coal seams with hard roofs: Numerical simulation and case study. Eng. Fract. Mech. 2024, 303, 110129. [Google Scholar]

- Gao, R.; Yang, J.; Kuang, T.; Liu, H. Investigation on the Ground Pressure Induced by Hard Roof Fracturing at Different Layers during Extra Thick Coal Seam Mining. Geofluids 2020, 2020, 8834235. [Google Scholar] [CrossRef]

- Ma, Z. Compaction and seepage characterization of fractured rock body in the air-mining zone. Xuzhou China Univ. Min. Technol. 2009, 29–34. [Google Scholar]

- Fu, M.; Zhang, Y.; Huang, Z.; Gao, Y.; Feng, C.; Xiao, S. Study on gas disturbance in upper corner by arc roof collapse. J. Min. Saf. Eng. 2016, 33, 185–190. [Google Scholar]

- Yu, B.; Gao, R.; Xia, B.; Kuang, T. Fracturing technology and Application of hard roof in large space. J. China Coal Soc. 2021, 46, 800–811. [Google Scholar]

- Gao, R.; Kuang, T.J.; Meng, X.B.; Huo, B. Effects of Ground Fracturing with Horizontal Fracture Plane on Rock Breakage Characteristics and Mine Pressure Control. Rock Mech. Rock Eng. 2021, 54, 3229–3243. [Google Scholar]

- Gao, R.; Kuang, T.J.; Zhang, Y.Q.; Zhang, W.Y. Controlling mine pressure by subjecting high-level hard rock strata to ground fracturing. Int. J. Coal Sci. Technol. 2021, 8, 1336–1350. [Google Scholar] [CrossRef]

- Lan, Y.; Gao, R.; Yu, B.; Meng, X. In Situ Studies on the Characteristics of Strata Structures and Behaviors in Mining of a Thick Coal Seam with Hard Roofs. Energies 2018, 11, 2470. [Google Scholar] [CrossRef]

| Borehole Number | Absolute Gas Pressure/MPa | Gas Content Coefficient/m3/(m3·MPa0.5) | Flow Rate of Gas in Boreholes/m3/d | Air Pressure/MPa | Gas Permeability Coefficient/(m2/MPa2·d) |

|---|---|---|---|---|---|

| 1# | 0.22 | 6.78 | 0.003 | 0.10 | 1.108 × 10−4 |

| 2# | 0.19 | 6.70 | 0.002 | 0.10 | 1.328 × 10−4 |

| Time of Emission/d | Borehole Flow Rate (m3/d) | |

|---|---|---|

| 3# | 4# | |

| 1 | 0.0080 | 0.0069 |

| 2 | 0.0023 | 0.0021 |

| 3 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, R.; Huang, X.; Zhang, C.; Bai, D.; Yu, B.; Tai, Y. Investigation of Uneven Gas Emission Mechanisms with Hard Roofs and Control Strategies by Ground Fracturing. Sustainability 2025, 17, 1564. https://doi.org/10.3390/su17041564

Gao R, Huang X, Zhang C, Bai D, Yu B, Tai Y. Investigation of Uneven Gas Emission Mechanisms with Hard Roofs and Control Strategies by Ground Fracturing. Sustainability. 2025; 17(4):1564. https://doi.org/10.3390/su17041564

Chicago/Turabian StyleGao, Rui, Xiao Huang, Chenxi Zhang, Dou Bai, Bin Yu, and Yang Tai. 2025. "Investigation of Uneven Gas Emission Mechanisms with Hard Roofs and Control Strategies by Ground Fracturing" Sustainability 17, no. 4: 1564. https://doi.org/10.3390/su17041564

APA StyleGao, R., Huang, X., Zhang, C., Bai, D., Yu, B., & Tai, Y. (2025). Investigation of Uneven Gas Emission Mechanisms with Hard Roofs and Control Strategies by Ground Fracturing. Sustainability, 17(4), 1564. https://doi.org/10.3390/su17041564