From Volcanic Popcorn to the Material of the Future: A Critical Review of Expanded Perlite Applications and Environmental Impacts

Abstract

1. Introduction

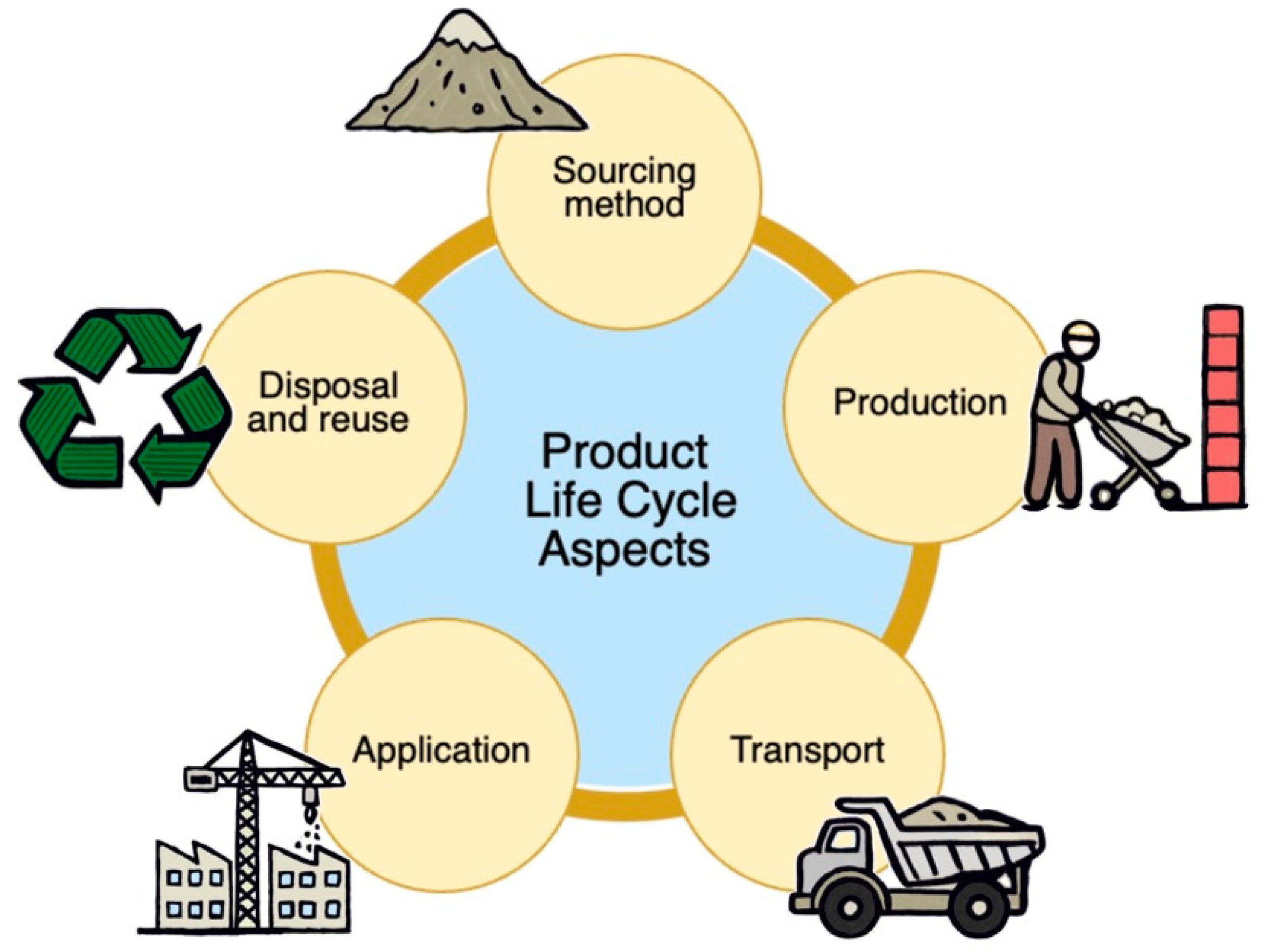

2. Life Cycle Assessment (LCA) of Perlite

3. Impact of Perlite on Plants

3.1. Perlite in Heavy Metal Remediation

3.2. Perlite as a Growth Medium in Green Roofs and Soilless Cultivation

3.3. Effects of Perlite on Microorganisms and Environmental Aspects

4. Impact of Perlite on Living Organisms

4.1. Toxicological Impact

4.2. Pro-Ecological and Pest Control Applications

4.3. Applications in Animal Husbandry

5. Discussion

6. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ballenger, C.; Dunlop, R. That Wonderful Volcanic Popcorn. Popular Mechanics, December 1954; pp. 136–139, 234. [Google Scholar]

- Jalaei, F.; Jalaei, F.; Mohammadi, S. An Integrated BIM-LEED Application to Automate Sustainable Design Assessment Framework at the Conceptual Stage of Building Projects. Sustain. Cities Soc. 2020, 53, 101979. [Google Scholar] [CrossRef]

- Ferreira, A.; Pinheiro, M.D.; Brito, J.d.; Mateus, R. A Critical Analysis of LEED, BREEAM and DGNB as Sustainability Assessment Methods for Retail Buildings. J. Build. Eng. 2023, 66, 105825. [Google Scholar] [CrossRef]

- Marchi, L.; Antonini, E.; Politi, S. Green Building Rating Systems (GBRSs). Encyclopedia 2021, 1, 998–1009. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of Construction and Demolition Waste Management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An Overview of the Waste Hierarchy Framework for Analyzing the Circularity in Construction and Demolition Waste Management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

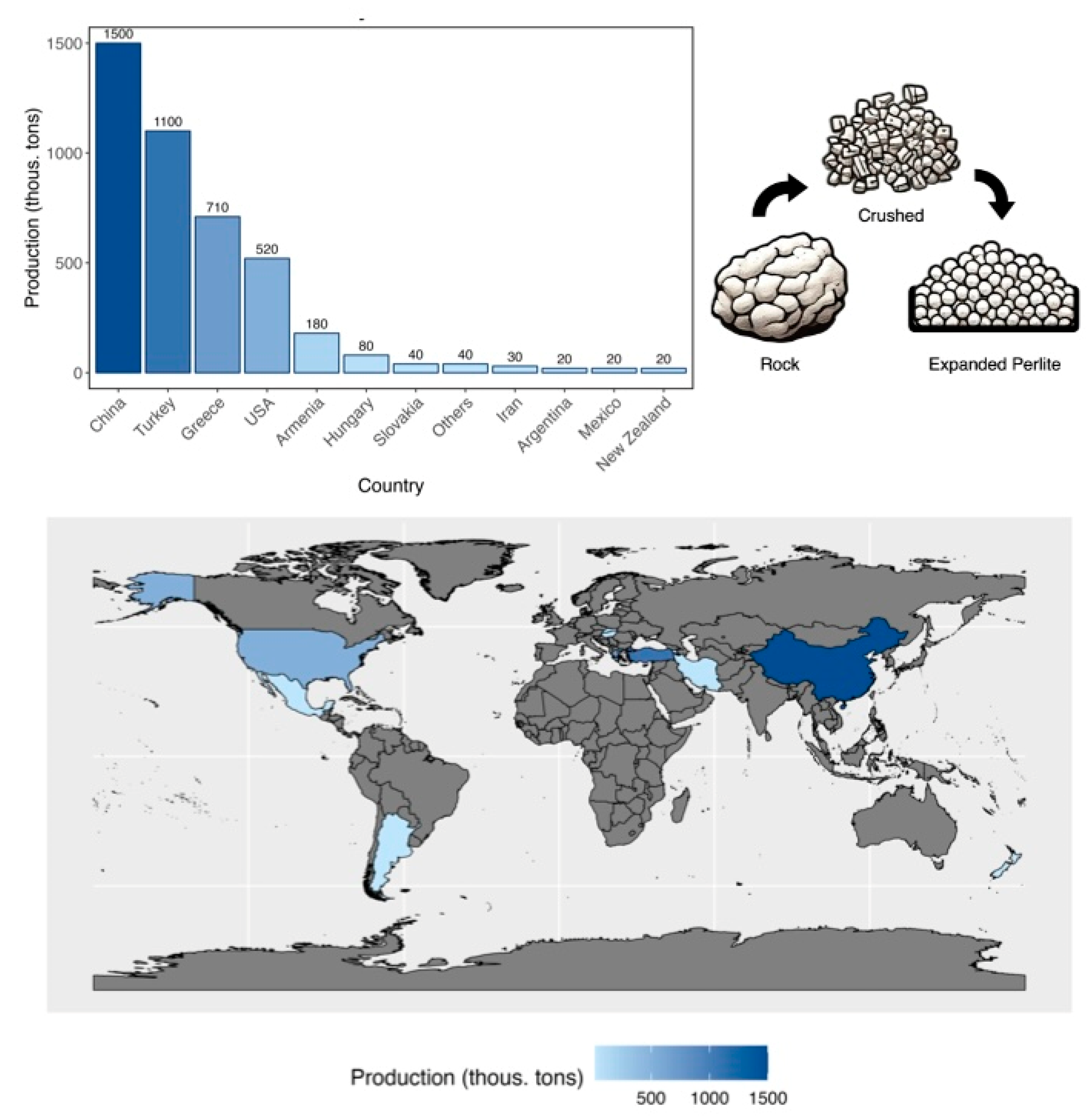

- U.S. Department of the Interior. U.S. Geological Survey Mineral Commodity Summaries 2023. Available online: https://pubs.usgs.gov/periodicals/mcs2023/mcs2023.pdf (accessed on 3 February 2025).

- Koukouzas, N.K.; Dunham, A.C.; Scott, P.W. Suitability of Greek Perlite for Industrial Applications. Trans. Inst. Min. Metall. Sect. B Appl. Earth Sci. 2000, 109, 105–111. [Google Scholar] [CrossRef]

- Burkowicz, A.; Czerw, H.; Figarska-Warchoł, B.; Galos, K.; Gałaś, A.; Guzik, K.; Kamyk, J.; Kot-Niewiadomska, A.; Lewicka, E.; Szlugaj, J. Management of Mineral Resources in Poland in 2011–2020. 2022. Available online: https://min-pan.krakow.pl/wydawnictwo/wp-content/uploads/sites/4/2022/03/Rocznik-GSM.pdf (accessed on 3 February 2025).

- Portugal Vermiculite, Perlite and Chlorites Unexpanded Imports by Country|2019|Data. Available online: https://wits.worldbank.org/trade/comtrade/en/country/PRT/year/2019/tradeflow/Imports/partner/ALL/product/253010 (accessed on 12 January 2024).

- Burriesci, N.; Arcoraci, C.; Antonucci, P.L.; Polizzotti, G. Physico-Chemical Characterization of Perlite of Various Origins. Mater. Lett. 1985, 3, 103–110. [Google Scholar] [CrossRef]

- Sodeyama, K.; Sakka, Y.; Kamino, Y.; Seki, H. Preparation of Fine Expanded Perlite. J. Mater. Sci. 1999, 34, 2461–2468. [Google Scholar] [CrossRef]

- Jia, G.; Li, Z.; Liu, P.; Jing, Q. Preparation and Characterization of Aerogel/Expanded Perlite Composite as Building Thermal Insulation Material. J. Non-Cryst. Solids 2018, 482, 192–202. [Google Scholar] [CrossRef]

- Karakaş, H.; İlkentapar, S.; Durak, U.; Örklemez, E.; Özuzun, S.; Karahan, O.; Atiş, C.D. Properties of Fly Ash-Based Lightweight-Geopolymer Mortars Containing Perlite Aggregates: Mechanical, Microstructure, and Thermal Conductivity Coefficient. Constr. Build. Mater. 2023, 362, 129717. [Google Scholar] [CrossRef]

- Saǧlik, A.U.; Erdoǧan, S.T. Chemical and Thermal Activation of Perlite-Containing Cementitious Mixtures. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 1517–1527. [Google Scholar]

- Wolfthaler, A.; Harsányi, P.; Schneider, M. Development and Performance of High Strength Lightweight Concrete with Perlites; Springer: Cham, Switzerland, 2024; pp. 126–133. [Google Scholar]

- Acar, M.C.; Çelik, A.İ.; Kayabaşı, R.; Şener, A.; Özdöner, N.; Özkılıç, Y.O. Production of Perlite-Based-Aerated Geopolymer Using Hydrogen Peroxide as Eco-Friendly Material for Energy-Efficient Buildings. J. Mater. Res. Technol. 2023, 24, 81–99. [Google Scholar] [CrossRef]

- Alkan, M.; Karadaş, M.; Doǧan, M.; Demirbaş, Ö. Zeta Potentials of Perlite Samples in Various Electrolyte and Surfactant Media. Colloids Surf. A Physicochem. Eng. Asp. 2005, 259, 155–166. [Google Scholar] [CrossRef]

- Singh, M.; Garg, M. Perlite-Based Building Materials—A Review of Current Applications. Constr. Build. Mater. 1991, 5, 75–81. [Google Scholar] [CrossRef]

- Topçu, I.B.; Işikdaǧ, B. Manufacture of High Heat Conductivity Resistant Clay Bricks Containing Perlite. Build. Environ. 2007, 42, 3540–3546. [Google Scholar] [CrossRef]

- Huang, G.; Pudasainee, D.; Gupta, R.; Liu, W.V. Thermal Properties of Calcium Sulfoaluminate Cement-Based Mortars Incorporated with Expanded Perlite Cured at Cold Temperatures. Constr. Build. Mater. 2021, 274, 122082. [Google Scholar] [CrossRef]

- Burkowicz, A. Perlit Ekspandowany—Materiał Termoizolacyjny Mało Znany w Polsce. Zesz. Nauk. Inst. Gospod. Surowcami Miner. I Energią Pol. Akad. Nauk. 2016, 96, 7–21. [Google Scholar]

- Szymczak-Graczyk, A.; Gajewska, G.; Laks, I.; Kostrzewski, W. Influence of Variable Moisture Conditions on the Value of the Thermal Conductivity of Selected Insulation Materials Used in Passive Buildings. Energies 2022, 15, 2626. [Google Scholar] [CrossRef]

- Ariyaratne, I.E.; Ariyanayagam, A.; Mahendran, M. Bushfire-Resistant Lightweight Masonry Blocks with Expanded Perlite Aggregate. Fire 2022, 5, 132. [Google Scholar] [CrossRef]

- Wang, X.; Wu, D.; Geng, Q.; Hou, D.; Wang, M.; Li, L.; Wang, P.; Chen, D.; Sun, Z. Characterization of Sustainable Ultra-High Performance Concrete (UHPC) Including Expanded Perlite. Constr. Build. Mater. 2021, 303, 124245. [Google Scholar] [CrossRef]

- Kaufhold, S.; Reese, A.; Schwiebacher, W.; Dohrmann, R.; Grathoff, G.H.; Warr, L.N.; Halisch, M.; Müller, C.; Schwarz-Schampera, U.; Ufer, K. Porosity and Distribution of Water in Perlite from the Island of Milos, Greece. J. Korean Phys. Soc. 2014, 3, 598. [Google Scholar] [CrossRef]

- Aksoy, Ö.; Alyamaç, E.; Mocan, M.; Sütçü, M.; Özveren-Uçar, N.; Seydibeyoğlu, M.Ö. Characterization of Perlite Powders from Izmir, Türkiye Region. Physicochem. Probl. Miner. Process. 2022, 58, 155277. [Google Scholar] [CrossRef]

- Maxim, L.D.; Niebo, R.; Mcconnell, E.E. Perlite Toxicology and Epidemiology—A Review. Inhal. Toxicol. 2014, 26, 259–270. [Google Scholar] [CrossRef]

- Chou, Y.S.; Singh, B.; Chen, Y.S.; Yen, S.C. Study on Volume Reduction of Radioactive Perlite Thermal Insulation Waste by Heat Treatment with Potassium Carbonate. Nucl. Eng. Technol. 2022, 54, 220–225. [Google Scholar] [CrossRef]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A Review and Evaluation of Thermal Insulation Materials and Methods for Thermal Energy Storage Systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- ASTM C728-17a(2022); Standard Specification for Perlite Thermal Insulation Board. ASTM: West Conshohocken, PA, USA, 2015.

- Zhang, X.; Yu, P.; Li, Y.; Yao, Z. Mechanical Properties and Thermal Insulation of Straw Fiber-Reinforced Perlite Concrete. Int. J. Heat Technol. 2023, 41, 247–252. [Google Scholar] [CrossRef]

- Nastac, S.; Nechita, P.; Debeleac, C.; Simionescu, C.; Seciureanu, M. The Acoustic Performance of Expanded Perlite Composites Reinforced with Rapeseed Waste and Natural Polymers. Sustainability 2022, 14, 103. [Google Scholar] [CrossRef]

- Yilmazer, S.; Ozdeniz, M.B. The Effect of Moisture Content on Sound Absorption of Expanded Perlite Plates. Build. Environ. 2005, 40, 311–318. [Google Scholar] [CrossRef]

- Li, T.T.; Chuang, Y.C.; Huang, C.H.; Lou, C.W.; Lin, J.H. Applying Vermiculite and Perlite Fillers to Sound-Absorbing/Thermal-Insulating Resilient PU Foam Composites. Fibers Polym. 2015, 16, 691–698. [Google Scholar] [CrossRef]

- Yanjun, X.; Rui, L.; Haiping, S.; Ran, J.; Jiayu, Z. The Characteristics of Perlite Sound Absorption Board Formed by Vibration Molding. Open Mater. Sci. J. 2015, 9, 39–42. [Google Scholar] [CrossRef]

- Khoshvatan, M.; Pouraminia, M. The Effects of Additives to Lightweight Aggregate on the Mechanical Properties of Structural Lightweight Aggregate Concrete. Civil. Environ. Eng. Rep. 2021, 31, 139–160. [Google Scholar] [CrossRef]

- Tie, T.S.; Mo, K.H.; Alengaram, U.J.; Kaliyavaradhan, S.K.; Ling, T.C. Study on the Use of Lightweight Expanded Perlite and Vermiculite Aggregates in Blended Cement Mortars. Eur. J. Environ. Civil. Eng. 2022, 26, 3612–3631. [Google Scholar] [CrossRef]

- Ibrahim, M.; Ahmad, A.; Barry, M.S.; Alhems, L.M.; Mohamed Suhoothi, A.C. Durability of Structural Lightweight Concrete Containing Expanded Perlite Aggregate. Int. J. Concr. Struct. Mater. 2020, 14, 50. [Google Scholar] [CrossRef]

- Szabó, R.; Dolgos, F.; Debreczeni, Á.; Mucsi, G. Characterization of Mechanically Activated Fly Ash-Based Lightweight Geopolymer Composite Prepared with Ultrahigh Expanded Perlite Content. Ceram. Int. 2022, 48, 4261–4269. [Google Scholar] [CrossRef]

- Stefanidou, M.; Pachta, V.; Konstantinidis, G. Exploitation of Waste Perlite Products in Lime-Based Mortars and Grouts. Sustain. Chem. Pharm. 2023, 32, 101024. [Google Scholar] [CrossRef]

- Mladenovič, A.; Šuput, J.S.; Ducman, V.; Škapin, A.S. Alkali-Silica Reactivity of Some Frequently Used Lightweight Aggregates. Cem. Concr. Res. 2004, 34, 1809–1816. [Google Scholar] [CrossRef]

- Bakhshi, M.; Dalalbashi, A.; Soheili, H. Energy Dissipation Capacity of an Optimized Structural Lightweight Perlite Concrete. Constr. Build. Mater. 2023, 389, 131765. [Google Scholar] [CrossRef]

- Guijarro-Miragaya, P.; Ferrández, D.; Atanes-Sánchez, E.; Zaragoza-Benzal, A. Characterization of a New Lightweight Plaster Material with Superabsorbent Polymers and Perlite for Building Applications. Buildings 2023, 13, 1641. [Google Scholar] [CrossRef]

- Basfar, S.; Al Jaberi, J.; Elkatatny, S.; Bageri, B.S. Prevention of Hematite Settling Using Perlite in Water-Based Drilling Fluid. J. Pet. Sci. Eng. 2022, 210, 110030. [Google Scholar] [CrossRef]

- Al Jaberi, J.; Bageri, B.; Elkatatny, S.; Solling, T. Performance of Perlite as Viscosifier in Manganese Tetroxide Water Based-Drilling Fluid. J. Mol. Liq. 2023, 374, 121218. [Google Scholar] [CrossRef]

- Mulidzi, A.R. Evaluating Sustainable Use and Management of Winery Solid Wastes through Composting. S. Afr. J. Enol. Vitic. 2021, 42, 193–200. [Google Scholar] [CrossRef]

- Jiang, L.; Jia, G.; Jiang, C.; Li, Z. Sugar-Coated Expanded Perlite as a Bacterial Carrier for Crack-Healing Concrete Applications. Constr. Build. Mater. 2020, 232, 117222. [Google Scholar] [CrossRef]

- Mohamed, A.; Basfar, S.; Elkatatny, S.; Bageri, B. Impact of Perlite on the Properties and Stability of Water-Based Mud in Elevated-Temperature Applications. ACS Omega 2020, 5, 32573–32582. [Google Scholar] [CrossRef]

- Roulia, M.; Chassapis, K.; Fotinopoulos, C.; Savvidis, T.; Katakis, D. Dispersion and Sorption of Oil Spills by Emulsifier-Modified Expanded Perlite. Spill Sci. Technol. Bull. 2003, 8, 425–431. [Google Scholar] [CrossRef]

- Bastani, D.; Safekordi, A.A.; Alihosseini, A.; Taghikhani, V. Study of Oil Sorption by Expanded Perlite at 298.15 K. Sep. Purif. Technol. 2006, 52, 295–300. [Google Scholar] [CrossRef]

- Painer, F.; Baldermann, A.; Gallien, F.; Eichinger, S.; Steindl, F.; Dohrmann, R.; Dietzel, M. Synthesis of Zeolites from Fine-Grained Perlite and Their Application as Sorbents. Materials 2022, 15, 4474. [Google Scholar] [CrossRef]

- Yudakov, A.; Ksenik, T.; Tsybulskaya, O.; Kisel, A. INSTRUMENTATION AND FEATURES OF PRODUCING THE OLEOPHILIC SORBENT ON THE PERLITE BASIS. Procedia Environ. Sci. Eng. Manag. 2021, 8, 103–113. [Google Scholar]

- Pastor-Bueis, R.; Sánchez-Cañizares, C.; James, E.K.; González-Andrés, F. Formulation of a Highly Effective Inoculant for Common Bean Based on an Autochthonous Elite Strain of Rhizobium Leguminosarum Bv. Phaseoli, and Genomic-Based Insights Into Its Agronomic Performance. Front. Microbiol. 2019, 10, 2724. [Google Scholar] [CrossRef] [PubMed]

- Bamdad, H.; Papari, S.; Lazarovits, G.; Berruti, F. Soil Amendments for Sustainable Agriculture: Microbial Organic Fertilizers. Soil. Use Manag. 2022, 38, 94–120. [Google Scholar] [CrossRef]

- Lebedeva, E.Y.; Kazmina, O.V. Nature and Quantity of Silicate Filler Influence on Silicate Paint Properties with Lowered Content of Volatile Compounds. ChemChemTech 2018, 61, 70–76. [Google Scholar] [CrossRef]

- Bian, Z.; Carchi, N.; Liu, X. A Literature Review on Railroad Tank Car Thermal Protection Systems. In Proceedings of the 2020 Joint Rail Conference, JRC, St. Louis, MO, USA, 20–22 April 2020. [Google Scholar]

- Hochmuth, G.J.; Hochmuth, R.C. Nutrient Solution Formulation for Hydroponic (Perlite, Rockwool, NFT) Tomatoes in Florida. Hortic. Sci. Dep. 2018, 2018, 1–10. [Google Scholar] [CrossRef]

- He, C.; Liu, Z.; Wu, J.; Pan, X.; Fang, Z.; Li, J.; Bryan, B.A. Future Global Urban Water Scarcity and Potential Solutions. Nat. Commun. 2021, 12, 4667. [Google Scholar] [CrossRef]

- PKN PN-EN ISO 14040:2009; Environmental Management—Life Cycle Assessment—Principles and Structure. International Organization for Standardization: Geneva, Switzerland, 2009. Available online: https://sklep.pkn.pl/pn-en-iso-14040-2009p.html (accessed on 18 July 2023).

- Toboso-Chavero, S.; Madrid-López, C.; Villalba, G.; Gabarrell Durany, X.; Hückstädt, A.B.; Finkbeiner, M.; Lehmann, A. Environmental and Social Life Cycle Assessment of Growing Media for Urban Rooftop Farming. Int. J. Life Cycle Assess. 2021, 26, 2085–2102. [Google Scholar] [CrossRef]

- Abed, M.; Fořt, J.; Rashid, K. Multicriterial Life Cycle Assessment of Eco-Efficient Self-Compacting Concrete Modified by Waste Perlite Powder and/or Recycled Concrete Aggregate. Constr. Build. Mater. 2022, 348, 128696. [Google Scholar] [CrossRef]

- Addington, M.; Schodek, D. Smart Materials and New Technologies for the Architecture and Design Professions; Elsevier: Amsterdam, The Netherlands, 2005; Volume 1. [Google Scholar]

- Mohamed, A.S.Y. Smart Materials Innovative Technologies in Architecture; Towards Innovative Design Paradigm. Energy Procedia 2017, 115, 139–154. [Google Scholar] [CrossRef]

- Vazquez, E.; Randall, C.; Duarte, J.P. Shape-Changing Architectural Skins A Review on Materials, Design and Fabrication Strategies and Performance Analysis. J. Facade Des. Eng. 2019, 7, 93–114. [Google Scholar]

- Vinci, G.; Rapa, M. Hydroponic Cultivation: Life Cycle Assessment of Substrate Choice. Br. Food J. 2019, 121, 1801–1812. [Google Scholar] [CrossRef]

- Pushkar, S. Modeling the Substitution of Natural Materials with Industrial Byproducts in Green Roofs Using Life Cycle Assessments. J. Clean. Prod. 2019, 227, 652–661. [Google Scholar] [CrossRef]

- Gómez-Cuervo, S.; Alfonsín, C.; Hernández, J.; Feijoo, G.; Moreira, M.T.; Omil, F. Diffuse Methane Emissions Abatement by Organic and Inorganic Packed Biofilters: Assessment of Operational and Environmental Indicators. J. Clean. Prod. 2017, 143, 1191–1202. [Google Scholar] [CrossRef]

- Kucharczyk, S.; Pichór, W. The Effect of Waste-Expanded Perlite on Alkali Activation of Ground Granulated Blast Furnace Slag. Mater. Struct./Mater. Constr. 2023, 56, 58. [Google Scholar] [CrossRef]

- El-Mir, A.; Hwalla, J.; El-Hassan, H.; Assaad, J.J.; El-Dieb, A.; Shehab, E. Valorization of Waste Perlite Powder in Geopolymer Composites. Constr. Build. Mater. 2023, 368, 130491. [Google Scholar] [CrossRef]

- Dacić, A.; Fenyvesi, O.; Kopecskó, K. Investigation of Waste Perlite and Recycled Concrete Powders as Supplementary Cementitious Materials. Period. Polytech. Civil. Eng. 2023, 67, 683–694. [Google Scholar] [CrossRef]

- Dzięcioł, J.; Radziemska, M. Blast Furnace Slag, Post-Industrial Waste or Valuable Building Materials with Remediation Potential? Minerals 2022, 12, 478. [Google Scholar] [CrossRef]

- Radziemska, M.; Dzięcioł, J.; Gusiatin, Z.M.; Bęś, A.; Sas, W.; Głuchowski, A.; Gawryszewska, B.; Mazur, Z.; Brtnicky, M. Recycling of Blast Furnace and Coal Slags in Aided Phytostabilisation of Soils Highly Polluted with Heavy Metals. Energies 2021, 14, 4300. [Google Scholar] [CrossRef]

- Khoshraftar, Z.; Masoumi, H.; Ghaemi, A. On the Performance of Perlite as a Mineral Adsorbent for Heavy Metals Ions and Dye Removal from Industrial Wastewater: A Review of the State of the Art. Case Stud. Chem. Environ. Eng. 2023, 8, 100385. [Google Scholar] [CrossRef]

- Nedjimi, B. Phytoremediation: A Sustainable Environmental Technology for Heavy Metals Decontamination. SN Appl. Sci. 2021, 3, 286. [Google Scholar] [CrossRef]

- Agra, H.; Solodar, A.; Bawab, O.; Levy, S.; Kadas, G.J.; Blaustein, L.; Greenbaum, N. Comparing Grey Water versus Tap Water and Coal Ash versus Perlite on Growth of Two Plant Species on Green Roofs. Sci. Total Environ. 2018, 633, 1272–1279. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Altland, J.E.; Samarakoon, U.C. Evaluation of Substrates for Cucumber Production in the Dutch Bucket Hydroponic System. Sci. Hortic. 2023, 308, 111578. [Google Scholar] [CrossRef]

- Martini, A.N.; Papafotiou, M.; Massas, I.; Chorianopoulou, N. Growing of the Cretan Therapeutic Herb Origanum Dictamnus in The Urban Fabric: The Effect of Substrate and Cultivation Site on Plant Growth and Potential Toxic Element Accumulation. Plants 2023, 12, 336. [Google Scholar] [CrossRef]

- Kapczyńska, A.; Kowalska, I.; Prokopiuk, B.; Pawłowska, B. Rooting Media and Biostimulator Goteo Treatment Effect the Adventitious Root Formation of Pennisetum ‘Vertigo’ Cuttings and the Quality of the Final Product. Agriculture 2020, 10, 570. [Google Scholar] [CrossRef]

- Ilahi, W.F.F.; Ahmad, D. A Study on the Physical and Hydraulic Characteristics of Cocopeat Perlite Mixture as a Growing Media in Containerized Plant Production. Sains Malays. 2017, 46, 975–980. [Google Scholar] [CrossRef]

- Rezaei, Z.; Jafarirad, S.; Kosari-Nasab, M. Modulation of Secondary Metabolite Profiles by Biologically Synthesized MgO/Perlite Nanocomposites in Melissa Officinalis Plant Organ Cultures. J. Hazard. Mater. 2019, 380, 120878. [Google Scholar] [CrossRef] [PubMed]

- Savvas, D.; Gruda, N. Application of Soilless Culture Technologies in the Modern Greenhouse Industry—A Review. Eur. J. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Bilderback, T.E.; Warren, S.L.; Owen, J.S.; Albano, J.P. Healthy Substrates Need Physicals Too! Horttechnology 2005, 15, 747–751. [Google Scholar] [CrossRef]

- Knavel, D.E. Fertility Levels in Soil-Substitute Media: Their Influence on Transplant Development, Macro-Nutrient Content, and Yield in Tomato1. J. Am. Soc. Hortic. Sci. 2022, 94, 132–135. [Google Scholar] [CrossRef]

- Herrera, F.; Castillo, J.E.; Chica, A.F.; López Bellido, L. Use of Municipal Solid Waste Compost (MSWC) as a Growing Medium in the Nursery Production of Tomato Plants. Bioresour. Technol. 2008, 99, 287–296. [Google Scholar] [CrossRef] [PubMed]

- Ayipio, E.; Wells, D.E.; Smith, M.; Blanchard, C. Performance of Greenhouse-Grown Beit Alpha Cucumber in Pine Bark and Perlite Substrates Fertigated with Biofloc Aquaculture Effluent. Horticulturae 2021, 7, 144. [Google Scholar] [CrossRef]

- Al-Shammari, A.M.A.; Abood, M.A.; Hamdi, G.J. Perlite Affects Some Plant Indicators and Reduces Water Deficit in Tomato. Int. J. Veg. Sci. 2018, 24, 490–500. [Google Scholar] [CrossRef]

- Klados, E.; Tzortzakis, N. Effects of Substrate and Salinity in Hydroponically Grown Cichorium Spinosum. J. Soil. Sci. Plant Nutr. 2014, 14, 211–222. [Google Scholar] [CrossRef]

- Kaya, C.; Tuna, A.L.; Ashraf, M.; Altunlu, H. Improved Salt Tolerance of Melon (Cucumis melo L.) by the Addition of Proline and Potassium Nitrate. Environ. Exp. Bot. 2007, 60, 397–403. [Google Scholar] [CrossRef]

- Yelboğa, M.N.M. LCA Analysis of Grafted Tomato Seedling Production in Turkey. Sustainability 2020, 12, 25. [Google Scholar] [CrossRef]

- Del Amor, F.M.; Martinez, V.; Cerdá, A. Salinity Duration and Concentration Affect Fruit Yield and Quality, and Growth and Mineral Composition of Melon Plants Grown in Perlite. HortScience 1999, 34, 1234–1237. [Google Scholar] [CrossRef]

- Silber, A.; Bar-Yosef, B.; Levkovitch, I.; Soryano, S. PH-Dependent Surface Properties of Perlite: Effects of Plant Growth. Geoderma 2010, 158, 275–281. [Google Scholar] [CrossRef]

- Vázquez, M.D.; Poschenrieder, C.H.; Barceló, J. Chromium vi Induced Structural and Ultrastructural Changes in Bush Bean Plants (Phaseolus vulgaris L.). Ann. Bot. 1987, 59, 427–438. [Google Scholar] [CrossRef]

- Barceló, J.; Vázquez, M.D.; Poschenrieder, C. Structural and Ultrastructural Disorders in Cadmium-treated Bush Bean Plants (Phaseolus vulgaris L.). New Phytol. 1988, 108, 37–49. [Google Scholar] [CrossRef] [PubMed]

- Manios, T.; Stentiford, E.I.; Millner, P.A. The Effect of Heavy Metals Accumulation on the Chlorophyll Concentration of Typha Latifolia Plants, Growing in a Substrate Containing Sewage Sludge Compost and Watered with Metaliferus Water. Ecol. Eng. 2003, 20, 65–74. [Google Scholar] [CrossRef]

- Işık, H.; Topalcengiz, Z.; Güner, S.; Aksoy, A. Generic and Shiga Toxin-Producing Escherichia Coli (O157:H7) Contamination of Lettuce and Radish Microgreens Grown in Peat Moss and Perlite. Food Control 2020, 111, 107079. [Google Scholar] [CrossRef]

- Hawkins, H.J.; Johansen, A.; George, E. Uptake and Transport of Organic and Inorganic Nitrogen by Arbuscular Mycorrhizal Fungi. Plant Soil 2000, 226, 275–285. [Google Scholar] [CrossRef]

- Szlachetka, O.; Dzięcioł, J.; Dohojda, M. Mechanical Properties of Perlite Concrete in Context to Its Use in Buildings’ External Walls. Materials 2024, 17, 5790. [Google Scholar] [CrossRef] [PubMed]

- Dzięcioł, J.; Szlachetka, O. Waste or Raw Material? Perlite Concrete as Part of a Sustainable Materials Management Process in the Construction Sector. Sustainability 2024, 16, 6818. [Google Scholar] [CrossRef]

- McMichael, R.F.; DiPalma, J.R.; Blumenstein, R.; Amenta, P.S.; Freedman, A.P.; Barbieri, E.J. A Small Animal Model Study of Perlite and Fir Bark Dust on Guinea Pig Lungs. J. Pharmacol. Methods 1983, 9, 209–217. [Google Scholar] [CrossRef] [PubMed]

- Roubik, K.; Sykora, K.; Sieger, L.; Ort, V.; Horakova, L.; Walzel, S. Perlite Is a Suitable Model Material for Experiments Investigating Breathing in High Density Snow. Sci. Rep. 2022, 12, 2070. [Google Scholar] [CrossRef]

- Saitoh, S.; Fujii, S.; Takeda, H. Evaluation of the Bottom-up Force of Accumulated Organic Matter on Microarthropods in a Temperate Forest Floor. Eur. J. Soil. Biol. 2011, 47, 409–413. [Google Scholar] [CrossRef]

- Showler, A.T.; Saelao, P. Integrative Alternative Tactics for Ixodid Control. Insects 2022, 13, 302. [Google Scholar] [CrossRef]

- Showler, A.T.; Harlien, J.L. Lethal Effects of Imergard WP, a Perlite-Based Dust, on Amblyomma Americanum (Ixodida: Ixodidae) Larvae and Nymphs. J. Med. Entomol. 2023, 60, 326–332. [Google Scholar] [CrossRef] [PubMed]

- Showler, A.T.; Harlien, J.L. Desiccant Dusts, With and Without Bioactive Botanicals, Lethal to Rhipicephalus (Boophilus) Microplus Canestrini (Ixodida: Ixodidae) in the Laboratory and on Cattle. J. Med. Entomol. 2023, 60, 346–355. [Google Scholar] [CrossRef] [PubMed]

- Dracheva, E.E.; Iatsyna, I.V.; Lapina, N.E.; Ianin, V.A.; Antoshina, L.I.; Zhadan, I.I.; Krasavina, E.K. [Influence of Perlite Sand on the Skin in Experiment]. Med. Tr. Prom. Ekol. 2012, 30–34. [Google Scholar] [PubMed]

- Popova, O.S.; Baryshev, V.A. Use of Sorption Premixes in Fish Farming as a Prevention of Nutritional Toxicosis. Leg. Regul. Vet. Med. 2023, 109–111. [Google Scholar] [CrossRef]

- Ghalehkandi, J.G.; Valilu, M.R.; Shayegh, J.; Eshratkhah, B.; Issabeagloo, E.; Ghaemmaghami, S. Effect of Different Levels of Perlite on Mucosal Lipase Enzymes Activity in Small Intestine of Broiler Chicks. Asian J. Anim. Vet. Adv. 2011, 6, 838–843. [Google Scholar] [CrossRef]

- Oguz, F.K.; Gumus, H.; Oguz, M.N.; Bugdayci, K.E.; Dagli, H.; Ozturk, Y. Effects of Different Levels of Expanded Perlite on the Performance and Egg Quality Traits of Laying Hens. Rev. Bras. Zootec. 2017, 46, 20–24. [Google Scholar] [CrossRef]

- Lin, I.J. Vermiculite & Perlite for Animal Feedstuff & Crop Farming. Ind. Miner. 1989, 262, 44–49. [Google Scholar]

- Öncel, I.; Keleş, Y.; Üstün, A.S. Interactive Effects of Temperature and Heavy Metal Stress on the Growth and Some Biochemical Compounds in Wheat Seedlings. Environ. Pollut. 2000, 107, 315–320. [Google Scholar] [CrossRef]

- Dzięcioł, J.; Sas, W. Estimation of the Coefficient of Permeability as an Example of the Application of the Random Forest Algorithm in Civil Engineering. Arch. Civil. Eng. 2024, 70, 119–134. [Google Scholar] [CrossRef]

- Dzięcioł, J.; Sas, W. Perspective on the Application of Machine Learning Algorithms for Flow Parameter Estimation in Recycled Concrete Aggregate. Materials 2023, 16, 1500. [Google Scholar] [CrossRef]

- Bedriñana, L.A.; Sucasaca, J.; Tovar, J.; Burton, H. Design-Oriented Machine-Learning Models for Predicting the Shear Strength of Prestressed Concrete Beams. J. Bridge Eng. 2023, 28, 04023009. [Google Scholar] [CrossRef]

- Naranjo-Pérez, J.; Infantes, M.; Fernando Jiménez-Alonso, J.; Sáez, A. A Collaborative Machine Learning-Optimization Algorithm to Improve the Finite Element Model Updating of Civil Engineering Structures. Eng. Struct. 2020, 225, 111327. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, X.; Tang, L.; Yin, Y.; Liu, D.; Zhang, Y. Application of Machine Learning, Deep Learning and Optimization Algorithms in Geoengineering and Geoscience: Comprehensive Review and Future Challenge. Gondwana Res. 2022, 109, 1–17. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| pH | from 6.6 to 8 [18] |

| bulk density (loose) | 25–400 kg/m3 [8,19,20] |

| true (skeletal) density | 0.84 g/cm3 to 2.45 g/cm3 |

| thermal conductivity | 0.034–0.04 W/m·K [21] for the bulk density of 90 kg/m3 at a room temperature of 24 °C to obtain 0.059 W/m·K [22,23] |

| specific heat | 837 J/kg·°C [24] |

| fire behavior | non-flammable—Fire class A1 |

| melting point | +1260 °C |

| chemical composition | the average values of main elements of chemical composition measured on XRF of expanded perlite from China [25], Greece [26], Turkey [27], and US [28] |

| 1—Environmental Engineering in Horticulture | |||

|---|---|---|---|

| Greatest Potential | The Reason for the Position in the Ranking | Possible Application Hazards | The Biggest Research Gap |

| Hydroponic substrates, production, and biofilters for the methane emission treatment | Effective for plants on green roofs, tomato seedlings, and soilless culture in commercial crop production. Extends greenhouse lifespan, allows recycling of used substrates, and improves nutrient and water management. Use of siderophore-producing microorganisms in perlite-containing soil helps plants combat heavy metal toxicity. Toxicological studies suggest that perlite has relatively low toxicity. | Sorption of heavy metals in perlite depends on experimental conditions such as pH, cation exchange capacity of soils, metal concentration, ligand concentration, competing ions, and particle size. Heavy metals are non-biodegradable and can lead to bioconcentration, biomagnification, and bioaccumulation in living organisms, causing various illnesses and disorders. | Further research is needed to optimize plant growth in perlite under different conditions, such as heat stress, salinity, drought, and heavy metal action. Lack of comprehensive, long-term environmental impact assessment research should focus on evaluating the extended environmental effects of using perlite as a growth medium, especially considering potential cumulative impacts and changes in soil properties over an extended period. |

| 2—Environmental Engineering in Animal Husbandry | |||

| Greatest Potential | The Reason for the Position in the Ranking | Possible Application Hazards | The Biggest Research Gap |

| As a feed additive | Studies indicate positive effects of perlite as a feed additive in animal husbandry. Specifically noted for enhancing enzyme activity in broiler chickens and improving egg quality in laying hens. It is used as litter in poultry houses, fillers, anti-caking agents, and adsorbent additives in veterinary preparations, pesticides, and fertilizers. Perlite demonstrates promise as an alternative control tactic for hard ticks. Effective in immobilizing and killing ticks without causing environmental degradation. A sorption complex containing perlite shows potential in reducing toxins in guppy aquarium fish. Suggests a possible preventive measure for food toxicosis in aquarium fish. | Although toxicological studies suggest that perlite has relatively low toxicity, it is regulated as a “nuisance dust” in most countries. Prolonged contact with perlite sand may contribute to the development of skin diseases, so protective measures are recommended for workers in contact with the substance. The introduction of microorganisms in perlite-containing soil may pose risks, especially if not managed properly. Adequate precautions should be taken to prevent the growth of harmful microorganisms. Fine perlite particles can become airborne during handling and processing. Prolonged inhalation of perlite dust may lead to respiratory irritation. | Lack of comprehensive research on the potential long-term health impacts on humans and animals exposed to perlite-containing products. Research should focus on monitoring and assessing the health outcomes of individuals, workers, or animals over extended periods of exposure to perlite, considering inhalation, dermal contact, and ingestion. Addressing this gap would provide a more thorough understanding of any chronic health risks associated with prolonged use or exposure to perlite-based materials in diverse settings, helping to establish appropriate safety guidelines and regulations. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzięcioł, J.; Szlachetka, O.; Rodrigues Tavares, J.M. From Volcanic Popcorn to the Material of the Future: A Critical Review of Expanded Perlite Applications and Environmental Impacts. Sustainability 2025, 17, 1454. https://doi.org/10.3390/su17041454

Dzięcioł J, Szlachetka O, Rodrigues Tavares JM. From Volcanic Popcorn to the Material of the Future: A Critical Review of Expanded Perlite Applications and Environmental Impacts. Sustainability. 2025; 17(4):1454. https://doi.org/10.3390/su17041454

Chicago/Turabian StyleDzięcioł, Justyna, Olga Szlachetka, and Jorge Manuel Rodrigues Tavares. 2025. "From Volcanic Popcorn to the Material of the Future: A Critical Review of Expanded Perlite Applications and Environmental Impacts" Sustainability 17, no. 4: 1454. https://doi.org/10.3390/su17041454

APA StyleDzięcioł, J., Szlachetka, O., & Rodrigues Tavares, J. M. (2025). From Volcanic Popcorn to the Material of the Future: A Critical Review of Expanded Perlite Applications and Environmental Impacts. Sustainability, 17(4), 1454. https://doi.org/10.3390/su17041454