The Energy Potential of Agricultural Biomass Residues for Household Use in Rural Areas in the Department La Guajira (Colombia)

Abstract

1. Introduction

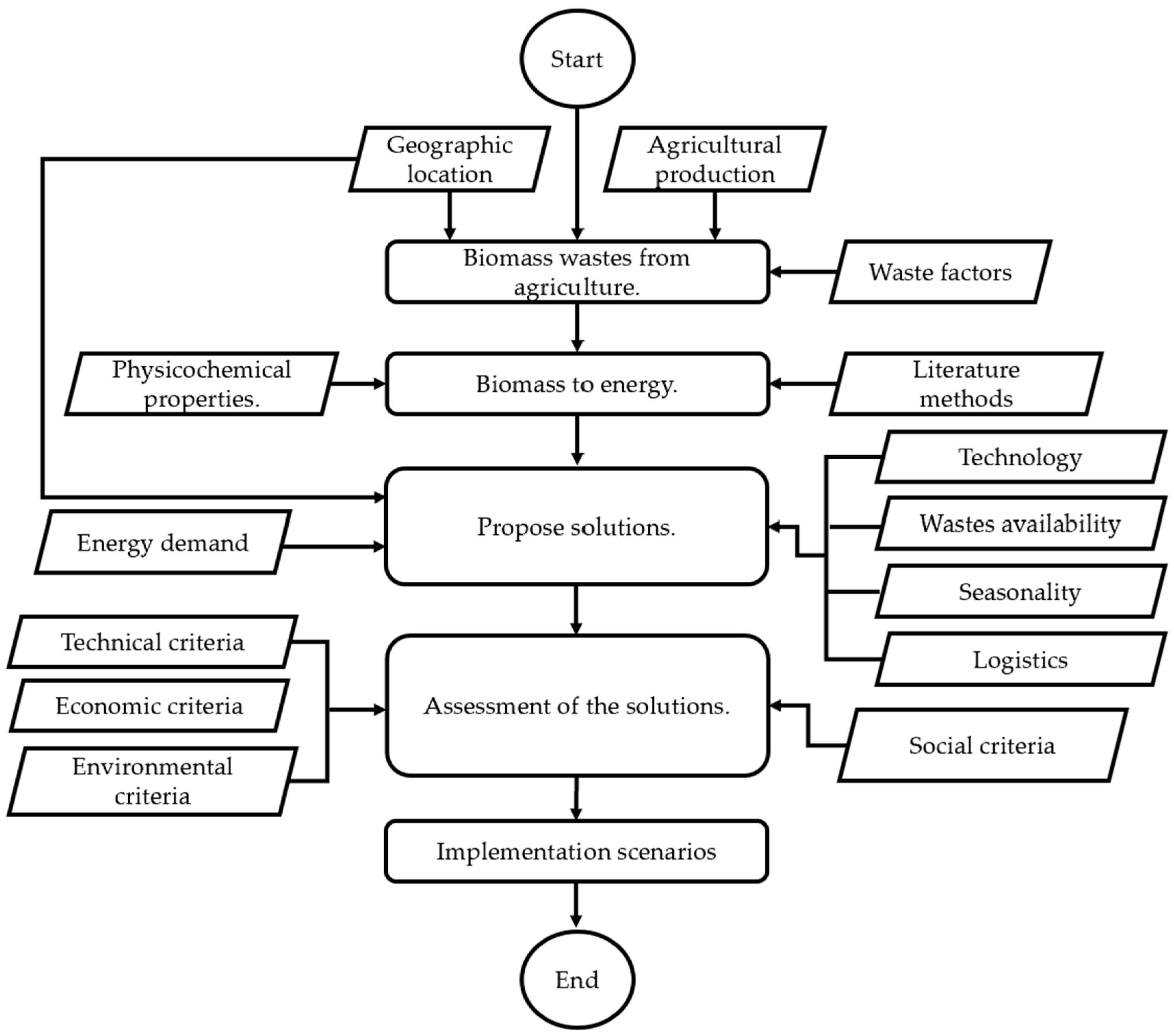

2. Materials and Methods

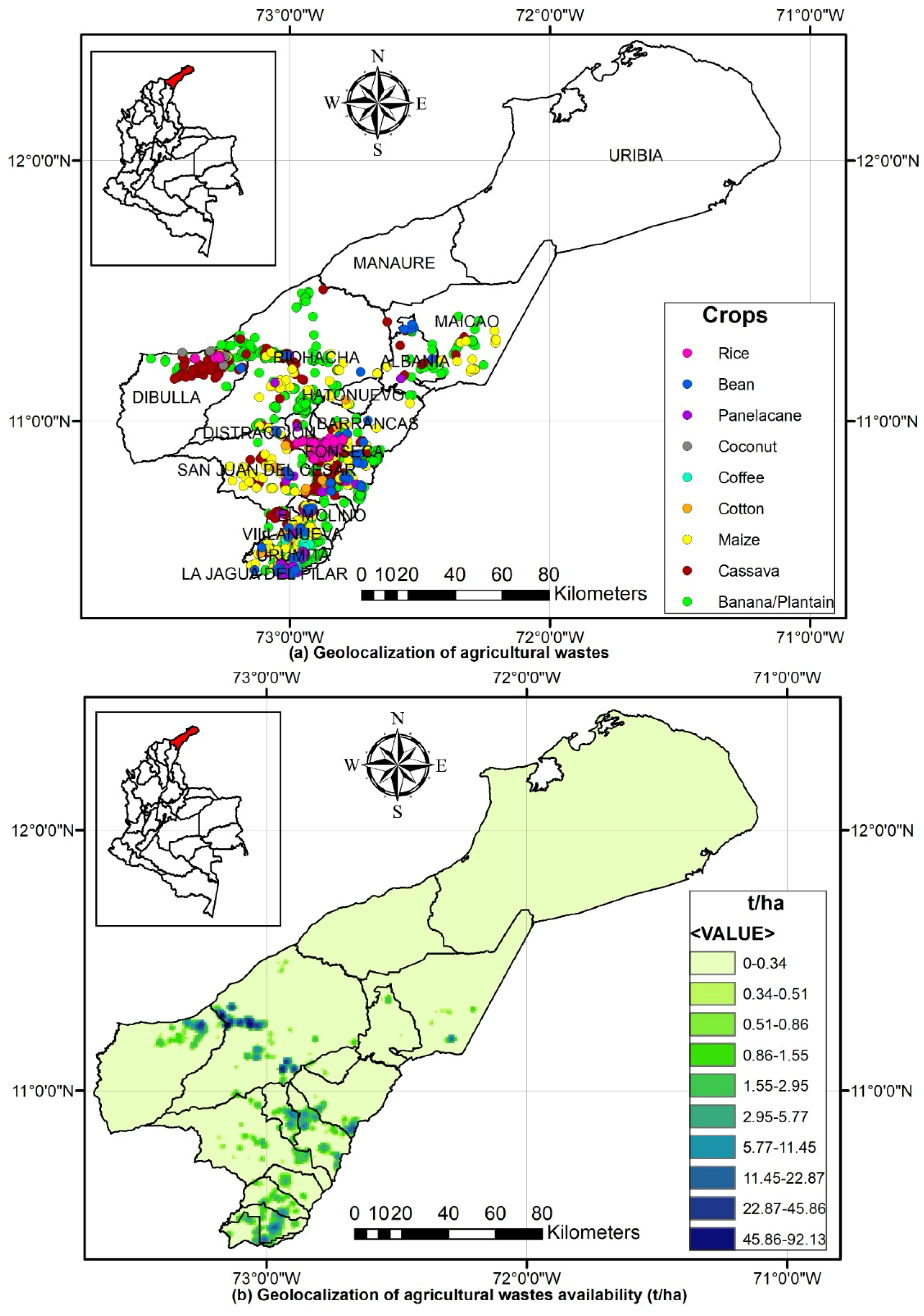

2.1. La Guajira Department

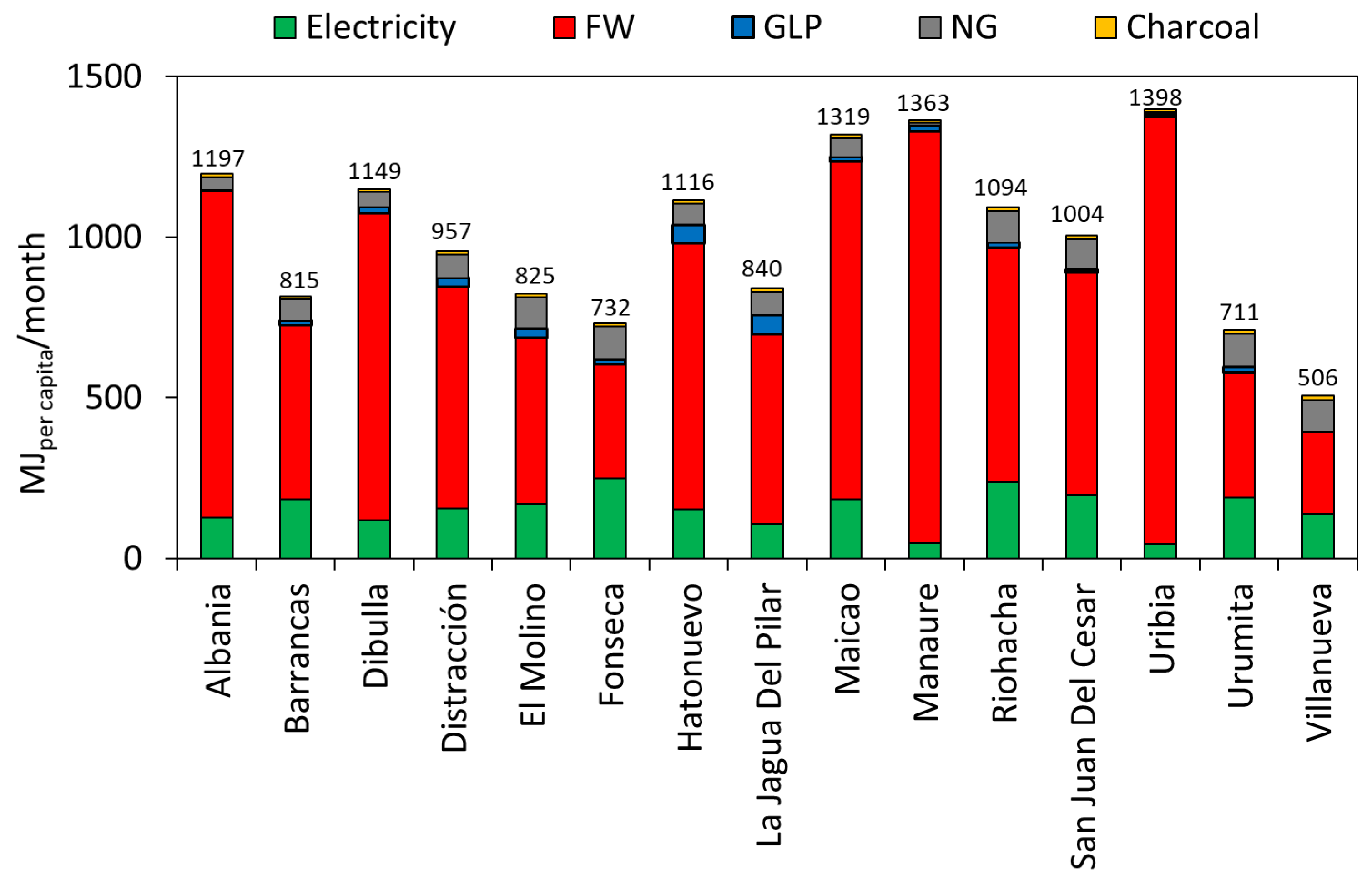

2.2. Energy Mix and Access to Modern Energy

Firewood Demand

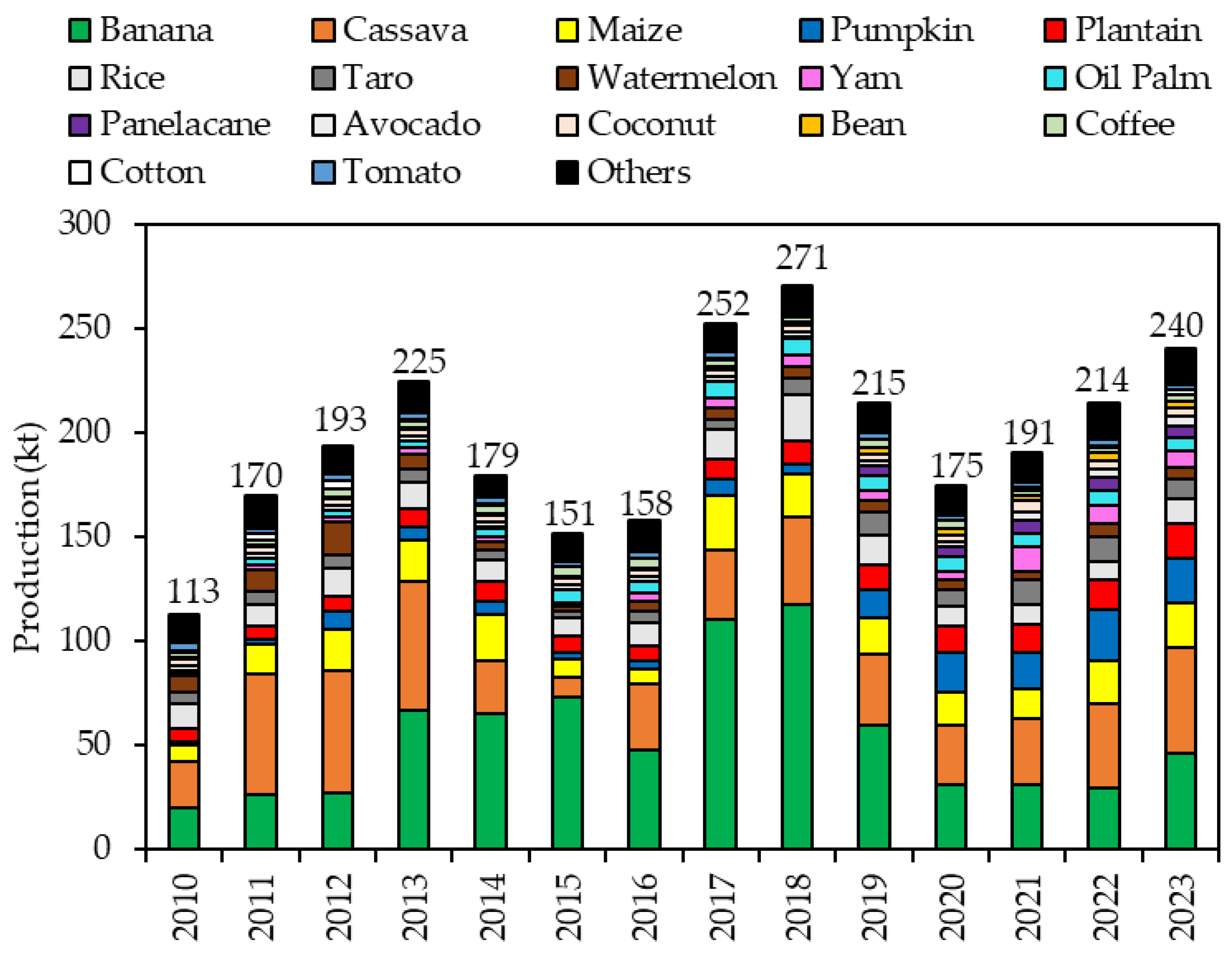

2.3. Agricultural Production

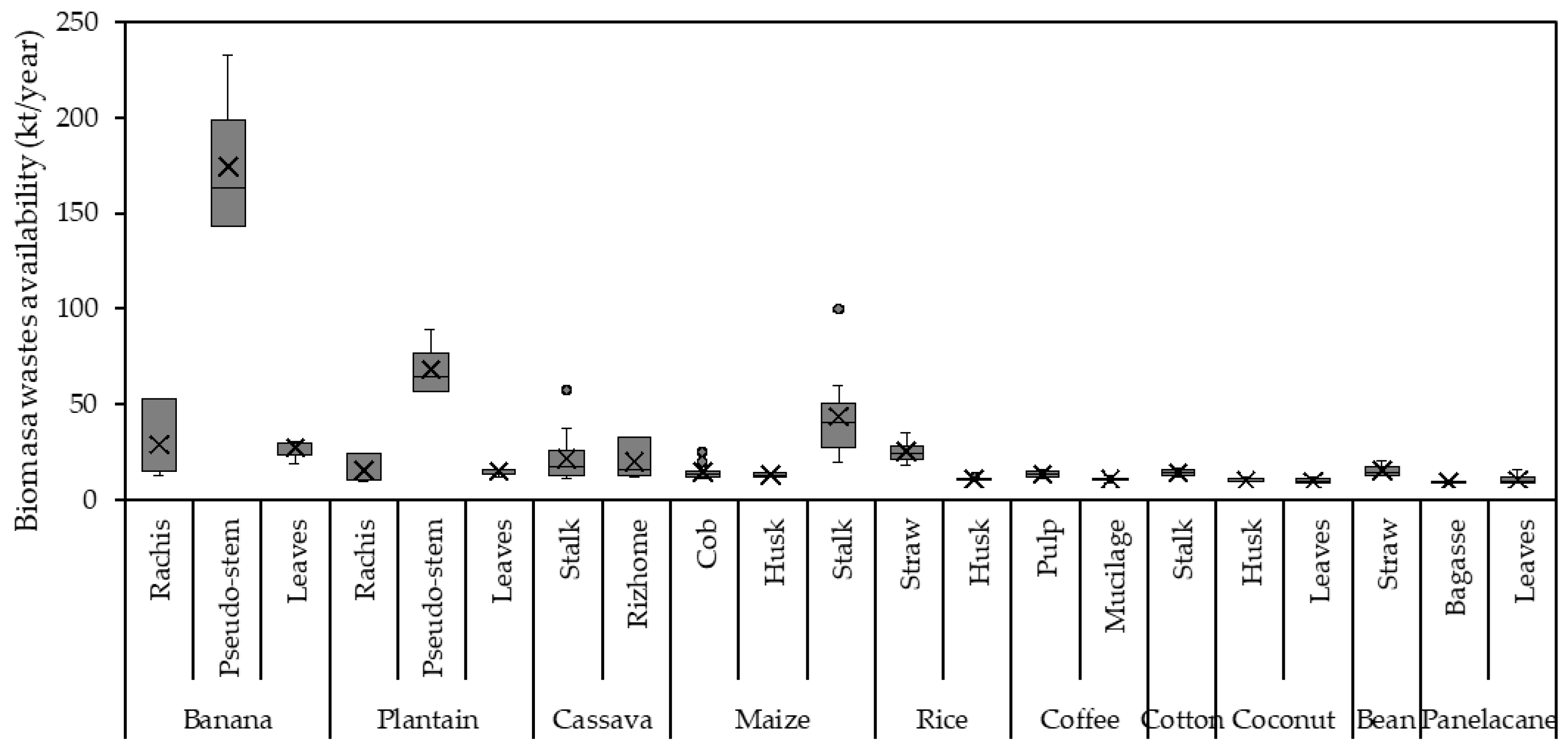

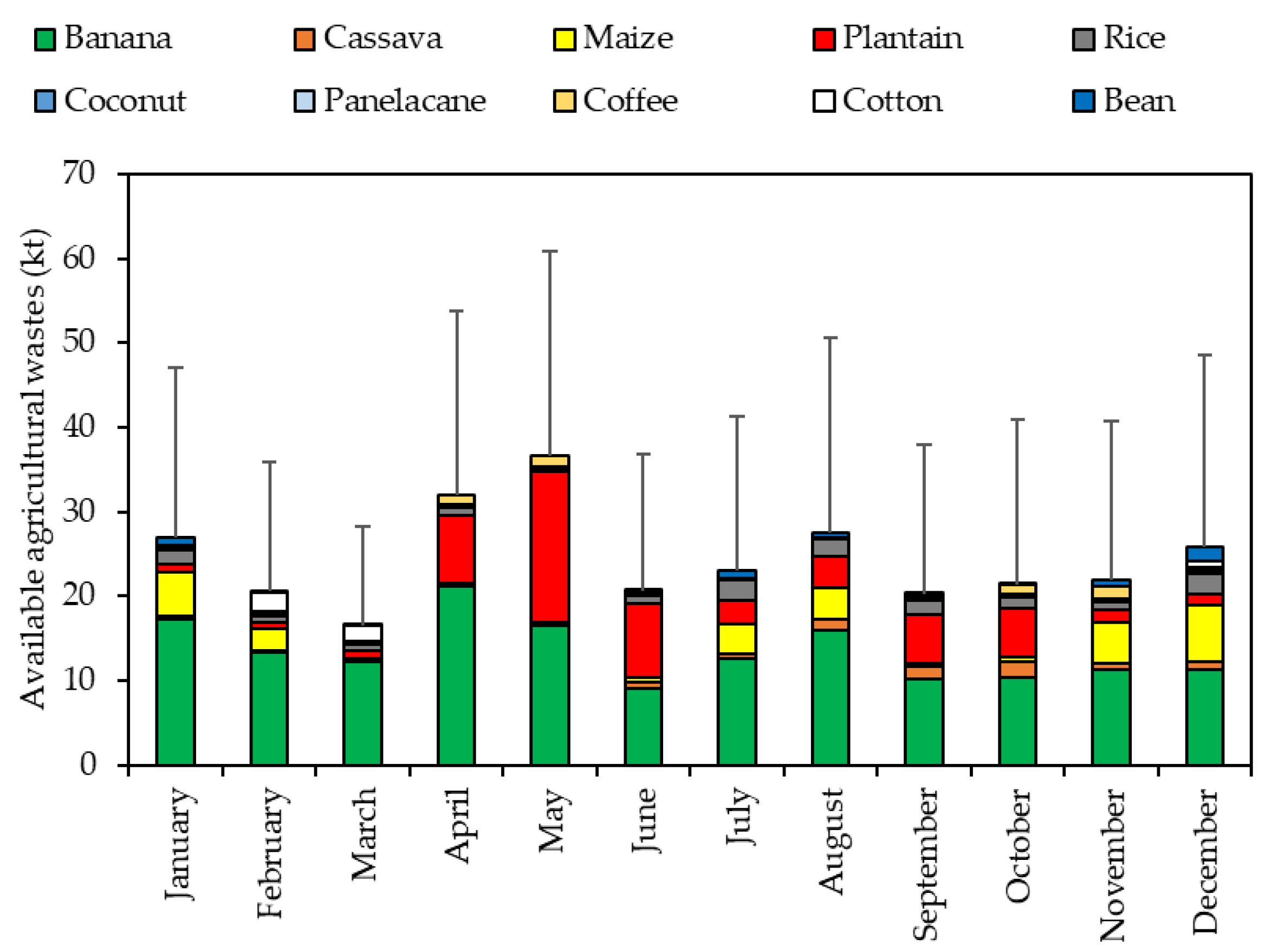

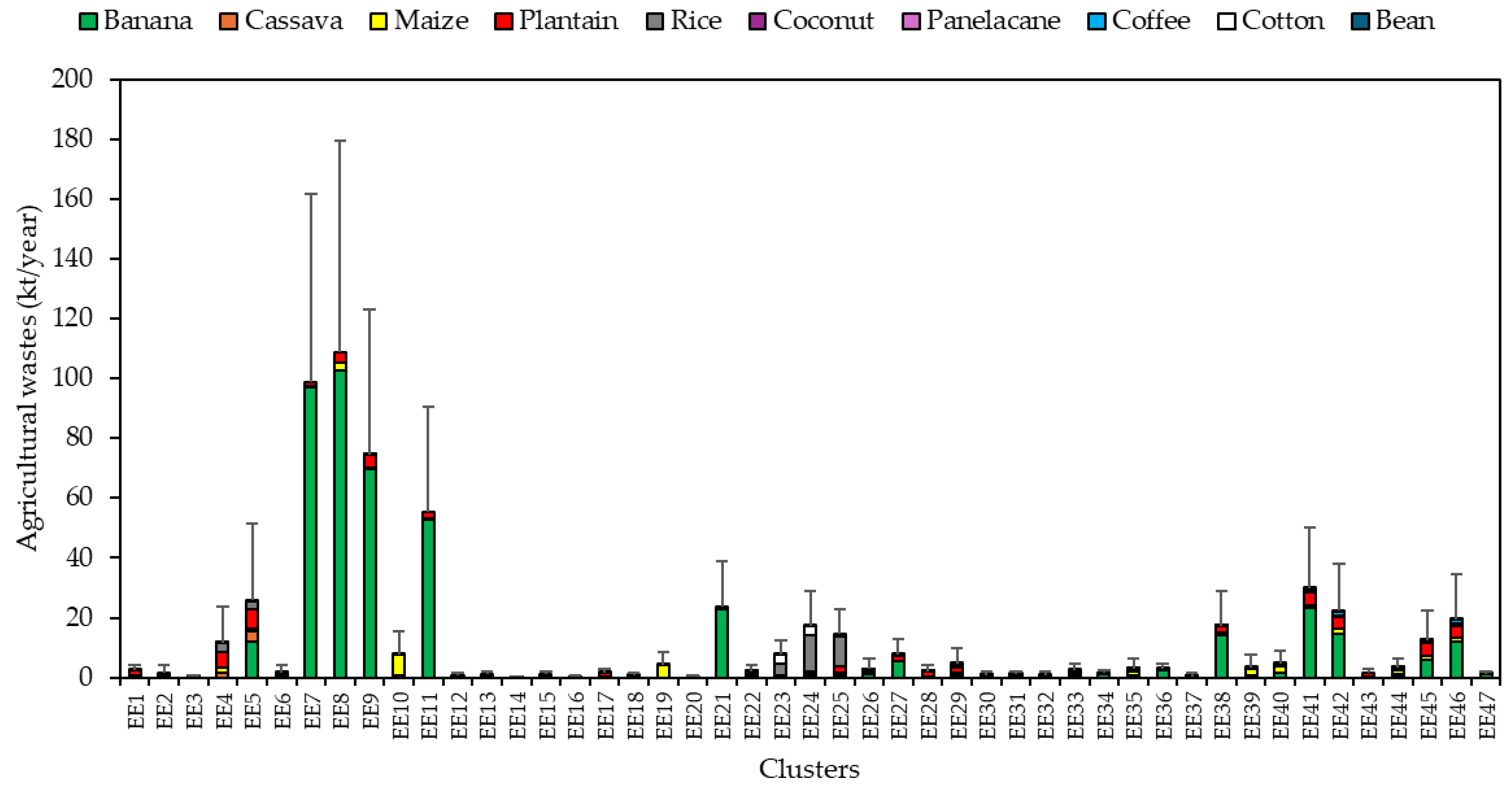

Biomass Wastes from Agriculture

2.4. Physicochemical Properties of Agricultural Biomass Wastes

2.5. Biomass to Energy

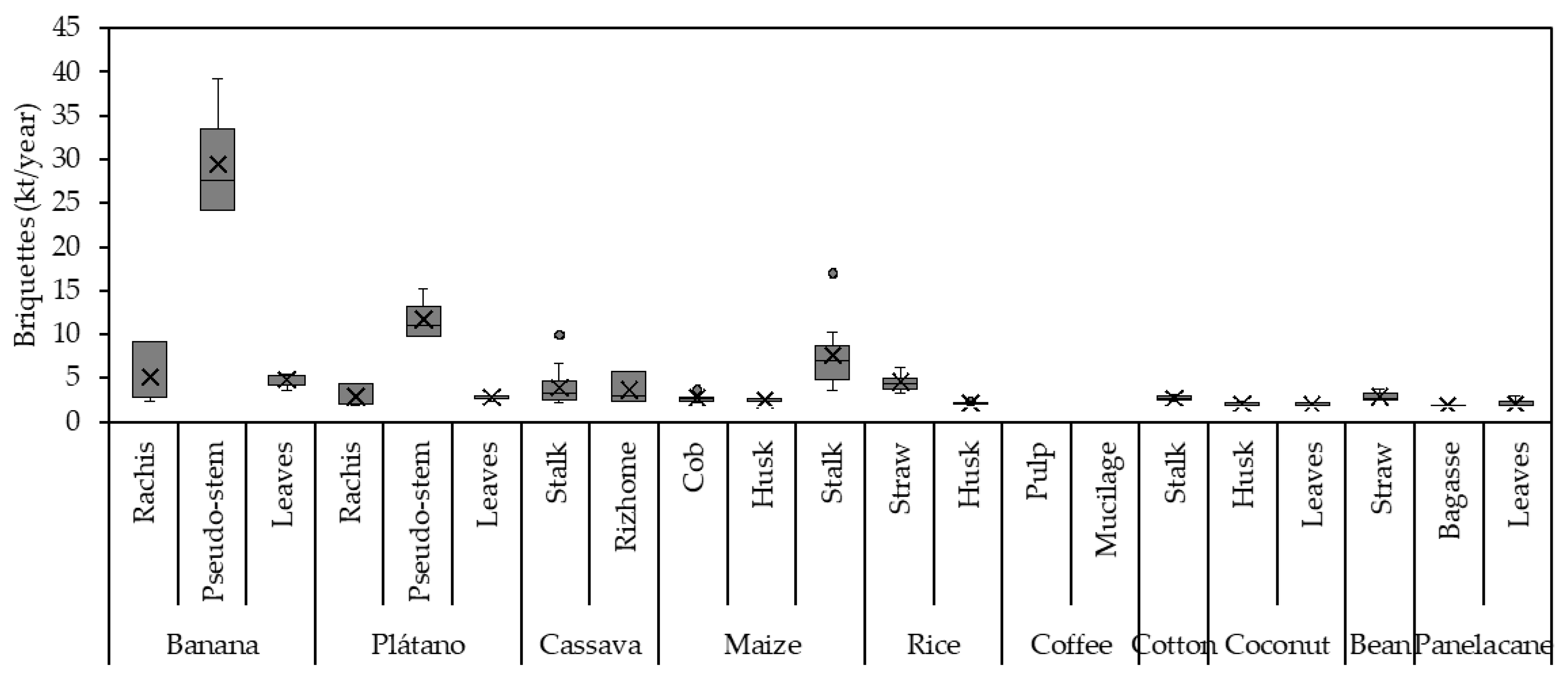

2.5.1. Briquettes

- );

- waste/product ratio;

- crop production (kt);

- low heat value of biomass briquettes (MJ/kt);

- mass ratio of briquettes produced to briquetting residues;

- biomass briquette energy potential from each residue;

- total energy potential.

2.5.2. Anaerobic Digestion (AD)

- Hydrolysis;

- Acidogenesis;

- Acetogenesis;

- Methanogenesis.

- —biochemical methane potential of biomass source i ;

- —cellulose fraction of biomass I;

- —hemicellulose fraction of biomass i;

- —lignin fraction of biomass i;

- —fraction of the remaining biomass constituents.

- —technical methane potential of biomass source i ;

- —specific heat of the raw material (taken as );

- —operational temperature of the digester ;

- —average atmospheric temperature ;

- —lower heating value of methane .

2.5.3. Direct Combustion

- —energy potential of direct combustion for biomass i (GWh);

- —residual biomass mass i (kt);

- —lower heating value on a wet basis for biomass i (GWh/kt).

2.5.4. Energy Clusters

2.6. Emissions of Particulate Matter (PM)

3. Results

3.1. Briquetting Potential

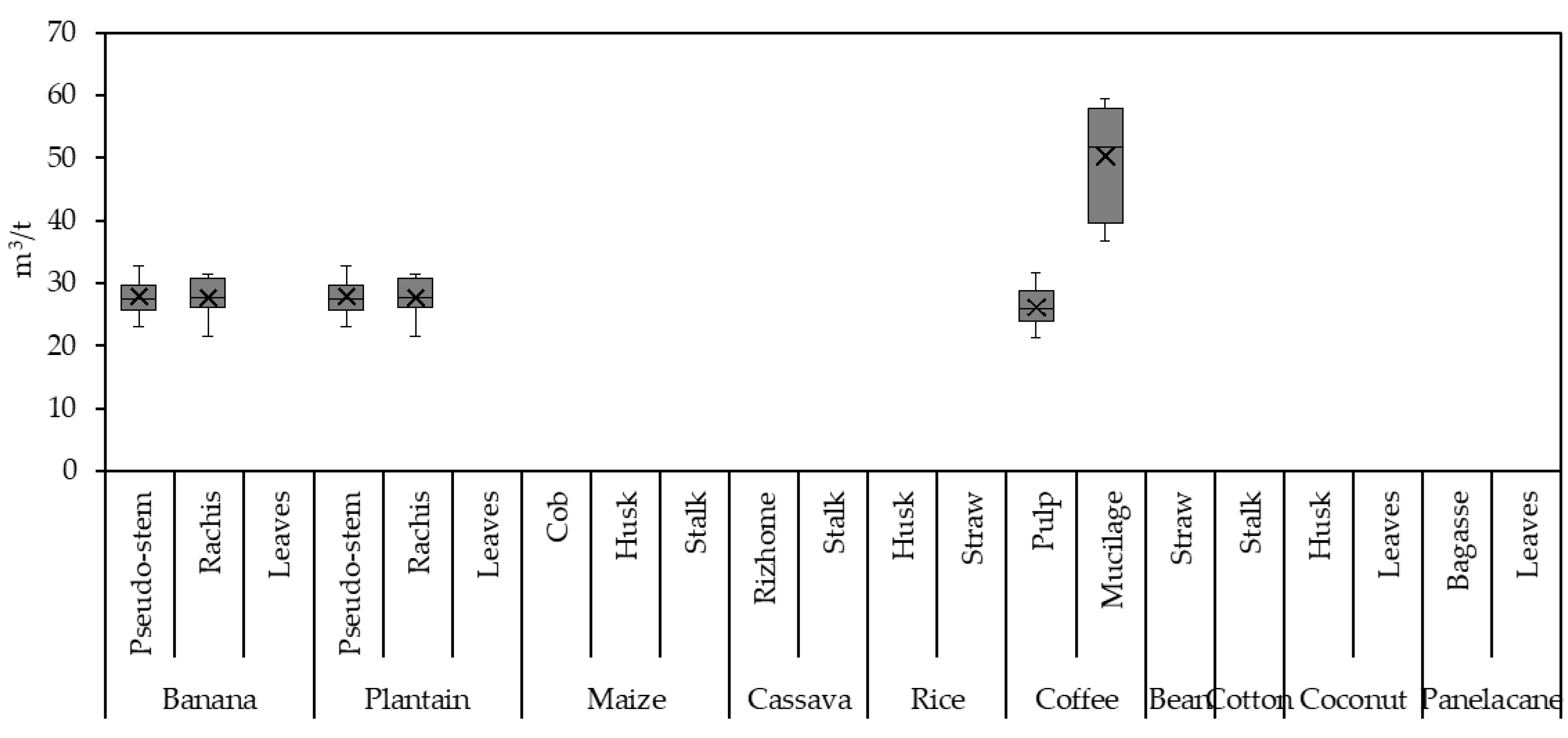

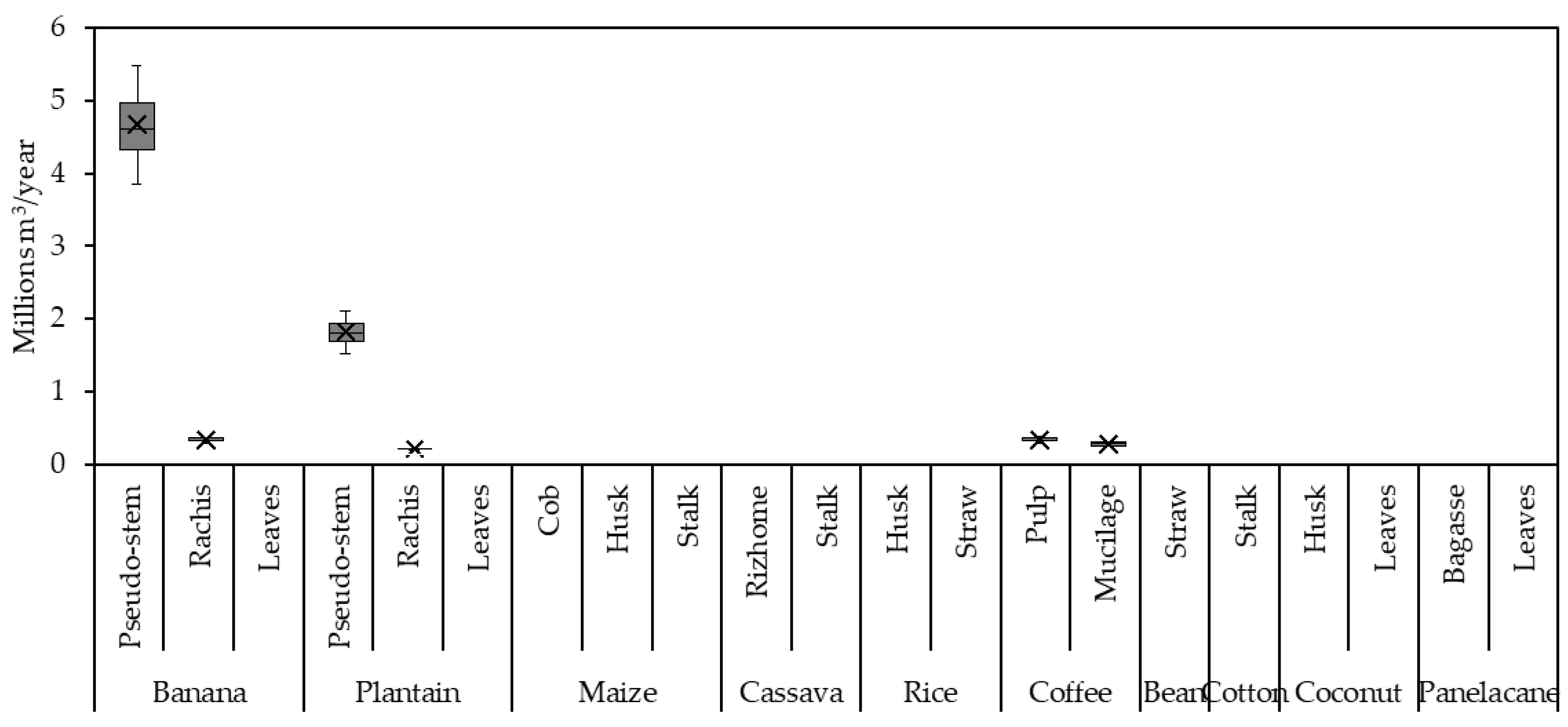

3.2. Potential of Anaerobic Digestion

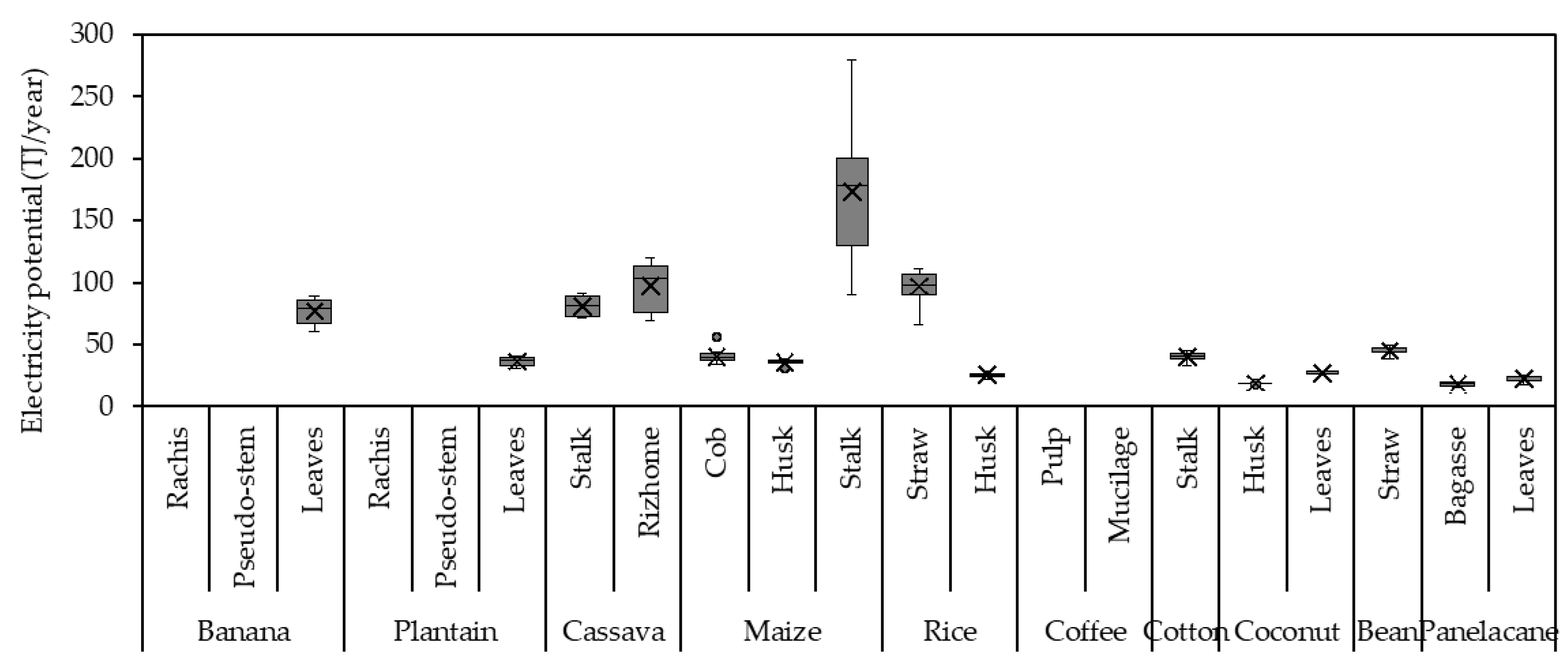

3.3. Direct Combustion Results

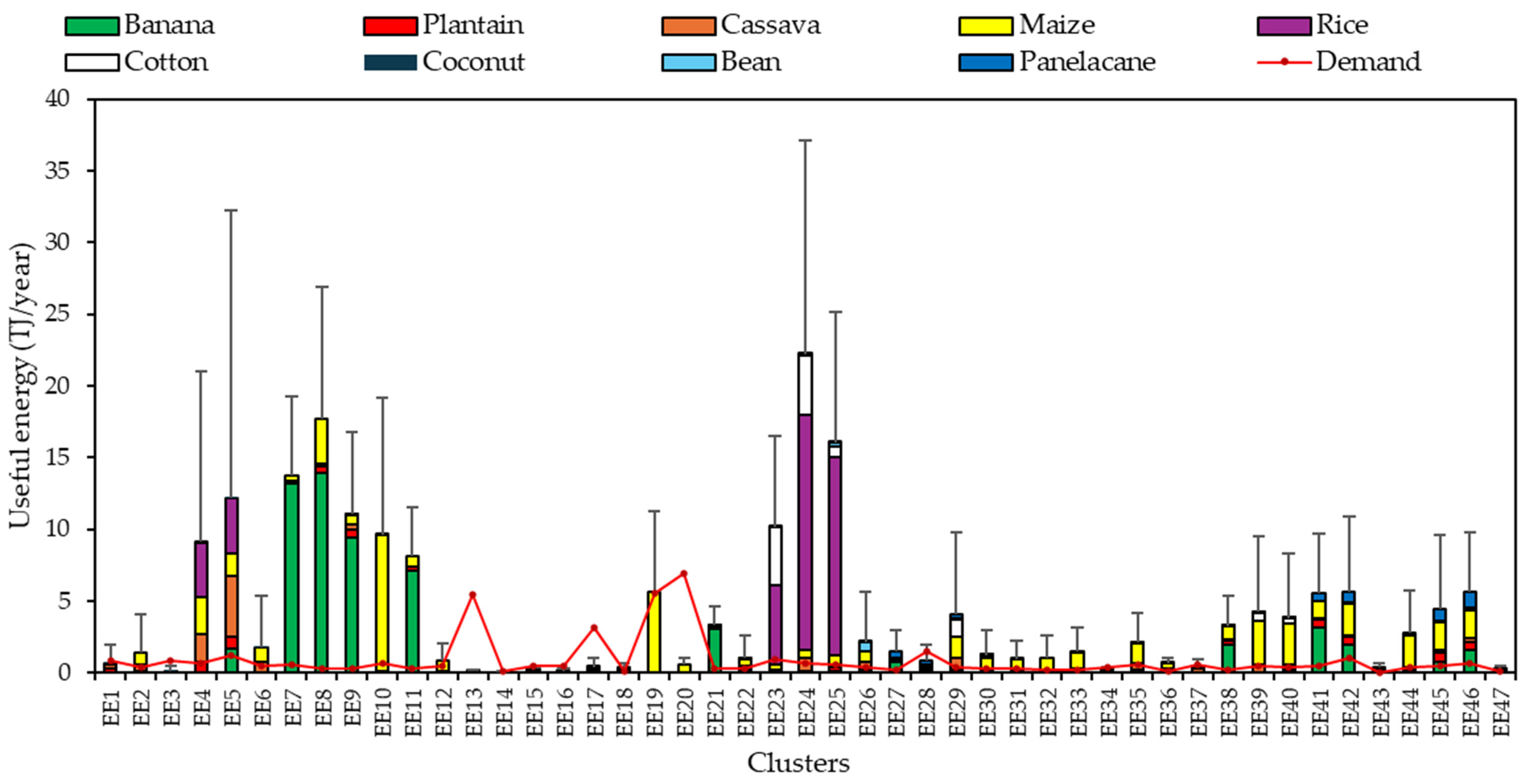

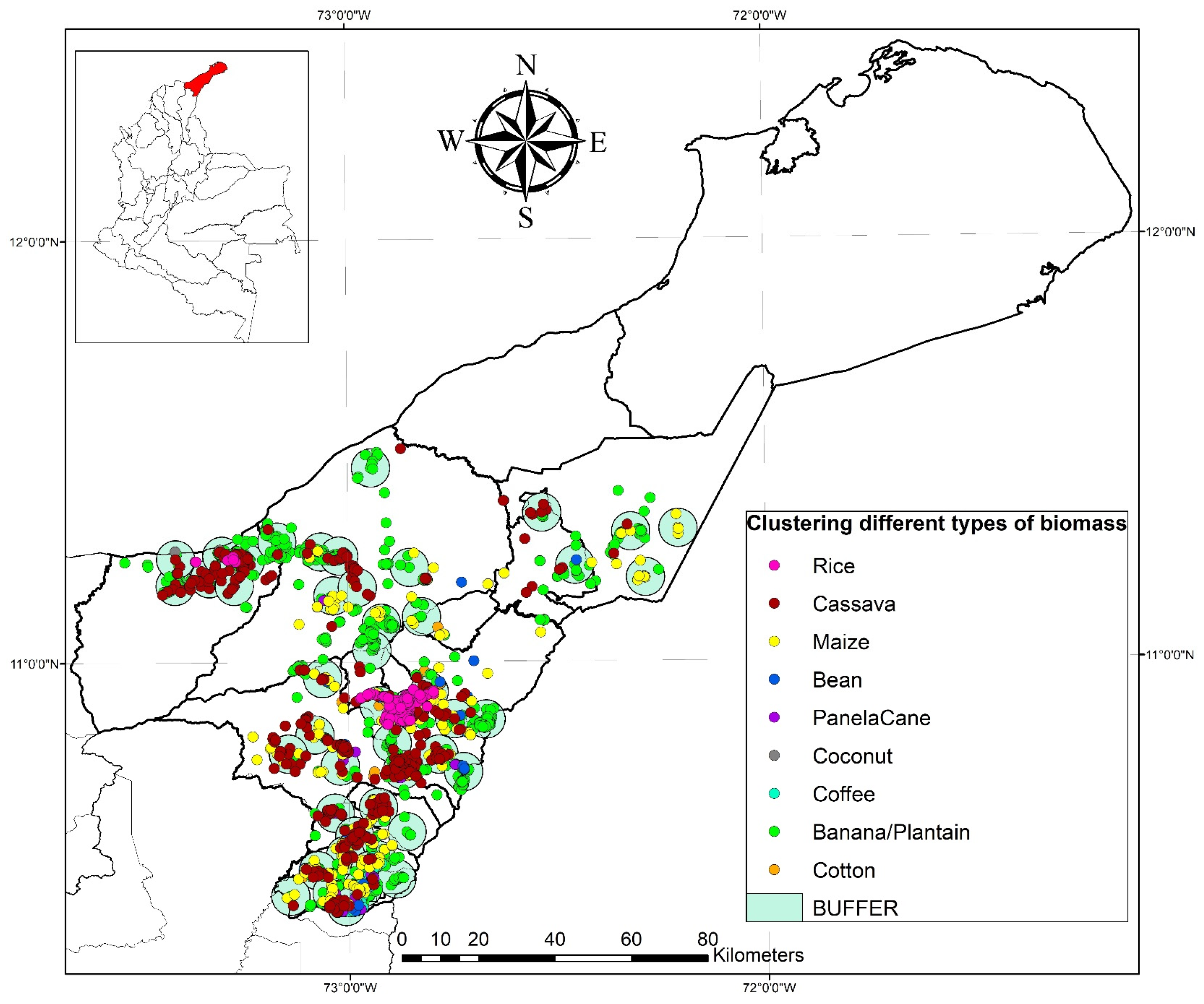

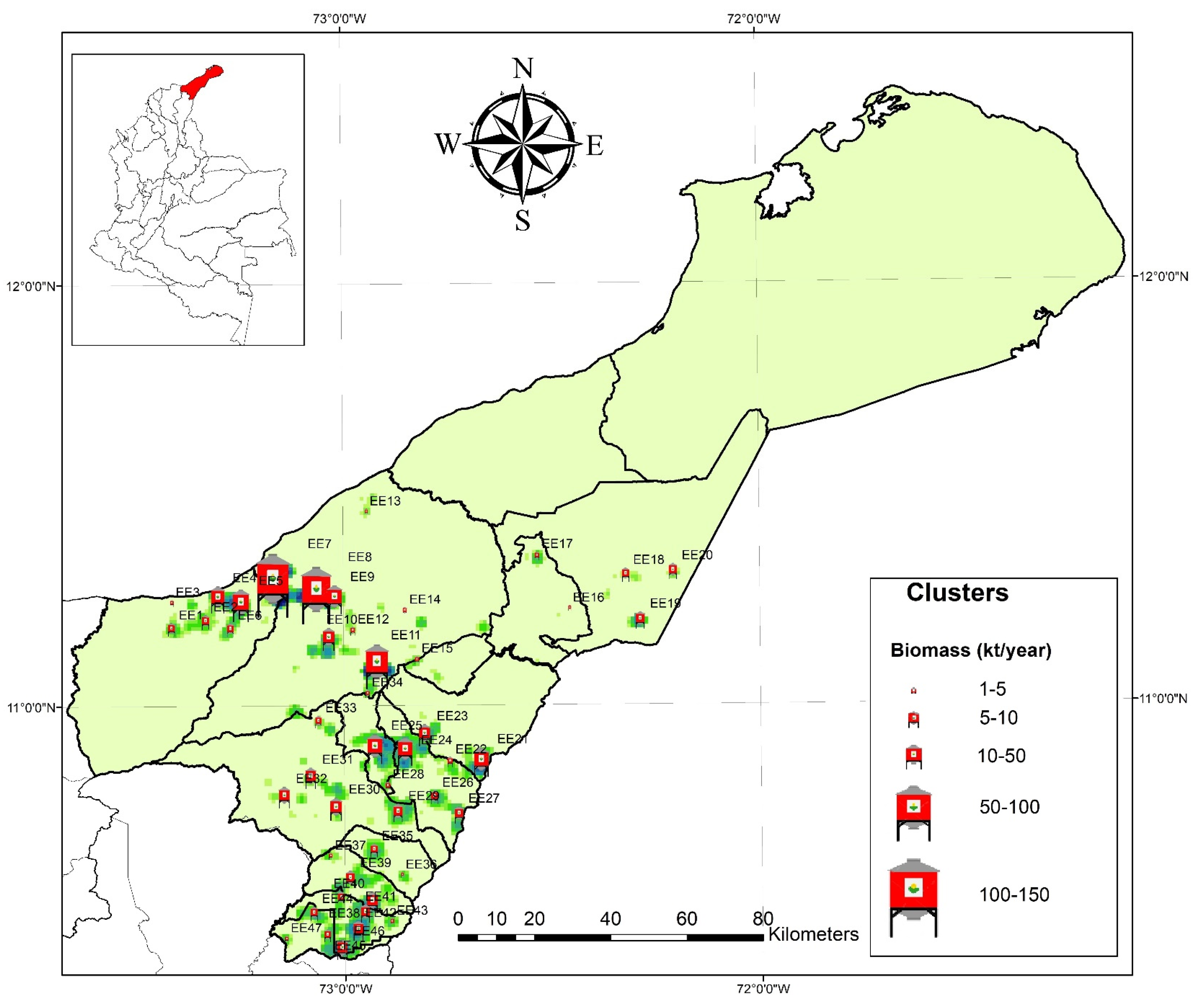

3.4. Potential Energy Clusters

Energy Clusters to Replace Firewood in Rural Areas

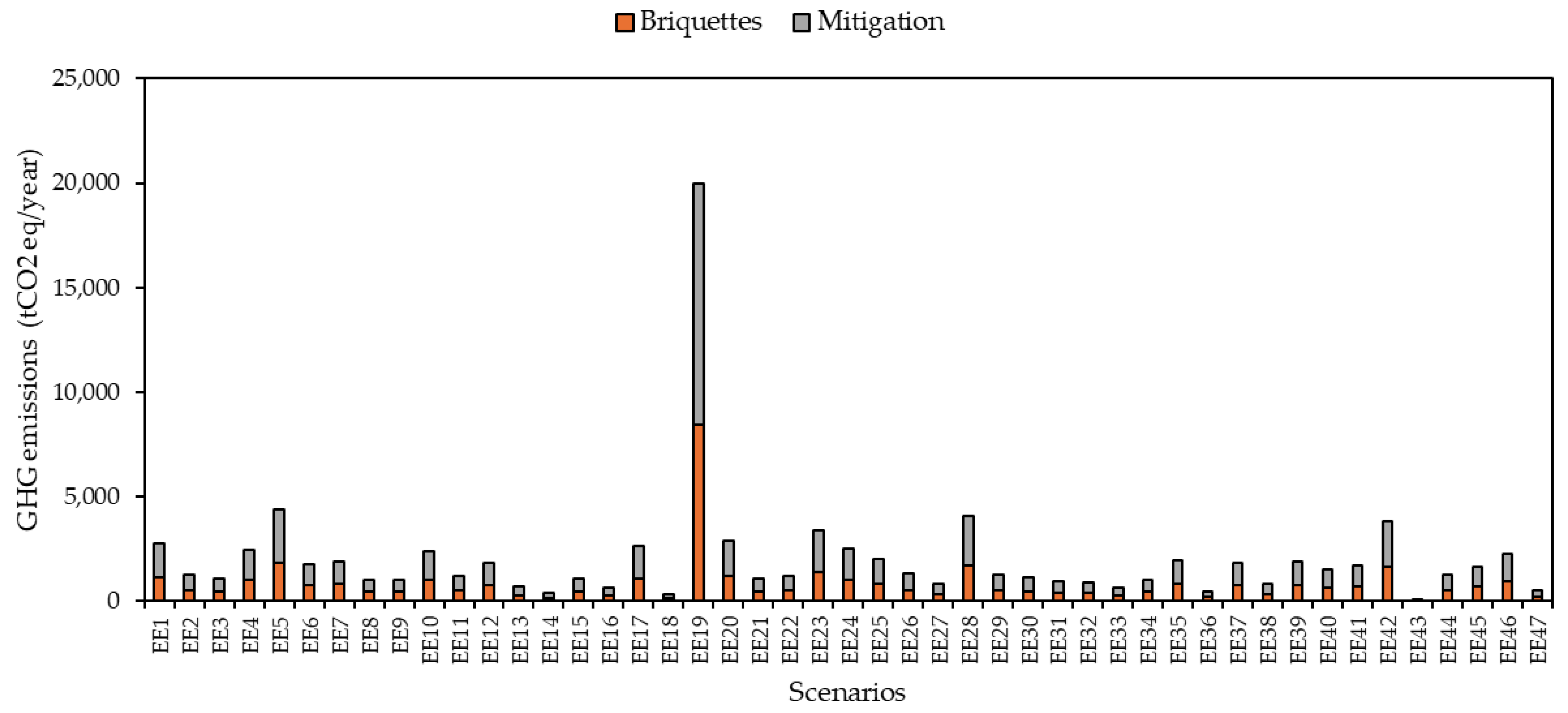

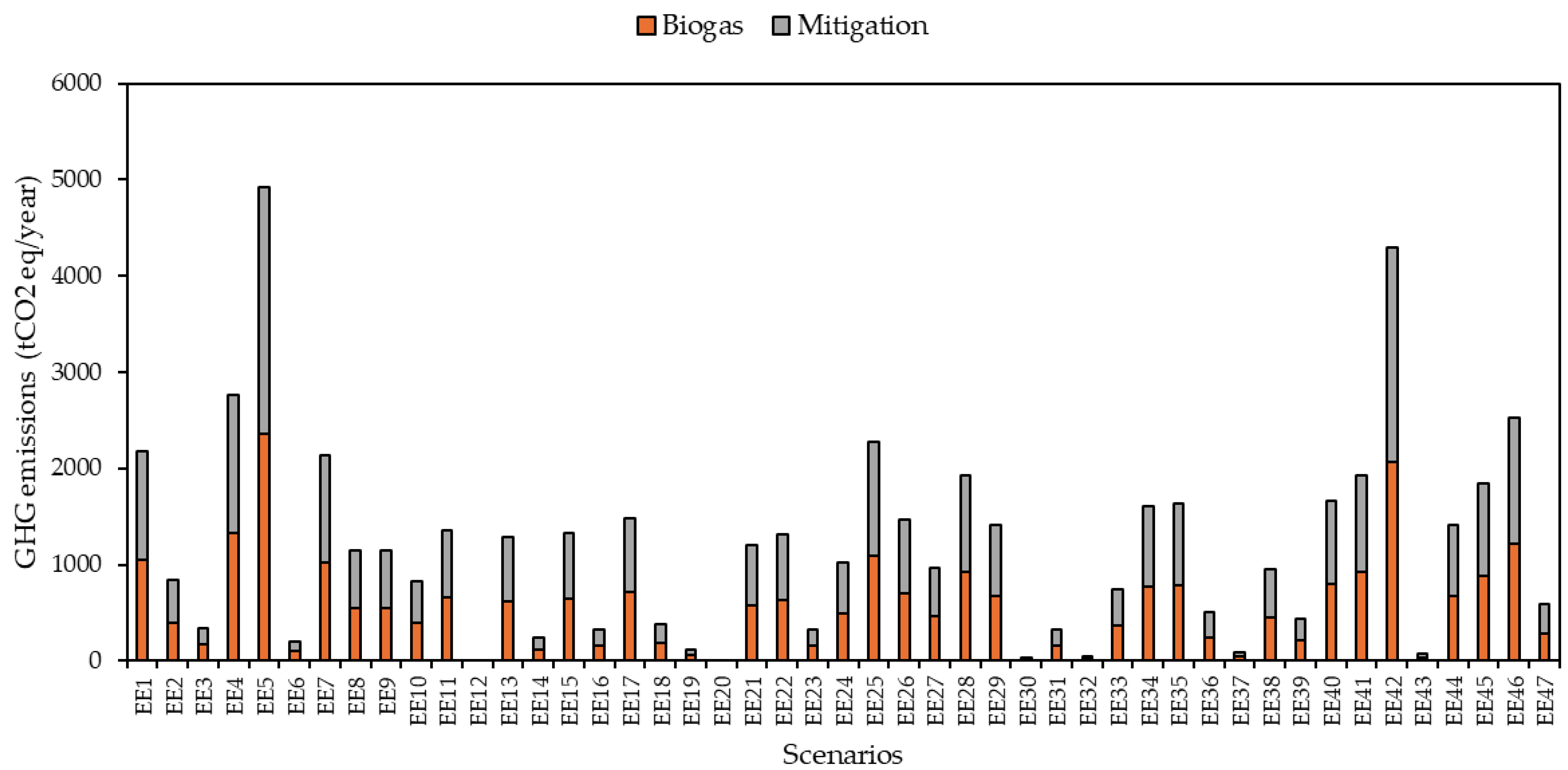

3.5. Greenhouse Gas (GHG) Emissions Savings

3.6. Mitigation of PM Emissions

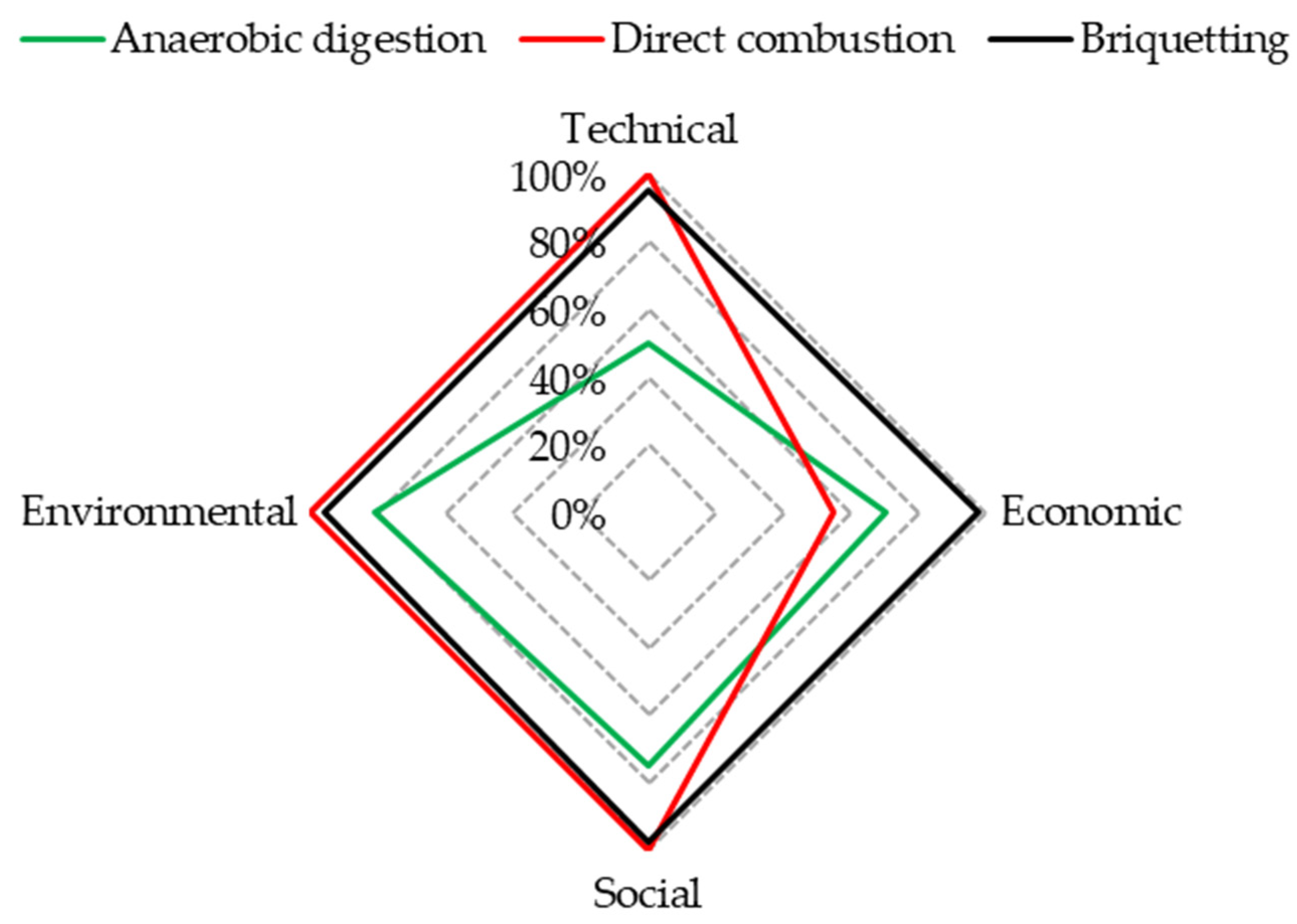

3.7. Assessment of the Technology Performance

4. Discussion

- Insecurity: the possibility of armed attacks in rural areas hinders investments.

- Poor coordination between public and private agencies.

- Energy infrastructure: non-interconnected zones (ZNI) in La Guajira highlight a shortage of energy infrastructure. In the department, 78% of the population has access to electricity, which reduces to 9 and 15% in Uribia and Manaure, with the highest demand for firewood [170].

5. Conclusions

- Direct combustion: scenarios EE1, EE2, EE4, EE5, EE6, EE7, EE8, EE9, EE10, EE11, EE12, EE18, EE19, EE21, EE22, EE23, EE24, EE25, EE26, EE27, EE29, EE30, EE31, EE32, EE33, EE35, EE36, EE37, EE38, EE39, EE40, EE41, EE42, EE43, EE44, EE45, EE46, and EE47.

- Anaerobic digestion: scenarios EE4, EE5, EE7, EE8, EE9, EE11, EE18, EE21, EE22, EE25, EE26, EE27, EE29, EE33, EE36, EE38, EE40, EE41, EE42, EE43, EE44, EE45, EE46, and EE47.

- Briquetting: scenarios EE2, EE4, EE5, EE7, EE8, EE9, EE10, EE11, EE12, EE18, EE19, EE21, EE22, EE23, EE24, EE25, EE26, EE27, EE29, EE30, EE31, EE32, EE33, EE35, EE36, EE37, EE38, EE39, EE40, EE41, EE42, EE43, EE44, EE45, EE46, and EE47.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Figures

Appendix B. Tables

| Crop | Waste | Lignocellulosic Components (%) | Physicochemical Properties (%) | Heating Value (MJ/Kg) | Reference | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| XH | XH | XH | MC | MV | Ash | CF | LHV | HHV | |||

| Banana/ Plantain | Pseudo -Stem | 20.20 | 35.20 | 13.90 | 92.40 | - | - | - | - | - | [171] |

| 25.36 | 38.48 | 5.77 | 79.80 | 89.43 | 9.36 | 1.21 | 13.63 | 15.04 | [83] | ||

| 23.50 | 32.50 | 13.00 | - | - | - | - | - | - | [172] | ||

| - | - | - | - | - | - | - | 13.63 | 16.16 | [173] | ||

| - | - | - | - | 76.00 | 19.00 | 5.00 | 12.96 | 15.60 | [174] | ||

| 14.98 | 32.50 | 15.07 | - | 80.60 | 12.50 | 6.90 | 10.80 | 12.40 | [80] | ||

| 29.05 | 38.36 | 17.81 | 76.50 | 8.64 | 14.86 | - | - | [175] | |||

| 19.62 | 60.84 | 17.26 | - | - | - | - | - | - | [82] | ||

| 36.09 | 49.12 | 8.22 | - | - | - | - | - | - | [176] | ||

| 16.00 | 54.00 | 21.00 | 90.00 | 88.80 | - | - | - | - | [79] | ||

| Rachis | 11.20 | 23.00 | 10.80 | - | - | 29.90 | - | - | - | [76] | |

| 10.20 | 26.40 | 9.40 | - | - | 26.60 | - | 10.00 | - | [77] | ||

| 22.30 | 36.50 | 26.2 | 93.58 | - | - | - | - | - | [78] | ||

| 8.80 | 32.10 | 19.0 | 93.60 | - | 23.0 | - | 12.88 | 13.53 | [165] | ||

| 9.80 | 26.20 | 8.60 | - | 9.95 | - | - | - | [75] | |||

| - | - | - | - | 57.78 | 26.02 | 5.73 | 11.22 | - | [177] | ||

| - | - | - | - | 59.30 | 5.24 | 19.59 | 9.91 | - | [178] | ||

| 17.00 | 53.00 | 16.00 | 93.60 | 79.10 | 11.00 | 8.80 | 11.17 | 14.40 | [179] | ||

| 10–20 | 37.81 | 10–20 | - | 70.5–75.2 | 17.3–22.7 | - | 10.9–12.8 | 14.5–15.7 | [180] | ||

| Leaves | 34.34 | 43.34 | 15.00 | - | - | 12.40 | - | - | [75] | ||

| 32.59 | 29.39 | 15.35 | - | - | - | - | - | - | [181] | ||

| 12.80 | 21.90 | 21.50 | - | - | 15.70 | - | 16.50 | - | [77] | ||

| 25.8–28.5 | 26.7–53.5 | 15.4–17.0 | 12.38 | 77.79 | 10.90 | 11.31 | 14.69 | 15.90 | [84] | ||

| - | - | - | 40.0 | - | - | - | 11.37 | 12.12 | [68] | ||

| 26.70 | 25.80 | 17.00 | 7.80 | 78.20 | 6.20 | 15.60 | 15.60 | 17.10 | [182] | ||

| 15.73 | 17.51 | [48] | |||||||||

| 23.46 | 35.58 | 10.58 | 6.67 | 83.35 | 9.05 | 7.60 | 16.16 | 17.57 | [83] | ||

| 14.63 | 31.40 | 22.36 | 7.46 | 78.13 | 7.47 | 7.48 | - | 17.22 | [183] | ||

| Maize | Cob | 34.00 | 46.00 | 17.00 | - | - | 1.35 | - | - | - | [184] |

| 30.14 | 27.41 | 21.03 | 12.72 | - | 1.94 | - | - | - | [64] | ||

| 33.12 | 45.01 | 13.81 | - | - | 3.10 | - | - | - | [65] | ||

| 35.00 | 45.00 | 15.00 | 8.70 | - | 1.36 | - | 12.60 | - | [53] | ||

| - | - | - | 7.53 | - | - | - | 16.30 | - | [68] | ||

| - | - | - | 15.00 | - | - | - | 15.50 | 18.50 | [72] | ||

| - | - | - | 80.79 | 1.81 | 17.40 | 17.97 | 19.34 | [67] | |||

| - | - | - | 10.52 | 65.23 | 7.71 | 16.54 | 15.08 | 16.50 | [185] | ||

| - | - | - | 9.29 | 71.83 | 1.67 | 17.21 | 15.51 | 17.35 | [186] | ||

| - | - | - | 13.10 | 67.00 | 3.50 | 16.40 | 17.34 | 19.30 | [187] | ||

| Husk | - | - | - | 11.10 | - | - | - | 17.27 | - | [72] | |

| - | - | - | 11.11 | - | - | - | 15.56 | - | [68] | ||

| - | - | - | - | - | - | - | 16.37 | 19.90 | [48] | ||

| - | - | - | - | - | - | - | 12.6–15.6 | - | [70] | ||

| 12.72 | 43.14 | 23.00 | - | - | - | - | - | - | [188] | ||

| 25.00 | 40.00 | 14.00 | 7.00 | - | - | - | 15.96 | - | [24] | ||

| 35.72 | 43.14 | 23.00 | 12.12 | 82.66 | 2.52 | 7.94 | 16.60 | - | [189] | ||

| 24.63 | 29.19 | 15.44 | - | - | - | - | - | - | [190] | ||

| 19.10 28.10 | 39.00 32.60 | 15.10 16.60 | 6.06 5.90 | 75.17 79.61 | 4.30 9.70 | 19.25 20.39 | 16.44 17.41 | 17.65 18.69 | [191] | ||

| Stalk | - | - | - | 5.50 | 71.69 | 10.10 | 12.71 | 17.50 | [192] | ||

| - | - | - | 6.8 | 73.1 | 7.4 | 12.7 | 15.30 | 16.6 | [193] | ||

| 25.52 | 49.77 | 8.69 | - | - | - | - | - | - | [194] | ||

| - | - | - | 2.86 | 64.49 | 6.58 | 28.93 | 13.49 | - | [95] | ||

| 20–30 | 40–50 | 10–15 | - | - | - | - | - | - | [195] | ||

| 21.16 | 32.32 | 18.70 | - | - | - | - | - | - | [196] | ||

| 20.10 | 37.10 | 17.10 | - | - | 4.20 | - | - | - | [197] | ||

| - | - | - | 3.55 | 73.93 | 5.51 | 17.01 | 15.74 | - | [198] | ||

| 30.88 | 51.53 | 17.59 | 15.00 | - | - | - | 16.30 | - | [53] | ||

| 21.37 | 34.65 | 20.51 | - | - | - | - | - | - | [199] | ||

| Cassava | Stalk | - | - | - | 15.50 | 79.90 | 6.00 | 14.10 | - | - | [179] |

| - | - | - | 8.50 | 69.70 | 7.10 | 14.70 | 16.80 | 18.10 | [200] | ||

| 31.61 | 33.70 | 27.04 | - | - | - | - | - | - | [201] | ||

| 21.12 | 28.86 | 30.62 | - | - | 7.34 | - | - | - | [202] | ||

| 28.80 | 22.80 | 22.10 | 15.50 | 79.90 | - | - | 13.40 | - | [56] | ||

| - | - | - | 15.50 | 64.90 | 4.70 | 14.40 | 14.28 | 15.76 | [203] | ||

| 24.30 | 35.20 | 15.00 | - | - | - | - | - | - | [204] | ||

| - | - | - | 15.00 | - | - | - | 16.99 | - | [68] | ||

| 31.61 | 33.70 | 27.04 | 20.00 | - | - | - | 13.10 | - | [53] | ||

| - | - | - | 15.50 | 79.90 | 6.00 | 14.10 | 17.60 | 18.00 | [205] | ||

| Rizhome | - | - | - | 8.30 | 77.80 | 4.10 | 18.20 | - | - | [179] | |

| - | - | - | 1.80 | 81.50 | 3.60 | 14.90 | 18.80 | 20.30 | [206] | ||

| - | - | - | 10.60 | 70.70 | 5.20 | 13.50 | 17.10 | - | [52] | ||

| 11.00 | 49.00 | 20.00 | - | - | - | - | - | - | [203] | ||

| 13.81 13.17 | 52.52 48.01 | 21.45 26.31 | - | - | - | - | - | - | [207] | ||

| 10.57 | 33.89 | 23.91 | - | - | 4.77 | - | - | - | [208] | ||

| 15–35 | 40–50 | 18–35 | - | - | - | - | - | - | [209] | ||

| - | - | 8.80 | 65.00 | 11.20 | 15.00 | 15.90 | 17.10 | [200] | |||

| 27.80 | 39.70 | 21.70 | 8.30 | 71.30 | 3.70 | 16.70 | - | - | [210] | ||

| - | - | - | 8.30 | 77.70 | 4.10 | 18.20 | 18.50 | 23.70 | [205] | ||

| - | - | - | - | 81.90 | 7.30 | 10.70 | 20.00 | 21.70 | [211] | ||

| 17.00 | 34.00 | 28.00 | 8.30 | - | - | - | 10.61 | - | [24] | ||

| 11.07 | 63.13 | 25.80 | - | - | 3.60 | - | 13.10 | - | [53] | ||

| - | - | - | 8.60 | 74.70 | 0.74 | 15.96 | 15.37 | - | [212] | ||

| Rice | Straw | 20.00 | 32.00 | 25.00 | - | - | - | - | - | - | [184] |

| - | - | - | 5.60 | 65.20 | 12.60 | 16.60 | 14.40 | - | [213] | ||

| - | - | - | 9.8 | 76.32 | 13.91 | 9.08 | 15.76 | - | [93] | ||

| - | - | - | 6.43 | 76.84 | 10.86 | 12.30 | 14.40 | - | [214] | ||

| - | - | - | 10.29 | 67.87 | 8.69 | 13.15 | 13.06 | - | [156] | ||

| - | - | - | 7.93 | 54.68 | 19.19 | 18.2 | 12.65 | 13.89 | [187] | ||

| 18.00 | 35.00 | 20.89 | - | - | 10.20 | - | - | - | [215] | ||

| 23.73 | 39.17 | 21.50 | - | 71.78 | 14.41 | 13.81 | - | 19.01 | [216] | ||

| 31.82 | 37.65 | 6.18 | 8.08 | 69.99 | 8.79 | 13.40 | 14.21 | - | [217] | ||

| 19.73 | 33.14 | 13.1 | - | - | - | - | - | - | [218] | ||

| 19.7–35.7 | 32.0–38.6 | 13.5–22.3 | - | - | 10 –17 | - | - | - | [219] | ||

| - | - | - | - | 70.41 | 13.80 | 15.79 | 15.39 | - | [217] | ||

| 23.0–25.9 | 29.2–34.7 | 17.0–19.0 | - | - | - | - | - | - | [220] | ||

| Husk | 30.00 | 35.00 | 18.00 | - | - | - | - | - | - | [75] | |

| - | - | - | 9.00 | 70.83 | 11.07 | 18.10 | 16.41 | - | [69] | ||

| 26.40 | 38.20 | 24.10 | 9.50 | 63.00 | 8.10 | 19.40 | 12.77 | 14.37 | [221] | ||

| 21.30 | 38.57 | 21.10 | 7.73 | 64.20 | 12.57 | 15.50 | 15.39 | - | [217] | ||

| 22.0–29.7 | 28.6–43.3 | 19.2–24.4 | - | - | 17–20 | - | - | - | [219] | ||

| - | - | - | - | 76.56 | 9.48 | 14.02 | 14.21 | - | [222] | ||

| - | - | - | 10.1 | 52.3 | 14.2 | 23.4 | 12.84 | 14.09 | [187] | ||

| 21.34 | 36.06 | 21.16 | - | - | 10.99 | - | 12.90 | - | [53] | ||

| 12.0–29.3 | 28.7–35.6 | 15.4–20.0 | - | - | - | - | - | - | [220] | ||

| - | - | - | 3.31 | 69.12 | 16.20 | 14.69 | 11.66 | - | [95] | ||

| - | - | - | - | - | - | 15.5–17.44 | - | [70] | |||

| - | - | - | 12.40 | - | - | - | 12.90 | - | [72] | ||

| Bean | Straw | 19.60 | 21.40 | 10.20 | 6.30 | 72.70 | 6.20 | 21.10 | 16.41 | 17.30 | [223] [224] |

| - | - | - | 4.50 | - | - | - | 14.70 | - | [53] | ||

| 19.60 | 21.40 | 10.20 | 10.63 | 69.10 | 6.80 | 24.10 | 15.47 | 17.60 | [225] | ||

| - | - | - | 10.00 | - | - | - | 12.38 | - | [68] | ||

| - | - | - | 15.00 | - | - | - | 14.90 | - | [72] | ||

| - | - | - | - | - | - | - | 14.65 | 17.20 | [70] | ||

| 16.00 | 38.00 | 16.00 | - | 75.30 | 5.93 | 18.77 | 16.24 | 17.46 | [191] | ||

| Coffee | Pulp | 9.20 | 35.60 | - | 80–82 | - | - | - | - | - | [226] |

| 2.30 | 63.00 | 17.50 | - | - | - | - | - | - | [63] | ||

| 4.37 | 25.84 | 12.46 | - | - | - | - | - | - | [227] | ||

| 3.60 | 20.70 | 14.30 | 82.44 | - | - | - | - | - | [228] | ||

| 27.80 | 43.98 | 6.88 | - | - | - | - | - | - | [229] | ||

| 19.03 | 24.80 | 19.35 | - | - | - | - | - | - | [230] | ||

| 28.66 | 32.56 | 26.40 | - | - | - | - | - | - | [231] | ||

| 11.00 | 18.60 | 17.20 | - | - | 7.10 | - | - | - | [61] | ||

| 7.00 | 43.00 | 9.00 | 15.00 | - | 2.50 | - | 15.90 | - | [53] | ||

| - | - | - | - | 69.48 | 6.55 | 21.23 | 14.95 | 16.28 | [232] | ||

| 17.35 | 20.33 | 21.04 | - | 53.19 | 8.53 | 33.08 | 13.49 | 14.79 | [62] | ||

| - | - | - | 57.90 | 34.73 82.50 | - | 7.19 17.09 | 8.56 | 10.65 | [191] | ||

| - | - | - | 83.60 | - | - | - | [233] | ||||

| - | - | - | - | - | - | - | 12.60 | 15.90 | [70] | ||

| Mucilage | - | - | - | 97.56 | - | - | - | 2.00 | - | [59,228] | |

| Panelacane | Bagasse | 20–25 | 33–45 | 27–32 | - | - | 5–9 | - | - | - | [184] |

| 23–32 | 40 | 18–23 | 11.00 | 85.30 | 6.70 | 8.00 | 17.00 | 19.40 | [234] | ||

| 27 | 46.00 | 23.00 | - | - | 1.94 | - | 17.80 | - | [53] | ||

| 28–32 | 25.0–45.0 | 15.0–25.0 | - | - | - | - | - | - | [220] | ||

| - | - | - | 50.0 | - | - | - | 9.30 | 17.2 | [56] | ||

| - | - | - | 9.9 | 76.00 | 4.00 | 10.00 | 13.86 | 17.32 | [235] | ||

| - | - | - | 21.0 | 82.50 | 2.50 | 15.00 | 17.60 | - | [236] | ||

| 370 | 42.00 | 21.00 | 50.00 | - | - | - | 7.50 | - | [237] | ||

| - | - | - | 5.92 | 88.40 | 2.31 | 9.12 | 15.96 | 18.29 | [86] | ||

| - | - | - | 50.00 | 79.06 | 2.94 | 18.00 | 16.10 | 18.50 | [87] | ||

| - | - | - | 50.00 | - | 2.20 | - | 7.50 | - | [88] | ||

| - | - | - | 50–75 | - | - | - | 8.6–15.40 | - | [72] | ||

| - | - | - | - | - | - | - | 17.90 | 20.00 | [70] | ||

| Leaves | - | - | - | 6.70 | 79.00 | 5.70 | 8.60 | 17.00 | 18.40 | [200] | |

| - | - | - | 50.00 | - | - | - | 15.80 | - | [49] | ||

| 32.00 | 39.70 | 21.70 | - | - | 4.70 | - | - | - | [53] | ||

| 32.99 | 43.55 | 21.76 | 40.00 | - | - | - | 7.40 | 17.30 | [56] | ||

| - | - | - | 3.50 | 76.5 | 7.4 | 16.10 | 16.80 | 17.80 | [89] | ||

| 33.28 | 39.81 | 21.63 | 8.42 | 86.64 | 3.85 | 9.51 | 15.72 | 18.61 | [90] | ||

| 30.4–30.8 | 40.5–44.5 | 12.3–22.8 | - | 80.6–84.5 | 3.7–7.5 | 11.6–15.7 | - | 17.40 | [91] | ||

| - | - | - | - | - | - | - | 17.90 | - | [70] | ||

| - | - | - | 9.20 | 68.00 | 6.10 | 16.90 | - | - | [54] | ||

| Cotton | Stalk | - | - | - | 7.88 | 75.18 | 4.67 | 20.15 | 15.94 | 17.5 | [238] |

| - | - | - | 7.49 | 61.21 | 6.18 | 25.12 | 15.21 | - | [198] | ||

| - | - | - | 75.56 | 6.61 | 17.83 | 16.69 | 17.84 | [239] | |||

| - | - | - | 4.66 | 74.96 | 4.59 | 15.80 | 11.63 | - | [240] | ||

| - | - | - | 4.55 | 78.61 | 2.74 | 18.65 | 15.97 | - | [95] | ||

| - | - | - | 8.60 | 69.90 | 4.60 | 16.9 | 17.06 | 18.32 | [241] | ||

| 20–28 | 32–46 | - | - | 73.29 | 5.51 | 21.20 | 17.10 | - | [85] | ||

| 13.70 | 36.40 | 25.50 | - | - | - | - | - | - | [199] | ||

| 16.00 | 48.70 | 21.80 | 6.80 | 69.83 | 1.34 | 22.03 | - | - | [242] | ||

| 32.00 | 38.00 | 21.00 | 7.00 | - | - | - | 15.85 | 17.23 | [24] | ||

| 20–28 | 39.85 | 23.92 | 8–9 | - | - | - | - | - | [243] | ||

| 14.40 | 32.00 | 24.50 | - | - | - | - | - | - | [244] | ||

| 11.90 | 45.50 | 18.20 | - | - | - | - | - | - | [245] | ||

| 12.50 | 43.70 | 28.60 | - | - | - | - | - | - | [246] | ||

| 17.40 | 48.80 | 25.30 | - | - | - | - | - | - | [247] | ||

| - | - | - | 12.00 | - | - | - | 14.6–18.20 | - | [72] | ||

| Coconut | Husk | 25.50 | 31.60 | 35.10 | - | - | - | - | - | - | [176] |

| 25.42–27.81 | 29.58–54.00 | 25.02–42.00 | 0.18–11.28 | 72.60–84.13 | 0.92–3.95 | 5.88–15.54 | 15.83 | 18.15 | [248] | ||

| 15.20 | 37.60 | 41.30 | - | - | 2.50 | - | - | - | [249] | ||

| - | - | - | - | - | 3.10 | - | 19.02 | 20.27 | [250] | ||

| - | - | - | 7.50 | 85.30 | 5.30 | 14.70 | - | - | [251] | ||

| - | - | - | 8.50 | 61.50 | 5.39 | - | 18.22 | 19.31 | [252] | ||

| 17.33 | 21.26 | 46.36 | - | - | - | - | - | [253] | |||

| - | - | - | 7.25 | 71.01 | 4.07 | 17.68 | 18.00 | - | [177] | ||

| - | - | - | 10.30 | - | - | - | 18.60 | - | [68] | ||

| 20.00 | 39.00 | 37.00 | 10.00 | - | - | - | 18.62 | 20.95 | [24] | ||

| Leaves/ fronds | 10.66 | 56.71 | 28.44 | 2.55 | 83.32 | 6.97 | 7.16 | 17.67 | 18.37 | [254] | |

| 8.45 | 59.39 | 27.97 | - | - | - | - | - | - | [255] | ||

| 22.49 | 39.05 | 21.46 | - | 89.96 | 4.67 | 5.37 | - | - | [256] | ||

| - | - | - | 4.77 | 80.75 | 6.33 | 12.92 | 19.71 | 20.83 | [257] | ||

| - | - | - | 10.49 | - | 6.17 | - | 17.95 | - | [257] | ||

| 31.58 | 43.91 | 18.15 | 7.08 | 78.03 | 4.96 | 17.01 | 17.77 | 19.00 | [258] | ||

| 22.49–31.58 | 39.05–43.91 | 18.15–21.46 | - | - | 4.96 | - | - | - | [259] | ||

| - | - | - | 4.77–7.08 | 78.03–87.75 | 4.96–6.33 | 12.92–17.01 | 16.80–19.36 | 17.77–20.83 | [248] | ||

| Scenario | Geolocation | Briquettes | Biogas | Electricity | Firewood Demand | ||

|---|---|---|---|---|---|---|---|

| Latitude | Longitude | (kt/year) | (106 m3/year) | (TJ/year) | Community | Households | |

| EE1 | 11.1821 | −73.4134 | 0.08–0.24 | 0.06–0.07 | 2.74–3.84 | 3 | 227 |

| EE2 | 11.1998 | −73.3311 | 0.17–0.50 | 0.02–0.03 | 5.80–8.39 | 2 | 93 |

| EE3 | 11.2452 | −73.4119 | 0.02–0.05 | 0.01–0.01 | 0.67–0.88 | 2 | 221 |

| EE4 | 11.2531 | −73.3013 | 1.12–2.58 | 0.16–0.19 | 31.83–43.47 | 4 | 181 |

| EE5 | 11.2388 | −73.2460 | 1.50–3.96 | 0.57–0.66 | 46.54–64.04 | 5 | 322 |

| EE6 | 11.1812 | −73.2720 | 0.22–0.66 | 0.01–0.01 | 7.54–10.92 | 4 | 131 |

| EE7 | 11.2860 | −73.1694 | 1.69–2.37 | 3.02–3.50 | 34.87–47.33 | 10 | 140 |

| EE8 | 11.2618 | −73.0646 | 2.18–3.30 | 3.26–3.79 | 47.34–65.33 | 7 | 75 |

| EE9 | 11.2519 | −73.0213 | 1.36–2.06 | 2.26–2.63 | 29.33–40.09 | 7 | 75 |

| EE10 | 11.1576 | −73.0357 | 1.17–2.35 | 0.02–0.03 | 31.41–46.19 | 12 | 176 |

| EE11 | 11.0921 | −72.9201 | 0.99–1.42 | 1.68–1.95 | 20.75–28.32 | 8 | 89 |

| EE12 | 11.1770 | −72.9773 | 0.10–0.25 | 0.00–0.00 | 3.08–4.50 | 9 | 133 |

| EE13 | 11.4599 | −72.9436 | 0.02–0.03 | 0.04–0.04 | 0.40–0.54 | 15 | 1444 |

| EE14 | 11.2239 | −72.8521 | 0.01–0.02 | 0.01–0.01 | 0.25–0.36 | 5 | 38 |

| EE15 | 11.1071 | −72.8242 | 0.03–0.05 | 0.04–0.04 | 0.65–0.90 | 3 | 130 |

| EE16 | 11.2284 | −72.4559 | 0.01–0.03 | 0.01–0.01 | 0.39–0.56 | 4 | 125 |

| EE17 | 11.3525 | −72.5343 | 0.05–0.13 | 0.04–0.05 | 1.57–2.13 | 3 | 828 |

| EE18 | 11.3064 | −72.3218 | 0.04–0.08 | 0.02–0.03 | 1.09–1.57 | 2 | 25 |

| EE19 | 11.1981 | −72.2871 | 0.69–1.39 | 0.00–0.00 | 18.50–27.21 | 4 | 1456 |

| EE20 | 11.3135 | −72.2082 | 0.07–0.13 | 0.00–0.00 | 1.74–2.56 | 6 | 1818 |

| EE21 | 10.8644 | −72.6713 | 0.40–0.57 | 0.73–0.84 | 8.39–11.37 | 3 | 79 |

| EE22 | 10.8659 | −72.7464 | 0.12–0.32 | 0.04–0.05 | 3.83–5.48 | 3 | 86 |

| EE23 | 10.9291 | −72.8070 | 1.25–2.03 | 0.01–0.01 | 29.87–35.91 | 4 | 247 |

| EE24 | 10.8901 | −72.8536 | 2.72–4.56 | 0.03–0.03 | 64.05–78.40 | 3 | 182 |

| EE25 | 10.8974 | −72.9266 | 1.97–3.10 | 0.09–0.11 | 43.69–53.57 | 5 | 149 |

| EE26 | 10.7822 | −72.7844 | 0.27–0.69 | 0.04–0.05 | 8.53–11.50 | 3 | 96 |

| EE27 | 10.7404 | −72.7259 | 0.18–0.37 | 0.22–0.26 | 4.45–6.38 | 3 | 63 |

| EE28 | 10.8089 | −72.8961 | 0.10–0.24 | 0.05–0.06 | 2.81–3.93 | 5 | 383 |

| EE29 | 10.7456 | −72.8719 | 0.50–1.20 | 0.05–0.06 | 15.09–20.64 | 3 | 92 |

| EE30 | 10.7556 | −73.0206 | 0.15–0.36 | 0.00–0.00 | 4.54–6.49 | 3 | 82 |

| EE31 | 10.8292 | −73.0808 | 0.11–0.27 | 0.01–0.01 | 3.38–4.92 | 3 | 72 |

| EE32 | 10.7843 | −73.1447 | 0.13–0.31 | 0.00–0.00 | 3.91–5.71 | 3 | 64 |

| EE33 | 10.9622 | −73.0615 | 0.18–0.39 | 0.04–0.05 | 5.08–7.31 | 3 | 49 |

| EE34 | 11.0279 | −72.9432 | 0.03–0.04 | 0.05–0.05 | 0.62–0.85 | 7 | 113 |

| EE35 | 10.6575 | −72.9298 | 0.26–0.67 | 0.05–0.05 | 8.05–11.62 | 5 | 144 |

| EE36 | 10.5994 | −72.8622 | 0.08–0.14 | 0.08–0.09 | 1.99–2.83 | 3 | 33 |

| EE37 | 10.6444 | −73.0338 | 0.06–0.21 | 0.00–0.00 | 2.28–3.31 | 4 | 140 |

| EE38 | 10.5343 | −72.9349 | 0.40–0.65 | 0.51–0.59 | 9.14–12.77 | 4 | 62 |

| EE39 | 10.5896 | −72.9871 | 0.52–1.17 | 0.01–0.01 | 15.04–21.39 | 4 | 136 |

| EE40 | 10.5446 | −73.0093 | 0.47–1.02 | 0.06–0.07 | 13.21–18.93 | 4 | 109 |

| EE41 | 10.5084 | −72.9517 | 0.68–1.19 | 0.88–1.03 | 15.87–22.39 | 4 | 126 |

| EE42 | 10.4679 | −72.9685 | 0.70–1.33 | 0.62–0.73 | 17.23–24.71 | 6 | 281 |

| EE43 | 10.4886 | −72.8873 | 0.05–0.08 | 0.05–0.06 | 1.13–1.59 | 1 | 5 |

| EE44 | 10.5089 | −73.0750 | 0.34–0.71 | 0.05–0.05 | 9.38–13.47 | 4 | 92 |

| EE45 | 10.4564 | −73.0424 | 0.55–1.17 | 0.32–0.37 | 14.49–20.97 | 3 | 121 |

| EE46 | 10.4242 | −73.0077 | 0.70–1.49 | 0.53–0.62 | 18.34–26.43 | 3 | 165 |

| EE47 | 10.4489 | −73.1407 | 0.03–0.06 | 0.03–0.04 | 0.83–1.13 | 3 | 39 |

References

- United Nations. Ending Poverty. 2023. Available online: https://www.un.org/es/global-issues/ending-poverty (accessed on 30 July 2024).

- World Bank. Pobreza: Panorama General. Available online: https://www.bancomundial.org/es/topic/poverty/overview (accessed on 30 July 2024).

- Tang, L.; Chen, M.; Tang, Y.; Xiong, Y. Can E-commerce development alleviate farm household poverty vulnerability: Evidence from rural China. Cities 2024, 153, 105297. [Google Scholar] [CrossRef]

- Callan, T.; Nolan, B. Concepts of Poverty and the Poverty Line. J. Econ. Surv. 1991, 5, 243–261. [Google Scholar] [CrossRef]

- IEA. Defining Energy Access: 2020 Methodology—Analysis—IEA. Available online: https://www.iea.org/articles/defining-energy-access-2020-methodology (accessed on 31 July 2024).

- Sy, S.A.; Mokaddem, L. Energy poverty in developing countries: A review of the concept and its measurements. Energy Res. Soc. Sci. 2022, 89, 2214–6296. [Google Scholar] [CrossRef]

- IRENA. Un Nuevo Informe Revela Retrasos en el Acceso a Energías Básicas y la Necesidad de Invertir en Renovables. Available online: https://www.irena.org/News/pressreleases/2023/Jun/Basic-Energy-Access-Lags-Amid-Renewable-Opportunities-New-Report-Shows-ES (accessed on 30 July 2024).

- Martey, E.; Etwire, P.M.; Adusah-Poku, F.; Akoto, I. Off-farm work, cooking energy choice and time poverty in Ghana: An empirical analysis. Energy Policy 2022, 163, 112853. [Google Scholar] [CrossRef]

- Navarro-Espinosa, A.; Thomas-Galán, M. Firewood electrification in Chile: Effects on household expenditure and energy poverty. Energy Policy 2023, 173, 113337. [Google Scholar] [CrossRef]

- World Health Organization. Household Air Pollution. Available online: https://www.who.int/news-room/fact-sheets/detail/household-air-pollution-and-health?gad_source=1&gclid=Cj0KCQjwwae1BhC_ARIsAK4Jfrye8v7KkFj3N8pTtaHbOhJw9La6E3hogYA07ocmwLXkvtD0GVGbpZ8aAomZEALw_wcB (accessed on 30 July 2024).

- Intergovernmental Panel on Climate Change—IPCC. The Physical Science Basis: Working Group I Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. In Climate Change 2021—The Physical Science Basis; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar] [CrossRef]

- OLADE. Uso Racional y Sostenible de la leña en los países de SICA; OLADE: Quito, Ecuador, 2023. [Google Scholar]

- Ministerio De Minas Y Energía. Plan Nacional de Sustitución de Leña y otros Combustibles de uso Ineficiente y Altamente Contaminante para la Cocción Doméstica de Alimentos Tomo I: Documento de Formulación del Plan Documento de consulta República de Colombia. 2022. Available online: https://www1.upme.gov.co/ (accessed on 13 March 2023).

- García, C.L.E.; Toro-García, G.L. Multidimensional energy poverty in Colombia: A department-level review from 2018 to 2022. Heliyon 2024, 10, e34395. [Google Scholar] [CrossRef]

- DANE. DANE—Encuesta Nacional de Calidad de Vida (ECV) 2022. Available online: https://www.dane.gov.co/index.php/estadisticas-por-tema/salud/calidad-de-vida-ecv/encuesta-nacional-de-calidad-de-vida-ecv-2022?highlight=WyJlY3YiXQ== (accessed on 26 March 2024).

- ACOLGEN. Matriz de Generación Eléctrica Colombiana. 2021. Available online: https://acolgen.org.co/ (accessed on 13 September 2024).

- UPME. Integración de las Energías Renovables no Convencionales en Colombia. 2020. Available online: https://www1.upme.gov.co/DemandaEnergetica/INTEGRACION_ENERGIAS_RENOVANLES_WEB.pdf (accessed on 13 September 2024).

- DANE. Censo Nacional de Población y Vivienda 2018. Available online: https://www.dane.gov.co/index.php/estadisticas-por-tema/demografia-y-poblacion/censo-nacional-de-poblacion-y-vivenda-2018 (accessed on 8 July 2022).

- Mazzone, A.; Cruz, T.; Bezerra, P. Firewood in the forest: Social practices, culture, and energy transitions in a remote village of the Brazilian Amazon. Energy Res. Soc. Sci. 2021, 74, 101980. [Google Scholar] [CrossRef]

- González, T.; Valencia, J.A. Integración de las Energías Renovables no Convencionales en Colombia; La Imprenta Editores: Bogota, Colombia, 2015. [Google Scholar]

- Ferrer-Martí, L.; Ferrer, I.; Sánchez, E.; Garfí, M. A multi-criteria decision support tool for the assessment of household biogas digester programmes in rural areas. A case study in Peru. Renew. Sustain. Energy Rev. 2018, 95, 74–83. [Google Scholar] [CrossRef]

- Garfí, M.; Castro, L.; Montero, N.; Escalante, H.; Ferrer, I. Evaluating environmental benefits of low-cost biogas digesters in small-scale farms in Colombia: A life cycle assessment. Bioresour. Technol. 2019, 274, 541–548. [Google Scholar] [CrossRef]

- Sagastume, A.; Mendoza, J.M.; Cabello, J.J.; Sofan, S.J. Potential of livestock manure and agricultural wastes to mitigate the use of firewood for cooking in rural areas. The case of the department of Cordoba (Colombia). Dev. Eng. 2022, 7, 100093. [Google Scholar] [CrossRef]

- Sagastume, A.; Mendoza, J.M.; Cabello, J.J.; Rhenals, J.D. The available waste-to-energy potential from agricultural wastes in the department of Córdoba, Colombia. Int. J. Energy Econ. Policy 2021, 11, 44–50. [Google Scholar] [CrossRef]

- PNUD. LA GUAJIRA, Retos y desafíos para el Desarrollo Sostenible. 2020. Available online: https://www.undp.org/es/colombia/publications/la-guajira-retos-y-desafios-para-el-desarrollo-sostenible (accessed on 13 September 2024).

- Gaona, E.E.; Trujillo, C.L.; Guacaneme, J.A. Rural microgrids and its potential application in Colombia. Renew. Sustain. Energy Rev. 2015, 51, 125–137. [Google Scholar] [CrossRef]

- Cámara de Comercio de La Guajira. Informe Socioeconómico del Departamento de La Guajira 2022; Cámara de Comercio de La Guajira: Riohacha, Colombia, 2023. [Google Scholar]

- Cámara de Comercio de La Guajira. Informe Socioeconómico de La Guajira 2020; Cámara de Comercio de La Guajira: Riohacha, Colombia, 2021. [Google Scholar]

- DANE. Informes de Estadística Sociodemográfica Aplicada; DANE: Bogota, Colombia, 2023. [Google Scholar]

- DANE. Demografía y Población. Available online: https://www.dane.gov.co/index.php/estadisticas-por-tema/demografia-y-poblacion (accessed on 8 October 2020).

- Promigas. IMPE—Fundación Promigas. Available online: https://fundacionpromigas.org.co/impe/ (accessed on 21 March 2024).

- Public Utility Information Systems (SUI). Reportes del Sector|Portal SUI|Superintendencia de Servicios Públicos Domiciliarios. Available online: https://sui.superservicios.gov.co/Reportes/Filtro?q=Reportes/Filtro&field_sspd_sui_reporte_entidad_value=4&field_sspd_sui_reporte_categoria_value=All&page=1 (accessed on 26 March 2024).

- UPME. Primer balance de Energía Útil para Colombia y Cuantificación de las Perdidas energéticas relacionadas y la brecha de eficiencia energética Resumen Ejecutivo BEU Sector Residencial y Terciario. 2019. Available online: https://www1.upme.gov.co/DemandayEficiencia/Documents/Balance_energia_util/BEU-Residencial.pdf (accessed on 30 March 2024).

- DANE. DANE—Medida de Pobreza Multidimensional de Fuente Censal. Available online: https://www.dane.gov.co/index.php/estadisticas-por-tema/pobreza-y-condiciones-de-vida/pobreza-y-desigualdad/medida-de-pobreza-multidimensional-de-fuente-censal (accessed on 31 March 2024).

- Consorcio Estrategia Rural Sostenible and UPME. Realizar un Estudio que Permita Formular un Programa Actualizado de Sustitución Progresiva de Leña Como Energético en el Sector Residencial en Colombia, con los Componentes Necesarios para su Ejecución; Consorcio Estrategia Rural Sostenible and UPME: Bogotá, Colombia, 2019. [Google Scholar]

- CORPOGUAJIRA; UPME; USAID. Plan de Energización Rural del Departamento de La Guajira. Available online: https://sig.upme.gov.co/SIPERS (accessed on 31 March 2024).

- M. G. N. (MGN) DANE. Geoportal DANE—Página de descarga. Available online: https://www.dane.gov.co/files/geoportal-provisional/index.html (accessed on 3 August 2024).

- G. pers. Plan de Energización Rural Sostenible Para el Departamento de la Guajira. 2016. Available online: https://sig.upme.gov.co/SIPERS/Files/Index/1037 (accessed on 13 September 2024).

- Torres-Torres, J.J.; Mena-Mosquera, V.E.; Álvarez-Dávila, E. Carbono aéreo almacenado en tres bosques del Jardín Botánico del Pacifíco, Chocó, Colombia. Entramado 2017, 13, 200–209. [Google Scholar] [CrossRef]

- Yepes-Quintero, A.; Duque-Montoya, Á.J.; Navarrete-Encinales, D.; Phillips-Bernal, J.; Cabrera-Montenegro, E.; Corrales-Osorio, A.; Álvarez-Dávila, E.; Galindo-García, G.; García-Dávila, M.C.; Idárraga, Á.; et al. Estimación de las reservas y pérdidas de carbono por deforestación en los bosques del departamento de Antioquia, Colombia. Actual. Biol. 2017, 33, 193–208. [Google Scholar] [CrossRef]

- Global Forest Watch. Biomasa Maderera Viva por Encima del Suelo en la Guajira, Colombia. Available online: https://www.globalforestwatch.org/dashboards/country/COL/18/?category=climate&dashboardPrompts=eyJzaG93UHJvbXB0cyI6dHJ1ZSwicHJvbXB0c1ZpZXdlZCI6WyJkYXNoYm9hcmRBbmFseXNlcyIsImRvd25sb2FkRGFzaGJvYXJkU3RhdHMiLCJzaGFyZVdpZGdldCJdLCJzZXR0aW5ncyI6eyJzaG93UHJvbXB0 (accessed on 13 September 2024).

- UPME; Fecop. UPME Calculadora de Emisiones. Available online: https://www.upme.gov.co/calculadora_emisiones/aplicacion/calculadora.html (accessed on 13 September 2024).

- IDEAM. Inventario Nacional y Departamental de Gases Efecto Invernadero. Colombia; IDEAM: Bogotá, Colombia, 2016. [Google Scholar]

- UPME. UPME a 2019-12-19 Informe Final—Plan de Sustitución Progresiva de Leña. 2019. Available online: www.corpoema.net (accessed on 30 March 2024).

- Zulay, S.; Guillen, E. Evaluación de Emisiones Atmosféricas por Consumo de Carbón Vegetal en Viviendas Familiares de las Comunidades de Ishotshimana y Pujuru, Cabo de la Vela, Uribia-la Guajira, Colombia. Ph.D. Thesis, Universidad de La Guajira, La Guajira, Colombia, 2022. [Google Scholar]

- MINAGRICULTURA. Evaluaciones Agropecuarias Municipales—EVA; MINAGRICULTURA: Bogota, Colombia, 2021. [Google Scholar]

- ICA. Protección Vegetal; ICA: Sydney, NSW, Australia, 2022. [Google Scholar]

- Ukoba, M.O.; Diemuodeke, E.O.; Briggs, T.A.; Imran, M.; Owebor, K.; Nwachukwu, C.O. Geographic information systems (GIS) approach for assessing the biomass energy potential and identification of appropriate biomass conversion technologies in Nigeria. Biomass Bioenergy 2023, 170, 106726. [Google Scholar] [CrossRef]

- Okello, C.; Pindozzi, S.; Faugno, S.; Boccia, L. Bioenergy potential of agricultural and forest residues in Uganda. Biomass Bioenergy 2013, 56, 515–525. [Google Scholar] [CrossRef]

- Sivamani, S.; Chandrasekaran, A.P.; Balajii, M.; Shanmugaprakash, M.; Hosseini-Bandegharaei, A.; Baskar, R. Evaluation of the potential of cassava-based residues for biofuels production. Rev. Environ. Sci. Biotechnol. 2018, 17, 553–570. [Google Scholar] [CrossRef]

- Idris, S.; Rosnah, S.; Nor, M.Z.M.; Mokhtar, M.N.; Abdul Gani, S.S. Physicochemical composition of different parts of cassava (Manihot esculenta Crantz) plant. Food Res. 2020, 4 (Suppl. S1), 78–84. [Google Scholar] [CrossRef]

- Tippayawong, N.; Rerkkriangkrai, P.; Aggarangsi, P.; Pattiya, A. Biochar Production from Cassava Rhizome in a Semi-continuous Carbonization System. Energy Procedia 2017, 141, 109–113. [Google Scholar] [CrossRef]

- Eliasson, J.; Carlsson, V. Agricultural Wastes and Wood Waste for Pyrolysis and Biochar: An Assessment for Rwanda. 2020. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-283611 (accessed on 12 April 2024).

- Lecksiwilai, N.; Gheewala, S.H.; Sagisaka, M.; Yamaguchi, K. Net Energy Ratio and Life cycle greenhouse gases (GHG) assessment of bio-dimethyl ether (DME) produced from various agricultural residues in Thailand. J. Clean. Prod. 2016, 134, 523–531. [Google Scholar] [CrossRef]

- FAO. Bioenergía y Seguridad Alimentaria Évaluación Rápida (BEFS RA) Manual de Usuario Briquetas; FAO: Rome, Italy, 2014. [Google Scholar]

- Sagastume Gutiérrez, A.; Cabello Eras, J.J.; Hens, L.; Vandecasteele, C. The energy potential of agriculture, agroindustrial, livestock, and slaughterhouse biomass wastes through direct combustion and anaerobic digestion. The case of Colombia. J. Clean. Prod. 2020, 269, 122317. [Google Scholar] [CrossRef]

- Yazmín, I.; Muñoz, R. Fermentación del Mucílago de Café Para la Obtención de Celulosa Bacteriana con Aislados Nativos de Komagataeibacter spp. Ph.D. Thesis, Universidad Nacional de Colombia, Bogotá, Colombia, 2023. [Google Scholar]

- Castro, E.C.; Virgüez Garzón, N.V. Evaluación del Mucílago del café (Coffea arabica L. Caturra) como Potencial Prebiótico en una Bebida de Arroz. 2019. Available online: https://ciencia.lasalle.edu.co/ (accessed on 30 April 2024).

- Rodríguez, N.; Zambrano, D.A.; Ramírez, C.A. Manejo y Disposición de los Subproductos y de las Aguas Residuales del Beneficio del Café; Cenicafé: Chinchiná, Colombia, 2013. [Google Scholar]

- Reza Rizkiansyah, R.; Mardiyati, Y.; Hariyanto, A.; Steven, S.; Dirgantara, T. Non-Wood paper from coffee pulp Waste: How its performance as coffee filter. Clean. Mater. 2024, 12, 100241. [Google Scholar] [CrossRef]

- Posada Ochoa, S.L.; Rosero Noguera, J.R. Efecto del Método de Secado Sobre la Digestibilidad In Situ de la Pulpa de Café (Coffea arabica). 2017. Available online: https://bibliotecadigital.udea.edu.co/handle/10495/31335 (accessed on 8 April 2024).

- Paredes, J.; Pretell, V.; Pilco, A.; Ramos, W.; Ubillas, C. Characterization of Two Lignocellulosic Biomasses Coffea arabica L. for the production of Biochar. In Proceedings of the LACCEI International Multi-Conference for Engineering, Education and Technology, Boca Raton, FL, USA, 18–22 July 2022. [Google Scholar] [CrossRef]

- Aristizábal-Marulanda, V.; Chacón-Perez, Y.; Alzate, C.A.C. The biorefinery concept for the industrial valorization of coffee processing by-products. In Handbook of Coffee Processing By-Products: Sustainable Applications; Academic Press: Cambridge, MA, USA, 2017; pp. 63–92. [Google Scholar] [CrossRef]

- Martins-Vieira, J.C.; Lachos-Perez, D.; Draszewski, C.P.; Celante, D.; Castilhos, F. Sugar, hydrochar and bio-oil production by sequential hydrothermal processing of corn cob. J. Supercrit. Fluids 2023, 194, 105838. [Google Scholar] [CrossRef]

- Louis, A.C.F.; Venkatachalam, S. Energy efficient process for valorization of corn cob as a source for nanocrystalline cellulose and hemicellulose production. Int. J. Biol. Macromol. 2020, 163, 260–269. [Google Scholar] [CrossRef] [PubMed]

- da Silva, J.C.; de Oliveira, R.C.; da Silva Neto, A.; Pimentel, V.C.; dos Santos, A.D.A. Extraction, Addition and Characterization of Hemicelluloses from Corn Cobs to Development of Paper Properties. Procedia Mater. Sci. 2015, 8, 793–801. [Google Scholar] [CrossRef]

- Martillo Aseffe, J.A.; Martínez González, A.; Jaén, R.L.; Silva Lora, E.E. The corn cob gasification-based renewable energy recovery in the life cycle environmental performance of seed-corn supply chain: An Ecuadorian case study. Renew. Energy 2021, 163, 1523–1535. [Google Scholar] [CrossRef]

- Mboumboue, E.; Njomo, D. Biomass resources assessment and bioenergy generation for a clean and sustainable development in Cameroon. Biomass Bioenergy 2018, 118, 16–23. [Google Scholar] [CrossRef]

- Inna, S. Energy Potential of Waste Derived from Some Food Crop Products in the Northern Part of Cameroon. Int. J. Energy Power Eng. 2015, 4, 342. [Google Scholar] [CrossRef]

- Tolessa, A. Bioenergy potential from crop residue biomass resources in Ethiopia. Heliyon 2023, 9, e13572. [Google Scholar] [CrossRef]

- Akinbomi, J.; Brandberg, T.; Sanni, S.A.; Taherzadeh, M.J. Development and dissemination strategies for accelerating biogas production in Nigeria. Bioresources 2014, 9, 5707–5737. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:hb:diva-1982 (accessed on 21 April 2024).

- Akter, M.M.; Surovy, I.Z.; Sultana, N.; Faruk, M.O.; Gilroyed, B.H.; Tijing, L.; Didar-ul-Alam, M.; Shon, H.K.; Nam, S.Y.; Kabir, M.M. Techno-economics and environmental sustainability of agricultural biomass-based energy potential. Appl. Energy 2024, 359, 122662. [Google Scholar] [CrossRef]

- UPME. Atlas del Potencial Energético de la Biomasa Residual en Colombia; UPME: Bogota, Colombia, 2010. [Google Scholar]

- Barry, F.; Sawadogo, M.; Ouédraogo, I.W.K.; Traoré, M.; Dogot, T. Geographical and economic assessment of feedstock availability for biomass gasification in Burkina Faso. Energy Convers. Manag. X 2022, 13, 100163. [Google Scholar] [CrossRef]

- Zaini, H.M.; Saallah, S.; Roslan, J.; Sulaiman, N.S.; Munsu, E.; Wahab, N.A.; Pindi, W. Banana biomass waste: A prospective nanocellulose source and its potential application in food industry—A review. Heliyon 2023, 9, e18734. [Google Scholar] [CrossRef] [PubMed]

- Redondo-Gómez, C.; Quesada, M.R.; Astúa, S.V.; Zamora, J.P.M.; Lopretti, M.; Vega-Baudrit, J.R. Biorefinery of Biomass of Agro-Industrial Banana Waste to Obtain High-Value Biopolymers. Molecules 2020, 25, 3829. [Google Scholar] [CrossRef]

- Guerrero, A.B.; Aguado, P.L.; Sánchez, J.; Curt, M.D. GIS-Based Assessment of Banana Residual Biomass Potential for Ethanol Production and Power Generation: A Case Study. Waste Biomass Valorization 2016, 7, 405–415. [Google Scholar] [CrossRef]

- Larenas, C. Banana Rachis as a Potential Source of Second Generation Ethanol. 2022. Available online: https://sfera.unife.it/handle/11392/2488182 (accessed on 11 April 2024).

- Khan, M.T.; Brulé, M.; Maurer, C.; Argyropoulos, D.; Müller, J.; Oechsner, H. Batch anaerobic digestion of banana waste-energy potential and modelling of methane production kinetics. Agric. Eng. Int. CIGR J. 2016, 18, 110–128. [Google Scholar]

- Taib, R.M.; Abdullah, N.; Aziz, N.S.M. Bio-oil derived from banana pseudo-stem via fast pyrolysis process. Biomass Bioenergy 2021, 148, 106034. [Google Scholar] [CrossRef]

- Gómez, J.A.; Matallana, L.G.; Teixeira, J.A.; Sánchez, Ó.J. A framework for the design of sustainable multi-input second-generation biorefineries through process simulation: A case study for the valorization of lignocellulosic and starchy waste from the plantain agro-industry. Chem. Eng. Res. Des. 2023, 195, 551–571. [Google Scholar] [CrossRef]

- Shimizu, F.L.; Monteiro, P.Q.; Ghiraldi, P.H.C.; Melati, R.B.; Pagnocca, F.C.; de Souza, W.; Sant’Anna, C.; Brienzo, M. Acid, alkali and peroxide pretreatments increase the cellulose accessibility and glucose yield of banana pseudostem. Ind. Crops Prod. 2018, 115, 62–68. [Google Scholar] [CrossRef]

- Kabenge, I.; Omulo, G.; Banadda, N.; Seay, J.; Zziwa, A.; Kiggundu, N. Characterization of Banana Peels Wastes as Potential Slow Pyrolysis Feedstock. J. Sustain. Dev. 2018, 11, 14. [Google Scholar] [CrossRef]

- Alves, J.L.F.; da Silva, J.C.G.; Sellin, N.; Prá, F.D.B.; Sapelini, C.; Souza, O.; Marangoni, C. Upgrading of banana leaf waste to produce solid biofuel by torrefaction: Physicochemical properties, combustion behaviors, and potential emissions. Environ. Sci. Pollut. Res. 2022, 29, 25733–25747. [Google Scholar] [CrossRef] [PubMed]

- Schaffer, S.; Pröll, T.; Al Afif, R.; Pfeifer, C. A mass- and energy balance-based process modelling study for the pyrolysis of cotton stalks with char utilization for sustainable soil enhancement and carbon storage. Biomass Bioenergy 2019, 120, 281–290. [Google Scholar] [CrossRef]

- Costa, M.A.M.; Schiavon, N.C.B.; Felizardo, M.P.; Souza, A.J.D.; Dussán, K.J. Emission analysis of sugarcane bagasse combustion in a burner pilot. Sustain. Chem. Pharm. 2023, 32, 101028. [Google Scholar] [CrossRef]

- Motta, I.L.; Miranda, N.T.; Filho, R.M.; Maciel, M.R.W. Sugarcane bagasse gasification: Simulation and analysis of different operating parameters, fluidizing media, and gasifier types. Biomass Bioenergy 2019, 122, 433–445. [Google Scholar] [CrossRef]

- Wiesberg, I.L.; de Medeiros, J.L.; de Mello, R.V.P.; Maia, J.G.S.S.; Bastos, J.B.V.; Ofélia de Queiroz, F.A. Bioenergy production from sugarcane bagasse with carbon capture and storage: Surrogate models for techno-economic decisions. Renew. Sustain. Energy Rev. 2021, 150, 111486. [Google Scholar] [CrossRef]

- Pattiya, A.; Suttibak, S. Fast pyrolysis of sugarcane residues in a fluidised bed reactor with a hot vapour filter. J. Energy Inst. 2017, 90, 110–119. [Google Scholar] [CrossRef]

- Rueda-Ordóñez, Y.J.; Tannous, K. Isoconversional kinetic study of the thermal decomposition of sugarcane straw for thermal conversion processes. Bioresour. Technol. 2015, 196, 136–144. [Google Scholar] [CrossRef]

- Cortez, L.A.B.; Baldassin, R.; De Almeida, E. Energy from sugarcane. In Sugarcane Biorefinery, Technology and Perspectives; Academic Press: Cambridge, MA, USA, 2020; pp. 117–139. [Google Scholar] [CrossRef]

- Carvalho, D.J.; Veiga, J.P.S.; Bizzo, W.A. Analysis of energy consumption in three systems for collecting sugarcane straw for use in power generation. Energy 2017, 119, 178–187. [Google Scholar] [CrossRef]

- Sakhiya, A.K.; Anand, A.; Aier, I.; Vijay, V.K.; Kaushal, P. Suitability of rice straw for biochar production through slow pyrolysis: Product characterization and thermodynamic analysis. Bioresour. Technol. Rep. 2021, 15, 100818. [Google Scholar] [CrossRef]

- Singh, R.; Patel, M. Effective utilization of rice straw in value-added by-products: A systematic review of state of art and future perspectives. Biomass Bioenergy 2022, 159, 106411. [Google Scholar] [CrossRef]

- Yang, W.; Zhu, Y.; Li, Y.; Cheng, W.; Zhang, W.; Yang, H.; Tan, Z.; Chen, H. Mitigation of particulate matter emissions from co-combustion of rice husk with cotton stalk or cornstalk. Renew. Energy 2022, 190, 893–902. [Google Scholar] [CrossRef]

- Longdong, I.A.; Tooy, D. Technical Study of a Downdraft Reactor In the Gasification Process of Coconut Husks. In Proceedings of the International Conference on Food, Agriculture and Biology (FAB-2014), Kuala Lumpur, Malaysia, 11–12 June 2014. [Google Scholar] [CrossRef]

- CORPOGUAJIRA. Predicción Climática para la Guajira. 2021. Available online: https://corpoguajira.gov.co/wp/wp-content/uploads/2021/12/Prediccion-climatica-La-Guajira-diciembre21.pdf (accessed on 7 August 2024).

- IDEAM. LA GUAJIRA—Atlas Interactivo—IDEAM; IDEAM: Santander, Colombia, 2022. [Google Scholar]

- Manyi-Loh, C.E.; Lues, R. Anaerobic Digestion of Lignocellulosic Biomass: Substrate Characteristics (Challenge) and Innovation. Fermentation 2023, 9, 755. [Google Scholar] [CrossRef]

- Ai, P.; Zhang, X.; Ran, Y.; Meng, L.; Elsayed, M.; Fan, Q.; Abomohra, A.E.F. Biomass briquetting reduces the energy loss during long-term ensiling and enhances anaerobic digestion: A case study on rice straw. Bioresour. Technol. 2019, 292, 121912. [Google Scholar] [CrossRef]

- Falemara, B.C.; Joshua, V.I.; Aina, O.O.; Nuhu, R.D. Performance evaluation of the physical and combustion properties of briquettes produced from agro-wastes and wood residues. Recycling 2018, 3, 37. [Google Scholar] [CrossRef]

- Abrar, I.; Arora, T.; Khandelwal, R. Bioalcohols as an alternative fuel for transportation: Cradle to grave analysis. Fuel Process. Technol. 2023, 242, 107646. [Google Scholar] [CrossRef]

- Chala, B.; Oechsner, H.; Latif, S.; Müller, J. Biogas potential of coffee processing waste in Ethiopia. Sustainability 2018, 10, 2678. [Google Scholar] [CrossRef]

- Bot, B.V.; Axaopoulos, P.J.; Sakellariou, E.I.; Sosso, O.T.; Tamba, J.G. Energetic and economic analysis of biomass briquettes production from agricultural residues. Appl. Energy 2022, 321, 119430. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A Review of Technical and Economic Aspects of Biomass Briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Brunerová, A.; Brožek, M.; Van Dung, D.; Hasanudin, U.; Iryan, D.A.; Chaloupková, V.; Roubík, H. Manual wooden low-pressure briquetting press: An alternative technology of waste biomass utilisation in developing countries of Southeast Asia. J. Clean. Prod. 2024, 436, 140624. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Bioenergía y Seguridad Alimentaria Évaluación Rápida (BEFs RA). Manual de Usuario Briquetas; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2014. [Google Scholar]

- Young, P.; Khennas, S. FINAL DRAFT Feasibility and Impact Assessment of a Proposed Project to Briquette Municipal Solid Waste for Use as a Cooking Fuel in Rwanda. In Consultancy Report to the Business Linkages Challenge Fund (BLCF); Intermediate Technology Consultants (ITC): Kigali, Rwanda, 2003. [Google Scholar]

- Mohammad Firman, L.O.; Adji, R.B.; Ismail; Rahman, R.A. Increasing the feasibility and storage property of cellulose-based biomass by forming shape-stabilized briquette with hydrophobic compound. Case Stud. Chem. Environ. Eng. 2023, 8, 100443. [Google Scholar] [CrossRef]

- Akhator, P.E.; Bazuaye, L.; Ewere, A.; Oshiokhai, O. Production and characterisation of solid waste-derived fuel briquettes from mixed wood wastes and waste pet bottles. Heliyon 2023, 9, e21432. [Google Scholar] [CrossRef]

- Chen, L.; Xing, L.; Han, L. Renewable energy from agro-residues in China: Solid biofuels and biomass briquetting technology. Renew. Sustain. Energy Rev. 2009, 13, 2689–2695. [Google Scholar] [CrossRef]

- Bot, B.V.; Tamba, J.G.; Sosso, O.T. Assessment of biomass briquette energy potential from agricultural residues in Cameroon. Biomass Convers. Biorefin. 2024, 14, 1905–1917. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S. Critical review on life cycle assessment of conventional and innovative waste-to-energy technologies. Sci. Total Environ. 2019, 672, 708–721. [Google Scholar] [CrossRef] [PubMed]

- Thomsen, S.T.; Spliid, H.; Østergård, H. Statistical prediction of biomethane potentials based on the composition of lignocellulosic biomass. Bioresour. Technol. 2014, 154, 80–86. [Google Scholar] [CrossRef]

- Wang, S.; Jena, U.; Das, K.C. Biomethane production potential of slaughterhouse waste in the United States. Energy Convers. Manag. 2018, 173, 143–157. [Google Scholar] [CrossRef]

- Boundy, R.G.; Diegel, S.W.; Wright, L.L.; Davis, S.C. Biomass Energy Data Book, 4th ed.; US Department of Energy: Washington, DC, USA, 2011. [Google Scholar] [CrossRef]

- Cheng, W.; Zhang, Y.; Wang, P. Effect of spatial distribution and number of raw material collection locations on the transportation costs of biomass thermal power plants. Sustain. Cities Soc. 2020, 55, 102040. [Google Scholar] [CrossRef]

- Tang, Z.H.; Liang, C.; Zhang, R.C. Optimizing crop residues collection patterns in rural areas to reduce transportation costs and carbon emissions. Environ. Technol. Innov. 2023, 32, 103367. [Google Scholar] [CrossRef]

- Djomo, S.N.; Staritsky, I.; Elbersen, B.; Gabrielle, B. Supply costs, energy use, and GHG emissions of biomass from marginal lands in Brittany, France. Renew. Sustain. Energy Rev. 2023, 181, 113244. [Google Scholar] [CrossRef]

- Xu, X.L.; Chen, Y.J. A comprehensive model to analyze straw recycling logistics costs for sustainable development: Evidence from biomass power generation. Environ. Prog. Sustain. Energy 2020, 39, e13394. [Google Scholar] [CrossRef]

- Ma, C.; Zhang, Y.; Ma, K. The effect of biomass raw material collection distance on energy surplus factor. J. Environ. Manag. 2022, 317, 115461. [Google Scholar] [CrossRef] [PubMed]

- Njenga, M.; Gitau, J.K.; Mendum, R. Women’s work is never done: Lifting the gendered burden of firewood collection and household energy use in Kenya. Energy Res. Soc. Sci. 2021, 77, 102071. [Google Scholar] [CrossRef]

- Démurger, S.; Fournier, M. Poverty and firewood consumption: A case study of rural households in northern China. China Econ. Rev. 2011, 22, 512–523. [Google Scholar] [CrossRef]

- Barría, R.M.; Calvo, M.; Pino, P. Contaminación intradomiciliaria por material particulado fino (MP2,5) en hogares de recién nacidos. Rev. Chil. Pediatr. 2016, 87, 343–350. [Google Scholar] [CrossRef]

- US EPA. Particulate Matter (PM) Pollution|US EPA. Available online: https://www.epa.gov/pm-pollution (accessed on 7 October 2024).

- OMS. La Organización Mundial de la Salud Publica Nuevos Datos Sobre la Contaminación del aire a Nivel Mundial|Coalición Clima y Aire Limpio. Available online: https://www.ccacoalition.org/es/news/world-health-organization-releases-new-global-air-pollution-data (accessed on 5 October 2024).

- Seljeskog, M.; Goile, F.; Skreiberg, O. Recommended Revisions of Norwegian Emission Factors for Wood Stoves. Energy Procedia 2017, 105, 1022–1028. [Google Scholar] [CrossRef]

- Nielsen, O.-K.; Nielsen, M.; Plejdrup, M.S. AU Scientific Report from DCE-Danish Centre for Environment and Energy no. 442 Updating the Emission Model for Residential Wood Combustion; Danish Centre for Environment and Energy: Roskilde, Denmark, 2021. [Google Scholar]

- Skreiberg, Ø.; Seljeskog, M.; Kausch, F. A Critical Review and Discussion on Emission Factors for Wood Stoves. Chem. Eng. Trans. 2022, 92, 235–240. [Google Scholar] [CrossRef]

- Deng, M.; Li, P.; Ma, R.; Shan, M.; Yang, X. Air pollutant emission factors of solid fuel stoves and estimated emission amounts in rural Beijing. Environ. Int. 2020, 138, 105608. [Google Scholar] [CrossRef]

- Hays, M.D.; Kinsey, J.; George, I.; Preston, W.; Singer, C.; Patel, B. Carbonaceous Particulate Matter Emitted from a Pellet-Fired Biomass Boiler. Atmosphere 2019, 10, 536. [Google Scholar] [CrossRef]

- Mitchell, E.J.S.; Gudka, B.; Whittaker, C.; Shield, I.; Price-Allison, A.; Maxwell, D.; Jones, J.M.; Williams, A. The use of agricultural residues, wood briquettes and logs for small-scale domestic heating. Fuel Process. Technol. 2020, 210, 106552. [Google Scholar] [CrossRef]

- Zhang, W.; Li, C.; Ye, K.; Xu, Y.; Li, J.; Liu, G.; Xue, C. Field evaluation of pollutant emissions and reduction effects of biomass pellets burning in improved heating stoves in rural China. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 229–235. [Google Scholar]

- Sun, J.; Shen, Z.; Zhang, Y.; Zhang, Q.; Wang, F.; Wang, T.; Chang, X.; Lei, Y.; Xu, H.; Cao, J.; et al. Effects of biomass briquetting and carbonization on PM2.5 emission from residential burning in Guanzhong Plain, China. Fuel 2019, 244, 379–387. [Google Scholar] [CrossRef]

- Zhu, X.; Ho, K.F.; Yang, T.T.; Laiman, V.; Sun, J.; Shen, Z.; Chuang, H.C. Emission Factors of PAHs Components and Bioreactivity in PM2.5 from Biomass Burning. Aerosol Air Qual. Res. 2024, 24, 230068. [Google Scholar] [CrossRef]

- Weyant, C.L.; Thompson, R.; Lam, N.L.; Upadhyay, B.; Shrestha, P.; Maharjan, S.; Rai, K.; Adhikari, C.; Fox, M.C.; Pokhrel, A.K. In-Field Emission Measurements from Biogas and Liquified Petroleum Gas (LPG) Stoves. Atmosphere 2019, 10, 729. [Google Scholar] [CrossRef]

- Uma, R.; Lata, K.; Joshi, V. GREENHOUSE GASES FROM SMALL-SCALE COMBUSTION DEVICES IN DEVELOPING COUNTRIES: PHASE IIA Household Stoves in India; EPA: Washington, DC, USA, 2000. [Google Scholar]

- Shen, G.; Hays, M.D.; Smith, K.R.; Williams, C.; Faircloth, J.W.; Jetter, J.J. Evaluating the Performance of Household Liquefied Petroleum Gas Cookstoves. Environ. Sci. Technol. 2018, 52, 904–915. [Google Scholar] [CrossRef] [PubMed]

- Ministerio de Ambiente y Desarrollo Sostenible. Guidelines for a National Program of Efficient Wood-Burning Stoves; Ministerio de Ambiente y Desarrollo Sostenible: Bogotá, Colombia, 2015. [Google Scholar]

- Giwa, A.S.; Sheng, M.; Maurice, N.J.; Liu, X.; Wang, Z.; Chang, F.; Huang, B.; Wang, K. Biofuel Recovery from Plantain and Banana Plant Wastes: Integration of Biochemical and Thermochemical Approach. J. Renew. Mater. 2023, 11, 2593–2629. [Google Scholar] [CrossRef]

- Castro, L.; Escalante, H.; Jaimes-Estévez, J.; Díaz, L.J.; Vecino, K.; Rojas, G.; Mantilla, L. Low cost digester monitoring under realistic conditions: Rural use of biogas and digestate quality. Bioresour. Technol. 2017, 239, 311–317. [Google Scholar] [CrossRef]

- Tavera-Ruiz, C.; Martí-Herrero, J.; Mendieta, O.; Jaimes-Estévez, J.; Gauthier-Maradei, P.; Azimov, U.; Escalante, H.; Castro, L. Current understanding and perspectives on anaerobic digestion in developing countries: Colombia case study. Renew. Sustain. Energy Rev. 2023, 173, 113097. [Google Scholar] [CrossRef]

- Pöschl, M.; Ward, S.; Owende, P. Evaluation of energy efficiency of various biogas production and utilization pathways. Appl. Energy 2010, 87, 3305–3321. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life cycle assessment of pyrolysis, gasification and incineration waste-to-energy technologies: Theoretical analysis and case study of commercial plants. Sci. Total Environ. 2018, 626, 744–753. [Google Scholar] [CrossRef]

- Marelli, L.; Edwards, R.; Agostini, A.; Giuntoli, J. Solid and Gaseous Bioenergy Pathways: Input Values and GHG Emissions; Calculated according to methodology set in COM(2016) 767: Version 2; European Commission: Brussels, Belgium, 2017; p. 222. [Google Scholar] [CrossRef]

- CML—Department of Industrial Ecology. CML-IA Characterisation Factors. 2016. Available online: https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors (accessed on 12 August 2024).

- IRENA. Renewable Energy Technologies: Cost Analysis Series Biomass for Power Generation Acknowledgement. 2012. Available online: www.irena.org/Publications (accessed on 4 March 2024).

- Mana, A.A.; Allouhi, A.; Ouazzani, K.; Jamil, A. Feasibility of agriculture biomass power generation in Morocco: Techno-economic analysis. J. Clean. Prod. 2021, 295, 126293. [Google Scholar] [CrossRef]

- Shen, W.; Chen, X.; Qiu, J.; Hayward, J.A.; Sayeef, S.; Osman, P.; Meng, K.; Dong, Z.Y. A comprehensive review of variable renewable energy levelized cost of electricity. Renew. Sustain. Energy Rev. 2020, 133, 110301. [Google Scholar] [CrossRef]

- Kamaruzaman, N.; Manaf, N.A.; Milani, D.; Abbas, A. Assessing the current state of biomass gasification technology in advancing circular economies: A holistic analysis from techno-economic-policy perspective in Malaysia and beyond. Chem. Eng. Res. Des. 2023, 199, 593–619. [Google Scholar] [CrossRef]

- Tan, L.; Cai, L.; Xiang, Y.; Guan, Y.; Liu, W. Investigation on oxy-fuel biomass integrated gasification combined cycle system with flue gas as gasifying agent. Biomass Bioenergy 2022, 166, 106621. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Van Doan, Q.; Khan, A.; Derdouri, A.; Anand, P.; Niyogi, D. The potential of agricultural and livestock wastes as a source of biogas in Vietnam: Energetic, economic and environmental evaluation. Renew. Sustain. Energy Rev. 2024, 199, 114440. [Google Scholar] [CrossRef]

- dos Santos, R.E.; dos Santos, I.F.S.; Barros, R.M.; Bernal, A.P.; Tiago Filho, G.L.; da Silva, F.D.G.B. Generating electrical energy through urban solid waste in Brazil: An economic and energy comparative analysis. J. Environ. Manag. 2019, 231, 198–206. [Google Scholar] [CrossRef]

- Silva, L.A.; dos Santos, I.F.S.; de Oliveira Machado, G.; Tiago Filho, G.L.; Barros, R.M. Rice husk energy production in Brazil: An economic and energy extensive analysis. J. Clean. Prod. 2021, 290, 125188. [Google Scholar] [CrossRef]

- Pinto, J.A.; Barros, R.M.; dos Santos, I.F.S.; Tiago Filho, G.L.; de Oliveira Botan, M.C.; Bôas, T.F.V.; de Cássia Crispim, A.M. Study of the anaerobic co-digestion of bovine and swine manure: Technical and economic feasibility analysis. Clean. Waste Syst. 2023, 5, 100097. [Google Scholar] [CrossRef]

- Chiang, L.E.; Castro, F.A.; Molina, F.A. Socioeconomic and environmental benefits of substituting firewood with charcoal briquettes produced from biomass residues in the Forestry Belt in Chile. Energy Sustain. Dev. 2023, 77, 101341. [Google Scholar] [CrossRef]

- Moura, P.; Henriques, J.; Alexandre, J.; Oliveira, A.C.; Abreu, M.; Gírio, F.; Catarino, J. Sustainable value methodology to compare the performance of conversion technologies for the production of electricity and heat, energy vectors and biofuels from waste biomass. Clean. Waste Syst. 2022, 3, 100029. [Google Scholar] [CrossRef]

- Simeone, B.R.; Peña, F.; Andrea, B.; Rosario, D.; Franco, V. Efectos Del Pretratamiento De Biomasa Sobre Poder Calorífico Y Nivel De Emisiones De Briquetas De Residuos Del Olivar Y Orégano. 2022. Available online: https://repositorio.upt.edu.pe/bitstream/handle/20.500.12969/2635/Falcon-Pena-Velarde-Franco.pdf?sequence=1&isAllowed=y (accessed on 13 September 2024).

- Luis, A.; Gamarra, R.; Zamorano, H. Fabricación y Evaluación de Eficiencia y Emisiones de Briquetas a base de Residuos Agrícolas como Alternativa Energética al uso de leña. 2010. Available online: https://bdigital.zamorano.edu/handle/11036/537 (accessed on 28 May 2024).

- Hernandez, J.C.B.; Gutierrez, A.S.; Ramírez-Contreras, N.E.; Eras, J.J.C.; García-Nunez, J.A.; Agudelo, O.R.B.; Lora, E.E.S. Biomass-based energy potential from the oil palm agroindustry in Colombia: A path to low carbon energy transition. J. Clean. Prod. 2024, 449, 141808. [Google Scholar] [CrossRef]

- José, V.; Campo, I.; Naidee, N.; Riveira, M.; José, A.; Moscote, P. Sistema híbrido de energías alternativas y su percepción social en la Alta Guajira. Aglala 2021, 12, 173–191. Available online: https://dialnet.unirioja.es/servlet/articulo?codigo=8458746&info=resumen&idioma=ENG (accessed on 15 May 2024).

- Figueroa Cuello, A.N. Determinantes de la Aceptación Social de las Tecnologías Energéticas Renovables desde la Perspectiva del Usuario líder en La Guajira—Colombia. Available online: https://repository.upb.edu.co/handle/20.500.11912/4924 (accessed on 15 May 2024).

- Alfaro, K.A.; Alfaro, K.A.; García, L.A. Análisis del abordaje social en la incorporación de proyectos de energías renovables: Una revisión documental. Rev. Nuevo Humanismo 2023, 11, 107–135. [Google Scholar] [CrossRef]

- Santa-Maria, M.; Ruiz-Colorado, A.A.; Cruz, G.; Jeoh, T. Assessing the Feasibility of Biofuel Production from Lignocellulosic Banana Waste in Rural Agricultural Communities in Peru and Colombia. Bioenergy Res. 2013, 6, 1000–1011. [Google Scholar] [CrossRef]

- Velásquez-Arredondo, H.I.; Ruiz-Colorado, A.A.; De Oliveira, S. Ethanol production process from banana fruit and its lignocellulosic residues: Energy analysis. Energy 2010, 35, 3081–3087. [Google Scholar] [CrossRef]

- Gonzalez-Salazar, M.A.; Morini, M.; Pinelli, M.; Spina, P.R.; Venturini, M.; Finkenrath, M.; Poganietz, W.R. Methodology for estimating biomass energy potential and its application to Colombia. Appl. Energy 2014, 136, 781–796. [Google Scholar] [CrossRef]

- Gómez-Navarro, T.; Ribó-Pérez, D. Assessing the obstacles to the participation of renewable energy sources in the electricity market of Colombia. Renew. Sustain. Energy Rev. 2018, 90, 131–141. [Google Scholar] [CrossRef]

- IEA. Technology Roadmap: Delivering Sustainable Bioenergy|Bioenergy. Available online: https://www.ieabioenergy.com/blog/publications/technology-roadmap-delivering-sustainable-bioenergy/ (accessed on 2 February 2023).

- Olaya, Y.; Arango-Aramburo, S.; Larsen, E.R. How capacity mechanisms drive technology choice in power generation: The case of Colombia. Renew. Sustain. Energy Rev. 2016, 56, 563–571. [Google Scholar] [CrossRef]

- UPME. Cobertura de Energía Eléctrica base por Municipio en Colombia. Available online: http://www.upme.gov.co/generadorconsultas/Consulta_Series.aspx?idModulo=2&tipoSerie=206&grupo=558 (accessed on 2 February 2023).

- Nurfaezzah, A.J.; Nurashikin, S.; Salwani, A.A.D. Enhancement of glucose recovery from banana stem by 4-cycle enzymatic hydrolysis. Res. J. Biotechnol. 2023, 18, 192–199. [Google Scholar] [CrossRef]

- Dilkushi, H.A.S.; Jayarathna, S.; Manipura, A.; Chamara, H.K.B.S.; Edirisinghe, D.; Vidanarachchi, J.K.; Priyashantha, H. Development and characterization of biocomposite films using banana pseudostem, cassava starch and poly(vinyl alcohol): A sustainable packaging alternative. Carbohydr. Polym. Technol. Appl. 2024, 7, 100472. [Google Scholar] [CrossRef]

- Bhushan, S.; Rana, M.S.; Mamta; Nandan, N.; Prajapati, S.K. Energy harnessing from banana plant wastes: A review. Bioresour. Technol. Rep. 2019, 7, 100212. [Google Scholar] [CrossRef]

- Islam, M.A.; Akber, M.A.; Limon, S.H.; Akbor, M.A.; Islam, M.A. Characterization of solid biofuel produced from banana stalk via hydrothermal carbonization. Biomass Convers. Biorefin. 2019, 9, 651–658. [Google Scholar] [CrossRef]

- Kumar, A.; Mylapilli, S.V.P.; Reddy, S.N. Thermogravimetric and kinetic studies of metal (Ru/Fe) impregnated banana pseudo-stem (Musa acuminate). Bioresour. Technol. 2019, 285, 121318. [Google Scholar] [CrossRef] [PubMed]

- Baruah, J.; Bardhan, P.; Mukherjee, A.K.; Deka, R.C.; Mandal, M.; Kalita, E. Integrated pretreatment of banana agrowastes: Structural characterization and enhancement of enzymatic hydrolysis of cellulose obtained from banana peduncle. Int. J. Biol. Macromol. 2022, 201, 298–307. [Google Scholar] [CrossRef] [PubMed]

- Saini, R.; Mahajani, S.M.; Barma, S.D.; Rao, D.S. Valorization of coconut and banana wastes with petcoke and coal via steam gasification in a fluidized bed reactor. J. Clean. Prod. 2024, 434, 139955. [Google Scholar] [CrossRef]

- Cardona, S.; Orozco, L.M.; Gómez, C.L.; Solís, W.A.; Velásquez, J.A.; Rios, L.A. Valorization of banana residues via gasification coupled with electricity generation. Sustain. Energy Technol. Assess. 2021, 44, 101072. [Google Scholar] [CrossRef]

- Abdullah, N.; Sulaiman, F.; Taib, R.M. Characterization of banana (Musa spp.) plantation wastes as a potential renewable energy source. AIP Conf. Proc. 2013, 1528, 325–330. [Google Scholar] [CrossRef]

- Sulaiman, S.M.; Nugroho, G.; Saputra, H.M.; Djaenudin; Permana, D.; Fitria, N.; Putra, H.E. Valorization of Banana Bunch Waste as a Feedstock via Hydrothermal Carbonization for Energy Purposes. J. Ecol. Eng. 2023, 24, 61–74. [Google Scholar] [CrossRef]

- Shankar, K.; Kulkarni, N.S.; Sajjanshetty, R.; Jayalakshmi, S.K.; Sreeramulu, K. Co-production of xylitol and ethanol by the fermentation of the lignocellulosic hydrolysates of banana and water hyacinth leaves by individual yeast strains. Ind. Crops Prod. 2020, 155, 112809. [Google Scholar] [CrossRef]

- Sellin, N.; Krohl, D.R.; Marangoni, C.; Souza, O. Oxidative fast pyrolysis of banana leaves in fluidized bed reactor. Renew. Energy 2016, 96, 56–64. [Google Scholar] [CrossRef]

- Priyadarsini, A.; Swain, B.; Mishra, A.; Nanda, S.; Dash, M.; Swain, N.; Jena, P.K.; Mohanty, M.K. Study on biofuel efficiency of tropical banana leaf biomass using spectroscopy, kinetic and thermodynamic parameters. Bioresour. Technol. Rep. 2023, 23, 101522. [Google Scholar] [CrossRef]

- Ansari, S.A.; Shakeel, A.; Sawarkar, R.; Maddalwar, S.; Khan, D.; Singh, L. Additive facilitated co-composting of lignocellulosic biomass waste, approach towards minimizing greenhouse gas emissions: An up to date review. Environ. Res. 2023, 224, 115529. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Vásquez, R.D.; Castiblanco, E.A.; Zapata Benabithe, Z.; Bula Silvera, A.J.; Camargo-Trillos, D.A. CaCO3 and air/steam effect on the gasification and biohydrogen performance of corn cob as received: Application in the Colombian Caribbean region. Biomass Bioenergy 2021, 153, 106207. [Google Scholar] [CrossRef]

- Arenas Castiblanco, E.; Montoya, J.H.; Rincón, G.V.; Zapata-Benabithe, Z.; Gómez-Vásquez, R.; Camargo-Trillos, D.A. A new approach to obtain kinetic parameters of corn cob pyrolysis catalyzed with CaO and CaCO3. Heliyon 2022, 8, e10195. [Google Scholar] [CrossRef] [PubMed]

- Chakravarty, K.H.; Sadi, M.; Chakravarty, H.; Andersen, J.; Choudhury, B.; Howard, T.J.; Arabkoohsar, A. Pyrolysis kinetics and potential utilization analysis of cereal biomass by-products; an experimental analysis for cleaner energy productions in India. Chemosphere 2024, 353, 141420. [Google Scholar] [CrossRef]

- Prado-Martínez, M.; Anzaldo-Hernández, J.; Becerra-Aguilar, B.; Palacios-Juárez, H.; Vargas-Radillo, J.D.J.; Rentería-Urquiza, M. Caracterización de hojas de mazorca de maíz y de bagazo de caña para la elaboración de una pulpa celulósica mixta. Madera Bosques 2012, 18, 37–51. [Google Scholar] [CrossRef][Green Version]

- Causil Villalba, R.D.; Guzmán Mestra, V.A. Caracterización de las Fibras de Capacho de Maíz (Zea mays) como Material de Refuerzo Alternativo para el Concreto Mediante Ensayos Mecánicos. 8 April 2018. Available online: https://repositorio.unicordoba.edu.co/handle/ucordoba/670 (accessed on 13 April 2024).

- Escobar, L.M.A.; Álvarez, U.S.; Peñuela, M. Inmovilización de levaduras en residuos lignocelulósicos para la producción de etanol en biorreactor de lecho empacado. Rev. Fac. Ing. Univ. Antioq. 2012, 62, 66–76. [Google Scholar] [CrossRef]

- Phyllis2. Phyllis2—Clasificación ECN Phyllis. Available online: https://phyllis.nl/Browse/Standard/ECN-Phyllis#tomato (accessed on 27 January 2023).

- Wang, Z.; Wu, M.; Chen, G.; Zhang, M.; Sun, T.; Burra, K.G.; Guo, S.; Chen, Y.; Yang, S.; Li, Z.; et al. Co-pyrolysis characteristics of waste tire and maize stalk using TGA, FTIR and Py-GC/MS analysis. Fuel 2023, 337, 127206. [Google Scholar] [CrossRef]

- Parvez, A.M.; Afzal, M.T.; Jiang, P.; Wu, T. Microwave-assisted biomass pyrolysis polygeneration process using a scaled-up reactor: Product characterization, thermodynamic assessment and bio-hydrogen production. Biomass Bioenergy 2020, 139, 105651. [Google Scholar] [CrossRef]

- Sun, Y.; Fan, S.; Yang, T.; Zhang, H.; Chen, Y. Study on the Characteristics of Pyrolysis Gas and Oil from Corn Stalk Pyrolysis. IOP Conf. Ser. Earth Environ. Sci. 2020, 446, 032099. [Google Scholar] [CrossRef]

- Liang, J.; Li, Z.; Dai, S.; Tian, G.; Wang, Z. Production of hemicelluloses sugars, cellulose pulp, and lignosulfonate surfactant using corn stalk by prehydrolysis and alkaline sulfite cooking. Ind. Crops Prod. 2023, 192, 115880. [Google Scholar] [CrossRef]

- Liao, K.; Han, L.; Yang, Z.; Huang, Y.; Du, S.; Lyu, Q.; Shi, Z.; Shi, S. A novel in-situ quantitative profiling approach for visualizing changes in lignin and cellulose by stained micrographs. Carbohydr. Polym. 2022, 297, 119997. [Google Scholar] [CrossRef] [PubMed]

- Longaresi, R.H.; de Menezes, A.J.; Pereira-da-Silva, M.A.; Baron, D.; Mathias, S.L. The maize stem as a potential source of cellulose nanocrystal: Cellulose characterization from its phenological growth stage dependence. Ind. Crops Prod. 2019, 133, 232–240. [Google Scholar] [CrossRef]

- Guo, X.; Xu, Z.; Zheng, X.; Jin, X.; Cai, J. Understanding pyrolysis mechanisms of corn and cotton stalks via kinetics and thermodynamics. J. Anal. Appl. Pyrolysis 2022, 164, 105521. [Google Scholar] [CrossRef]

- Nathalíe, S.; Rincón, R. Aprovechamiento de Biomasa Lignocelulósica Proveniente de rosas Utilizando el Proceso Organosolv. Master’s Thesis, Universidad Nacional de Colombia, Bogotá, Colombia, 2020. [Google Scholar]

- Pattiya, A.; Sukkasi, S.; Goodwin, V. Fast pyrolysis of sugarcane and cassava residues in a free-fall reactor. Energy 2012, 44, 1067–1077. [Google Scholar] [CrossRef]

- Dewi, P.; Millati, R.; Indrati, R.; Sardjono, S. Effect of Lime Pretreatment on Microstructure of Cassava Stalk Fibers and Growth of Aspergillus niger. Biosaintifika 2018, 10, 205–212. [Google Scholar] [CrossRef][Green Version]

- Kouteu Nanssou, P.A.; Jiokap Nono, Y.; Kapseu, C. Pretreatment of cassava stems and peelings by thermohydrolysis to enhance hydrolysis yield of cellulose in bioethanol production process. Renew. Energy 2016, 97, 252–265. [Google Scholar] [CrossRef]

- Cruz, G.; Rodrigues, A.D.L.P.; da Silva, D.F.; Gomes, W.C. Physical–chemical characterization and thermal behavior of cassava harvest waste for application in thermochemical processes. J. Therm. Anal. Calorim. 2021, 143, 3611–3622. [Google Scholar] [CrossRef]

- Han, M.; Kim, Y.; Kim, Y.; Chung, B.; Choi, G.W. Bioethanol production from optimized pretreatment of cassava stem. Korean J. Chem. Eng. 2011, 28, 119–125. [Google Scholar] [CrossRef]

- Pattiya, A. Bio-oil production via fast pyrolysis of biomass residues from cassava plants in a fluidised-bed reactor. Bioresour. Technol. 2011, 102, 1959–1967. [Google Scholar] [CrossRef]

- Suttibak, S.; Sriprateep, K.; Pattiya, A. Production of Bio-oil via Fast Pyrolysis of Cassava Rhizome in a Fluidised-Bed Reactor. Energy Procedia 2012, 14, 668–673. [Google Scholar] [CrossRef]

- Kanchanasuta, S.; Sillaparassamee, O.; Champreda, V.; Singhakant, C.; Pisutpaisal, N. Optimization of pretreatment process of cassava rhizome for bio-succinic fermentation by Actinobacillus succinogenes. Biomass Convers. Biorefin. 2022, 12, 4917–4924. [Google Scholar] [CrossRef]

- Sombatpraiwan, S.; Junyusen, T.; Treeamnak, T.; Junyusen, P. Optimization of microwave-assisted alkali pretreatment of cassava rhizome for enhanced enzymatic hydrolysis glucose yield. Food Energy Secur. 2019, 8, e00174. [Google Scholar] [CrossRef]

- Nakason, K.; Khemthong, P.; Mahasandana, S.; Panyapinyopol, B.; Sci, C.J.M.; Kraithong, W. Effect of Alkaline Pretreatment on the Properties of Cassava Rhizome. Artic. Chiang Mai J. Sci. 2021, 48, 1511–1523. Available online: http://epg.science.cmu.ac.th/ejournal/ (accessed on 12 April 2024).

- Pattiya, A.; Titiloye, J.O.; Bridgwater, A.V. Evaluation of catalytic pyrolysis of cassava rhizome by principal component analysis. Fuel 2010, 89, 244–253. [Google Scholar] [CrossRef]

- Sirijanusorn, S.; Sriprateep, K.; Pattiya, A. Pyrolysis of cassava rhizome in a counter-rotating twin screw reactor unit. Bioresour. Technol. 2013, 139, 343–348. [Google Scholar] [CrossRef]

- Sornkade, P.; Atong, D.; Sricharoenchaikul, V. Conversion of cassava rhizome using an in-situ catalytic drop tube reactor for fuel gas generation. Renew. Energy 2015, 79, 38–44. [Google Scholar] [CrossRef]

- Pan, Z.; Li, X.; Fu, L.; Li, Q.; Li, X. Environmental sustainability by a comprehensive environmental and energy comparison analysis in a wood chip and rice straw biomass-fueled multi-generation energy system. Process Saf. Environ. Prot. 2023, 177, 868–879. [Google Scholar] [CrossRef]

- Osat, M.; Shojaati, F.; Osat, M. A solar-biomass system associated with CO2 capture, power generation and waste heat recovery for syngas production from rice straw and microalgae: Technological, energy, exergy, exergoeconomic and environmental assessments. Appl. Energy 2023, 340, 120999. [Google Scholar] [CrossRef]

- Krishania, M.; Kumar, V.; Sangwan, R.S. Integrated approach for extraction of xylose, cellulose, lignin and silica from rice straw. Bioresour. Technol. Rep. 2018, 1, 89–93. [Google Scholar] [CrossRef]

- Li, S.; Song, H.; Hu, J.; Yang, H.; Zou, J.; Zhu, Y.; Tang, Z.; Chen, H. CO2 gasification of straw biomass and its correlation with the feedstock characteristics. Fuel 2021, 297, 120780. [Google Scholar] [CrossRef]

- Chen, C.; Qu, B.; Wang, W.; Wang, W.; Ji, G.; Li, A. Rice husk and rice straw torrefaction: Properties and pyrolysis kinetics of raw and torrefied biomass. Environ. Technol. Innov. 2021, 24, 101872. [Google Scholar] [CrossRef]

- Mothe, S.; Jugal, S.M.; Rao, P.V.; Sridhar, P. Rice straw anaerobic co-digestion: Comparing various pre-treatment techniques to enhance biogas production. Bioresour. Technol. Rep. 2024, 25, 101788. [Google Scholar] [CrossRef]

- Goodman, B.A. Utilization of waste straw and husks from rice production: A review. J. Bioresour. Bioprod. 2020, 5, 143–162. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef]

- Yousefian, F.; Babatabar, M.A.; Eshaghi, M.; Poor, S.M.; Tavasoli, A. Pyrolysis of Rice husk, Coconut shell, and Cladophora glomerata algae and application of the produced biochars as support for cobalt catalyst in Fischer–Tropsch synthesis. Fuel Process. Technol. 2023, 247, 107818. [Google Scholar] [CrossRef]

- Chen, C.; Yang, R.; Wang, X.; Qu, B.; Zhang, M.; Ji, G.; Li, A. Effect of in-situ torrefaction and densification on the properties of pellets from rice husk and rice straw. Chemosphere 2022, 289, 133009. [Google Scholar] [CrossRef]

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N.; Manning, D.A.C. Kinetics of maize cob and bean straw pyrolysis and combustion. Heliyon 2023, 9, e17236. [Google Scholar] [CrossRef]

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Thermo-chemical behaviour of maize cob and bean straw briquettes. Energy Convers. Manag. X 2022, 16, 100313. [Google Scholar] [CrossRef]

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Briquetting characteristics of bean straw-maize cob blend. Biomass Bioenergy 2019, 126, 150–158. [Google Scholar] [CrossRef]

- Rodríguez Frómeta, R.A.; Sánchez, J.L.; Ros García, J.M. Evaluation of coffee pulp as substrate for polygalacturonase production in solid state fermentation. Emir. J. Food Agric. 2020, 32, 117–124. [Google Scholar] [CrossRef]

- Setyobudi, R.H.; Wahono, S.K.; Adinurani, P.G.; Wahyudi, A.; Widodo, W.; Mel, M.; Nugroho, Y.A.; Prabowo, B.; Liwang, T. Characterisation of Arabica Coffee Pulp—Hay from Kintamani—Bali as Prospective Biogas Feedstocks. MATEC Web Conf. 2018, 164, 01039. [Google Scholar] [CrossRef][Green Version]

- Hikichi, S.E.; Andrade, R.P.; Dias, E.S.; Duarte, W.F. Biotechnological applications of coffee processing by-products. In Handbook of Coffee Processing By-Products: Sustainable Applications; Academic Press: Cambridge, MA, USA, 2017; pp. 221–244. [Google Scholar] [CrossRef]

- Corro, G.; Pal, U.; Cebada, S. Enhanced biogas production from coffee pulp through deligninocellulosic photocatalytic pretreatment. Energy Sci. Eng. 2014, 2, 177–187. [Google Scholar] [CrossRef]

- Vega, A.; De León, J.A.; Miranda, S.; Reyes, S.M. Agro-industrial waste improves the nutritional and antioxidant profile of Pleurotus djamor. Clean. Waste Syst. 2022, 2, 100018. [Google Scholar] [CrossRef]

- Londoño-Hernandez, L.; Ruiz, H.A.; Cristina Ramírez, T.; Ascacio, J.A.; Rodríguez-Herrera, R.; Aguilar, C.N. Fungal detoxification of coffee pulp by solid-state fermentation. Biocatal. Agric. Biotechnol. 2020, 23, 101467. [Google Scholar] [CrossRef]

- Parascanu, M.M.; Sandoval-Salas, F.; Soreanu, G.; Valverde, J.L.; Sanchez-Silva, L. Valorization of Mexican biomasses through pyrolysis, combustion and gasification processes. Renew. Sustain. Energy Rev. 2017, 71, 509–522. [Google Scholar] [CrossRef]

- Serna-Jiménez, J.A.; Torres-Valenzuela, L.S.; Villarreal, A.S.; Roldan, C.; Martín, M.A.; Siles, J.A.; Chica, A.F. Advanced extraction of caffeine and polyphenols from coffee pulp: Comparison of conventional and ultrasound-assisted methods. LWT 2023, 177, 114571. [Google Scholar] [CrossRef]

- Fernandes, E.R.K.; Marangoni, C.; Souza, O.; Sellin, N. Thermochemical characterization of banana leaves as a potential energy source. Energy Convers. Manag. 2013, 75, 603–608. [Google Scholar] [CrossRef]

- Allende, S.; Brodie, G.; Jacob, M.V. Energy recovery from sugarcane bagasse under varying microwave-assisted pyrolysis conditions. Bioresour. Technol. Rep. 2022, 20, 101283. [Google Scholar] [CrossRef]

- Pati, S.; De, S.; Chowdhury, R. Exploring the hybrid route of bio-ethanol production via biomass co-gasification and syngas fermentation from wheat straw and sugarcane bagasse: Model development and multi-objective optimization. J. Clean. Prod. 2023, 395, 136441. [Google Scholar] [CrossRef]

- Osaki, M.R. An energy optimization model comparing the use of sugarcane bagasse for power or ethanol production. Ind. Crops Prod. 2022, 187, 115284. [Google Scholar] [CrossRef]

- Rabea, K.; Bakry, A.I.; Khalil, A.; El-Fakharany, M.K.; Kadous, M. Real-time performance investigation of a downdraft gasifier fueled by cotton stalks in a batch-mode operation. Fuel 2021, 300, 120976. [Google Scholar] [CrossRef]

- Karatas, H.; Olgun, H.; Akgun, F. Experimental results of gasification of cotton stalk and hazelnut shell in a bubbling fluidized bed gasifier under air and steam atmospheres. Fuel 2013, 112, 494–501. [Google Scholar] [CrossRef]

- Sui, H.; Shao, J.; Agblevor, F.A.; Zhang, Y.; Wang, X.; Yang, H.; Chen, H. Fractional condensation and aging of pyrolysis oil from cotton stalk. Biomass Bioenergy 2023, 174, 106837. [Google Scholar] [CrossRef]

- Al Afif, R.; Anayah, S.S.; Pfeifer, C. Batch pyrolysis of cotton stalks for evaluation of biochar energy potential. Renew. Energy 2020, 147, 2250–2258. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, X.; Gao, Y.; Lin, Y.; Xu, J.; Zhu, C.; Zhu, Y. Parametric study of catalytic co-gasification of cotton stalk and aqueous phase from wheat straw using hydrothermal carbonation. Energy 2021, 216, 119266. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, D.; Wang, Y.; Wei, S.; Yang, W.; Kuang, M.; Ma, L.; Fang, D.; Xu, S.; Du, S.K. Bioethanol production from cotton stalk: A comparative study of various pretreatments. Fuel 2016, 184, 527–532. [Google Scholar] [CrossRef]