Study on the Properties of a Polyvinyl Alcohol-Modified Ultrafine Cement Grouting Material for Weathered Zone Coal Seams

Abstract

1. Introduction

2. Materials and Methods

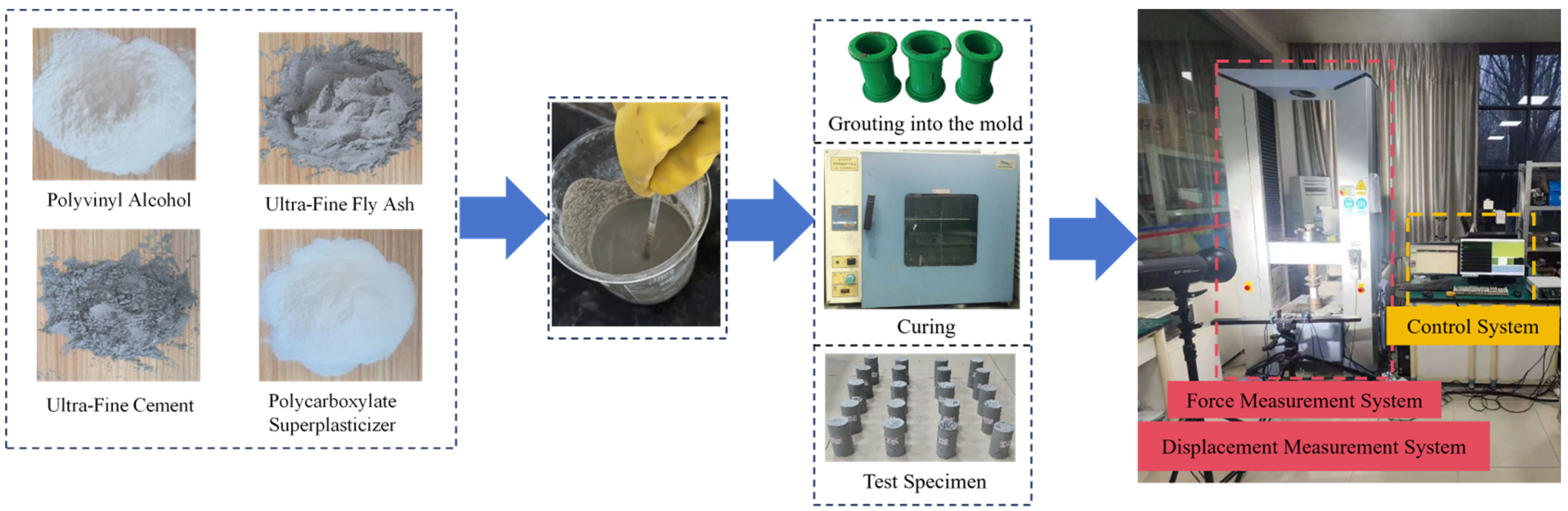

2.1. Test Materials

- (1)

- Ultrafine cement

- (2)

- Ultrafine fly ash

- (3)

- Polyvinyl alcohol (PVA)

- (4)

- Polycarboxylate superplasticizer

2.2. Experimental Design

- (1)

- Parameter Design

- (2)

- Orthogonal Experimental Design

2.3. Test Methods

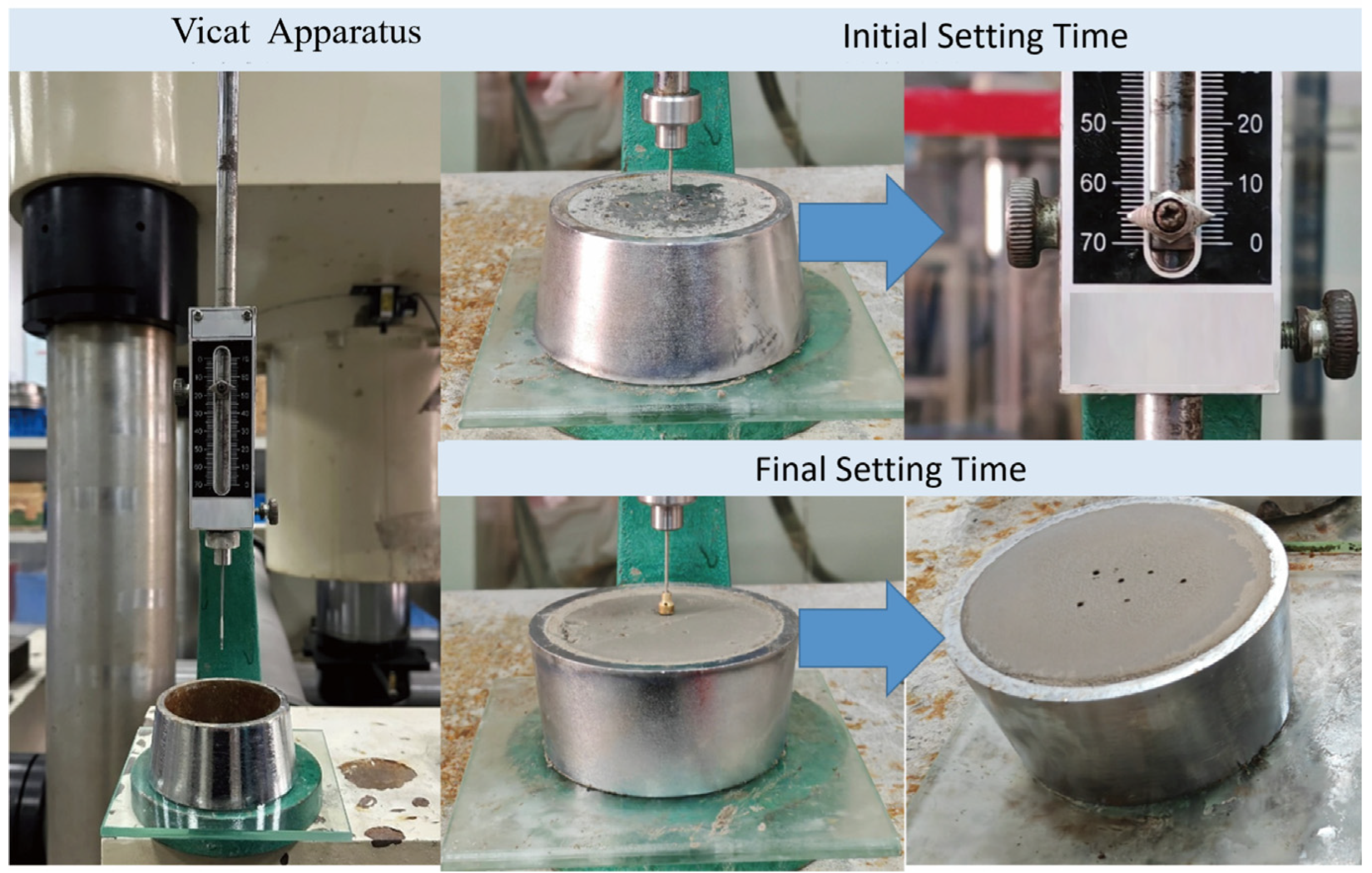

2.3.1. Setting Time Test

2.3.2. Fluidity Test

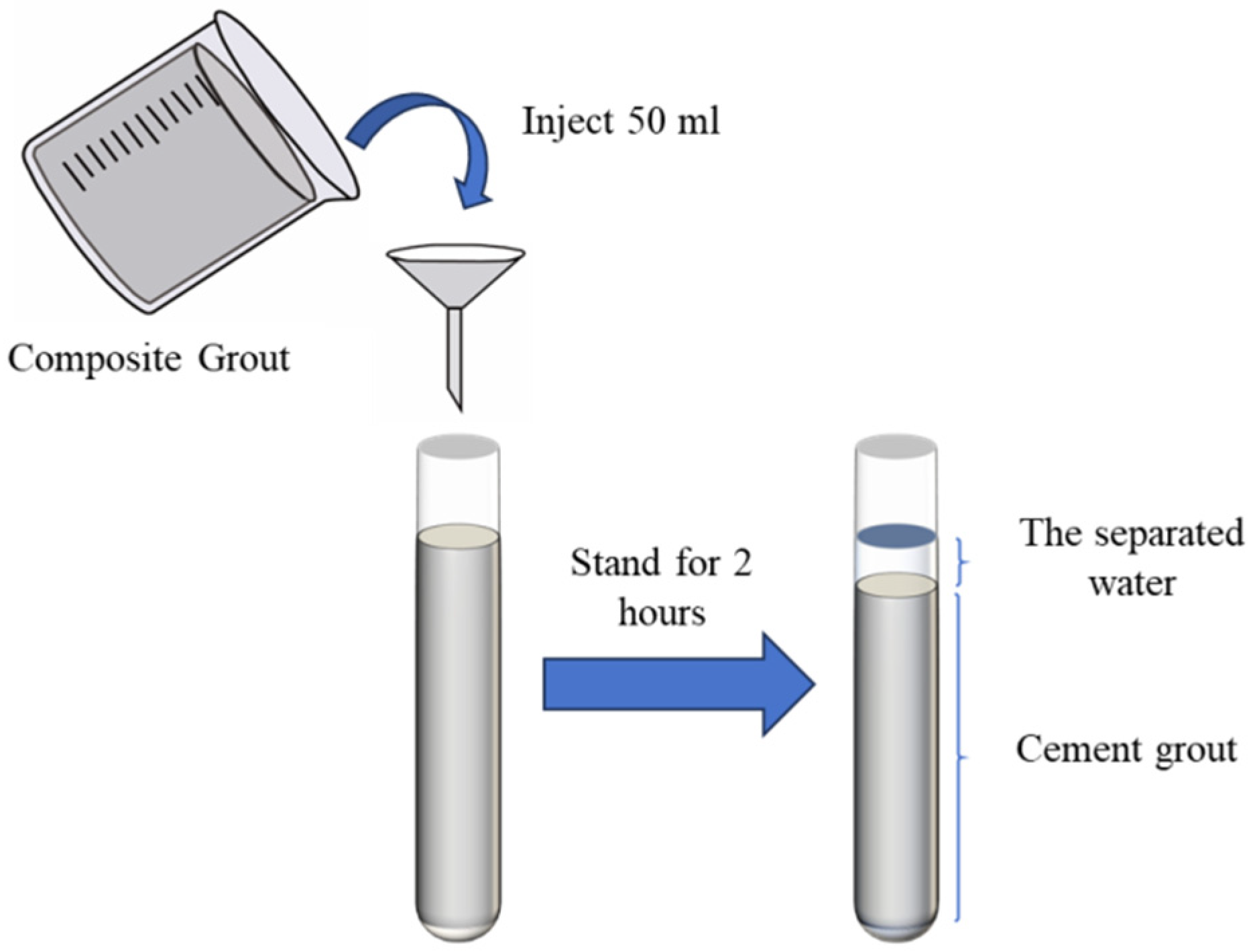

2.3.3. Water Separation Rate Test

2.3.4. Viscosity Test

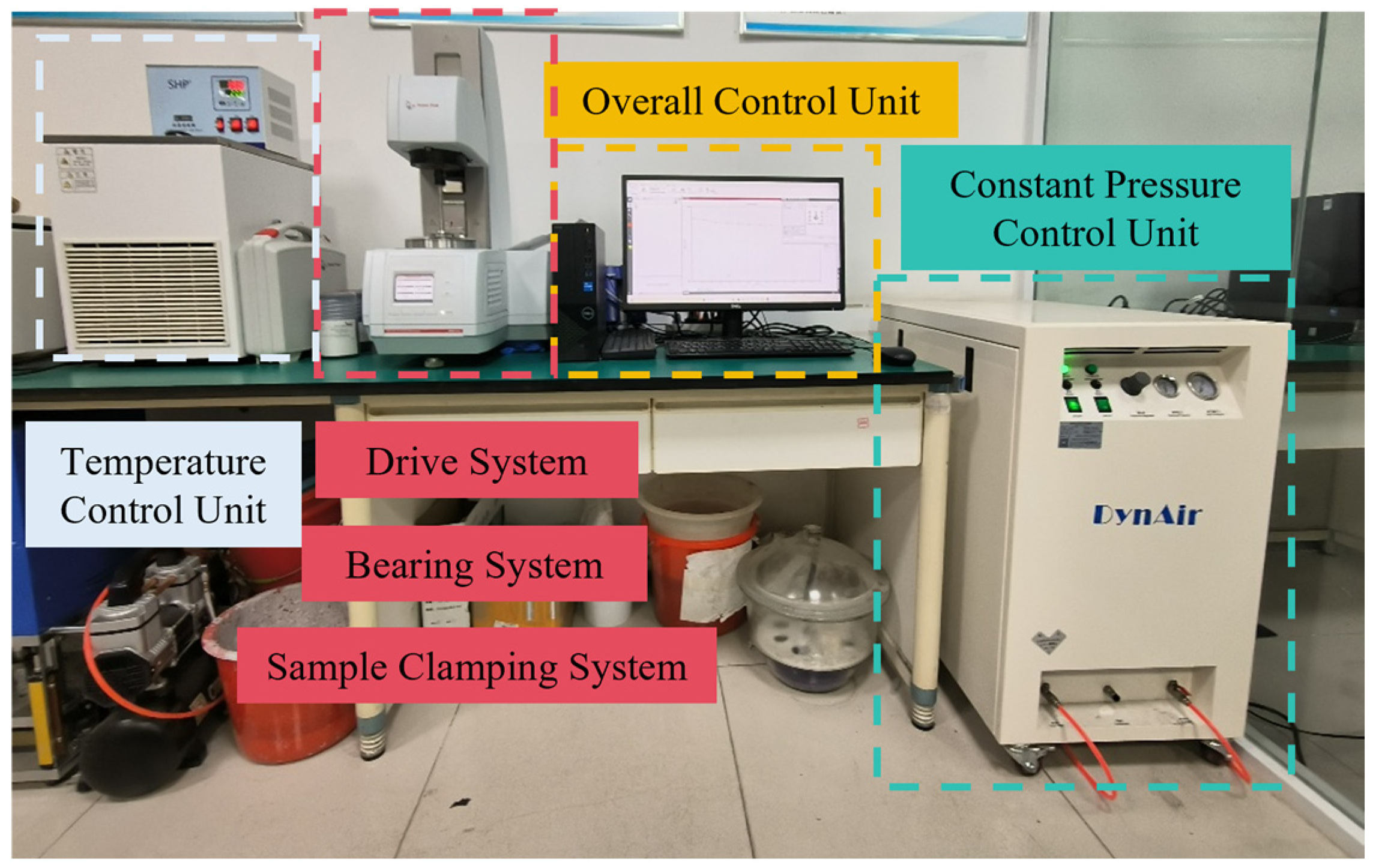

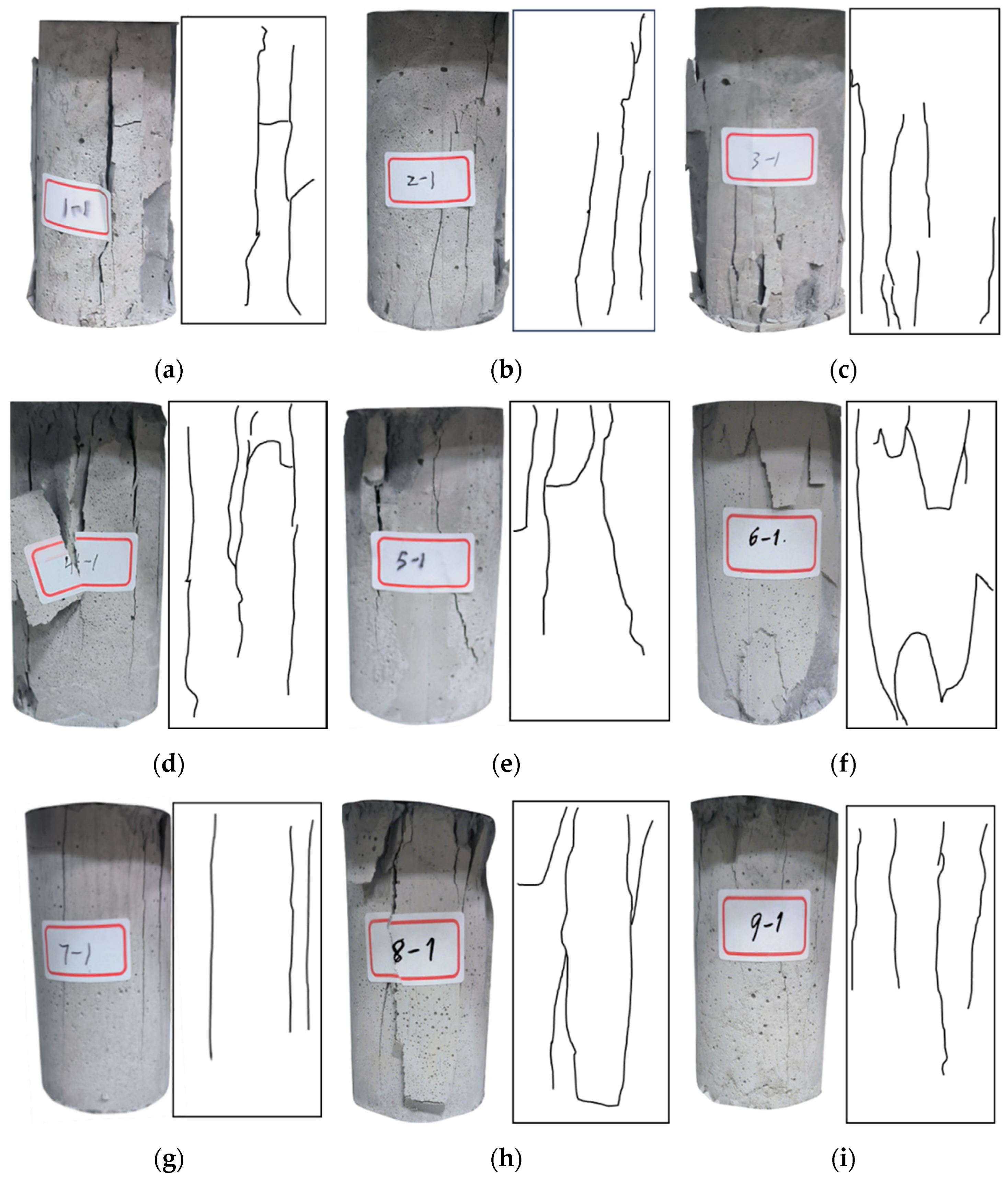

2.3.5. Uniaxial Compressive Strength Test

3. Results Analysis and Discussion

3.1. Results Analysis of PVAM-UFCG Slurry Performance

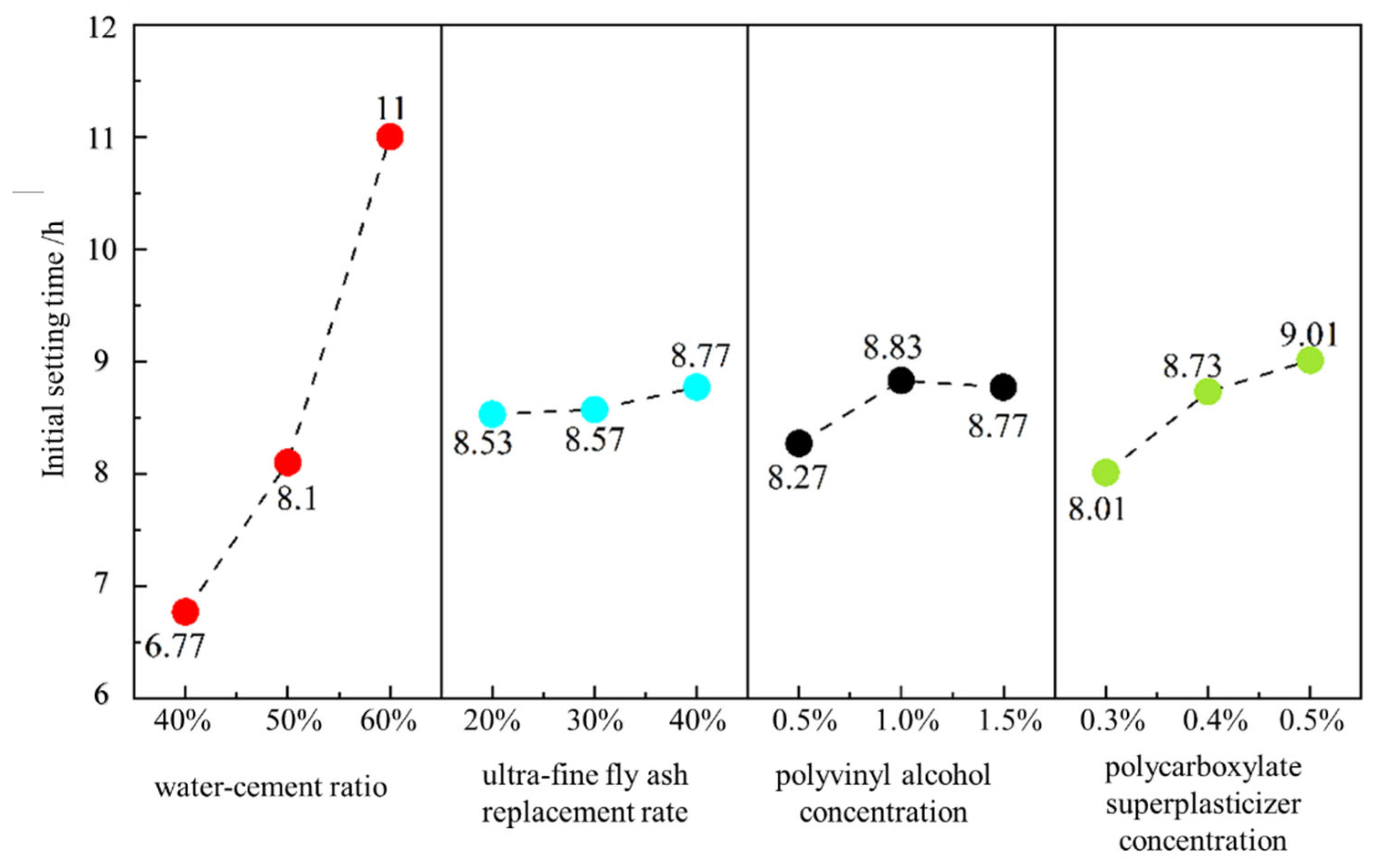

3.1.1. Analysis of Setting Time Results

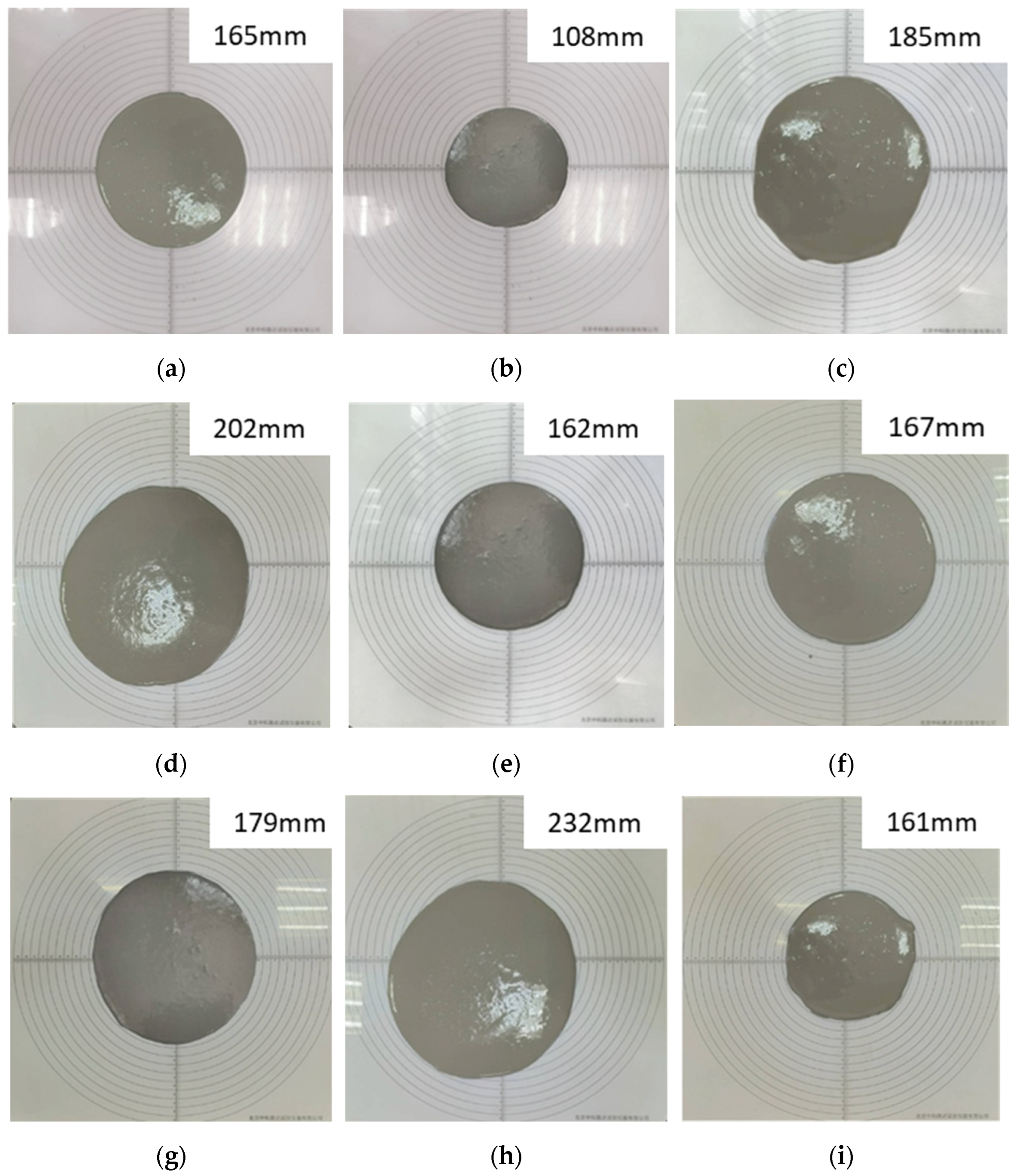

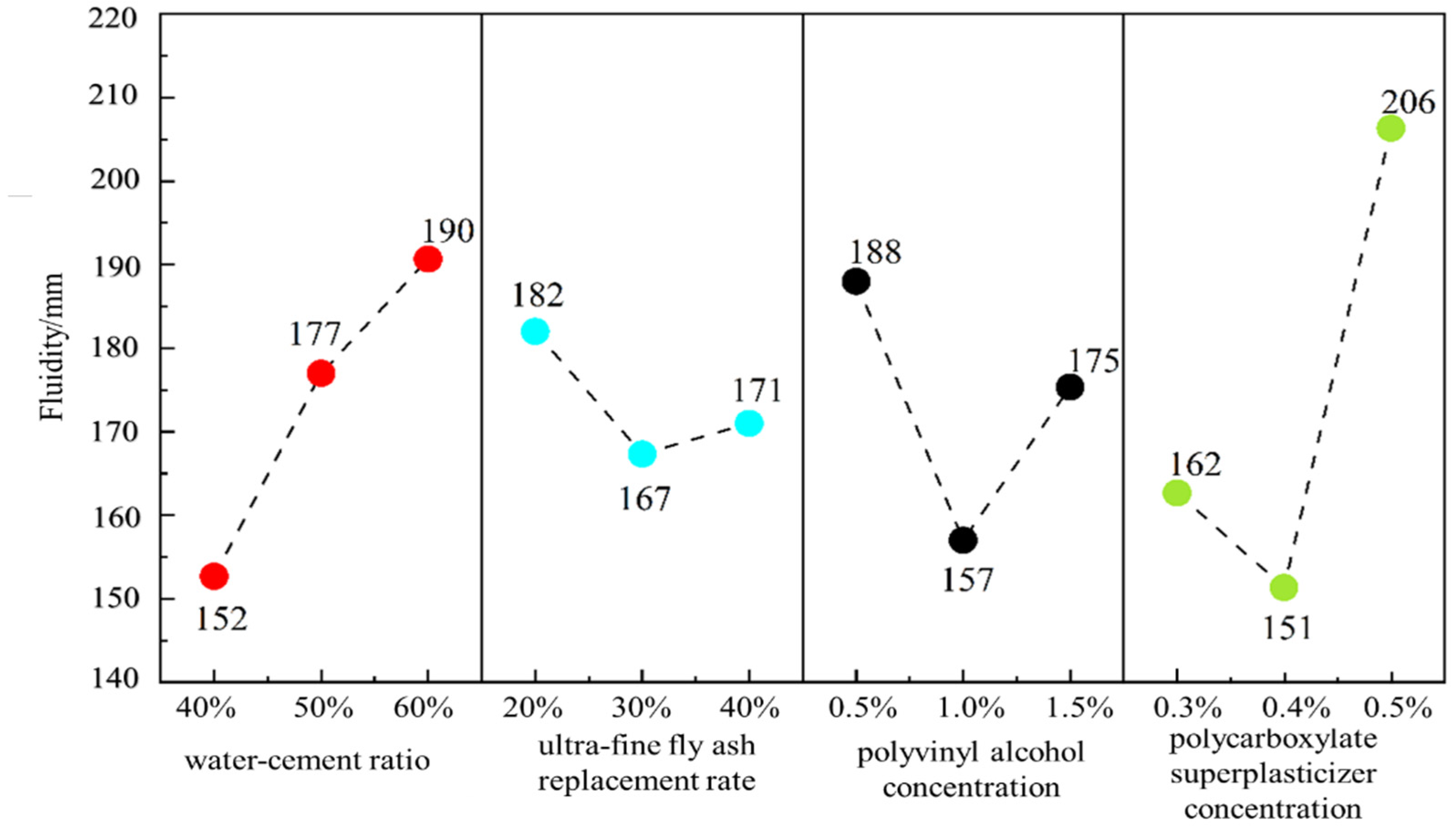

3.1.2. Analysis of Fluidity Results

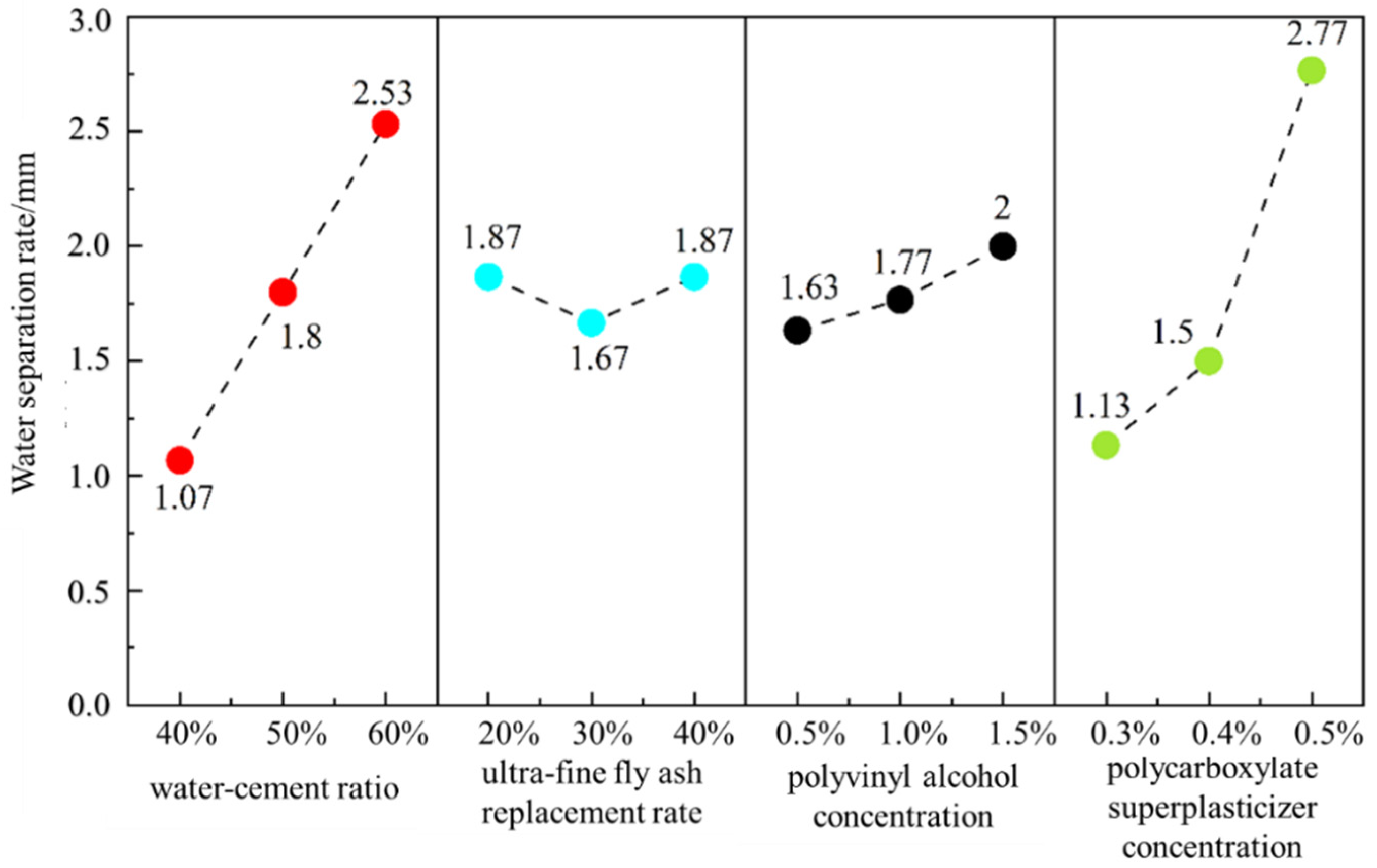

3.1.3. Analysis of Water Separation Rate Results

3.1.4. Analysis of Viscosity Results

3.1.5. Analysis of Uniaxial Compressive Strength Results

3.2. Orthogonal Experiment Results Analysis

- (1)

- Water–Cement Ratio: As can be seen from Table 21, the water–cement ratio is the primary factor affecting the setting time, viscosity, and 28-day uniaxial compressive strength of the grout, and also a secondary factor influencing the water separation rate and fluidity of the grout. It exerts a multi-dimensional regulatory effect on material performance. When the water–cement ratio increases from 0.4 to 0.6, the increased free water content results in a 69.5% decrease in grout viscosity, while the water separation rate increases significantly by 136.4%. Meanwhile, a high water–cement ratio prolongs the initial setting time by 62.5% and the final setting time by 35.7%, and reduces the 28-day uniaxial compressive strength by 42.4%. Mix A1 falls into the category of “high viscosity, low fluidity” grouts, which are unable to penetrate fine fractures under field grouting conditions and require extremely high grouting pressure for injection. This may lead to secondary fracturing of the roadway surrounding rock. In contrast, the low viscosity of Mix A3 is sufficient to penetrate the fine fractures in the weathering and oxidation zone without requiring excessively high grouting pressure, thereby avoiding secondary damage to the surrounding rock. The surrounding rock in the weathering and oxidation zone is prone to weathering and disintegration on its own. The core objective of grouting is to “bind loose rock masses into an integrated whole” rather than pursuing extremely high uniaxial strength. The 28-day uniaxial compressive strength of Mix A3 is 10.48 MPa. Although lower than the 20.71 MPa of Mix A1, it far exceeds the inherent strength of the weathered and oxidized surrounding rock, fully meeting the requirements for “cementation and reinforcement.” Moreover, as free water can promote the hydration reaction at the interface between the grout and the rock surface, the bonding performance between the solidified grout body and the surrounding rock is superior when a high water–cement ratio is used. From the perspective of setting time, the initial setting time of Mix A3 is longer than that of Mix A1, allowing the grout to diffuse within the fractures before it fully hardens. Therefore, considering the above reasons, Mix A3 with a water–cement ratio of 0.6 is selected as the optimal mix proportion.

- (2)

- Ultra-Fine Fly Ash Replacement Ratio: As can be seen from Table 21, the ultra-fine fly ash replacement rate is a secondary factor affecting the 28-day uniaxial compressive strength. Ultra-fine fly ash synergistically enhances performance through both chemical reactions and physical filling. At a replacement rate of 20%, the 28-day uniaxial compressive strength reaches 20.11 MPa, representing a 41.3% increase compared to the 30% level. When the replacement rate is increased to 40%, although the fluidity may improve, the 28-day uniaxial compressive strength drops to 45.08 MPa, representing a 25.3% decrease. Range analysis shows that the ultra-fine fly ash replacement rate has a weaker influence on the 28-day uniaxial compressive strength than the water–cement ratio. Therefore, a 20% ultra-fine fly ash replacement rate at the B1 level is selected to achieve the optimal mix ratio.

- (3)

- Polyvinyl Alcohol Concentration, PVA Concentration: As can be seen from Table 21, the polyvinyl alcohol (PVA) concentration is a secondary factor affecting viscosity. PVA concentration exerts a non-linear effect on grout stability. At a concentration of 1.0%, the viscosity reaches 4572.6 mPa·s. When the concentration exceeds 1.0%, flocculent structure instability is prone to occur. PVA’s property of enhancing grout cohesion through a hydrogen bond network enables it to be an effective means to regulate water retention. Therefore, the C2 level PVA concentration of 1.0% is selected as the optimal mix ratio.

- (4)

- Polycarboxylate Superplasticizer (PCE) Concentration: As can be seen from Table 21, the polycarboxylate superplasticizer (PCE) concentration is the primary factor affecting fluidity and water separation rate, and also a secondary factor influencing setting time. There is a trade-off relationship between fluidity and stability for the polycarboxylate superplasticizer (PCE) concentration. At a concentration of 0.5%, the fluidity reaches 206.33 mm; however, the water separation rate increases by 144% compared with the 0.3% concentration. Excessive dispersion leads to a decrease in grout structural strength. Therefore, a compromise is made to select the D2 level PCE concentration of 0.4% as the optimal mix ratio.

4. Conclusions

- (1)

- The factors influencing the setting time of the grout, ranked in descending order of their influence, are as follows: water/cement ratio > polycarboxylate superplasticizer (PCE) > polyvinyl alcohol (PVA) concentration > ultra-fine fly ash replacement rate. Among these, the water–cement ratio exerts a significant influence on the setting time; as the water–cement ratio increases, the setting time of the grout is prolonged.

- (2)

- The factors influencing the fluidity of the grout, ranked in descending order of their influence, are: polycarboxylate superplasticizer (PCE) concentration > water–cement ratio > polyvinyl alcohol (PVA) concentration > ultra-fine fly ash replacement rate. Among these, the PCE concentration exerts a significant influence on the grout’s fluidity. As the PCE concentration increases, the fluidity of the grout gradually increases.

- (3)

- The factors influencing the water separation rate of the grout, ranked in descending order of their influence, are: polycarboxylate superplasticizer (PCE) concentration > water–cement ratio > polyvinyl alcohol (PVA) concentration > ultra-fine fly ash replacement rate. Among these, the PCE concentration exerts the most significant influence on the grout’s water separation rate. However, none of the water separation rates exceeded 5%, indicating the grout remained relatively stable.

- (4)

- The factors influencing the viscosity of the grout, ranked in descending order of their influence, are: water–cement ratio > polyvinyl alcohol (PVA) concentration > polycarboxylate superplasticizer (PCE) concentration > ultra-fine fly ash replacement rate. Among these, the water–cement ratio exerts a significant influence on the grout’s viscosity. As the water–cement ratio increases, the viscosity of the grout gradually decreases.

- (5)

- The factors influencing the 28-day uniaxial compressive strength of the grout, ranked in descending order of their influence, are: water–cement ratio > ultra-fine fly ash replacement rate > polyvinyl alcohol (PVA) concentration > polycarboxylate superplasticizer (PCE) concentration. Among these, the water–cement ratio has a significant influence on the grout’s 28-day uniaxial compressive strength. As the water–cement ratio increases, the 28-day uniaxial compressive strength of the grout gradually decreases.

- (6)

- The optimal mix ratio proposed in this study—water–cement ratio 0.6, ultrafine fly ash replacement rate 20%, polyvinyl alcohol concentration 1.0%, and polycarboxylate superplasticizer concentration 0.4%—can comprehensively meet the grouting requirements for the weathering and oxidation zone because it stems from the synergistic effects of its components at the micro-level: The water–cement ratio regulates the free water content, ensuring slurry penetrability and operational time while influencing pore structure and the formation of the interfacial transition zone. Ultrafine fly ash optimizes particle gradation and enhances matrix denseness through its micro-filling effect and pozzolanic activity. Polyvinyl alcohol molecules significantly improve slurry stability and interfacial bonding strength by forming hydrogen bond networks that bind water and encapsulate particles. The polycarboxylate superplasticizer optimizes particle dispersion through steric hindrance effects, balancing fluidity and stability. These four components work in concert to systematically optimize macroscopic performance in terms of rheological properties, structural compactness, moisture retention, and interfacial enhancement, providing a reliable material solution for grouting reinforcement of fractured surrounding rock in the weathering and oxidation zone.

5. Research Limitations and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J. Tectonic Evolution and Coal Seam Occurrence Regularity in Southeastern Hebei; China University of Mining and Technology Press: Xuzhou, China, 2009. [Google Scholar]

- Chen, S.; Li, F.; Yin, D. Experimental study on deformation failure characteristics of limestone-coal composite with different rock-coal height ratios. J. Cent. South. Univ. 2023, 54, 2459–2472. [Google Scholar] [CrossRef]

- Xie, H.; Wang, J.; Wang, G. New ideas of coal revolution and layout of coal science and technology development. J. China Coal Soc. 2018, 43, 1187–1197. [Google Scholar] [CrossRef]

- Chen, S.; Qu, X.; Liu, Y. Optimization and numerical analysis of mining roadway support parameters. Chin. J. Min. 2017, 26, 93–97,101. [Google Scholar]

- Jing, H.; Meng, Q.; Zhu, J. Theoretical and technical progress of stability control of broken rock zone of deep roadway surrounding rock. J. Min. Saf. Eng. 2020, 37, 429–442. [Google Scholar] [CrossRef]

- Xie, P.; Yan, D. Research on roof support technology of wind and oxidation zone in driving face. Coal Mine Mod. 2021, 30, 85–89. [Google Scholar] [CrossRef]

- Wang, D. Construction And Support Method Selection of Soft Rock with Large Section for Roof-cutting under Weathering And Oxidation Zone. Shanxi Coking Coal Sci. Technol. 2021, 45, 33–35+39. [Google Scholar] [CrossRef]

- Wang, Y.; Kong, D.; Wu, G.; Xiong, Y. Study on failure of roof overburden and high ground pressure control under deep repeated mining. Eng. Fail. Anal. 2026, 183, 110226. [Google Scholar] [CrossRef]

- Teng, T.; Li, Z.; Liu, K.; Zhu, Y.; Jia, W. Overburden Failure and Fracture Propagation Behavior Under Repeated Mining. Min. Metall. Explor. 2025, 42, 219–234. [Google Scholar] [CrossRef]

- Chu, C.-Q.; Bao, X.-J.; Wu, S.-C.; Nian, Y.-Y.; Xia, L.; Zhang, G. Research on the mechanical behaviour and rockburst mechanism of deep high-stress roadway excavation. Appl. Geophys. 2025, 22, 1–20, prepublish. [Google Scholar] [CrossRef]

- He, M.; Ren, F.; Liu, D. Rockburst mechanism research and its control. Int. J. Min. Sci. Technol. 2018, 28, 829–837. [Google Scholar] [CrossRef]

- Ogata, S.; Yasuhara, H. Numerical simulations for describing generation of excavation damaged zone: Important case study at Horonobe underground research laboratory. Rock. Mech. Bull. 2023, 2, 100063. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, X.; Liu, J.; Ma, H.; Wang, C.; Zhang, H.; Wang, J. Progress on rock mechanics research of Beishan granite for geological disposal of high-level radioactive waste in China. Rock. Mech. Bull. 2023, 2, 100046. [Google Scholar] [CrossRef]

- Li, X.L.; Chen, S.; Liu, S.; Li, Z. AE waveform characteristics of rock mass under uniaxial loading based on Hilbert-Huang transform. J. Cent. South. Univ. 2021, 28, 1843–1856. [Google Scholar] [CrossRef]

- Li, X.; Chen, S.; Li, Z.; Wang, E. Rockburst mechanism in coal rock with structural surface and the microseismic (MS) and electromagnetic radiation (EMR) response. Eng. Fail. Anal. 2021, 124, 105396. [Google Scholar] [CrossRef]

- Li, X.; Wang, E.; Li, Z.; Liu, Z.; Song, D.; Qiu, L. Rock burst monitoring by integrated microseismic and electromagnetic radiation methods. Rock. Mech. Rock. Eng. 2016, 49, 4393–4406. [Google Scholar] [CrossRef]

- Liu, S.; Sun, H.; Zhang, D.; Yang, K.; Li, X.; Wang, D.; Li, Y. Experimental study of effect of liquid nitrogen cold soaking on coal pore structure and fractal characteristics. Energy 2023, 275, 127470. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Fu, J.; Zhu, N.; Chen, D.; Wang, Y.; Ding, S. Experimental study on compressive behavior and failure characteristics of imitation steel fiber concrete under uniaxial load imitation steel ffber concrete under uniaxial load. Constr. Build. Mater. 2023, 399, 132599. [Google Scholar] [CrossRef]

- Liu, Q.; Lu, C.; Liu, B. Research on the grouting diffusion mechanism and its application of grouting reinforcement in deep roadway. J. Min. Saf. Eng. 2014, 31, 333–339. [Google Scholar] [CrossRef]

- Tian, M.; Gao, X.; Zhang, A. Study on the deformation failure mechanism and coupling support technology of soft rock roadways in strong wind oxidation zones. Eng. Fail. Anal. 2024, 156, 107840. [Google Scholar] [CrossRef]

- Wang, E.; Yin, S.; Cheng, Z.; Xie, S.; Chen, L.; Kang, Q.; Duan, Y. Failure mechanism analysis of ultra-large-section soft-rock roadway in kilometer deep coal mine and its collaborative control of “grouting-anchoring-pouring”. Eng. Fail. Anal. 2025, 170, 109338. [Google Scholar] [CrossRef]

- Gao, F. Research status of underground grouting materials. Coal 2017, 26, 52–55. [Google Scholar]

- Zhao, G.; Wang, Y.; Ai, J. Development and prospect of cement-based grouting materials for coal mine. J. China Univ. Min. Technol. 2024, 53, 1–22. [Google Scholar] [CrossRef]

- Xue, H.; Deng, Z.; Li, J. Study on tensile properties and toughness of PVA fiber-reinforced cementitious composites. J. Zhengzhou Univ. 2009, 30, 92–95. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, W.; Meng, S. Study on Mechanical Properties of Hybrid PVA Fibers Reinforced Cementitious Composites. J. Tongji Univ. 2015, 43, 33–40. [Google Scholar] [CrossRef]

- Zhang, J.; Ju, X.; Guo, Z. Tensile Properties of Fiber Reinforced Cement Composite with Different PVA Fibers. J. Build. Mater. 2009, 12, 706–710. [Google Scholar] [CrossRef]

- Fan, J.; Li, G. Mechanical Properties and Microstructure of Polyvinyl Alcohol (PVA) Modified Cement Mortar. China Concr. Cem. Prod. 2018, 11, 18–22. [Google Scholar] [CrossRef]

- Liu, B.; Yin, L.; Chen, J. Experimental Study on the Influence of PVA Content on the Performance of Grouting Material in Deep Stope. Geofluids 2021, 2021, 6684754. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Liu, Y. Mechanical properties and impermeability strength evolution of the consolidated body of fiber-modified coal-based solid wastes grouting materials. Conster Build. Mater. 2024, 450, 138556. [Google Scholar] [CrossRef]

- Zhou, J.; Zha, L.; Meng, S. Optimization on overall performance of Modified Ultrafine Cementitious Grout Materials (MUCG) and hydration mechanism analysis. PLoS ONE 2024, 9, e0309312. [Google Scholar] [CrossRef]

- Lu, H.; Dong, Q.; Yan, S. Development of flexible grouting material for cement-stabilized macadam base using response surface and genetic algorithm optimization methodologies. Constr. Build. Mater. 2023, 409, 133823. [Google Scholar] [CrossRef]

- Gan, X.; Zhu, Y.; Ma, K. Water resistance, mechanical properties, hydration characteristic and microstructure of magnesium ammonium phosphate cement modified by polyvinyl alcohol powder. Constr. Build. Mater. 2024, 40, 12. [Google Scholar] [CrossRef]

- Yao, X.; Xu, Y.; Dong, X. Assessing the desiccation crack propagation performance of cemented soil reinforced by modified polyvinyl alcohol fiber. Measurement 2024, 35, 5. [Google Scholar] [CrossRef]

- Elhadary, R.; Bassuoni, M.T. Nano-modified slag-based cementitious composites reinforced with basalt pellets and polyvinyl alcohol fibers. J. Sustain. Cem.-Based Mater. 2023, 12, 305–316. [Google Scholar] [CrossRef]

- Cao, M.; Wang, C.; Xia, R. Preparation and performance of the modified high-strength/high-modulus polyvinyl alcohol fiber/polyurethane grouting materials. Conster Build. Mater. 2018, 186, 482–489. [Google Scholar] [CrossRef]

- Wei, F.; Yang, F.; Wang, H. Preparation and mechanical properties of cementitious composites reinforced by modified polyvinyl alcohol fiber. J. Text. Res. 2021, 42, 53–60. [Google Scholar] [CrossRef]

- Sun, M.; Zhu, J.; Sun, T. Multiple effects of nano-CaCO3 and modified polyvinyl alcohol fiber on flexure-tension-resistant performance of engineered cementitious composites. Constr. Build. Mater. 2021, 303, 124426. [Google Scholar] [CrossRef]

- Curosu, I.; Liebscher, M.; Alsous, G. Tailoring the crack-bridging behavior of strain-hardening cement-based composites (SHCC) by chemical surface modification of poly(vinyl alcohol) (PVA) fibers. Cem. Concr. Compos. 2020, 114, 103722. [Google Scholar] [CrossRef]

- Ding, C.; Guo, L.; Chen, B. Orientation distribution of polyvinyl alcohol fibers and its influence on bridging capacity and mechanical performances for high ductility cementitious composites. Constr. Build. Mater. 2020, 247, 118491. [Google Scholar] [CrossRef]

- Fan, J.; Li, G.; Deng, S.; Wang, Z. Mechanical Properties and Microstructure of Polyvinyl Alcohol (PVA) Modified Cement Mortar. Appl. Sci. 2019, 9, 2178. [Google Scholar] [CrossRef]

- Wang, B.; Xing, Y. Effect of Degree of Hydrolysis of Polyvinyl Alcohol on Adhesive Properties of Cement Mortar. J. Test. Eval. 2021, 49, 1–14. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R. Investigation of properties and performances of Polyvinyl Alcohol (PVA) fiber-reinforced rubber concrete. Constr. Build. Mater. 2018, 193, 631–642. [Google Scholar] [CrossRef]

- Cao, Z.; Xiong, Y.; Xue, Y.; Du, F.; Li, Z.; Huang, C.; Wang, S.; Yu, Y.; Wang, W.; Zhai, M.; et al. Diffusion Evolution Rules of Grouting Slurry in Mining-induced Cracks in Overlying Strata. Rock. Mech. Rock. Eng. 2025, 58, 1–20. [Google Scholar] [CrossRef]

- Cheng, B.; Li, H.; Pan, G.; Deng, R.; Gong, Y.A.; Xu, S.; Zhou, K.; Zheng, Z. Study on hydrodynamic diffusion law of the swelling particle slurry in karst pipeline. Particuology 2024, 87, 218–231. [Google Scholar] [CrossRef]

- Huang, S.; Pei, Q.; Ding, X.; Zhang, Y.; Liu, D.; He, J.; Bian, K. Grouting diffusion mechanism in an oblique crack in rock masses considering temporal and spatial variation of viscosity of fast-curing grouts. Geomech. Eng. 2020, 23, 151–163. [Google Scholar] [CrossRef]

- Zang, H.; Wang, S.; Carter, P. Forward and inverse models of magnetically-susceptible grout in rock fracture grouting. Acta Geotech. 2025, 20, 1–29. [Google Scholar] [CrossRef]

- Lin, X.; You, Q.; Li, H. Effect of polyvinyl alcohol on bonding properties of potassium magnesium phosphate cement mortar. Fujian Constr. Sci. Technol. 2022, 1, 51–53. [Google Scholar] [CrossRef]

- Deng, J.; Huo, J.; Song, Y. Properties Experiment on Foamed Concrete with Polyvinyl Alcohol Fibe. China Concr. Cem. Prod. 2012, 2, 41–44. [Google Scholar] [CrossRef]

- Sheng, Y.; Li, S.; Dai, G. Permeability of Cutoff Walls Slurry Based on Modification of Polyvinyl Alcohol. Bull. Chin. Ceram. Soc. 2018, 37, 4050–4055. [Google Scholar] [CrossRef]

- Zhang, J.; Bai, P.; Yan, C. Experimental Investigation on Relations Between Impact Resistance and Tensile Properties of Cement-Based Materials Reinforced by Polyvinyl Alcohol Fibers. Appl. Sci. 2019, 9, 4434. [Google Scholar] [CrossRef]

- Wang, G. Innovation and Development of Safe, High-efficiency and Green Coal Mining Technology and Equipments. Coal Min. Technol. 2013, 18, 1–5. [Google Scholar] [CrossRef]

- Wang, S.; Liu, L.; Zhu, M. New way for green and low-carbon development of coal industry under the target of “daul-carbon”. J. China Coal Soc. 2024, 49, 152–171. [Google Scholar] [CrossRef]

| Chemical Composition | SiO2 | CaO | MaO | Al2O3 | R2O5 | Fe2O3 |

|---|---|---|---|---|---|---|

| Content/% | 19.26 | 61.77 | 4.21 | 3.91 | 3.35 | 0.065 |

| Chemical Composition | SiO2 | Al2O3 | SO3 | Fe2O3 | CaO | Na2O |

|---|---|---|---|---|---|---|

| Content/% | 45.1 | 36.8 | 1.2 | 0.85 | 4.5 | 2.14 |

| Degree of Hydrolysis /% | Sodium Acetate /% | Volatile Matter /% | Viscosity /mpa.s | Purity /% | Residual Acetate Ion /% |

|---|---|---|---|---|---|

| 80.2 | 0.9 | 4 | 40 | 95.1 | 15.12 |

| Level | Water–Binder Ratio (A) | Ultrafine Fly Ash Replacement Rate (B) | PVA Concentration (C) | PCE Concentration (D) |

|---|---|---|---|---|

| 1 | 0.4 | 20% | 0.5% | 0.3% |

| 2 | 0.5 | 30% | 1.0% | 0.4% |

| 3 | 0.6 | 40% | 1.5% | 0.5% |

| Test No. | Water–Binder Ratio (A) | Ultrafine Fly Ash Replacement Rate (B) | PVA Concentration (C) | PCE Concentration (D) |

|---|---|---|---|---|

| 1 | 0.5 | 20% | 0.5% | 0.3% |

| 2 | 0.5 | 30% | 1.5% | 0.4% |

| 3 | 0.5 | 40% | 1.0% | 0.5% |

| 4 | 0.4 | 20% | 1.5% | 0.5% |

| 5 | 0.4 | 30% | 1.0% | 0.3% |

| 6 | 0.4 | 40% | 0.5% | 0.4% |

| 7 | 0.6 | 20% | 1.0% | 0.4% |

| 8 | 0.6 | 30% | 0.5% | 0.5% |

| 9 | 0.6 | 40% | 1.5% | 0.3% |

| Test Number | Initial Setting Time/h | Final Setting Time/h | Fluidity/mm | Water Separation Rate/% | Viscosity/mPa·s | 28-Day Uniaxial Compressive Strength/MPa |

|---|---|---|---|---|---|---|

| 1 | 5.8 | 11.1 | 165 | 0.3 | 4562 | 23.61 |

| 2 | 7 | 12.4 | 108 | 0.6 | 6800.1 | 20.45 |

| 3 | 7.5 | 12.6 | 185 | 2.3 | 6573.3 | 18.07 |

| 4 | 8.7 | 14 | 202 | 2.8 | 4324 | 23.85 |

| 5 | 7.6 | 12.8 | 162 | 1.2 | 4404.2 | 13.02 |

| 6 | 8 | 13.3 | 167 | 1.4 | 4604.9 | 17.66 |

| 7 | 11.2 | 16.6 | 179 | 2.5 | 2070.7 | 12.86 |

| 8 | 11 | 16.2 | 232 | 3.2 | 805.37 | 9.23 |

| 9 | 10.8 | 16.2 | 161 | 1.9 | 2593.7 | 9.35 |

| Evaluation Parameters | Water–Cement ratio (A) | Ultra-Fine Fly Ash Replacement Rate (B) | Polyvinyl Alcohol Concentration (C) | Polycarboxylate Superplasticizer Concentration (D) |

|---|---|---|---|---|

| K1 | 20.3 | 25.7 | 24.8 | 24.2 |

| K2 | 24.3 | 25.6 | 26.5 | 26.2 |

| K3 | 33 | 26.3 | 26.3 | 27.2 |

| k1 | 6.77 | 8.53 | 8.27 | 8.01 |

| k2 | 8.1 | 8.57 | 8.83 | 8.73 |

| k3 | 11 | 8.77 | 8.77 | 9.01 |

| R | 4.23 | 0.23 | 0.57 | 1 |

| Primary and Secondary Order | A > D > C > B | |||

| Optimal Combination | A3B3C2D3 | |||

| Source of Variation | Sum of Squares (SS) | Degrees of Freedom (df) | Mean Square (MS) | F-Value | Significance |

|---|---|---|---|---|---|

| Water–Cement Ratio (A) | 28.11 | 2 | 14.06 | 281.20 | Highly Significant |

| PVA Concentration (C) | 0.58 | 2 | 0.29 | 5.80 | - |

| PCE Concentration (D) | 1.56 | 2 | 0.78 | 15.60 | - |

| Error (B combined) | 0.10 | 2 | 0.05 | - | - |

| Total Variation | 3.50 | 8 | - | - | - |

| Evaluation Parameters | Water–Cement Ratio (A) | Ultra-Fine Fly Ash Replacement Rate (B) | Polyvinyl Alcohol Concentration (C) | Polycarboxylate Superplasticizer Concentration (D) |

|---|---|---|---|---|

| K1 | 36.1 | 41.7 | 40.6 | 40.1 |

| K2 | 40.1 | 41.4 | 42.6 | 42.3 |

| K3 | 49 | 42.1 | 42 | 42.8 |

| k1 | 12.03 | 13.8 | 13.53 | 13.37 |

| k2 | 13.37 | 13.9 | 14.2 | 14.1 |

| k3 | 16.33 | 14.03 | 14 | 14.27 |

| R | 4.3 | 0.23 | 0.67 | 0.9 |

| Primary and Secondary Order | A > D > C > B | |||

| Optimal Combination | A3B3C2D3 | |||

| Source of Variation | Sum of Squares (SS) | Degrees of Freedom (df) | Mean Square (MS) | F-Value | Significance |

|---|---|---|---|---|---|

| Water–Cement Ratio (A) | 29.07 | 2 | 14.54 | 363.50 | Highly Significant |

| PVA Concentration (C) | 0.70 | 2 | 0.35 | 8.75 | - |

| PCE Concentration (D) | 1.38 | 2 | 0.69 | 17.25 | - |

| Error (B combined) | 0.08 | 2 | 0.04 | - | - |

| Total Variation | 34.67 | 8 | - | - | - |

| Evaluation Parameters | Water–Cement Ratio (A) | Ultra-Fine Fly Ash Replacement Rate (B) | Polyvinyl Alcohol Concentration (C) | Polycarboxylate Superplasticizer Concentration (D) |

|---|---|---|---|---|

| K1 | 458 | 546 | 564 | 488 |

| K2 | 531 | 502 | 471 | 454 |

| K3 | 572 | 513 | 526 | 619 |

| k1 | 152.67 | 182 | 188 | 162.67 |

| k2 | 177 | 167.33 | 157 | 151.33 |

| k3 | 190.67 | 171 | 175.33 | 206.33 |

| R | 38 | 14.67 | 31 | 55 |

| Primary and Secondary Order | D > A > C > B | |||

| Optimal Combination | A1B1C2D2 | |||

| Source of Variation | Sum of Squares (SS) | Degrees of Freedom (df) | Mean Square (MS) | F-Value | Significance |

|---|---|---|---|---|---|

| Water–Cement Ratio (A) | 2222.89 | 2 | 1111.45 | 6.36 | - |

| PVA Concentration (C) | 1457.55 | 2 | 728.78 | 4.17 | - |

| PCE Concentration (D) | 5060.22 | 2 | 2530.11 | 14.48 | - |

| Error (B combined) | 349.55 | 2 | 174.78 | - | - |

| Total Variation | 5368.22 | 8 | - | - | - |

| Evaluation Parameters | Water–Cement Ratio (A) | Ultra-Fine Fly Ash Replacement Rate (B) | Polyvinyl Alcohol Concentration (C) | Polycarboxylate Superplasticizer Concentration (D) |

|---|---|---|---|---|

| K1 | 3.2 | 5.6 | 4.9 | 3.4 |

| K2 | 5.4 | 5 | 5.3 | 4.5 |

| K3 | 7.6 | 5.6 | 6 | 8.3 |

| k1 | 1.07 | 1.87 | 1.63 | 1.13 |

| k2 | 1.8 | 1.67 | 1.77 | 1.5 |

| k3 | 2.53 | 1.87 | 2 | 2.77 |

| R | 1.47 | 0.2 | 0.37 | 1.63 |

| Primary and Secondary Order | D > A > C > B | |||

| Optimal Combination | A1B2C1D1 | |||

| Source of Variation | Sum of Squares (SS) | Degrees of Freedom (df) | Mean Square (MS) | F-Value | Significance |

|---|---|---|---|---|---|

| Water–Cement Ratio (A) | 3.23 | 2 | 1.62 | 40.50 | Highly Significant |

| PVA Concentration (C) | 0.21 | 2 | 0.11 | 2.75 | - |

| PCE Concentration (D) | 4.41 | 2 | 2.21 | 55.25 | Highly Significant |

| Error (B combined) | 0.08 | 2 | 0.04 | - | - |

| Total Variation | 7.98 | 8 | - | - | - |

| Evaluation Parameters | Water–Cement Ratio (A) | Ultra-Fine Fly Ash Replacement Rate (B) | Polyvinyl Alcohol Concentration (C) | Polycarboxylate Superplasticizer Concentration (D) |

|---|---|---|---|---|

| K1 | 17,935.4 | 10,956.7 | 9972.27 | 11,559.9 |

| K2 | 13,333.1 | 12,009.67 | 13,717.8 | 13,475.7 |

| K3 | 5469.77 | 13,771.9 | 13,048.2 | 11,702.67 |

| k1 | 5978.47 | 3652.23 | 3324.09 | 3853.3 |

| k2 | 4444.37 | 4003.22 | 4572.6 | 4491.9 |

| k3 | 1823.26 | 4590.63 | 4349.4 | 3900.89 |

| R | 4155.21 | 938.4 | 1248.51 | 638.6 |

| Primary and Secondary Order | A > C > B > D | |||

| Optimal Combination | A1B3C2D2 | |||

| Source of Variation | Sum of Squares (SS) | Degrees of Freedom (df) | Mean Square (MS) | F-Value | Significance |

|---|---|---|---|---|---|

| Water–Cement Ratio (A) | 26,490,562.1 | 2 | 13,245,281.05 | 34.86 | Significant |

| Ultrafine Fly Ash Replacement Rate (B) | 1,316,616.9 | 2 | 658,308.45 | 1.73 | - |

| PVA Concentration (C) | 2,660,633.9 | 2 | 1,330,316.95 | 3.50 | - |

| Error (D merged) | 759,812.1 | 2 | 379,906.05 | - | - |

| Total Variation | 31,894,218.3 | 8 | - | - | - |

| Evaluation Parameters | Water–Cement Ratio (A) | Ultra-Fine Fly Ash Replacement Rate (B) | Polyvinyl Alcohol Concentration (C) | Polycarboxylate Superplasticizer Concentration (D) |

|---|---|---|---|---|

| K1 | 62.13 | 60.32 | 50.5 | 45.98 |

| K2 | 54.53 | 42.7 | 53.65 | 50.97 |

| K3 | 31.44 | 45.08 | 43.95 | 51.15 |

| k1 | 20.71 | 20.11 | 16.83 | 15.33 |

| k2 | 18.18 | 14.23 | 17.89 | 16.99 |

| k3 | 10.48 | 15.03 | 14.65 | 17.05 |

| R | 10.23 | 5.87 | 3.23 | 1.72 |

| Primary and Secondary Order | A > B > C > D | |||

| Optimal Combination | A1B1C2D3 | |||

| Source of Variation | Sum of Squares (SS) | Degrees of Freedom (df) | Mean Square (MS) | F-Value | Significance |

|---|---|---|---|---|---|

| Water–Cement Ratio (A) | 170.31 | 2 | 85.16 | 29.67 | Significant |

| Ultrafine Fly Ash Replacement Rate (B) | 60.92 | 2 | 30.46 | 10.61 | - |

| PVA Concentration (C) | 16.32 | 2 | 8.16 | 2.84 | - |

| Error (D merged) | 5.74 | 2 | 2.87 | - | - |

| Total Variation | 331.15 | 8 | - | - | - |

| Indicator | Information Entropy (ej) | Coefficient of Variation (gj) | Objective Weight (wj) | Weight Ranking |

|---|---|---|---|---|

| 28-day Uniaxial Compressive Strength | 0.912 | 0.088 | 0.273 | 1 |

| Viscosity | 0.925 | 0.075 | 0.233 | 2 |

| Fluidity | 0.937 | 0.063 | 0.196 | 3 |

| Water Separation Rate | 0.951 | 0.049 | 0.152 | 4 |

| Initial Setting Time | 0.963 | 0.037 | 0.146 | 5 |

| Test No. | Water–Cement Ratio (A) | Ultrafine Fly Ash Replacement Rate (B) | PVA Concentration (C) | Polycarboxylate Superplasticizer Concentration (D) | Comprehensive Score (Si) | Ranking |

|---|---|---|---|---|---|---|

| 7 (A3B1C2D2) | 0.6 | 20% | 1.0% | 0.4% | 0.792 | 1 |

| 1 (A2B1C1D1) | 0.5 | 20% | 0.5% | 0.3% | 0.746 | 2 |

| 4 (A1B1C3D3) | 0.4 | 20% | 1.5% | 0.5% | 0.703 | 3 |

| 6 (A1B3C1D2) | 0.4 | 40% | 0.5% | 0.4% | 0.681 | 4 |

| 3 (A2B3C3D3) | 0.5 | 40% | 1.0% | 0.5% | 0.652 | 5 |

| 2 (A2B2C3D2) | 0.5 | 30% | 1.5% | 0.4% | 0.635 | 6 |

| 5 (A1B2C2D1) | 0.4 | 30% | 1.0% | 0.3% | 0.618 | 7 |

| 9 (A3B3C3D1) | 0.6 | 40% | 1.5% | 0.3% | 0.574 | 8 |

| 8 (A3B2C1D3) | 0.6 | 30% | 0.5% | 0.5% | 0.532 | 9 |

| Indicator | Initial Setting Time/h | Final Setting Time/h | Fluidity/mm | Water Separation Rate/% | Viscosity/mPa·s | 28-day Uniaxial Compressive Strength/MPa |

|---|---|---|---|---|---|---|

| Single-Indicator Optimal Level | A3B3C3D3 | A3B3C3D3 | A1B1C2D2 | A1B2C1D1 | A1B3C2D2 | A1B1C2D3 |

| Single-Indicator Primary and Secondary Factors | A > D > C > B | A > D > C > B | D > A > C > B | D > A > C > B | A > C > B > D | A > B > C > D |

| Significance Test | A is significant, while C and D have a certain impact | A is significant, while C and D have a certain impact | D is significant, while A and C have a certain impact | A and D have a certain impact | A is significant | A is significant, while B has a certain impact |

| Optimal Mix Ratio Based on Comprehensive Score | A3B1C2D2 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, Y.; Han, L.; Liu, Y.; Liu, Z.; Tian, M.; Deng, B. Study on the Properties of a Polyvinyl Alcohol-Modified Ultrafine Cement Grouting Material for Weathered Zone Coal Seams. Sustainability 2025, 17, 11341. https://doi.org/10.3390/su172411341

Wen Y, Han L, Liu Y, Liu Z, Tian M, Deng B. Study on the Properties of a Polyvinyl Alcohol-Modified Ultrafine Cement Grouting Material for Weathered Zone Coal Seams. Sustainability. 2025; 17(24):11341. https://doi.org/10.3390/su172411341

Chicago/Turabian StyleWen, Yanxiang, Lijun Han, Yanlong Liu, Zishuo Liu, Maolin Tian, and Benliang Deng. 2025. "Study on the Properties of a Polyvinyl Alcohol-Modified Ultrafine Cement Grouting Material for Weathered Zone Coal Seams" Sustainability 17, no. 24: 11341. https://doi.org/10.3390/su172411341

APA StyleWen, Y., Han, L., Liu, Y., Liu, Z., Tian, M., & Deng, B. (2025). Study on the Properties of a Polyvinyl Alcohol-Modified Ultrafine Cement Grouting Material for Weathered Zone Coal Seams. Sustainability, 17(24), 11341. https://doi.org/10.3390/su172411341